sensor OPEL VECTRA 1988 Service User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 54 of 525

12•40Wiring diagrams

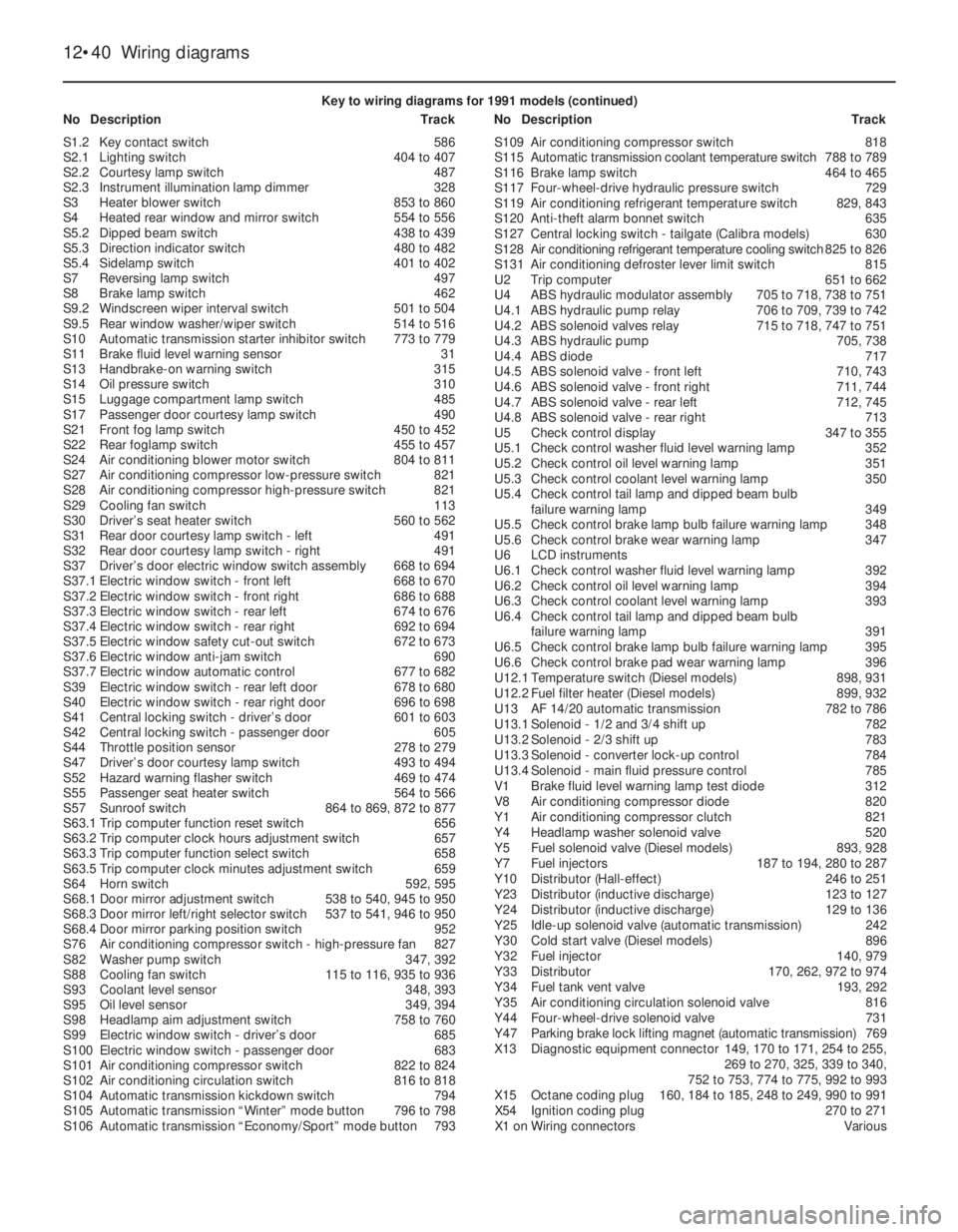

Key to wiring diagrams for 1991 models (continued)

NoDescriptionTrackNoDescriptionTrack

S1.2Key contact switch586

S2.1Lighting switch404 to 407

S2.2Courtesy lamp switch487

S2.3Instrument illumination lamp dimmer328

S3Heater blower switch853 to 860

S4Heated rear window and mirror switch554 to 556

S5.2Dipped beam switch438 to 439

S5.3Direction indicator switch480 to 482

S5.4Sidelamp switch401 to 402

S7Reversing lamp switch497

S8Brake lamp switch462

S9.2Windscreen wiper interval switch501 to 504

S9.5Rear window washer/wiper switch514 to 516

S10Automatic transmission starter inhibitor switch773 to 779

S11Brake fluid level warning sensor31

S13Handbrake-on warning switch315

S14Oil pressure switch310

S15Luggage compartment lamp switch485

S17Passenger door courtesy lamp switch490

S21Front fog lamp switch450 to 452

S22Rear foglamp switch455 to 457

S24Air conditioning blower motor switch804 to 811

S27Air conditioning compressor low-pressure switch821

S28Air conditioning compressor high-pressure switch821

S29Cooling fan switch113

S30Driver’s seat heater switch560 to 562

S31Rear door courtesy lamp switch - left491

S32Rear door courtesy lamp switch - right491

S37Driver’s door electric window switch assembly668 to 694

S37.1Electric window switch - front left668 to 670

S37.2Electric window switch - front right686 to 688

S37.3Electric window switch - rear left674 to 676

S37.4Electric window switch - rear right692 to 694

S37.5Electric window safety cut-out switch672 to 673

S37.6Electric window anti-jam switch690

S37.7Electric window automatic control677 to 682

S39Electric window switch - rear left door678 to 680

S40Electric window switch - rear right door696 to 698

S41Central locking switch - driver’s door601 to 603

S42Central locking switch - passenger door605

S44Throttle position sensor278 to 279

S47Driver’s door courtesy lamp switch493 to 494

S52Hazard warning flasher switch469 to 474

S55Passenger seat heater switch564 to 566

S57Sunroof switch864 to 869, 872 to 877

S63.1Trip computer function reset switch656

S63.2Trip computer clock hours adjustment switch657

S63.3Trip computer function select switch658

S63.5Trip computer clock minutes adjustment switch659

S64Horn switch592, 595

S68.1Door mirror adjustment switch538 to 540, 945 to 950

S68.3Door mirror left/right selector switch537 to 541, 946 to 950

S68.4Door mirror parking position switch952

S76Air conditioning compressor switch - high-pressure fan827

S82Washer pump switch347, 392

S88Cooling fan switch115 to 116, 935 to 936

S93Coolant level sensor348, 393

S95Oil level sensor349, 394

S98Headlamp aim adjustment switch758 to 760

S99Electric window switch - driver’s door685

S100Electric window switch - passenger door683

S101Air conditioning compressor switch822 to 824

S102Air conditioning circulation switch816 to 818

S104Automatic transmission kickdown switch794

S105Automatic transmission “Winter” mode button796 to 798

S106Automatic transmission “Economy/Sport” mode button793S109Air conditioning compressor switch818

S115Automatic transmission coolant temperature switch788 to 789

S116Brake lamp switch464 to 465

S117Four-wheel-drive hydraulic pressure switch729

S119Air conditioning refrigerant temperature switch829, 843

S120Anti-theft alarm bonnet switch635

S127Central locking switch - tailgate (Calibra models)630

S128Air conditioning refrigerant temperature cooling switch825 to 826

S131Air conditioning defroster lever limit switch815

U2Trip computer651 to 662

U4ABS hydraulic modulator assembly705 to 718, 738 to 751

U4.1ABS hydraulic pump relay706 to 709, 739 to 742

U4.2ABS solenoid valves relay715 to 718, 747 to 751

U4.3ABS hydraulic pump705, 738

U4.4ABS diode717

U4.5ABS solenoid valve - front left710, 743

U4.6ABS solenoid valve - front right711, 744

U4.7ABS solenoid valve - rear left712, 745

U4.8ABS solenoid valve - rear right713

U5Check control display347 to 355

U5.1Check control washer fluid level warning lamp352

U5.2Check control oil level warning lamp351

U5.3Check control coolant level warning lamp350

U5.4Check control tail lamp and dipped beam bulb

failure warning lamp349

U5.5Check control brake lamp bulb failure warning lamp348

U5.6Check control brake wear warning lamp347

U6LCD instruments

U6.1Check control washer fluid level warning lamp392

U6.2Check control oil level warning lamp394

U6.3Check control coolant level warning lamp393

U6.4Check control tail lamp and dipped beam bulb

failure warning lamp391

U6.5Check control brake lamp bulb failure warning lamp395

U6.6Check control brake pad wear warning lamp396

U12.1Temperature switch (Diesel models)898, 931

U12.2Fuel filter heater (Diesel models)899, 932

U13AF14/20automatic transmission782 to 786

U13.1Solenoid - 1/2 and 3/4 shift up782

U13.2Solenoid - 2/3 shift up783

U13.3Solenoid - converter lock-up control784

U13.4Solenoid - main fluid pressure control785

V1Brake fluid level warning lamp test diode312

V8Air conditioning compressor diode820

Y1Air conditioning compressor clutch821

Y4Headlamp washer solenoid valve520

Y5Fuel solenoid valve (Diesel models)893, 928

Y7Fuel injectors187 to 194, 280 to 287

Y10Distributor (Hall-effect)246 to 251

Y23Distributor (inductive discharge)123 to 127

Y24Distributor (inductive discharge)129 to 136

Y25Idle-up solenoid valve (automatic transmission)242

Y30Cold start valve (Diesel models)896

Y32Fuel injector140, 979

Y33Distributor170, 262, 972 to 974

Y34Fuel tank vent valve193, 292

Y35Air conditioning circulation solenoid valve816

Y44Four-wheel-drive solenoid valve731

Y47Parking brake lock lifting magnet (automatic transmission)769

X13Diagnostic equipment connector149, 170 to 171, 254 to 255,

269 to 270, 325, 339 to 340,

752 to 753, 774 to 775, 992 to 993

X15Octane coding plug160, 184 to 185, 248 to 249, 990 to 991

X54Ignition coding plug270 to 271

X1 onWiring connectorsVarious

Page 70 of 525

12•56Wiring diagrams

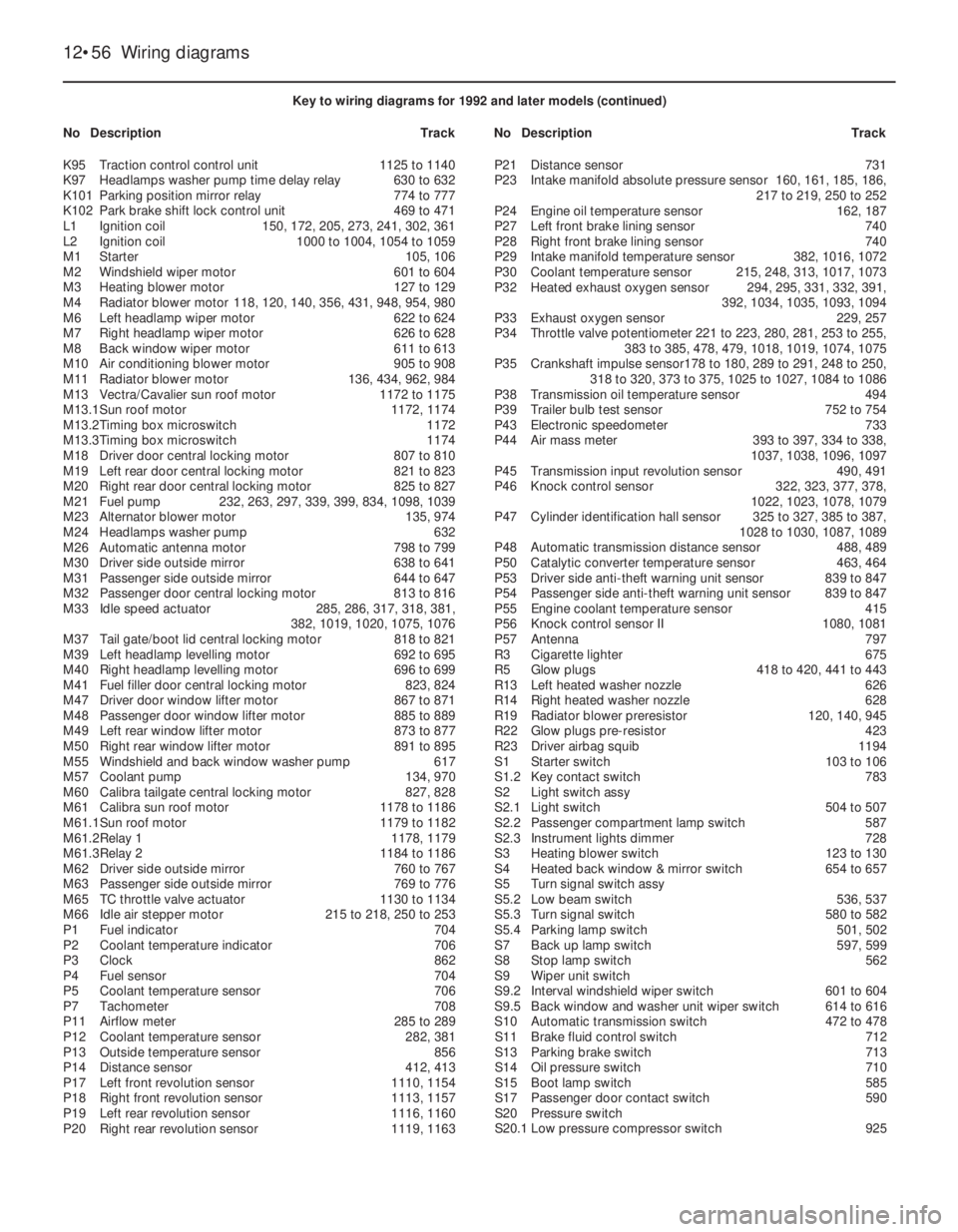

Key to wiring diagrams for 1992 and later models (continued)

NoDescriptionTrackNoDescriptionTrack

K95Traction control control unit1125 to 1140

K97Headlamps washer pump time delay relay630 to 632

K101Parking position mirror relay774 to 777

K102Park brake shift lock control unit 469 to 471

L1Ignition coil150, 172, 205, 273, 241, 302, 361

L2Ignition coil1000 to 1004, 1054 to 1059

M1Starter105, 106

M2Windshield wiper motor601 to 604

M3Heating blower motor127 to 129

M4Radiator blower motor118, 120, 140, 356, 431, 948, 954, 980

M6Left headlamp wiper motor622 to 624

M7Right headlamp wiper motor 626 to 628

M8Back window wiper motor611 to 613

M10Air conditioning blower motor905 to 908

M11Radiator blower motor136, 434, 962, 984

M13Vectra/Cavalier sun roof motor1172 to 1175

M13.1Sun roof motor1172, 1174

M13.2Timing box microswitch1172

M13.3Timing box microswitch1174

M18Driver door central locking motor807 to 810

M19Left rear door central locking motor821 to 823

M20Right rear door central locking motor825 to 827

M21Fuel pump232, 263, 297, 339, 399, 834, 1098, 1039

M23Alternator blower motor135, 974

M24Headlamps washer pump632

M26Automatic antenna motor798 to 799

M30Driver side outside mirror638 to 641

M31Passenger side outside mirror644 to 647

M32Passenger door central locking motor813 to 816

M33Idle speed actuator285, 286, 317, 318, 381,

382, 1019, 1020, 1075, 1076

M37Tail gate/boot lid central locking motor818 to 821

M39Left headlamp levelling motor 692 to 695

M40Right headlamp levelling motor696 to 699

M41Fuel filler door central locking motor823, 824

M47Driver door window lifter motor867 to 871

M48Passenger door window lifter motor885 to 889

M49Left rear window lifter motor873 to 877

M50Right rear window lifter motor891 to 895

M55Windshield and back window washer pump617

M57Coolant pump134, 970

M60Calibra tailgate central locking motor827, 828

M61Calibra sun roof motor1178 to 1186

M61.1Sun roof motor1179 to 1182

M61.2Relay 11178, 1179

M61.3Relay 21184 to 1186

M62Driver side outside mirror760 to 767

M63Passenger side outside mirror769 to 776

M65TC throttle valve actuator1130 to 1134

M66Idle air stepper motor215 to 218, 250 to 253

P1Fuel indicator704

P2Coolant temperature indicator706

P3Clock862

P4Fuel sensor704

P5Coolant temperature sensor706

P7Tachometer708

P11Airflow meter 285 to 289

P12Coolant temperature sensor282, 381

P13Outside temperature sensor856

P14Distance sensor412, 413

P17Left front revolution sensor1110, 1154

P18Right front revolution sensor1113, 1157

P19Left rear revolution sensor1116, 1160

P20Right rear revolution sensor1119, 1163P21Distance sensor731

P23Intake manifold absolute pressure sensor160, 161, 185, 186,

217 to 219, 250 to 252

P24Engine oil temperature sensor162, 187

P27Left front brake lining sensor740

P28Right front brake lining sensor740

P29Intake manifold temperature sensor382, 1016, 1072

P30Coolant temperature sensor215, 248, 313, 1017, 1073

P32Heated exhaust oxygen sensor294, 295, 331, 332, 391,

392, 1034, 1035, 1093, 1094

P33Exhaust oxygen sensor229, 257

P34Throttle valve potentiometer221 to 223, 280, 281, 253 to 255,

383 to 385, 478, 479, 1018, 1019, 1074, 1075

P35Crankshaft impulse sensor178 to 180, 289 to 291, 248 to 250,

318 to 320, 373 to 375, 1025 to 1027, 1084 to 1086

P38Transmission oil temperature sensor494

P39Trailer bulb test sensor752 to 754

P43Electronic speedometer733

P44Air mass meter393 to 397, 334 to 338,

1037, 1038, 1096, 1097

P45Transmission input revolution sensor490, 491

P46Knock control sensor322, 323, 377, 378,

1022, 1023, 1078, 1079

P47Cylinder identification hall sensor325 to 327, 385 to 387,

1028 to 1030, 1087, 1089

P48Automatic transmission distance sensor488, 489

P50Catalytic converter temperature sensor463, 464

P53Driver side anti-theft warning unit sensor839 to 847

P54Passenger side anti-theft warning unit sensor839 to 847

P55Engine coolant temperature sensor415

P56Knock control sensor II1080, 1081

P57Antenna797

R3Cigarette lighter675

R5Glow plugs418 to 420, 441 to 443

R13Left heated washer nozzle 626

R14Right heated washer nozzle628

R19Radiator blower preresistor120, 140, 945

R22Glow plugs pre-resistor423

R23Driver airbag squib1194

S1Starter switch103 to 106

S1.2Key contact switch783

S2Light switch assy

S2.1Light switch504 to 507

S2.2Passenger compartment lamp switch587

S2.3Instrument lights dimmer728

S3Heating blower switch123 to 130

S4Heated back window & mirror switch654 to 657

S5Turn signal switch assy

S5.2Low beam switch536, 537

S5.3Turn signal switch580 to 582

S5.4Parking lamp switch501, 502

S7Back up lamp switch597, 599

S8Stop lamp switch562

S9Wiper unit switch

S9.2Interval windshield wiper switch601 to 604

S9.5Back window and washer unit wiper switch614 to 616

S10Automatic transmission switch472 to 478

S11Brake fluid control switch712

S13Parking brake switch713

S14Oil pressure switch710

S15Boot lamp switch585

S17Passenger door contact switch590

S20Pressure switch

S20.1Low pressure compressor switch925

Page 71 of 525

Wiring diagrams 12•57

12

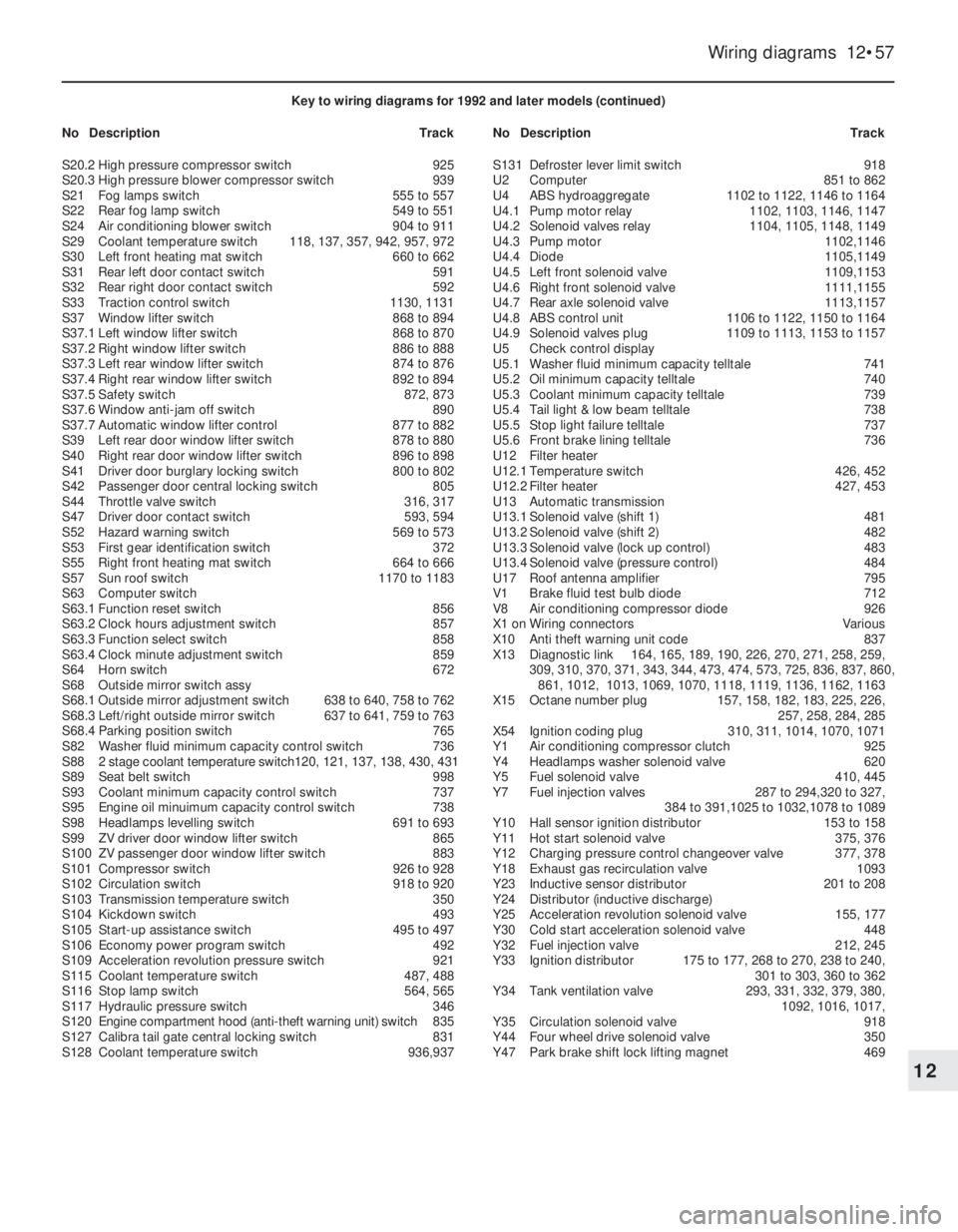

Key to wiring diagrams for 1992 and later models (continued)

NoDescriptionTrackNoDescriptionTrack

S20.2High pressure compressor switch925

S20.3High pressure blower compressor switch939

S21Fog lamps switch555 to 557

S22Rear fog lamp switch549 to 551

S24Air conditioning blower switch904 to 911

S29Coolant temperature switch118, 137, 357, 942, 957, 972

S30Left front heating mat switch660 to 662

S31Rear left door contact switch591

S32Rear right door contact switch592

S33Traction control switch1130, 1131

S37Window lifter switch868 to 894

S37.1Left window lifter switch868 to 870

S37.2Right window lifter switch886 to 888

S37.3Left rear window lifter switch874 to 876

S37.4Right rear window lifter switch892 to 894

S37.5Safety switch872, 873

S37.6Window anti-jam off switch890

S37.7Automatic window lifter control877 to 882

S39Left rear door window lifter switch878 to 880

S40Right rear door window lifter switch896 to 898

S41Driver door burglary locking switch800 to 802

S42Passenger door central locking switch805

S44Throttle valve switch316, 317

S47Driver door contact switch593, 594

S52Hazard warning switch569 to 573

S53First gear identification switch372

S55Right front heating mat switch664 to 666

S57Sun roof switch1170 to 1183

S63Computer switch

S63.1Function reset switch856

S63.2Clock hours adjustment switch857

S63.3Function select switch858

S63.4Clock minute adjustment switch859

S64Horn switch672

S68Outside mirror switch assy

S68.1Outside mirror adjustment switch638 to 640, 758 to 762

S68.3Left/right outside mirror switch637 to 641, 759 to 763

S68.4Parking position switch765

S82Washer fluid minimum capacity control switch736

S882 stage coolant temperature switch120, 121, 137, 138, 430, 431

S89Seat belt switch998

S93Coolant minimum capacity control switch737

S95Engine oil minuimum capacity control switch738

S98Headlamps levelling switch691 to 693

S99ZV driver door window lifter switch865

S100ZV passenger door window lifter switch883

S101Compressor switch926 to 928

S102Circulation switch918 to 920

S103Transmission temperature switch350

S104Kickdown switch493

S105Start-up assistance switch495 to 497

S106Economy power program switch492

S109Acceleration revolution pressure switch921

S115Coolant temperature switch487, 488

S116Stop lamp switch564, 565

S117Hydraulic pressure switch346

S120Engine compartment hood (anti-theft warning unit) switch835

S127Calibra tail gate central locking switch831

S128Coolant temperature switch936,937S131Defroster lever limit switch918

U2Computer851 to 862

U4ABS hydroaggregate1102 to 1122, 1146 to 1164

U4.1Pump motor relay1102, 1103, 1146, 1147

U4.2Solenoid valves relay1104, 1105, 1148, 1149

U4.3Pump motor1102,1146

U4.4Diode1105,1149

U4.5Left front solenoid valve1109,1153

U4.6Right front solenoid valve1111,1155

U4.7Rear axle solenoid valve1113,1157

U4.8ABS control unit1106 to 1122, 1150 to 1164

U4.9Solenoid valves plug1109 to 1113, 1153 to 1157

U5Check control display

U5.1Washer fluid minimum capacity telltale741

U5.2Oil minimum capacity telltale740

U5.3Coolant minimum capacity telltale739

U5.4Tail light & low beam telltale738

U5.5Stop light failure telltale737

U5.6Front brake lining telltale736

U12Filter heater

U12.1Temperature switch426, 452

U12.2Filter heater427, 453

U13Automatic transmission

U13.1Solenoid valve (shift 1)481

U13.2Solenoid valve (shift 2)482

U13.3Solenoid valve (lock up control)483

U13.4Solenoid valve (pressure control)484

U17Roof antenna amplifier795

V1Brake fluid test bulb diode712

V8Air conditioning compressor diode926

X1 onWiring connectorsVarious

X10Anti theft warning unit code837

X13Diagnostic link164, 165, 189, 190, 226, 270, 271, 258, 259,

309, 310, 370, 371, 343, 344, 473, 474, 573, 725, 836, 837, 860,

861, 1012, 1013, 1069, 1070, 1118, 1119, 1136, 1162, 1163

X15Octane number plug157, 158, 182, 183, 225, 226,

257, 258, 284, 285

X54Ignition coding plug310, 311, 1014, 1070, 1071

Y1Air conditioning compressor clutch925

Y4Headlamps washer solenoid valve620

Y5Fuel solenoid valve410, 445

Y7Fuel injection valves287 to 294,320 to 327,

384 to 391,1025 to 1032,1078 to 1089

Y10Hall sensor ignition distributor153 to 158

Y11Hot start solenoid valve375, 376

Y12Charging pressure control changeover valve377, 378

Y18Exhaust gas recirculation valve1093

Y23Inductive sensor distributor201 to 208

Y24Distributor (inductive discharge)

Y25Acceleration revolution solenoid valve155, 177

Y30Cold start acceleration solenoid valve 448

Y32Fuel injection valve212, 245

Y33Ignition distributor175 to 177, 268 to 270, 238 to 240,

301 to 303, 360 to 362

Y34Tank ventilation valve293, 331, 332, 379, 380,

1092, 1016, 1017,

Y35Circulation solenoid valve918

Y44Four wheel drive solenoid valve350

Y47Park brake shift lock lifting magnet469

Page 88 of 525

5

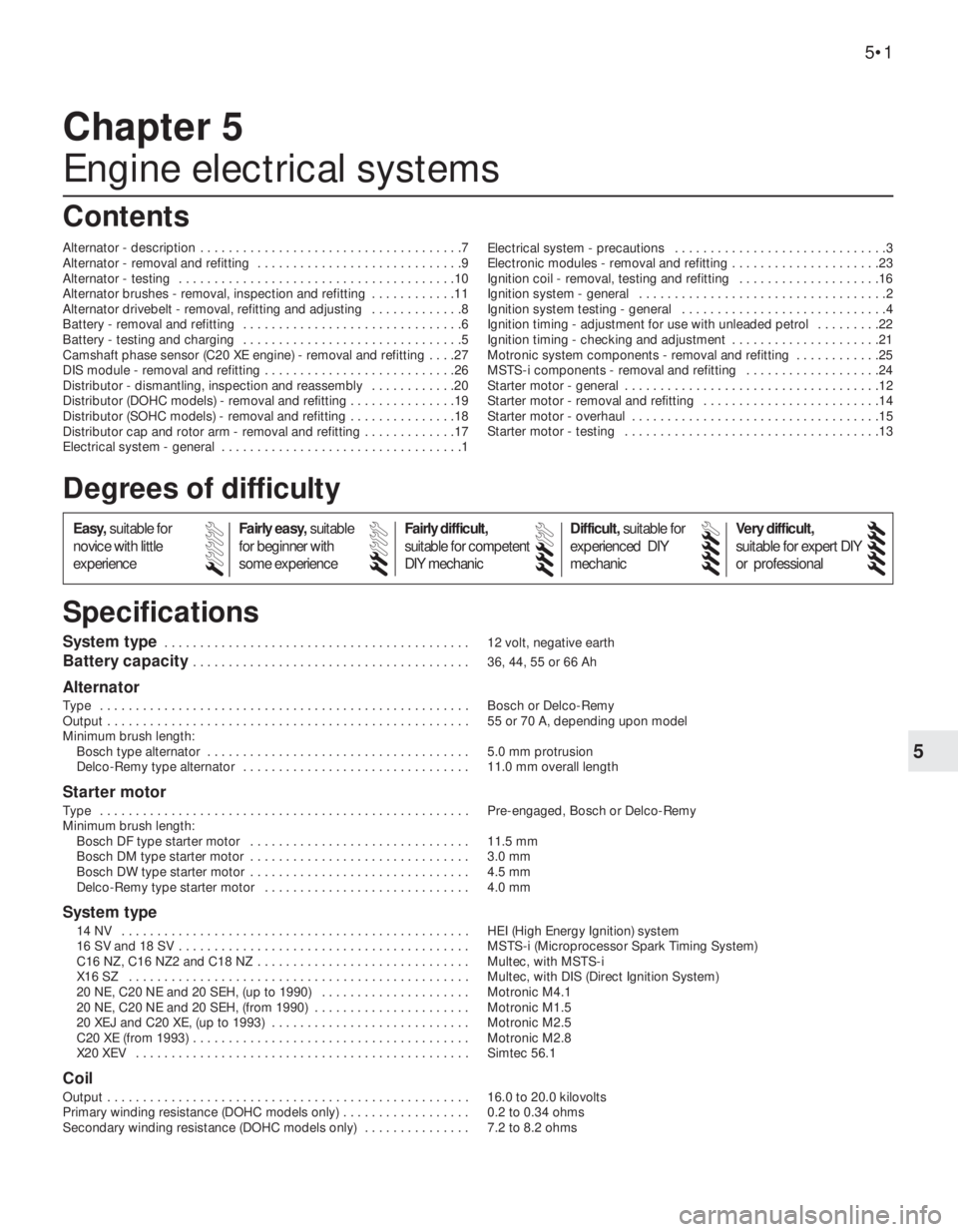

System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 volt, negative earth

Battery capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36, 44, 55 or 66 Ah

Alternator

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bosch or Delco-Remy

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 or 70 A, depending upon model

Minimum brush length:

Bosch type alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.0 mm protrusion

Delco-Remy type alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.0 mm overall length

Starter motor

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pre-engaged, Bosch or Delco-Remy

Minimum brush length:

Bosch DF type starter motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.5 mm

Bosch DM type starter motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 mm

Bosch DW type starter motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 mm

Delco-Remy type starter motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 mm

System type

14 NV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HEI (High Energy Ignition) system

16 SV and 18 SV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MSTS-i (Microprocessor Spark Timing System)

C16 NZ, C16 NZ2 and C18 NZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Multec, with MSTS-i

X16 SZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Multec, with DIS (Direct Ignition System)

20 NE, C20 NE and 20 SEH, (up to 1990) . . . . . . . . . . . . . . . . . . . . . Motronic M4.1

20 NE, C20 NE and 20 SEH, (from 1990) . . . . . . . . . . . . . . . . . . . . . . Motronic M1.5

20 XEJ and C20 XE, (up to 1993) . . . . . . . . . . . . . . . . . . . . . . . . . . . . Motronic M2.5

C20 XE (from 1993) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Motronic M2.8

X20 XEV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Simtec 56.1

Coil

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16.0 to 20.0 kilovolts

Primary winding resistance (DOHC models only) . . . . . . . . . . . . . . . . . . 0.2 to 0.34 ohms

Secondary winding resistance (DOHC models only) . . . . . . . . . . . . . . . 7.2 to 8.2 ohms

Chapter 5

Engine electrical systems

Alternator - description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Alternator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Alternator - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Alternator brushes - removal, inspection and refitting . . . . . . . . . . . .11

Alternator drivebelt - removal, refitting and adjusting . . . . . . . . . . . . .8

Battery - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Battery - testing and charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Camshaft phase sensor (C20 XE engine) - removal and refitting . . . .27

DIS module - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Distributor - dismantling, inspection and reassembly . . . . . . . . . . . .20

Distributor (DOHC models) - removal and refitting . . . . . . . . . . . . . . .19

Distributor (SOHC models) - removal and refitting . . . . . . . . . . . . . . .18

Distributor cap and rotor arm - removal and refitting . . . . . . . . . . . . .17

Electrical system - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1Electrical system - precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electronic modules - removal and refitting . . . . . . . . . . . . . . . . . . . . .23

Ignition coil - removal, testing and refitting . . . . . . . . . . . . . . . . . . . .16

Ignition system - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Ignition system testing - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Ignition timing - adjustment for use with unleaded petrol . . . . . . . . .22

Ignition timing - checking and adjustment . . . . . . . . . . . . . . . . . . . . .21

Motronic system components - removal and refitting . . . . . . . . . . . .25

MSTS-i components - removal and refitting . . . . . . . . . . . . . . . . . . .24

Starter motor - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Starter motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .14

Starter motor - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Starter motor - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 89 of 525

Distributor

Direction of rotor arm rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Anti-clockwise (viewed from cap)

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3-4-2 (No 1 cylinder at timing belt end of engine)

Dwell angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Automatically controlled by electronic module (not adjustable)

Ignition timing

14 NV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5°BTDC

16 SV, X 16 SZ, C 16 NZ, C 16 NZ2 and C 18 NZ . . . . . . . . . . . . . . . .10°BTDC *

18 SV and 2.0 litres models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 12°BTDC *

* Ignition timing electronically controlled no adjustment possible

Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .See Chapter 1 Specifications

Torque wrench settingNmlbf ft

Alternator mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Camshaft phase sensor disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Camshaft phase sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1511

‘Compact’ series alternator lower mounting bolt . . . . . . . . . . . . . . . . . .3526

‘Compact’ series alternator upper mounting bolts . . . . . . . . . . . . . . . . .2015

DIS module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Inductive pulse pick-up to block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Starter motor mounting bracket-to-cylinder block . . . . . . . . . . . . . . . . .2518

Starter motor mounting:

1.4 and 1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

1.8 and 2.0 litre models:

Engine side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4533

Transmission side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7555

1Electrical system - general

1The electrical system is of the 12 volt

negative earth type, and consists of a 12 volt

battery, alternator with integral voltage

regulator, starter motor, and related electrical

accessories, components and wiring.

2The battery is of the maintenance-free

“sealed for life” type, and is charged by an

alternator, which is belt-driven from the

crankshaft pulley. The starter motor is of the

pre-engaged type, incorporating an integral

solenoid. On starting, the solenoid moves the

drive pinion into engagement with the flywheel

ring gear before the starter motor is

energised. Once the engine has started, a

one-way clutch prevents the motor armature

being driven by the engine until the pinion

disengages from the flywheel.

3It is necessary to take extra care when

working on the electrical system, to avoid

damage to semi-conductor devices (diodes

and transistors), and to avoid the risk of

personal injury. Along with the precautions

given in the “Safety first!” Section at the

beginning of this manual, take note of the

following points when working on the system.4Always remove rings, watches, etc. before

working on the electrical system. Even with

the battery disconnected, discharge could

occur if a component live terminal is earthed

through a metal object. This could cause a

shock or nasty burn.

5Do not reverse the battery connections.

Components such as the alternator, or any

other component having semi-conductor

circuitry, could be irreparably damaged.

6If the engine is being started using jump

leads and a slave battery, connect the

batteries positive to positive and negative to

negative. This also applies when connecting a

battery charger.

7Never disconnect the battery terminals, or

alternator multi-plug connector, when the

engine is running.

8The battery leads and alternator wiring

must be disconnected before carrying out any

electric welding on the vehicle.

9Never use an ohmmeter of the type

incorporating a hand-cranked generator for

circuit or continuity testing.

2Ignition system - general

1The ignition system is responsible for

igniting the air/fuel mixture in each cylinder at

the correct moment, in relation to engine

speed and load. A number of different types

of ignition systems are fitted to models within

the range. Ranging from a basic breakerless

electronic system, to a fully integrated engine

management system controlling both ignition

and fuel injection systems. Each system isdescribed in further detail later in this Section.

2The ignition system is based on feeding low

tension voltage from the battery to the coil,

where it is converted to high tension voltage.

The high tension voltage is powerful enough

to jump the spark plug gap in the cylinders

many times a second under high compression

pressures, providing that the system is in

good condition. The low tension (or primary)

circuit consists of the battery, the lead to the

ignition switch. The lead from the ignition

switch to the low tension coil windings and

the supply terminal on the electronic module.

The lead from the low tension coil windings to

the control terminal on the electronic module.

The high tension (or secondary) circuit

consists of the high tension coil windings, the

HT (high tension) lead from the coil to the

distributor cap, the rotor arm, the HT leads to

the spark plugs, and the spark plugs.

3The system functions in the following

manner. Current flowing through the low

tension coil windings produces a magnetic

field around the high tension windings. As the

engine rotates, a sensor produces an

electrical impulse that is amplified in the

electronic module and used to switch off the

low tension circuit.

4The subsequent collapse of the magnetic

field over the high tension windings produces

a high tension voltage, which is then fed to the

relevant spark plug through the distributor

cap and rotor arm. The low tension circuit is

automatically switched on again by the

electronic module, to allow the magnetic field

to build up again before the firing of the next

spark plug. The ignition is advanced and

retarded automatically, to ensure that the

spark occurs at the correct instant with the

engine speed and load.

5•2Engine electrical systems

Caution: Before carrying out

any work on the vehicle

electrical system, read through

the precautions given in the

“Safety first!” Section at the beginning of

this manual, and in Section 3 of this

Chapter.

Page 90 of 525

HEI (High Energy Ignition)

system

5This comprises of a breakerless distributor

and an electronic switching/amplifier module

along with the coil and spark plugs.

6The electrical impulse that is required to

switch off the low tension circuit is generated

by a magnetic trigger coil in the distributor. A

trigger wheel rotates within a magnetic stator,

the magnetic field being provided by a

permanent magnet. The magnetic field across

the two poles (stator arm and trigger wheel) is

dependent on the air gap between the two

poles. When the air gap is at its minimum, the

trigger wheel arm is directly opposite the

stator arm, and this is the trigger point. As the

magnetic flux between the stator arm and

trigger wheel varies, a voltage is induced in the

trigger coil mounted below the trigger wheel.

This voltage is sensed and then amplified by

the electronic module, and used to switch off

the low tension circuit. There is one trigger arm

and one stator arm for each cylinder.

7The ignition advance is a function of the

distributor, and is controlled both

mechanically and by a vacuum-operated

system. The mechanical governor mechanism

consists of two weights that move out from

the distributor shaft due to centrifugal force as

the engine speed rises. As the weights move

outwards, they rotate the trigger wheel

relative to the distributor shaft and so

advance the spark. The weights are held in

position by two light springs, and it is the

tension of the springs that is largely

responsible for correct spark advancement.

8The vacuum control consists of a

diaphragm, one side of which is connected by

way of a small-bore hose to the carburettor,

and the other side to the distributor.

Depression in the inlet manifold and

carburettor, which varies with engine speed

and throttle position, causes the diaphragm to

move, so moving the baseplate and

advancing or retarding the spark. A fine

degree of control is achieved by a spring in

the diaphragm assembly.

MSTS-i (Microprocessor-

controlled Spark Timing System)

9This system comprises a “Hall-effect”

distributor (or a crankshaft speed/position

sensor on X 16 SZ models), a manifold pressure

sensor, an oil temperature sensor, and a

module, along with the coil and spark plugs.

10On 1.6 litre models, the electrical impulse

that is required to switch off the low tension

circuit is generated by a sensor in the

distributor. A trigger vane rotates in the gap

between a permanent magnet and the sensor.

The trigger vane has four cut-outs, one for

each cylinder. When one of the trigger vane

cut-outs is in line with the sensor, magnetic

flux can pass between the magnet and the

sensor. When a trigger vane segment is in line

with the sensor, the magnetic flux is diverted

through the trigger vane away from thesensor. The sensor senses the change in

magnetic flux, and sends an impulse to the

MSTS-i module, which switches off the low

tension circuit.

11On 1.8 litre models, the electrical impulse

that is required to switch off the low tension

circuit is generated by a crankshaft

speed/position sensor, which is activated by a

toothed wheel on the crankshaft. The toothed

wheel has 35 equally spaced teeth, with a gap

in the 36th position. The gap is used by the

sensor to determine the crankshaft position

relative to TDC (top dead centre) of No 1 piston.

12Engine load information is supplied to the

MSTS-i module by a pressure sensor, which

is connected to the carburettor by a vacuum

pipe. Additional information is supplied by an

oil temperature sensor. The module selects

the optimum ignition advance setting based

on the information received from the sensors.

The degree of advance can thus be constantly

varied to suit the prevailing engine conditions.

Multec, with MSTS-i

13The ignition system is fully electronic in

operation and incorporates the Electronic

Control Unit (ECU) mounted in the driver’s

footwell. A distributor (driven off the camshaft

left-hand end and incorporating the amplifier

module) as well as the octane coding plug,

the spark plugs, HT leads, ignition HT coil and

associated wiring.

14The ECU controls both the ignition system

and the fuel injection system, integrating the

two in a complete engine management

system. Refer to Chapters 4B and 4C for

further information that is not detailed here.

15For ignition the ECU receives information

in the form of electrical impulses or signals

from the distributor (giving it the engine speed

and crankshaft position), from the coolant

temperature sensor (giving it the engine

temperature) and from the manifold absolute

pressure sensor (giving it the load on the

engine). In addition, the ECU receives input

from the octane coding plug (to provide

ignition timing appropriate to the grade of fuel

used) and from, where fitted, the automatic

transmission control unit (to smooth gear

changing by retarding the ignition as changes

are made).

16All these signals are compared by the

ECU with set values pre-programmed

(mapped) into its memory. Considering this

information, the ECU selects the ignition

timing appropriate to those values and

controls the ignition HT coil by way of the

amplifier module accordingly.

17The system is so sensitive that, at idle

speed, the ignition timing may be constantly

changing; this should be remembered if trying

to check the ignition timing.

18The system fitted to C18 NZ models, is

similar to that described above, except that

the amplifier module is separate. The ECU

determines engine speed and crankshaft

position using a sensor mounted in the

right-hand front end of the engine’s cylinderblock; this registers with a 58-toothed disc

mounted on the crankshaft so that the gap left

by the missing two teeth provides a reference

point, so enabling the ECU to recognise TDC.

19Note that this simplifies the distributor’s

function, which is merely to distribute the HT

pulse to the appropriate spark plug; it has no

effect whatsoever on the ignition timing.

DIS (Direct Ignition System)

20On all X16 SZ engines, and on C20 XE

(DOHC) engines from 1993-on, a DIS (Direct

Ignition System) module is used in place of

the distributor and coil. On the X16 SZ engine

the DIS module is attached to the camshaft

housing in the position normally occupied by

the distributor. On the C20 XE engine, a

camshaft phase sensor is attached to the

cylinder head at the non-driven end of the

exhaust camshaft, in the position normally

occupied by the distributor. The DIS module

is attached, by a bracket, to the cylinder head

at the non-driven end of the inlet camshaft.

21The DIS module consists of two ignition

coils and an electronic control module housed

in a cast casing. Each ignition coil supplies

two spark plugs with HT voltage. One spark is

provided in a cylinder with its piston on the

compression stroke, and one spark is

provided to a cylinder with its piston on the

exhaust stroke. This means that a “wasted

spark” is supplied to one cylinder during each

ignition cycle, but this has no detrimental

effect. This system has the advantage that

there are no moving parts (therefore there is

no wear), and the system is largely

maintenance-free.

Motronic M4.1 and M1.5

22This system controls both the ignition and

the fuel injection systems.

23The Motronic module receives information

from a crankshaft speed/position sensor, an

engine coolant temperature sensor mounted

in the thermostat housing. A throttle position

sensor, an airflow meter, and on models fitted

with a catalytic converter, an oxygen sensor

mounted in the exhaust system (Chapter 4C).

24The module provides outputs to control

the fuel pump, fuel injectors, idle speed and

ignition circuit. Using the inputs from the

various sensors, the module computes the

optimum ignition advance, and fuel injector

pulse duration, to suit the prevailing engine

conditions. This system gives very accurate

control of the engine under all conditions,

improving fuel consumption and driveability,

and reducing exhaust gas emissions.

25Further details of the fuel injection system

components are given in Chapter 4B.

Motronic M2.5 and M2.8

26The system is similar to that described for

SOHC models, with the following differences.

27Along with the crankshaft speed/position

sensor, a “Hall-effect” distributor is used

(similar to that described in this Section, with

the MSTS-i system).

Engine electrical systems 5•3

5

Page 91 of 525

28The system also incorporates a separate

ignition amplifier module that transmits

amplified signals from the main system

module to trigger the HT pulse from the

ignition coil. The module is mounted on the

ignition coil’s bracket/baseplate.

29Additionally, the Motronic module

receives information from a cylinder

block-mounted knock sensor, which senses

“knocking” (or pre-ignition) just as it begins to

occur, enabling the module to retard the

ignition timing, thus preventing engine

damage.

Simtec 56.1

30This system uses increased amount of

electronic components instead of mechanical

parts as sensors and actuators with the

Simtec engine management system. This

provides more precise operating data as well

as greater problem free motoring.

31The control unit is equipped with

electronic ignition control. Called ‘Micropro-

cessor Spark Timing System, inductive

triggered’, (or MSTS-i), and means that the

mechanical high voltage distributor is no

longer needed. It is located behind the trim

panel, on the right-hand side footwell (door

pillar).

32The ignition coil is replaced by a dual

spark ignition coil, which is switched directly

by the output stages in the control unit.

33A camshaft sensor will maintain

emergency operation, should the crankshaft

inductive pulse pick-up, malfunction. These

sense TDC (‘Top Dead Centre’), crankshaft

angle and engine speed. The signals are used

by the control unit to calculate ignition point

and for fuel injection.

34The ‘hot film airflow meter’ determines the

mass of air taken in by the engine. The system

uses this information to calculate the correct

amount of fuel needed for injection in the

engine.

35The air inlet temperature sensor (NTC), is

fitted in the air inlet duct between the air

cleaner and the hot mass air flow meter.

36A controlled canister purge valve is

actuated by the system. The tank ventilation is

monitored closely with the Lambda control (or

oxygen sensor) and adaptation by the

computer within the control unit.

37A knock control system is also fitted. This

eliminates the need for octane number

adjustment, as it is performed automatically

through the control unit.

3Electrical system -

precautions

1It is necessary to take extra care when

working on the electrical system, to avoid

damage to semi-conductor devices (diodes

and transistors), and to avoid the risk of

personal injury. Along with the precautions

given in the “Safety first!” Section at the

beginning of this manual, take note of the

following points when working on the system.

2Always remove rings, watches, etc. before

working on the electrical system. Even with

the battery disconnected, discharge could

occur if a component live terminal is earthed

through a metal object. This could cause a

shock or nasty burn.

3Do not reverse the battery connections.

Components such as the alternator, or any

other component having semi-conductor

circuitry, could be irreparably damaged.

4If the engine is being started using jump

leads and a slave battery, connect the

batteries positive to positive and negative to

negative. This also applies when connecting a

battery charger.

5Never disconnect the battery terminals, or

alternator multi-plug connector, when the

engine is running.

6The battery leads and alternator wiring

must be disconnected before carrying out any

electric welding on the vehicle.

7Never use an ohmmeter of the type

incorporating a hand-cranked generator for

circuit or continuity testing.

8Engine management modules are very

sensitive components, and certain

precautions must be taken, to avoid damage

to the module when working on a vehicle

equipped with an engine management

system, as follows.

9When carrying out welding operations on

the vehicle using electric welding equipment,

the battery and alternator should be

disconnected.

10Although underbonnet-mounted modules

will tolerate normal underbonnet conditions,

they can be adversely affected by excess heat

or moisture. If using welding equipment or

pressure washing equipment near the

module, take care not to direct heat, or jets of

water or steam, at the module. If this cannot

be avoided, remove the module from the

vehicle, and protect its wiring plug with a

plastic bag.

11Before disconnecting any wiring, or

removing components, always ensure that the

ignition is switched off.

12Do not attempt to improvise fault

diagnosis procedures using a test lamp or

multimeter, as irreparable damage could be

caused to the module.13After working on ignition/engine

management system components, ensure

that all wiring is correctly reconnected before

reconnecting the battery or switching on the

ignition.

14Any ignition system that uses a

“Hall-effect” generator in the distributor,

cannot be tested. Test equipment that uses

its own power source (e.g. an ohmmeter),

when connected to the distributor or the

“Hall-effect” generator, will be damaged.

4Ignition system testing -

general

3

Note: Refer to Section 3 before proceeding.

Always switch off the ignition before

disconnecting or connecting any component

and when using a multi-meter to check

resistances. Any voltmeter or multi-meter

used to test ignition system components must

have an impedance of 10 meg ohms or

greater

1Electronic ignition system components are

normally very reliable. Most faults are far more

likely to be due to loose or dirty connections,

or to “tracking” of HT voltage due to dirt,

dampness or damaged insulation than to

component failure. Always check all wiring

thoroughly before condemning an electrical

component and work methodically to

eliminate all other possibilities before deciding

that a particular component is faulty.

2The old practice of checking for a spark by

holding the live end of a HT lead a short

distance away from the engine is not

recommended. Not only is there a high risk of

a powerful electric shock, but the ignition coil

or amplifier module will be damaged.

Similarly, never try to “diagnose” misfires by

pulling off one HT lead at a time. Note also

that the ECU is at risk if the system is

triggered with an open (i.e., not properly

earthed) HT circuit; ECU’s are very expensive

to replace, so take care!

3If you are in any doubt as to your skill and

ability to test an ignition system component or

if you do not have the required equipment,

take the vehicle to a suitably equipped

Vauxhall dealer. It is better to pay the labour

charges involved in having the vehicle

checked by an expert than to risk damage to

the system or to yourself.

4If the engine either will not turn over at all,

or only turns very slowly, check the battery

and starter motor. Connect a voltmeter across

the battery terminals (meter positive probe to

battery positive terminal) and disconnect the

ignition coil HT lead from the distributor cap

and earth. Note the voltage reading obtained

while turning over the engine on the starter for

(no more than) ten seconds. If the reading

obtained is less than approximately 9.5 volts,

check the battery, battery connections, starter

motor and charging system.

5•4Engine electrical systems

Warning: The HT voltage

generated by an electronic

ignition system is extremely

high and, in certain

circumstances, could prove fatal. Take

care to avoid receiving electric shocks

from the HT side of the ignition system.

Do not handle HT leads, or touch the

distributor or coil, when the engine is

running. If tracing faults in the HT circuit,

use well-insulated tools to manipulate live

leads

Page 92 of 525

5If the engine turns over at normal speed but

will not start, check the HT circuit by

connecting a timing light and turning the

engine over on the starter motor. If the light

flashes, voltage is reaching the spark plugs,

so these should be checked first. If the light

does not flash, check the HT leads

themselves followed by the distributor cap,

carbon brush and rotor arm.

6If there is a spark, check the fuel system for

faults as far as possible (Chapters 4A or 4B).

7If there is still no spark, check the voltage at

the ignition coil “+” or “15” terminal; it should

be the same as the battery voltage (i.e., at

least 11.7 volts). If the voltage at the coil is

more than 1 volt less than that at the battery,

check the connections back through the

ignition switch to the battery and its earth until

the fault is found. Note, however, that the

ECU controls the coil’s feed; do not attempt

to “test” the ECU with anything other than the

correct test equipment, which will be available

only to a Vauxhall dealer. If any of the wires

are to be checked which lead to the ECU,

always first unplug the relevant connector

from the ECU so that there is no risk of the

ECU being damaged by the application of

incorrect voltages from test equipment.

8If the feed to the ignition coil is sound,

check the coil’s primary and secondary

windings (refer to Section 16). Renew the coil

if faulty, but check the condition of the LT

connections themselves before doing so, to

ensure that the fault is not due to dirty or

poorly fastened connectors.

9If the ignition coil is in good condition, the

fault may be within the amplifier module or the

distributor on the C16 NZ and C16 NZ2

engines, or the amplifier or the crankshaft

speed/position sensor on the C18 NZ engine.

A quick check of these components can be

made by connecting a low-wattage bulb

across the ignition coil’s (disconnected) LT

terminals. If the bulb flickers or flashes when

the engine is turned over, the amplifier and

distributor (C16 NZ and C16 NZ2 engines), or

amplifier and crankshaft speed/position

sensor (C18 NZ engine), are sound.

10If this is the case, the entire LT circuit is in

good condition; the fault, if it lies in the

ignition system, must be in the HT circuit

components. These should be checked

carefully, as outlined above.

11If the indicator or bulb does not flash, the

fault is in either the amplifier or the distributor

(C16 NZ and C16 NZ2 engines), or the

amplifier or crankshaft speed/position sensor

(C18 NZ engine). Owners should note,

however, that by far the commonest cause of

“failure” of either of these is a poor

connection, either between the components

themselves or in the LT circuit wiring

connections. If such a fault is suspected, the

vehicle must be taken to a suitably equipped

Vauxhall dealer for testing; no information is

available to eliminate these components by

other means.12An irregular misfire suggests either a

loose connection or intermittent fault on the

primary circuit, or a HT fault on the coil side of

the rotor arm.

13With the ignition switched off, check

carefully through the system ensuring that all

connections are clean and securely fastened.

If the equipment is available, check the LT

circuit as described in paragraphs 7 to 11

above.

14Check that the HT coil, the distributor cap

and the HT leads are clean and dry. Check the

leads and the spark plugs (by substitution, if

necessary), then check the distributor cap,

carbon brush and rotor arm.

15Regular misfiring is almost certainly due to

a fault in the distributor cap, HT leads or spark

plugs. Use a timing light (paragraph 5, above)

to check whether HT voltage is present at all

leads.

16If HT voltage is not present on any

particular lead, the fault will be in that lead or

in the distributor cap. If HT is present on all

leads, the fault will be in the spark plugs;

check and renew them if there is any doubt

about their condition.

17If no HT voltage is present, check the

ignition coil; its secondary windings may be

breaking down under load.

18If all components have been checked for

signs of obvious faults but the system is still

thought to be faulty, take the vehicle to a

Vauxhall dealer for testing on special

equipment.

5Battery - testing and charging

2

Note: Refer to Section 3 before proceeding.

Testing

1Topping-up and testing of the electrolyte in

each cell is not possible. The condition of the

battery can therefore only be tested by

observing the battery condition indicator.

2The battery condition indicator is fitted in

the top of the battery casing, and indicates

the condition of the battery from its colour. If

the indicator shows green, then the battery is

in a good state of charge. If the indicator turns

darker, eventually to black, then the battery

requires charging, as described later in this

Section. If the indicator shows clear/yellow,

then the electrolyte level in the battery is too

low to allow further use, and the battery

should be renewed.

Charging

3Do not attempt to charge, load or jump start

a battery when the indicator shows

clear/yellow. If the battery is to be charged,

remove it from the vehicle and charge it as

follows.

4The maintenance-free type battery takes

considerably longer to fully recharge than the

standard type, the time taken being

dependent on the extent of discharge.5A constant-voltage type charger is required,

to be set, when connected, to 13.9 to 14.9

volts with a charger current below 25 amps.

6If the battery is to be charged from a fully

discharged state (less than 12.2 volts output),

have it recharged by a Vauxhall dealer or

battery specialist, as the charge rate will be

high and constant supervision during charging

is necessary.

6Battery - removal and refitting

2

Note: Refer to Section 3 before proceeding.

Removal

1The battery is located at the left-hand front

corner of the engine compartment.

2Disconnect the lead(s) at the negative

(earth) terminal by unscrewing the retaining

nut and removing the terminal clamp.

3Disconnect the positive terminal lead(s) in

the same way.

4Unscrew the clamp bolt sufficiently to

enable the battery to be lifted from its

location. Keep the battery in an upright

position, to avoid spilling electrolyte on the

bodywork.

Refitting

5Refitting is a reversal of removal, but smear

petroleum jelly on the terminals when

reconnecting the leads, and always connect

the positive lead first and the negative lead

last.

7Alternator - description

1A Delco-Remy or Bosch alternator may be

fitted, depending on model and engine

capacity. The maximum output of the

alternator varies accordingly.

2The alternator is belt-driven from the

crankshaft pulley. Cooling is provided by a

fan, mounted outside the casing on the end of

the rotor shaft. An integral voltage regulator is

incorporated, to control the output voltage.

3The alternator provides a charge to the

battery even at very low engine speed, and

consists of a coil-wound stator in which a

rotor rotates. The rotor shaft is supported in

ball-bearings, and slip rings are used to

conduct current to and from the field coils

through the carbon brushes.

4The alternator generates ac (alternating

current), which is rectified by an internal diode

circuit to dc (direct current) for supply to the

battery.

5Later models are fitted with a Delco-Remy,

‘compact’ series alternators (see illustration).

They use a ribbed V-belt type drivebelt with

automatic tensioner. They are rigidly mounted

to the engine.

Engine electrical systems 5•5

5

Page 99 of 525

been removed, check that No 1 cylinder is on

its firing stroke by removing No 1 cylinder

spark plug and placing a finger over the plug

hole. Turn the crankshaft until compression

can be felt, which indicates that No 1 piston is

rising on its compression stroke. Continue

turning the crankshaft until the relevant timing

marks are in alignment.

11Turn the rotor arm to the position noted in

paragraph 6c, and hold the rotor arm in this

position as the distributor is fitted. Note that

the distributor driveshaft will only engage with

the camshaft in one position. If the original

distributor is being refitted, align the marks

made on the distributor body and camshaft

housing before removal.

12Refit the clamp plate and nut, but do not

fully tighten the nut at this stage.

13On the Bosch distributor, remove the rotor

arm, then refit the plastic shield and the rotor

arm.

14On 14 NV models, reconnect the vacuum

pipe to the diaphragm unit.

15Reconnect the distributor wiring plug.

16Refit the distributor cap as described in

Section 17.

17Reconnect the battery negative lead.

18Check and if necessary adjust the ignition

timing, as described in Section 21.

19Distributor (DOHC models),

where applicable - removal

and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the distributor cap, as described in

Section 17.

3Disconnect the distributor wiring plug.

4Unscrew the two securing bolts, and

remove the distributor from the cylinder head.

5Examine the O-ring on the rear of the

distributor, and renew if necessary.

Refitting

6Refitting is a reversal of removal. However,

note that the distributor should be fitted so

that the wiring plug is positioned on the upper

left-hand side of the distributor body, when

viewed from the distributor cap end.

20Distributor - dismantling,

inspection and reassembly

3

Note: Before contemplating dismantling of a

distributor, check the cost and availability of

replacement parts. It may prove more

economical to renew the complete distributor

assembly

14 NV models

Dismantling

1With the distributor removed as described

in Section 18, continue as follows.

2Pull off the rotor arm, and remove the

plastic shield.

3The top bearing plate can be removed after

unscrewing the two securing screws, however

(other than the vacuum diaphragm unit), no

spares are available for the distributor and no

adjustments are required.

4If desired, the vacuum diaphragm unit can

be removed by extracting the two securing

screws and unhooking the operating arm from

the distributor baseplate. Note that the

screws are of differing lengths, the longer

screw also secures one of the distributor cap

clips.

Inspection

5The vacuum unit can be tested by applying

suction to the vacuum port, and checking that

the operating rod moves into the unit as

suction is applied. Remove the suction, and

check that the operating rod returns to its

original position. If the operating rod does not

move as described, renew the vacuum unit.

6Check the distributor cap for corrosion of

the segments, and for signs of tracking,

indicated by a thin black line between the

segments. Make sure that the carbon brush in

the centre of the cap moves freely and stands

proud of the surface of the cap. Renew the

cap if necessary.

7If the metal portion of the rotor arm is badly

burnt or loose, renew it. If slightly burnt or

corroded; it may be cleaned with a fine file.

8Examine the seal ring at the rear of the

distributor body, and renew if necessary.

Reassembly

9Reassembly is a reversal of dismantling,

ensuring that the vacuum unit operating arm

is correctly engaged with the peg on the

baseplate, several attempts may be required

to reconnect it.

10Refit the distributor as described in

Section 18, and then check and if necessary

adjust the ignition timing, as described in

Section 21.

16 SV models

Dismantling

11With the distributor removed as described

in Section 18, pull off the rotor arm and, on

the Bosch distributor, remove the plastic

shield.

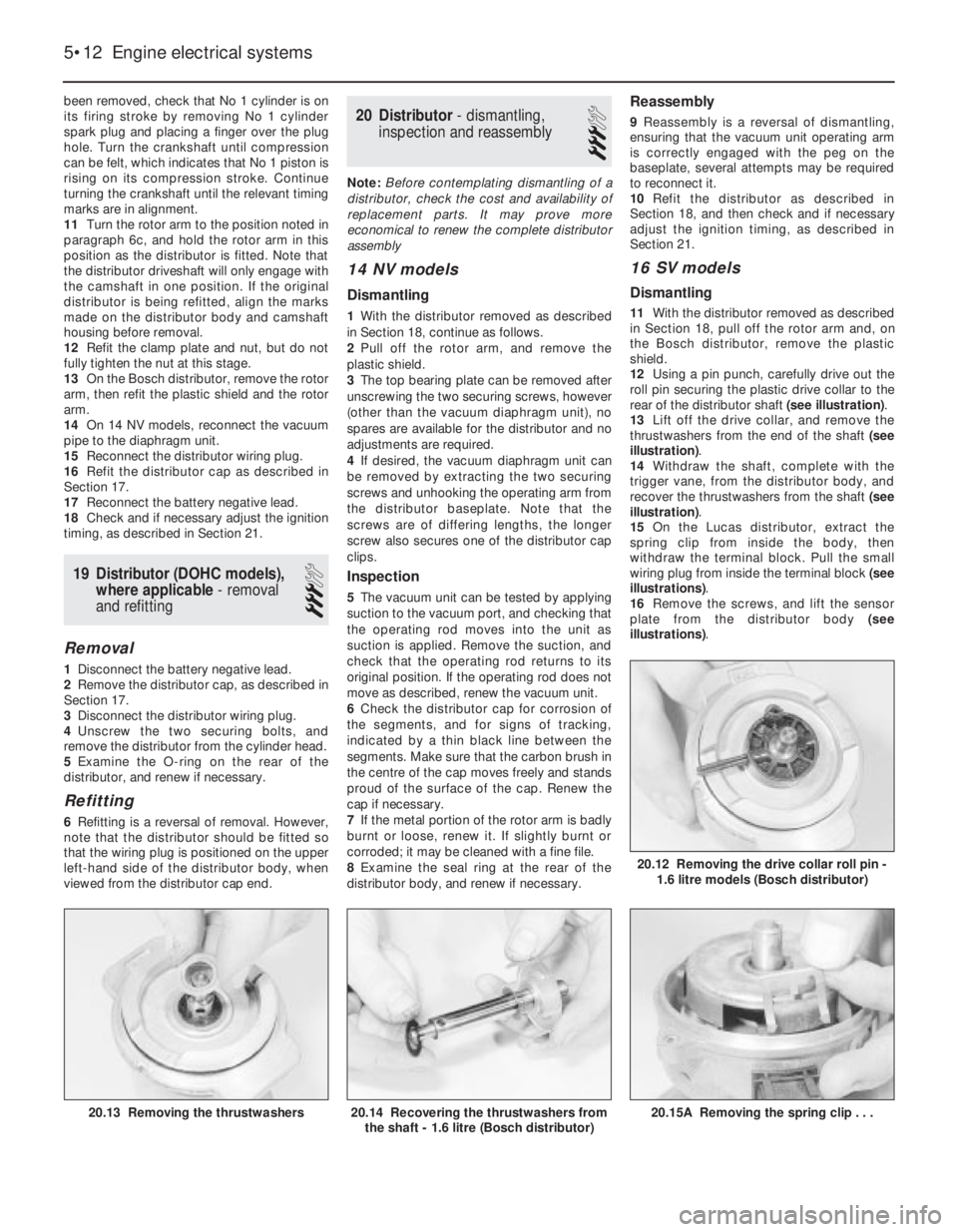

12Using a pin punch, carefully drive out the

roll pin securing the plastic drive collar to the

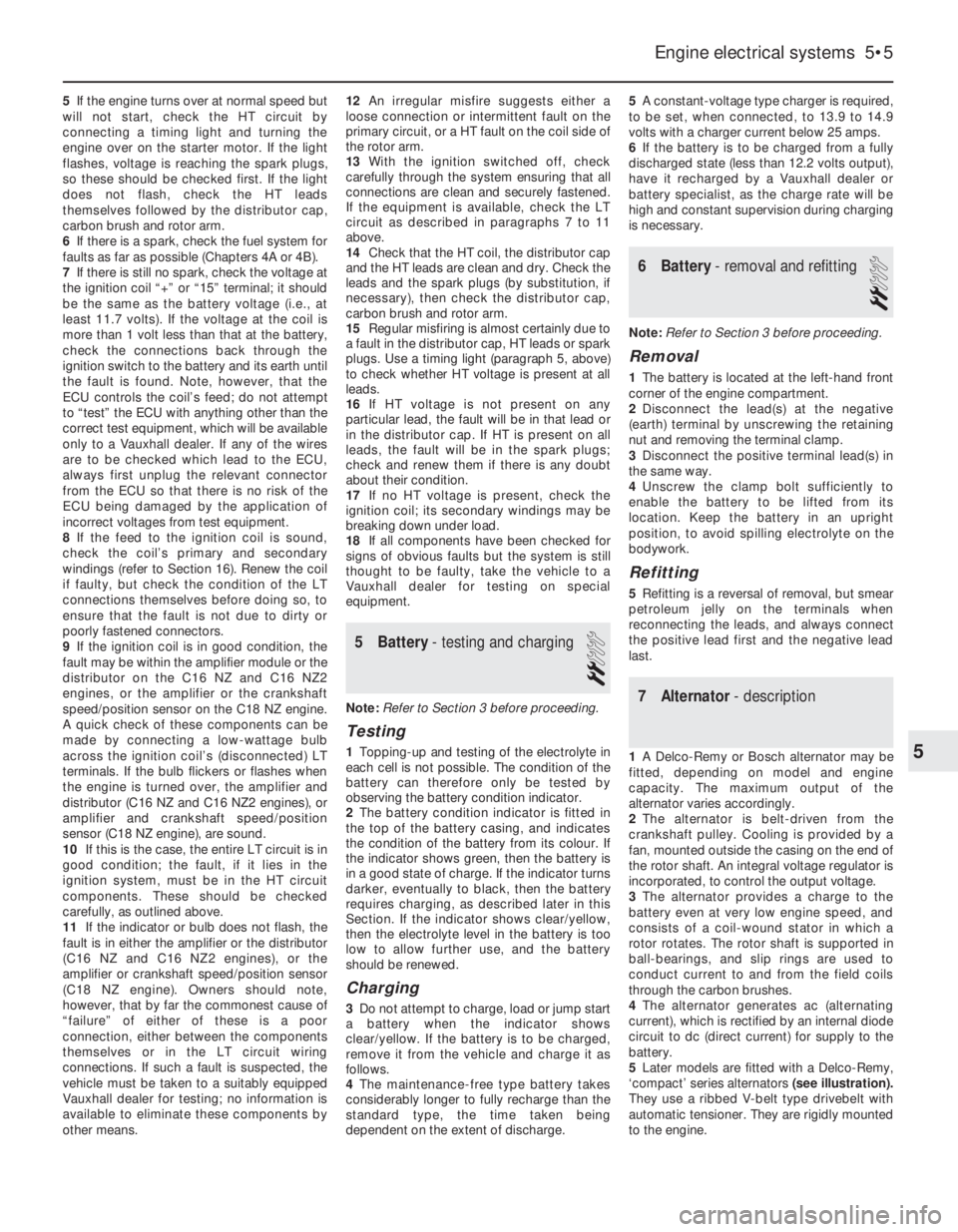

rear of the distributor shaft (see illustration).

13Lift off the drive collar, and remove the

thrustwashers from the end of the shaft (see

illustration).

14Withdraw the shaft, complete with the

trigger vane, from the distributor body, and

recover the thrustwashers from the shaft (see

illustration).

15On the Lucas distributor, extract the

spring clip from inside the body, then

withdraw the terminal block. Pull the small

wiring plug from inside the terminal block (see

illustrations).

16Remove the screws, and lift the sensor

plate from the distributor body (see

illustrations).

5•12Engine electrical systems

20.15A Removing the spring clip . . .20.14 Recovering the thrustwashers from

the shaft - 1.6 litre (Bosch distributor)20.13 Removing the thrustwashers

20.12 Removing the drive collar roll pin -

1.6 litre models (Bosch distributor)

Page 100 of 525

Inspection

17Examine the distributor cap and rotor arm,

as described in paragraphs 6 and 7. Examine

the O-rings at the rear of the distributor body,

and on the rear of the shaft, and renew if

necessary.

Reassembly

18Reassembly is a reversal of dismantling,

ensuring that the thrustwashers are correctly

located. Note that the drive collar should be

refitted so that the drive peg on the collar is

aligned with the groove in the top of the

distributor shaft (it is possible to fit the drive

collar 180°out of position).

19Refit the distributor as described in

Section 18, and then check and if necessary

adjust the ignition timing, as described in

Section 21.

DOHC models (where

applicable)

20The distributor cap and rotor arm can be

examined as described in paragraphs 6 and 7.

21Ignition timing -checking and

adjustment

4

Note: Refer to Section 3 before proceeding. A

tachometer and a timing light will be required

during this procedure. For details of ignition

timing adjustment required to operate vehicles

on unleaded petrol, refer to Section 22.

14 NV and 16 SV models

Checking

1Start the engine and run it until it reaches

normal operating temperature, then switch

off.

2On 14 NV models, disconnect the vacuum

pipe from the distributor vacuum diaphragm

unit.

3On all models use a spanner applied to the

crankshaft pulley bolt to rotate the crankshaft

clockwise until the notch in the pulley’s

inboard rim aligns with the pointer protruding

from the oil pump housing. On 14 NV models,

where two notches (indicating 10°and 5°

BTDC respectively) are found, rotate the

crankshaft until the second notch (in thedirection of rotation -i.e. 5°BTDC) aligns. Use

white paint or similar to emphasise the pointer

and notch, to make them easier to see.

4Connect a timing light to No 1 cylinder

(nearest the timing belt end of the engine) HT

lead, also a tachometer; follow the equipment

manufacturer’s instructions for connection.

5Start the engine and allow it to idle -the

speed should be between 700 and 1000 rpm.

6On 14 NV models, aim the timing light at the

pointer and check that it is aligned with the

crankshaft pulley notch.

7On early 16 SV models, disconnect the

ignition timing basic adjustment coding plug.

This can be identified by a length of Black

wire joining Brown/Red and Brown/Yellow

wires in a connector plug clipped to the wiring

or heater/cooling system hoses beneath the

battery/ignition coil (see illustration, 16.1). This

causes the MSTS-i module to adopt its basic

adjustment mode, sending a constant firing

signal corresponding to 10°BTDC and

eliminating any advance below 2000 rpm. Aim

the timing light at the pointer and check that it

is aligned with the crankshaft pulley notch.

8On later 16 SV, C 16 NZ and C 16 NZ2

models, the coding plugs are no longer fitted.

For accurate checking, special Vauxhall test

equipment must be used which causes the

MSTS module to adopt its basic adjustment

mode.

9Without access to such equipment, it is

possible to check and adjust the ignition

timing, accurate results cannot be

guaranteed. Owners are therefore advised to

have this work carried out by a suitably

equipped Vauxhall dealer; at the very least,

make the initial setting yourself and then have

it checked as soon as possible.

10If you do attempt to check the ignition

timing yourself, note that the fixed reference

mark is now an extended line embossed on

the timing belt lower outer cover.

Adjustment

11If the notch and pointer are not aligned,

loosen the distributor clamp nut and turn the

distributor body slightly in the required

direction to align.

12Tighten the distributor clamp nut, and

check that the notch and pointer are still

aligned. 13Stop the engine, and disconnect the

timing light and tachometer.

14On 16 SV models, reconnect the basic

adjustment coding plug. On 14 NV models,

reconnect the vacuum pipe to the distributor

vacuum diaphragm unit.

Other models

15No adjustment of the ignition timing is

possible on 1.8 and 2.0 litre models, as the

adjustment is carried out automatically by the

electronic control module.

16The ignition timing can be checked by a

Vauxhall dealer using specialist dedicated test

equipment, if a fault is suspected.

22Ignition timing -adjustment

for use with unleaded petrol

3

14 NV models

1All models with the 14 NV engine have the

ignition timing adjusted for use with 95 RON

unleaded petrol before they leave the factory,

and no further adjustment is required.

2Leaded petrol (98 RON) can be used if

desired, with no adverse effects.

1.6, 1.8 and 2.0 SOHC models

Note: Models equipped with a catalytic

converter must be operated on 95 R0N

unleaded petrol at all times, and although an

octane coding plug may be fitted, it should

not be tampered with

3Models, other than 14 NV, are equipped

with an octane coding plug, which is located

Engine electrical systems 5•13

20.16B . . .and withdraw the sensor plate -

1.6 litre (Bosch distributor)

20.16C Sensor plate screw (arrowed) -

1.6 litre (Lucas distributor)

20.16A Remove the securing screws . . .20.15B . . .and disconnecting the small

wiring plug - 1.6 litre (Lucas distributor)

5