charging RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 90 of 365

13B-90

MR-372-J84-13B200$288.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of faults

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

DF055

CONTINUED 2

2.DEF

NOTESPriority when dealing with a number of faults:

Deal with fault DF004 Turbocharging pressure sensor

circuit first if it is present or stored.

Check the turbocharging pressure sensor connections,

Check the connections of the turbocharging solenoid valve,

Check the injection computer connections.

Repair if necessary.

Check the conformity of the turbocharging pressure signal (refer to the interpretation of parameter PR041

Turbocharging pressure).

Make sure the turbocharging pressure relief solenoid valve is not jammed open:

– With the engine switched off, disconnect the inlet and outlet hoses from the solenoid valve.

– connect a vacuum pump to the inlet union and apply a vacuum pressure.

– If the vacuum pressure is not maintained, replace the solenoid valve.

Check that the turbocharger control rod has not seized:

– With the engine stopped, check that the turbocharger control rod is in the rest position (the control rod

engaged),

– apply a vacuum of 700 mbar < X < 900 mbar to the hose connected to the turbocharger control diaphragm,

– if the diaphragm retains the vacuum, check the movement and setting of the turbocharger control rod (see MR

364 (Mégane II), MR 370 (Scénic II), MR 395 (Laguna II), Mechanical, 12B, Turbocharging).

If the control rod is seized, replace the turbocharger.

If the fault is still present, run test 2 Air line at the turbocharger, test 6 Turbocharger control solenoid valve

check and test 7 Turbocharger.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

Page 132 of 365

13B-132

MR-372-J84-13B200$360.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of faults

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

DF308

CONTINUED 2

Step 2:

Check whether one or more faults, in the list below, are present or stored.

If at least one exists:

–Deal with the present and stored faults,

– replace the particle filter,

–run command SC036 Reinitialise programming (see Interpretation of commands) and select "After

particle filter replacement".

– Clear fault DF308, if Present or Stored

IMPORTANT: DF308 must be cleared within the 3 minutes following the last power latch.

– Check the weight of soot: PR383 Weight of soot in the particle filter.

– If PR383

≥ 1 g. Apply the procedure for test 8 Manual clearing of the soot weight.

If no faults are present or stored, move on to step 3.

List of faults:

– DF001 Coolant temperature sensor circuit.

– DF003 Atmospheric pressure sensor circuit.

– DF011 Sensor supply voltage no. 1.

– DF013 Sensor supply voltage no. 3.

– DF038 Computer.

– DF039 Inlet air temperature sensor circuit.

– DF055 Turbocharging pressure regulation circuit, 1.DEF Pressure too low.

– DF056 Air flowmeter circuit.

– DF310 Particle filter upstream temp* sensor.

– DF315 Particle filter diff* pressure sensor.

– DF717 Particle filter upstream pressure.

– DF778 Turbine upstream temperature regulation.

– DF953 Particle filter absent.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

Page 149 of 365

13B-149

MR-372-J84-13B200$360.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of faults

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

DF619

PRESENT

OR

STOREDEGR VALVE JAMMED OPEN

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after a road test.

Priorities when dealing with a number of faults:

– DF118 EGR solenoid valve servo-control,

– DF209 EGR valve position sensor circuit,

– DF272 EGR valve control circuit,

if they are present or stored.

Special note:

If the fault is present:

– The EGR and turbocharging functions are inhibited,

– the level 1 warning light is illuminated.

Use bornier Elé.1681 or Elé.1590 for any operation on the injection computer

connectors.

IMPORTANT

This fault can result in a rapid and significant fouling of the particle filter. If the EGR

valve needs to be replaced to resolve the fault, use command SC036 Reinitialise

programming and select EGR valve to reinitialise the EGR valve offsets (see

Replacement of components).

Check the EGR valve connections.

Check the injection computer connections.

Repair if necessary.

Check the operation of the EGR valve:

– exit fault finding mode in CLIP,

– switch off the vehicle ignition,

– disconnect the EGR valve connector,

– remove the EGR valve.

– Check that there are no particles blocking the movement of the piston.

– Clean the EGR valve, (see Technical Note 3916A Cleaning the EGR valve).

– Refit the EGR valve, run command SC036 Reinitialise programming and select EGR valve to reinitialise the

EGR valve offsets (see Replacement of components).

If the valve is jammed or irrevocably seized, replace the EGR valve. Run command SC036 Reinitialise

programming and select EGR valve to reinitialise the EGR valve offsets (see Replacement of components).

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V50_DF619/EDC16_V58_DF619/EDC16_V5C_DF619/EDC16_V18_DF619/EDC16_V1C_DF619/EDC16_V20_DF619

Page 150 of 365

13B-150

MR-372-J84-13B200$360.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of faults

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

DF620

PRESENT

OR

STOREDEGR VALVE FOULED

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after a road test.

Priorities when dealing with a number of faults:

– DF118 EGR solenoid valve servo-control,

– DF209 EGR valve position sensor circuit,

– DF272 EGR valve control circuit,

if they are present or stored.

Special note:

If the fault is present:

– the EGR function is inhibited,

– particle filter regeneration is inhibited,

– turbocharging is inhibited,

– the level 1 warning light is lit.

Use bornier Elé.1681 or Elé.1590 for any operation on the injection computer

connectors.

IMPORTANT

This fault can result in a rapid and significant fouling of the particle filter. If the EGR

valve needs to be replaced to resolve the fault, use command SC036 Reinitialise

programming and select EGR valve to reinitialise the EGR valve offsets (see

Replacement of components).

Check the EGR valve connections.

Check the injection computer connections.

Repair if necessary.

Check the operation of the EGR valve:

– exit fault finding mode in CLIP,

– switch off the vehicle ignition,

– disconnect the EGR valve connector,

– remove the EGR valve.

– Check that there are no particles blocking the movement of the piston.

– Clean the EGR valve, (see Technical Note 3916A Cleaning the EGR valve).

– Refit the EGR valve, run command SC036 Reinitialise programming and select EGR valve to reinitialise the

EGR valve offsets (see Replacement of components).

If the valve is jammed or irrevocably seized, replace the EGR valve. Run command SC036 Reinitialise

programming and select EGR valve to reinitialise the EGR valve offsets (see Replacement of components).

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V50_DF620/EDC16_V58_DF620/EDC16_V5C_DF620/EDC16_V18_DF620/EDC16_V1C_DF620/EDC16_V20_DF620

Page 210 of 365

13B-210

MR-372-J84-13B200$576.mif

V13

13B

DIESEL INJECTION

Fault finding – Parameter summary table

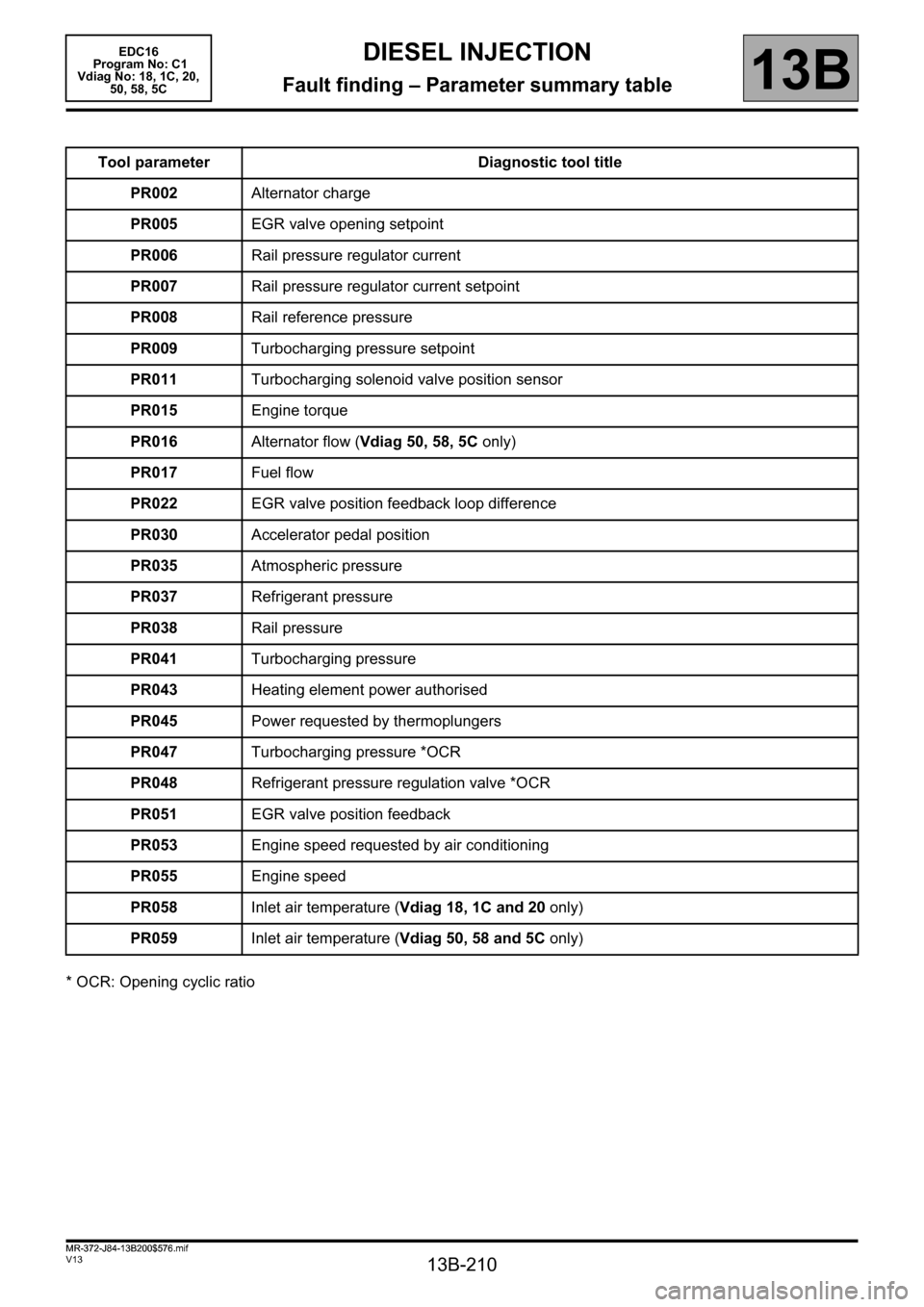

* OCR: Opening cyclic ratioTool parameter Diagnostic tool title

PR002Alternator charge

PR005EGR valve opening setpoint

PR006Rail pressure regulator current

PR007Rail pressure regulator current setpoint

PR008Rail reference pressure

PR009Turbocharging pressure setpoint

PR011Turbocharging solenoid valve position sensor

PR015Engine torque

PR016Alternator flow (Vdiag 50, 58, 5C only)

PR017Fuel flow

PR022EGR valve position feedback loop difference

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR041Turbocharging pressure

PR043Heating element power authorised

PR045Power requested by thermoplungers

PR047Turbocharging pressure *OCR

PR048Refrigerant pressure regulation valve *OCR

PR051EGR valve position feedback

PR053Engine speed requested by air conditioning

PR055Engine speed

PR058Inlet air temperature (Vdiag 18, 1C and 20 only)

PR059Inlet air temperature (Vdiag 50, 58 and 5C only)

MR-372-J84-13B200$576.mif

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

Page 211 of 365

13B-211

MR-372-J84-13B200$576.mif

V13

DIESEL INJECTION

Fault finding – Parameter summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

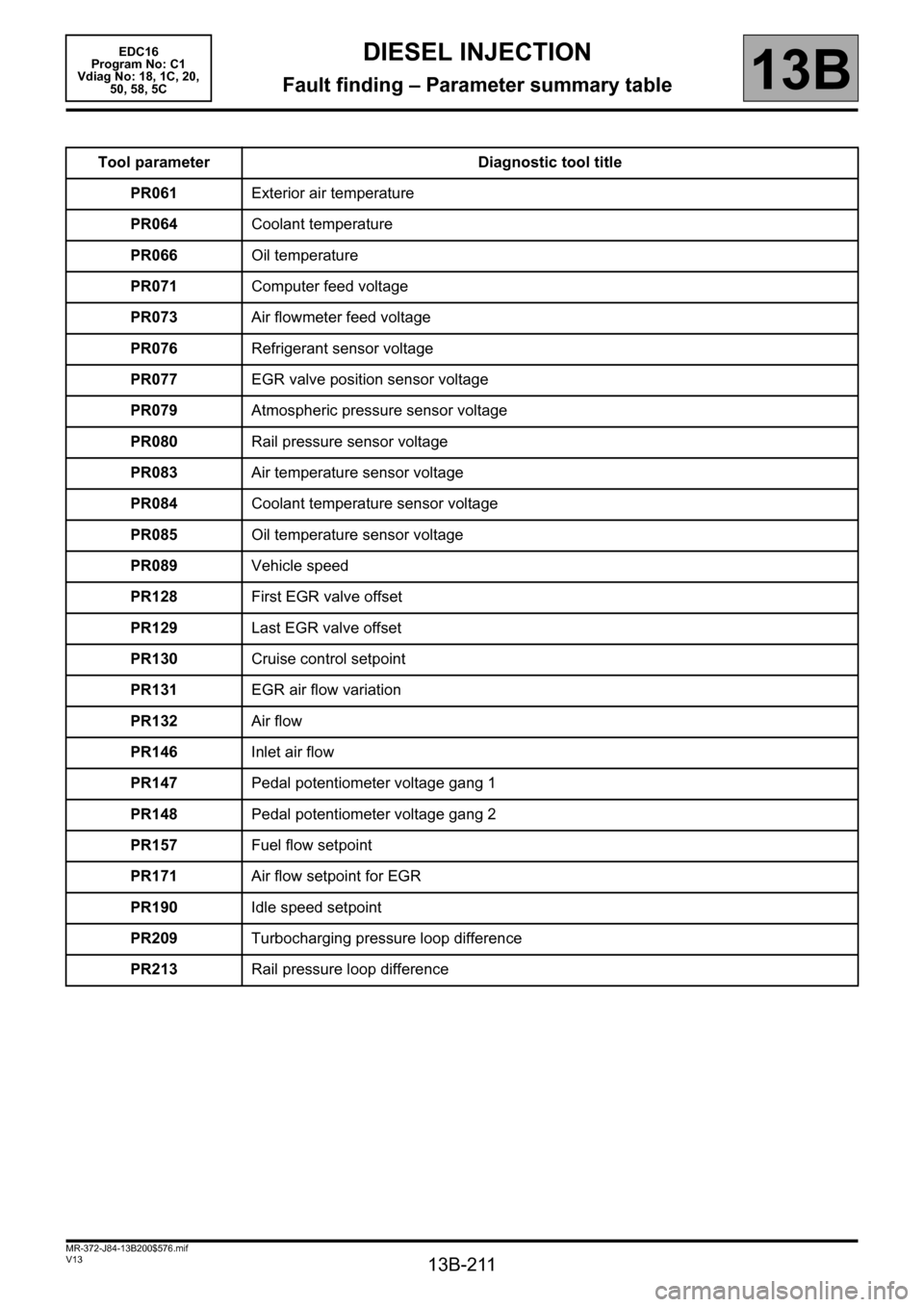

Tool parameter Diagnostic tool title

PR061Exterior air temperature

PR064Coolant temperature

PR066Oil temperature

PR071Computer feed voltage

PR073Air flowmeter feed voltage

PR076Refrigerant sensor voltage

PR077EGR valve position sensor voltage

PR079Atmospheric pressure sensor voltage

PR080Rail pressure sensor voltage

PR083Air temperature sensor voltage

PR084Coolant temperature sensor voltage

PR085Oil temperature sensor voltage

PR089Vehicle speed

PR128First EGR valve offset

PR129Last EGR valve offset

PR130Cruise control setpoint

PR131EGR air flow variation

PR132Air flow

PR146Inlet air flow

PR147Pedal potentiometer voltage gang 1

PR148Pedal potentiometer voltage gang 2

PR157Fuel flow setpoint

PR171Air flow setpoint for EGR

PR190Idle speed setpoint

PR209Turbocharging pressure loop difference

PR213Rail pressure loop difference

Page 219 of 365

13B-219

MR-372-J84-13B200$612.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of parameters

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

PR009

TURBOCHARGING PRESSURE SETPOINTS

PARAMETER

DEFINITIONThis parameter indicates the theoretical turbocharging pressure setpoint value

in bar.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

>80 °C.

The theoretical turbocharging pressure value is a setpoint of:

Pressure ≈ 1 bar

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16_V50_PR009/EDC16_V58_PR009/EDC16_V5C_PR009/EDC16_V18_PR009/EDC16_V1C_PR009/EDC16_V20_PR009

Page 220 of 365

13B-220

MR-372-J84-13B200$612.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of parameters

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

PR011

TURBOCHARGING SOLENOID VALVE POSITION CORRECTION

PARAMETER

DEFINITIONThis parameter indicates the turbocharging solenoid valve position correction in %.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

>80 °C.

This value must be PR011 < 5%.

The Opening Cyclic Ratio should be identical to the correction of the solenoid valve position

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16_V50_PR011/EDC16_V58_PR011/EDC16_V5C_PR011/EDC16_V18_PR011/EDC16_V1C_PR011/EDC16_V20_PR011

Page 230 of 365

13B-230

MR-372-J84-13B200$612.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of parameters

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

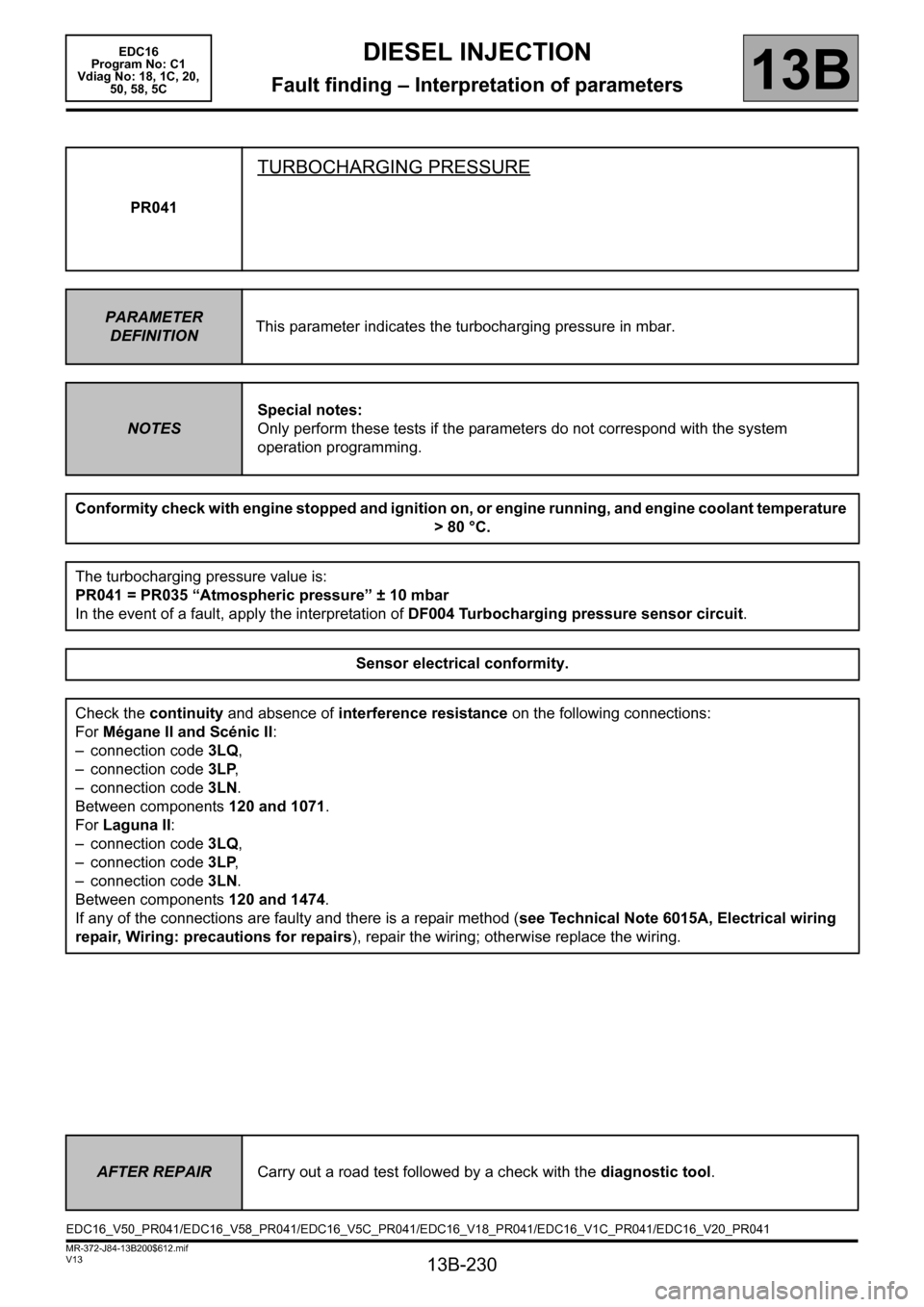

PR041

TURBOCHARGING PRESSURE

PARAMETER

DEFINITIONThis parameter indicates the turbocharging pressure in mbar.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

>80 °C.

The turbocharging pressure value is:

PR041 = PR035 “Atmospheric pressure” ± 10 mbar

In the event of a fault, apply the interpretation of DF004 Turbocharging pressure sensor circuit.

Sensor electrical conformity.

Check the continuity and absence of interference resistance on the following connections:

For Mégane II and Scénic II:

– connection code 3LQ,

– connection code 3LP,

– connection code 3LN.

Between components 120 and 1071.

For Laguna II:

– connection code 3LQ,

– connection code 3LP,

– connection code 3LN.

Between components 120 and 1474.

If any of the connections are faulty and there is a repair method (see Technical Note 6015A, Electrical wiring

repair, Wiring: precautions for repairs), repair the wiring; otherwise replace the wiring.

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

EDC16_V50_PR041/EDC16_V58_PR041/EDC16_V5C_PR041/EDC16_V18_PR041/EDC16_V1C_PR041/EDC16_V20_PR041

Page 231 of 365

13B-231

MR-372-J84-13B200$612.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of parameters

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

PR041

CONTINUED

Vehicle with ignition on, and the engine stopped for over 1 minute:

Compare the values of PR041 and PR035 Atmospheric pressure.

If the difference between PR041 and PR035 Atmospheric pressure is greater than 0.1 bar,

check the value of PR035 Atmospheric pressure by comparing it with the reading on a vehicle in the workshop

which is correct.

If the value of PR035 Atmospheric pressure is not correct (difference greater than 0.1 bar between

the 2 vehicles), contact the Techline.

Otherwise (when the value PR035 Atmospheric pressure is correct), change the turbocharging pressure

sensor.

If the difference between PR041 and PR035 Atmospheric pressure is less than 0.1 bar.

Start the engine, with the engine idling:

Compare the values of PR041 and PR035 Atmospheric pressure.

If the difference between PR041 and PR035 Atmospheric pressure is greater than 0.2 bar.

Check the air inlet circuit:

absence of leaks or blockages in the low and high pressure air circuit: ducts, presence and tightness of the

mounting clips, mounting of the turbocharger pressure sensor, intercooler, etc.

Check that the damper valve is not jammed closed.

Repair if necessary.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.