clock RAM 1500 2021 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 380 of 496

378IN CASE OF EMERGENCY

6. Block both the front and rear wheel

diagonally opposite of each jacking

position. For example, if the driver’s front

wheel is being changed, block the

passenger’s rear wheel.

Wheel Blocked

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being raised or lifted.

JACK LOCATION

The jack and tools are stored under the front

passenger seat.

REMOVAL OF JACK AND TOOLS

To access the jack and tools, you must remove

the plastic access cover located on the side of

the front passenger’s seat. To remove the

cover, pull the front part of the cover (closest to

the front of the seat) toward you to release a

locking tab. Once the front of the cover is loose,

slide the cover toward the front of the seat until

it is free from the seat frame.

Pull Jack Access Cover From Front

Remove the jack and tools by turning the wing

bolt counterclockwise, remove the wing bolt

and then slide the assembly out from under the

seat.

Jack And Tools

Release the tool bag straps from the jack and

remove tools from bag.

Jack And Tool Bag

21_DT_OM_EN_USC_t.book Page 378

Page 382 of 496

380IN CASE OF EMERGENCY

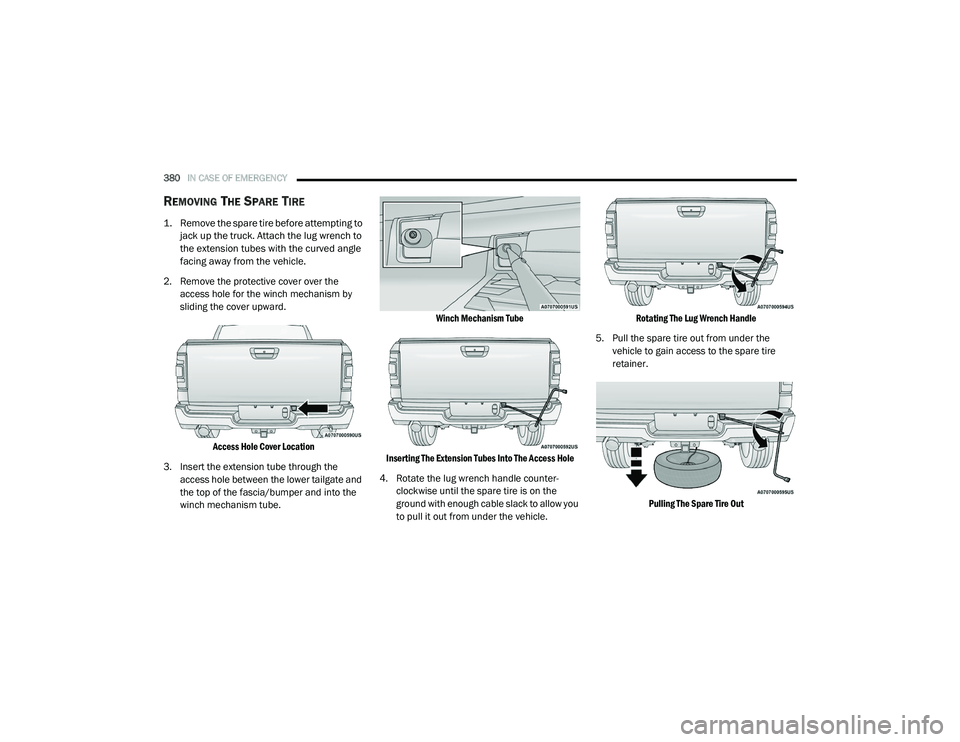

REMOVING THE SPARE TIRE

1. Remove the spare tire before attempting to

jack up the truck. Attach the lug wrench to

the extension tubes with the curved angle

facing away from the vehicle.

2. Remove the protective cover over the access hole for the winch mechanism by

sliding the cover upward.

Access Hole Cover Location

3. Insert the extension tube through the access hole between the lower tailgate and

the top of the fascia/bumper and into the

winch mechanism tube.

Winch Mechanism Tube

Inserting The Extension Tubes Into The Access Hole

4. Rotate the lug wrench handle counter -

clockwise until the spare tire is on the

ground with enough cable slack to allow you

to pull it out from under the vehicle.

Rotating The Lug Wrench Handle

5. Pull the spare tire out from under the vehicle to gain access to the spare tire

retainer.

Pulling The Spare Tire Out

21_DT_OM_EN_USC_t.book Page 380

Page 384 of 496

382IN CASE OF EMERGENCY

1. Remove the spare tire, jack, and tools from

the stored location.

2. Using the lug wrench, loosen the wheel nuts (but do not remove), by turning them

counterclockwise one turn while the wheel

is still on the ground.

3. Assemble the jack and jacking tools. Connect the jack handle driver to the

extension, then to the lug wrench.

Assembled Jack And Tools

4. Placement for the front and rear jacking

locations are critical. See below images for

proper jacking locations.

Jack / Extensions Placement

Front Jacking Location

When changing a front wheel, place the

scissor jack under the rear portion of the

lower control arm as shown. Access the

front jacking location from behind the front

tire.

Front Lifting Point

Front Jacking Location

Rear Jacking Location

Operate the jack using the extension with

jack hook and the lug wrench. The exten -

sion tubes may be used but is not required.

CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

21_DT_OM_EN_USC_t.book Page 382

Page 385 of 496

IN CASE OF EMERGENCY383

When changing a rear wheel, assemble the

extension with jack hook to the jack and

connect the extension tubes. Access the

rear jacking location from behind the rear

tire. Place the jack under the Jack Lifting

Point located on the rear axle lower control

arm bracket. Then locate the slot in the jack

lift plate onto the rear axle Jack Lifting Point.

Attach the extension with jack hook extend -

ing to the rear of the vehicle.

Rear Lifting Point Rear Jacking Location

Connect the long extensions to the lug

wrench.

5. By rotating the lug wrench clockwise, raise the vehicle until the wheel just clears the

ground surface. 6. Remove the lug nuts and pull the wheel off.

Install the spare wheel and lug nuts with the

cone shaped end of the lug nuts toward the

wheel. Hand tighten the lug nuts with the

vehicle lifted. To avoid the risk of forcing the

vehicle off the jack, do not fully tighten the

lug nuts until the vehicle has been

completely lowered.

7. Finish tightening the lug nuts. Push down on the wrench handle for increased leverage.

Tighten the lug nuts in a star pattern until

each lug nut has been tightened twice

Úpage 467. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a

service station.

CAUTION!

Before raising the wheel off the ground, make

sure that the jack will not damage

surrounding truck parts and adjust the jack

position as required.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

7

21_DT_OM_EN_USC_t.book Page 383

Page 387 of 496

IN CASE OF EMERGENCY385

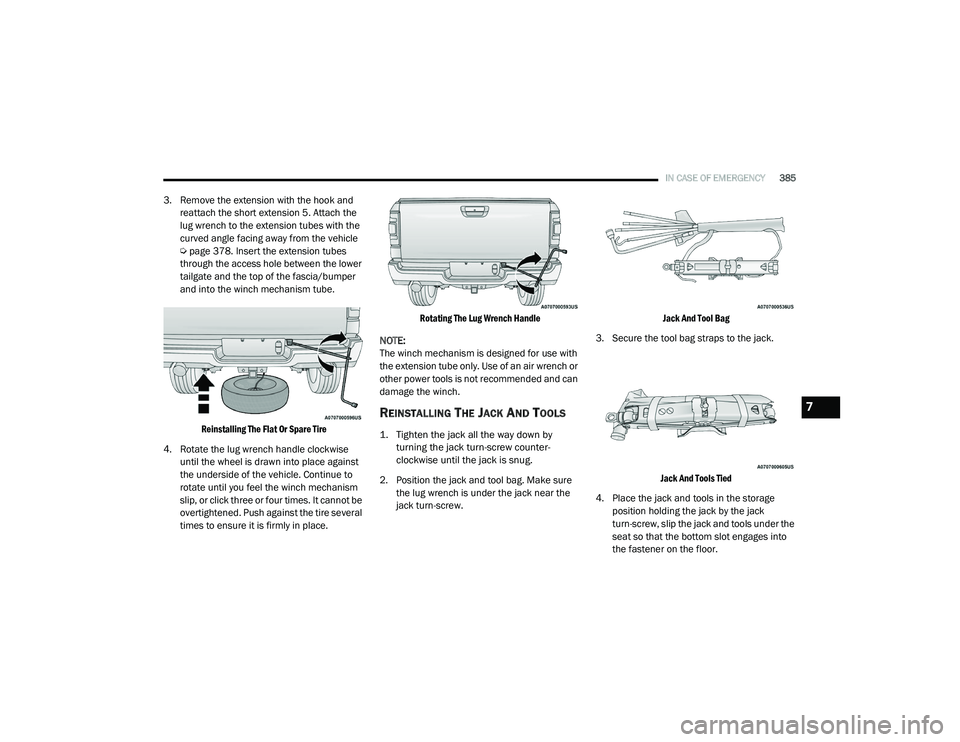

3. Remove the extension with the hook and

reattach the short extension 5. Attach the

lug wrench to the extension tubes with the

curved angle facing away from the vehicle

Úpage 378. Insert the extension tubes

through the access hole between the lower

tailgate and the top of the fascia/bumper

and into the winch mechanism tube.

Reinstalling The Flat Or Spare Tire

4. Rotate the lug wrench handle clockwise until the wheel is drawn into place against

the underside of the vehicle. Continue to

rotate until you feel the winch mechanism

slip, or click three or four times. It cannot be

overtightened. Push against the tire several

times to ensure it is firmly in place.

Rotating The Lug Wrench Handle

NOTE:

The winch mechanism is designed for use with

the extension tube only. Use of an air wrench or

other power tools is not recommended and can

damage the winch.

REINSTALLING THE JACK AND TOOLS

1. Tighten the jack all the way down by turning the jack turn-screw counter -

clockwise until the jack is snug.

2. Position the jack and tool bag. Make sure the lug wrench is under the jack near the

jack turn-screw.

Jack And Tool Bag

3. Secure the tool bag straps to the jack.

Jack And Tools Tied

4. Place the jack and tools in the storage position holding the jack by the jack

turn-screw, slip the jack and tools under the

seat so that the bottom slot engages into

the fastener on the floor.

7

21_DT_OM_EN_USC_t.book Page 385

Page 388 of 496

386IN CASE OF EMERGENCY

NOTE:

Ensure that the jack slides into the front hold

down location.

5. Turn the wing bolt clockwise to secure to the

floor pan. Reinstall the plastic cover.

Jack Hold Down Wing Bolt

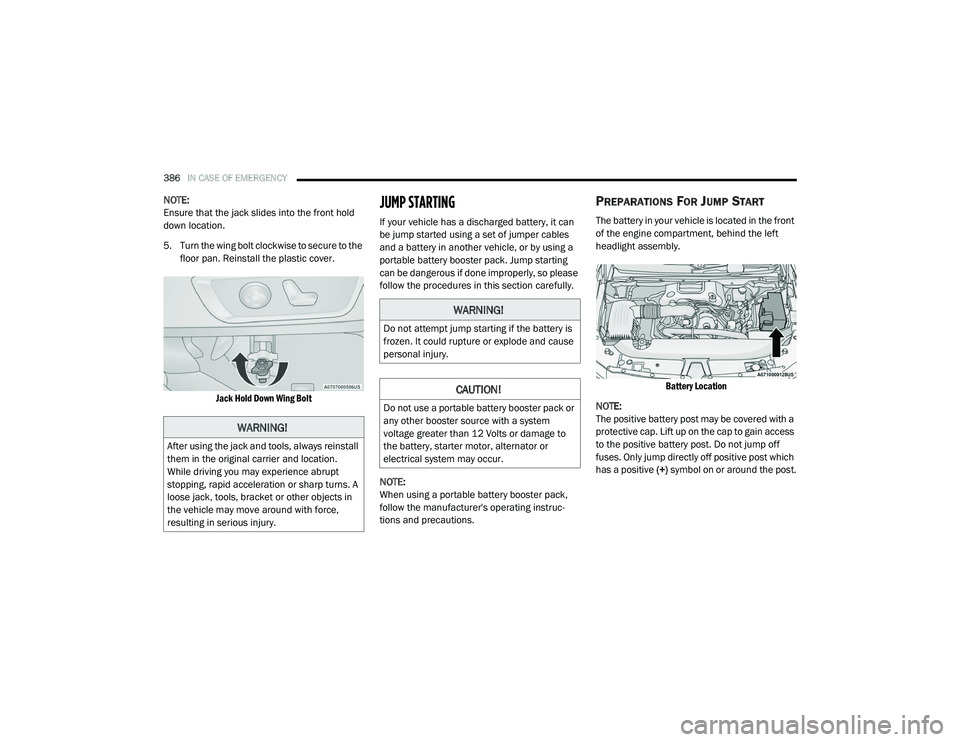

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle, or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so please

follow the procedures in this section carefully.

NOTE:

When using a portable battery booster pack,

follow the manufacturer's operating instruc -

tions and precautions.

PREPARATIONS FOR JUMP START

The battery in your vehicle is located in the front

of the engine compartment, behind the left

headlight assembly.

Battery Location

NOTE:

The positive battery post may be covered with a

protective cap. Lift up on the cap to gain access

to the positive battery post. Do not jump off

fuses. Only jump directly off positive post which

has a positive (+) symbol on or around the post.

WARNING!

After using the jack and tools, always reinstall

them in the original carrier and location.

While driving you may experience abrupt

stopping, rapid acceleration or sharp turns. A

loose jack, tools, bracket or other objects in

the vehicle may move around with force,

resulting in serious injury.

WARNING!

Do not attempt jump starting if the battery is

frozen. It could rupture or explode and cause

personal injury.

CAUTION!

Do not use a portable battery booster pack or

any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

21_DT_OM_EN_USC_t.book Page 386

Page 415 of 496

SERVICING AND MAINTENANCE413

Drain the fuel/water separator filter when the

“Water In Fuel Indicator Light” is ON. Within

10 minutes of vehicle shutdown, turn the filter

drain valve (located on the bottom of the filter

housing) counterclockwise to drain fuel/water,

then turn the ignition switch to the ON position,

and allow any accumulated water to drain.

Leave the drain valve open until all water and

contaminants have been removed. When clean

fuel is visible, close the drain valve by turning it

clockwise, and turn the ignition switch to OFF.

If more than two ounces or 60 milliliters of fuel

have been drained Úpage 414.

UNDERBODY MOUNTED FUEL FILTER

R

EPLACEMENT — DIESEL ENGINE

NOTE:

Using a fuel filter that does not meet FCA’s filtra-

tion and water separating requirements can

severely impact fuel system life and reliability.

Under normal conditions the diesel fuel filter

should be replaced every 20,000 miles (every

other oil change). If the vehicle is being used in

severe operating conditions, or In certain

geographical areas of the country (Pennsyl -

vania, New York, Ohio, Maryland, West Virginia,

Arkansas, Oklahoma, Kansas, Iowa, Missouri and Nebraska) due to fuel cleanliness’ issues,

it’s recommended to replace the fuel filter every

10,000 miles.

Fuel Filter Assembly

1. Turn engine off.

2. Place a drain pan under the fuel filter

assembly.

3. Open the water drain valve, and let any accumulated water drain.

4. Close the water drain valve.

5. Remove bottom cover using a strap wrench. Rotate counterclockwise for removal.

Remove the used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of it according to your

local regulations.

7. Wipe the sealing surfaces of the lid and housing clean.

8. Install a new o-ring into the ring groove on the filter housing and lubricate with clean

engine oil.

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter

during this action. It is best to install the

filter dry and allow the in-tank lift pump to

prime the fuel system.

1 — Water In Fuel Drain Valve

2 — Fuel Filter Access

8

21_DT_OM_EN_USC_t.book Page 413

Page 441 of 496

SERVICING AND MAINTENANCE439

Replacing Exterior Bulbs

Base Quad: Low Beam Headlamp, High Beam

Headlamp, Front Park And Turn — If Equipped

Low Beam

See below steps to replace:

1. Open the hood.

2. Disconnect and isolate the negative battery

cable.

3. Locate the low beam access cover, which can be found on the back side of the

headlamps.

Low Beam Headlight Cover

NOTE:

It may be necessary to remove/reposition Air

Cleaner Assembly to access passenger side

headlamp/side marker light bulbs.

4. Disengage the bulb access cover by rotating

counterclockwise.

5. Disconnect the internal lamp wiring harness connector from the low beam bulb.

6. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the lamp.

7. Pull the bulb straight out from the housing.

8. Reverse the procedure for installation of new bulb and covers. High Beam

High Beam Headlight Cover

See below steps to replace:

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Locate the high beam access cover, which can be found on the back side of the

headlamps.

NOTE:

It may be necessary to remove/reposition Air

Cleaner Assembly to access passenger side

headlamp/side marker light bulbs.

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened

bulb life will result.

Always use the correct bulb size and type

for replacement. An incorrect bulb size or

type may overheat and cause damage to

the lamp, the bulb socket, or the lamp

wiring.

8

21_DT_OM_EN_USC_t.book Page 439

Page 442 of 496

440SERVICING AND MAINTENANCE

4. Reach behind the headlamp and disengage

the access cover by rotating counter -

clockwise.

5. Disconnect the internal lamp wiring harness connector from the high beam bulb.

6. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the lamp.

7. Pull the bulb straight out from the housing.

8. Reverse the procedure for installation of new bulb and cover. Front Park And Turn

See below steps to replace:

1. Open the hood.

2. Disconnect and isolate the negative battery

cable.

3. Locate the park and turn socket, which can be found on the back side of the

headlamps.

Park And Turn Socket

4. Reach behind the headlamp and unlock the park and turn socket from the lamp by

rotating counterclockwise a quarter turn.

5. Pull the bulb straight out from the housing. 6. Separate the bulb from the socket without

twisting.

7. Reverse the procedure for installation of new bulb and covers.

Side Marker Lamp

See below steps to replace:

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Locate the side marker lamp, which can be found on the back side of the headlamps.

Side Marker Lamp

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened

bulb life will result.

Always use the correct bulb size and type

for replacement. An incorrect bulb size or

type may overheat and cause damage to

the lamp, the bulb socket, or the lamp

wiring.

21_DT_OM_EN_USC_t.book Page 440

Page 443 of 496

SERVICING AND MAINTENANCE441

4. Disengage the side marker socket by

rotating counterclockwise a quarter turn.

5. Pull the socket and bulb straight out from the housing.

6. Separate the bulb from the socket without twisting.

7. Reverse the procedure for installation of new bulb and covers.

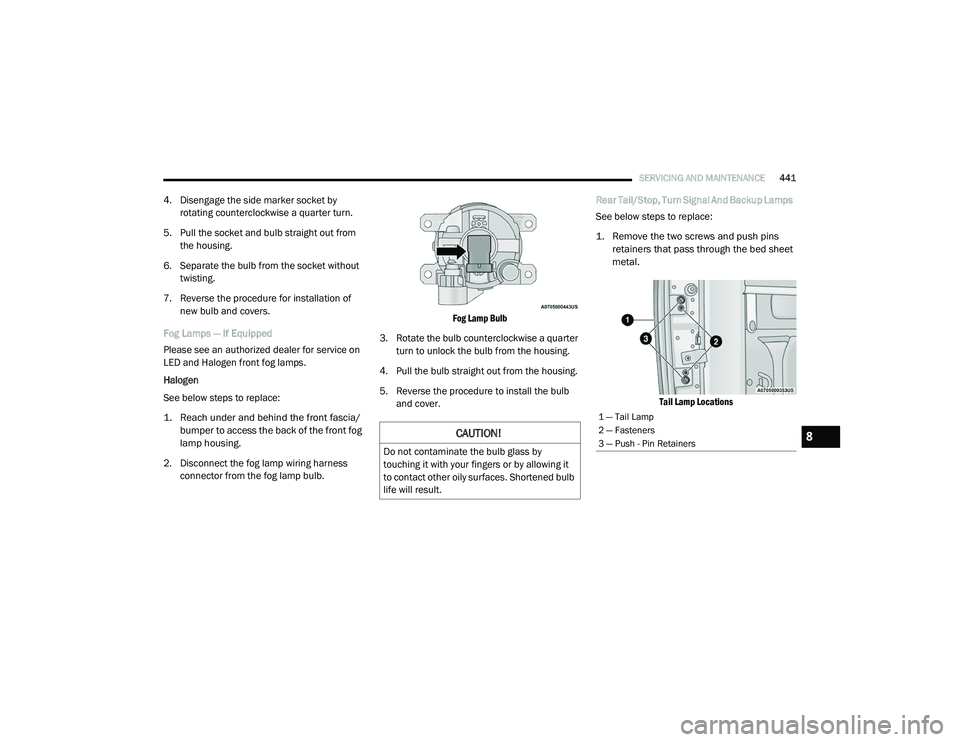

Fog Lamps — If Equipped

Please see an authorized dealer for service on

LED and Halogen front fog lamps.

Halogen

See below steps to replace:

1. Reach under and behind the front fascia/ bumper to access the back of the front fog

lamp housing.

2. Disconnect the fog lamp wiring harness connector from the fog lamp bulb.

Fog Lamp Bulb

3. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the housing.

4. Pull the bulb straight out from the housing.

5. Reverse the procedure to install the bulb and cover. Rear Tail/Stop, Turn Signal And Backup Lamps

See below steps to replace:

1. Remove the two screws and push pins

retainers that pass through the bed sheet

metal.

Tail Lamp Locations

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened bulb

life will result.

1 — Tail Lamp

2 — Fasteners

3 — Push - Pin Retainers

8

21_DT_OM_EN_USC_t.book Page 441