warning RENAULT TWINGO RS 2009 2.G Chasiss Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 71 of 281

31A-28

FRONT AXLE COMPONENTS

Front hub carrier bearing: Removal - Refitting

31A

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the bearing using a hydraulic press, taking hold

of the outer bush with a pipe with an outer diame-

ter of 70 mm (8) .

aRefit the circlip.aRefit the hub (9) using a hydraulic press, taking hold

of the bearing's internal bush with a pipe with an

outer diameter of 50 mm (10) .

III - FINAL OPERATION.

aRefit:

-the front driveshaft hub carrier (see 31A, Front

axle components, Front driveshaft hub carrier:

Removal - Refitting, page 31A-23) ,

-the brake disc (see 31A, Front axle components,

Front brake disc: Removal - Refitting, page 31A-

19) ,

-the calliper mounting (see 31A, Front axle com-

ponents, Front brake calliper mounting: Re-

moval - Refitting, page 31A-14) ,

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) ,

-the front wheel on the side in question (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) .

114182

WARNING

Do not press the bearing's inner bush so as to

avoid damaging the bearing (very high shrink-fit-

ting force).

Note:

the black side of the bearing must be fitted on the

circlip side.

114183

Page 74 of 281

31A-31

FRONT AXLE COMPONENTS

Front shock absorber and spring: Removal - Refitting31A

a

II - REFITTING OPERATION FOR PART

CONCERNED

aPlace the spring compressor tool in the vice fitted

with jaws.

aCompress the spring.

aInsert the spring in the neck of the cup.aRespect the order and direction of fitting for the con-

stituent parts.

aTorque tighten the new shock absorber rod nut

(62 N.m).

aDecompress the spring.

aRemove the spring compressor tool.

aRefit:

-the « spring/shock absorber » assembly,

-the shock absorber cup,

-the shock absorber nut cover.

aRemove the safety strap(s).

aRefit:

-the shock absorber base bolts,

-the shock absorber base nuts,

-the wheel speed sensor wiring bracket,

-the bolt of the wheel speed sensor wiring bracket.

aTighten to torque:

-the new shock absorber base nuts (105 N.m),

-the wheel speed sensor wiring bracket bolt (8

N.m). RIGHT-HAND DRIVE

139405

WARNING

Only the left-hand shock absorber is supplied

with its marking to prevent the left and right-hand

shock absorbers from being mixed up.

119654

Page 77 of 281

31A-34

FRONT AXLE COMPONENTS

Front driveshaft lower arm: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

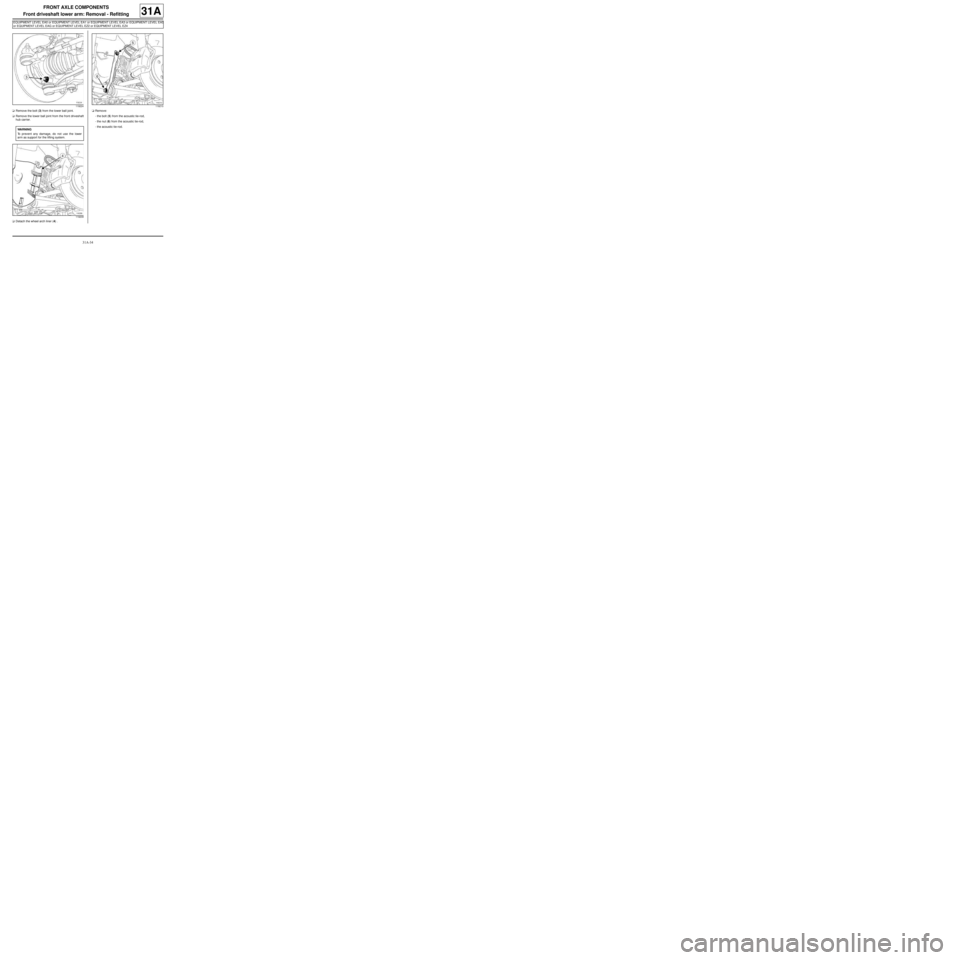

aRemove the bolt (3) from the lower ball joint.

aRemove the lower ball joint from the front driveshaft

hub carrier.

aDetach the wheel arch liner (4) .aRemove:

-the bolt (5) from the acoustic tie-rod,

-the nut (6) from the acoustic tie-rod,

-the acoustic tie-rod.

119224

WARNING

To prevent any damage, do not use the lower

arm as support for the lifting system.

119209

119210

Page 78 of 281

31A-35

FRONT AXLE COMPONENTS

Front driveshaft lower arm: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

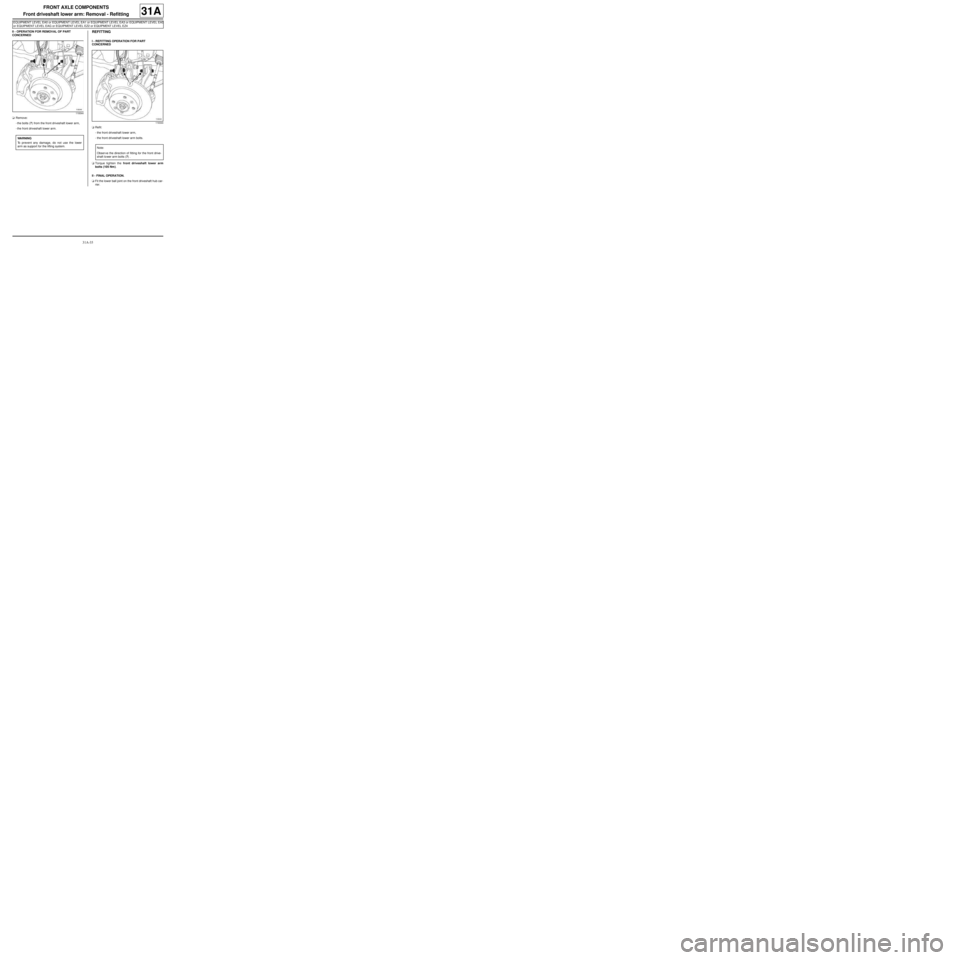

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the bolts (7) from the front driveshaft lower arm,

-the front driveshaft lower arm.REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the front driveshaft lower arm,

-the front driveshaft lower arm bolts.

aTorque tighten the front driveshaft lower arm

bolts (105 Nm).

II - FINAL OPERATION.

aFit the lower ball joint on the front driveshaft hub car-

rier.

119344

WARNING

To prevent any damage, do not use the lower

arm as support for the lifting system.

119344

Note:

Obser ve the direction of fitting for the front drive-

shaft lo wer arm bolts (7) .

Page 81 of 281

31A-38

FRONT AXLE COMPONENTS

Front driveshaft lower arm: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the studs (4) from the front driveshaft lower

arm.aRemove the lower ball joint nut (5) .

aRemove the lower ball joint from the front driveshaft

hub carrier.

aRemove the lower arm.

119344

WARNING

To prevent any damage, do not use the lower

arm as support for the lifting system.

132460

Page 84 of 281

31A-41

FRONT AXLE COMPONENTS

Front driveshaft lower arm ball joint: Removal - Refitting31A

aRemove:

-the bolt (4) from the acoustic tie-rod,

-the nut (5) from the acoustic tie-rod,

-the acoustic tie-rod.

aUndo the front driveshaft lower arm nuts (6) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the lower ball joint nut (7) ,

-the lower ball joint bolt.

aRemove the lower ball joint from the front driveshaft

hub carrier.

119210

119344

119224

WARNING

To prevent any damage, do not use the lower

ar m as support for the lifting system.

Page 99 of 281

33A-1

REAR AXLE COMPONENTS

Rear brake pads: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

When replacing brake pads, be sure to replace the

pads on the opposite side.

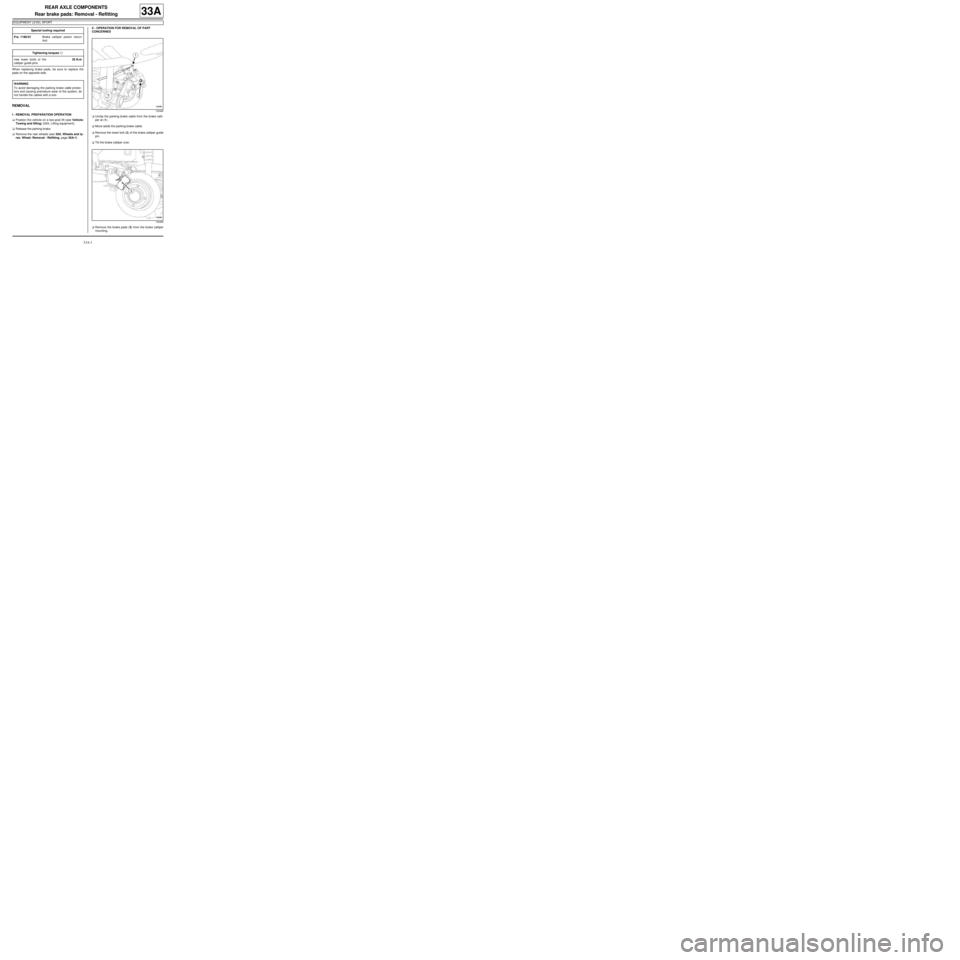

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip the parking brake cable from the brake calli-

per at (1) .

aMove aside the parking brake cable.

aRemove the lower bolt (2) of the brake calliper guide

pin.

aTilt the brake calliper over.

aRemove the brake pads (3) from the brake calliper

mounting. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Tightening torquesm

new lower bolts of the

calliper guide pins35 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

132466

Page 102 of 281

33A-4

REAR AXLE COMPONENTS

Rear brake hose: Removal - Refitting

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aFit the pedal press to the brake pedal to limit the

outflow of brake fluid.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUndo the rigid pipe unions (1) on the rear brake hose

concerned.

aRemove the rear brake hose concerned.

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the rear brake hose concerned,

-the rigid brake pipe unions on the rear brake hose

concerned.

aScrew on the rigid brake pipe unions on the rear

brake hose concerned without tightening them.

aTorque tighten the rigid pipe unions on the rear

brake hose concerned ( 17 Nm).

III - FINAL OPERATION.

aRemove the pedal press from the brake pedal to

limit the outflow of brake fluid.

aBleed the brake circuit (see 30A, General informa-

tion, Braking circuit: Bleed, page 30A-4) . Equipment requiredpedal press

Tightening torquesm

rigid pipe unions on the

rear brake hose con-

cerned17 Nm

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

119339

WARNING

In order to not damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

Page 103 of 281

33A-5

REAR AXLE COMPONENTS

Rear brake hose: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

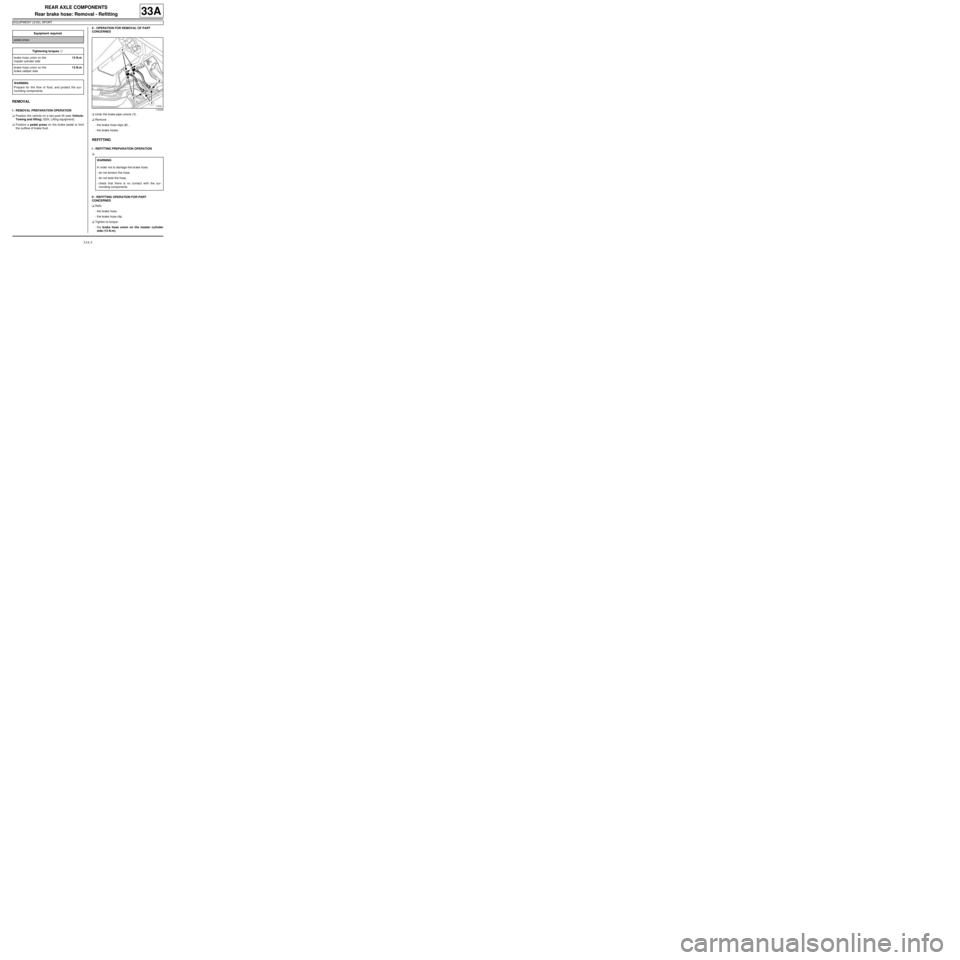

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aPosition a pedal press on the brake pedal to limit

the outflow of brake fluid.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUndo the brake pipe unions (1) .

aRemove:

-the brake hose clips (2) ,

-the brake hoses.

REFITTING

I - REFITTING PREPARATION OPERATION

a

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the brake hose,

-the brake hose clip.

aTighten to torque:

-the brake hose union on the master cylinder

side (13 N.m), Equipment required

pedal press

Tightening torquesm

brake hose union on the

master cylinder side13 N.m

brake hose union on the

brake calliper side13 N.m

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

119339

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

Page 105 of 281

33A-7

REAR AXLE COMPONENTS

Rear brake calliper: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aPosition a pedal press on the brake pedal to limit

the outflow of brake fluid.

aRemove the rear wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip the parking brake cable from the brake calli-

per at (1) .

aMove aside the parking brake cable.

aLoosen the calliper brake pipe union (2) .

aRemove:

-the brake calliper guide pin bolts (3) ,

-the brake calliper from the mounting,

-the union between the brake pipe and the calliper,

-the brake calliper.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean using a wire brush and BRAKE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products):

-the calliper supports,

-the callipers.

aAlways replace the brake calliper guide pin bolts. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

pedal press

Tightening torquesm

new bolts on the brake

calliper guide pins35 N.m

brake pipe union on the

calliper13 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468