remote control OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 138 of 625

dOORS2D-15

3. Unhook con&cting rod out of old support and

hook into new support and door lock.

the water deflector foil is inserted in lower door slot.See Figure

2D-6. Reverse procedure for installation.2D-i-

Figure

2D-7 Removing Support

4. Screw support onto door inner panel so that it canbe shifted in both holes. Adjust remote control so

that the connecting rod has a clearance at the door

lock of

.02 inch (0.5 mm).

5. Tighten support to door inner panel.

b. Install door trim pad

REMOVAL AND INSTALLATION OF FRONT

DOOR

BELT REVEAL MOLDING

1. Bend up ends of molding.2. With a wooden wedge, pry off molding towards

the top. See Figure

2D-8.Figure

2D-6 Installing Water Deflector

REMOVAL AND INSTALLATION OF FRONT

DOOR

INSIDEHANDLE WITH SUPPORT

1. Remove door trim pad.

2. Unscrew support and unhook connecting rod out

of door lock. See Figure

2D-7.Figure

2D-6 Removing Molding

3. Check retaining clamps in outer door panel for

proper position and tight seat. Push new molding

onto retaining clamps and bend both ends inwards.

REMOVAL AND INSTALLATION OF FRONT

DOOR

WINDOW LIFTER

Removal1. Remove door trim pad.

Page 356 of 625

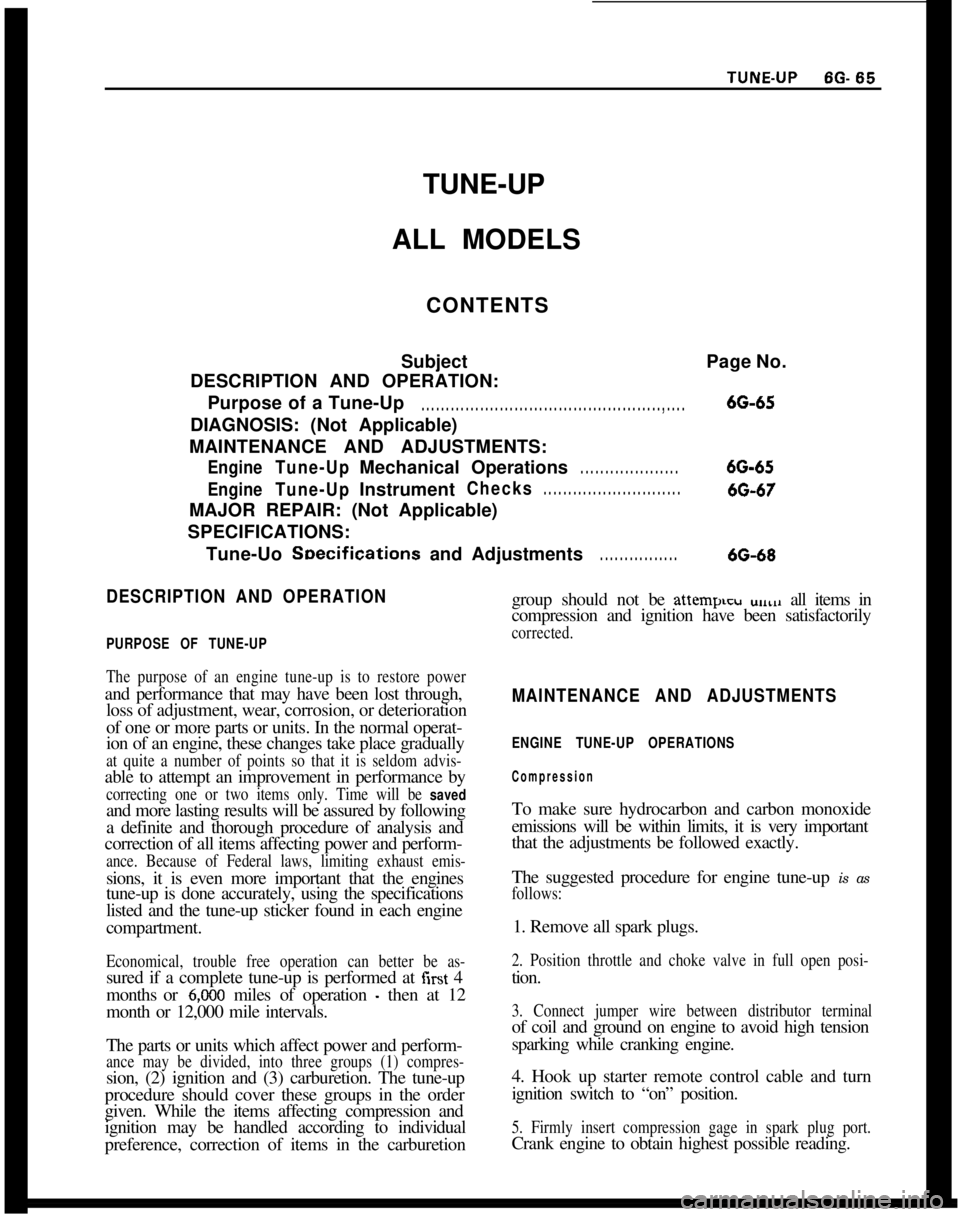

TUNE-UP

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Purpose of a Tune-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

EngineTune-UpMechanicalOperations. . . . . . . . . . . . . . . . . . . .

EngineTune-UpInstrumentChecks. . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR: (Not Applicable)

SPECIFICATIONS:

Tune-Uo Soecifications and Adjustments

. . . . . . . . . . . . . . . .Page No.6G-65

6G-6566-6766-68

DESCRIPTION AND OPERATION

PURPOSE OF TUNE-UP

The purpose of an engine tune-up is to restore powerand performance that may have been lost through,

loss of adjustment, wear, corrosion, or deterioration

of one or more parts or units. In the normal operat-

ion of an engine, these changes take place gradually

at quite a number of points so that it is seldom advis-able to attempt an improvement in performance by

correcting one or two items only. Time will be savedand more lasting results will be assured by following

a definite and thorough procedure of analysis and

correction of all items affecting power and perform-

ance. Because of Federal laws, limiting exhaust emis-sions, it is even more important that the engines

tune-up is done accurately, using the specifications

listed and the tune-up sticker found in each engine

compartment.

Economical, trouble free operation can better be as-sured if a complete tune-up is performed at first 4

months or

6,ooO miles of operation - then at 12

month or 12,000 mile intervals.

The parts or units which affect power and perform-

ance may be divided, into three groups (1) compres-sion, (2) ignition and (3) carburetion. The tune-up

procedure should cover these groups in the order

given. While the items affecting compression and

ignition may be handled according to individual

preference, correction of items in the carburetiongroup should not be attemplcu

ulllll all items in

compression and ignition have been satisfactorily

corrected.

MAINTENANCE AND ADJUSTMENTS

ENGINE TUNE-UP OPERATIONS

CompressionTo make sure hydrocarbon and carbon monoxide

emissions will be within limits, it is very important

that the adjustments be followed exactly.

The suggested procedure for engine tune-up is as

follows:1. Remove all spark plugs.

2. Position throttle and choke valve in full open posi-tion.

3. Connect jumper wire between distributor terminalof coil and ground on engine to avoid high tension

sparking while cranking engine.

4. Hook up starter remote control cable and turn

ignition switch to “on” position.

5. Firmly insert compression gage in spark plug port.Crank engine to obtain highest possible reading.