code NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2882 of 3066

SC-10

BATTERY

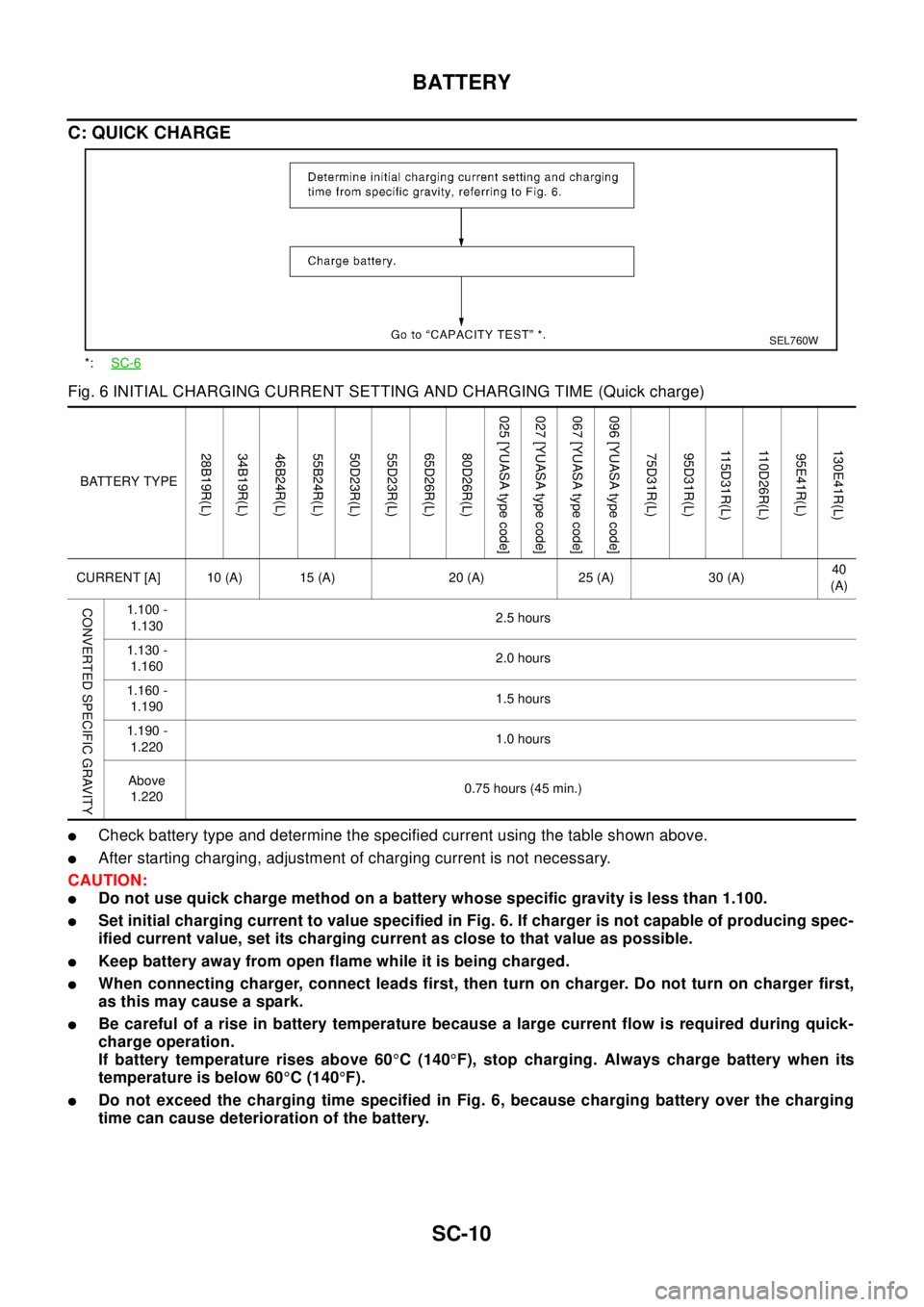

C: QUICK CHARGE

Fig. 6 INITIAL CHARGING CURRENT SETTING AND CHARGING TIME (Quick charge)

lCheck battery type and determine the specified current using the table shown above.

lAfter starting charging, adjustment of charging current is not necessary.

CAUTION:

lDo not use quick charge method on a battery whose specific gravity is less than 1.100.

lSet initial charging current to value specified in Fig. 6. If charger is not capable of producing spec-

ified current value, set its charging current as close to that value as possible.

lKeep battery away from open flame while it is being charged.

lWhen connecting charger, connect leads first, then turn on charger. Do not turn on charger first,

as this may cause a spark.

lBe careful of a rise in battery temperature because a large current flow is required during quick-

charge operation.

If battery temperature rises above 60°C (140°F), stop charging. Always charge battery when its

temperature is below 60°C(140°F).

lDo not exceed the charging time specified in Fig. 6, because charging battery over the charging

time can cause deterioration of the battery.

*:SC-6

SEL760W

BATTERY TYPE

28B19R(L) 34B19R(L) 46B24R(L)

55B24R(L) 50D23R(L) 55D23R(L)

65D26R(L) 80D26R(L) 025 [YUASA type code] 027 [YUASA type code] 067 [YUASA type code]

096 [YUASA type code]75D31R(L)

95D31R(L) 115D31R(L) 110D26R(L)95E41R(L) 130E41R(L)

CURRENT [A] 10 (A) 15 (A) 20 (A) 25 (A) 30 (A)40

(A)

CONVERTED SPECIFIC GRAVITY1.100 -

1.1302.5 hours

1.130 -

1.1602.0 hours

1.160 -

1.1901.5 hours

1.190 -

1.2201.0 hours

Above

1.2200.75 hours (45 min.)

Page 2923 of 3066

SRS-1

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

H RESTRAINTS

CONTENTS

C

D

E

F

G

I

J

K

L

M

SECTION

A

B

SRS

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

PRECAUTIONS .......................................................... 3

Supplemental Restraint System (SRS) “AIR BAG”

and “SEAT BELT PRE-TENSIONER” ...................... 3

Precautions for SRS “AIR BAG” and “SEAT BELT

PRE-TENSIONER” Service ..................................... 3

Trouble Diagnosis Precaution .................................. 3

PREPARATION ........................................................... 4

Special Service Tool ................................................. 4

Commercial Service Tool ......................................... 4

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ....... 5

SRS Configuration ................................................... 5

Front Seat Belt Pre-tensioner with Load Limiter ...... 5

Front Side Air Bag .................................................... 5

TROUBLE DIAGNOSIS .............................................. 7

Trouble Diagnoses-Introduction ............................... 7

DIAGNOSIS FUNCTION ....................................... 7

HOW TO PERFORM TROUBLE DIAGNOSES

FOR QUICK AND ACCURATE REPAIR ............... 7

WORK FLOW ........................................................ 7

SRS Components Parts Location ............................. 9

Wiring Diagram — SRS — /LHD models ............... 10

Wiring Diagram-SRS-/RHD models ....................... 12

CONSULT-II FUNCTION ........................................ 14

DIAGNOSIS MODE FOR CONSULT-II ............... 14

HOW TO CHANGE SELF-DIAGNOSIS MODE

WITH CONSULT-II .............................................. 14

HOW TO ERASE SELF-DIAGNOSIS RESULTS... 14

SELF-DIAGNOSIS FUNCTION (WITHOUT CON-

SULT-II) .................................................................. 15

HOW TO CHANGE SELF-DIAGNOSIS MODE... 15

HOW TO ERASE SELF-DIAGNOSIS RESULTS... 15

SRS Operation Check ............................................ 15

DIAGNOSTIC PROCEDURE 1 ........................... 15

Trouble Diagnoses with CONSULT–II .................... 17

DIAGNOSTIC PROCEDURE 2 ........................... 17

DIAGNOSTIC PROCEDURE 3 ........................... 20

DIAGNOSTIC PROCEDURE 4 ........................... 20

Trouble Diagnoses Without CONSULT-II ............... 22

DIAGNOSTIC PROCEDURE 5 ........................... 22

WARNING LAMP FLASH CODE CHART ........... 23Trouble Diagnoses: “AIR BAG” Warning Lamp Does

Not Turn Off ............................................................ 25

DIAGNOSTIC PROCEDURE 6 ........................... 25

Trouble Diagnoses: “AIR BAG” Warning Lamp Does

Not Turn On ............................................................ 26

DIAGNOSTIC PROCEDURE 7 ........................... 26

DRIVER AIR BAG MODULE .................................... 27

Removal and Installation/With 4-Spoke Steering

Wheel ..................................................................... 27

REMOVAL ........................................................... 27

INSTALLATION ................................................... 28

Removal and Installation/With 3-Spoke Steering

Wheel ..................................................................... 29

REMOVAL ........................................................... 29

INSTALLATION ................................................... 30

SPIRAL CABLE ........................................................ 31

Removal and Installation ........................................ 31

REMOVAL ........................................................... 31

INSTALLATION ................................................... 32

Components Inspection .......................................... 32

FRONT PASSENGER AIR BAG MODULE .............. 33

Removal and Installation ........................................ 33

REMOVAL ........................................................... 33

INSTALLATION ................................................... 33

FRONT SIDE AIR BAG MODULE ............................ 35

Removal and Installation ........................................ 35

REMOVAL ........................................................... 35

INSTALLATION ................................................... 36

SIDE AIR BAG (SATELLITE) SENSOR ................... 37

Removal and Installation ........................................ 37

REMOVAL ........................................................... 37

INSTALLATION ................................................... 37

FRONT SEAT BELT PRE-TENSIONER ................... 38

Removal and Installation ........................................ 38

DIAGNOSIS SENSOR UNIT ..................................... 39

Removal and Installation ........................................ 39

REMOVAL ........................................................... 39

INSTALLATION ................................................... 39

ECU DISCRIMINATED NO. ................................ 39

DISPOSAL OF AIR BAG MODULE AND SEAT BELT

Page 2941 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

SRS-19

C

D

E

F

G

I

J

K

L

MA

B

SRS

a. Touch “SELF-DIAG [CURRENT]”.

lDiagnostic code is displayed on “SELF-DIAG [CURRENT]”.

i. If the malfunction is displayed in the “SRS Ope NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

SRS-19

C

D

E

F

G

I

J

K

L

MA

B

SRS

a. Touch “SELF-DIAG [CURRENT]”.

lDiagnostic code is displayed on “SELF-DIAG [CURRENT]”.

i. If the malfunction is displayed in the “SRS Ope](/img/5/57402/w960_57402-2940.png)

TROUBLE DIAGNOSIS

SRS-19

C

D

E

F

G

I

J

K

L

MA

B

SRS

a. Touch “SELF-DIAG [CURRENT]”.

lDiagnostic code is displayed on “SELF-DIAG [CURRENT]”.

i. If the malfunction is displayed in the “SRS Operation Check (Air bag warning lamp blinking) but no mal-

function is displayed in the “SELF-DIAG [CURRENT]”, the following possibilities shall be checked.

lAfter the malfunction part is repaired, the diagnosis results in “SELF-DIAG [PAST]” has not been

erased.

lAn intermittent malfunction has been stored in the past.

NOTE:

Intermittent malfunction is a malfunction that has occurred once in the past, but soon recovered. Refer to

“SRS-20, "

DIAGNOSTIC PROCEDURE 3"andSRS-20, "DIAGNOSTIC PROCEDURE 4".

b. Touch “SELF-DIAG [PAST].

lThe diagnostic code is displayed until erasing the memory in

the “SELF-DIAG [CURRENT]”.

c. Touch “TROUBLE DIAG RECORD”.

lThe diagnosis results (malfunction parts stored in the diagno-

sis sensor unit) stored in the self-diagnosis results are dis-

played.

lThe memory of “TROUBLE DIAG RECORD” cannot be

erased.

7. Each diagnostic code is displayed.

8. Touch “PRINT,” if required.

9. Based on each diagnosis result, repair or replace the malfunc-

tion parts.

CAUTION:

Be sure to start the work after the following steps. Turn the

ignition switch OFF, and disconnect the battery ground

cable. Then wait for at least 3 minutes.

SHIA0203E

SHIA0181E

SHIA0182E

SHIA0180E

Page 2943 of 3066

TROUBLE DIAGNOSIS

SRS-21

C

D

E

F

G

I

J

K

L

MA

B

SRS

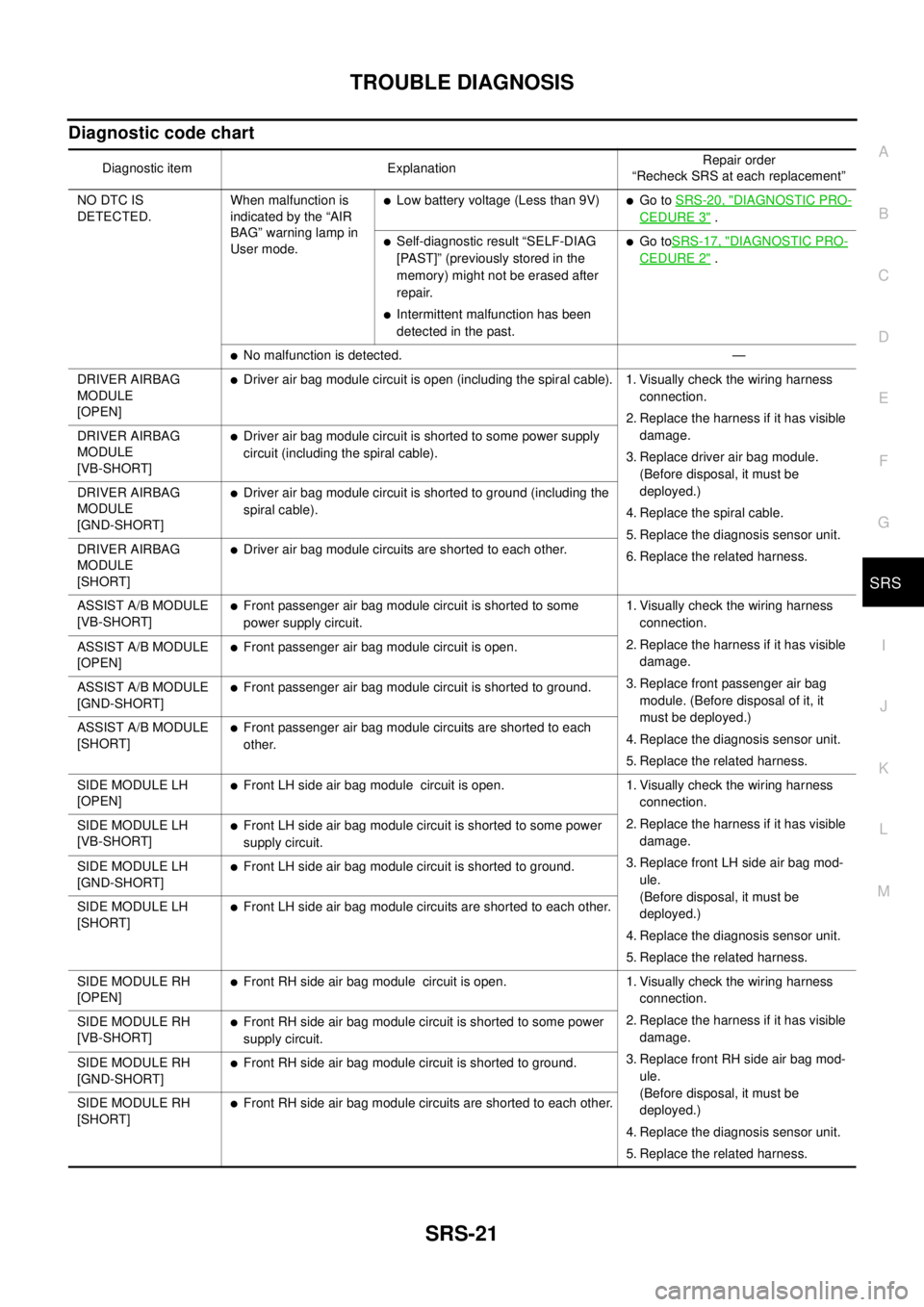

Diagnostic code chart

Diagnostic item ExplanationRepair order

“Recheck SRS at each replacement”

NO DTC IS

DETECTED.When malfunction is

indicated by the “AIR

BAG” warning lamp in

User mode.

lLow battery voltage (Less than 9V)lGo toSRS-20, "DIAGNOSTIC PRO-

CEDURE 3".

lSelf-diagnostic result “SELF-DIAG

[PAST]” (previously stored in the

memory) might not be erased after

repair.

lIntermittent malfunction has been

detected in the past.

lGo toSRS-17, "DIAGNOSTIC PRO-

CEDURE 2".

lNo malfunction is detected. —

DRIVER AIRBAG

MODULE

[OPEN]

lDriver air bag module circuit is open (including the spiral cable). 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace driver air bag module.

(Before disposal, it must be

deployed.)

4. Replace the spiral cable.

5. Replace the diagnosis sensor unit.

6. Replace the related harness. DRIVER AIRBAG

MODULE

[VB-SHORT]

lDriver air bag module circuit is shorted to some power supply

circuit (including the spiral cable).

DRIVER AIRBAG

MODULE

[GND-SHORT]

lDriver air bag module circuit is shorted to ground (including the

spiral cable).

DRIVER AIRBAG

MODULE

[SHORT]

lDriver air bag module circuits are shorted to each other.

ASSIST A/B MODULE

[VB-SHORT]

lFront passenger air bag module circuit is shorted to some

power supply circuit.1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace front passenger air bag

module. (Before disposal of it, it

must be deployed.)

4. Replace the diagnosis sensor unit.

5. Replace the related harness. ASSIST A/B MODULE

[OPEN]

lFront passenger air bag module circuit is open.

ASSIST A/B MODULE

[GND-SHORT]

lFront passenger air bag module circuit is shorted to ground.

ASSIST A/B MODULE

[SHORT]

lFront passenger air bag module circuits are shorted to each

other.

SIDE MODULE LH

[OPEN]

lFront LH side air bag module circuit is open. 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace front LH side air bag mod-

ule.

(Before disposal, it must be

deployed.)

4. Replace the diagnosis sensor unit.

5. Replace the related harness. SIDE MODULE LH

[VB-SHORT]

lFront LH side air bag module circuit is shorted to some power

supply circuit.

SIDE MODULE LH

[GND-SHORT]

lFront LH side air bag module circuit is shorted to ground.

SIDE MODULE LH

[SHORT]

lFront LH side air bag module circuits are shorted to each other.

SIDE MODULE RH

[OPEN]

lFront RH side air bag module circuit is open. 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace front RH side air bag mod-

ule.

(Before disposal, it must be

deployed.)

4. Replace the diagnosis sensor unit.

5. Replace the related harness. SIDE MODULE RH

[VB-SHORT]

lFront RH side air bag module circuit is shorted to some power

supply circuit.

SIDE MODULE RH

[GND-SHORT]

lFront RH side air bag module circuit is shorted to ground.

SIDE MODULE RH

[SHORT]

lFront RH side air bag module circuits are shorted to each other.

Page 2945 of 3066

TROUBLE DIAGNOSIS

SRS-23

C

D

E

F

G

I

J

K

L

MA

B

SRS

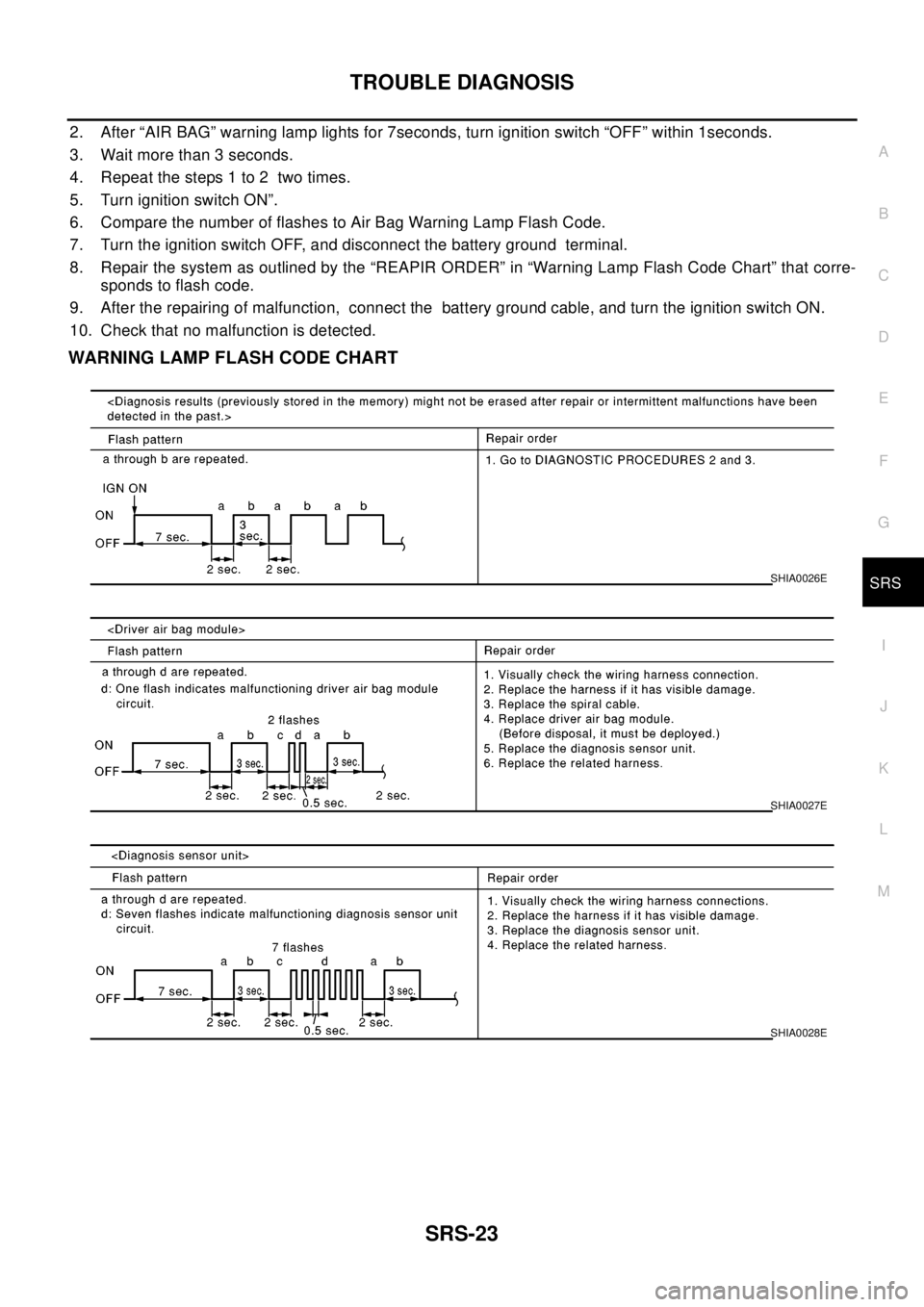

2. After “AIR BAG” warning lamp lights for 7seconds, turn ignition switch “OFF” within 1seconds.

3. Wait more than 3 seconds.

4. Repeat the steps 1 to 2 two times.

5. Turn ignition switch ON”.

6. Compare the number of flashes to Air Bag Warning Lamp Flash Code.

7. Turn the ignition switch OFF, and disconnect the battery ground terminal.

8. Repair the system as outlined by the “REAPIR ORDER” in “Warning Lamp Flash Code Chart” that corre-

sponds to flash code.

9. After the repairing of malfunction, connect the battery ground cable, and turn the ignition switch ON.

10. Check that no malfunction is detected.

WARNING LAMP FLASH CODE CHART

SHIA0026E

SHIA0027E

SHIA0028E

Page 3020 of 3066

TF-50

TROUBLE DIAGNOSIS

G-SENSOR SYSTEM

Inspection Procedure

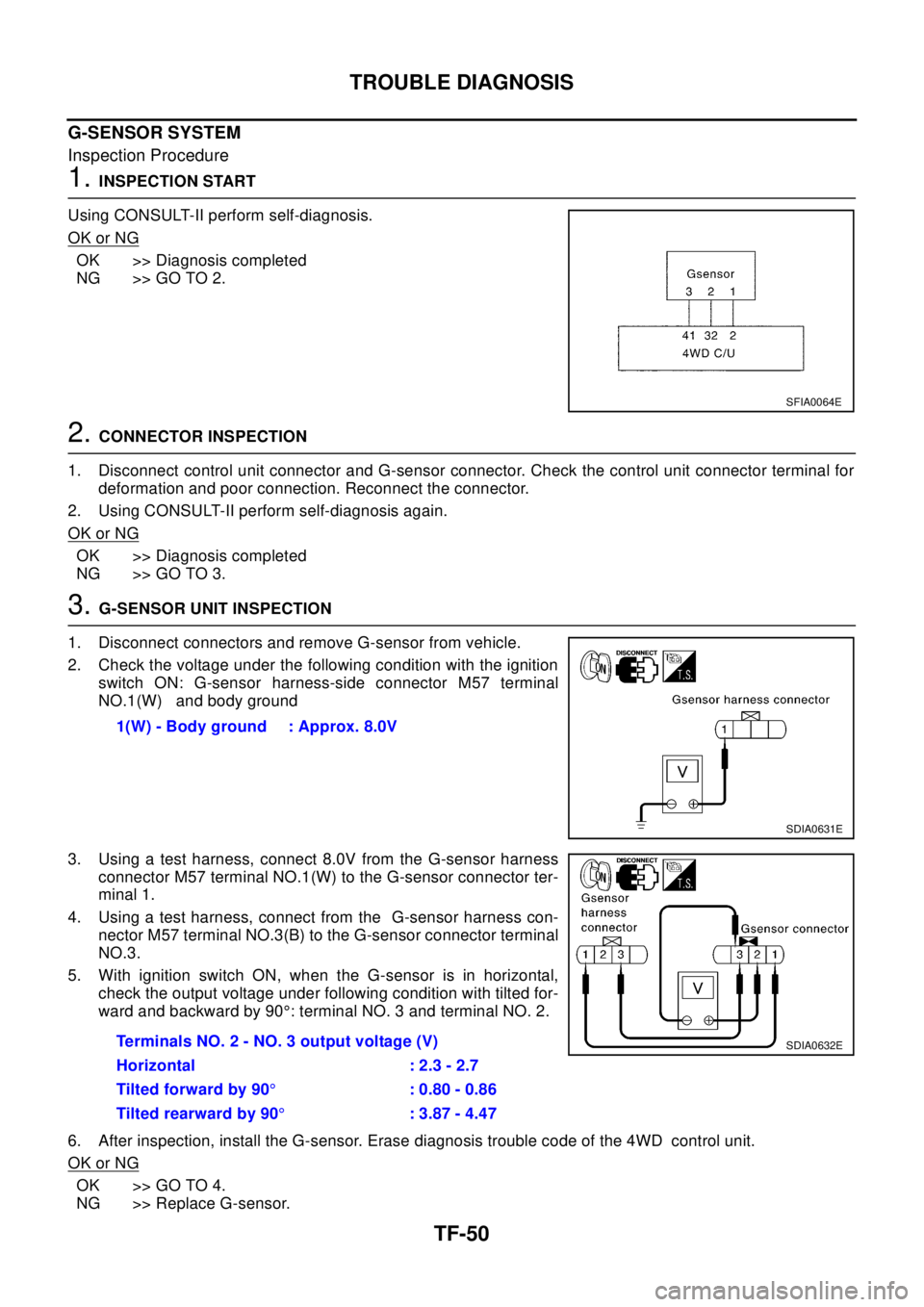

1.INSPECTION START

Using CONSULT-II perform self-diagnosis.

OK or NG

OK >> Diagnosis completed

NG >> GO TO 2.

2.CONNECTOR INSPECTION

1. Disconnect control unit connector and G-sensor connector. Check the control unit connector terminal for

deformation and poor connection. Reconnect the connector.

2. Using CONSULT-II perform self-diagnosis again.

OK or NG

OK >> Diagnosis completed

NG >> GO TO 3.

3.G-SENSOR UNIT INSPECTION

1. Disconnect connectors and remove G-sensor from vehicle.

2. Check the voltage under the following condition with the ignition

switch ON: G-sensor harness-side connector M57 terminal

NO.1(W) and body ground

3. Using a test harness, connect 8.0V from the G-sensor harness

connector M57 terminal NO.1(W) to the G-sensor connector ter-

minal 1.

4. Using a test harness, connect from the G-sensor harness con-

nector M57 terminal NO.3(B) to the G-sensor connector terminal

NO.3.

5. With ignition switch ON, when the G-sensor is in horizontal,

check the output voltage under following condition with tilted for-

ward and backward by 90°: terminal NO. 3 and terminal NO. 2.

6. After inspection, install the G-sensor. Erase diagnosis trouble code of the 4WD control unit.

OK or NG

OK >> GO TO 4.

NG >> Replace G-sensor.

SFIA0064E

1(W) - Body ground : Approx. 8.0V

SDIA0631E

TerminalsNO.2-NO.3outputvoltage(V)

Horizontal : 2.3 - 2.7

Tilted forward by 90°:0.80-0.86

Tilted rearward by 90°:3.87-4.47SDIA0632E

Page 3025 of 3066

TROUBLE DIAGNOSIS

TF-55

C

E

F

G

H

I

J

K

L

MA

B

TF

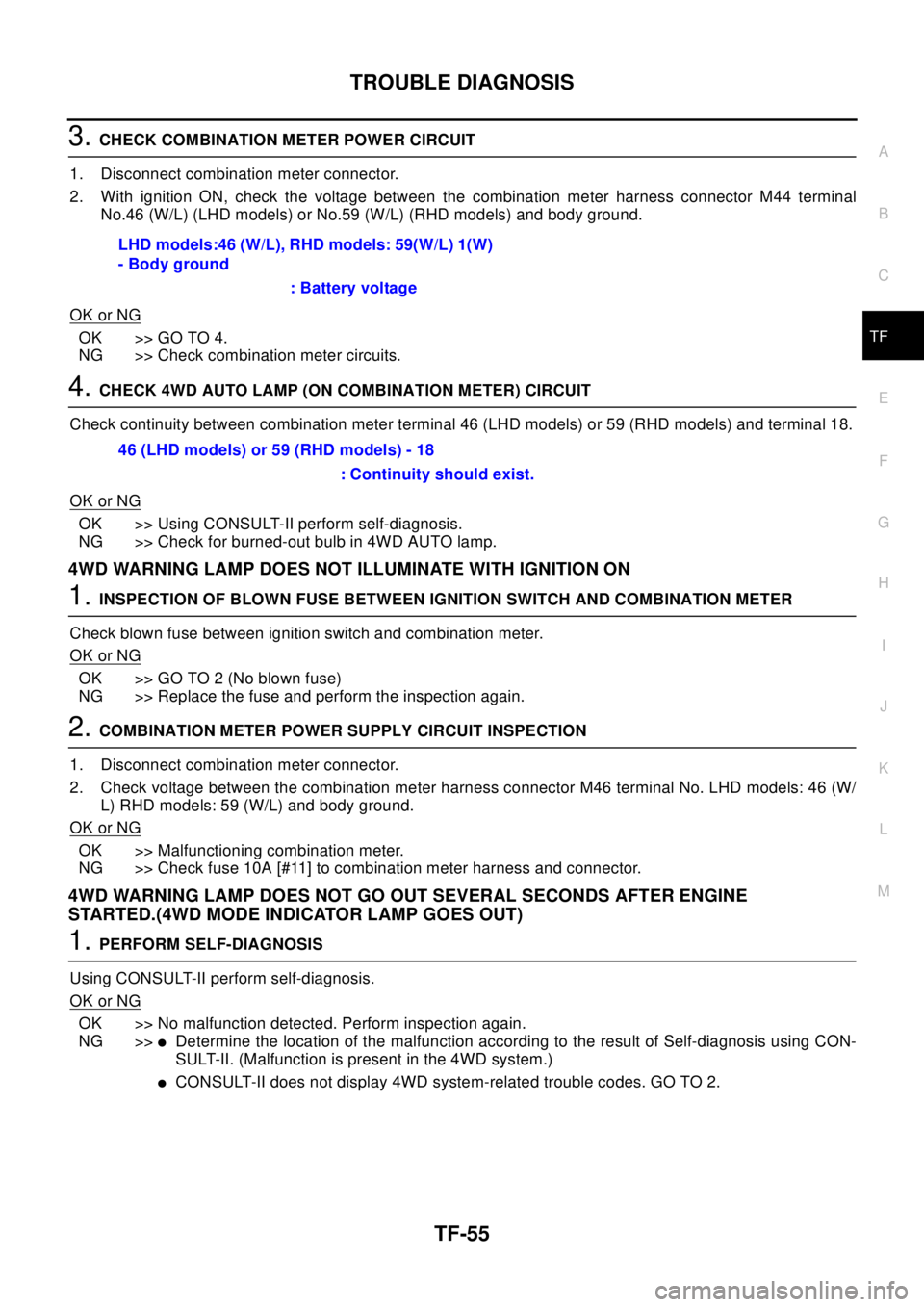

3.CHECK COMBINATION METER POWER CIRCUIT

1. Disconnect combination meter connector.

2. With ignition ON, check the voltage between the combination meter harness connector M44 terminal

No.46 (W/L) (LHD models) or No.59 (W/L) (RHD models) and body ground.

OK or NG

OK >> GO TO 4.

NG >> Check combination meter circuits.

4.CHECK 4WD AUTO LAMP (ON COMBINATION METER) CIRCUIT

Check continuity between combination meter terminal 46 (LHD models) or 59 (RHD models) and terminal 18.

OK or NG

OK >> Using CONSULT-II perform self-diagnosis.

NG >> Check for burned-out bulb in 4WD AUTO lamp.

4WD WARNING LAMP DOES NOT ILLUMINATE WITH IGNITION ON

1.INSPECTION OF BLOWN FUSE BETWEEN IGNITION SWITCH AND COMBINATION METER

Check blown fuse between ignition switch and combination meter.

OK or NG

OK >> GO TO 2 (No blown fuse)

NG >> Replace the fuse and perform the inspection again.

2.COMBINATION METER POWER SUPPLY CIRCUIT INSPECTION

1. Disconnect combination meter connector.

2. Check voltage between the combination meter harness connector M46 terminal No. LHD models: 46 (W/

L) RHD models: 59 (W/L) and body ground.

OK or NG

OK >> Malfunctioning combination meter.

NG >> Check fuse 10A [#11] to combination meter harness and connector.

4WD WARNING LAMP DOES NOT GO OUT SEVERAL SECONDS AFTER ENGINE

STARTED.(4WD MODE INDICATOR LAMP GOES OUT)

1.PERFORM SELF-DIAGNOSIS

Using CONSULT-II perform self-diagnosis.

OK or NG

OK >> No malfunction detected. Perform inspection again.

NG >>

lDetermine the location of the malfunction according to the result of Self-diagnosis using CON-

SULT-II. (Malfunction is present in the 4WD system.)

lCONSULT-II does not display 4WD system-related trouble codes. GO TO 2. LHD models:46 (W/L), RHD models: 59(W/L) 1(W)

- Body ground

: Battery voltage

46 (LHD models) or 59 (RHD models) - 18

: Continuity should exist.