tow OPEL KARL 2017.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.5, Model line: KARL, Model: OPEL KARL 2017.5Pages: 203, PDF Size: 5.4 MB

Page 107 of 203

Climate control105Press A/C again to switch off cooling.

The air conditioning system cools and

dehumidifies (dries) as soon as the

outside temperature is slightly above

the freezing point. Therefore

condensation may form and drip from

under the vehicle.

If no cooling or drying is required,

switch off the cooling system for fuel

saving reasons.

Activated cooling might inhibit

Autostops.

Stop-start system 3 111.

Air recirculation mode 4

Press 4 to activate air recirculation

mode. The LED in the button

illuminates to indicate activation.

Press 4 again to deactivate air

recirculation mode.9 Warning

The exchange of fresh air is

reduced in air recirculation mode.

In operation without cooling, the

air humidity increases, so the

windows may mist up from inside.

The quality of the passenger

compartment air deteriorates,

which may cause the vehicle

occupants to feel drowsy.

In warm and very humid ambient air conditions, the windscreen may mist

up from outside when cold air is

directed towards it. If windscreen

mists up from outside, activate

windscreen wiper.

Maximum cooling Briefly open the windows so that hotair can disperse quickly.

● Switch on cooling A/C.

● Switch on Air recirculation system 4.

● Set temperature control to coldest level.

● Set fan speed to highest level.

● Set air distribution control to M.

● Open all vents.

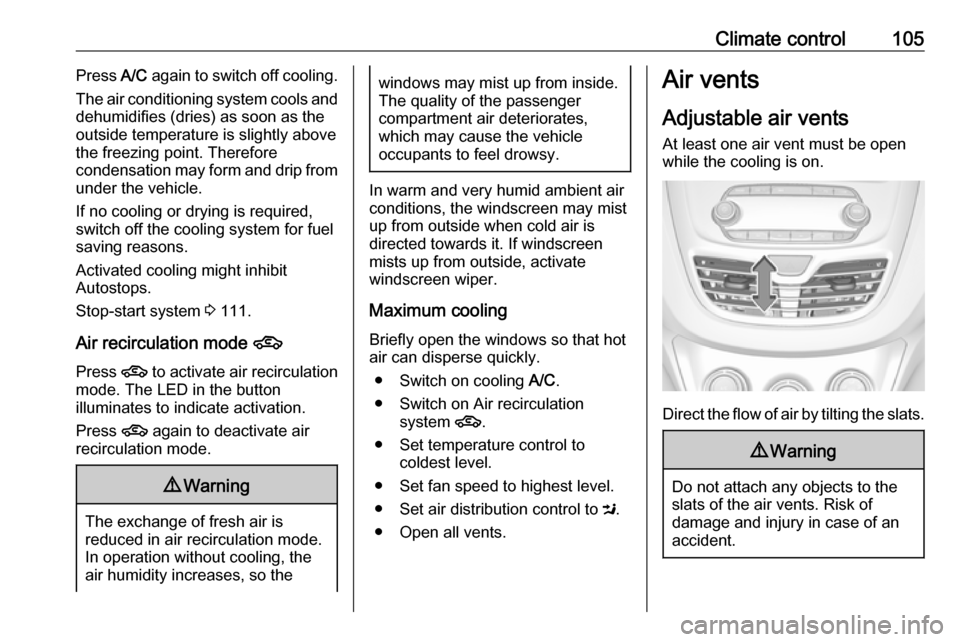

Air vents

Adjustable air vents

At least one air vent must be open

while the cooling is on.

Direct the flow of air by tilting the slats.

9 Warning

Do not attach any objects to the

slats of the air vents. Risk of

damage and injury in case of an

accident.

Page 116 of 203

114Driving and operatingParking9Warning

● Do not park the vehicle on an

easily ignitable surface. The

high temperature of the

exhaust system could ignite the

surface.

● Always apply the parking brake. Activate the manual

parking brake without pressing the release button. Apply as

firmly as possible on a downhill slope or uphill slope. Depress

brake pedal at the same time to

reduce operating force.

● Switch off the engine.

● If the vehicle is on a level surface or uphill slope, engage

first gear before removing the ignition key. On an uphill slope,

turn the front wheels away from

the kerb.

If the vehicle is on a downhill

slope, engage reverse gear

before removing the ignition

key. Turn the front wheels

towards the kerb.

● Close the windows and the sunroof.

● Remove the ignition key from the ignition switch. Turn the

steering wheel until the

steering wheel lock is felt to

engage.

For vehicles with manual

transmission automated, the key

can only be removed from the

ignition switch when the parking

brake is applied.

● Lock the vehicle.

● Activate the anti-theft alarm system.

● The engine cooling fans may run

after the engine has been

switched off 3 139.

Caution

After running at high engine

speeds or with high engine loads,

operate the engine briefly at a low

load or run in neutral for

approx. 30 seconds before

switching off, in order to protect

the turbocharger.

Note

In the event of an accident with

airbag deployment, the engine is

switched off automatically if the

vehicle comes to a standstill within a

certain time.

Page 117 of 203

Driving and operating115Engine exhaust9Danger

Engine exhaust gases contain

poisonous carbon monoxide,

which is colourless and odourless and could be fatal if inhaled.

If exhaust gases enter the interior

of the vehicle, open the windows.

Have the cause of the fault

rectified by a workshop.

Avoid driving with an open load

compartment, otherwise exhaust

gases could enter the vehicle.

Catalytic converter

The catalytic converter reduces the

amount of harmful substances in the

exhaust gases.

Caution

Fuel grades other than those listed on pages 3 129, 3 184 could

damage the catalytic converter or

electronic components.

Unburnt petrol will overheat and

damage the catalytic converter.

Therefore avoid excessive use of the starter, running the fuel tank

dry and starting the engine by

pushing or towing.

In the event of misfiring, uneven

engine running, a reduction in engine performance or other unusual

problems, have the cause of the fault

rectified by a workshop as soon as

possible. In an emergency, driving

can be continued for a short period,

keeping vehicle speed and engine

speed low.

Manual transmission

To engage reverse, depress the

clutch pedal and engage the reverse

gear.

If the gear does not engage, set the

lever to neutral, release the clutch

pedal and depress again; then repeat

gear selection.

Do not slip the clutch unnecessarily.

When operating, depress the clutch

pedal completely. Do not use the

pedal as a foot rest.

Page 121 of 203

Driving and operating119Have the cause of the fault remedied

by a workshop.Brakes

The brake system comprises twoindependent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek

the assistance of a workshop before

continuing the journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has

been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 73.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.ABS starts to regulate brake pressure as soon as a wheel shows a tendency to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that

the pedal is pulsating. Do not reduce

the pressure on the pedal.

After starting-off the system performs a self-test which may be audible.

Control indicator u 3 74.

Adaptive brake light

During full braking, all three brake

lights flash for the duration of ABS

control.

Page 136 of 203

134Driving and operating

Unscrew protective cap from the filler

neck.

Caution

Screw and unscrew the protective cap by hand only.

Protective cap is magnetic. Place it on

fuel filler door while refuelling.

Screw the required adapter hand-

tight onto the filler neck.

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH filler neck: Place the filler nozzle

into the adapter. Press locking lever

on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn clockwise or

anticlockwise through one quarter

turn. Pull locking lever of filler nozzle

fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button at the liquid gas

supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

may escape.

Remove adapter and stow securely in vehicle.

Page 139 of 203

Vehicle care137Vehicle careGeneral Information...................137

Accessories and vehicle modifications .......................... 137

Vehicle storage ........................138

End-of-life vehicle recovery .....138

Vehicle checks ........................... 139

Performing work ......................139

Bonnet ..................................... 139

Engine oil ................................. 140

Engine coolant ......................... 141

Washer fluid ............................ 142

Brakes ..................................... 142

Brake fluid ............................... 142

Vehicle battery ......................... 142

Wiper blade replacement ........144

Bulb replacement .......................145

Halogen headlights ..................145

Fog lights ................................. 147

Front turn signal lights .............147

Tail lights ................................. 148

Side turn signal lights ..............149

Centre high-mounted brake light ......................................... 149

Number plate light ...................150Interior lights ............................ 150

Instrument panel illumination ...150

Electrical system ........................151

Fuses ....................................... 151

Engine compartment fuse box . 152

Instrument panel fuse box .......154

Vehicle tools .............................. 155

Tools ........................................ 155

Wheels and tyres .......................156

Winter tyres ............................. 156

Tyre designations ....................156

Tyre pressure .......................... 157

Tyre pressure monitoring

system .................................... 158

Tread depth ............................. 161

Changing tyre and wheel size . 161 Wheel covers ........................... 162

Tyre chains .............................. 162

Tyre repair kit .......................... 162

Wheel changing .......................165

Spare wheel ............................ 168

Jump starting ............................. 170

Towing ....................................... 171

Towing the vehicle ...................171

Appearance care .......................172

Exterior care ............................ 172

Interior care ............................. 174General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory approved parts specific for your

vehicle type. We cannot assess or

guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control

units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may affect driver assistance

systems, may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the type approval,

impacting the validity of your vehicle

registration.

Page 167 of 203

Vehicle care16513. Detach the tyre repair kit. Pushcatch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

14. Remove any excess sealant using a cloth.

15. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

16. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

10 km (but no more than ten

minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than 1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

17. Stow away tyre repair kit in load compartment.

Reinstall floor cover. Rear floor

storage cover 3 57.

Note

The driving characteristics of the

repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of seven bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the

underside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

Page 169 of 203

Vehicle care167

3. Ensure the jack is correctlypositioned under the relevant

vehicle jacking point.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

5. Unscrew the wheel bolts.

6. Change the wheel.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each bolt in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover of the steel wheel with the

tyre valve before installing.

Install wheel bolt caps or centre

cap on alloy wheel.

11. Stow and secure the replaced wheel, the vehicle tools 3 155 and

the adapter for the locking wheel

bolts 3 53.

12. Check the tyre pressure of the installed tyre and the wheel bolt

torque as soon as possible.Have the defective tyre renewed or

repaired as soon as possible.

Jacking position for lifting platform

Rear arm position of the lifting

platform, located centrally under the

recess of the sill.

Page 170 of 203

168Vehicle care

Front arm position of the lifting

platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.

Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured in the recess

with a wing bolt.

The spare wheel well is not designed for all permitted tyre sizes. If a wheel

wider than the spare must be stowed

in the spare wheel well after changing

wheels, the floor cover can be placed on the projecting wheel.

Temporary spare wheelCaution

The use of the temporary spare

wheel could affect driveability.

Have the defective tyre renewed

or repaired as soon as possible.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not

use for a long period of time.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel in

the front and the full size tyre in the

rear.

Tyre chains 3 162.

Storing a damaged wheel in the

load compartment using a strap

Use the strap placed in the tool box.

Vehicle tools 3 155.

Page 173 of 203

Vehicle care1713. Connect the black lead to thenegative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After five minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

one minute.

3. Allow both engines to idle for approx. three minutes with the

leads connected.4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle The towing eye is stowed with thevehicle tools 3 155.

1. Disengage cap by using the

screwdriver and remove the cap.