run flat RAM CHASSIS CAB 2020 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2020Pages: 516, PDF Size: 16.57 MB

Page 78 of 516

76GETTING TO KNOW YOUR VEHICLE

Storage Bin (Regular Cab)

The storage bin is located behind the front

seats and runs the length of the cab.

Storage Bin

Fold Flat Load Floor — If Equipped

Crew Cab models with a 60/40 rear seat may

be equipped with a folding load floor. Unfolding The Load Floor/Crew Cab

1. Lift the 60/40 seat cushion(s) to the

upward position.

Load Floor Legs In Stowed Position

2. Unfold both the legs using the straps.

Load Floor Legs In Opened Position

3. Lift the front panel until the load floor

unfolds into position.

Load Floor In Open Position

4. Reverse the procedure to store the load floor.

Positioning The Load Floor For Storage Access

Under The Seat

1. Lift the 60/40 seat cushion(s) to the upward position.

2. Unsnap the securing snap located at either side of the load floor.

3. Lift the load floor up to access storage under the load floor.

WARNING!

Do not operate the vehicle with loose items

stored on the load floor. While driving or in an

accident you may experience abrupt stopping,

rapid acceleration, or sharp turns. Loose

objects stored on the load floor may move

around with force and strike occupants,

resulting in serious or fatal injury.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 76

Page 139 of 516

SAFETY137

Trailer Tire Pressure Sensor Pairing

In order use this feature, the provided tire pres -

sure sensors must be installed in the desired

trailer tires and the sensors must be paired to

the truck. If the target trailer requires more than

the provided four sensors, additional sensors

can be purchased at an authorized Ram dealer -

ship.

With the sensors installed and the trailer near

or connected to your Ram truck, initiate the

pairing process by entering the settings menu in

the radio and select trailer. Refer to “Uconnect

Settings” in “Multimedia” for further informa -

tion. Select the desired trailer profile to pair to,

open the “Tire Pressure” menu, and hit “Setup

All Tires.” Follow the on screen prompts to select the

number of axles (1 - 3), the number of trailer

tires (2, 4, 6, 8, or 12), and the set trailer tire

pressure. The range is selectable anywhere

between 25-125 PSI (172-862 kPa).

Once PSI (kPa) is programmed, the pairing

screen appears. Tire sensors must be paired in

order shown. Starting with Tire 1, deflate tire by

5 PSI (34 kPa) and wait for a horn chirp. It may

take up to three minutes for the chirp to occur,

indicating that the sensor has paired. Repeat

process on each tire, in order, until complete.

Do not exit the pairing screen until process is

complete. If pairing was unsuccessful, a double

horn chirp will sound, and a prompt on the touchscreen will allow you to retry the proce

-

dure; “Retry” will only appear when setup fails.

Each tire must be successfully paired during a

single pairing process to receive the success

screen.

NOTE:

If the pairing process times out after three

minutes of no communication with a sensor, a

double horn chirp will occur indicating the

pairing has failed and a message will display on

the radio indicating the process was unsuc -

cessful. Under certain circumstances, the

double horn chirp may continue to happen

every three minutes indicating the failed

pairing. If this happens, the horn chirping may

be canceled by cycling the ignition button OFF

and then back to ON/RUN position.

Tire Pres sure Monitoring Lo w Pre ssure

Warnings

When a tire pressure low in one or more of the

active road tires is detected, the instrument

cluster will display a message stating “Trailer

Tire Pressure Low”. The instrument cluster will

then display the TTPMS graphic showing the

pressure values of each tire with the low tire

pressure values in a different color.

4

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 137

Page 140 of 516

138SAFETY

Should this occur, you should stop as soon as

possible and inflate the tires with a low pressure

condition (those in a different color in the instru -

ment cluster graphic) to the customer

programmed target tire pressure value as

shown at the top of the TTPMS instrument

cluster graphic. Once the tire(s) are inflated, the

system will automatically update the graphic

display in the instrument cluster, returning to

it’s original color. The vehicle may need to be

driven for up to 10 minutes above 15 mph

(24 km/h) in order for the TTPMS to receive the

updated information.

Service TTPMS Warning

If a system fault is detected, the instrument

cluster will display a “Trailer Tire Pressure

System Service Required” message for a

minimum of five seconds.

Once the system fault is corrected the "Trailer

Tire Pressure System Service Required"

message will no longer be displayed. The

vehicle may need to be driven for up to

10 minutes above 15 mph (24 km/h) in order

for the TTPMS to receive the trailer tire pressure

information. Trailer Tire Pressure System Not Configured

A “Trailer Tire Pressure System Not Configured”

message will be displayed in the Instrument

Cluster on the TTPM instrument cluster graphic

when a trailer number is selected that has not

had trailer tire pressure sensors paired. To

correct this condition, see “Trailer Tire Pressure

Sensor Pairing” in “Multimedia”.

Trailer Sensors Detected Do Not Match Active

Trailer

The “Trailer Sensors Detected Do Not Match

Active Trailer” message will be displayed in the

Instrument Cluster when the trailer sensors

being received by the TTPM module do not

match the trailer sensors paired to the current

trailer number selected. This message will be

displayed when the sensors being received

completely match the sensors paired to another

trailer number configured in the TTPM module.

To correct this condition, the correct trailer

number must be selected in the radio. Refer to

the “Uconnect Settings” in “Multimedia” for

further information.Tire Fill Alert — If Equipped

This feature notifies the user when the placard

tire pressure is attained while inflating or

deflating the tire.

The customer may choose to disable or enable

the Tire Fill Alert feature through use of the

customer settings in the radio.

NOTE:

Only one tire can be filled at a time when

using the Tire Fill Alert system.

The Tire Fill Alert feature cannot be entered if

an existing TPM system fault is set to “active”

or if the system is in deactivation mode (if

equipped).

The system will be activated when the TPM

receiver module detects a change in tire pres -

sure. The ignition must be in the RUN mode,

with the transmission in PARK (P).

NOTE:

It is not required to have the engine running to

enter Tire Fill Alert mode.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 138

Page 141 of 516

SAFETY139

The hazard lamps will come on to confirm the

vehicle is in Tire Fill Alert mode.

When Tire Fill Alert Mode is entered, the tire

pressure display screen will be displayed in the

instrument cluster.

Operation:

The horn will chirp once to let the user know

when to stop filling the tire, when it reaches

recommended pressure.

The horn will chirp three times if the tire is

over filled and will continue to chirp every five

seconds if the user continues to inflate the

tire.

The horn will chirp once again when enough

air is let out to reach proper inflation level.

The horn will also chirp three times if the tire

is then under-inflated and will continue to

chirp every five seconds if the user continues

to deflate the tire. Selectable Tire Fill Alert (STFA) — If Equipped

The Selectable Tire Fill Alert (STFA) system is an

optional feature that is included as part of the

normal Tire Fill Alert system. The system is

designed to allow the customer to select a pres

-

sure to inflate or deflate the vehicle's front and

rear axle tires to and to provide feedback to the

customer while inflating or deflating the

vehicle's tires.

In the Selectable Tire Fill Alert customer

settings menu in the radio, the customer will be

able to select a pressure setting for both the

front and rear axle tire pressures by scrolling

through a pressure range from XX to 15 psi in

1 psi increments for each axle setting. XX = the

vehicle’s cold placard pressure values for the

front and rear axles as shown on the vehicle

placard pressure label.

The customer may also store the pressure

values chosen for each axle in the radio as a

preset pressure. The customer will be allowed

to store up to two sets of preset values in the

radio for the front and rear axle pressure values.

Once the customer selects the tire pressures for

the front and rear axles that they want to inflate

or deflate to, they can begin inflating or

deflating one tire at a time. NOTE:

The STFA system will only support inflating or

deflating one tire at a time.

The system will be activated when the TPM

receiver module detects a change in tire pres

-

sure. The ignition must be in the RUN mode,

with the transmission in PARK (P).

The hazard lamps will come on to confirm the

vehicle is in Tire Fill Alert mode.

When Tire Fill Alert Mode is entered, the tire

pressure display screen will be displayed in the

instrument cluster.

Operation:

The horn will chirp once when the selected

pressure is reached to let the user know

when to stop inflating or deflating the tire.

The horn will chirp three times if the tire is

over inflated or over deflated and will

continue to chirp every five seconds if the

user continues to inflate or deflate the tire.

The horn will chirp once again when enough

air is added or removed to reach proper

selected pressure level.

4

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 139

Page 153 of 516

SAFETY151

Supplemental Restraint Systems (SRS)

Some of the safety features described in this

section may be standard equipment on some

models, or may be optional equipment on

others. If you are not sure, ask an authorized

dealer.

The air bag system must be ready to protect you

in a collision. The Occupant Restraint Controller

(ORC) monitors the internal circuits and inter -

connecting wiring associated with the electrical

Air Bag System Components. Your vehicle may

be equipped with the following Air Bag System

Components:

Air Bag System Components

Occupant Restraint Controller (ORC)

Air Bag Warning Light

Steering Wheel and Column

Instrument Panel

Knee Impact Bolsters

Driver and Front Passenger Air Bags

Seat Belt Buckle Switch

Supplemental Side Air Bags — If Equipped

Front and Side Impact Sensors — If Equipped

Seat Belt Pretensioners — If Equipped

Air Bag Warning Light

The ORC monitors the readiness of

the electronic parts of the air bag

system whenever the ignition switch

is in the START or ON/RUN position. If

the ignition switch is in the OFF position or in the

ACC position, the air bag system is not on and

the air bags will not inflate.

The ORC contains a backup power supply

system that may deploy the air bag system even

if the battery loses power or it becomes discon -

nected prior to deployment.

The ORC turns on the Air Bag Warning Light in

the instrument panel for approximately four to

eight seconds for a self-check when the ignition

switch is first in the ON/RUN position. After the

self-check, the Air Bag Warning Light will turn

off. If the ORC detects a malfunction in any part

of the system, it turns on the Air Bag Warning

Light, either momentarily or continuously. A

single chime will sound to alert you if the light

comes on again after initial startup. The ORC also includes diagnostics that will illu-

minate the instrument panel Air Bag Warning

Light if a malfunction is detected that could

affect the air bag system. The diagnostics also

record the nature of the malfunction. While the

air bag system is designed to be maintenance

free, if any of the following occurs, have an

authorized dealer service the air bag system

immediately.

The Air Bag Warning Light does not come on

during the four to eight seconds when the

ignition switch is first in the ON/RUN position.

The Air Bag Warning Light remains on after

the four to eight-second interval.

The Air Bag Warning Light comes on intermit

-

tently or remains on while driving.

NOTE:

If the speedometer, tachometer, or any engine

related gauges are not working, the Occupant

Restraint Controller (ORC) may also be

disabled. In this condition the air bags may not

be ready to inflate for your protection. Have an

authorized dealer service the air bag system

immediately.

4

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 151

Page 328 of 516

326IN CASE OF EMERGENCY

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial towing service. If the transmission and drivetrain are operable,

disabled vehicles may also be towed as described under “Recreational Towing” in the “Starting And Operating” section.

Proper towing or lifting equipment is required to

prevent damage to your vehicle. Use only tow

bars and other equipment designed for this

purpose, following equipment manufacturer’s

instructions. Use of safety chains is mandatory.

Attach a tow bar or other towing device to main

structural members of the vehicle, not to

bumpers or associated brackets. State and

local laws regarding vehicles under tow must be

observed. If you must use the accessories (wipers,

defrosters, etc.) while being towed, the ignition

must be in the ON/RUN mode, not the ACC

mode.

If the key fob is unavailable or the vehicle's

battery is discharged, refer to “Manual Park

Release” or “Gear Selector Override” in this

section for instructions on shifting the auto

-

matic transmission out of PARK for towing.

Towing Condition Wheels OFF The

Ground 2WD Models

4WD Models

Flat Tow NONE If transmission is operable:

• Transmission in NEUTRAL

• 30 mph (48 km/h) max speed

• 15 miles (24 km) max distance (6–speed

transmission)

• 30 miles (48 km) max distance (8–speed

transmission) See instructions in “Recreational Towing” under

“Starting And Operating”

• Auto Transmission in PARK

• Transfer Case in NEUTRAL

• Tow in forward direction

Wheel Lift Or Dolly Tow Front

NOT ALLOWED

Rear OK NOT ALLOWED

Flatbed ALL

BEST METHOD BEST METHOD

CAUTION!

Do not use sling type equipment when

towing. Vehicle damage may occur.

When securing the vehicle to a flat bed

truck, do not attach to front or rear suspen-

sion components. Damage to your vehicle

may result from improper towing.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 326

Page 331 of 516

329

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GAS ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indi-

cator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will

influence when the “Oil Change Required”

message is displayed. Severe Operating Condi-

tions can cause the change oil message to illu -

minate as early as 3,500 miles (5,600 km)

since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles

(805 km). An authorized dealer will reset the oil change

indicator message after completing the sched

-

uled oil change. If a scheduled oil change is

performed by someone other than an autho -

rized dealer, the message can be reset by refer -

ring to the steps described under “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.

Gas Engines:

Under no circumstances should oil change

intervals exceed 8,000 miles (13,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty:

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominately at idle or very low

engine RPM. This type of vehicle use is consid -

ered Severe Duty. Once A Month Or Before A Long Trip:Check engine oil level.

Check windshield washer fluid level.

Check the tire inflation pressures and look

for unusual wear or damage. Rotate at the

first sign of irregular wear.

Check the fluid levels of the coolant reservoir,

brake master cylinder, power steering and

automatic transmission (six-speed only), and

fill as needed.

Check function of all interior and exterior

lights.

7

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 329

Page 386 of 516

384SERVICING AND MAINTENANCE

Radial Ply Tires

Tire Repair

If your tire becomes damaged, it may be

repaired if it meets the following criteria:

The tire has not been driven on when flat.

The damage is only on the tread section of

your tire (sidewall damage is not repairable).

The puncture is no greater than a ¼ of an

inch (6 mm).

Consult an authorized tire dealer for tire repairs

and additional information. Damaged Run Flat tires, or Run Flat tires that

have experienced a loss of pressure should be

replaced immediately with another Run Flat tire

of identical size and service description (Load

Index and Speed Symbol). Replace the tire pres

-

sure sensor as well as it is not designed to be

reused.

Run Flat Tires — If Equipped

Run Flat tires allow you the capability to drive

50 miles (80 km) at 50 mph (80 km/h) after a

rapid loss of inflation pressure. This rapid loss

of inflation is referred to as the Run Flat mode.

A Run Flat mode occurs when the tire inflation

pressure is of/or below 14 psi (96 kPa). Once a

Run Flat tire reaches the run flat mode it has

limited driving capabilities and needs to be

replaced immediately. A Run Flat tire is not

repairable. When a run flat tire is changed after

driving with underinflated tire condition, please

replace the TPM sensor as it is not designed to

be reused when driven under run flat mode

14 psi (96 kPa) condition. NOTE:

TPM Sensor must be replaced after driving the

vehicle on a flat tire condition.

It is not recommended driving a vehicle loaded

at full capacity or to tow a trailer while a tire is in

the run flat mode.

See the tire pressure monitoring section for

more information.Tire Spinning

When stuck in mud, sand, snow, or ice condi

-

tions, do not spin your vehicle's wheels above

30 mph (48 km/h) or for longer than 30

seconds continuously without stopping.

Refer to “Freeing A Stuck Vehicle” in “In Case Of

Emergency” for further information.

WARNING!

Combining radial ply tires with other types of

tires on your vehicle will cause your vehicle to

handle poorly. The instability could cause a

collision. Always use radial ply tires in sets of

four. Never combine them with other types of

tires.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause tire damage or failure. A tire could

explode and injure someone. Do not spin your

vehicle's wheels faster than 30 mph

(48 km/h) for more than 30 seconds

continuously when you are stuck, and do not

let anyone near a spinning wheel, no matter

what the speed.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 384

Page 395 of 516

SERVICING AND MAINTENANCE393

Temperature Grades

The Temperature grades are A (the

highest), B, and C, representing the tire's

resistance to the generation of heat and

its ability to dissipate heat, when tested

under controlled conditions on a speci -

fied indoor laboratory test wheel.

Sustained high temperature can cause

the material of the tire to degenerate

and reduce tire life, and excessive

temperature can lead to sudden tire

failure. The grade C corresponds to a

level of performance, which all

passenger vehicle tires must meet

under the Federal Motor Vehicle Safety

Standard No. 109. Grades B and A repre -sent higher levels of performance on the

laboratory test wheel, than the minimum

required by law.

STORING THE VEHICLE

If you are storing your vehicle for more than 21

days, we recommend that you take the following

steps to minimize the drain on your vehicle's

battery:

Disconnect the negative cable from battery.

Any time you store your vehicle or keep it out

of service (i.e., vacation) for two weeks or

more, run the air conditioning system at idle

for about five minutes in the fresh air and

high blower setting. This will ensure

adequate system lubrication to minimize the

possibility of compressor damage when the

system is started again.

BODYWORK

Protection From Atmospheric Agents

Vehicle body care requirements vary according

to geographic locations and usage. Chemicals

that make roads passable in snow and ice and

those that are sprayed on trees and road

surfaces during other seasons are highly corro

-

sive to the metal in your vehicle. Outside

parking, which exposes your vehicle to airborne

contaminants, road surfaces on which the

vehicle is operated, extreme hot or cold weather

and other extreme conditions will have an

adverse effect on paint, metal trim, and under -

body protection.

The following maintenance recommendations

will enable you to obtain maximum benefit from

the corrosion resistance built into your vehicle.

WARNING!

The traction grade assigned to this tire is

based on straight-ahead braking traction

tests, and does not include acceleration,

cornering, hydroplaning, or peak traction

characteristics.

WARNING!

The temperature grade for this tire is

established for a tire that is properly inflated

and not overloaded. Excessive speed,

under-inflation, or excessive loading, either

separately or in combination, can cause heat

buildup and possible tire failure.

7

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 393

Page 507 of 516

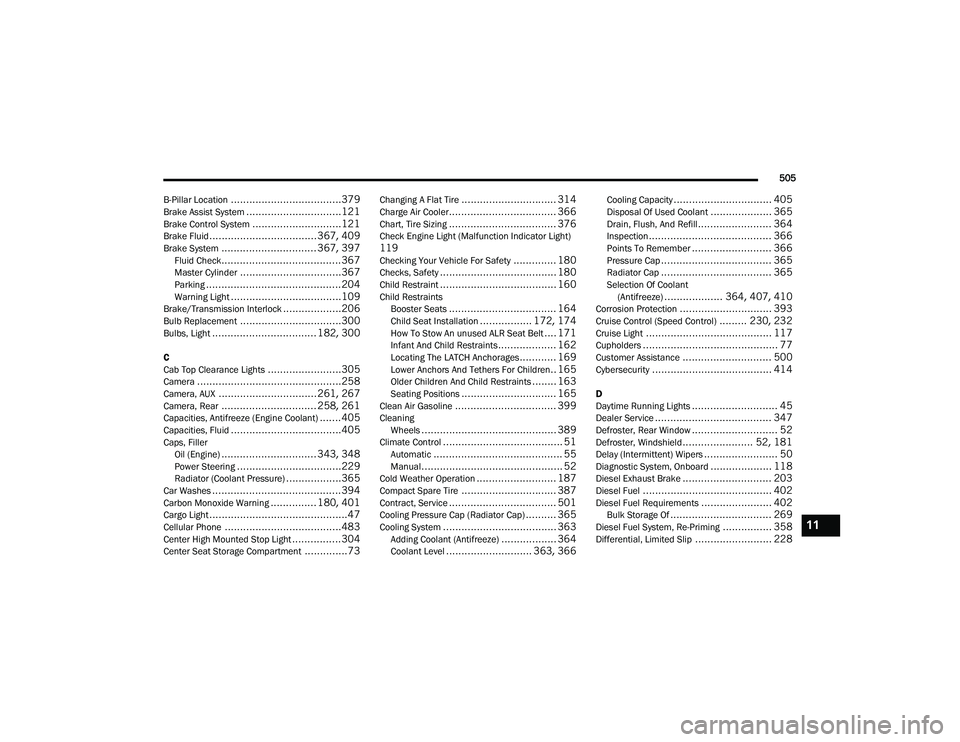

505

B-Pillar Location

....................................379Brake Assist System...............................121Brake Control System.............................121Brake Fluid...................................367, 409Brake System............................... 367, 397Fluid Check.......................................367Master Cylinder.................................367Parking............................................204Warning Light....................................109Brake/Transmission Interlock...................206Bulb Replacement.................................300Bulbs, Light.................................. 182, 300

C

Cab Top Clearance Lights........................305Camera...............................................258Camera, AUX................................ 261, 267Camera, Rear............................... 258, 261Capacities, Antifreeze (Engine Coolant).......405Capacities, Fluid....................................405Caps, Filler Oil (Engine)............................... 343, 348Power Steering..................................229Radiator (Coolant Pressure)..................365Car Washes..........................................394Carbon Monoxide Warning............... 180, 401Cargo Light.............................................47Cellular Phone......................................483Center High Mounted Stop Light................304Center Seat Storage Compartment..............73

Changing A Flat Tire............................... 314Charge Air Cooler................................... 366Chart, Tire Sizing................................... 376Check Engine Light (Malfunction Indicator Light)119Checking Your Vehicle For Safety.............. 180Checks, Safety...................................... 180Child Restraint...................................... 160Child RestraintsBooster Seats................................... 164Child Seat Installation................. 172, 174How To Stow An unused ALR Seat Belt.... 171Infant And Child Restraints................... 162Locating The LATCH Anchorages............ 169Lower Anchors And Tethers For Children.. 165Older Children And Child Restraints........ 163Seating Positions............................... 165Clean Air Gasoline................................. 399CleaningWheels............................................ 389Climate Control....................................... 51Automatic.......................................... 55Manual.............................................. 52Cold Weather Operation.......................... 187Compact Spare Tire............................... 387Contract, Service................................... 501Cooling Pressure Cap (Radiator Cap).......... 365Cooling System..................................... 363Adding Coolant (Antifreeze).................. 364Coolant Level............................ 363, 366

Cooling Capacity................................ 405Disposal Of Used Coolant.................... 365Drain, Flush, And Refill........................ 364Inspection........................................ 366Points To Remember.......................... 366Pressure Cap.................................... 365Radiator Cap.................................... 365Selection Of Coolant(Antifreeze)................... 364, 407, 410Corrosion Protection.............................. 393Cruise Control (Speed Control)......... 230, 232Cruise Light......................................... 117Cupholders............................................ 77Customer Assistance............................. 500Cybersecurity....................................... 414

D

Daytime Running Lights............................ 45Dealer Service...................................... 347Defroster, Rear Window............................ 52Defroster, Windshield....................... 52, 181Delay (Intermittent) Wipers........................ 50Diagnostic System, Onboard.................... 118Diesel Exhaust Brake............................. 203Diesel Fuel.......................................... 402Diesel Fuel Requirements....................... 402Bulk Storage Of................................. 269Diesel Fuel System, Re-Priming................ 358Differential, Limited Slip......................... 228

11

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 505