brake light NISSAN TIIDA 2010 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2211 of 3745

![NISSAN TIIDA 2010 Service Service Manual EC-946

< SERVICE INFORMATION >[MR18DE]

DTC P1805 BRAKE SWITCH

Diagnosis Procedure

INFOID:0000000005532828

1.CHECK STOP LAMP SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Check the stop lamp when depr NISSAN TIIDA 2010 Service Service Manual EC-946

< SERVICE INFORMATION >[MR18DE]

DTC P1805 BRAKE SWITCH

Diagnosis Procedure

INFOID:0000000005532828

1.CHECK STOP LAMP SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Check the stop lamp when depr](/img/5/57397/w960_57397-2210.png)

EC-946

< SERVICE INFORMATION >[MR18DE]

DTC P1805 BRAKE SWITCH

Diagnosis Procedure

INFOID:0000000005532828

1.CHECK STOP LAMP SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Check the stop lamp when depressing and releasing the brake pedal.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2.CHECK STOP LAMP SWIT CH POWER SUPPLY CIRCUIT

1. Disconnect stop lamp switch (1) harness connector.

- Brake pedal (2)

2. Check voltage between stop lamp switch terminal 1 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors M69, E7

• 10 A fuse

• Harness for open and short between stop lamp switch and battery

TERMI- NAL NO. WIRE

COLOR ITEM

CONDITION DATA (DC Voltage)

99 R Stop lamp switch [Ignition switch: OFF]

• Brake pedal: Fully released

Approximately 0 V

[Ignition switch: OFF]

• Brake pedal: Slightly depressed BATTERY VOLTAGE

(11 - 14 V)

Brake pedal Stop lamp

Fully released Not illuminated

Slightly depressed Illuminated

BBIA0710E

Voltage: Battery voltage

PBIB3317E

Revision: January 20102010 Versa

Page 2212 of 3745

![NISSAN TIIDA 2010 Service Service Manual DTC P1805 BRAKE SWITCHEC-947

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK STOP LAMP SW NISSAN TIIDA 2010 Service Service Manual DTC P1805 BRAKE SWITCHEC-947

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK STOP LAMP SW](/img/5/57397/w960_57397-2211.png)

DTC P1805 BRAKE SWITCHEC-947

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK STOP LAMP SWITCH INPUT SI

GNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect stop lamp switch (1) harness connector.

2. Disconnect ECM harness connector.

3. Check harness continuity between stop lamp switch terminal 2 and ECM terminal 99. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness connectors.

5.CHECK STOP LAMP SWITCH

Refer to EC-947, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace stop lamp switch.

6.CHECK INTERMITTENT INCIDENT

Refer to EC-632

.

>> INSPECTION END

Component InspectionINFOID:0000000005532829

STOP LAMP SWITCH

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check continuity between stop lamp switch terminals 1 and 2 under the following conditions.

If NG, adjust stop lamp switch installation, refer to BR-6

, and perform step 3 again.

Continuity should exist.

Condition

Continuity

Brake pedal: Fully released. Should not exist.

Brake pedal: Slightly depressed. Should exist.

PBIB3318E

Revision: January 20102010 Versa

Page 2261 of 3745

![NISSAN TIIDA 2010 Service Service Manual EC-996

< SERVICE INFORMATION >[MR18DE]

ASCD BRAKE SWITCH

ASCD BRAKE SWITCH

Component DescriptionINFOID:0000000005532893

When depress on the brake pedal, ASCD brake switch (2) is turned

OFF and stop la NISSAN TIIDA 2010 Service Service Manual EC-996

< SERVICE INFORMATION >[MR18DE]

ASCD BRAKE SWITCH

ASCD BRAKE SWITCH

Component DescriptionINFOID:0000000005532893

When depress on the brake pedal, ASCD brake switch (2) is turned

OFF and stop la](/img/5/57397/w960_57397-2260.png)

EC-996

< SERVICE INFORMATION >[MR18DE]

ASCD BRAKE SWITCH

ASCD BRAKE SWITCH

Component DescriptionINFOID:0000000005532893

When depress on the brake pedal, ASCD brake switch (2) is turned

OFF and stop lamp switch (1) is turned ON. ECM detects the state of

the brake pedal by this input of two kinds (ON/OFF signal)

Refer to

EC-522

for the ASCD function.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005532894

Specification data are reference values.

BBIA0708E

Monitor item ConditionSpecification

BRAKE SW1

(ASCD brake switch) • Ignition switch: ON• Brake pedal: Fully released (A/T, CVT)

• Brake pedal and clutch pedal: Fully released

(M/T) ON

• Brake pedal: Slightly depressed (A/T, CVT)

• Brake pedal and/or clutch pedal: Slightly de- pressed (M/T) OFF

BRAKE SW2

(Stop lamp switch) • Ignition switch: ONBrake pedal: Fully released

OFF

Brake pedal: Slightly depressed ON

Revision: January 20102010 Versa

Page 2263 of 3745

![NISSAN TIIDA 2010 Service Service Manual EC-998

< SERVICE INFORMATION >[MR18DE]

ASCD BRAKE SWITCH

Diagnosis Procedure

INFOID:0000000005532896

1.CHECK OVERALL FUNCTION-I

With CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” NISSAN TIIDA 2010 Service Service Manual EC-998

< SERVICE INFORMATION >[MR18DE]

ASCD BRAKE SWITCH

Diagnosis Procedure

INFOID:0000000005532896

1.CHECK OVERALL FUNCTION-I

With CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1”](/img/5/57397/w960_57397-2262.png)

EC-998

< SERVICE INFORMATION >[MR18DE]

ASCD BRAKE SWITCH

Diagnosis Procedure

INFOID:0000000005532896

1.CHECK OVERALL FUNCTION-I

With CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DAT A MONITOR” mode with CONSULT-III.

3. Check “BRAKE SW1” indication under the following conditions.

M/T models

A/T and CVT models

Without CONSULT-III

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 100 and ground under the following conditions.

M/T models

A/T and CVT models

OK or NG

OK >> GO TO 2.

NG (M/T models) >>GO TO 3.

NG (A/T and CVT models) >>GO TO 4.

2.CHECK OVERALL FUNCTION-II

With CONSULT-III

Check “BRAKE SW2” indication in “DATA MONITOR” mode.

TERMI-

NAL NO. WIRE

COLOR ITEM

CONDITION DATA (DC Voltage)

99 R Stop lamp switch [Ignition switch: ON]

• Brake pedal: Fully released

Approximately 0 V

[Ignition switch: ON]

• Brake pedal: Slightly depressed BATTERY VOLTAGE

(11 - 14 V)

100 G ASCD brake switch [Ignition switch: ON]

• Brake pedal: Slightly depressed (A/T, CVT)

• Brake pedal and/or clutch pedal: Slightly de-

pressed (M/T) Approximately 0 V

[Ignition switch: ON]

• Brake pedal: Fully released (A/T, CVT)

• Brake pedal and clutch pedal: Fully released (M/T) BATTERY VOLTAGE

(11 - 14 V)

Condition Indication

Clutch pedal and/or brake pedal: Slightly depressed OFF

Clutch pedal and brake pedal: Fully released ON

Condition Indication

Brake pedal: Slightly depressed OFF

Brake pedal: Fully released ON

Condition Voltage

Clutch pedal and/or brake pedal: Slightly depressed Approximately 0 V

Clutch pedal and brake pedal: Fully released Battery voltage

Condition Voltage

Brake pedal: Slightly depressed Approximately 0 V

Brake pedal: Fully released Battery voltage

PBIB3315E

Revision: January 20102010 Versa

Page 2264 of 3745

![NISSAN TIIDA 2010 Service Service Manual ASCD BRAKE SWITCHEC-999

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Without CONSULT-III

Check voltage between ECM terminal 99 and ground under the fol-

lowing conditions.

OK or N NISSAN TIIDA 2010 Service Service Manual ASCD BRAKE SWITCHEC-999

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Without CONSULT-III

Check voltage between ECM terminal 99 and ground under the fol-

lowing conditions.

OK or N](/img/5/57397/w960_57397-2263.png)

ASCD BRAKE SWITCHEC-999

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Without CONSULT-III

Check voltage between ECM terminal 99 and ground under the fol-

lowing conditions.

OK or NG

OK >> INSPECTION END.

NG >> GO TO 11.

3.CHECK ASCD CLUTCH SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ASCD clutch switch (1) harness connector.

- Clutch pedal (2)

3. Turn ignition switch ON.

4. Check voltage between ASCD clutch switch terminal 1 and ground under the following conditions with CONSULT-III or

tester.

OK or NG

OK >> GO TO 9.

NG >> GO TO 4.

4.CHECK ASCD BRAKE SWITCH POWER SUPPLY

1. Turn ignition switch OFF.

Condition Indication

Brake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

ConditionVoltage

Brake pedal: Fully released Approximately 0 V

Brake pedal: Slightly depressed Battery voltage

PBIB0311E

BBIA0709E

ConditionVoltage

Brake pedal: Fully released Battery voltage

Brake pedal: Slightly depressed Approx. 0 V

PBIB0857E

Revision: January 20102010 Versa

Page 2267 of 3745

![NISSAN TIIDA 2010 Service Service Manual EC-1002

< SERVICE INFORMATION >[MR18DE]

ASCD BRAKE SWITCH

• Harness for open or short between stop lamp switch and battery

>> Repair open circuit or short to ground or short to power in harness or c NISSAN TIIDA 2010 Service Service Manual EC-1002

< SERVICE INFORMATION >[MR18DE]

ASCD BRAKE SWITCH

• Harness for open or short between stop lamp switch and battery

>> Repair open circuit or short to ground or short to power in harness or c](/img/5/57397/w960_57397-2266.png)

EC-1002

< SERVICE INFORMATION >[MR18DE]

ASCD BRAKE SWITCH

• Harness for open or short between stop lamp switch and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

13.CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 99 and stop lamp switch terminal 2. Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 14.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

14.CHECK STOP LAMP SWITCH

Refer to EC-938, "

Component Inspection".

OK or NG

OK >> GO TO 15.

NG >> Replace stop lamp switch.

15.CHECK INTERMITTENT INCIDENT

Refer to EC-632

.

>> INSPECTION END

Component InspectionINFOID:0000000005532897

ASCD BRAKE SWITCH

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Check continuity between ASCD brake switch terminals 1 and 2

under the following conditions.

If NG, adjust ASCD brake switch installation, refer to BR-6

, and

perform step 3 again.

ASCD CLUTCH SWITCH

1. Turn ignition switch OFF.

2. Disconnect ASCD clutch switch harness connector. Continuity should exist.

Condition

Continuity

Brake pedal: Fully released. Should exist.

Brake pedal: Slightly depressed. Should not exist.

SEC023D

Revision: January 20102010 Versa

Page 2268 of 3745

![NISSAN TIIDA 2010 Service Service Manual ASCD BRAKE SWITCHEC-1003

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Check continuity between ASCD clutch switch terminals 1 and 2

under the following conditions.

If NG, adjust NISSAN TIIDA 2010 Service Service Manual ASCD BRAKE SWITCHEC-1003

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Check continuity between ASCD clutch switch terminals 1 and 2

under the following conditions.

If NG, adjust](/img/5/57397/w960_57397-2267.png)

ASCD BRAKE SWITCHEC-1003

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Check continuity between ASCD clutch switch terminals 1 and 2

under the following conditions.

If NG, adjust ASCD clutch switch installation, refer to CL-6

, and

perform step 3 again.

STOP LAMP SWITCH

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check continuity between stop lamp switch terminals 1 and 2 under the following conditions.

If NG, adjust stop lamp switch installation, refer to BR-6

, and perform step 3 again.

ConditionContinuity

Clutch pedal: Fully released. Should exist.

Clutch pedal: Slightly depressed. Should not exist.

SEC023D

ConditionContinuity

Brake pedal: Fully released. Should not exist.

Brake pedal: Slightly depressed. Should exist.

PBIB3318E

Revision: January 20102010 Versa

Page 2553 of 3745

![NISSAN TIIDA 2010 Service Service Manual EM-194

< SERVICE INFORMATION >[MR18DE]

ENGINE ASSEMBLY

• Do not allow engine oil to get on engine mounting insulator. Be careful not to damage engine mounting insu-

lator.

• When installation dire NISSAN TIIDA 2010 Service Service Manual EM-194

< SERVICE INFORMATION >[MR18DE]

ENGINE ASSEMBLY

• Do not allow engine oil to get on engine mounting insulator. Be careful not to damage engine mounting insu-

lator.

• When installation dire](/img/5/57397/w960_57397-2552.png)

EM-194

< SERVICE INFORMATION >[MR18DE]

ENGINE ASSEMBLY

• Do not allow engine oil to get on engine mounting insulator. Be careful not to damage engine mounting insu-

lator.

• When installation directions are specified, install parts according to the directions. Refer to EM-191, "

Com-

ponent".

• Prior to installing the upper torque rod, apply a light coat of silicone lubricant (A) to the washer facing side of the bushing inner tube as

shown.

NOTE:

• Apply silicone lubricant (A) by dabbing the outward facing tube

surface with a sponge or suitable tool.

• Do not apply excess lubricant.

• Make sure that each mounting insulator is seated properly, and tighten nuts and bolts.

• Tighten engine mounting insulator (RH) bolts in the numerical order shown.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14

.

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids includ- ing engine oil and engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the specified level, if necessary.

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc. : Vehicle front

LBIA0470E

: Vehicle front

WBIA0785E

Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Other oils and fluid* LevelLeakage Level

Fuel LeakageLeakageLeakage

Exhaust gases —Leakage —

Revision: January 20102010 Versa

Page 2612 of 3745

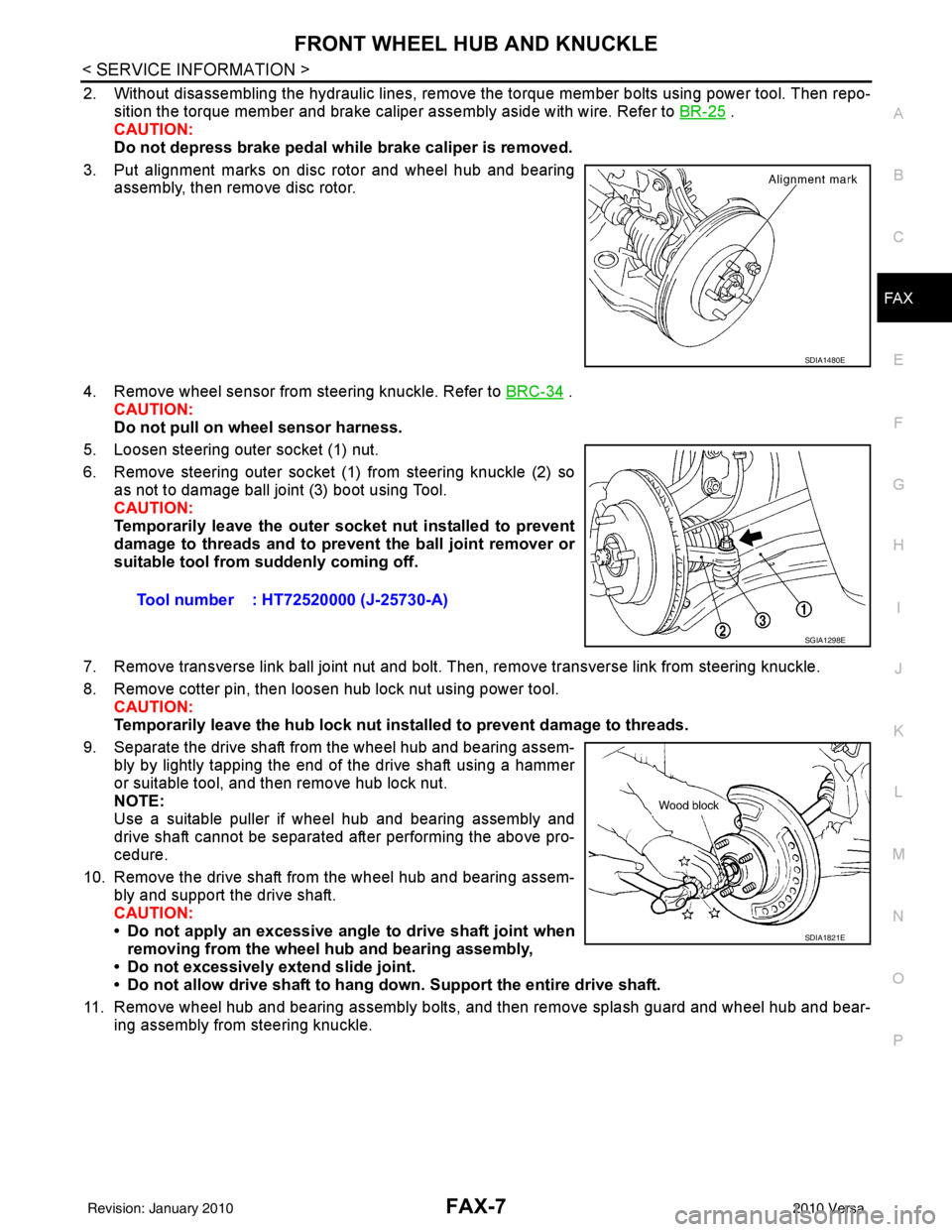

FRONT WHEEL HUB AND KNUCKLEFAX-7

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

2. Without disassembling the hydraulic lines, remove the torque member bolts using power tool. Then repo- sition the torque member and brake caliper assembly aside with wire. Refer to BR-25

.

CAUTION:

Do not depress brake pedal while brake caliper is removed.

3. Put alignment marks on disc rotor and wheel hub and bearing assembly, then remove disc rotor.

4. Remove wheel sensor from steering knuckle. Refer to BRC-34

.

CAUTION:

Do not pull on wheel sensor harness.

5. Loosen steering outer socket (1) nut.

6. Remove steering outer socket (1) from steering knuckle (2) so as not to damage ball joint (3) boot using Tool.

CAUTION:

Temporarily leave the outer socket nut installed to prevent

damage to threads and to prevent the ball joint remover or

suitable tool from suddenly coming off.

7. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

8. Remove cotter pin, then loosen hub lock nut using power tool. CAUTION:

Temporarily leave the hub lock nut inst alled to prevent damage to threads.

9. Separate the drive shaft from the wheel hub and bearing assem- bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

10. Remove the drive shaft from the wheel hub and bearing assem- bly and support the drive shaft.

CAUTION:

• Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang do wn. Support the entire drive shaft.

11. Remove wheel hub and bearing assembly bolts, and then remove splash guard and wheel hub and bear- ing assembly from steering knuckle.

SDIA1480E

Tool number : HT72520000 (J-25730-A)

SGIA1298E

SDIA1821E

Revision: January 20102010 Versa

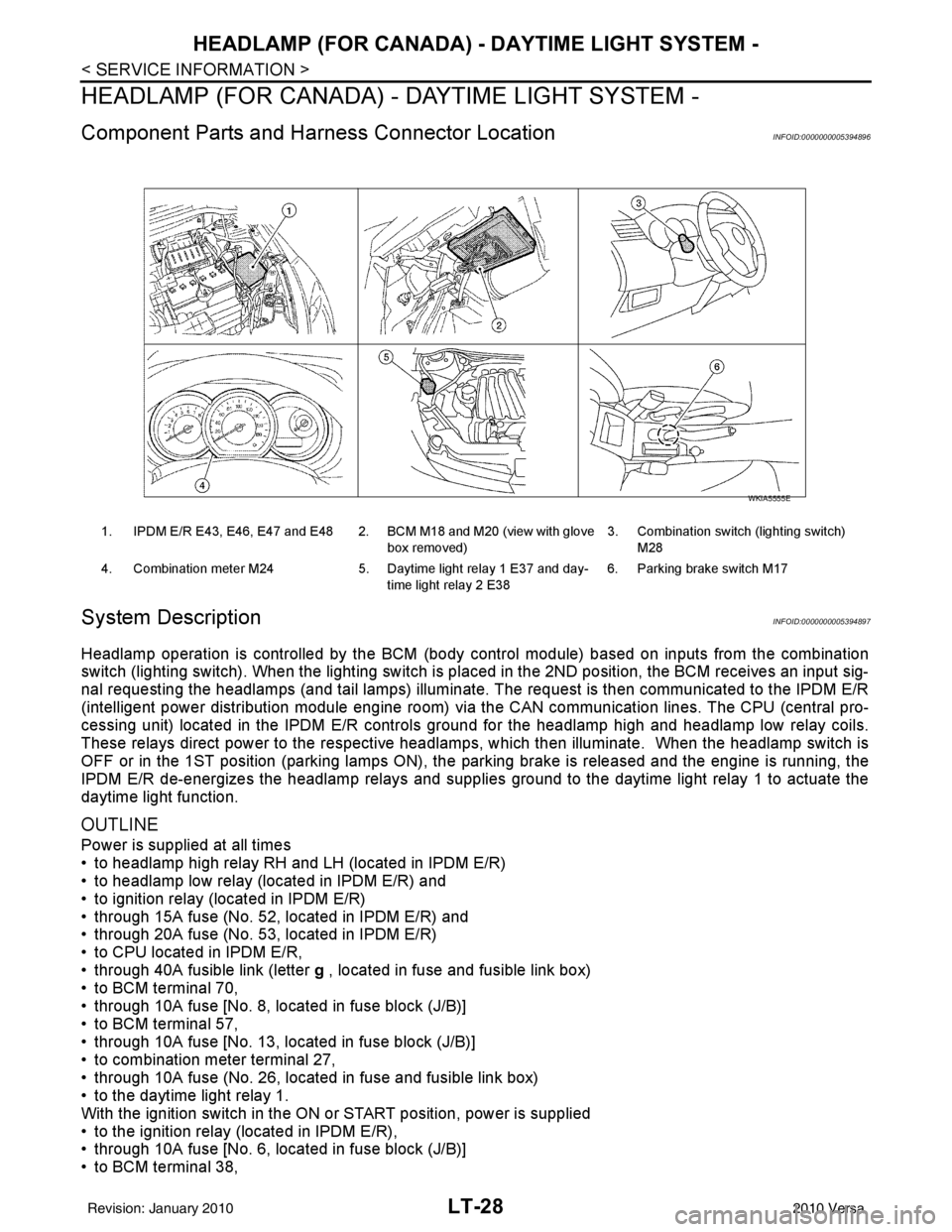

Page 3023 of 3745

LT-28

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Component Parts and Harness Connector LocationINFOID:0000000005394896

System DescriptionINFOID:0000000005394897

Headlamp operation is controlled by the BCM (body c ontrol module) based on inputs from the combination

switch (lighting switch). When the lighting switch is pl aced in the 2ND position, the BCM receives an input sig-

nal requesting the headlamps (and tail lamps) illuminate. The request is then communicated to the IPDM E/R

(intelligent power distribution module engine room) vi a the CAN communication lines. The CPU (central pro-

cessing unit) located in the IPDM E/R controls ground for the headlamp high and headlamp low relay coils.

These relays direct power to the respective headlamps , which then illuminate. When the headlamp switch is

OFF or in the 1ST position (parking lamps ON), the parking brake is released and the engine is running, the

IPDM E/R de-energizes the headlamp relays and supplies ground to the daytime light relay 1 to actuate the

daytime light function.

OUTLINE

Power is supplied at all times

• to headlamp high relay RH and LH (located in IPDM E/R)

• to headlamp low relay (located in IPDM E/R) and

• to ignition relay (located in IPDM E/R)

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27,

• through 10A fuse (No. 26, located in fuse and fusible link box)

• to the daytime light relay 1.

With the ignition switch in the ON or START position, power is supplied

• to the ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

1. IPDM E/R E43, E46, E47 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Combination switch (lighting switch)

M28

4. Combination meter M24 5. Daytime light relay 1 E37 and day-

time light relay 2 E38 6. Parking brake switch M17

WKIA5555E

Revision: January 20102010 Versa