ECU Seat Leon 5D 2009 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2009, Model line: Leon 5D, Model: Seat Leon 5D 2009Pages: 304, PDF Size: 7.72 MB

Page 219 of 304

Checking and refilling levels217

Safety First

Controls and equipment

Practical tips

Technical Data

For the sake of the environment

Service fluids leaks are harmful to the environment. For this reason you

should make regular checks on the ground underneath your vehicle. If you

find spots of oil or other fluids, have your vehicle inspected in a qualified

workshop.Opening the bonnet

The bonnet is released from inside the vehicle.

Before opening the bonnet ensure that the windscreen wipers are in

rest position.

– To release the bonnet, pull the lever under the dashboard

⇒fig. 142 in the direction indicated (arrow). The bonnet will be

released by a spring action ⇒.

– Lift the bonnet using the release lever (arrow) and open the bonnet.

– Release the bonnet stay and secure it in fixture designed for this

in the bonnet.

WARNING

Hot coolant can scald!•Never open the bonnet if you see steam, smoke or coolant escaping

from the engine compartment.

Fig. 142 Detail of foot-

well area on driver's side:

lever for unlocking the

bonnet.

Fig. 143 Arrester hook

for bonnet.

Leon_EN.book Seite 217 Dienstag, 8. September 2009 5:25 17

Page 220 of 304

Checking and refilling levels

218•Wait until no more steam, smoke or coolant is emitted from the bonnet,

then carefully open the bonnet.•When working in the engine compartment, always observe the safety

warnings ⇒page 215.

Closing the bonnet– Raise the bonnet slightly.

– Release the bonnet stay and replace it in its support.

– At a height of about 30 cm let it fall so it is locked.If the b onn et d o es n ot clos e , do not p ress d ownwa rds . Op e n it o nce m or e an d

let it fall as before.

WARNING

If the bonnet is not closed properly, it could open while you are driving and

completely obscure your view of the road. Risk of accident.•After closing the bonnet, always check that it is properly secured. The

bonnet must be flush with the surrounding body panels.•If you notice that the bonnet latch is not secured when the vehicle is

moving, stop the vehicle immediately and close the bonnet properly. Risk

of accident.

Engine oilEngine oil specifications

The engine oil used must conf orm with exact specifications.Specifications

The engine comes with a special, high quality, multi grade oil that can be

used in all seasons of the year except for those regions affected by extreme

cold.

As the use of high quality oil is essential for the correct operation of the

engine and its long useful life, when topping up or replacement is necessary

use only those oils that conform to the requirements of the VW standards.

If it is not possible to find oil conforming to the VW standards then oil

conforming to the ACEA or API standards with an appropriate viscosity at

atmospheric temperature should be used instead. The use of this type of oil

may have some repercussions on the performance of the engine for example,

long starting time, increased consumption and a higher emission level.

If a top up is required then different oils may be mixed as long as they all

conform to the VW standards.

The specifications (VW standards) set out in the following page should

appear on the container of the service oil; the container will display together

the different standards for petrol and diesel engines, the oil can be used for

both types of engines.

WARNING (continued)

Leon_EN.book Seite 218 Dienstag, 8. September 2009 5:25 17

Page 240 of 304

Wheels and tyres

238Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you may not use wheel bolts from a different car -

even if it is the same model ⇒page 206.

After the wheels have been changed, the tightening torque of the wheel bolts

s ho uld b e che cke d as s o on as p ossible wit h a to rqu e w re nch. ⇒ The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.•Use only wheel bolts which belong to the wheel.•If the torque of the wheel bolts is too low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.Caution

The prescribed torque for wheel bolts for steel and alloy wheels is 120 Nm.

Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.In winter conditions winter tyres will considerably improve the vehicles

handling. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pressures

specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's regis-

tration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

Winter tyres lose their effectiveness when the tread is worn down to a depth

of 4 mm.

The speed rating code ⇒ page 237, “New tyres and wheels” determines the

following speed limits for winter tyres: ⇒

Q max. 160 km/h

S max. 180 km/h

T max. 190 km/h

H max. 210 km/h

In some countries, vehicles which can exceed the speed rating of the fitted

tyre must have an appropriate sticker in the driver's field of view. These

stickers are available from your Authorised Service Centre. The legal require-

ments of each country must be followed.

Do not have winter tyres fitted for unnecessarily long periods. Vehicles with

summer tyres handle better when the roads are free of snow and ice.

If you have a flat tyre, please refer to the notes on the spare wheel

⇒ page 237, “New tyres and wheels”.

Leon_EN.book Seite 238 Dienstag, 8. September 2009 5:25 17

Page 242 of 304

If and when

240If and whenTools, tyre repair kit and spare wheelVehicle Tools

The vehicle onboard tools are located under the floor panel in

the luggage compartment.– Lift the cover of the luggage compartment, by pulling it up with a

finger in the fitting.

– Take the onboard tools out of the vehicle.The tool kit includes:•Jack*•Hook for removing wheel covers* or hub caps*•Box spanner for wheel bolts*•Reversible screwdriver with handle (including hexagonal interior) for the

wheel bolts. The screwdriver is a combination tool.•Towi ng e ye•Adapter for the anti-theft wheel bolts*

Some of the items listed are only provided in certain models / model years,

or are optional extras.WARNING

•Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts as with this it is not possible to tighten the bolts to the

required torque. Risk of accident.

•The jack* supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads. Risk of injury.•Use the jack* only on firm, level ground.•Never start the engine when the vehicle is on the jack. Risk of accident.•If work is to be carried out underneath the vehicle, this must be secured

by suitable stands. Otherwise, there is a risk of injury.WARNING (continued)

Leon_EN.book Seite 240 Dienstag, 8. September 2009 5:25 17

Page 245 of 304

If and when243

Safety First

Controls and equipment

Practical tips

Technical Data

–Remove the wheel and then mount the spare wheel

– Lower the vehicle.

– Tighten the wheel bolts firmly with the box spanner.

– Replace the wheel trim.After changing a wheel

After changing the wheel there are still tasks to complete.– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart-

ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as possible.

– Have the tightening torque of th e wheel bolts checked as soon as

possible with a torque wrench. Th e prescribed torque must be

120 Nm.

Note•If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt torque

checked.•For your safety, drive at moderate speeds until the wheel bolt torque has

been checked.

Wheel trims

The wheel trims must be removed to gain access to the wheel

bolts.Removing

– Insert the extraction hook from the tools into the designated

ring, located in one of the bolt hole covers of the wheel cover

⇒ fig. 156 .

–Pull off the hub cap.

Fig. 156 Changing the

wheel: Removing a hub

cap

Leon_EN.book Seite 243 Dienstag, 8. September 2009 5:25 17

Page 246 of 304

If and when

244Wheel covers*

The wheel covers must be removed for access to the wheel

boltsRemoving

– Remove the wheel cover using the wire hook.

– Hook this into one of the cut-outs of the wheel cover.

Fitting

– Fit the wheel cover onto the wheel rim by pressing it firmly. Put

pressure initially on the point of the cut-out for the valve. Then

press the wheel cover onto the st eel rim so that it engages all

round.

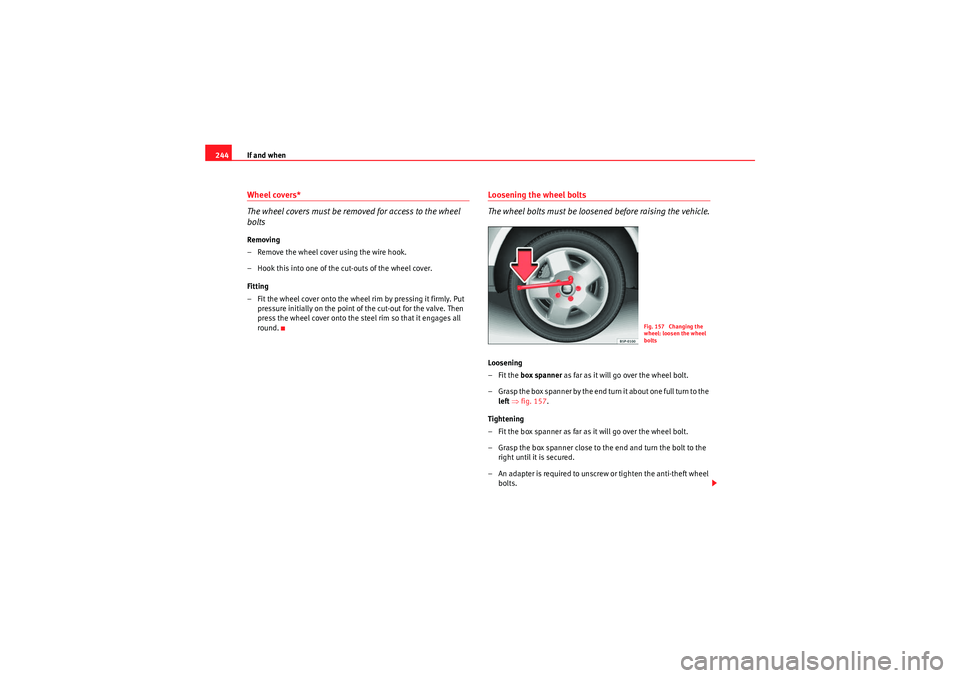

Loosening the wheel bolts

The wheel bolts must be loosened before raising the vehicle.Loosening

–Fit the box spanner as far as it will go over the wheel bolt.

– Grasp the box spanner by the end turn it about one full turn to the left ⇒ fig. 157 .

Tightening

– Fit the box spanner as far as it will go over the wheel bolt.

– Grasp the box spanner close to the end and turn the bolt to the right until it is secured.

– An adapter is required to unscrew or tighten the anti-theft wheel bolts.

Fig. 157 Changing the

wheel: loosen the wheel

bolts

Leon_EN.book Seite 244 Dienstag, 8. September 2009 5:25 17

Page 262 of 304

If and when

260

– Take the lampholder out pressing on the securing pins and extract it outwards ⇒page 259, fig. 174 .

– Replace the faulty lamp, rotating it to the left and outwards.

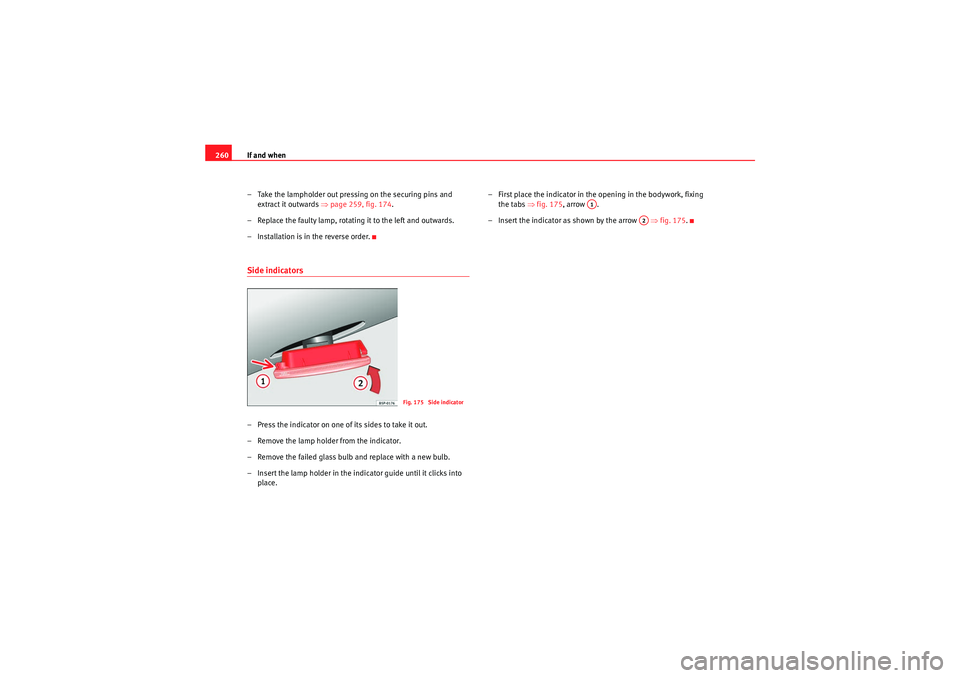

– Installation is in the reverse order.Side indicators– Press the indicator on one of its sides to take it out.

– Remove the lamp holder from the indicator.

– Remove the failed glass bulb and replace with a new bulb.

– Insert the lamp holder in the indicator guide until it clicks into place. – First place the indicator in the opening in the bodywork, fixing

the tabs ⇒ fig. 175, arrow .

– Insert the indicator as shown by the arrow ⇒fig. 175 .

Fig. 175 Side indicator

A1

A2

Leon_EN.book Seite 260 Dienstag, 8. September 2009 5:25 17

Page 296 of 304

Index

294Braking distance . . . . . . . . . . . . . . . . . . . . . . . . 188

Bulb changes

general notes . . . . . . . . . . . . . . . . . . . . . . . 254

Bulb defect warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 82

Buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118, 157CCar care Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Catalytic converter . . . . . . . . . . . . . . . . . . . . . . 189

Central locking . . . . . . . . . . . . . . . . . . . . . . . . . . 93 Automatic locking system for involuntary unlocking . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Automatic speed dependent locking and un- locking system* . . . . . . . . . . . . . . . . . . . . . 95

Emergency unlocking system . . . . . . . . . . . . 95

Selective unlocking system* . . . . . . . . . . . . 94

Unlocking system* . . . . . . . . . . . . . . . . . . . . 95

Central locking button Central locking . . . . . . . . . . . . . . . . . . . . . . . 96

unlocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Centre console with drinks holder . . . . . . . . . . 135

Cetane number . . . . . . . . . . . . . . . . . . . . . . . . . 214

Changing gear See Manual gearbox . . . . . . . . . . . . . . . . . . 165

Changing gear with the Tiptronic gear system 169

Changing the lamps Main headlight lamps . . . . . . . . . . . . . . . . . 255

rear lights . . . . . . . . . . . . . . . . . . . . . . . . . . . 258 Changing the main headlight lamps

dipped beam lights . . . . . . . . . . . . . . . . . . . 256

main beam lights . . . . . . . . . . . . . . . . . . . . 257

Side lights . . . . . . . . . . . . . . . . . . . . . . . . . . 258

turn signal lamps . . . . . . . . . . . . . . . . . . . . 256

Changing the rear light lamps Position light, fog light and rear light on the tailgate . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Changing the rear lights Indicator, side and brake lights on the bodywork . . . . . . . . . . . . . . . . . . . . . . . . . 259

luggage compartment lights . . . . . . . . . . . 261

Chassis number . . . . . . . . . . . . . . . . . . . . . . . . 270

Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Checking battery electrolyte level . . . . . . . . . . 230

Checking engine oil level . . . . . . . . . . . . . . . . . 219

Child safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Child seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 Categorisation in groups . . . . . . . . . . . . . . . 46

Group 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Group 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Group 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Groups 0 and 0+ . . . . . . . . . . . . . . . . . . . . . . 46

ISOFIX system . . . . . . . . . . . . . . . . . . . . . . . . 49

Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Securing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Child seats on the front passenger seat . . . . . . . . . . . . . 30

Cigarette lighter* . . . . . . . . . . . . . . . . . . . . . . . . 137

Cleaning alloy wheel rims . . . . . . . . . . . . . . . . 202

Cleaning and caring for your vehicle . . . . . . . . 197 Cleaning chrome . . . . . . . . . . . . . . . . . . . . . . . . 201

Cleaning engine compartment . . . . . . . . . . . . . 203

Cleaning steel wheel rims . . . . . . . . . . . . . . . . 202

Cleaning windows . . . . . . . . . . . . . . . . . . . . . . . 200

Climatic* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Climatronic

General notes . . . . . . . . . . . . . . . . . . . . . . . 153

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cloth seat covers cleaning . . . . . . . . . . . . . . . . 204

Clothes hook . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Cockpit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Coming/leaving home function . . . . . . . . . . . . 114

Control lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Control lighting . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Controls Electric windows . . . . . . . . . . . . . . . . . . . . . 106

Light switches . . . . . . . . . . . . . . . . . . . . . . . 111

Convenience closing Sliding/tilting roof . . . . . . . . . . . . . . . . . . . 109

Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Convenience opening Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . 222, 223 Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Coolant Level . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Coolant level warning light . . . . . . . . . . . . . . . . . . . . . . . . . 77

Coolant Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Leon_EN.book Seite 294 Dienstag, 8. September 2009 5:25 17