warning lights SKODA OCTAVIA 2010 2.G / (1Z) Repair Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2010, Model line: OCTAVIA, Model: SKODA OCTAVIA 2010 2.G / (1Z)Pages: 275, PDF Size: 16.43 MB

Page 174 of 275

Intelligent Technology173

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

one wheel per axle was changed.

Basic setting of the system

After changing the tyre inflation pressures, after changing one or several wheels, the

position of a wheel on the vehicle (e.g. exch anging the wheels between the axles) or

when the warning light lights up while drivin g, a basic setting of the system must be

carried out as follows.

Inflate all tyres to the specified inflation pressure page 208.

Switch on the ignition.

Press button page 172, fig. 151 for more than 2 seconds. While pressing

the button, the warning light

lights up. At the same time the memory of the system

is erased and the new calibration is started, which is confirmed with an audible signal

and then the warning light

goes out.

If the warning light

does not go out after the basic setting, there is a fault in the

system. Have the vehicle inspected by your nearest specialist garage.

Warning light

lights up

If the tyre inflation pressure of at least one wheel is insufficiently inflated in comparison

to the stored basic value, the warning light

lights up.

Warning light

flashes

If the warning light flashes, there is a system fault. Have the vehicle inspected by your

nearest specialist garage.

WARNING

When the warning light

lights up, immediately reduce the speed and

avoid sudden steering and brake manoeuvr es. Please stop the vehicle without

delay at the nearest possible stop and in spect the tyres and their inflation pres-

sures.

The driver is responsible for the correct tyre inflation pressures. For this

reason, the tyre inflation pressu res must be checked regularly.

Under certain circumstances (e.g. sporty style of driving, wintry or unpaved

roads) the warning light

can be delayed or does not light up at all.

The tyre pressure monitoring system does not take away the responsibility

from the driver for the correct tyre inflation pressure.

Note

The tyre pressure monitoring system:

does not replace the regular tyre inflatio n pressure control, because the system

cannot detect an even pressure loss,

cannot warn in case of very rapid tyre inflation pressure loss, e.g. in case of sudden

tyre damage. In this case ca refully bring the vehicle to a standstill without sudden

steering movements and without sharp braking.

In order to ensure a proper functioning of the tyre inflation pressure-control

system, it is necessary to carry out the ba sic setting again every 10 000 km or 1x a

year.

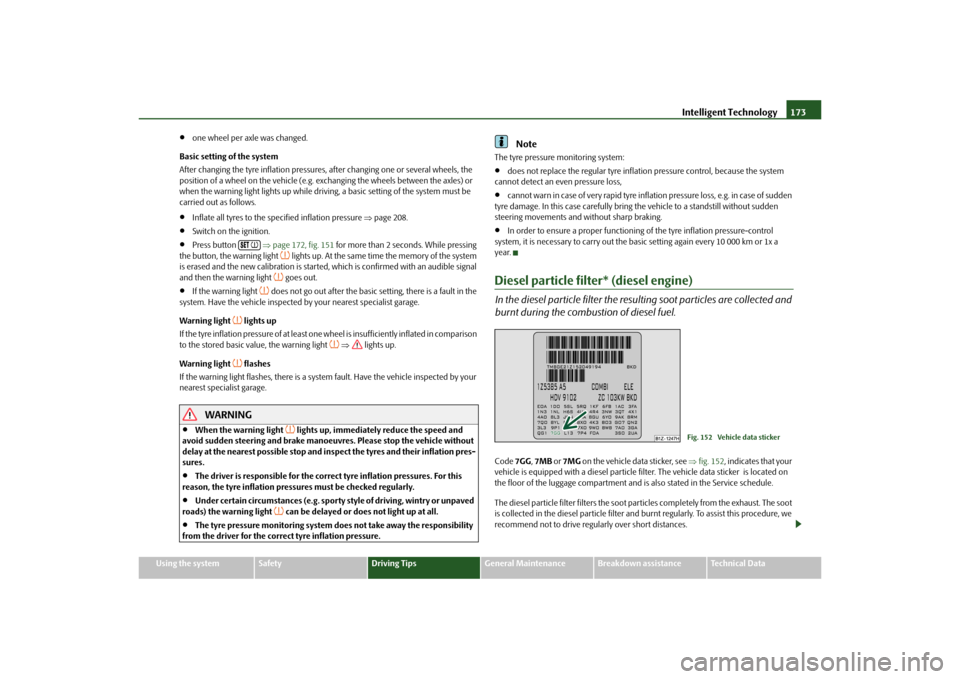

Diesel particle filter* (diesel engine)In the diesel particle filter the resu lting soot particles are collected and

burnt during the combustion of diesel fuel.Code 7GG, 7MB or 7MG on the vehicle data sticker, see fig. 152 , indicates that your

vehicle is equipped with a diesel particle fi lter. The vehicle data sticker is located on

the floor of the luggage compartment and is also stated in the Service schedule.

The diesel particle filter filters the soot particles completely from the exhaust. The soot

is collected in the diesel particle filter and burnt regularly. To assist this procedure, we

recommend not to drive regu larly over short distances.

Fig. 152 Vehicle data sticker

s43s.1.book Page 173 Thursday, May 13, 2010 1:21 PM

Page 184 of 275

Towing a trailer183

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Headlights

Before starting off with a hitched trailer, also check the setting of the headlights. Alter

the setting as necessary with the ai

d of the headlight beam adjuster page 56.

Detachable ball head

The ball rod is detachable on vehicles which feature a factory-fitted towing device. It is

stowed together with separate fitting instru ctions in the spare wheel well in the luggage

compartment of the vehicle.

Further information on the towing device page 184.

Note

We recommend that you also have your vehicle inspected between service inter-

vals if you tow a trailer frequently.

The handbrake on the towing vehicle must be put on when coupling and decou-

pling the trailer.

Driving Tips

Particular caution is required when towing a trailer.– Do not, as far as possible, drive with your vehicle unladen and the trailer laden.

– Do not make full use of the legal maximum speeds. This applies in particular to downhill sections.

– Apply the brakes in good time.

– Keep a check on the coolant temperature gauge if the outside temperature is high.

Distribution of weight

The distribution of the weight is very poor if your vehicle is unladen and the trailer is

laden. Maintain a particularly low speed if you cannot avoid driving with this combina-

tion.

Driving speed

Do not drive faster than 80 km/hour for safety reasons. This also applies for countries

in which higher speeds are allowed. The fact that the driving stability of the vehicle + trailer combination reduces with

increasing speed means that the legally allowed speed should not be used when there

are unfavourable road, weather or wind cond

itions, particularly near accident black

spots.

You must always reduce your speed immediat ely as soon as you detect even just the

slightest swaying of the trailer. On no account attempt to stop the trailer from

“swaying” by accelerating.

Apply the brakes in good time! If the trailer is fitted with a trailer brake, apply the

brakes gently at first and then brake firmly. This will avoid brake jolts resulting from the

trailer wheels locking. Shift down gears in good time before negotiating a downhill

section to allow the engine to also act as a brake.

Engine overheating

Please keep a check on the coolant temperature gauge if you have to negotiate a

lengthy slope in a low gear at a high engi ne speed when the outside temperature is

very high page 16, “Coolant temperature gauge”.

If the needle of the coolant temperature gauge moves into the right-hand area or even

the red area of the scale, reduce your speed immediately. Stop and switch off the

engine if the warning light

in the instrument cluster begins flashing. Wait a few

minutes and check the level of coolant in the coolant expansion bottle page 201,

“Inspecting the coolant level”.

Please refer to the following guidelines page 31, “Coolant temperature/coolant

level ”.

The coolant temperature can be reduced by switching on the heating.

Any increase in the cooling effect of the coolant fan through shifting down a gear and

increasing the engine speed is not possible since the fan speed is independent of the

engine speed. One should also not drop a gear for this reason when towing a trailer as

long as the engine can manage th e slope without any drop in speed.

s43s.1.book Page 183 Thursday, May 13, 2010 1:21 PM

Page 189 of 275

Taking care of your vehicle and cleaning the vehicle

188

Do not use window leathers which you have us ed to polish the vehicle body to dry off

the windows. Residues of preservatives in the window leather can dirty the window

and reduce visibility.

Do not affix any stickers over the inside of the rear window to avoid damage to the

heating elements of the rear window heater .

We recommend using a preserva tive from Škoda genuine accessories offered by your

Škoda dealer.

Caution

Never remove snow or ice from the glass parts with warm or hot water - risk of forma-

tion of cracks in the glass!The headlight lensesPlease do not use any aggressi ve cleaning or chemical solvent products for cleaning

the front headlights - risk of damage to the plastic lenses. Please use soap and clean

warm water.

Caution

Never wipe the headlights dry and do not use any sharp objects for cleaning the plastic

lenses, this may result in damage to the protective paintwork and consequently in

formation of cracks on the headlight lenses, e.g through effect of chemical products.Door and window sealsThe rubber seals on the doors, boot lid, bonnet and windows remain supple and last

longer if you treat them from time to time with a rubber care product (e.g. with a spray

with silicone-free oil). You also avoid premature wear of the seals and prevent leakages

in this way. It is also easier to open the doors. Rubber seals which are well cared for also

do not stick together in cold winter weather.Locking cylinderWe recommend that you use the spray from Škoda original accessories with regreasing

and anticorrosive effect for de-icing locking cylinders.

Note

When washing your vehicle, ensure that as little water as possible gets into the locking

cylinders.WheelsSteel wheels

You should also thoroughly wash the wheels and wheel trims when giving your vehicle

its regular wash. This prevents any brake dust, dirt and road salt from sticking to the

wheel hubs. You can remove stubborn brake abrasion adhering to the wheels with an

industrial cleaner. Touch up any damage to the paintwork on the wheels before rust is

able to form.

Light alloy wheels

Regular care of light alloy wh eels is necessary in order to retain their decorative

appearance over long periods. It is particul arly important to remove regularly any road

salt and brake abrasion from light alloy wheels, otherwise the light metal will suffer.

Wash thoroughly and then treat the wheels with a protective product for light alloy

wheels which does not cont ain any acidic components. We recommend to apply a

hard wax layer onto the wheel hubs every three months. You must not use any prod-

ucts which cause abrasion when treating the wheel hubs. Any damage to the paint

layer on the wheel hubs must be touched up immediately.

We recommend using a preservative from Šk oda genuine accessories offered by your

Škoda dealer.

WARNING

One should remember when cleaning th e wheels that moisture, ice and road

salt may adversely affect braking ef ficiency - risk of an accident!

Note

Severe layers of dirt on the wheels can also result in wheel imbalance. This may show

itself in the form of a wheel vibration which is transmitted to the steering wheel which,

in certain circumstances, can cause premature wear of the steering. This means it is

necessary to remove the dirt.

s43s.1.book Page 188 Thursday, May 13, 2010 1:21 PM

Page 208 of 275

Inspecting and replenishing207

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

We recommend having the vehicle checked by a Škoda Service Partner to ensure full

functionality of all electrical systems.

Replacing the batteryYou should only replace a battery with a ne

w battery of the same capacity, voltage (12

V), amperage and of the same size. Škoda Service Partners have a range of suitable

batteries available.

We recommend that you only have an old ba ttery disposed of by your Škoda Service

Partner since it does require special disposal.

For the sake of the environment

Batteries contain poisonous substances such as sulphuric acid and lead. They must be

disposed of in accordance with local environmental protection regulations and on no

account as domestic waste.

In view of the problems involved with it s proper disposal, we recommend having

the battery replaced by a specialist garage.

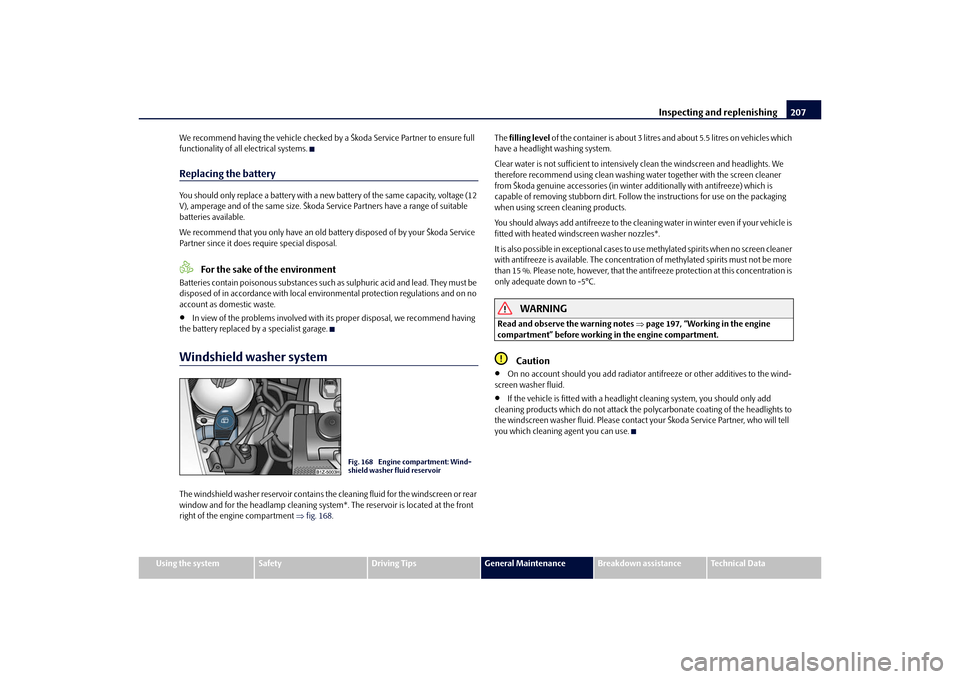

Windshield washer systemThe windshield washer reservoir contains the cleaning fluid for the windscreen or rear

window and for the headlamp cleaning system*. The reservoir is located at the front

right of the engine compartment fig. 168 . The

filling level of the container is about 3 litres and about 5.5 litres on vehicles which

have a headlight washing system.

Clear water is not sufficient to intensively clean the windscreen and headlights. We

therefore recommend using clean washing water together with the screen cleaner

from Škoda genuine accessories (in winter additionally with antifreeze) which is

capable of removing stubborn dirt. Follow the instructions for use on the packaging

when using screen cleaning products.

You should always add antifreeze to the cleaning water in winter even if your vehicle is

fitted with heated wind screen washer nozzles*.

It is also possible in exceptional cases to use methylated spirits when no screen cleaner

with antifreeze is available. The concentration of methylated spirits must not be more

than 15 %. Please note, however, that the anti freeze protection at this concentration is

only adequate down to -5°C.

WARNING

Read and observe the warning notes page 197, “Working in the engine

compartment” before working in the engine compartment.

Caution

On no account should you add radiator an tifreeze or other additives to the wind-

screen washer fluid.

If the vehicle is fitted with a headlight cleaning system, you should only add

cleaning products which do not attack the polycarbonate coating of the headlights to

the windscreen washer fluid. Please contac t your Škoda Service Partner, who will tell

you which cleaning agent you can use.

Fig. 168 Engine compartment: Wind-

shield washer fluid reservoir

s43s.1.book Page 207 Thursday, May 13, 2010 1:21 PM

Page 217 of 275

Breakdown assistance

216WARNING

If the fire extinguisher is not correctl y attached, in case of sudden manoeuvres

or an accident it can be “thrown” through the interior compartment and cause

injuries.

Note

The fire extinguisher must comply with the relevant and valid legal requirements.

Pay attention to the expiration date of the fire extinguisher. If the fire extinguisher

is used after the expiration date, its proper function is no longer assured.

The fire extinguisher is only supplied in certain countries within the scope of

delivery.

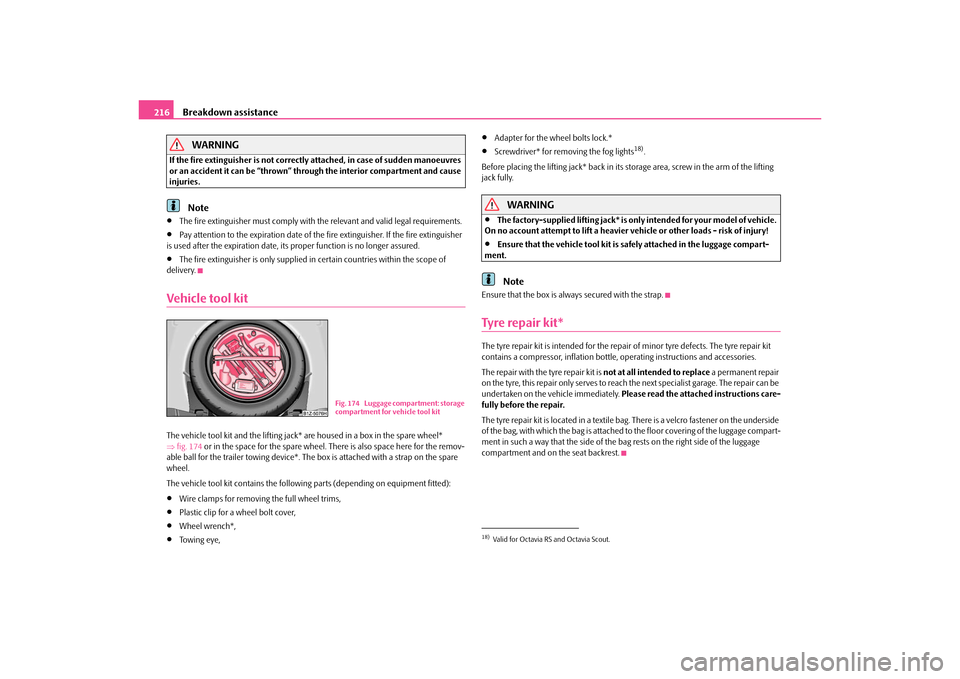

Vehicle tool kitThe vehicle tool kit and the lifting jack* are housed in a box in the spare wheel*

fig. 174 or in the space for the spare wheel. There is also space here for the remov-

able ball for the trailer towing device*. Th e box is attached with a strap on the spare

wheel.

The vehicle tool kit contains the following parts (depending on equipment fitted):

Wire clamps for removing the full wheel trims,

Plastic clip for a wheel bolt cover,

Wheel wrench*,

To w i n g e y e ,

Adapter for the wheel bolts lock.*

Screwdriver* for removing the fog lights

18).

Before placing the lifting jack* back in its storage area, screw in the arm of the lifting

jack fully.

WARNING

The factory-supplied lifting jack* is only intended for your model of vehicle.

On no account attempt to lift a heavier vehicle or other loads - risk of injury!

Ensure that the vehicle tool kit is sa fely attached in the luggage compart-

ment.Note

Ensure that the box is always secured with the strap.Tyre repair kit*The tyre repair kit is intended for the repair of minor tyre defects. The tyre repair kit

contains a compressor, inflation bottle, operating instructions and accessories.

The repair with the tyre repair kit is not at all intended to replace a permanent repair

on the tyre, this repair only serves to reach the next specialist garage. The repair can be

undertaken on the vehicle immediately. Please read the attached instructions care-

fully before the repair.

The tyre repair kit is located in a textile bag. There is a velcro fastener on the underside

of the bag, with which the bag is attached to the floor covering of the luggage compart-

ment in such a way that the side of the bag rests on the right side of the luggage

compartment and on the seat backrest.

Fig. 174 Luggage compartment: storage

compartment for vehicle tool kit

18)Valid for Octavia RS and Octavia Scout.

s43s.1.book Page 216 Thursday, May 13, 2010 1:21 PM

Page 218 of 275

Breakdown assistance217

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

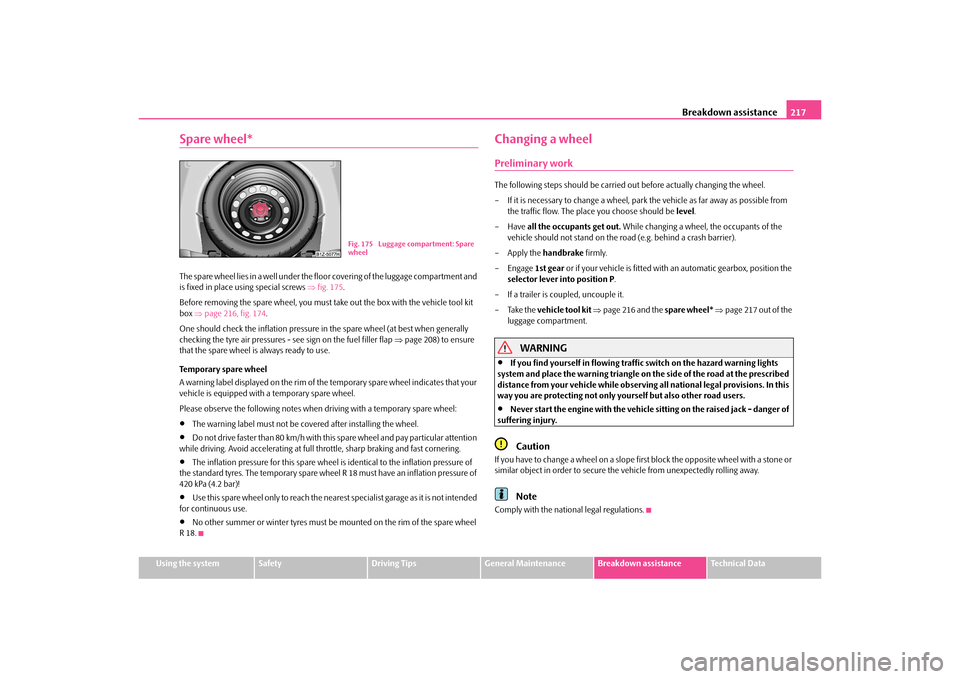

Spare wheel*The spare wheel lies in a well under the floor covering of the luggage compartment and

is fixed in place using special screws fig. 175 .

Before removing the spare wheel, you must take out the box with the vehicle tool kit

box page 216, fig. 174.

One should check the inflation pressure in the spare wheel (at best when generally

checking the tyre air pressures - see sign on the fuel filler flap page 208) to ensure

that the spare wheel is always ready to use.

Temporary spare wheel

A warning label displayed on the rim of the temporary spare wheel indicates that your

vehicle is equippe d with a temporary spare wheel.

Please observe the following notes when driving with a temporary spare wheel:

The warning label must not be covered after installing the wheel.

Do not drive faster than 80 km/h with this spare wheel and pay particular attention

while driving. Avoid accelerating at full throttle, sharp braking and fast cornering.

The inflation pressure for this spare wheel is identical to the inflation pressure of

the standard tyres. The temporary spare wheel R 18 must have an inflation pressure of

420 kPa (4.2 bar)!

Use this spare wheel only to reach the nearest specialist garage as it is not intended

for continuous use.

No other summer or winter tyres must be mounted on the rim of the spare wheel

R 18.

Changing a wheelPreliminary workThe following steps should be carried ou t before actually changing the wheel.

– If it is necessary to change a wheel, park the vehicle as far away as possible from

the traffic flow. The place you choose should be level.

–Have all the occupants get out. While changing a wheel, the occupants of the

vehicle should not stand on the ro ad (e.g. behind a crash barrier).

– Apply the handbrake firmly.

–Engage 1st gear or if your vehicle is fitted with an automatic gearbox, position the

selector lever into position P .

– If a trailer is coupled, uncouple it.

–Take the vehicle tool kit page 216 and the spare wheel* page 217 out of the

luggage compartment.

WARNING

If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle on the side of the road at the prescribed

distance from your vehicle while observin g all national legal provisions. In this

way you are protecting not only yourself but also other road users.

Never start the engine with the vehicle si tting on the raised jack - danger of

suffering injury.Caution

If you have to change a wheel on a slope fi rst block the opposite wheel with a stone or

similar object in order to secure the vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.

Fig. 175 Luggage compartment: Spare

wheel

s43s.1.book Page 217 Thursday, May 13, 2010 1:21 PM

Page 223 of 275

Breakdown assistance

222

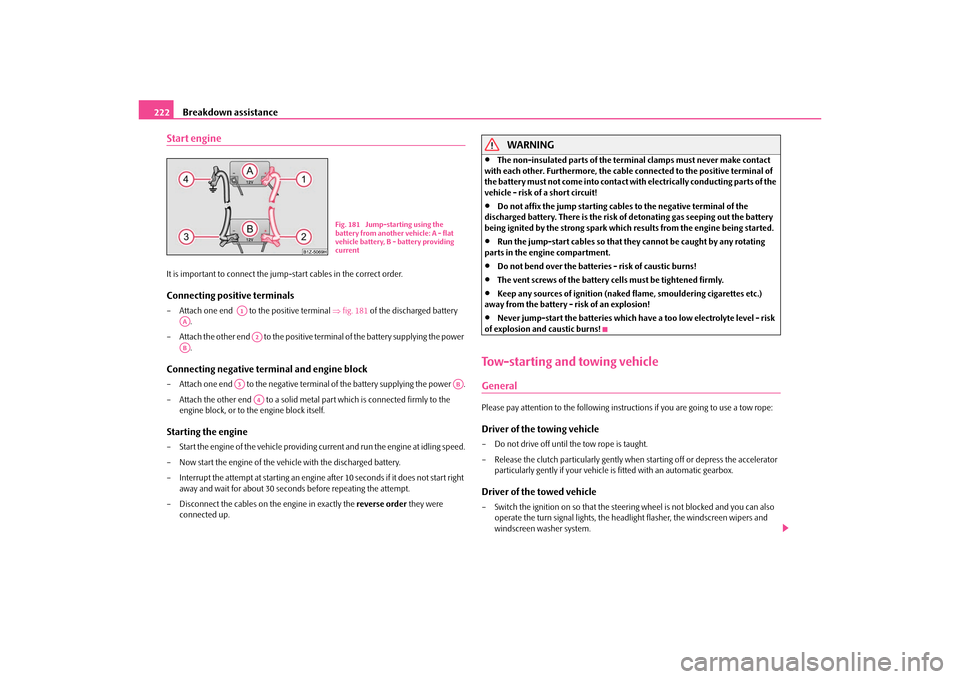

Start engineIt is important to connect the jump -start cables in the correct order.Connecting positive terminals– Attach one end to the positive terminal fig. 181 of the discharged battery

.

– Attach the other end to the positive term inal of the battery supplying the power

.Connecting negative terminal and engine block– Attach one end to the negative termin al of the battery supplying the power .

– Attach the other end to a solid metal part which is connected firmly to the

engine block, or to the engine block itself.Starting the engine– Start the engine of the vehicle providing current and run the engine at idling speed.

– Now start the engine of the vehicle with the discharged battery.

– Interrupt the attempt at starting an engine after 10 seconds if it does not start right

away and wait for about 30 seconds before repeating the attempt.

– Disconnect the cables on the engine in exactly the reverse order they were

connected up.

WARNING

The non-insulated parts of the terminal clamps must never make contact

with each other. Furthermore, the cable connected to the positive terminal of

the battery must not come into contact with electrically conducting parts of the

vehicle - risk of a short circuit!

Do not affix the jump starting cables to the negative terminal of the

discharged battery. There is the risk of detonating gas seeping out the battery

being ignited by the strong spark which results from the engine being started.

Run the jump-start cables so that they cannot be caught by any rotating

parts in the engine compartment.

Do not bend over the batteries - risk of caustic burns!

The vent screws of the battery cells must be tightened firmly.

Keep any sources of ignition (naked flame, smouldering cigarettes etc.)

away from the battery - risk of an explosion!

Never jump-start the batteries which ha ve a too low electrolyte level - risk

of explosion and caustic burns!

Tow-starting and towing vehicleGeneralPlease pay attention to the following instru ctions if you are going to use a tow rope:Driver of the towing vehicle– Do not drive off until the tow rope is taught.

– Release the clutch particularly gently wh en starting off or depress the accelerator

particularly gently if yo ur vehicle is fitted with an automatic gearbox.Driver of the towed vehicle– Switch the ignition on so that the steeri ng wheel is not blocked and you can also

operate the turn signal lights, the headlight flasher, the windscreen wipers and

windscreen washer system.

Fig. 181 Jump-starting using the

battery from another vehicle: A - flat

vehicle battery, B - battery providing

current

A1

AA

A2

AB

A3

AB

A4

s43s.1.book Page 222 Thursday, May 13, 2010 1:21 PM

Page 231 of 275

Fuses and light bulbs

230

We therefore recommend that you have an y bulbs changed by an authorised Škoda

Service Partner or, in exceptional cases, by calling on other professional assistance.

Please note that the engine compartment is a hazardous area page 197, “Working

in the engine compartment”.

We recommend that you always have a small box of replacement bulbs in your vehicle.

You can obtain replacement bulbs from Škoda original accessories or from a specialist

garage

21).

A stowage place for the bulbs is located in the box in the spare wheel.

Fitted with a xenon headlight

Change of bulbs on vehicles with Xenon lights (low beam lights, parking lights and

main beam lights) should be und ertaken by a specialist garage.

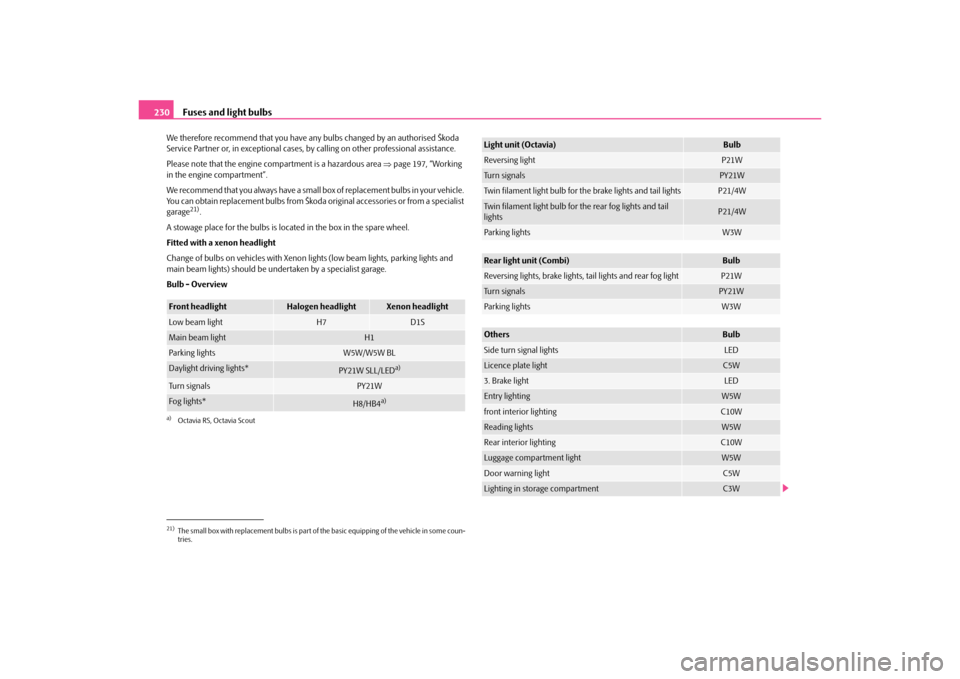

Bulb - Overview

21)The small box with replacement bulbs is part of the basic equipping of the vehicle in some coun-

tries.Front headlight

Halogen headlight

Xenon headlight

Low beam light

H7

D1S

Main beam light

H1

Parking lights

W5W/W5W BL

Daylight driving lights*

PY21W SLL/LED

a)

a)Octavia RS, Octavia ScoutTu r n s i g n a l s

PY21W

Fog lights*

H8/HB4

a)

Light unit (Octavia)

Bulb

Reversing light

P21W

Turn signals

PY21W

Twin filament light bulb for th e brake lights and tail lights

P21/4W

Twin filament light bulb for the rear fog lights and tail

lights

P21/4W

Parking lights

W3W

Rear light unit (Combi)

Bulb

Reversing lights, brake lights, tail lights and rear fog light

P21W

Turn signals

PY21W

Parking lights

W3W

Others

Bulb

Side turn signal lights

LED

Licence plate light

C5W

3. Brake light

LED

Entry lighting

W5W

front interior lighting

C10W

Reading lights

W5W

Rear interior lighting

C10W

Luggage compartment light

W5W

Door warning light

C5W

Lighting in storage compartment

C3W

s43s.1.book Page 230 Thursday, May 13, 2010 1:21 PM

Page 232 of 275

Fuses and light bulbs231

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

WARNING

Bulbs H7 and H1 are pressurised and may burst when changing the bulb -

risk of injury!

It is recommended to wear gloves and safety glasses when changing a bulb.

Gas discharge bulbs* (xenon bulbs) operate with a high voltage, profes-

sional knowledge is required - danger to life!Caution

Do not take hold of the glass bulb with naked fingers (even the smallest amount of dirt

reduces the working life of the light bulb). Use a clean cloth, serviette or something

similar.

Note

This Owner's Manual only describes the replacement of bulbs where it is assumed that

no major complications will arise. Other light bulbs should be replaced by your

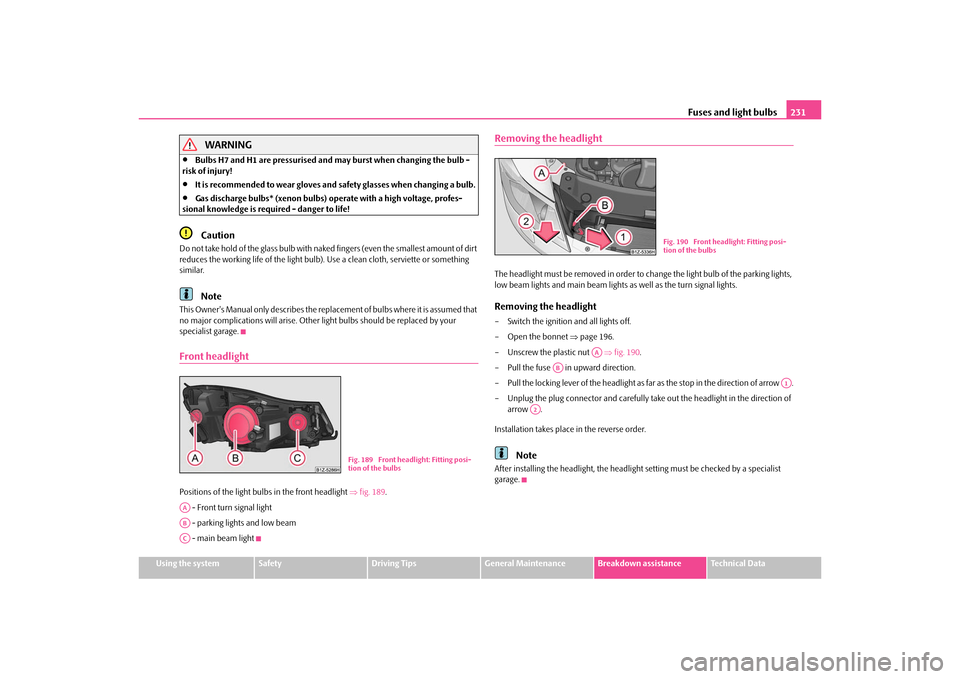

specialist garage.Front headlightPositions of the light bulbs in the front headlight fig. 189 .

- Front turn signal light

- parking lights and low beam

- main beam light

Removing the headlightThe headlight must be removed in order to ch ange the light bulb of the parking lights,

low beam lights and main beam lights as well as the turn signal lights.Removing the headlight– Switch the ignition and all lights off.

– Open the bonnet page 196.

– Unscrew the plastic nut fig. 190 .

– Pull the fuse in upward direction.

– Pull the locking lever of the headlight as far as the stop in the direction of arrow .

– Unplug the plug connector and carefully ta ke out the headlight in the direction of

arrow .

Installation takes place in the reverse order.

Note

After installing the headlight, the headligh t setting must be checked by a specialist

garage.

Fig. 189 Front headlight: Fitting posi-

tion of the bulbs

AAABAC

Fig. 190 Front headlight: Fitting posi-

tion of the bulbs

AA

AB

A1

A2

s43s.1.book Page 231 Thursday, May 13, 2010 1:21 PM

Page 265 of 275

Index

264

Child safety seat

on the front passenger seat . . . . . . . . . . . . . . . 160

Safety information . . . . . . . . . . . . . . . . . . . . . . . 159

Child seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161 Classification into groups . . . . . . . . . . . . . . . . . 161

ISOFIX system . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Use of child safety seats . . . . . . . . . . . . . . . . . . 162

Children and safety . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Chrome parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Cigarette lighter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Climatronic Defrosting windows . . . . . . . . . . . . . . . . . . . . . . 104

Recirculated air mode . . . . . . . . . . . . . . . . . . . . 103

Climatronic (automat ic air conditioning) . . . . . . 100

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Clothes hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Cockpit General view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Compartments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connection to the internet . . . . . . . . . . . . . . . . . . . 138

Convenience operation . . . . . . . . . . . . . . . . . . . . . . . . 48

Converting/masking over headlights . . . . . . . . . . 180

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 replenishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Coolant level Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Coolant quantity Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Coolant temperature gauge . . . . . . . . . . . . . . . . . . . . 16 Coolant temperature/coolant level

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cornering lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Correct seated position . . . . . . . . . . . . . . . . . . . . . . 142

Counter for distance driven . . . . . . . . . . . . . . . . . . . 17

Cruise control system . . . . . . . . . . . . . . . . . . . . . . . . 113 Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cup holder front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

DDaylight driving lights . . . . . . . . . . . . . . . . . . . . . . . . . 52

Deactivatingan airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Deactivating an airbag . . . . . . . . . . . . . . . . . . . . . . . 157

Defrosting rear window . . . . . . . . . . . . . . . . . . . . . . . 59

De-icing the windows . . . . . . . . . . . . . . . . . . . . . . . . 187

Detachable towing device . . . . . . . . . . . . . . . . . . . . 184

Diesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Diesel engines Starting the engine . . . . . . . . . . . . . . . . . . . . . . . 109

Diesel particle filter . . . . . . . . . . . . . . . . . . . . . . . . . . 173 Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Digital clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Direction indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Distance driven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Door Child safety lock . . . . . . . . . . . . . . . . . . . . . . . . . . 38 Driving economically . . . . . . . . . . . . . . . . . . . . . . . . 176

EEDL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Electric power-operated window

Operational faults . . . . . . . . . . . . . . . . . . . . . . . . . 48

Electric sliding/tilting roof . . . . . . . . . . . . . . . . . . . . . 48

Electrically adjustable exterior mirror . . . . . . . . . . . 65

Electronic Differential Lock . . . . . . . . . . . . . . . . . . . 168

Electronic immobiliser . . . . . . . . . . . . . . . . . . . . . . . . 38

Electronic stability programme . . . . . . . . . . . . . . . 167

Electronic stability programme (ESP) Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Engine starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Engine compartment Safety information . . . . . . . . . . . . . . . . . . . . . . . . 197

Engine electronics Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198 Changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

replenishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Engine oil level Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Engine revolutions counter . . . . . . . . . . . . . . . . . . . . 15

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Environmental compatibility . . . . . . . . . . . . . 176, 179

s43s.1.book Page 264 Thursday, May 13, 2010 1:21 PM