torque Ram ProMaster City 2018 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: ProMaster City, Model: Ram ProMaster City 2018Pages: 180, PDF Size: 7.52 MB

Page 100 of 180

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.

7. Lower the vehicle by turning the jack screw to the left. 8. Refer to “Torque Specifications” in

“Technical Specifications” for proper

wheel lug bolt torque.

9. Lower the jack to its fully-closed position.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

10. Stow the cable and wheel spacer before driving the vehicle. Refer to “Vehicles

With Alloy Wheels” in this section for

instructions on stowing alloy wheels.

11. Stow the jack and tools under the driv- er’s seat.

12. Check the spare tire pressure as soon as possible. Correct the tire pressure, as

required.

13. When you place the spare tire back on the winch or if you carry the tire in need

of repair on the winch, always check that

the tire is properly secured under the vehicle by pushing on the stowed tire

under the rear bumper at the back of the

vehicle. If the tire has motion when

pushed, use the tools to retighten the

winch until a loud click is heard.

Vehicles With Alloy Wheels

For stowing a damaged tire on vehicles with

alloy wheels, remove the adapter bracket and

bolts from the storage bag in the glove com-

partment and follow the steps below:

1. Take the adapter and fit the plastic spacer

between the spring and the flange of the

bracket (The adapter bracket is sold sepa-

rately through the dealer).

2. The plastic fin must be directed down- wards and perfectly coincide with the

flange cut part; fit the bracket in the

adapter, fold the bracket up and secure it

to the adapter with the fastening knob.

3. Position the tire vertically and lay the mounted adapter on the inner part of the

rim, using the supplied bolts fasten the

wheel to the adapter using the bolt install

wrench.

4. Tighten the bolts with the wrench handle.

Mounting Spare Tire

IN CASE OF EMERGENCY

98

Page 101 of 180

5. Rotate the winch mechanism clockwiseuntil the wheel is properly stowed under

the vehicle and until the wench makes

three audible noises.

6. Reach underneath and shake tire by hand to confirm that it is secure. The tire should

not move. If the tire is still loose and/or

three audible noises are not heard, place

and secure damaged wheel into the ve-

hicle and seek dealer assistance for the

winch mechanism.

This is for temporary use only.

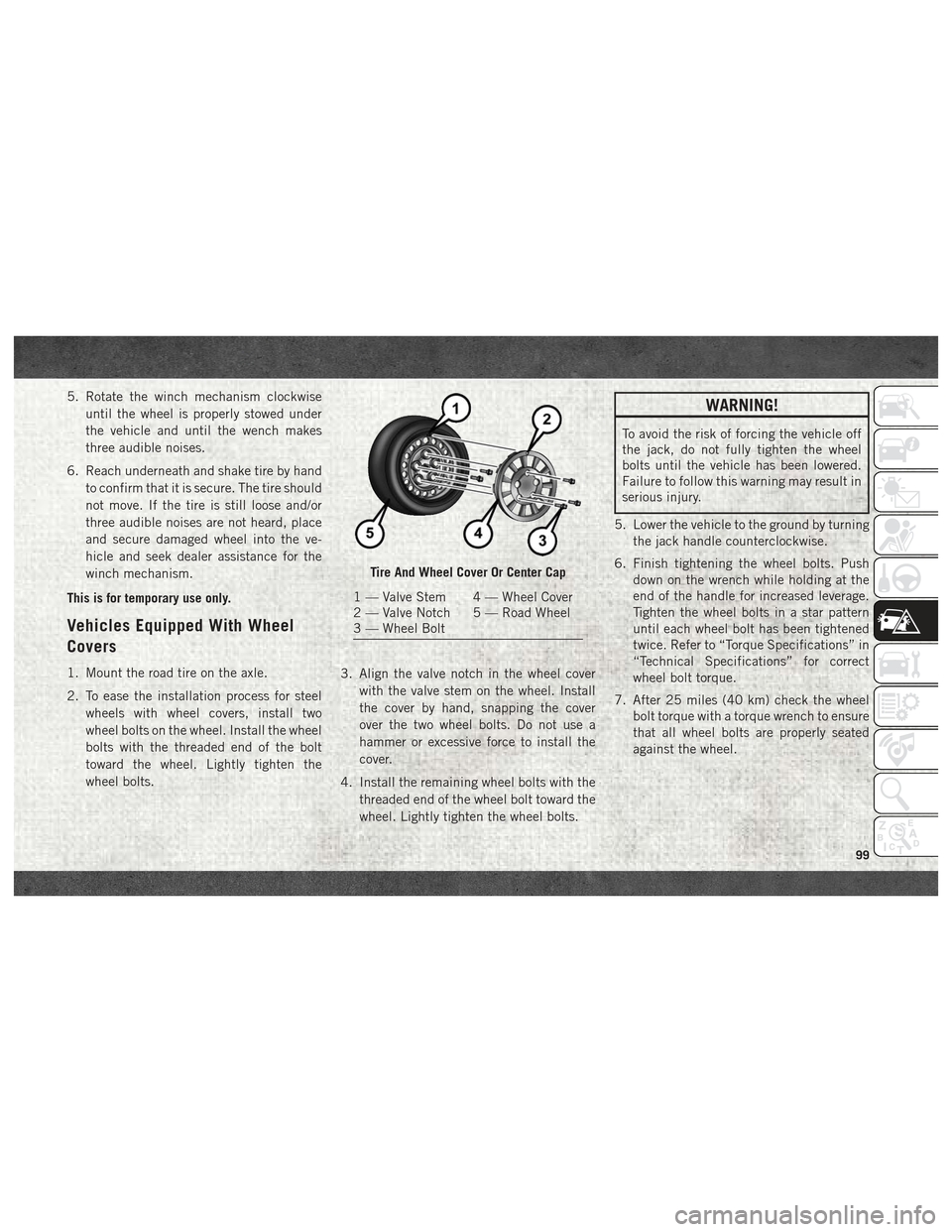

Vehicles Equipped With Wheel

Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two

wheel bolts on the wheel. Install the wheel

bolts with the threaded end of the bolt

toward the wheel. Lightly tighten the

wheel bolts. 3. Align the valve notch in the wheel cover

with the valve stem on the wheel. Install

the cover by hand, snapping the cover

over the two wheel bolts. Do not use a

hammer or excessive force to install the

cover.

4. Install the remaining wheel bolts with the threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not fully tighten the wheel

bolts until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the wheel bolts. Push down on the wrench while holding at the

end of the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Torque Specifications” in

“Technical Specifications” for correct

wheel bolt torque.

7. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure

that all wheel bolts are properly seated

against the wheel.

Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Road Wheel

3 — Wheel Bolt

99

Page 137 of 180

TECHNICAL SPECIFICATIONS

WHEEL AND TIRE TORQUE SPECIFICA-

TIONS.................... .136

Torque Specifications............136

FLUID CAPACITIES.............137

FLUIDS AND LUBRICANTS .........137

Engine.....................137 Chassis

....................138

MOPAR ACCESSORIES ...........139

Authentic Accessories By Mopar .....139

TECHNICAL SPECIFICATIONS

135

Page 138 of 180

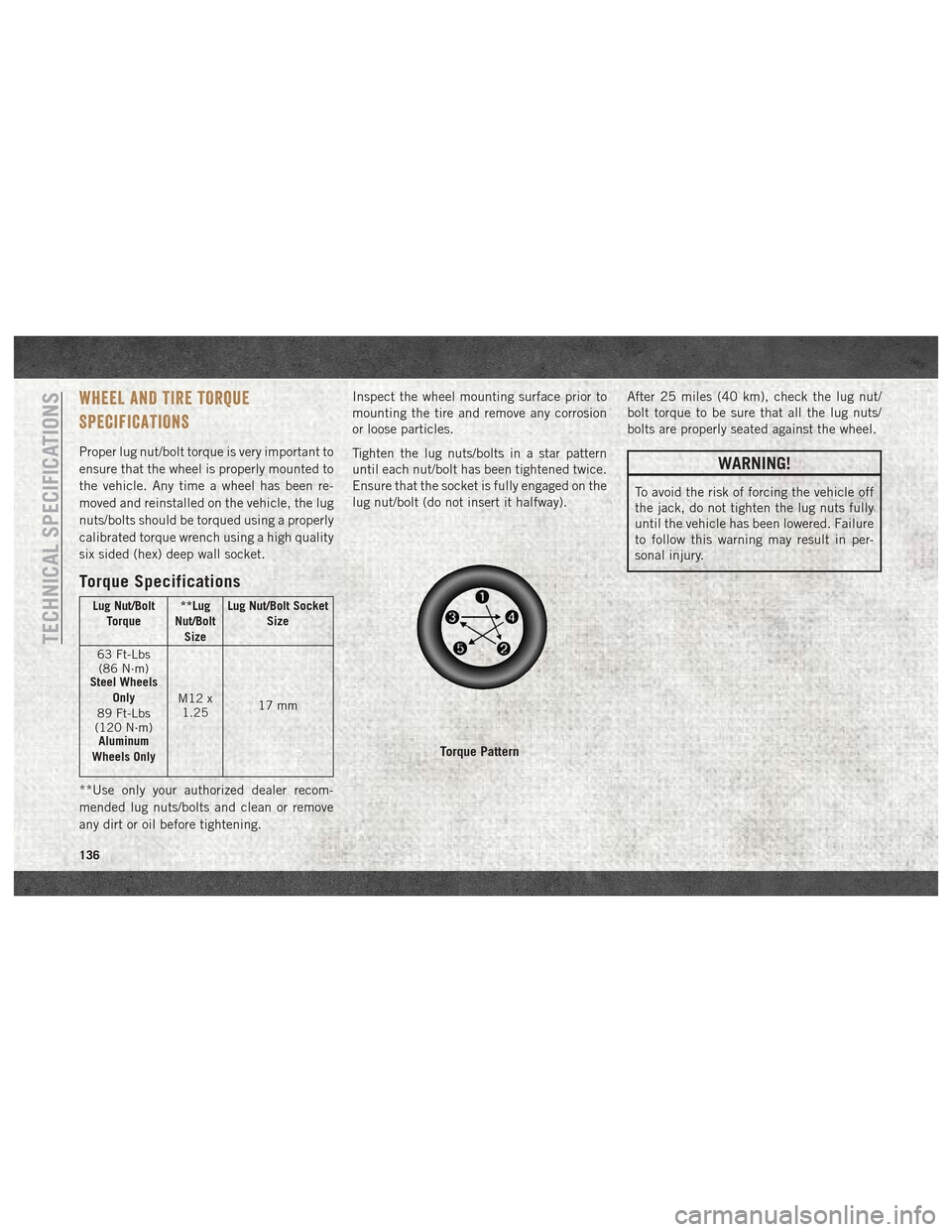

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle, the lug

nuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Lug Nut/BoltTorque **Lug

Nut/Bolt Size Lug Nut/Bolt Socket

Size

63 Ft-Lbs (86 N·m)

Steel Wheels

Only

89 Ft-Lbs

(120 N·m) Aluminum

Wheels Only M12 x

1.25 17 mm

**Use only your authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening. Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it halfway).

After 25 miles (40 km), check the lug nut/

bolt torque to be sure that all the lug nuts/

bolts are properly seated against the wheel.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in per-

sonal injury.

Torque Pattern

TECHNICAL SPECIFICATIONS

136

Page 173 of 180

Supplemental Restraint System - Air Bag. .54

Telescoping Steering Column ........16

Text Messaging ................156

Tilt Steering Column .............16

Tire And Loading Information Placard . .120

Tire Markings .................115

Tires ............78, 123, 128, 132

Aging (Life Of Tires) ..........126

Air Pressure ...............123

Changing ..............92, 115

Compact Spare .............129

General Information .......123, 128

High Speed ...............124

Inflation Pressures ...........124

Jacking ................92, 115

Life Of Tires ...............126

Load Capacity ..............120

Pressure Monitor System (TPMS) . . .42

Pressure Warning Light .........35

Quality Grading .............132

Radial ..................125

Replacement ..............126

Safety ...............115, 123 Sizes

...................116

Snow Tires ................128

Spare Tire .............128, 130

Spinning .................125

Tread Wear Indicators .........126

Wheel Nut Torque ...........136

Tire Safety Information ...........115

Tire Service Kit ...............100

To Open Hood .................25

Towing ......................85

Disabled Vehicle ............108

Guide ....................85

Recreational ...............85

Weight ...................85

Towing Vehicle Behind A Motorhome . . .85

Trailer Towing .................85

Trailer Towing Guide .............85

Trailer Weight .................85

Transporting Pets ...............

75

Tread Wear Indicators ............126

Turn Signals ..................37

Uconnect (Hands-Free Phone) Making A Phone Call ......150, 154 Receiving A Call

............150

Uconnect Phone ........150, 154, 156

Uconnect Voice Command . .154, 158, 160

Uniform Tire Quality Grades ........132

Untwisting Procedure, Seat Belt ......49

Vehicle Loading ...............120

Vehicle Storage ................24

Voice Command ...........154, 160

Voice Recognition System (VR) ..........154, 155, 158, 160

Warning Lights (Instrument Cluster Description) .................37

Washers, Windshield .............18

Wheel And Wheel Trim ...........130

Wheel And Wheel Trim Care ........130

Window Fogging ................25

Windshield Defroster .............76

Windshield Washers .............18

Windshield Wipers ..............18

Wrecker Towing ...............108

171