Back OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4209 of 6000

4C–3 DRIVE SHAFT SYSTEM

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

“Clank” When Accelerating From

“Coast”Loose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 4210 of 6000

4C–4

DRIVE SHAFT SYSTEM

Rear Axle Shaft

Rear Axle Shaft and Associated Parts

420RW014

Legend

(1) Brake Caliper

(2) Brake Disc

(3) Wheel Pin

(4) Axle Shaft Assembly

(5) Back Plate

(6) Parking Brake Assembly

(7) Bearing Holder(8) Bearing

(9) Retainer

(10) Snap Ring

(11) Bolt

(12) Nut

(13) Antilock Brake System (ABS) Speed Sensor (if

so equipped)

Removal

1. Raise the vehicle.

2. Remove tires and wheels. Refer to Wheel in Steering

section.3. Remove brake caliper. Use a wire to attach the brake

caliper to the frame. Refer to Disk Brakes in Brake

section.

4. Remove brake disc.

5. Remove ABS sensor (if so equipped).

6. Remove Parking brake assembly. Refer to Parking

Brakes in Brake section.

Page 4211 of 6000

4C–5 DRIVE SHAFT SYSTEM

7.Remove the parking brake cable mounting

bolts(Behind the back plate)(1).

311RS001

8. Remove the bearing holder mounting nuts.

9. Remove axle shaft assembly.

NOTE: Be sure not to damage the oil seal.

10. Remove snap ring.

11. Using a bearing remover 5–8840–2295–0 and press,

remove retainer together with the bearing holder.

420RW024

12. Remove bearing.

13. Remove bearing holder.

14. Remove back plate.15. Remove the wheel pins using a remover

5–8840–0079–0.

420RW023

Inspection and Repair

Make necessary correction or parts replacement if wear,

corrosion or any other abnormal conditions are found

through inspection.

Visual Check:

Check the following parts for wear, damage, noise or any

other abnormal conditions:

1. Axle shaft

2. Bearing

When checking the axle shaft, pay special attention to the

splined portions and replace the shaft if distortion or step

wear is noticeable. Correct slight step wear with a grinder.

420RS008

Page 4212 of 6000

4C–6

DRIVE SHAFT SYSTEM

Axle Shaft Run–out

Limit: 1.0 mm (0.039 in)

420RW025

Axle Shaft Flange Run–out

Limit: 0.08 mm (0.003 in)

420RS010

Oil Seal Replacement

Remove the oil seal carefully not to damage the bearing

holder bore .

When installing, use oil seal installer 5–8840–2310–0.

420RW026

Installation

1. Install wheel pin.

2. Install back plate.

3. Install bearing holder.

4. Install bearing.

5. Install retainer by using a bearing installer

5–8840–2296–0, press fit together with the bearing.

420RW027

6. Install snap ring.

7. Install axle shaft assembly.

NOTE: Be sure not to damage the oil seal.

8. Tighten the bearing holder mounting nut to the

specified torque.

Torque: 74Nꞏm (7.5kgꞏm/54 Ib ft)

Page 4213 of 6000

4C–7 DRIVE SHAFT SYSTEM

9. Fix the parking brake cable mounting bolt (Behind the

back plate).

10. Install parking brake assembly, refer to Parking

Brakes in Brake section.

11. Install antilock brake system sensor (if so equipped).

12. Install brake disc.

13. Install brake caliper, refer to Disk Brakes in Brake

section.

Page 4245 of 6000

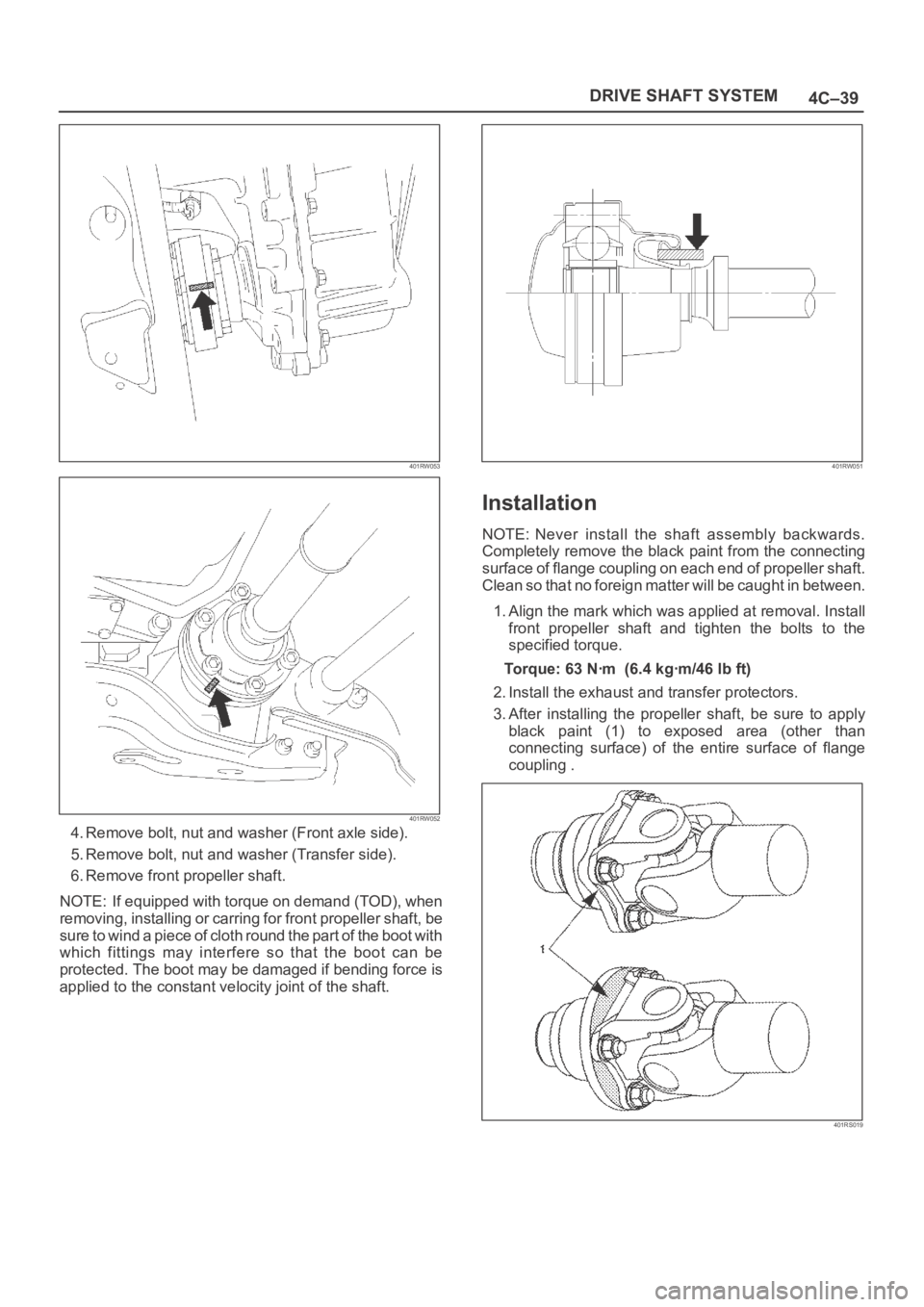

4C–39 DRIVE SHAFT SYSTEM

401RW053

401RW052

4. Remove bolt, nut and washer (Front axle side).

5. Remove bolt, nut and washer (Transfer side).

6. Remove front propeller shaft.

NOTE: If equipped with torque on demand (TOD), when

removing, installing or carring for front propeller shaft, be

sure to wind a piece of cloth round the part of the boot with

which fittings may interfere so that the boot can be

protected. The boot may be damaged if bending force is

applied to the constant velocity joint of the shaft.

401RW051

Installation

NOTE: Never install the shaft assembly backwards.

Completely remove the black paint from the connecting

surface of flange coupling on each end of propeller shaft.

Clean so that no foreign matter will be caught in between.

1. Align the mark which was applied at removal. Install

front propeller shaft and tighten the bolts to the

specified torque.

Torque:63Nꞏm (6.4kgꞏm/46lbft)

2. Install the exhaust and transfer protectors.

3. After installing the propeller shaft, be sure to apply

black paint (1) to exposed area (other than

connecting surface) of the entire surface of flange

coupling .

401RS019

Page 4249 of 6000

4C–43 DRIVE SHAFT SYSTEM

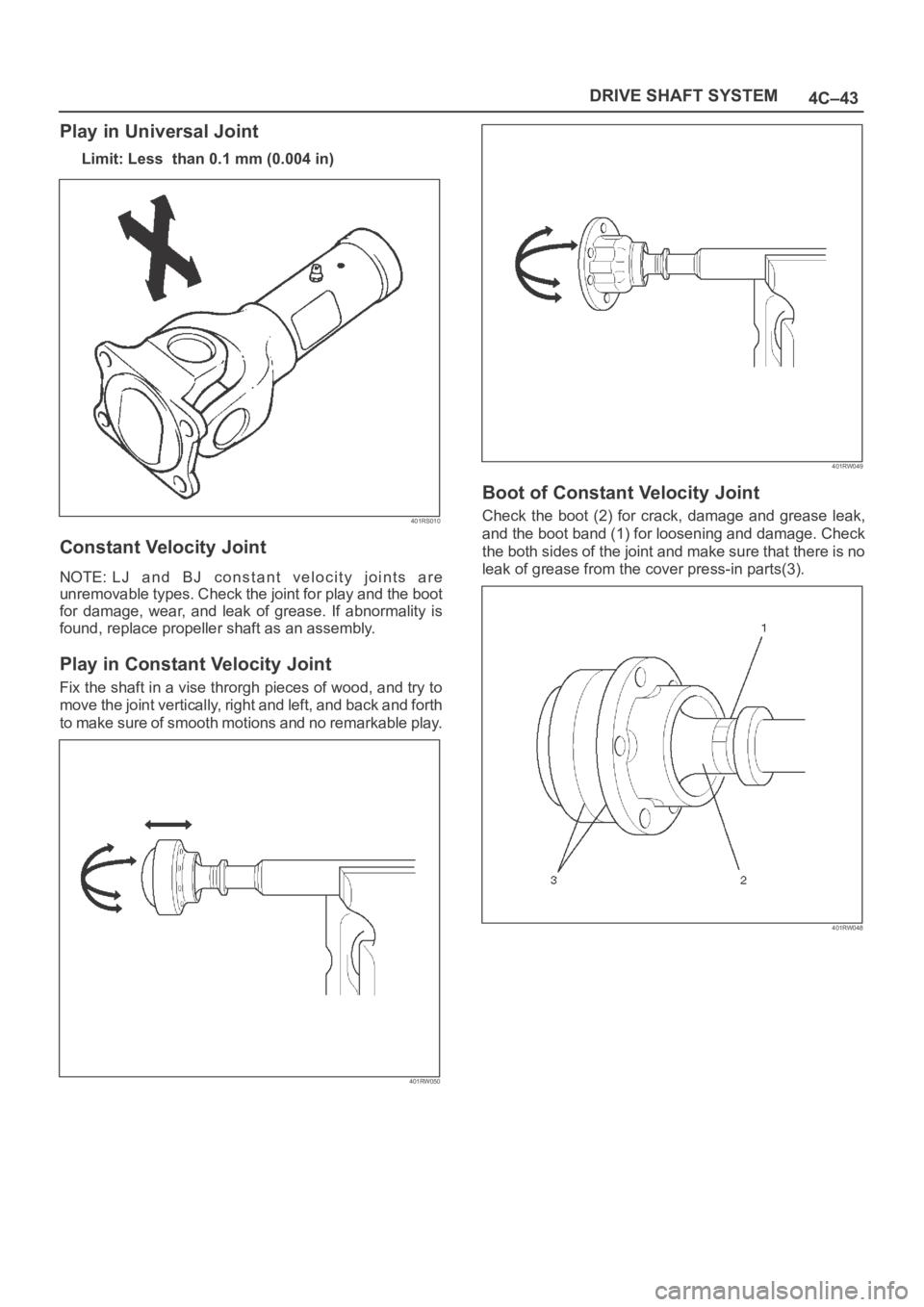

Play in Universal Joint

Limit: Less than 0.1 mm (0.004 in)

401RS010

Constant Velocity Joint

NOTE: LJ and BJ constant velocity joints are

unremovable types. Check the joint for play and the boot

for damage, wear, and leak of grease. If abnormality is

found, replace propeller shaft as an assembly.

Play in Constant Velocity Joint

Fix the shaft in a vise throrgh pieces of wood, and try to

move the joint vertically, right and left, and back and forth

to make sure of smooth motions and no remarkable play.

401RW050

401RW049

Boot of Constant Velocity Joint

Check the boot (2) for crack, damage and grease leak,

and the boot band (1) for loosening and damage. Check

the both sides of the joint and make sure that there is no

leak of grease from the cover press-in parts(3).

401RW048

Page 4255 of 6000

4C–49 DRIVE SHAFT SYSTEM

Removal

1. Jack up the vehicle and support it on the chassis

stands.

2. Gear shift lever should be placed in neutral position

and parking brake released.

NOTE: Apply alignment marks on the flange at the rear

propeller shaft both front and rear side.

401RS023

3. Remove bolt, nut and washer (Rear axle side).

4. Remove bolt, nut and washer (Transfer side).

5. Remove rear propeller shaft.

Installation

NOTE: Never install the shaft assembly backwards.

1. Completely remove the black paint from the

connecting surface of flange coupling on each end of

propeller shaft. Clean so that no foreign matter will be

caught in between.

2. Align the mark which is applied at removal .

Install rear propeller shaft and tighten the bolts to the

specified torque.

Torque: 63 Nꞏm (6.4 kgꞏm/46 lb ft)3. After installing the propeller shaft, be sure to apply

black paint (1) to exposed area (other than

connecting surface) of the entire surface of flange

coupling .

401RS022

Page 4320 of 6000

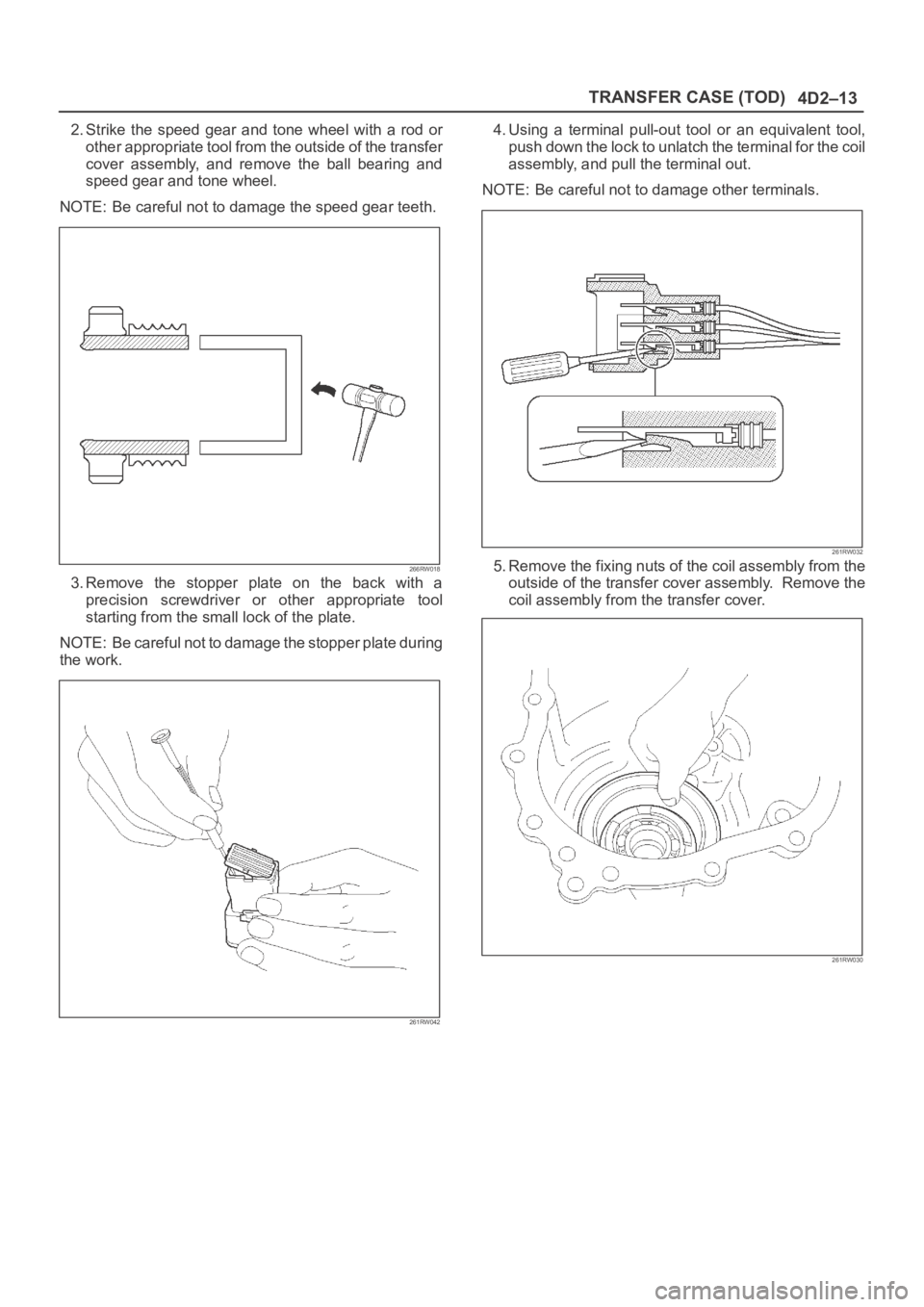

4D2–13 TRANSFER CASE (TOD)

2. Strike the speed gear and tone wheel with a rod or

other appropriate tool from the outside of the transfer

cover assembly, and remove the ball bearing and

speed gear and tone wheel.

NOTE: Be careful not to damage the speed gear teeth.

266RW018

3. Remove the stopper plate on the back with a

precision screwdriver or other appropriate tool

starting from the small lock of the plate.

NOTE: Be careful not to damage the stopper plate during

the work.

261RW042

4. Using a terminal pull-out tool or an equivalent tool,

push down the lock to unlatch the terminal for the coil

assembly, and pull the terminal out.

NOTE: Be careful not to damage other terminals.

261RW032

5. Remove the fixing nuts of the coil assembly from the

outside of the transfer cover assembly. Remove the

coil assembly from the transfer cover.

261RW030

Page 4354 of 6000

5A–4

BRAKE CONTROL SYSTEM

normal braking when a malfunction has occurred in the

ABS.

The EHCU has a self-diagnosing function which can

indicate faulty circuits during diagnosis.

The EHCU is mounted on the engine compartment front

right side. It consists of a Motor, Plunger Pump, Solenoid

Valves and Check Valve.

On the outside, the relay box containing a motor relay and

a valve relay is installed.

Solenoid Valves: Reduces or holds the caliper fluid

pressure for each front disc brake or both rear disc brakes

according to the signal sent from the EHCU.

Reservoir: Temporarily holds the brake fluid that returns

from the front and rear disc brake caliper so that pressure

of front disc brake caliper can be reduced smoothly.

Plunger Pump: Feeds the brake fluid held in the reservoir

to the master cylinder.

Motor: Drives the pump according to the signal from

EHCU.

Check Valve: Controls the brake fluid flow.

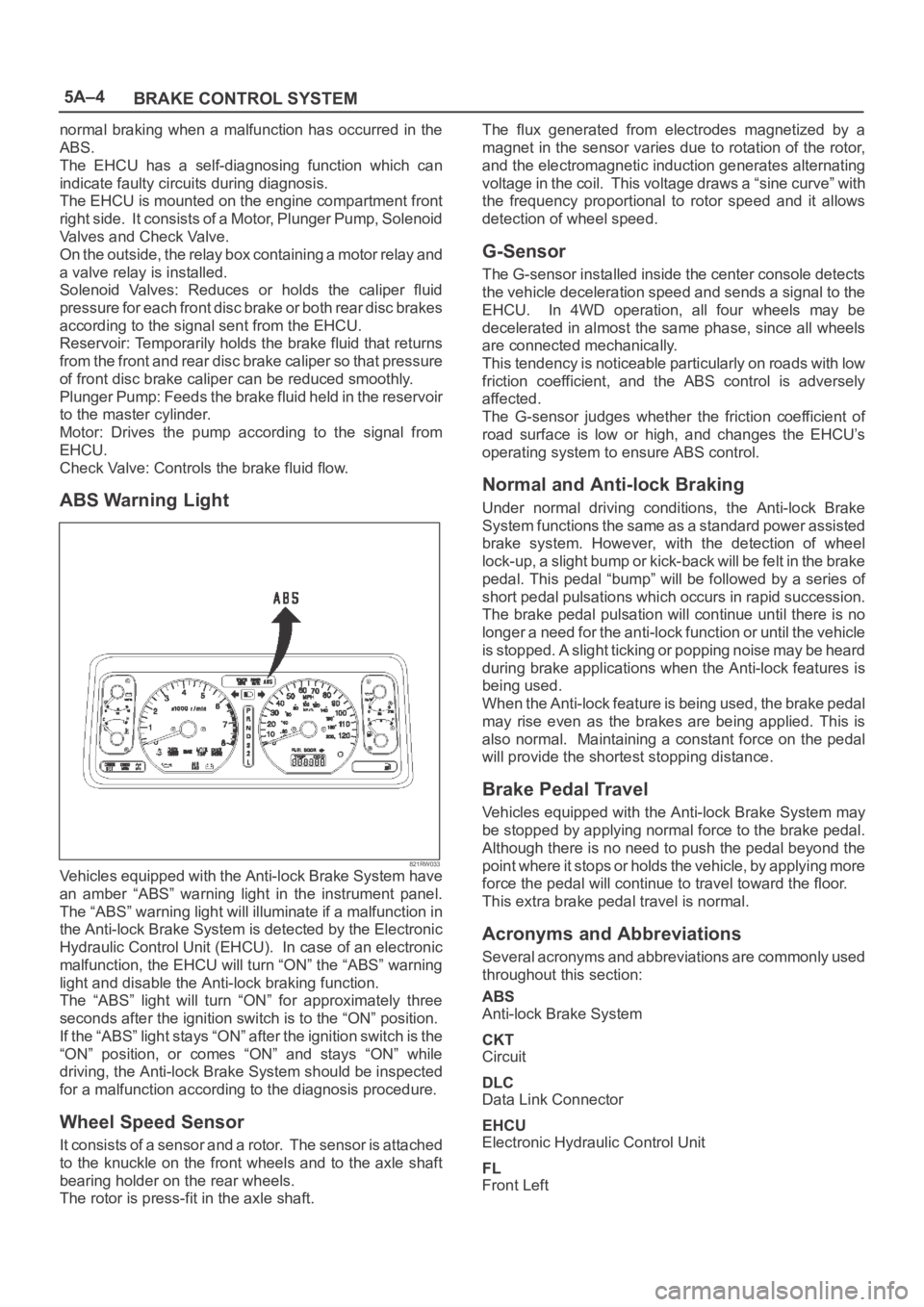

ABS Warning Light

821RW033Vehicles equipped with the Anti-lock Brake System have

an amber “ABS” warning light in the instrument panel.

The “ABS” warning light will illuminate if a malfunction in

the Anti-lock Brake System is detected by the Electronic

Hydraulic Control Unit (EHCU). In case of an electronic

malfunction, the EHCU will turn “ON” the “ABS” warning

light and disable the Anti-lock braking function.

The “ABS” light will turn “ON” for approximately three

seconds after the ignition switch is to the “ON” position.

If the “ABS” light stays “ON” after the ignition switch is the

“ON” position, or comes “ON” and stays “ON” while

driving, the Anti-lock Brake System should be inspected

for a malfunction according to the diagnosis procedure.

Wheel Speed Sensor

It consists of a sensor and a rotor. The sensor is attached

to the knuckle on the front wheels and to the axle shaft

bearing holder on the rear wheels.

The rotor is press-fit in the axle shaft.The flux generated from electrodes magnetized by a

magnet in the sensor varies due to rotation of the rotor,

and the electromagnetic induction generates alternating

voltage in the coil. This voltage draws a “sine curve” with

the frequency proportional to rotor speed and it allows

detection of wheel speed.

G-Sensor

The G-sensor installed inside the center console detects

the vehicle deceleration speed and sends a signal to the

EHCU. In 4WD operation, all four wheels may be

decelerated in almost the same phase, since all wheels

are connected mechanically.

This tendency is noticeable particularly on roads with low

friction coefficient, and the ABS control is adversely

affected.

The G-sensor judges whether the friction coefficient of

road surface is low or high, and changes the EHCU’s

operating system to ensure ABS control.

Normal and Anti-lock Braking

Under normal driving conditions, the Anti-lock Brake

System functions the same as a standard power assisted

brake system. However, with the detection of wheel

lock-up, a slight bump or kick-back will be felt in the brake

pedal. This pedal “bump” will be followed by a series of

short pedal pulsations which occurs in rapid succession.

The brake pedal pulsation will continue until there is no

longer a need for the anti-lock function or until the vehicle

is stopped. A slight ticking or popping noise may be heard

during brake applications when the Anti-lock features is

being used.

When the Anti-lock feature is being used, the brake pedal

may rise even as the brakes are being applied. This is

also normal. Maintaining a constant force on the pedal

will provide the shortest stopping distance.

Brake Pedal Travel

Vehicles equipped with the Anti-lock Brake System may

be stopped by applying normal force to the brake pedal.

Although there is no need to push the pedal beyond the

point where it stops or holds the vehicle, by applying more

force the pedal will continue to travel toward the floor.

This extra brake pedal travel is normal.

Acronyms and Abbreviations

Several acronyms and abbreviations are commonly used

throughout this section:

ABS

Anti-lock Brake System

CKT

Circuit

DLC

Data Link Connector

EHCU

Electronic Hydraulic Control Unit

FL

Front Left