parking brake switch SKODA SUPERB 2015 3.G / (B8/3V) User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: SUPERB, Model: SKODA SUPERB 2015 3.G / (B8/3V)Pages: 276, PDF Size: 42.14 MB

Page 138 of 276

WARNING (Continued)■If the vehicle is in the D, S , R or Tiptronic mode and comes to a standstill

while at idle the engine stops, then prevent the vehicle from rolling away

with the brake pedal, the parking brake of the auto-hold function. Even

when the engine is idling, the power transmission is never completely in-

terrupted – the vehicle creeps.■

When leaving the vehicle, the selector lever is always to put in the P

mode. Otherwise, the vehicle could start to move - risk of accident.

CAUTION

■ If the selector lever is moved to mode N while driving, the accelerator pedal

must be released and you will need to wait until the engine has reached its

idling speed before moving the selector lever to a forward driving mode again.■

When the outdoor temperature is below -10 ° C, the selector lever when

starting must always be in P mode.

■

When stopping on a slope, never try to hold the vehicle using the accelerator

pedal – this may lead to gear damage.

Note

After the ignition is switched off, the ignition key can only be withdrawn if the

selector lever is in the position P.

Modes and use of selector lever

Fig. 169

Selector lever/display

Read and observe and on page 135 first.

When the ignition is switched on, the gearbox mode and the currently selected

gear are indicated in the display » Fig. 169.

The following modes can be selected with the selector lever » Fig. 169.

P – Parking mode

The driven wheels are locked mechanically in this mode.

The parking mode must only be selected when the vehicle is stationary.R

- Reverse gear

Reverse gear can only be engaged when the vehicle is stationary and the en-

gine is at idling speed.

N

- Neutral

The power transmission to the drive wheels is interrupted in this mode.

D

/

S

- mode for driving forward (Normal program) / mode for driving

forward (Sport program)

The system switches from one mode to the other by moving the selector lever

into the spring-loaded position

» Fig. 169 .

In mode D or S, the forward gears are shifted automatically depending on the

engine load, the operation of the accelerator pedal, the vehicle speed, and the

selected driving mode .

In mode S , the forward gears are shifted automatically up and down at high-

er engine speeds than in mode D.

If the Sport driving mode is selected with the engine running » page 171, Se-

lection of the driving mode(Driving Mode Selection) , the transmission is auto-

matically set in the S mode.

E – Economical driving mode

If the driving mode Eco or Individual (engine - Eco) » page 171 is selected and

the selection lever is in the setting D/S, the transmission is automatically set

to mode E. This mode cannot be selected with the selector lever.

In mode E , the forward gears are shifted automatically up and down at lower

engine speeds than in mode D.

136Driving

Page 148 of 276

The automatic brake interventions can take place only if the following condi-

tions are met.

There was a front, side and rear-end collision of a certain severity.

The impact speed was higher than approx. 10 km/h.

The brakes, the ESL and other required electrical systems remain function-

al after impact.

The accelerator pedal is not actuated.

Trailer stabilization system (TSA)

Read and observe

on page 144 first.

The TSA helps the combination stable in situations where the trailer sways

and then the whole trailer combination.

TSA brakes the individual wheels of the towing vehicle in order to damp the rocking motion of the entire vehicle combination.

The following conditions are required for the correct TSA function. The trailer was shipped from the factory or purchased from the ŠKODA

genuine accessories.

The trailer is electrically connected to the towing vehicle via the trailer

socket.

The parking aid is activated.

The speed is higher than approx. 60 km/h.

Further information » page 184, Hitch and trailer .

Auto Hold function

Fig. 176

The Auto-Hold function button

Read and observe on page 144 first.

The Auto Hold function (hereinafter referred to only as system) prevents the

vehicle from rolling unintentionally when stopped. It is, for example, not nec-

essary to secure the vehicle with the brake pedal or parking brake at traffic

lights.

For the activation, deactivation and correct functioning of the system, the

following basic conditions are required.

The driver's door is closed.

The engine is running (or shut-down automatically by the START-STOP

system).

On vehicles with automatic transmission the selector lever is not in mode

N (in this mode, the system is not available).

Stopping and starting

When stopping the system prevents the vehicle from rolling away. The warn- ing light illuminates in the instrument cluster. The brake pedal can be re-

leased.

The vehicle's brakes are released at the moment of stating off. The warning

light in the instrument cluster goes out.

Should the vehicle start to roll away when starting on a downhill slope then

step on the accelerator or and turn on the parking brake.

If the vehicle is secured by the system and the driver's door is opened or the ignition is turned off, the vehicle is secured by the parking brake to prevent

unwanted movement.

In this case, the indicator light turns off in the instrument cluster and the

warning light illuminates.

Activation/deactivation

The activation and deactivation of the system is done by pressing the symbol

key

» Fig. 176 .

When the system is activated, the symbol illuminates.

After switching off and switching on the ignition system several times the sys-

tem remains either activated or deactivated depending on the last setting.

146Driving

Page 157 of 276

›Stop the vehicle and steer opposite until the yellow lines 6 the red line 8fade into each other (required roadway alignment). Hold the steering wheel

in this position.

Orientation lines are displayed » Fig. 187 on page 153 in the display.›

Carefully move backwards.

›

Stop the vehicle when

appears the display, or at a safe distance from the

obstacle situated behind the vehicle.

Note

The guidance in the parking space is cancelled due to the system when the

steering wheel is set for a period of time against the required road direction.

The parking is to be started again.

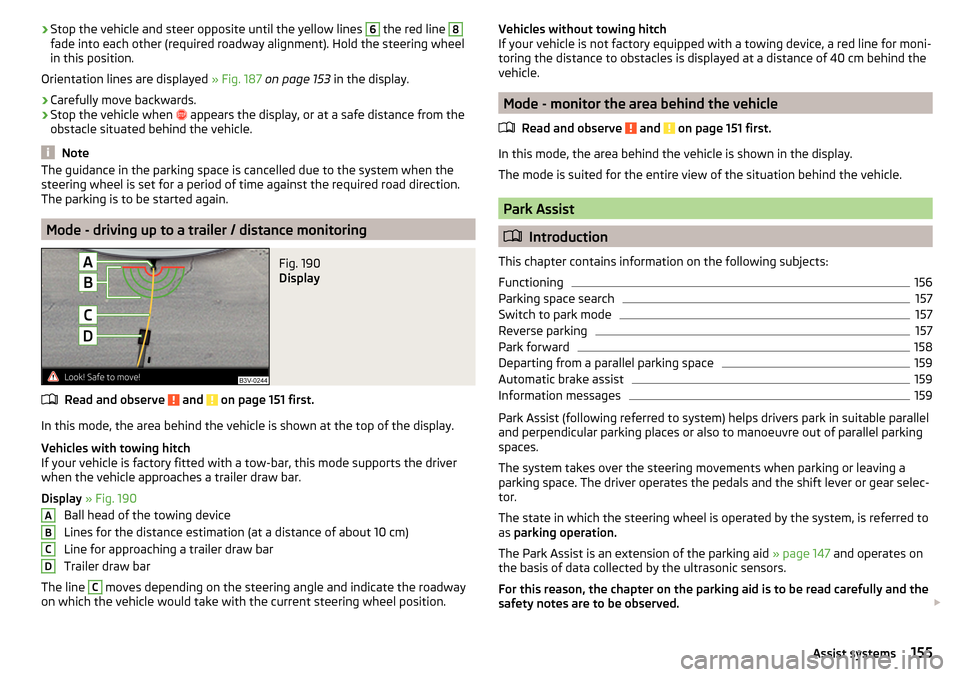

Mode - driving up to a trailer / distance monitoring

Fig. 190

Display

Read and observe and on page 151 first.

In this mode, the area behind the vehicle is shown at the top of the display.

Vehicles with towing hitch

If your vehicle is factory fitted with a tow-bar, this mode supports the driver

when the vehicle approaches a trailer draw bar.

Display » Fig. 190

Ball head of the towing device

Lines for the distance estimation (at a distance of about 10 cm)

Line for approaching a trailer draw bar

Trailer draw bar

The line

C

moves depending on the steering angle and indicate the roadway

on which the vehicle would take with the current steering wheel position.

ABCDVehicles without towing hitch

If your vehicle is not factory equipped with a towing device, a red line for moni-

toring the distance to obstacles is displayed at a distance of 40 cm behind the

vehicle.

Mode - monitor the area behind the vehicle

Read and observe

and on page 151 first.

In this mode, the area behind the vehicle is shown in the display.

The mode is suited for the entire view of the situation behind the vehicle.

Park Assist

Introduction

This chapter contains information on the following subjects:

Functioning

156

Parking space search

157

Switch to park mode

157

Reverse parking

157

Park forward

158

Departing from a parallel parking space

159

Automatic brake assist

159

Information messages

159

Park Assist (following referred to system) helps drivers park in suitable parallel

and perpendicular parking places or also to manoeuvre out of parallel parking

spaces.

The system takes over the steering movements when parking or leaving a

parking space. The driver operates the pedals and the shift lever or gear selec-

tor.

The state in which the steering wheel is operated by the system, is referred to

as parking operation.

The Park Assist is an extension of the parking aid » page 147 and operates on

the basis of data collected by the ultrasonic sensors.

For this reason, the chapter on the parking aid is to be read carefully and the safety notes are to be observed.

155Assist systems

Page 208 of 276

After refilling›After refilling AdBlue®

put the cap on the fuel filler neck and turn in the oppo-

site direction of the arrow 3

until it engages.

›

Close the fuel filler flap until it clicks into place.

Before driving

›

After filling AdBlue ®

only switch on the ignition and leave it on for at least 30

s, so that the refilling can be recognized by the system.

Only then start the engine.

CAUTION

The AdBlue ®

- tank is full when no AdBlue ®

flows from the refill bottle or as

soon as the correctly operated pump cuts out for the first time. Do not contin-

ue refilling AdBlue ®

.

Note

The working life of the AdBlue ®

solution is 4 years. Thereafter the solution

must be replaced by a specialist garage.

Engine compartment

Introduction

This chapter contains information on the following subjects:

Opening and closing the bonnet

207

Engine compartment overview

208

Radiator fan

208

Windscreen washer system

208WARNINGInjuries or scolding or risks of accident or fire may occur when working in

the engine compartment. For this reason, it is essential to comply with the

warning instructions outlined below and with the general applicable safety

rules. The engine compartment of your car is a hazardous area!WARNINGInstructions before beginning work in the engine compartment■Turn off the engine and remove the ignition key.■

The parking brake switch.

WARNING (Continued)■ For vehicles with manual transmission the lever into the neutral position.■On vehicles with automatic transmission, shift the selector lever into the

P position.■

Allow the engine to cool.

■

Never open the bonnet if you can see steam or coolant escaping from the

engine compartment – risk of scalding! Wait until no more steam or coolant

is escaping.

WARNINGInformation for working in the engine room■Keep all people, especially children, away from the engine compartment.■

Never touch the radiator fan. The fan might suddenly start running!

■

Do not touch any hot engine parts – risk of burns!

WARNINGInformation for working in the engine compartment with the engine run-

ning■

Pay particular attention to moving engine parts, e.g. V-ribbed belt, gener-

ator, radiator fan - danger to life!

■

Never touch the electric wiring on the ignition system.

■

Avoid short circuits in the electrical system, particularly on the vehicle's

battery.

■

Always make sure that no jewellery, loose clothing or long hair can get

caught in rotating engine parts – risk to life! Always remove any jewellery,

tie back long hair and wear tight fitting clothing before completing any

work.

WARNINGInformation for working on the fuel system or the electrical system■Always disconnect the vehicle battery from the electrical system.■

Do not smoke.

■

Never work near open flames.

■

Always have a functioning fire extinguisher nearby.

206General Maintenance

Page 226 of 276

WARNINGThe factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift heavier vehicles or other loads.

CAUTION

■ Screw the jack back into the starting position before storing in the box with

the tool kit.■

Ensure that the vehicle tool kit is safely secured in the boot.

■

Ensure that the box is always secured with the strap.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preparation

224

Removing/stowing the wheel

224

Full wheel trim

225

Wheel bolts

225

Anti-theft wheel bolts

225

Loosening/tightening wheel bolts

226

Raising the vehicle

226

Remove the wheel / fix

227

Follow-up tasks

227

For your own safety and the safety of the passengers, the following instruc-

tions must be observed before changing a wheel on the road.

Switch on the hazard warning lights system.

Place the warning triangle at the prescribed distance.

Park the vehicle as far away as possible from the flowing traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

Tyres with increased puncture resistance

Some vehicles may be fitted with tyres at the factory that have increased

puncture resistance (so-called “SEAL” tyres).

These vehicles are delivered without a puncture repair kit, spare wheel and

appropriate hand tools.

If the tyres with increased puncture resistance are replaced with tyres that

have no increased puncture resistance then the vehicle should be equipped

with a puncture repair kit, spare wheel and appropriate hand tools.

Preparation

Before changing the wheel, the following work must be carried out.

›

Switch off the engine.

›

For vehicles with manual transmission engage 1st gear.

›

On vehicles with

automatic transmission place the selector lever in the P po-

sition.

›

The parking brake switch.

›

Uncouple any trailers.

Removing/stowing the wheel

Fig. 242

Take out wheel

The wheel is located in a well under the floor covering in the boot and is fixed

in place with a special screw.

Take out wheel

›

Open the tailgate.

›

Lift up the floor in the luggage compartment.

›

Loosen the retaining belt and take out the box with the tool kit.

›

Unscrew the special screws in the direction of arrow » Fig. 242.

›

Remove the wheel.

224Do-it-yourself

Page 231 of 276

General informationRead and observe

on page 228 first.

For your own safety and the safety of your passengers, the following instruc-

tions must be observed before carrying out a wheel repair on the road.

Switch on the hazard warning lights system.

Place the warning triangle at the prescribed distance.

Park the vehicle as far away as possible from the flowing traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

The breakdown kit must not be used under the following circumstances. ▶ The rim is damaged.

▶ The outside temperature is below -20 ° C.

▶ The cut or puncture is larger than 4 mm.

▶ The tyre wall is damaged.

▶ After the expiration date (see inflation bottle).

Preparations for using the breakdown kit

Read and observe

on page 228 first.

The following preparatory work must be carried out before using the puncturerepair kit.

›

Switch off the engine.

›

For vehicles with manual transmission engage 1st gear.

›

On vehicles with

automatic transmission place the selector lever in the P po-

sition.

›

The parking brake switch.

›

Check that you can carry out the repairs with the breakdown kit » page 228.

›

Uncouple any trailers.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

1

» Fig. 248 on page 228 on the dashboard in the driver's

field of view.

›

Unscrew the valve cap.

›

Use the valve remover

2

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

Sealing and inflating the tyre

Read and observe

on page 228 first.

Sealing

›

Forcefully shake the tyre inflation bottle

10

» Fig. 248 on page 228 back and

forth several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

. The film on

the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the air compressor tyre inflation hose

7

» Fig. 248 on page 228 firmly

onto the tyre valve.

›

For vehicles with manual transmission the lever into the neutral position.

›

On vehicles with automatic transmission place the selector lever in the P po-

sition.

›

Start the engine and run it in idle.

›

Plug the connector

6

into 12 volt socket » page 100.

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

7

from the tyre valve.

Once a tyre inflation pressure of 2.0 - 2.5 bar is achieved, you can continue the journey.

229Emergency equipment and self-help

Page 239 of 276

›Fold the rear seat backrest forward

» page 85.›Insert a screwdriver or similar tool into the recess or the opening in the trim

» Fig. 262 as far as the stop.›

Unlock the lid by moving it in the direction of the arrow.

›

Open the tailgate.

Selector lever-emergency unlocking

Fig. 263

Selector lever-emergency unlocking

›

The parking brake switch.

›

Insert a flat-head screwdriver or similar tool into the gap in the arrow area

1

» Fig. 263 and lift the cover in arrow direction

2

.

›

Using a flat-head screwdriver or similar tool push on the yellow plastic part in

the direction of arrow

3

.

›

At the same time, press the locking button in the selector lever and move

the selector lever to position N.

If the selector lever is moved again to position P, it is once again blocked.

CAUTION

Make sure when lifting not to damage cover parts by the screwdriver in the

shift lever environment.

Replacing windscreen wiper blades

Introduction

This chapter contains information on the following subjects:

Replacing the windscreen wiper blades

237

Replacing the rear window wiper blade

238WARNINGReplace the windscreen wiper blades once or twice a year for safety rea-

sons. These can be purchased from a ŠKODA Partner.

Replacing the windscreen wiper blades

Fig. 264

Windscreen wiper blade

Read and observe

on page 237 first.

Adjust the windscreen wiper arms to the service position before replacing the

windscreen wiper blades.

Service position for changing wiper blades

›

Closing the bonnet.

›

Switch the ignition on and off again.

›

Within 10 seconds, press the lever in position

4

and hold it in position for

around 2 seconds » page 78, Windscreen wipers and washers .

The windscreen wiper arms move into the service position.

Removing the wiper blade

›

Lift the wiper arm from the windscreen in the direction of

1

» Fig. 264 .

›

Tilt the wiper blade to the stop in the same direction.

›

Hold the upper part of the wiper arm and press the securing mechanism

A

in the direction of arrow

2

.

›

Remove the wiper blade in the direction of the arrow

3

.

Attaching the windscreen wiper blade

›

Push the windscreen wiper blade to the stop until it locks into place.

›

Check that the windscreen wiper blade is correctly attached.

›

Fold the wiper arm back to the windscreen.

237Emergency equipment and self-help

Page 242 of 276

Installing the storage compartment›Raise the storage compartment in the direction of the arrow 4.›

Overcome the resistance of the detents

A

.

›

Insert the brake control linkage in the opposite direction to arrow

2

.

›

Lock the brake control linkage in the opposite direction to arrow

1

.

›

Close the storage compartment.

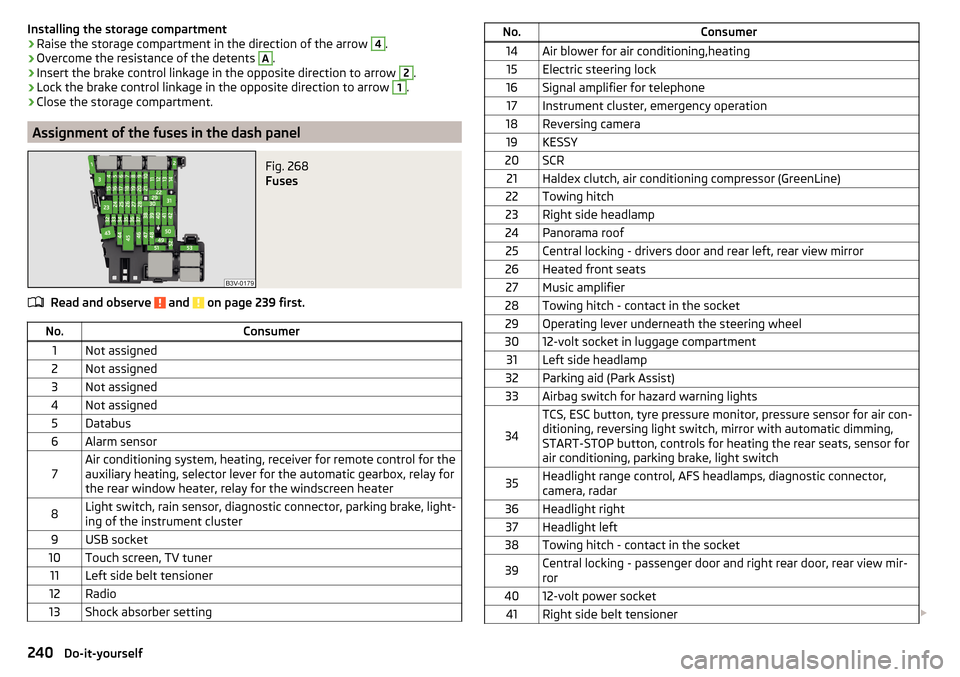

Assignment of the fuses in the dash panel

Fig. 268

Fuses

Read and observe and on page 239 first.

No.Consumer1Not assigned2Not assigned3Not assigned4Not assigned5Databus6Alarm sensor7Air conditioning system, heating, receiver for remote control for the

auxiliary heating, selector lever for the automatic gearbox, relay for

the rear window heater, relay for the windscreen heater8Light switch, rain sensor, diagnostic connector, parking brake, light-

ing of the instrument cluster9USB socket10Touch screen, TV tuner11Left side belt tensioner12Radio13Shock absorber settingNo.Consumer14Air blower for air conditioning,heating15Electric steering lock16Signal amplifier for telephone17Instrument cluster, emergency operation18Reversing camera19KESSY20SCR21Haldex clutch, air conditioning compressor (GreenLine)22Towing hitch23Right side headlamp24Panorama roof25Central locking - drivers door and rear left, rear view mirror26Heated front seats27Music amplifier28Towing hitch - contact in the socket29Operating lever underneath the steering wheel3012-volt socket in luggage compartment31Left side headlamp32Parking aid (Park Assist)33Airbag switch for hazard warning lights

34

TCS, ESC button, tyre pressure monitor, pressure sensor for air con-

ditioning, reversing light switch, mirror with automatic dimming,

START-STOP button, controls for heating the rear seats, sensor for

air conditioning, parking brake, light switch35Headlight range control, AFS headlamps, diagnostic connector,

camera, radar36Headlight right37Headlight left38Towing hitch - contact in the socket39Central locking - passenger door and right rear door, rear view mir-

ror4012-volt power socket41Right side belt tensioner 240Do-it-yourself

Page 243 of 276

No.Consumer42Boot lid, headlight washers, windscreen washer system43Visor for gas discharge bulbs, interior lighting44Towing hitch - contact in the socket45Operating the seat adjustment46230-Volt power socket47Rear window wiper48Blind spot detection49Coil on starter relay, clutch pedal switch50Opening the boot lid51Heating of the rear seats52Cooling of the front seats53Relay for rear window heater

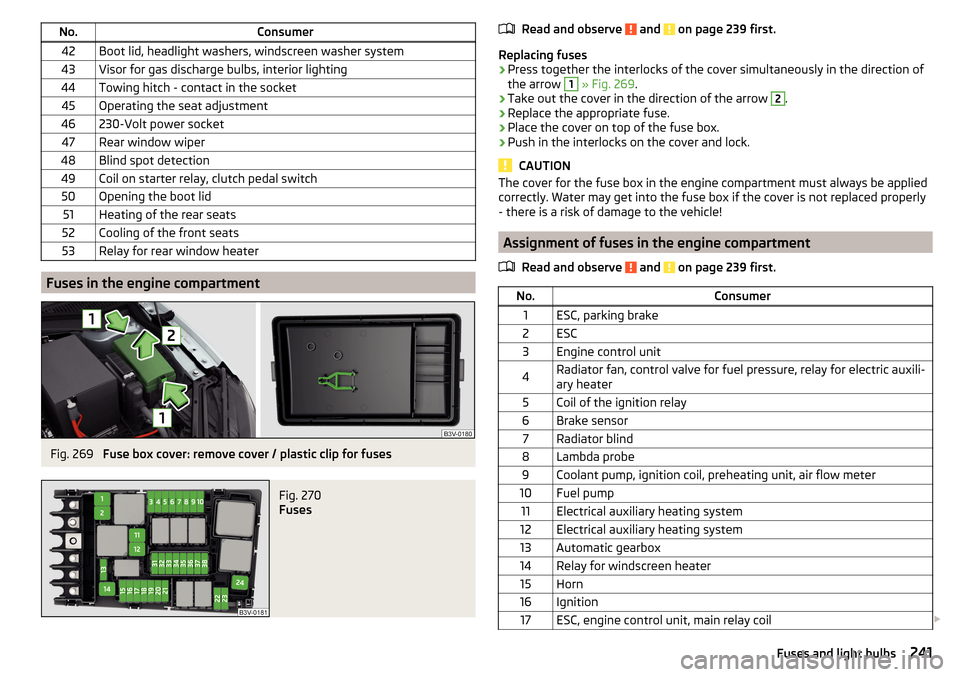

Fuses in the engine compartment

Fig. 269

Fuse box cover: remove cover / plastic clip for fuses

Fig. 270

Fuses

Read and observe and on page 239 first.

Replacing fuses

›

Press together the interlocks of the cover simultaneously in the direction of

the arrow

1

» Fig. 269 .

›

Take out the cover in the direction of the arrow

2

.

›

Replace the appropriate fuse.

›

Place the cover on top of the fuse box.

›

Push in the interlocks on the cover and lock.

CAUTION

The cover for the fuse box in the engine compartment must always be applied

correctly. Water may get into the fuse box if the cover is not replaced properly

- there is a risk of damage to the vehicle!

Assignment of fuses in the engine compartment

Read and observe

and on page 239 first.

No.Consumer1ESC, parking brake2ESC3Engine control unit4Radiator fan, control valve for fuel pressure, relay for electric auxili-

ary heater5Coil of the ignition relay6Brake sensor7Radiator blind8Lambda probe9Coolant pump, ignition coil, preheating unit, air flow meter10Fuel pump11Electrical auxiliary heating system12Electrical auxiliary heating system13Automatic gearbox14Relay for windscreen heater15Horn16Ignition17ESC, engine control unit, main relay coil 241Fuses and light bulbs

Page 259 of 276

automatic transmissionselector lever lock defect137

Automatic transmission135

Kick down138

Launch control138

Malfunctions37

Selector lever lock137

Warning light37

Warning messages37

AUX99

Auxiliary heating (auxiliary heating and ventila- tion)

123

Adjust124

Switching on/off124

Auxiliary heating (heating and ventilation) Radio remote control

125

Avoiding damage to your vehicle141

B

Bags on the backs of the front seats

97

on the inner sides of the front seats97

Battery In the remote control key

234

Replace the KESSY key234

Belts11

Belt tensioners14

Bonnet Closing

207

Opening207

Boot Class N1 vehicles

114

Non-contact opening61

See Boot lid59

Boot lid automatic locking

59

Closing59

Non-contact opening61

Opening59

Brake Information messages33

Warning light33

Brake Assist (HBA)145

Brake booster133

brake fluid specification

213

Brake fluid212

Checking212

Information messages33

Brake linings Warning light

36

Brake pedal (automatic transmission) Warning light

37

Brakes Brake booster

133

Brake fluid212

Braking and stabilisation systems143

Running-in139

Brakes and parking132

Brake system143

Braking Information on braking

132

Bulbs Replacing

242

C

Camera Lens care

197

Camera lens care

197

Car care Jack

197

Car computer see multifunction display

42

Care and maintenance190

Cargo element112

Car park134

Car park ticket holder91

Carrier Roof rack117

Cavity protection197

Central locking52

Problems57

Central locking button55

Change Bulb for indicator (halogen headlight)

243

engine oil209

light bulb in tail light244

Change engine oil

209

Changing Wheels

224

Changing a wheel Follow-up tasks

227

Preparation224

Changing wheels Wheel removal and fix

227

Charging a vehicle battery215

Checking Battery electrolyte level

214

Brake fluid212

Coolant211

Engine oil210

Oil level210

Windscreen washer fluid208

Checks Statutory checks

190

Children and safety20

Child safety Side airbag

22

Child safety lock57

Child safety seat Use of child safety seats

23

Child seat Classification

22

i-Size25

ISOFIX23

on the front passenger seat21

257Index