light RENAULT SCENIC 2007 J84 / 2.G Anti Lock Braking System Bosch 8.0 ABS User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2007, Model line: SCENIC, Model: RENAULT SCENIC 2007 J84 / 2.GPages: 64, PDF Size: 0.2 MB

Page 46 of 64

ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of statuses

38C

38C - 46V2 MR-372-J84-38C000$660_eng.mif

BOSCH ABS 8.0

Vdiag No.: 0C, 0D, 0E, 0F

ET017

CONTINUED

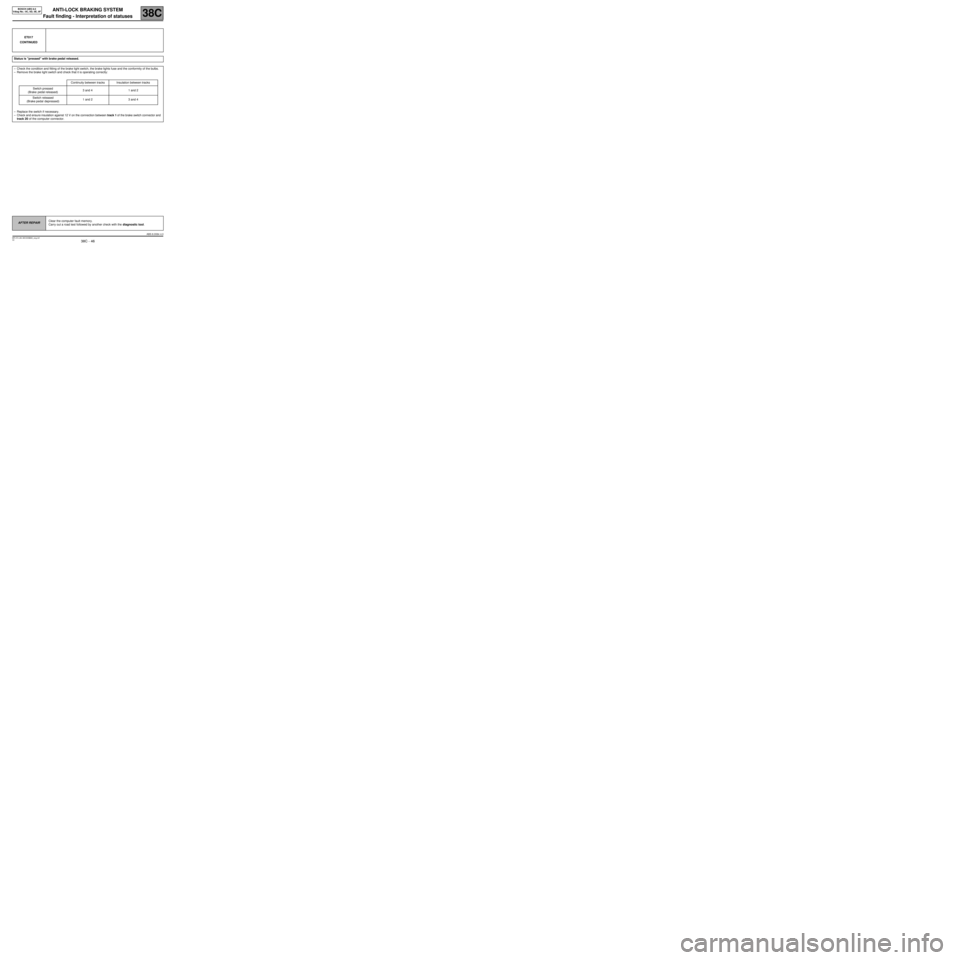

Status is "pressed" with brake pedal released.

–Check the condition and fitting of the brake light switch, the brake lights fuse and the conformity of the bulbs.

–Remove the brake light switch and check that it is operating correctly:

Continuity between tracks Insulation between tracks

Switch pressed

(Brake pedal released)3 and 4 1 and 2

Switch released

(Brake pedal depressed)1 and 2 3 and 4

–Replace the switch if necessary.

–Check and ensure insulation against 12 V on the connection between track 1 of the brake switch connector and

track 20 of the computer connector.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS 8.0X84 4.0

Page 48 of 64

ANTI-LOCK BRAKING SYSTEM

Fault finding - Dealing with commands

38C

38C - 48V2 MR-372-J84-38C000$792_eng.mif

BOSCH ABS 8.0

Vdiag No.: 0C, 0D, 0E, 0FANTI-LOCK BRAKING SYSTEM

Fault finding - Dealing with commands

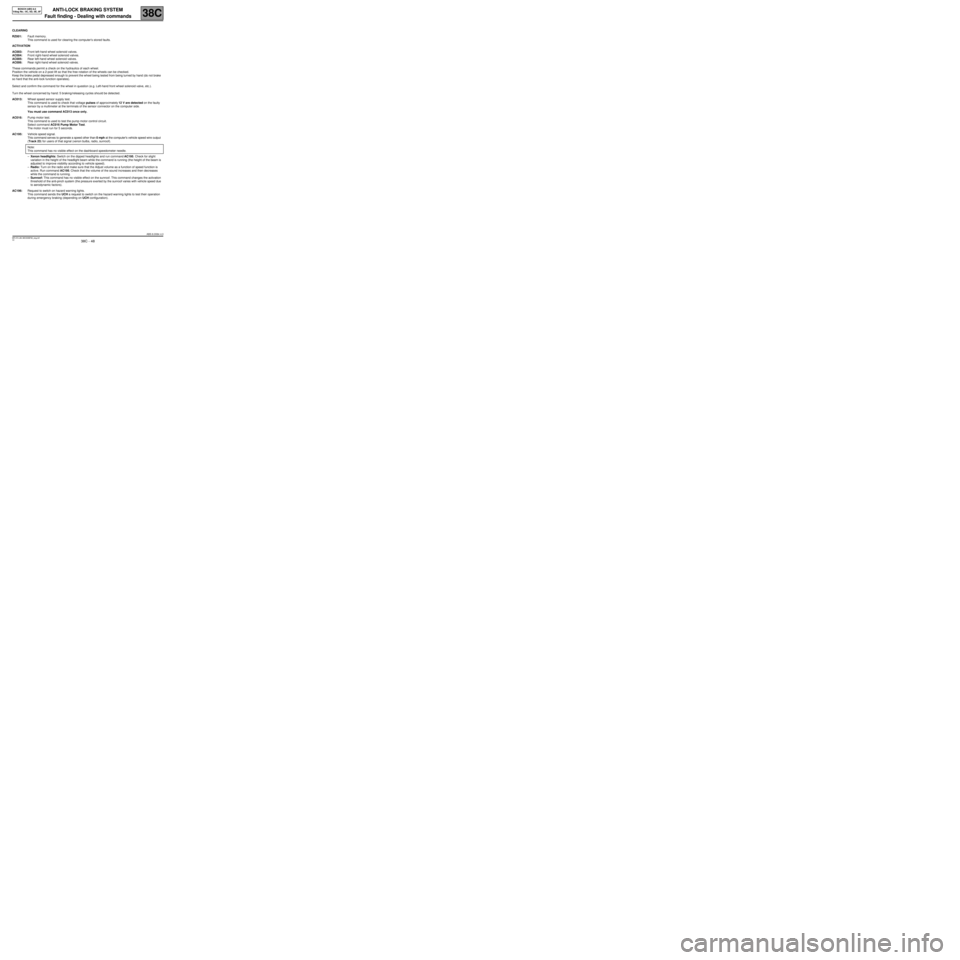

CLEARING

RZ001:Fault memory.

This command is used for clearing the computer's stored faults.

ACTIVATION

AC003:

AC004:

AC005:

AC006:Front left-hand wheel solenoid valves.

Front right-hand wheel solenoid valves.

Rear left-hand wheel solenoid valves.

Rear right-hand wheel solenoid valves.

These commands permit a check on the hydraulics of each wheel.

Position the vehicle on a 2-post lift so that the free rotation of the wheels can be checked.

Keep the brake pedal depressed enough to prevent the wheel being tested from being turned by hand (do not brake

so hard that the anti-lock function operates).

Select and confirm the command for the wheel in question (e.g. Left-hand front wheel solenoid valve, etc.).

Turn the wheel concerned by hand: 5 braking/releasing cycles should be detected.

AC013:Wheel speed sensor supply test.

This command is used to check that voltage pulses of approximately 12 V are detected on the faulty

sensor by a multimeter at the terminals of the sensor connector on the computer side.

You must use command AC013 once only.

AC016:Pump motor test.

This command is used to test the pump motor control circuit.

Select command AC016 Pump Motor Test.

The motor must run for 5 seconds.

AC195:Vehicle speed signal.

This command serves to generate a speed other than 0 mph at the computer's vehicle speed wire output

(Track 23) for users of that signal (xenon bulbs, radio, sunroof).

Note:

This command has no visible effect on the dashboard speedometer needle.

–Xenon headlights: Switch on the dipped headlights and run command AC195. Check for slight

variation in the height of the headlight beam while the command is running (the height of the beam is

adjusted to improve visibility according to vehicle speed).

–Radio: Turn on the radio and make sure that the Adjust volume as a function of speed function is

active. Run command AC195. Check that the volume of the sound increases and then decreases

while the command is running.

–Sunroof: This command has no visible effect on the sunroof. This command changes the activation

threshold of the anti-pinch system (the pressure exerted by the sunroof varies with vehicle speed due

to aerodynamic factors).

AC196:Request to switch on hazard warning lights.

This command sends the UCH a request to switch on the hazard warning lights to test their operation

during emergency braking (depending on UCH configuration).

ABS 8.0X84 4.0

MR-372-J84-38C000$792_eng.mif

Page 50 of 64

ANTI-LOCK BRAKING SYSTEM

Fault finding - Customer complaints

38C

38C - 50V2 MR-372-J84-38C000$858_eng.mif

BOSCH ABS 8.0

Vdiag No.: 0C, 0D, 0E, 0FANTI-LOCK BRAKING SYSTEM

Fault finding - Customer complaints

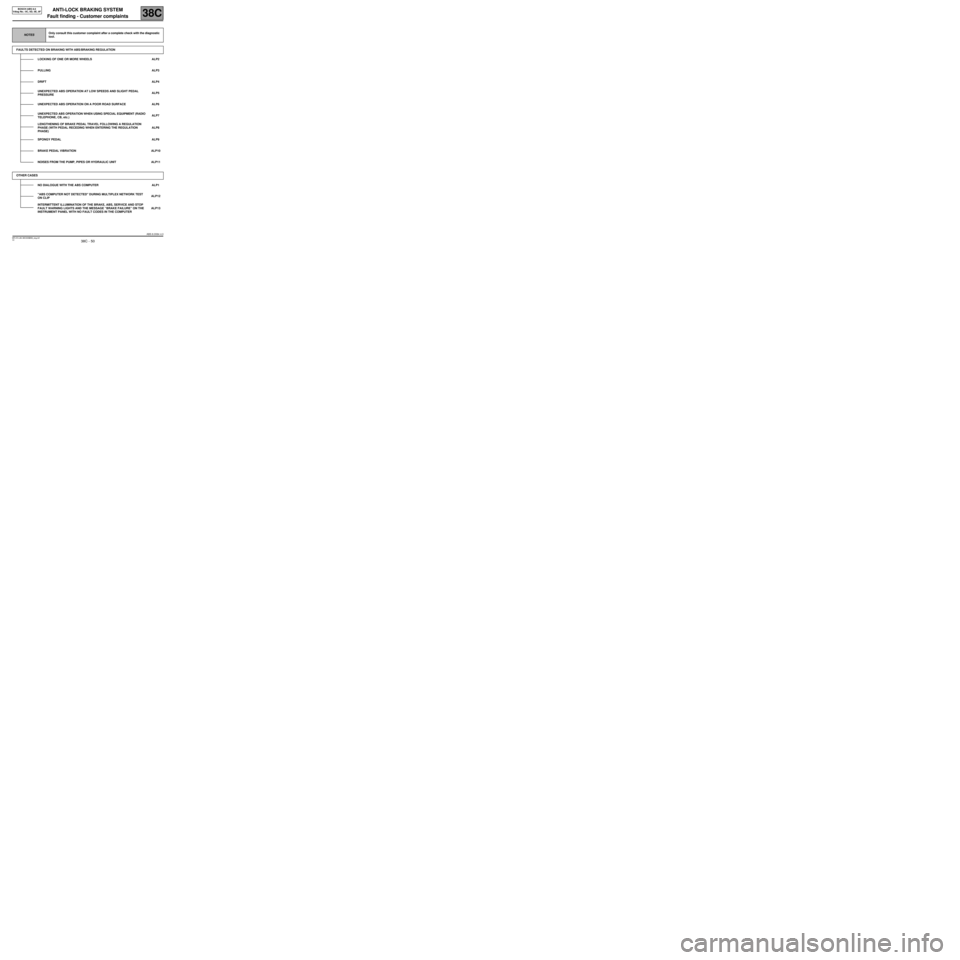

NOTESOnly consult this customer complaint after a complete check with the diagnostic

tool.

FAULTS DETECTED ON BRAKING WITH ABS/BRAKING REGULATION

LOCKING OF ONE OR MORE WHEELS ALP2

PULLINGALP3

DRIFTALP4

UNEXPECTED ABS OPERATION AT LOW SPEEDS AND SLIGHT PEDAL

PRESSUREALP5

UNEXPECTED ABS OPERATION ON A POOR ROAD SURFACE ALP6

UNEXPECTED ABS OPERATION WHEN USING SPECIAL EQUIPMENT (RADIO

TELEPHONE, CB, etc.)ALP7

LENGTHENING OF BRAKE PEDAL TRAVEL FOLLOWING A REGULATION

PHASE (WITH PEDAL RECEDING WHEN ENTERING THE REGULATION

PHASE)ALP8

SPONGY PEDAL ALP9

BRAKE PEDAL VIBRATION ALP10

NOISES FROM THE PUMP, PIPES OR HYDRAULIC UNIT ALP11

OTHER CASES

NO DIALOGUE WITH THE ABS COMPUTER ALP1

"ABS COMPUTER NOT DETECTED" DURING MULTIPLEX NETWORK TEST

ON CLIPALP12

INTERMITTENT ILLUMINATION OF THE BRAKE, ABS, SERVICE AND STOP

FAULT WARNING LIGHTS AND THE MESSAGE “BRAKE FAILURE” ON THE

INSTRUMENT PANEL WITH NO FAULT CODES IN THE COMPUTERALP13

ABS 8.0X84 4.0

MR-372-J84-38C000$858_eng.mif

Page 53 of 64

ANTI-LOCK BRAKING SYSTEM

Diagnostic - Fault finding chart

38C

38C - 53V2 MR-372-J84-38C000$924_eng.mif

BOSCH ABS 8.0

Vdiag No.: 0C, 0D, 0E, 0F

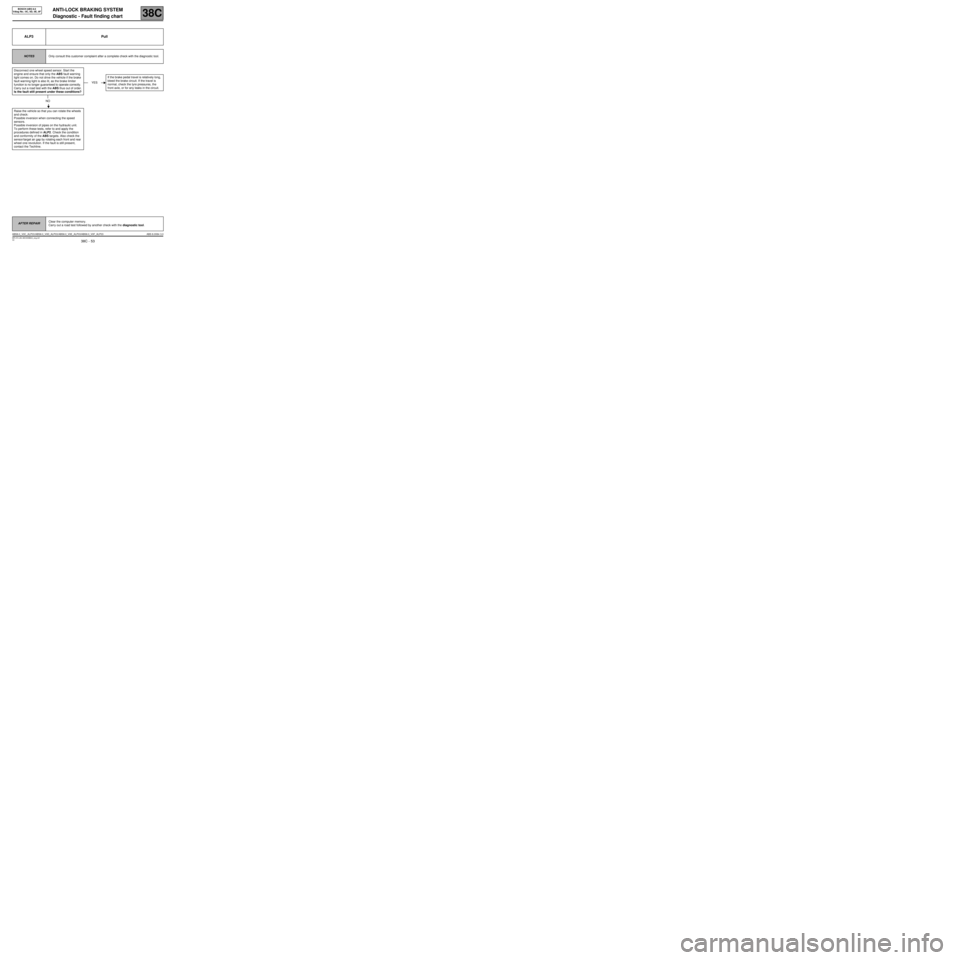

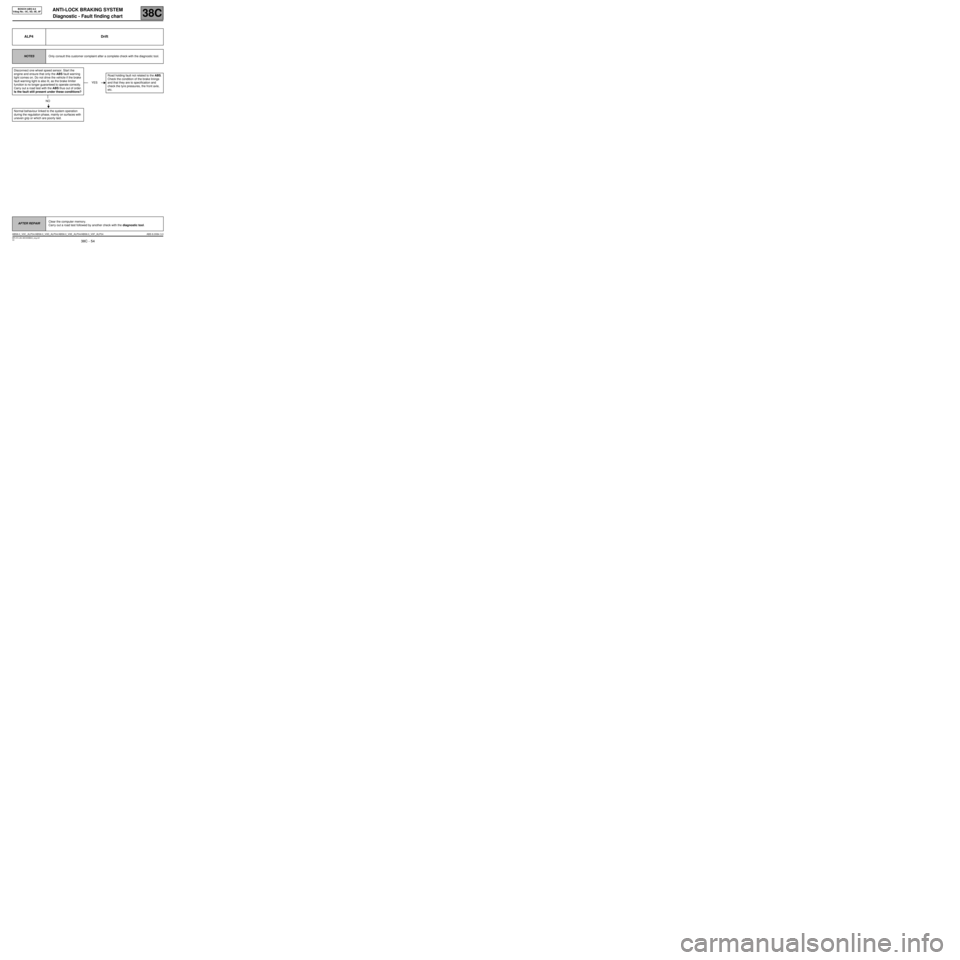

ALP3 Pull

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Disconnect one wheel speed sensor. Start the

engine and ensure that only the ABS fault warning

light comes on. Do not drive the vehicle if the brake

fault warning light is also lit, as the brake limiter

function is no longer guaranteed to operate correctly.

Carry out a road test with the ABS thus out of order.

Is the fault still present under these conditions?

NO

Raise the vehicle so that you can rotate the wheels

and check:

Possible inversion when connecting the speed

sensors.

Possible inversion of pipes on the hydraulic unit.

To perform these tests, refer to and apply the

procedures defined in ALP2. Check the condition

and conformity of the ABS targets. Also check the

sensor/target air gap by rotating each front and rear

wheel one revolution. If the fault is still present,

contact the Techline.

YESIf the brake pedal travel is relatively long,

bleed the brake circuit. If the travel is

normal, check the tyre pressures, the

front axle, or for any leaks in the circuit.

AFTER REPAIRClear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS8.0_V0C_ALP03 /ABS8.0_V0D_ALP03/ABS8.0_V0E_ALP03/ABS8.0_V0F_ALP03 ABS 8.0X84 3.0

Page 54 of 64

ANTI-LOCK BRAKING SYSTEM

Diagnostic - Fault finding chart

38C

38C - 54V2 MR-372-J84-38C000$924_eng.mif

BOSCH ABS 8.0

Vdiag No.: 0C, 0D, 0E, 0F

ALP4 Drift

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Disconnect one wheel speed sensor. Start the

engine and ensure that only the ABS fault warning

light comes on. Do not drive the vehicle if the brake

fault warning light is also lit, as the brake limiter

function is no longer guaranteed to operate correctly.

Carry out a road test with the ABS thus out of order.

Is the fault still present under these conditions?

NO

Normal behaviour linked to the system operation

during the regulation phase, mainly on surfaces with

uneven grip or which are poorly laid.

YESRoad holding fault not related to the ABS.

Check the condition of the brake linings

and that they are to specification and

check the tyre pressures, the front axle,

etc.

AFTER REPAIRClear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS8.0_V0C_ALP04 /ABS8.0_V0D_ALP04/ABS8.0_V0E_ALP04/ABS8.0_V0F_ALP04 ABS 8.0X84 3.0

Page 55 of 64

ANTI-LOCK BRAKING SYSTEM

Diagnostic - Fault finding chart

38C

38C - 55V2 MR-372-J84-38C000$924_eng.mif

BOSCH ABS 8.0

Vdiag No.: 0C, 0D, 0E, 0F

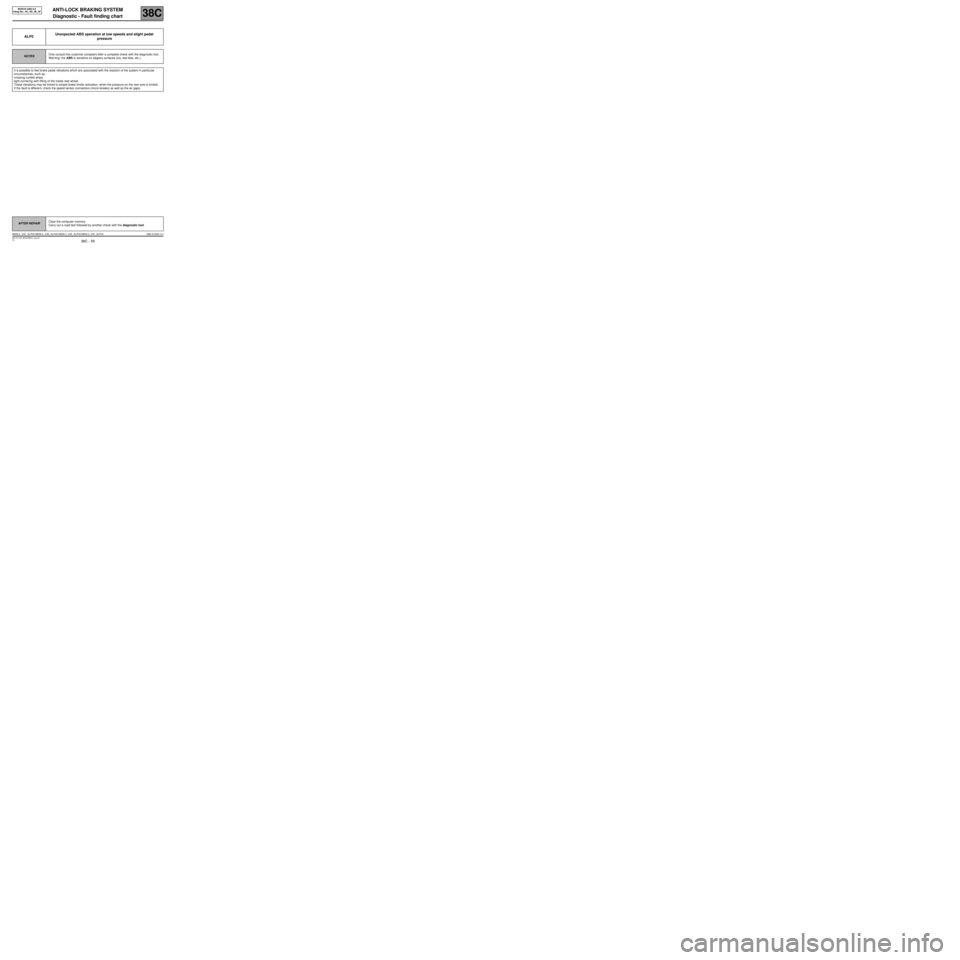

ALP5Unexpected ABS operation at low speeds and slight pedal

pressure

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Warning: the ABS is sensitive on slippery surfaces (ice, wet tiles, etc.).

It is possible to feel brake pedal vibrations which are associated with the reaction of the system in particular

circumstances, such as:

crossing rumble strips,

tight cornering with lifting of the inside rear wheel.

These vibrations may be linked to simple brake limiter activation, when the pressure on the rear axle is limited.

If the fault is different, check the speed sensor connectors (micro-breaks) as well as the air gaps.

AFTER REPAIRClear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS8.0_V0C_ALP05 /ABS8.0_V0D_ALP05/ABS8.0_V0E_ALP05/ABS8.0_V0F_ALP05 ABS 8.0X84 3.0

Page 63 of 64

ANTI-LOCK BRAKING SYSTEM

Diagnostic - Fault finding chart

38C

38C - 63V2 MR-372-J84-38C000$924_eng.mif

BOSCH ABS 8.0

Vdiag No.: 0C, 0D, 0E, 0F

ABS8.0_V0C_ALP13 /ABS8.0_V0D_ALP13/ABS8.0_V0E_ALP13/ABS8.0_V0F_ALP13

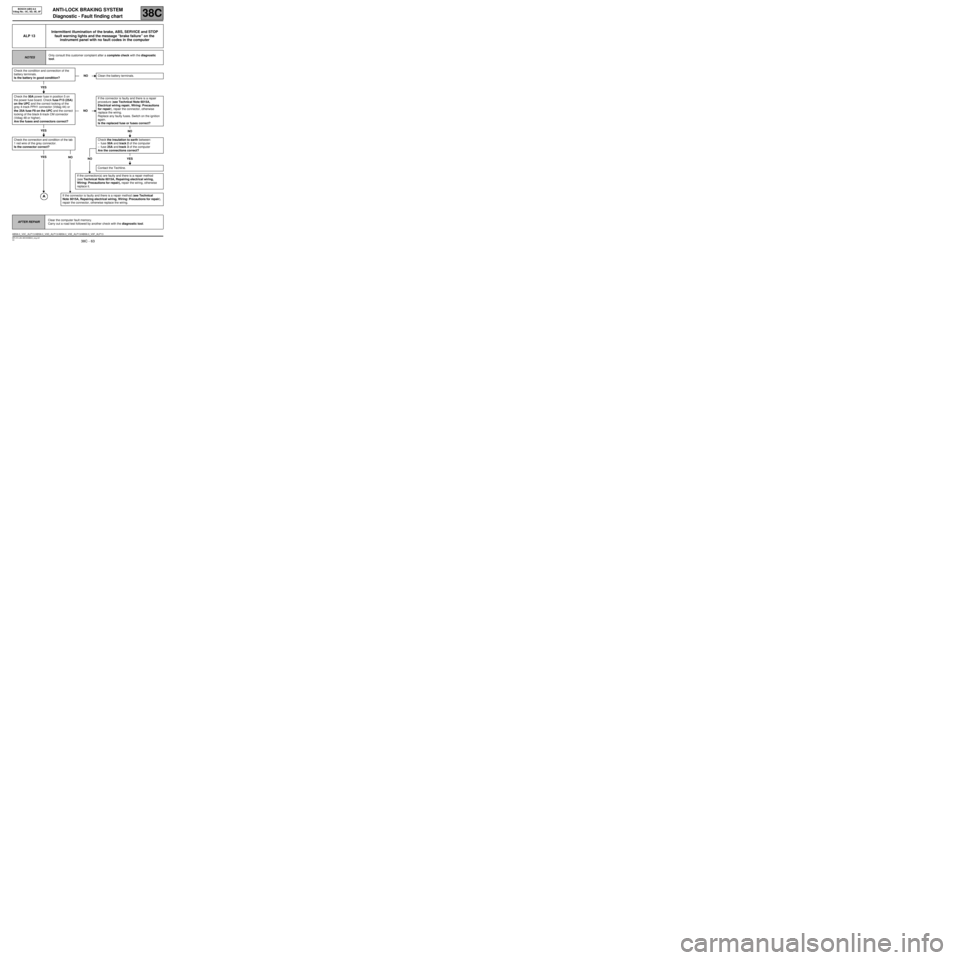

ALP 13Intermittent illumination of the brake, ABS, SERVICE and STOP

fault warning lights and the message “brake failure” on the

instrument panel with no fault codes in the computer

NOTESOnly consult this customer complaint after a complete check with the diagnostic

tool.

Check the condition and connection of the

battery terminals.

Is the battery in good condition?

YES

Check the 50A power fuse in position 5 on

the power fuse board. Check fuse F13 (25A)

on the UPC and the correct locking of the

grey 4-track PPH1 connector (Vdiag 44) or

the 25A fuse F8 on the UPC and the correct

locking of the black 6-track CM connector

(Vdiag 48 or higher).

Are the fuses and connectors correct?

YES

Check the connection and condition of the tab

1 red wire of the grey connector.

Is the connector correct?

YES

NOClean the battery terminals.

NOIf the connector is faulty and there is a repair

procedure (see Technical Note 6015A,

Electrical wiring repair, Wiring: Precautions

for repair), repair the connector, otherwise

replace the wiring.

Replace any faulty fuses. Switch on the ignition

again.

Is the replaced fuse or fuses correct?

NO

Check the insulation to earth between:

–fuse 50A and track 2 of the computer

–fuse 25A and track 3 of the computer

Are the connections correct?

NO YES

Contact the Techline.

If the connection(s) are faulty and there is a repair method

(see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise

replace it.

NO

If the connector is faulty and there is a repair method (see Technical

Note 6015A, Repairing electrical wiring, Wiring: Precautions for repair),

repair the connector, otherwise replace the wiring.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.