ECU SKODA RAPID SPACEBACK 2014 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2014 1.GPages: 204, PDF Size: 27.11 MB

Page 162 of 204

›Remove the fire extinguisher.›For mounting, fit the fire extinguisher back into the holder and secure it with

straps.

Please read carefully the instructions which are attached to the fire extin-

guisher.

The fire extinguisher must be checked by an authorised person once a year.

The national legal requirements must be observed.WARNINGThe fire extinguisher must always be secured safely so that they do not

come loose when making an emergency braking or in a vehicle collision

which could cause injuries to occupants.

Note

■ The fire extinguisher must comply with national legal requirements.■Pay attention to the expiration date of the fire extinguisher. Proper function-

ing of the fire extinguisher is not assured once it has passed its expiry date.■

The fire extinguisher is part of the scope of delivery in certain countries only.

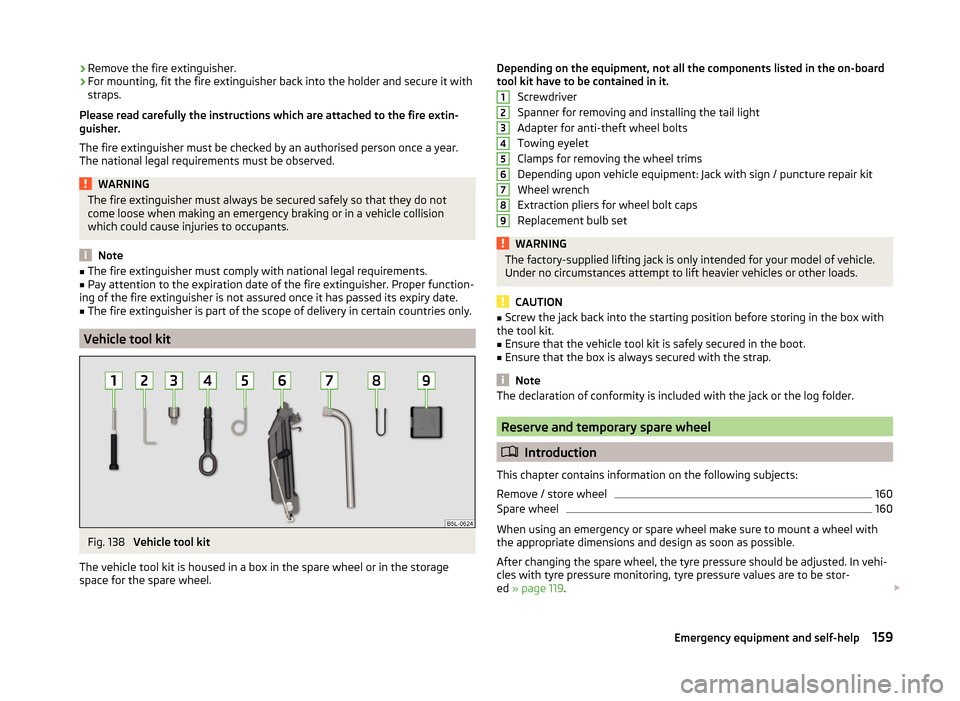

Vehicle tool kit

Fig. 138

Vehicle tool kit

The vehicle tool kit is housed in a box in the spare wheel or in the storage

space for the spare wheel.

Depending on the equipment, not all the components listed in the on-board

tool kit have to be contained in it.

Screwdriver

Spanner for removing and installing the tail light

Adapter for anti-theft wheel bolts

Towing eyelet

Clamps for removing the wheel trims

Depending upon vehicle equipment: Jack with sign / puncture repair kit

Wheel wrench

Extraction pliers for wheel bolt caps

Replacement bulb setWARNINGThe factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift heavier vehicles or other loads.

CAUTION

■ Screw the jack back into the starting position before storing in the box with

the tool kit.■

Ensure that the vehicle tool kit is safely secured in the boot.

■

Ensure that the box is always secured with the strap.

Note

The declaration of conformity is included with the jack or the log folder.

Reserve and temporary spare wheel

Introduction

This chapter contains information on the following subjects:

Remove / store wheel

160

Spare wheel

160

When using an emergency or spare wheel make sure to mount a wheel with

the appropriate dimensions and design as soon as possible.

After changing the spare wheel, the tyre pressure should be adjusted. In vehi- cles with tyre pressure monitoring, tyre pressure values are to be stor-

ed » page 119 .

123456789159Emergency equipment and self-help

Page 163 of 204

WARNING■If, in the case of puncture occurring, the spare tyre with a non-bound di-

rection or an opposite direction of rotation must be mounted, then drive

carefully. The best properties of the tyre are no longer present in this situa-

tion.■

If the dimensions or design of the spare wheel differ from the tyres fitted

to the vehicle (e.g. winter tyres or low-profile tyres), it must only be used

briefly in the event of a puncture and if an appropriately cautious style of

driving is adopted.

■

If the dimensions or design of the temporary spare wheel differ from the

fitted tyres, never drive faster than 80 km/h (or 50 mph).

■

Never use the temporary spare wheel if it is damaged.

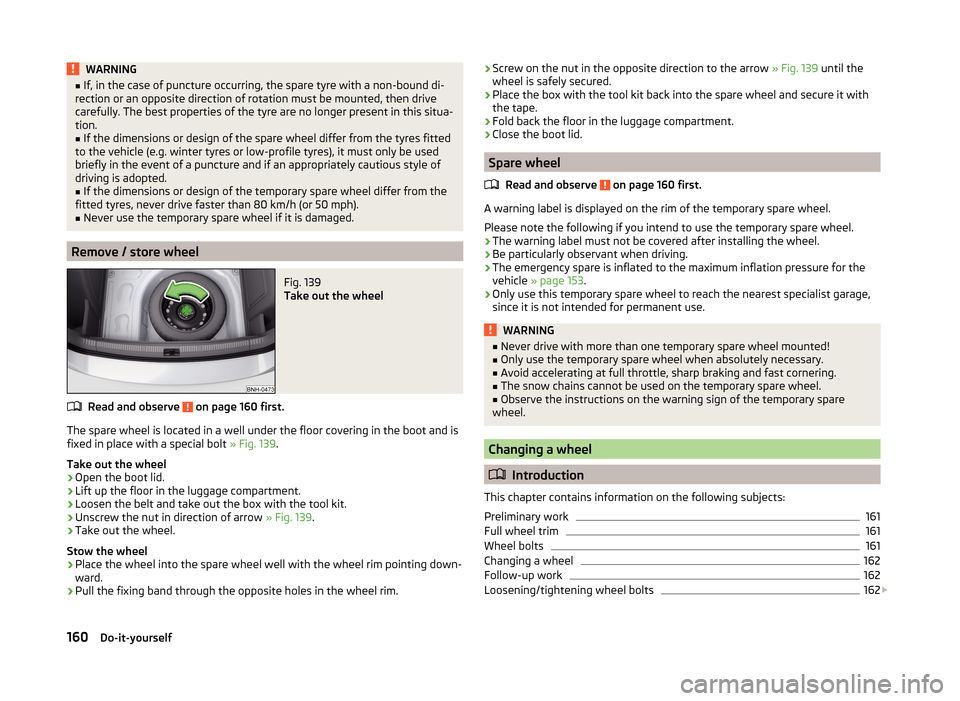

Remove / store wheel

Fig. 139

Take out the wheel

Read and observe on page 160 first.

The spare wheel is located in a well under the floor covering in the boot and is fixed in place with a special bolt » Fig. 139.

Take out the wheel

›

Open the boot lid.

›

Lift up the floor in the luggage compartment.

›

Loosen the belt and take out the box with the tool kit.

›

Unscrew the nut in direction of arrow » Fig. 139.

›

Take out the wheel.

Stow the wheel

›

Place the wheel into the spare wheel well with the wheel rim pointing down-

ward.

›

Pull the fixing band through the opposite holes in the wheel rim.

› Screw on the nut in the opposite direction to the arrow

» Fig. 139 until the

wheel is safely secured.›

Place the box with the tool kit back into the spare wheel and secure it with

the tape.

›

Fold back the floor in the luggage compartment.

›

Close the boot lid.

Spare wheel

Read and observe

on page 160 first.

A warning label is displayed on the rim of the temporary spare wheel.

Please note the following if you intend to use the temporary spare wheel. › The warning label must not be covered after installing the wheel.

› Be particularly observant when driving.

› The emergency spare is inflated to the maximum inflation pressure for the

vehicle » page 153 .

› Only use this temporary spare wheel to reach the nearest specialist garage,

since it is not intended for permanent use.

WARNING■ Never drive with more than one temporary spare wheel mounted!■Only use the temporary spare wheel when absolutely necessary.■

Avoid accelerating at full throttle, sharp braking and fast cornering.

■

The snow chains cannot be used on the temporary spare wheel.

■

Observe the instructions on the warning sign of the temporary spare

wheel.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preliminary work

161

Full wheel trim

161

Wheel bolts

161

Changing a wheel

162

Follow-up work

162

Loosening/tightening wheel bolts

162

160Do-it-yourself

Page 165 of 204

Installing›Push the cap onto the wheel bolt up to the stop.

Changing a wheel

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Alternately tighten wheel bolts opposite (diagonally) with the wheel wrench.

Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 155 .

WARNING■

Undo the wheel bolts only a little (about one turn) provided that the vehi-

cle has not yet been jacked up. Otherwise the wheel could become loose

and fall off.■

All bolts must be clean and must turn easily.

■

If it is established when changing a wheel that the wheel bolts are corro-

ded and difficult to move, then these must be replaced.

■

Under no circumstances grease or oil the wheel bolts!

Follow-up work

After changing the wheel, the following work must be carried out.

›

Stow and attach the replaced wheel in the spare wheel well using a special

screw » page 159 .

›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›Have the

tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.

After changing the wheel, the tyre pressure should be adjusted. In vehicles

with tyre pressure monitoring, tyre pressure values are to be stor-

ed » page 119 .

Replace the damaged wheel or consult a specialist garage about repair op-

tions.WARNINGInformation on the wheel bolts■The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving.

■

Drive cautiously and only at a moderate speed until the tightening torque

has been checked.

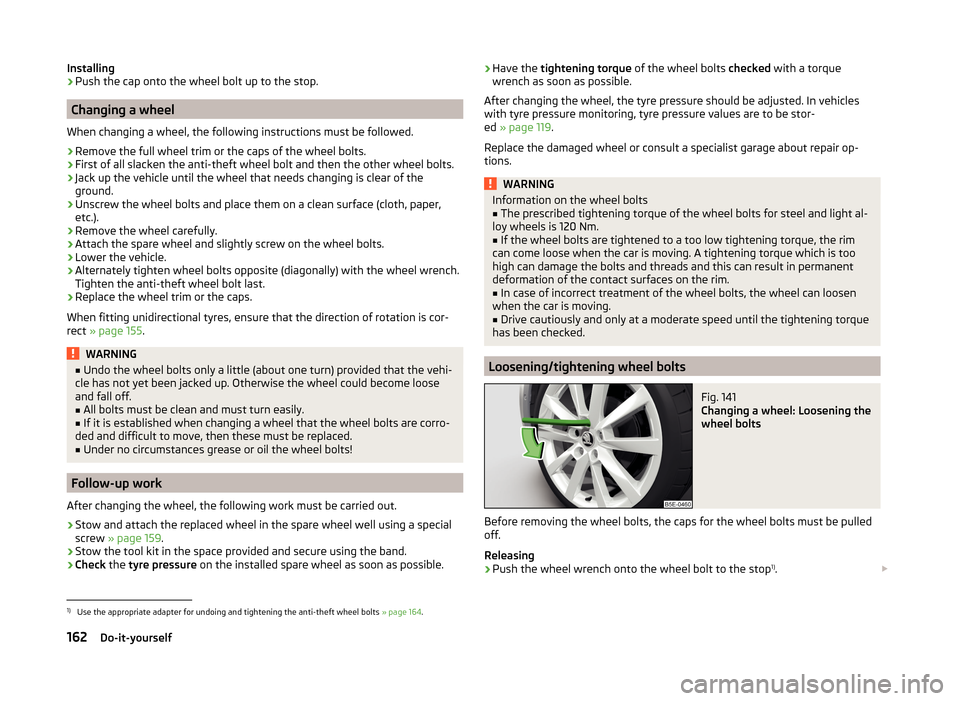

Loosening/tightening wheel bolts

Fig. 141

Changing a wheel: Loosening the

wheel bolts

Before removing the wheel bolts, the caps for the wheel bolts must be pulled

off.

Releasing

›

Push the wheel wrench onto the wheel bolt to the stop 1)

.

1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts

» page 164.

162Do-it-yourself

Page 166 of 204

›Grasp the end of the wrench and turn the bolt about

one turn in the direction

of the arrow » Fig. 141.

Tightening›

Push the wheel wrench onto the wheel bolt to the stop 1)

.

›

Grasp the end of the wrench and turn the bolt against the direction of the

arrow » Fig. 141 until it is tight.

After tightening the wheel bolts, the covering caps must be replaced.

WARNINGIf it proves difficult to undo the bolts, carefully apply pressure to the end of

the wrench with your foot. Keep hold of the vehicle when doing so, and

make sure you keep your footing.

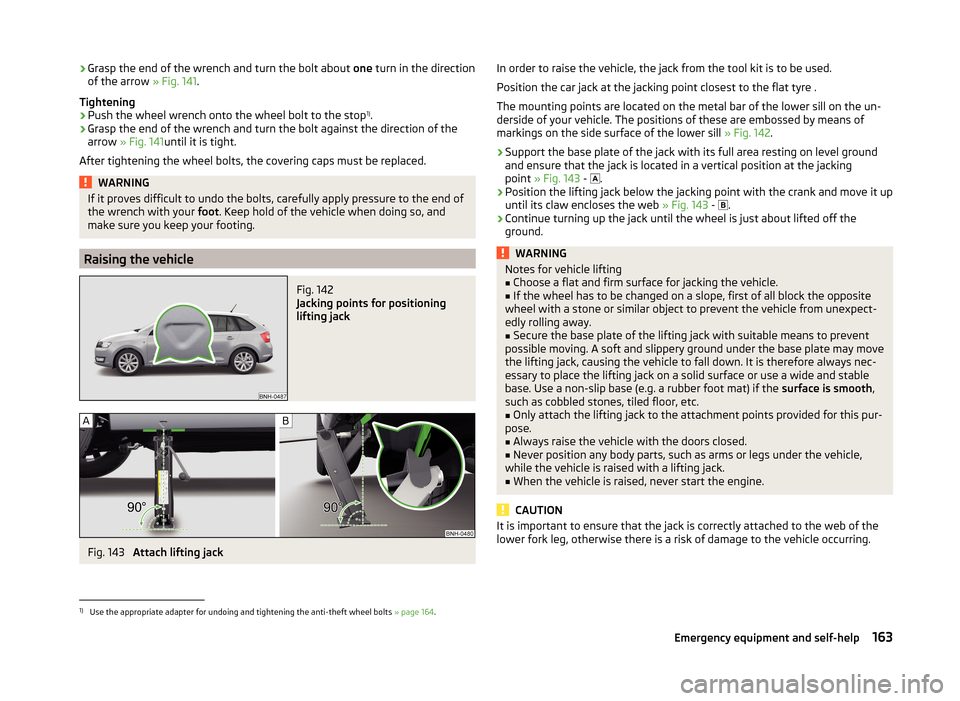

Raising the vehicle

Fig. 142

Jacking points for positioning

lifting jack

Fig. 143

Attach lifting jack

In order to raise the vehicle, the jack from the tool kit is to be used.

Position the car jack at the jacking point closest to the flat tyre .

The mounting points are located on the metal bar of the lower sill on the un-

derside of your vehicle. The positions of these are embossed by means of

markings on the side surface of the lower sill » Fig. 142.›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking

point » Fig. 143 -

.

›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 143 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNINGNotes for vehicle lifting■Choose a flat and firm surface for jacking the vehicle.■

If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.

■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the web of the

lower fork leg, otherwise there is a risk of damage to the vehicle occurring.1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts » page 164.

163Emergency equipment and self-help

Page 175 of 204

Replacing the windscreen wiper bladesFig. 155

Windscreen wiper blade

Read and observe

on page 171 first.

Before replacing the windscreen wiper blade, put the windscreen wiper arms

into the service position.

Service position for changing wiper blades

›

Close the bonnet.

›

Switch the ignition on and off again.

›

Place the operating lever in position

4

» page 66 , Activating the windscreen

wipers and washers .

Move the windscreen wiper arms into the service position.

Removing the wiper blade

›

Lift the wiper arm from the window in the direction of

1

» Fig. 155 .

›

Tilt the wiper blade to the stop in the same direction.

›

Hold the upper part of the wiper arm and press the securing mechanism

A

in the direction of arrow

2

.

›

Remove the wiper blade in the direction of the arrow

3

.

Attaching the windscreen wiper blade

›

Push the windscreen wiper blade to the stop until it locks into place.

›

Check that the windscreen wiper blade is correctly attached.

›

Fold the windscreen wiper arm back to the windscreen.

›

Turn on the ignition and press the lever into position

4

» page 66 , Activat-

ing the windscreen wipers and washers .

Move the windscreen wiper arms into the home position.

Replacing the rear window wiper bladeFig. 156

Rear window wiper blade

Read and observe

on page 171 first.

Removing the wiper blade

›

Lift the wiper arm from the window in the direction of

1

» Fig. 156 .

›

Tilt the wiper blade to the stop in the same direction.

›

Hold the upper part of the wiper arm and press the securing mechanism

A

in the direction of arrow

2

.

›

Remove the wiper blade in the direction of the arrow

3

.

Attaching the windscreen wiper blade

›

Push the windscreen wiper blade to the stop until it locks into place.

›

Check that the windscreen wiper blade is correctly attached.

›

Fold the windscreen wiper arm back to the windscreen.

172Do-it-yourself

Page 178 of 204

No.Power consumer43Horn44Windscreen wipers45Boot lid lock, central locking system46Alarm47Cigarette lighter48ABS49Turn signal lights, brake lights50DC-DC converter, radio51Electric windows (driver's window and rear left window)52Electric windows (front passenger's window and rear right)53Windscreen washer54START-STOP instrument cluster, operating lever under the steering

wheel, multifunction steering wheel55Control unit for automatic gearbox56Headlight cleaning system57Headlights front, rear58Headlights front, rear

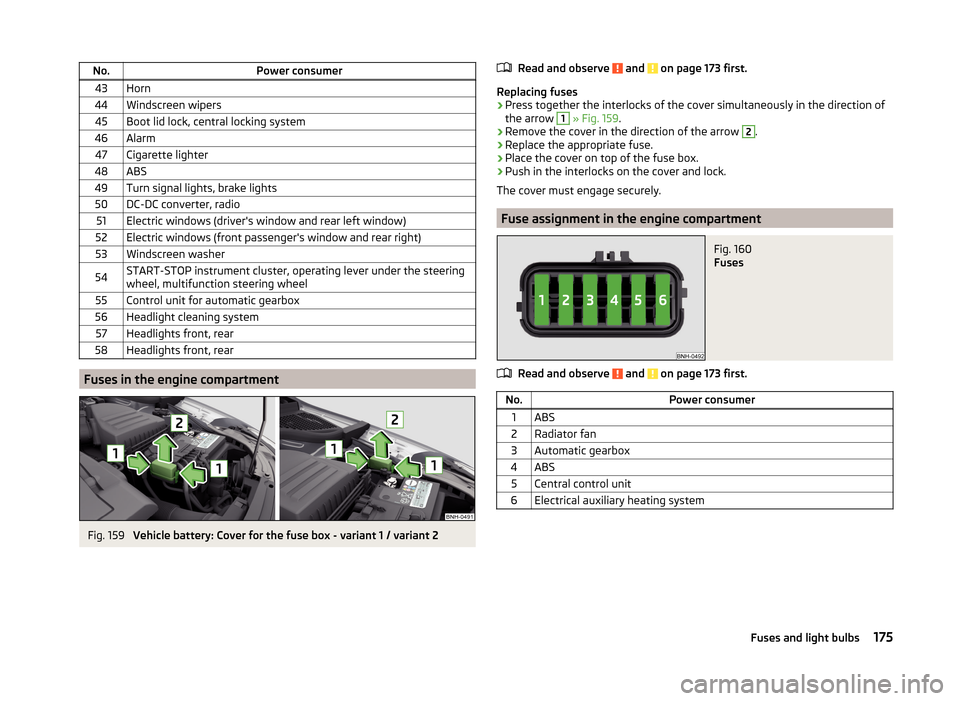

Fuses in the engine compartment

Fig. 159

Vehicle battery: Cover for the fuse box - variant 1 / variant 2

Read and observe and on page 173 first.

Replacing fuses

›

Press together the interlocks of the cover simultaneously in the direction of

the arrow

1

» Fig. 159 .

›

Remove the cover in the direction of the arrow

2

.

›

Replace the appropriate fuse.

›

Place the cover on top of the fuse box.

›

Push in the interlocks on the cover and lock.

The cover must engage securely.

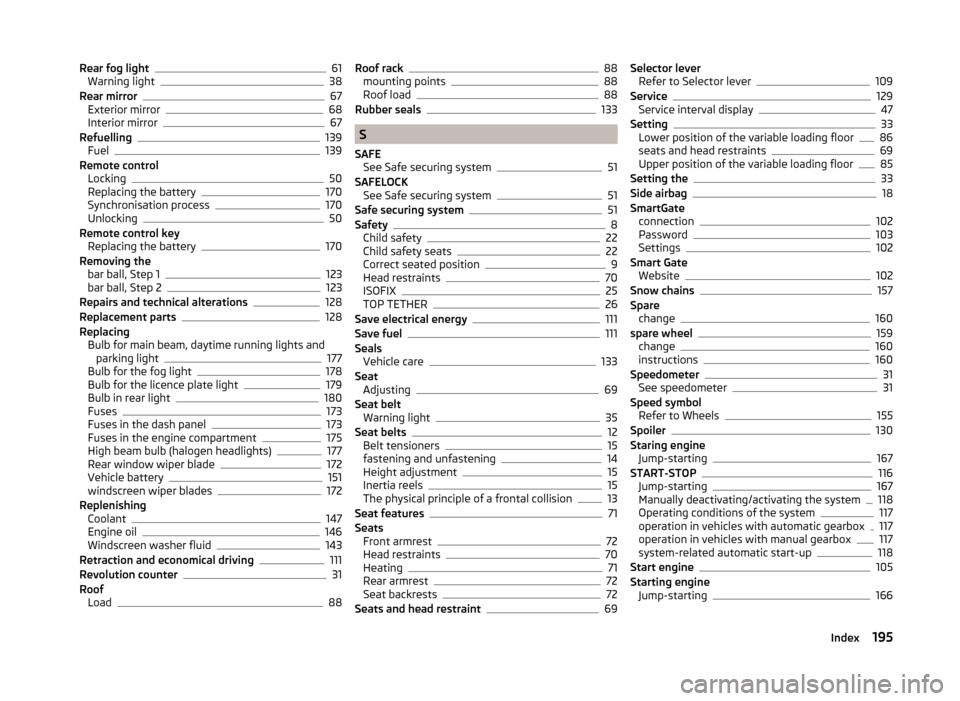

Fuse assignment in the engine compartment

Fig. 160

Fuses

Read and observe and on page 173 first.

No.Power consumer1ABS2Radiator fan3Automatic gearbox4ABS5Central control unit6Electrical auxiliary heating system175Fuses and light bulbs

Page 182 of 204

›Attach the connector.

Refit the headlight and grille›

Replace the fog light by inserting it in the opposite direction of the arrow

4

» Fig. 166 and tightening.

›

Insert the protective grille and carefully press it in.

The protective grille must engage firmly.

Replacing the bulb for the licence plate light

Fig. 167

Remove the number plate light/replace the bulb

Read and observe

and on page 176 first.

›

Open the boot lid.

›

Push in the lamp in the direction of the arrow

1

» Fig. 167 .

The lamp comes loose.

›

Swivel out the lamp in the direction of the arrow

2

and remove it.

›

Remove the faulty bulb from the holder in the direction of the arrow

3

.

›

Insert a new bulb into the holder.

›

Reinsert the lamp in the opposite direction to the arrow

1

.

›

Push on the light until the spring clicks into place.

Check that the light is securely inserted.

Rear LightFig. 168

Remove light / pull out connector

Read and observe

and on page 176 first.

Removing

›

Open the boot lid.

›

Insert the clamps for removing the full wheel covers » page 159, Vehicle tool

kit into opening

A

» Fig. 168 .

›

Remove the cover by pulling the hook in the direction of arrow

1

.

›

Unscrew the screws

B

with the key from the tool kit.

›

Grasp the lamp and carefully remove in the direction of arrow

2

.

›

Press the latch on the connector in the direction of arrow

3

.

›

Carefully remove the connector from the tail lamp assembly in the direction

of the arrow

4

.

Fitting

›

Insert the bulb holder into the lamp.

The lock on the plug must be inserted securely.

›

Insert the lamp with the pin

B

» Fig. 169 on page 180 into the recesses

C

» Fig. 168 in the body.

179Fuses and light bulbs

Page 183 of 204

›Carefully push the cover in

» .›Screw the tail lamp into place and install the cover.

The cover must engage securely.

CAUTION

■ Ensure that the cable bundle does not become pinched between the body

and the lamp when it is being refitted – risk of damage to the electrical instal-

lation and risk of water ingress.■

If you are not sure whether the cable bundle has become pinched, we recom-

mend that you have the light connection checked by a specialist garage.

■

Ensure that the vehicle paintwork and the tail lamp are not damaged when

removing and installing the tail lamp.

Replacing bulbs in rear light

Fig. 169

Outer part of the lamp/inner part of the lamp

Read and observe

and on page 176 first.

Outer part of the lamp

›

Rotate the lamp socket

A

» Fig. 169 in direction of arrow

1

and remove in

direction of arrow

2

from the lamp housing.

›

Changing the lamp, reinsert the holder with the bulb into the lamp housing

and turn in the opposite direction of the arrow

1

to the stop.

Inner parts of the lamp

›

Unlock the bulb holder using the marked area with arrows » Fig. 169 and re-

move the bulb holder from the light.

›

Turn the respective bulb counter clockwise until it stops.

›

Remove the holder from the lamp.

›

Insert a new bulb into the holder and turn in a clockwise direction to the

stop.

› Insert the bulb holder in the tail lamp assembly.

The lamp holder must engage firmly.180Do-it-yourself

Page 198 of 204

Rear fog light61

Warning light38

Rear mirror67

Exterior mirror68

Interior mirror67

Refuelling139

Fuel139

Remote control Locking

50

Replacing the battery170

Synchronisation process170

Unlocking50

Remote control key Replacing the battery

170

Removing the bar ball, Step 1

123

bar ball, Step 2123

Repairs and technical alterations128

Replacement parts128

Replacing Bulb for main beam, daytime running lights and parking light

177

Bulb for the fog light178

Bulb for the licence plate light179

Bulb in rear light180

Fuses173

Fuses in the dash panel173

Fuses in the engine compartment175

High beam bulb (halogen headlights)177

Rear window wiper blade172

Vehicle battery151

windscreen wiper blades172

Replenishing Coolant

147

Engine oil146

Windscreen washer fluid143

Retraction and economical driving111

Revolution counter31

Roof Load

88

Roof rack88

mounting points88

Roof load88

Rubber seals133

S

SAFE See Safe securing system

51

SAFELOCK See Safe securing system

51

Safe securing system51

Safety8

Child safety22

Child safety seats22

Correct seated position9

Head restraints70

ISOFIX25

TOP TETHER26

Save electrical energy111

Save fuel111

Seals Vehicle care

133

Seat Adjusting

69

Seat belt Warning light

35

Seat belts12

Belt tensioners15

fastening and unfastening14

Height adjustment15

Inertia reels15

The physical principle of a frontal collision13

Seat features71

Seats Front armrest

72

Head restraints70

Heating71

Rear armrest72

Seat backrests72

Seats and head restraint69

Selector lever Refer to Selector lever109

Service129

Service interval display47

Setting33

Lower position of the variable loading floor86

seats and head restraints69

Upper position of the variable loading floor85

Setting the33

Side airbag18

SmartGate connection

102

Password103

Settings102

Smart Gate Website

102

Snow chains157

Spare change

160

spare wheel159

change160

instructions160

Speedometer31

See speedometer31

Speed symbol Refer to Wheels

155

Spoiler130

Staring engine Jump-starting

167

START-STOP116

Jump-starting167

Manually deactivating/activating the system118

Operating conditions of the system117

operation in vehicles with automatic gearbox117

operation in vehicles with manual gearbox117

system-related automatic start-up118

Start engine105

Starting engine Jump-starting

166

195Index