warning RENAULT TWINGO RS 2009 2.G Chasiss Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 236 of 281

37A-57

MECHANICAL COMPONENT CONTROLS

Clutch circuit: Bleed

JH3 or JR5

37A

2 - Bleed using a new syringe.

aKeep the clutch pedal in the upper position using a

strap attached to the steering wheel to ensure conti-

nuity of the hydraulic circuit during the bleed opera-

tion.

aRemove the bleed plug from the clutch slave cylin-

der.

aConnect a transparent pipe of sufficient length to the

bleed hole (at least thirty centimetres) in order to

place it at the same height as the reservoir.

aOpen the bleed screw.

aFill the brake fluid master cylinder reservoir until

brake fluid flows out of the bleed screw.

aConnect a new hydraulic circuit bleed syringe

filled with a useful volume of 60 ml of approved

brake fluid to the end of the transparent pipe.

aSlowly inject the entire contents of the syringe into

the hydraulic clutch circuit without injecting any of

the air from the top section of the syringe.

aClose the bleed screw.

aRemove the transparent pipe from the bleed hole.

aRefit the bleed plug.

aTop up the brake fluid level in the master cylinder

reservoir.

aDisengage and engage the clutch quickly around

twenty times.

aCheck that the clutch system is operating correctly.

aRepeat the bleed operation if necessary.

aCheck the adjustment of the switch. (see 37A, Me-

chanical component controls, Clutch pedal

switch: Removal - Refitting, page 37A-52) (37A,

mechanical control elements).IV - BLEED PROCEDURE IF PARTS OF THE

HYDRAULIC CIRCUIT ARE REMOVED.

a

Note:

Take care not to disrupt the adjustment of the

clutch start of travel switch.

Note:

The transparent pipe must remain at the same

height as the master cylinder reservoir to prevent

air from entering inside the clutch circuit.

WARNING

The master cylinder pipe must be disconnected

from its take-off point on the br ake fluid reservoir,

to avoid any foreign matter penetrating inside the

hydraulic brake circuit.

WARNING

Prepare for the fl ow of fluid and protect the sur-

rounding components.

Note:

Prefill the hydraulic circuit pipe equipped with a

filter.

Position the filter head facing downwards to

ensure that it fills.

Page 240 of 281

37A-61

MECHANICAL COMPONENT CONTROLS

Clutch master cylinder: Removal - Refitting

JH3

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the front wheel on the driver's side (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) ,

-the front wheel arch liner on the driver's side (see

Front wheel arch liner: Removal - Refitting) (MR

412, 55A, Exterior protection).

aUse a syringe to empty the brake fluid reservoir.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip the hydraulic clutch master cylinder rod (1)

from the clutch pedal.aDisconnect the brake fluid fuel supply pipe (2) from

the hydraulic clutch master cylinder.

aInsert the blanking plugs.

aPull the clip (2) .

aDetach the end (3) of the hydraulic clutch control

pipe.

aInsert the blanking plugs.

121366

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

121340

121341

Page 242 of 281

37A-63

MECHANICAL COMPONENT CONTROLS

Clutch circuit: Removal - Refitting

JH3

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the front wheel on the driver's side (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) ,

-the front wheel arch liner on the driver's side (see

Front wheel arch liner: Removal - Refitting) (MR

412, 55A, Exterior protection),

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery).

aEmpty the brake fluid reservoir with a syringe.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aPress and hold the clip (1) .

aPull out the hydraulic clutch control pipe by one

notch.aPress and hold the clip (1) again.

aPull the hydraulic clutch control pipe out another

notch and collect the fluid in a container.

aDepress the clutch pedal to empty the hydraulic

clutch control circuit.

aDetach the pipe at (2) and (3) .

121354

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

121118

121114

Page 255 of 281

37A-76

MECHANICAL COMPONENT CONTROLS

Parking brake cables: Removal - Refitting

EQ UIPMENT LEVEL SPORT

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aFit:

-the vehicle on a two-post lift (see Vehicle: Towing

and lifting) (02A, Lifting equipment),

-the parking brake lever in the released position.

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

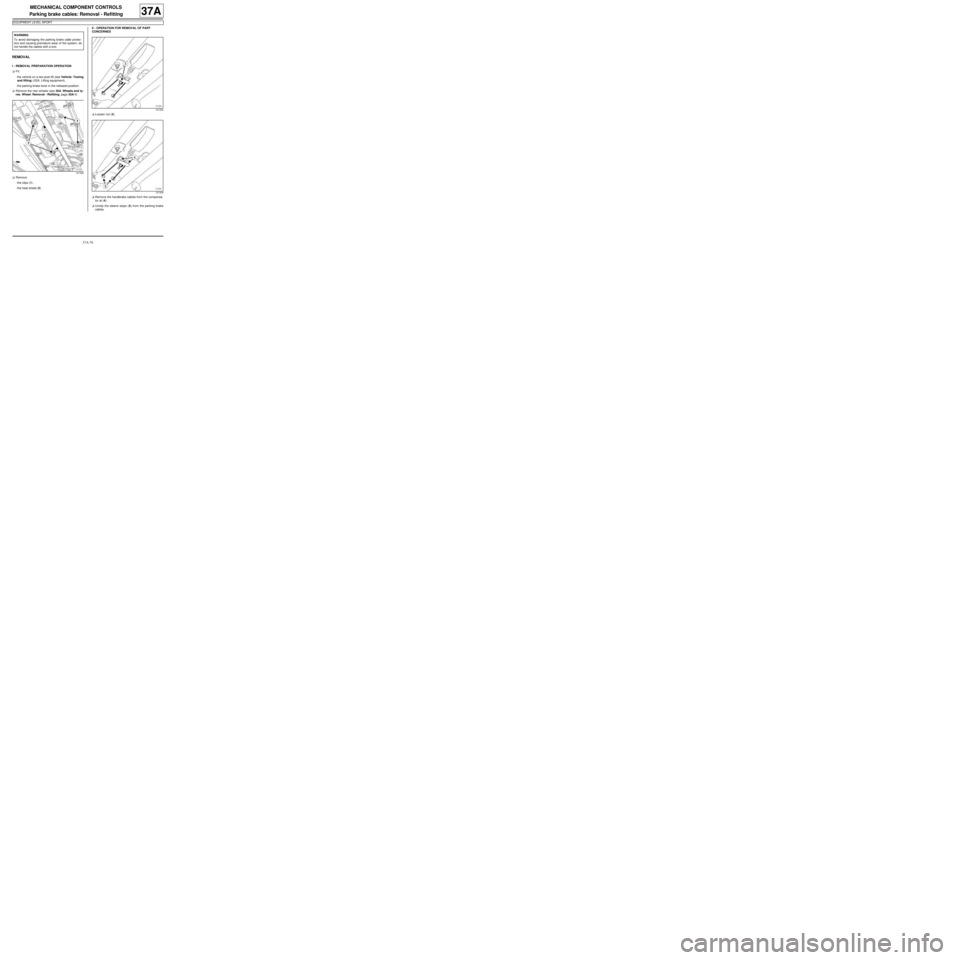

aRemove:

-the clips (1) ,

-the heat shield (2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLoosen nut (3) .

aRemove the handbrake cables from the compensa-

tor at (4) .

aUnclip the sleeve stops (5) from the parking brake

cables. WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

121326

121334

121334

Page 256 of 281

37A-77

MECHANICAL COMPONENT CONTROLS

Parking brake cables: Removal - Refitting

EQ UIPMENT LEVEL SPORT

37A

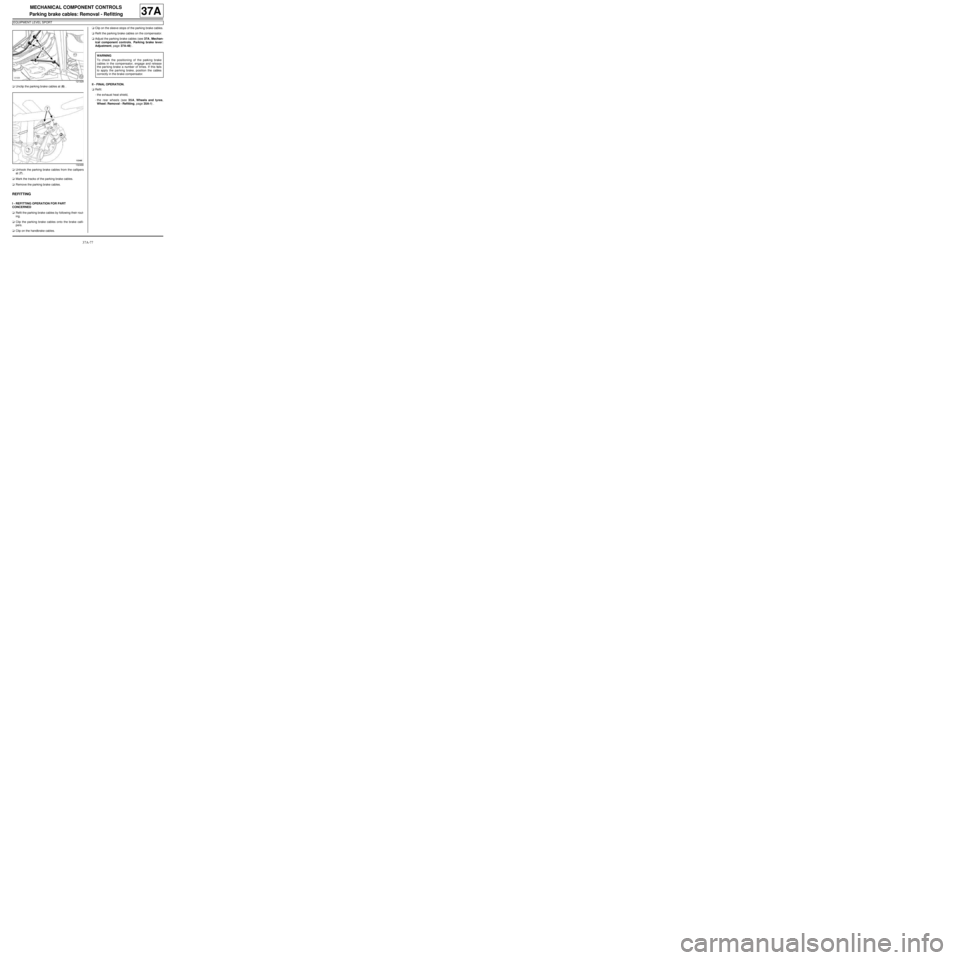

aUnclip the parking brake cables at (6) .

aUnhook the parking brake cables from the callipers

at (7) .

aMark the tracks of the parking brake cables.

aRemove the parking brake cables.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the parking brake cables by following their rout-

ing.

aClip the parking brake cables onto the brake calli-

pers.

aClip on the handbrake cables.aClip on the sleeve stops of the parking brake cables.

aRefit the parking brake cables on the compensator.

aAdjust the parking brake cables (see 37A, Mechan-

ical component controls, Parking brake lever:

Adjustment, page 37A-48) .

II - FINAL OPERATION.

aRefit:

-the exhaust heat shield,

-the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

121329

132468

WARNING

To check the positioning of the parking brake

cables in the compensator, engage and release

the par king brake a number of times. If this fails

to apply the par king brake, position the cables

correctly in the brake compensator.

Page 262 of 281

38C-3

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

K9K, and LEFT-HAND DRIVE

38C

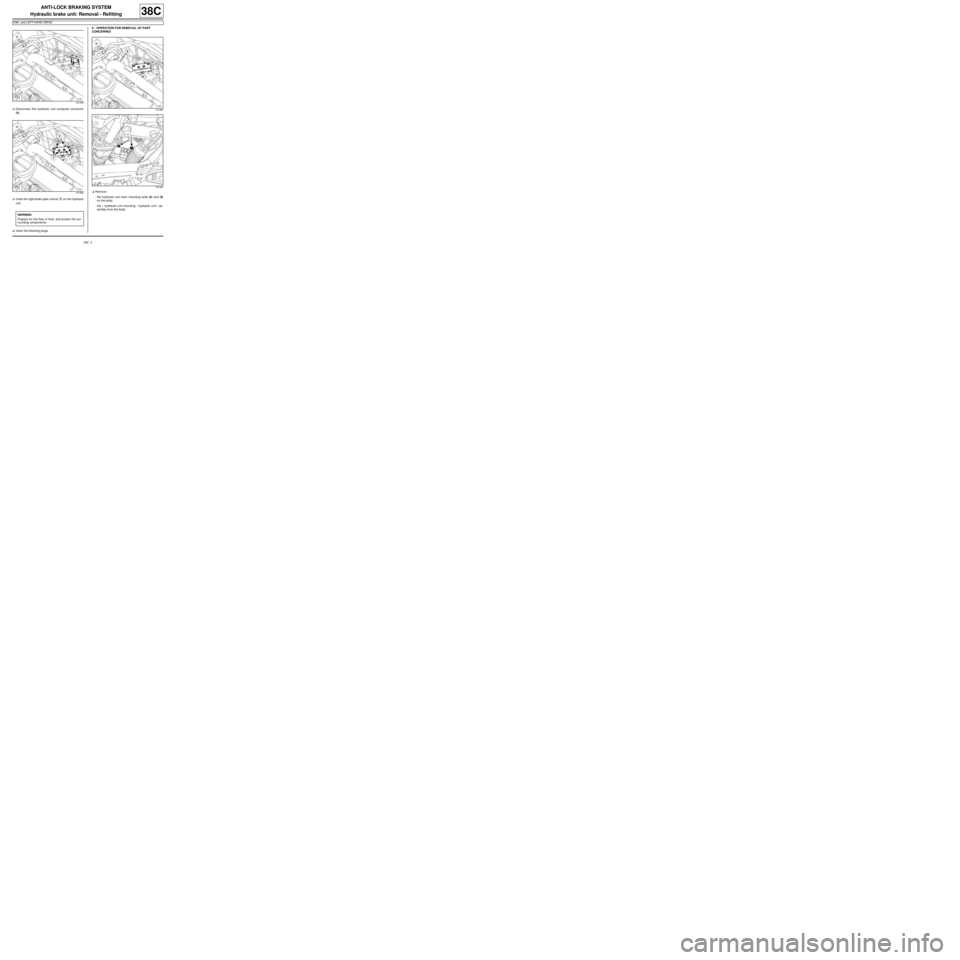

aDisconnect the hydraulic unit computer connector

(6) .

aUndo the rigid brake pipe unions (7) on the hydraulic

unit.

aInsert the blanking plugs.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the hydraulic unit main mounting bolts (8) and (9)

on the body,

-the « hydraulic unit mounting - hydraulic unit » as-

sembly from the body.

121359

121360

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

121360

121361

Page 264 of 281

38C-5

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

D4F or D7F, and LEFT-HAND DRIVE

38C

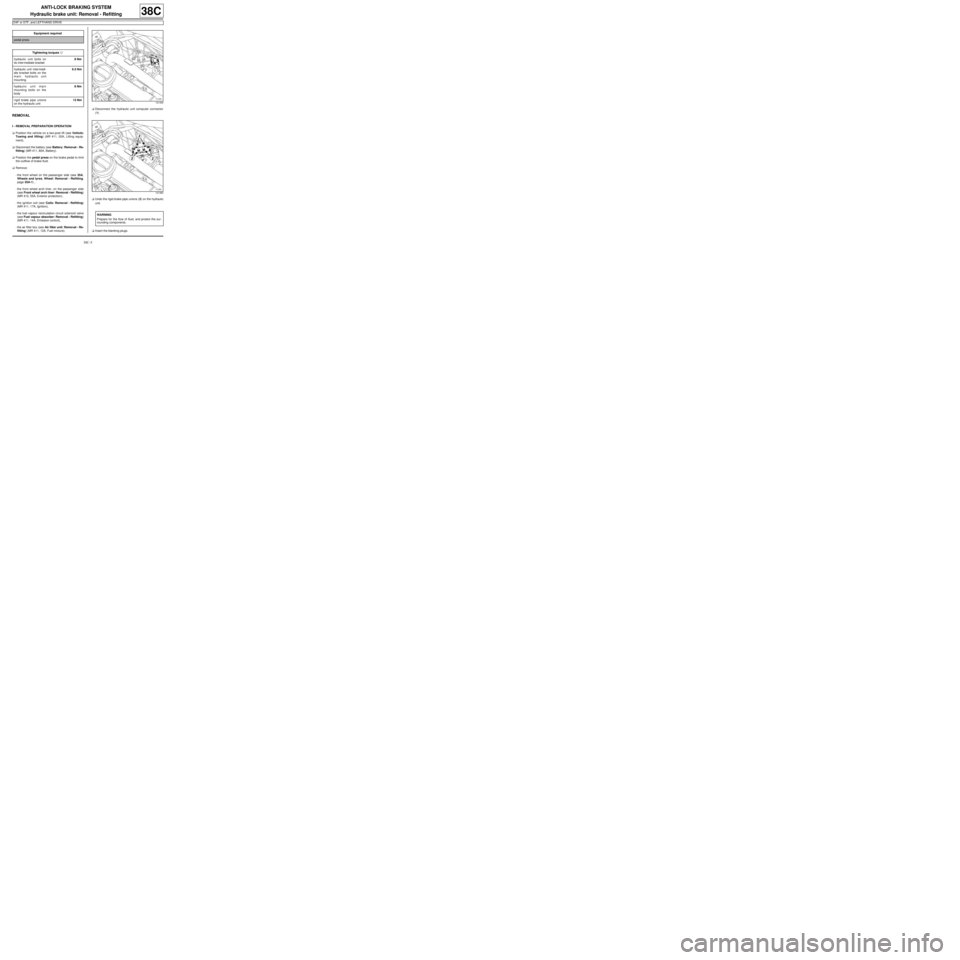

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aPosition the pedal press on the brake pedal to limit

the outflow of brake fluid.

aRemove:

-the front wheel on the passenger side (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) ,

-the front wheel arch liner, on the passenger side

(see Front wheel arch liner: Removal - Refitting)

(MR 412, 55A, Exterior protection),

-the ignition coil (see Coils: Removal - Refitting)

(MR 411, 17A, Ignition),

-the fuel vapour recirculation circuit solenoid valve

(see Fuel vapour absorber: Removal - Refitting)

(MR 411, 14A, Emission control),

-the air filter box (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture).aDisconnect the hydraulic unit computer connector

(1) .

aUndo the rigid brake pipe unions (2) on the hydraulic

unit.

aInsert the blanking plugs. Equipment required

pedal press

Tightening torquesm

hydraulic unit bolts on

its inter mediate bracket8 Nm

hydraulic unit inter medi-

ate bracket bolts on the

main hydraulic unit

mounting6.5 Nm

hydraulic unit main

mounting bolts on the

body8 Nm

rigid brake pipe unions

on the hydraulic unit13 Nm

121359

121360

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

Page 268 of 281

38C-9

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

D4F, and 780, and LEFT-HAND DRIVE – K4M, and LEFT-HAND DRIVE

38C

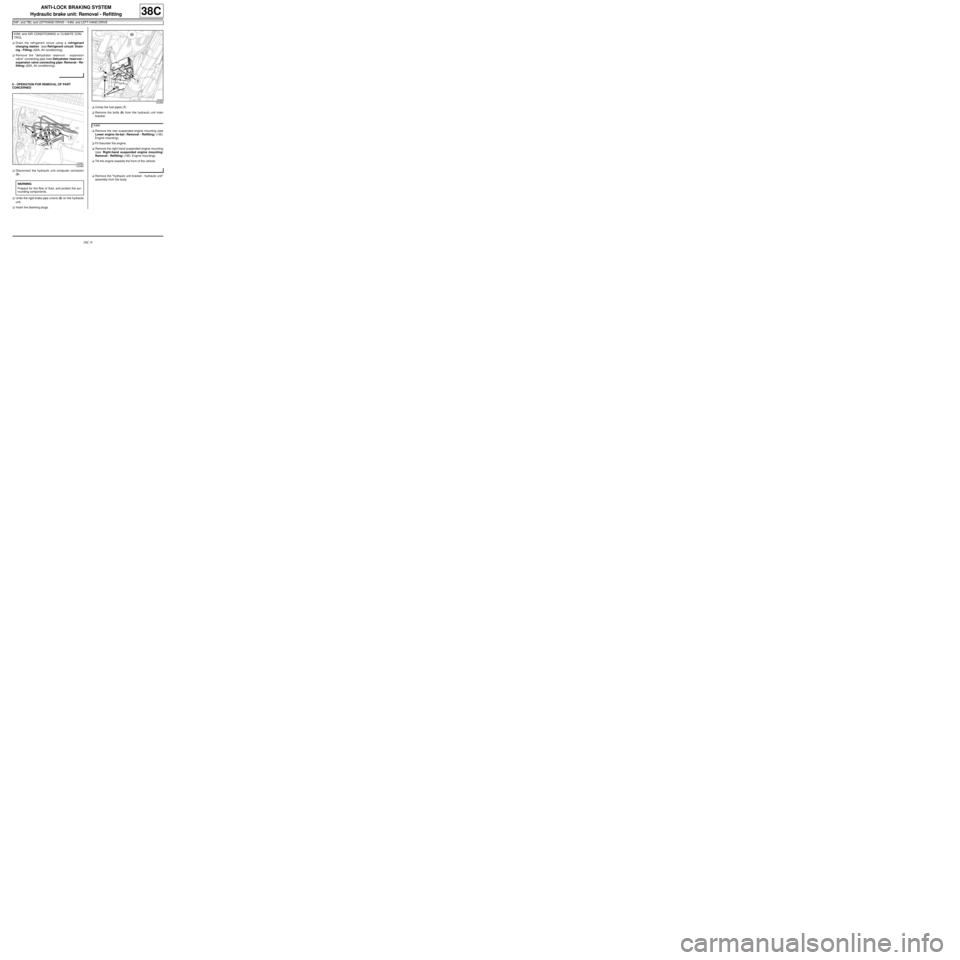

aDrain the refrigerant circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove the "dehydrator reservoir - expansion

valve" connecting pipe (see Dehydrator reservoir -

expansion valve connecting pipe: Removal - Re-

fitting) (62A, Air conditioning).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the hydraulic unit computer connector

(5) .

aUndo the rigid brake pipe unions (6) on the hydraulic

unit.

aInsert the blanking plugs.aUnclip the fuel pipes (7) .

aRemove the bolts (8) from the hydraulic unit main

bracket.

aRemove the rear suspended engine mounting (see

Lower engine tie-bar: Removal - Refitting) (19D,

Engine mounting).

aFit theunder the engine.

aRemove the right-hand suspended engine mounting

(see Right-hand suspended engine mounting:

Removal - Refitting) (19D, Engine mounting).

aTilt the engine towards the front of the vehicle.

aRemove the "hydraulic unit bracket - hydraulic unit"

assembly from the body. K4M, and AIR CONDITIONING or CLIMATE CON-

TROL

122386

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

122385

K4M

Page 272 of 281

38C-13

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

RIGHT-HAND DRIVE

38C

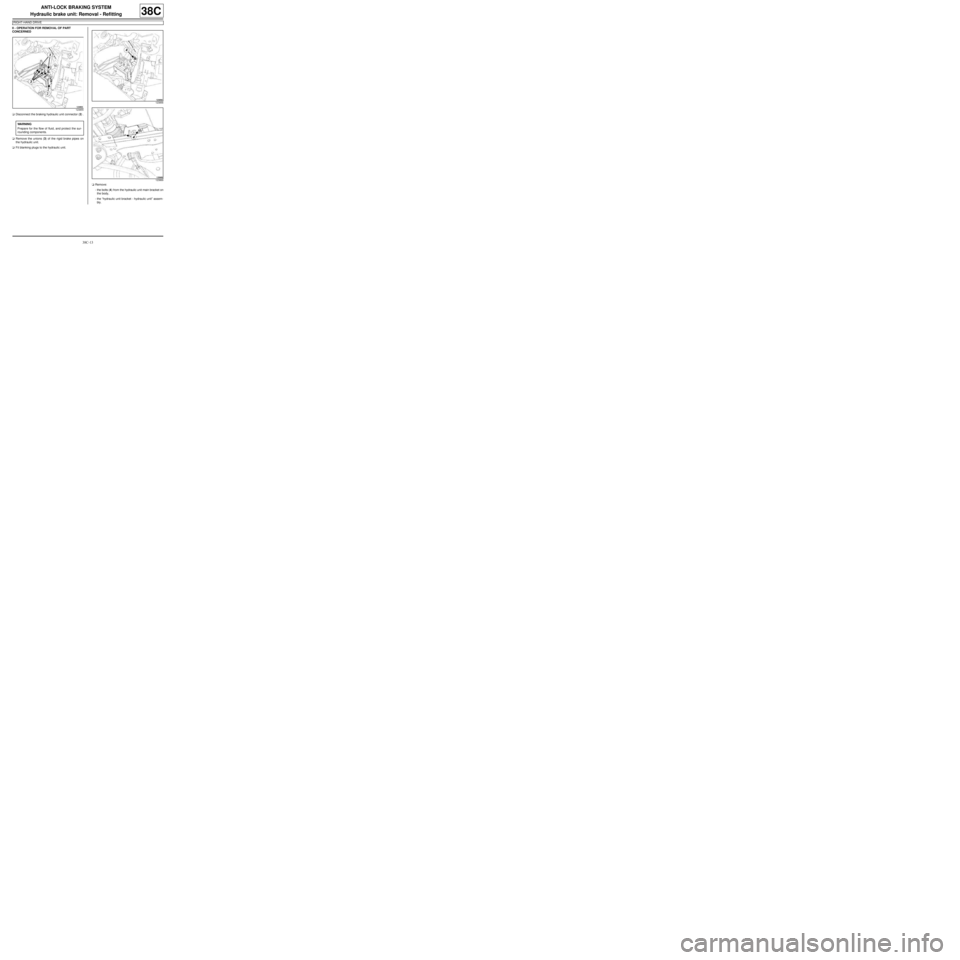

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the braking hydraulic unit connector (2) .

aRemove the unions (3) of the rigid brake pipes on

the hydraulic unit.

aFit blanking plugs to the hydraulic unit.

aRemove:

-the bolts (4) from the hydraulic unit main bracket on

the body,

-the “hydraulic unit bracket - hydraulic unit” assem-

bly.

123855

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

123856

123869

Page 275 of 281

38C-16

ANTI-LOCK BRAKING SYSTEM

Front wheel speed sensor: Removal - Refitting

38C

aRemove:

-the front wheel speed sensor bolt (7) ,

-the front wheel speed sensor.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the front wheel speed sensor,

-the front wheel speed sensor bolt.

aTorque tighten the front wheel speed sensor bolt

(8 Nm).

aConnect the front wheel speed sensor cable con-

nector.

aClip on the front wheel speed sensor cable.II - FINAL OPERATION.

aRefit the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

121477

WARNING

To avoid damaging the wheel speed sensor

cable:

-Do not tension the cable,

-Do not twist the cable,

-Check that there is no contact with the sur-

rounding components,

-Do not use tools that may damage the cable.