RENAULT TWINGO 2009 2.G Chasiss Workshop Manual

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 271 of 281

38C-12

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

RIGHT-HAND DRIVE

38C

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the battery (see Battery: Removal - Refit-

ting) (80A, Battery).aRemove:

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the bolts (1) from the secondary brake fluid reser-

voir.

aMove aside the secondary brake fluid reservoir.

aRemove:

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (17B, Petrol in-

jection),

-the computer mounting bolts,

-the computer bracket. Tightening torquesm

hydraulic unit bolts on

its inter mediate bracket8 Nm

hydraulic unit inter medi-

ate bracket bolts on the

main hydraulic unit

bracket8 Nm

hydraulic unit main

mounting bolts on the

body8 Nm

rigid brake pipe unions

on the hydraulic unit14 Nm

secondar y brake fluid

reservoir bolts8 Nm

123854

K4M

Page 272 of 281

38C-13

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

RIGHT-HAND DRIVE

38C

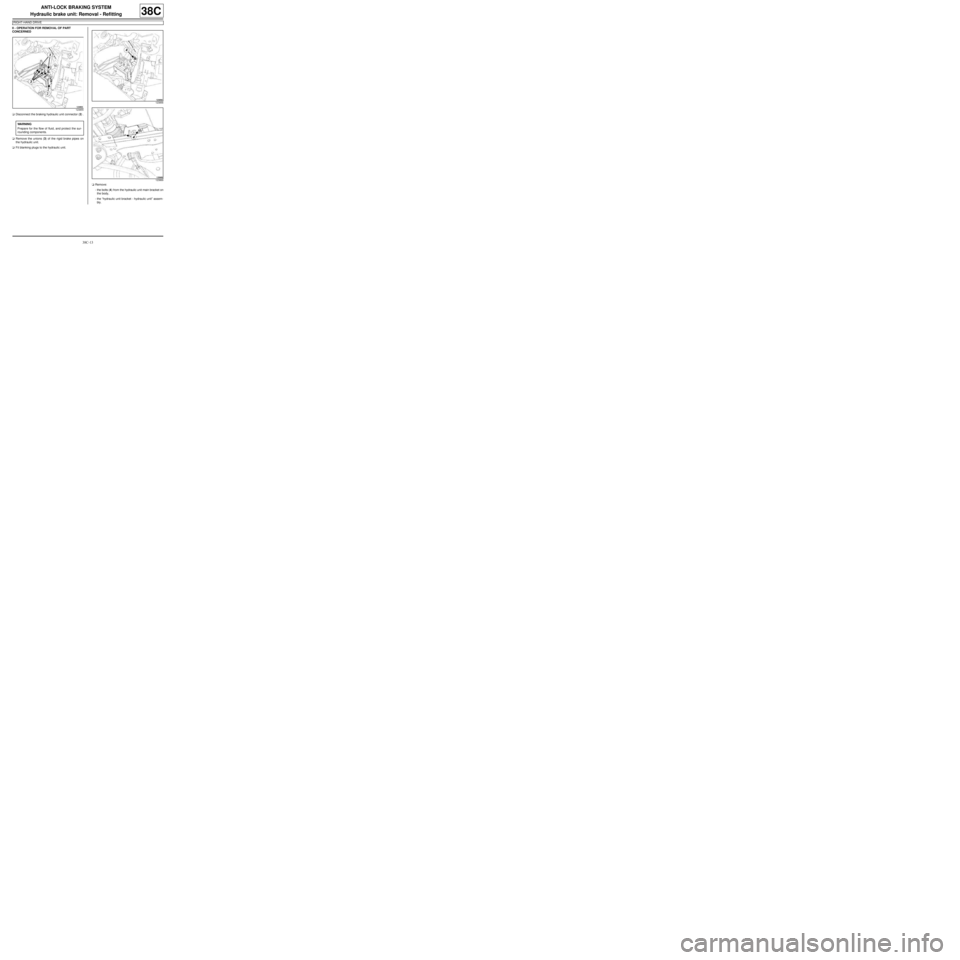

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the braking hydraulic unit connector (2) .

aRemove the unions (3) of the rigid brake pipes on

the hydraulic unit.

aFit blanking plugs to the hydraulic unit.

aRemove:

-the bolts (4) from the hydraulic unit main bracket on

the body,

-the “hydraulic unit bracket - hydraulic unit” assem-

bly.

123855

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

123856

123869

Page 273 of 281

38C-14

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

RIGHT-HAND DRIVE

38C

aRemove:

-the hydraulic assembly intermediate bracket bolts

(5) ,

-the “hydraulic unit intermediate bracket - hydraulic

unit” assembly (6) from the main bracket,

-the hydraulic unit bolts (7) ,

-the hydraulic unit from its intermediate bracket.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the hydraulic unit on its support.

aTorque tighten the hydraulic unit bolts on its inter-

mediate bracket (8 Nm).

aRefit the "hydraulic unit intermediate bracket - hy-

draulic unit" assembly on the main bracket.

aTorque tighten the hydraulic unit intermediate

bracket bolts on the main hydraulic unit bracket

(8 Nm).

aRefit the "hydraulic unit main bracket - hydraulic

brake unit" assembly on the body.

aTorque tighten the hydraulic unit main mounting

bolts on the body (8 Nm).

aRefit the rigid brake pipe unions on the hydraulic

unit.

aTorque tighten the rigid brake pipe unions on the

hydraulic unit (14 Nm).aConnect the braking hydraulic unit connector.

II - FINAL OPERATION.

aRefit:

-the computer bracket.

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (17B, Petrol in-

jection).

aFit the secondary brake fluid reservoir.

aTorque tighten the secondary brake fluid reser-

voir bolts ( 8 Nm).

aRefit:

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment).

aRefit the battery (see Battery: Removal - Refitting)

(80A, Battery).

aBleed the brake circuit (see 30A, General informa-

tion, Braking circuit: Bleed, page 30A-4) .

121456

K4M

Page 274 of 281

38C-15

ANTI-LOCK BRAKING SYSTEM

Front wheel speed sensor: Removal - Refitting

38C

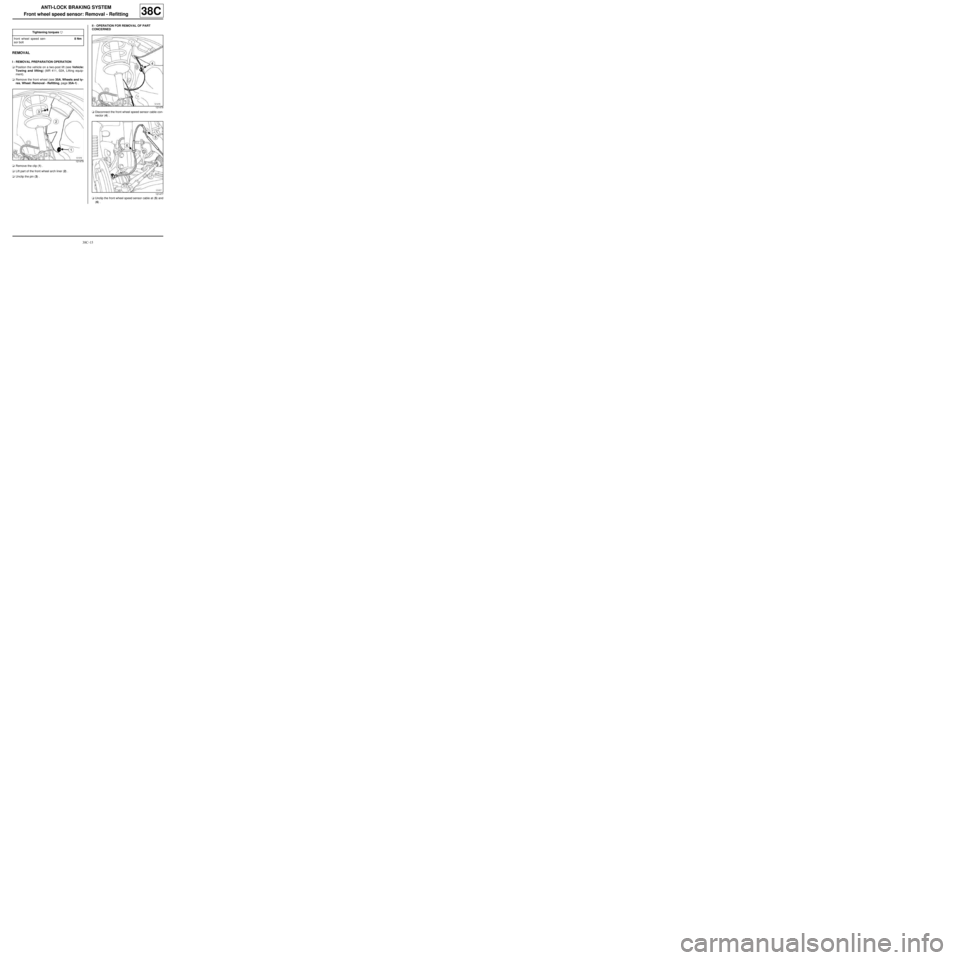

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove the front wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

aRemove the clip (1) .

aLift part of the front wheel arch liner (2) .

aUnclip the pin (3) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the front wheel speed sensor cable con-

nector (4) .

aUnclip the front wheel speed sensor cable at (5) and

(6) . Tightening torquesm

front wheel speed sen-

sor bolt8 Nm

121479

121478

121477

Page 275 of 281

38C-16

ANTI-LOCK BRAKING SYSTEM

Front wheel speed sensor: Removal - Refitting

38C

aRemove:

-the front wheel speed sensor bolt (7) ,

-the front wheel speed sensor.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the front wheel speed sensor,

-the front wheel speed sensor bolt.

aTorque tighten the front wheel speed sensor bolt

(8 Nm).

aConnect the front wheel speed sensor cable con-

nector.

aClip on the front wheel speed sensor cable.II - FINAL OPERATION.

aRefit the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

121477

WARNING

To avoid damaging the wheel speed sensor

cable:

-Do not tension the cable,

-Do not twist the cable,

-Check that there is no contact with the sur-

rounding components,

-Do not use tools that may damage the cable.

Page 276 of 281

38C-17

ANTI-LOCK BRAKING SYSTEM

Rear wheel speed sensor: Removal - Refitting

38C

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove the rear wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aOpen the rear wheel speed sensor connector pro-

tection unit flap (1) .

aDisconnect the rear wheel speed sensor cable con-

nector (2) .aUnclip the rear wheel speed sensor cable at (3) and

(4) . Tightening torquesm

rear wheel speed sen-

sor bolt8 Nm

121476

121476

Page 277 of 281

38C-18

ANTI-LOCK BRAKING SYSTEM

Rear wheel speed sensor: Removal - Refitting

38C

aRemove:

-the rear wheel speed sensor bolt (5) ,

-the rear wheel speed sensor.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the rear wheel speed sensor,

-the rear wheel speed sensor bolt.

aTorque tighten the rear wheel speed sensor bolt (8

Nm).

aClip on the rear wheel speed sensor cable.

aConnect the rear wheel speed sensor cable connec-

tor.II - FINAL OPERATION.

aClose the rear wheel speed sensor connector pro-

tection unit flap.

aRefit the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

121476

WARNING

To avoid damaging the wheel speed sensor

cable:

-Do not tension the cable,

-Do not twist the cable,

-Check that there is no contact with the sur-

rounding components,

-Do not use tools that may damage the cable.

Page 278 of 281

38C-19

ANTI-LOCK BRAKING SYSTEM

Lateral acceleration and yaw sensor: Removal - Refitting

ELECTRONIC STABILITY PROGRAM

38C

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

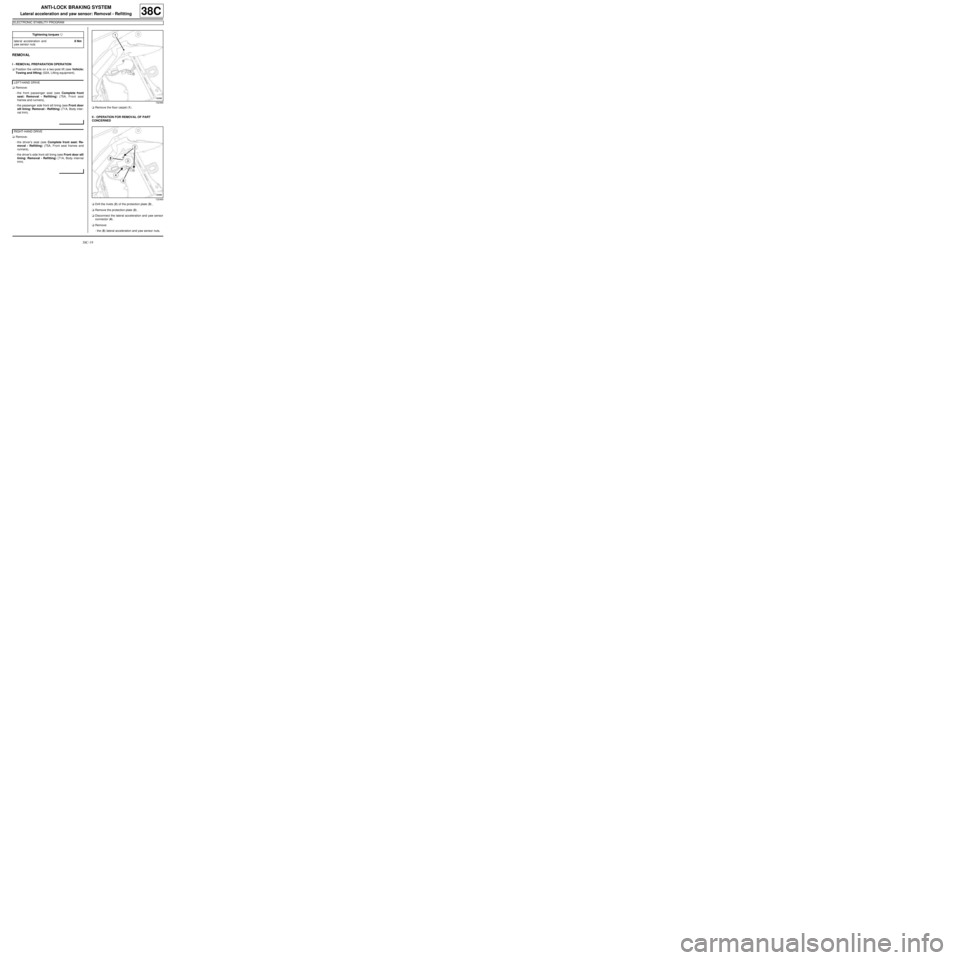

aRemove:

-the front passenger seat (see Complete front

seat: Removal - Refitting) (75A, Front seat

frames and runners),

-the passenger side front sill lining (see Front door

sill lining: Removal - Refitting) (71A, Body inter-

nal trim).

aRemove:

-the driver's seat (see Complete front seat: Re-

moval - Refitting) (75A, Front seat frames and

runners),

-the driver's side front sill lining (see Front door sill

lining: Removal - Refitting) (71A, Body internal

trim).aRemove the floor carpet (1) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDrill the rivets (2) of the protection plate (3) ,

aRemove the protection plate (3) .

aDisconnect the lateral acceleration and yaw sensor

connector (4) .

aRemove:

-the (5) lateral acceleration and yaw sensor nuts, Tightening torquesm

later al acceleration and

yaw sensor nuts8 Nm

LEFT-HAND DRIVE

RIGHT-HAND DRIVE

132469

132469

Page 279 of 281

38C-20

ANTI-LOCK BRAKING SYSTEM

Lateral acceleration and yaw sensor: Removal - Refitting

ELECTRONIC STABILITY PROGRAM

38C

-the lateral acceleration and yaw sensor.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the lateral acceleration yaw sensor.

aTorque tighten the lateral acceleration and yaw

sensor nuts (8 Nm ).

aConnect the lateral acceleration and yaw sensor

connector.

aRefit:

-the sensor protection plate,

-the rivets of the sensor protection plate.

II - FINAL OPERATION.

aRefit the floor carpet.

aRefit:

-the driver's side front sill lining (see Front door sill

lining: Removal - Refitting) (71A, Body internal

trim),

-the driver's seat (see Complete front seat: Re-

moval - Refitting) (75A, Front seat frames and

runners).

aRefit:

-the passenger side front sill lining (see Front door

sill lining: Removal - Refitting) (71A, Body inter-

nal trim),

-the front passenger seat (see Complete front

seat: Removal - Refitting) (75A, Front seat

frames and runners). RIGHT-HAND DRIVE

LEFT-HAND DRIVE

Page 280 of 281

38C-21

ANTI-LOCK BRAKING SYSTEM

Braking computer: Removal - Refitting

38C

This repair method only relates to vehicles without

ESP, equipped with TEVES brand hydraulic unit.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove the entire hydraulic unit (see 38C, Anti-

lock braking system, Hydraulic brake unit: Re-

moval - Refitting, page 38C-2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the braking computer bolts (1) on the hydraulic unit,

-the braking computer (2) .

REFITTING

I - REFITTING PREPARATION OPERATION

aDo not clean the pressure modulation unit (3) . Special tooling required

Mot. 1608Torque screwdriver 1 to 6.6

N.m.

Equipment required

Diagnostic tool

Tightening torquesm

braking computer bolts3 Nm

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

121457

19113