warning OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3463 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–26

Special Tools

WARNING: TO AVOID DEPLOYMENT WHEN

TROUBLESHOOTING THE SRS, DO NOT USE

ELECTRICAL TEST EQUIPMENT SUCH AS A

BATTERY–POWERED OR AC–POWERED

VOLTMETER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN THAT

SPECIFIED IN THIS MANUAL. DO NOT USE A

NONPOWERED PROBE–TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

5–8840–2421–0 SRS Driver/Passenger

Load Tool

901RS146The SRS Driver/Passenger Load Tool 5–8840–2421–0 is

used only when called for in this section. It is used as a

diagnostic aid and safety device to prevent inadvertent air

bag assembly deployment.

The load tool has three yellow connectors attached to its

case.

The three small connectors are electrically functional and

serve as resistive load substitutions.

No more than two connectors are used at any time. One

of the small connectors is used to substitute for the load of

the driver air bag assembly when it is connected at the top

of the column to the SRS coil assembly. Another small

connector is used to substitute for the load of the driver air

bag assembly and the SRS coil assembly when it is

connected at the base of the column to the SRS wiring

harness. The third small connector is used to substitute

for the load of the passenger air bag assembly and

pretensioner seat belt assembly when connected to the

passenger air bag assembly and pretensioner seat belt

assembly harness connector.

By substituting the resistance of the load tool when called

for, a determination can be made as to whether an inflator

circuit component is causing system malfunction and

which component is causing the malfunction. The loadtool should be used only when specifically called for in the

diagnostic procedures.

NOTE: If comand to use 5–8840–2421–0 load tool when

repair the pretensioner seat belt, connect load tool

connector to use for driver air bag and/or passenger air

bag connector.

5–8840–0285–0 DVM

901RS153The 5–8840–0285–0 DVM is the preferred DVM for use in

SRS diagnosis and repair. However, 5–8840–0366–0

may be used if 5–8840–0285–0 is not available. No other

DVMs are approved for SRS diagnosis and repair.

Scan Tool

901RW176The Tech 2 is used to read and clear SRS Diagnostic

Trouble Codes (DTCs). Refer to the Tech 2 Operators,

Manual for specific information on how to use the Tech 2.

Page 3467 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–30

Service Precautions for SRS

Component Service

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. If a fastener needs to be replaced, use

the correct part number fastener for that application.

If the correct part number fastener is not available, a

fastener of equal size and strength (or stronger) may

be used. fasteners that are not reused, and those

requiring thread locking compound will be called

out. The correct torque value must be used when

installing fasteners that require it. If the above

conditions are not followed, parts or system damage

could result.

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS REPAIRS.

The SDM in Driver–Passenger SRS can maintain

sufficient voltage to cause a deployment for up to 15

seconds after the ignition switch is turned “OFF,” the

battery is disconnected, or the fuse powering the SDM is

removed.

Many of the service procedures require removal of the

“C–21” fuse, and disconnection of the air bag assembly

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected from

the deployment loop as noted in the “Disabling the SRS”

procedure that follows, service can begin immediately

without waiting for the 15 second time period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “OFF” and turn the steering

wheel so that the vehicle’s wheels are pointing straight

ahead.

1. Remove SRS fuse “C–21” from left dash side lower

fuse block or disconnect battery.

2. Disconnect yellow 2–pin connector at the base of

steering column.

3 . R e m o v e g l o v e b o x a s s e m b l y ; R e f e r t o “ P a s s e n g e r a i r

bag assembly replacement” in this section.

4. Disconnect passenger air bag assembly yellow 2–pin

connector behind the glove box assembly.

CAUTION: W i t h t h e “ C – 2 1 ” f u s e r e m o v e d a n d

ignition switch “ON,” the “AIR BAG” warning lamp

will be “ON.” This is normal operation and does not

indicate an SRS malfunction.

Enabling The SRS

Installation

Turn ignition switch to “LOCK” and remove key.

1. Connect yellow 2–pin connector passenger air bag

assembly.2. Install glove box assembly. Refer to “Passenger Air

Bag Assembly Replacement” in this section.

3. Connect yellow 2–pin connector at the base of the

steering column.

4. Install “AIR BAG” fuse “C–21” to left dash side lower

fuse block or connect battery.

Turn ignition switch to “ON” and verify that the “AIR BAG”

warning lamp turn on 3.5 seconds and then turns “OFF.” If

it does not operate as described, perform the “SRS

Diagnostic System Check” in this section.

Handling / Installation / Diagnosis

1. Air bag assembly should not be subjected to

temperatures above 93

C (200F).

2. Air bag assembly, and SDM should not be used if they

have been dropped from a height of 100 centimeters

(3.28 feet) or more.

3. When a SDM is replaced, it must be oriented with the

arrow on the SDM pointing toward the front of the

vehicle. It is very important for the SDM to be located

flat on the mounting surface, parallel to the vehicle

datum line. It is important that the SDM mounting

surface is free of any dirt or other foreign material.

4. Do not apply power to the SRS unless all components

are connected or a diagnostic chart requests it, as

this will set a diagnostic trouble code.

5. The “SRS Diagnostic System Check” must be the

starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” will verify proper “AIR

BAG” warning lamp operation and will lead you to the

correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements.

Inspections Required After An Accident

CAUTION: C e r t a i n S R S c o m p o n e n t s m u s t b e

replaced after a frontal crash involving air bag

deployment.

In all types of accidents regardless of “Air Bag”

deployment, visually inspect all of the following

components and replace as required:

— Driver air bag assembly

— Passenger air bag assembly

— Driver pretensioner assembly

— Passenger pretensioner assembly

— Steering wheel

— SRS coil assembly

— Steering column

— Knee bolster and instrument panel mounting

attachments

— Driver seat and belt

— Passenger seat and belt

—SDM

SDM always should be checked according to “SDM

Replacement Guidelines.”

Page 3470 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–33

Sensing And Diagnostic Module (SDM)

Service Precautions

WARNING: DURING SERVICE PROCEDURES, BE

VERY CAREFUL WHEN HANDLING SDM. NEVER

STRIKE OR JAR SDM. UNDER SOME

CIRCUMSTANCES, IT COULD CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY

OR IMPROPER OPERATION OF THE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) . SDM

MOUNTING BRACKET BOLTS MUST BE

CAREFULLY TORQUED TO ASSURE PROPER

OPERATION. NEVER POWER UP THE SRS WHEN

SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE.

THE SDM COULD BE ACTIVATED WHEN POWERED

WHILE NOT RIGIDLY ATTACHED TO THE VEHICLE

WHICH COULD CAUSE DEPLOYMENT AND RESULT

IN PERSONAL INJURY.

WARNING: PROPER OPERATION OF THE SENSING

AND DIAGNOSTIC MODULE (SDM) REQUIRES THE

SDM TO BE RIGIDLY ATTACHED TO THE VEHICLE

STRUCTURE AND THAT THE ARROW ON THE

SENSOR BE POINTING TOWARD THE FRONT OF

THE VEHICLE.

SDM is specifically calibrated and is keyed to the SDM

location SRS wiring harness. Caution should be used to

ensure proper location of the SDM. The keying of the

SDM to its location and wiring harness connectors should

never be modified in the field.

Removal

1. Disable the SRS (Refer to “Disabling the SRS” in this

section).

2. Remove the transmission knob (for M/T) and transfer

lever knob.

3. Remove the front console assembly and disconnect

wiring harness connector.

4. Pull CPA (Connector Position Assurance) out and

push connector lock down to disconnect the SDM

harness connector.

5. Remove the three SDM fixing bolts and remove SDM.

827RW044

Legend

(1) SDM

(2) SRS Harness

(3) Connector Position Assurance

Installation

1. Install the SDM on bracket and fixing bolts and tighten

the fixing bolts to the specified torque.

Torque: 10 Nꞏm (1.0 Kgꞏm/87 Ib in)

2. Connect the SDM harness connector and after that,

put CPA into connector.

3. Install the front console.

4. Install the transmission knob (for M/T) and transfer

lever knob.

Page 3472 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–35

Driver Air Bag Assembly

Service Precautions

WARNING: SAFETY PRECAUTIONS MUST BE

FOLLOWED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE AIR

BAG ASSEMBLY SURFACE MAY CONTAIN A SMALL

AMOUNT OF SODIUM HYDROXIDE, A BY–PRODUCT

OF THE DEPLOYMENT REACTION, THAT IS

IRRITATING TO THE SKIN AND EYES. MOST OF THE

POWER ON THE AIR BAG ASSEMBLY IS

HARMLESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH YOUR

HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WARNING: WHEN CARRYING A LIVE AIR BAG

ASSEMBLY, MAKE SURE THE BAG AND TRIM

COVER ARE POINTED AWAY FROM YOU. NEVER

CARRY AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE. IN

THE CASE OF AN ACCIDENTAL DEPLOYMENT, THE

BAG WILL THEN DEPLOY WITH MINIMAL CHANCE

OF INJURY. WHEN PLACING ALIVE AIR BAG

ASSEMBLY ON A BENCH OR OTHER SURFACE,

ALWAYS FACE BAG AND TRIM COVER UP, AWAY

FROM THE SURFACE. NEVER REST A STEERING

COLUMN ASSEMBLY ON THE STEERING WHEEL

WITH THE AIR BAG ASSEMBLY FACE DOWN AND

COLUMN VERTICAL. THIS IS NECESSARY SO THAT

A FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY COULD RESULT.

NOTE: In the event deployment has occurred, inspect

coil assembly wire for any signs of scorching, melting or

any other damage due to excessive heat. If the coil has

been damaged, replace it.

Removal

1. Disable the SRS (Refer to “Disabling the SRS” in this

section).

2. Loosen the air bag assembly fixing bolts from behind

the steering wheel assembly using a TORX

d r i v e r o r

equivalent until the air bag assembly can be released

from steering wheel.

827RT008

3. Disconnect the yellow 2–pin connector located

behind the air bag assembly and remove air bag

assembly. Refer to “SRS Connectors” in this section

for removal and installation.

827RT009

Page 3474 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–37

Steering Wheel

Service Precautions

WARNING: SAFETY PRECAUTIONS MUST BE

FOLLOWED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE AIR

BAG ASSEMBLY SURFACE MAY CONTAIN A SMALL

AMOUNT OF SODIUM HYDROXIDE, A BY–PRODUCT

OF THE DEPLOYMENT REACTION, THAT IS

IRRITATING TO THE SKIN AND EYES. MOST OF THE

POWER ON THE AIR BAG ASSEMBLY IS

HARMLESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH YOUR

HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WARNING: WHEN CARRYING A LIVE AIR BAG

ASSEMBLY, MAKE SURE THE BAG AND TRIM

COVER ARE POINTED AWAY FROM YOU. NEVER

CARRY AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE. IN

THE CASE OF AN ACCIDENTAL DEPLOYMENT, THE

BAG WILL THEN DEPLOY WITH MINIMAL CHANCE

OF INJURY. WHEN PLACING ALIVE AIR BAG

ASSEMBLY ON A BENCH OR OTHER SURFACE,

ALWAYS FACE BAG AND RIM COVER UP, AWAY

FROM THE SURFACE. NEVER REST A STEERING

COLUMN ASSEMBLY ON THE STEERING WHEEL

WITH THE AIR BAG ASSEMBLY FACE DOWN AND

COLUMN VERTICAL. THIS IS NECESSARY SO THAT

A FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY COULD RESULT.

NOTE: In the event deployment has occurred, inspect

coil assembly wire for any signs of scorching, melting or

any other damage due to excessive heat. If the coil has

been damaged, replace it.

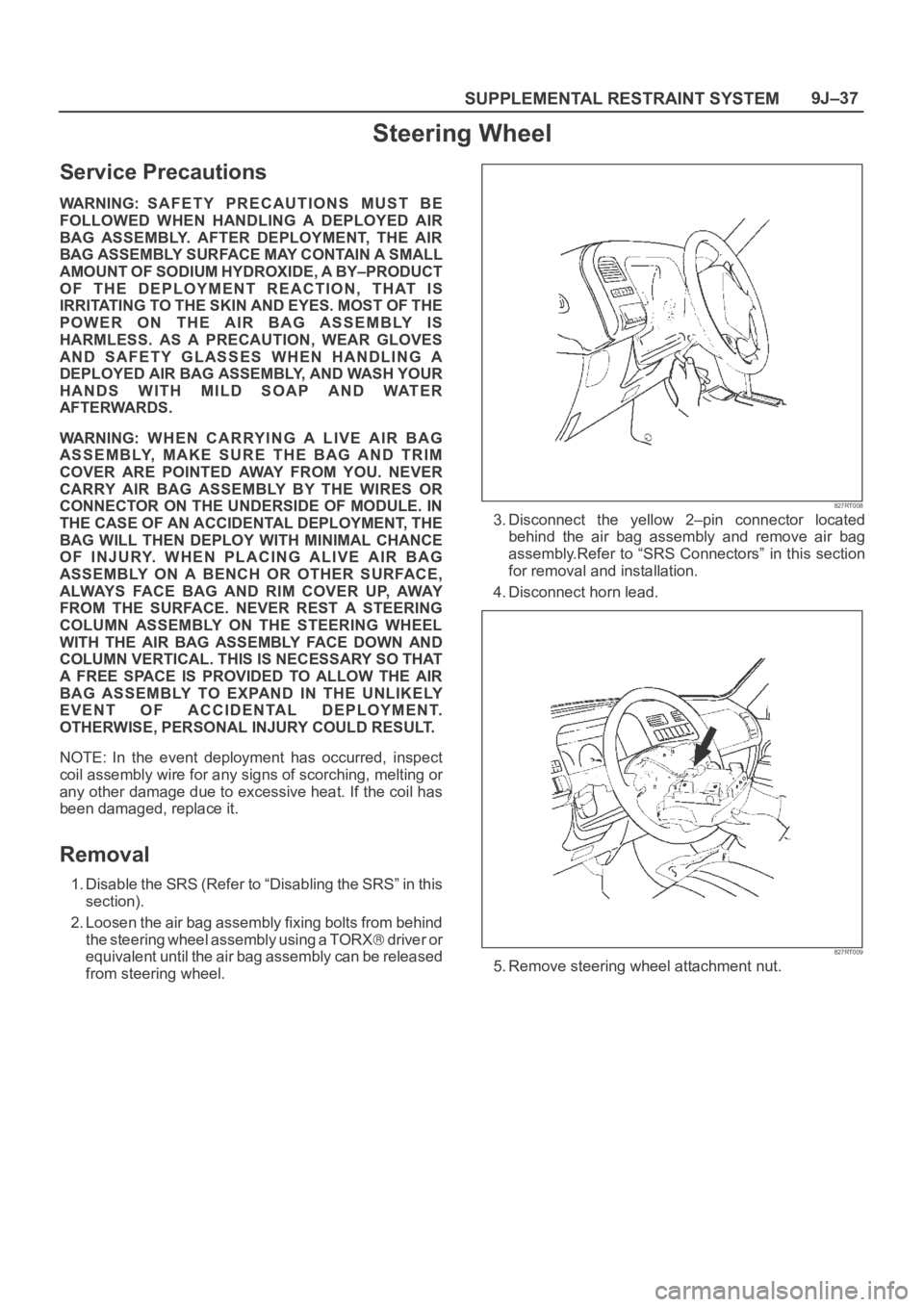

Removal

1. Disable the SRS (Refer to “Disabling the SRS” in this

section).

2. Loosen the air bag assembly fixing bolts from behind

the steering wheel assembly using a TORX

d r i v e r o r

equivalent until the air bag assembly can be released

from steering wheel.

827RT008

3. Disconnect the yellow 2–pin connector located

behind the air bag assembly and remove air bag

assembly.Refer to “SRS Connectors” in this section

for removal and installation.

4. Disconnect horn lead.

827RT009

5. Remove steering wheel attachment nut.

Page 3476 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–39

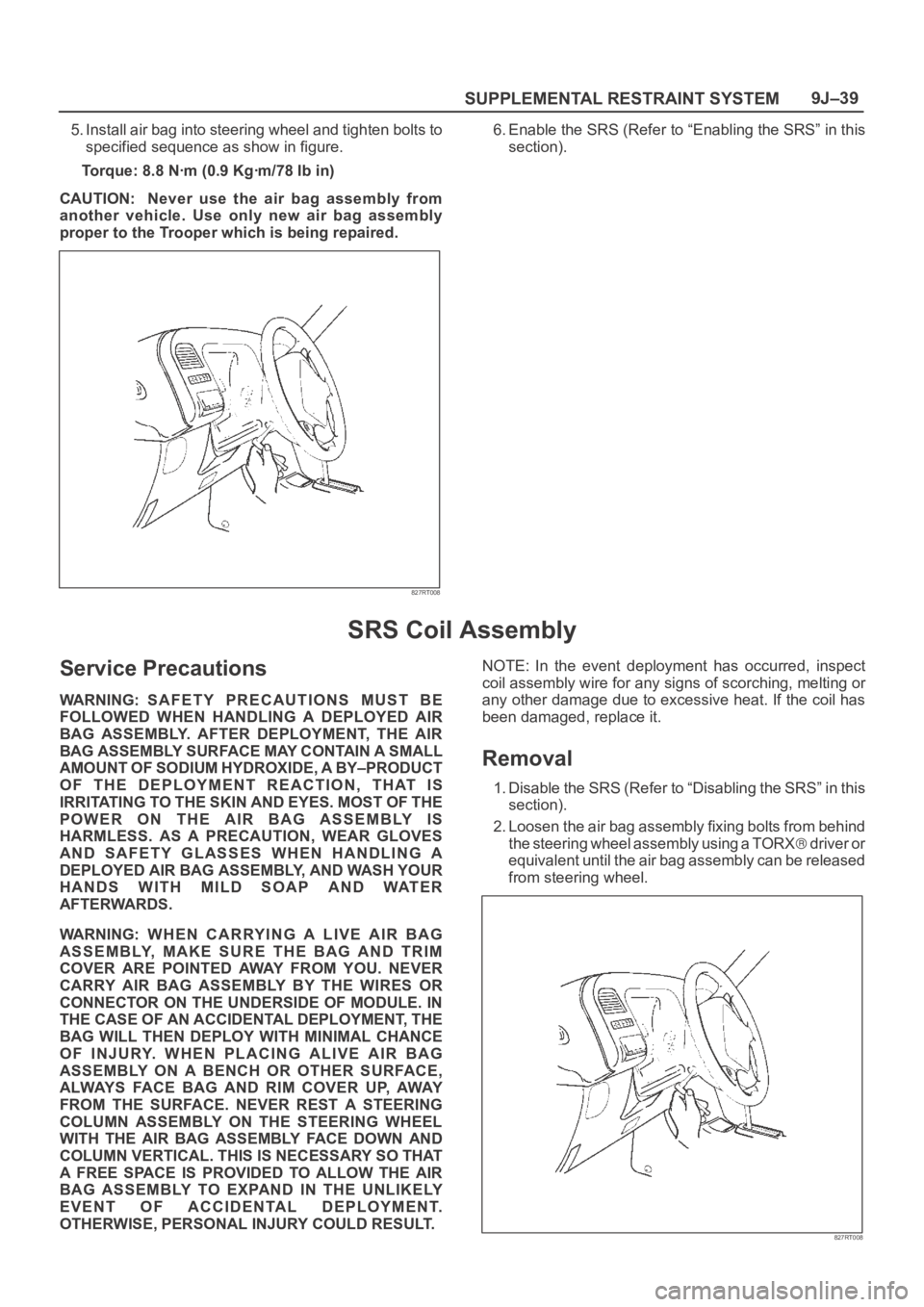

5. Install air bag into steering wheel and tighten bolts to

specified sequence as show in figure.

Torque: 8.8 Nꞏm (0.9 Kgꞏm/78 Ib in)

CAUTION: Never use the air bag assembly from

another vehicle. Use only new air bag assembly

proper to the Trooper which is being repaired.

827RT008

6. Enable the SRS (Refer to “Enabling the SRS” in this

section).

SRS Coil Assembly

Service Precautions

WARNING: SAFETY PRECAUTIONS MUST BE

FOLLOWED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE AIR

BAG ASSEMBLY SURFACE MAY CONTAIN A SMALL

AMOUNT OF SODIUM HYDROXIDE, A BY–PRODUCT

OF THE DEPLOYMENT REACTION, THAT IS

IRRITATING TO THE SKIN AND EYES. MOST OF THE

POWER ON THE AIR BAG ASSEMBLY IS

HARMLESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH YOUR

HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WARNING: WHEN CARRYING A LIVE AIR BAG

ASSEMBLY, MAKE SURE THE BAG AND TRIM

COVER ARE POINTED AWAY FROM YOU. NEVER

CARRY AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE. IN

THE CASE OF AN ACCIDENTAL DEPLOYMENT, THE

BAG WILL THEN DEPLOY WITH MINIMAL CHANCE

OF INJURY. WHEN PLACING ALIVE AIR BAG

ASSEMBLY ON A BENCH OR OTHER SURFACE,

ALWAYS FACE BAG AND RIM COVER UP, AWAY

FROM THE SURFACE. NEVER REST A STEERING

COLUMN ASSEMBLY ON THE STEERING WHEEL

WITH THE AIR BAG ASSEMBLY FACE DOWN AND

COLUMN VERTICAL. THIS IS NECESSARY SO THAT

A FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY COULD RESULT.NOTE: In the event deployment has occurred, inspect

coil assembly wire for any signs of scorching, melting or

any other damage due to excessive heat. If the coil has

been damaged, replace it.

Removal

1. Disable the SRS (Refer to “Disabling the SRS” in this

section).

2. Loosen the air bag assembly fixing bolts from behind

the steering wheel assembly using a TORX

d r i v e r o r

equivalent until the air bag assembly can be released

from steering wheel.

827RT008

Page 3481 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–44

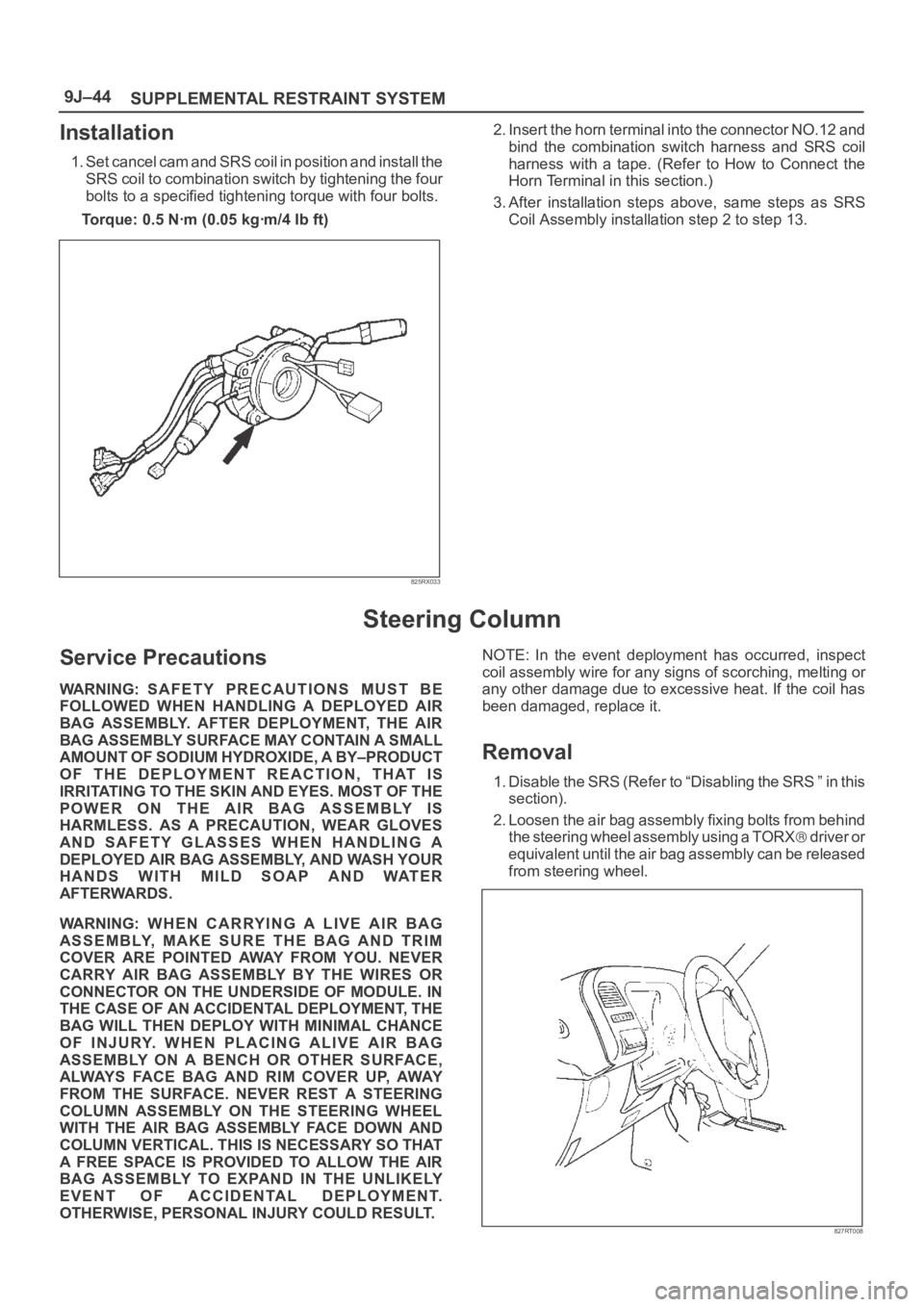

Installation

1. Set cancel cam and SRS coil in position and install the

SRS coil to combination switch by tightening the four

bolts to a specified tightening torque with four bolts.

Torque: 0.5 Nꞏm (0.05 kgꞏm/4 Ib ft)

825RX033

2. Insert the horn terminal into the connector NO.12 and

bind the combination switch harness and SRS coil

harness with a tape. (Refer to How to Connect the

Horn Terminal in this section.)

3. After installation steps above, same steps as SRS

Coil Assembly installation step 2 to step 13.

Steering Column

Service Precautions

WARNING: SAFETY PRECAUTIONS MUST BE

FOLLOWED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE AIR

BAG ASSEMBLY SURFACE MAY CONTAIN A SMALL

AMOUNT OF SODIUM HYDROXIDE, A BY–PRODUCT

OF THE DEPLOYMENT REACTION, THAT IS

IRRITATING TO THE SKIN AND EYES. MOST OF THE

POWER ON THE AIR BAG ASSEMBLY IS

HARMLESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH YOUR

HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WARNING: WHEN CARRYING A LIVE AIR BAG

ASSEMBLY, MAKE SURE THE BAG AND TRIM

COVER ARE POINTED AWAY FROM YOU. NEVER

CARRY AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE. IN

THE CASE OF AN ACCIDENTAL DEPLOYMENT, THE

BAG WILL THEN DEPLOY WITH MINIMAL CHANCE

OF INJURY. WHEN PLACING ALIVE AIR BAG

ASSEMBLY ON A BENCH OR OTHER SURFACE,

ALWAYS FACE BAG AND RIM COVER UP, AWAY

FROM THE SURFACE. NEVER REST A STEERING

COLUMN ASSEMBLY ON THE STEERING WHEEL

WITH THE AIR BAG ASSEMBLY FACE DOWN AND

COLUMN VERTICAL. THIS IS NECESSARY SO THAT

A FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY COULD RESULT.NOTE: In the event deployment has occurred, inspect

coil assembly wire for any signs of scorching, melting or

any other damage due to excessive heat. If the coil has

been damaged, replace it.

Removal

1. Disable the SRS (Refer to “Disabling the SRS ” in this

section).

2. Loosen the air bag assembly fixing bolts from behind

the steering wheel assembly using a TORX

d r i v e r o r

equivalent until the air bag assembly can be released

from steering wheel.

827RT008

Page 3485 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–48

Passenger Air Bag Assembly

Service Precautions

WARNING: SAFETY PRECAUTIONS MUST BE

FOLLOWED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE AIR

BAG ASSEMBLY SURFACE MAY CONTAIN A SMALL

AMOUNT OF SODIUM HYDROXIDE, A BY–PRODUCT

OF THE DEPLOYMENT REACTION, THAT IS

IRRITATING TO THE SKIN AND EYES. MOST OF THE

POWER ON THE AIR BAG ASSEMBLY IS

HARMLESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH YOUR

HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WARNING: WHEN CARRYING A LIVE AIR BAG

ASSEMBLY, MAKE SURE THE BAG AND TRIM

COVER ARE POINTED AWAY FROM YOU. NEVER

CARRY AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE. IN

THE CASE OF AN ACCIDENTAL DEPLOYMENT, THE

BAG WILL THEN DEPLOY WITH MINIMAL CHANCE

OF INJURY. WHEN PLACING ALIVE AIR BAG

ASSEMBLY ON A BENCH OR OTHER SURFACE,

ALWAYS FACE BAG AND RIM COVER UP, AWAY

FROM THE SURFACE. NEVER REST A STEERING

COLUMN ASSEMBLY ON THE STEERING WHEEL

WITH THE AIR BAG ASSEMBLY FACE DOWN AND

COLUMN VERTICAL. THIS IS NECESSARY SO THAT

A FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY COULD RESULT.

NOTE: IN THE EVENT DEPLOYMENT HAS

OCCURRED, INSPECT COIL ASSEMBLY WIRE FOR

ANY SIGNS OF SCORCHING, MELTING OR ANY

OTHER DAMAGE DUE TO EXCESSIVE HEAT. IF THE

COIL HAS BEEN DAMAGED, REPLACE IT.

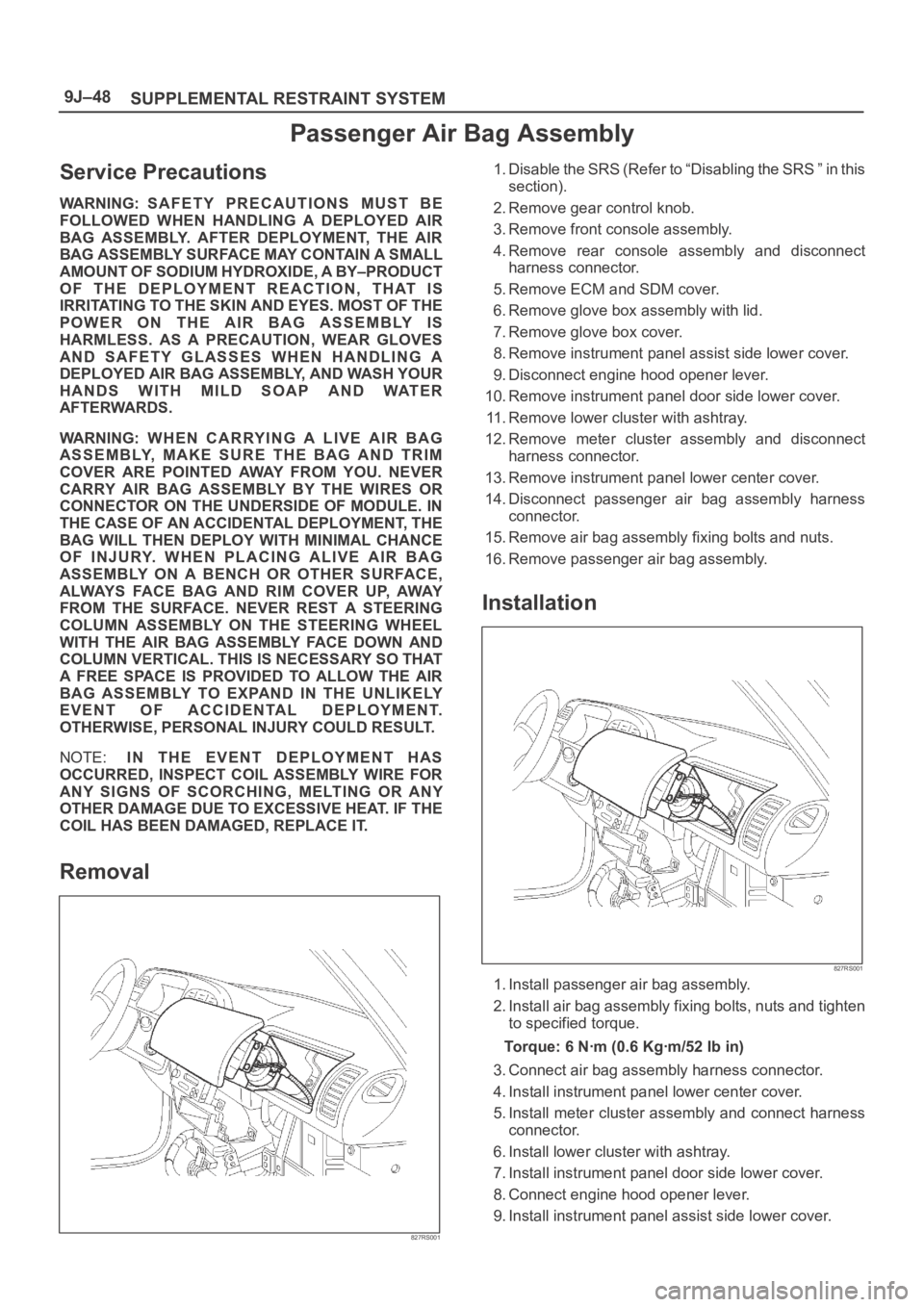

Removal

827RS001

1. Disable the SRS (Refer to “Disabling the SRS ” in this

section).

2. Remove gear control knob.

3. Remove front console assembly.

4. Remove rear console assembly and disconnect

harness connector.

5. Remove ECM and SDM cover.

6. Remove glove box assembly with lid.

7. Remove glove box cover.

8. Remove instrument panel assist side lower cover.

9. Disconnect engine hood opener lever.

10. Remove instrument panel door side lower cover.

11. Remove lower cluster with ashtray.

12. Remove meter cluster assembly and disconnect

harness connector.

13. Remove instrument panel lower center cover.

14. Disconnect passenger air bag assembly harness

connector.

15. Remove air bag assembly fixing bolts and nuts.

16. Remove passenger air bag assembly.

Installation

827RS001

1. Install passenger air bag assembly.

2. Install air bag assembly fixing bolts, nuts and tighten

to specified torque.

Torque: 6 Nꞏm (0.6 Kgꞏm/52 Ib in)

3. Connect air bag assembly harness connector.

4. Install instrument panel lower center cover.

5. Install meter cluster assembly and connect harness

connector.

6. Install lower cluster with ashtray.

7. Install instrument panel door side lower cover.

8. Connect engine hood opener lever.

9. Install instrument panel assist side lower cover.

Page 3486 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–49

10. Install glove box cover.

11. Install glove box assembly with lid.

12. Install ECM and SDM cover.

13. Install rear console assembly and connect harness

connector.14. Install front console assembly.

15. Install gear control knob.

16. Enable the SRS (Refer to “Enabling the SRS” in this

section).

Pretensioner Seat Belt (If so equipped)

Service Precaution

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND THE PRETENSIONER SEAT BELT OR THE

PRETENSIONER SEAT BELT WIRING, FOLLOW THE

PROCEDURES LISTED BELOW TO TEMPORARILY

DISABLE THE PRETENSIONER SEAT BELT.

FAILURE TO FOLLOW PROCEDURES COULD

RESULT IN POSSIBLE THE PRETENSIONER SEAT

BELT DEPLOYMENT, PERSONAL INJURY OR

OTHERWISE UNNEEDED THE PRETENSIONER

SEAT BELT REPAIR.

AS A PRECAUTION, WEAR GLOVES AND SAFETY

GLASSES WHEN PERFORMING THE

PRETENSIONER SEAT BELT. WHEN DEPLOY A LIVE

PRETENSIONER SEAT BELT AT OUTSIDE THE

VEHICLE, DEPLOYMENT HARNESS SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE PRETENSIONER SEAT BELT IS

TO BE DEPLOYED. THE PRETENSIONER SEAT

BELT WILL IMMEDIATELY DEPLOY WHEN A POWER

SOURCE IS CONNECTED TO IT. CONNECTING THE

DEPLOYMENT HARNESS SHOULED ALWAYS BE

THE FINAL STEP IN THE PRETENSIONER SEAT

BELT DEPLOYMENT PROCEDURE. FAILURE TO

FOLLOW PROCEDURES IN THE ORDER LISTED

COULD RESULT IN PERSONAL INJURY.

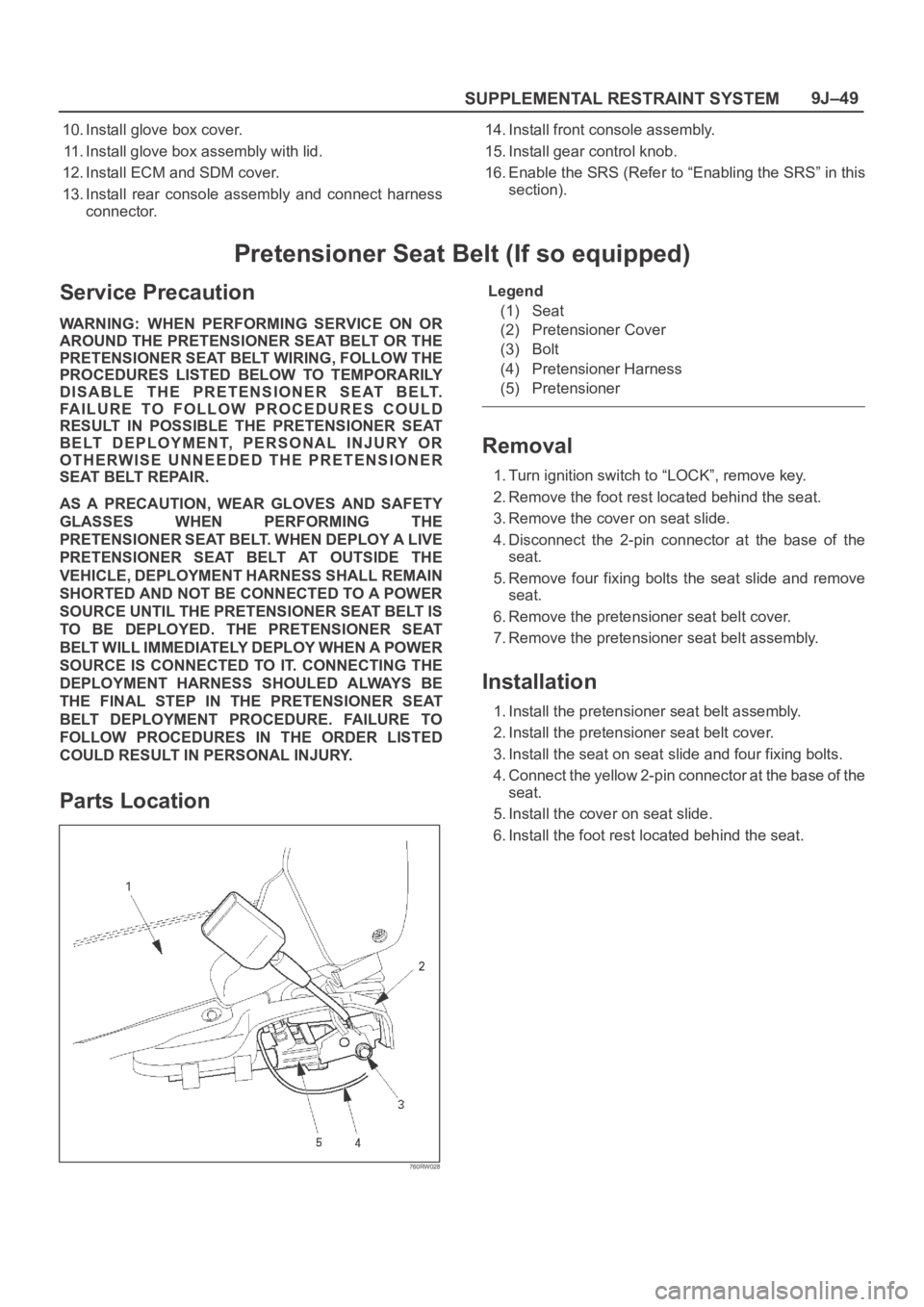

Parts Location

760RW028

Legend

(1) Seat

(2) Pretensioner Cover

(3) Bolt

(4) Pretensioner Harness

(5) Pretensioner

Removal

1. Turn ignition switch to “LOCK”, remove key.

2. Remove the foot rest located behind the seat.

3. Remove the cover on seat slide.

4. Disconnect the 2-pin connector at the base of the

seat.

5. Remove four fixing bolts the seat slide and remove

seat.

6. Remove the pretensioner seat belt cover.

7. Remove the pretensioner seat belt assembly.

Installation

1. Install the pretensioner seat belt assembly.

2. Install the pretensioner seat belt cover.

3. Install the seat on seat slide and four fixing bolts.

4. Connect the yellow 2-pin connector at the base of the

seat.

5. Install the cover on seat slide.

6. Install the foot rest located behind the seat.

Page 3488 of 6000

9J1–1

RESTRAINT CONTROL SYSTEM

RESTRAINT CONTROL SYSTEM

CONTENTS

Service Precaution 9J1–1. . . . . . . . . . . . . . . . . . . . . .

Diagnostic Information 9J1–2. . . . . . . . . . . . . . . . . . .

System Schematic 9J1–4. . . . . . . . . . . . . . . . . . . . . .

SRS Diagnostic System Check 9J1–4. . . . . . . . . . . .

Chart A SDM Integrity Check 9J1–6. . . . . . . . . . . . .

Chart B “AIR BAG” Warning Lamp

Comes “ON” Steady 9J1–8. . . . . . . . . . . . . . . . . . . .

Chart C “AIR BAG” Warning Lamp

Does Not Come “ON” Steady 9J1–10. . . . . . . . . . . . .

DTC 15 Passenger Deployment Loop

Resistance High 9J1–13. . . . . . . . . . . . . . . . . . . . . . . .

DTC 16 Passenger Deployment loop

Resistance Low 9J1–15. . . . . . . . . . . . . . . . . . . . . . . .

DTC 17 Passenger Deployment Loop

Open 9J1–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 18 Passenger Deployment Loop

Short To Ground 9J1–19. . . . . . . . . . . . . . . . . . . . . . . .

DTC 19 Passenger Deployment Loop

Short To B+ 9J1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 21 Driver Deployment Loop

Resistance High 9J1–23. . . . . . . . . . . . . . . . . . . . . . . .

DTC 22 Driver Deployment Loop

Resistance Low 9J1–26. . . . . . . . . . . . . . . . . . . . . . . .

DTC 24 Driver Deployment Loop

Short To Ground 9J1–29. . . . . . . . . . . . . . . . . . . . . . . .

DTC 25 Driver Deployment Loop

Short To B+ 9J1–31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 26 Driver Deployment Loop Open 9J1–33. . . . DTC 51 Air Bag Deployment Event

Commanded 9J1–35. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 53 Deployment Commanded With

Deployment Loop Fault Or Energy

Reserves Out Of Range 9J1–37. . . . . . . . . . . . . . . . .

DTC 61 Warning Lamp Circuit Failure 9J1–39. . . . .

DTC 71 Internal SDM Fault 9J1–41. . . . . . . . . . . . . .

DTC 29 Passenger Pretensioner Loop

Short To Ground 9J1–43. . . . . . . . . . . . . . . . . . . . . . . .

DTC 31 Passenger Pretensioner Loop

Resistance High 9J1–45. . . . . . . . . . . . . . . . . . . . . . . .

DTC 32 Passenger Pretensioner loop

Resistance Low 9J1–47. . . . . . . . . . . . . . . . . . . . . . . .

DTC 33 Passenger Pretensioner Loop

Short To Voltage 9J1–49. . . . . . . . . . . . . . . . . . . . . . . .

DTC 34 Passenger Pretensioner Loop

Open 9J1–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 41 Driver Pretensioner Loop

Resistance High 9J1–53. . . . . . . . . . . . . . . . . . . . . . . .

DTC 42 Driver Pretensioner Loop

Resistance Low 9J1–55. . . . . . . . . . . . . . . . . . . . . . . .

DTC 44 Driver Pretensioner Loop

Open 9J1–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 45 Driver Pretensioner Loop

Short To Ground 9J1–59. . . . . . . . . . . . . . . . . . . . . . . .

DTC 46 Driver Pretensioner Loop

Short To Voltage 9J1–61. . . . . . . . . . . . . . . . . . . . . . . .

DTC 52 Pretensioner Deployment

Event Commanded 9J1–63. . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.