ECU SKODA YETI 2009 1.G / 5L Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2009, Model line: YETI, Model: SKODA YETI 2009 1.G / 5LPages: 271, PDF Size: 16.24 MB

Page 145 of 271

Seat belts

144

WARNING

Adjust the height of the belt in such a way that the shoulder part of the belt is positioned approximately across the middle of your shoulder - on no account across your neck.

Note

It is also possible to adapt the routing of the belt webbing at the front seats by adjusting the height of the seat.Taking seat belts off– Press the red button in the belt lock

⇒fig. 136

. The spring force causes the tongue

of the lock to jump out.

– Guide the belt back with your hand to en

able the inertia reel to wind up the belt

webbing more easily.

A plastic knob in the belt webbing holds the be

lt tongue in a position which is easy to

get hold of.Three-point seat belt for the rear middle seat The three-point seat belt for the rear middle seat is anchored in the area of the luggage compartment on the left side of the headliner.Your car is equipped as standard

with the three-point seat belt.

Fastening the seat belt– Pull the belt with both lock to

ngues out of the headliner mount.

– Insert the lock tongue at the end of the belt

into the seat belt buckle on the left side

until it is heard to lock in place.

– Pull the second lock tongue, which is move

able on the seat belt, over the chest and

insert it into the belt buckle on the right side until it is heard to lock in place.

– Pull on the belt to check that both lock

tongues are reliably engaged in the locks.

– The belt tongues for the rear middle seat are shaped differently so that they only fit

into the respective belt buckle. If you attempt to insert a lock tongue into the wrong belt lock it will not lock.

Taking seat belt off– Take off the seat belt in the reverse order to fastening.

WARNING

•

The three-point safety belt for the rear middle seat can only fulfil its func-

tion reliably when the backrests are correctly locked into position

⇒page 74.

•

After releasing the seat belt hold it tight and let it slowly reel up until both

lock tongues lock into the headliner mount and are secured with a magnet - risk of injury.•

Never release simultaneously both tongues of the lock.

Belt tensionersSafety for the driver and front passenger

wearing their seat belts

is enhanced by the

belt tensioners fitted to the inertia reels of

the front three-point seat belts, in addition

to the protection afforded

by the airbag system.

The three-point seat belts are automatically te

nsioned in the event of a frontal collision

of a certain severity. The belt tensioners can

also be deployed if the seat belts are not

fastened.

Fig. 136 Releasing lock tongue from belt lock

sgg.6.book Page 144 Thursday, September 24, 2009 2:32 PM

Page 157 of 271

Transporting children safely

156

Transporting children safelyWhat you should know ab

out transporting children!

An introduction to the subject Accident statistics have revealed that children are generally more safely transported on the rear seats than on the front passenger seat.Children younger than 12 years of age should

normally travel on the rear seat of the

vehicle (take note of any national legal provis

ions which differ from this). They should

be secured there by means of a child restraint system or by using the existing seat belts depending on their age, body size and we

ight. The child seat should be mounted

behind the front passenger seat for safety reasons. The physical principle of an

accident does, of course, also apply to children

⇒ page 141, “The physical principle of a fronta

l collision”. They differ from adults in

that their muscles and bone structure of children are not yet fully developed. Thus chil- dren are exposed to increased risk of injury. Children should be transporte

d by using special child safety seats in order to reduce

this risk of injury. Use only child safety seats which are officia

lly approved and are suitable for children

and which comply with the ECE-R 44 standard, which classifies child safety seats into 5 groups

⇒page 158. Child restraint systems which have been tested for conformity

to ECE-R 44 standard have a non-detachable

test seal (a large E within a circle and

below this the test number) attached to the seat. We recommend that you use child safety seats from the Škoda genuine accessories. These child seats were developed and also tested for use in Škoda vehicles. They fulfil the ECE-R 44 standard.

WARNING

Always comply with national legal provisions and instructions from the rele-vant child safety seat manufacturer wh

en installing and using a child seat

⇒ page 156.

Note

Any varying national legal regulations take

priority over the information provided in

these instructions for use, or stated in this chapter.Important safety information regarding the use of child safety seats Correct use of child safety seats considerably reduces the risk of injury!

WARNING

•

All the occupants of the car - in particular children - must wear a seat belt

when the car is moving.•

Children who are less than 1.50 m in height and who weigh less than 36 kg

must not use a normal seat belt without a child restraint system otherwise this may result in injuries to the stomach and neck areas. Comply with the national legal requirements.•

One should never carry children, and also not babies! - on one's lap.

•

You can transport a child safely in a suitable child safety seat

⇒page 158,

“Child seat”!•

Only one child may be fastened with a seat belt into a child safety seat.

•

Never leave the child sitting unattended in the seat.

•

Certain outside climatic conditions can cause life-threatening tempera-

tures in the vehicle.•

Never allow your child to be transported in a vehicle without the use of a

suitable restraint system.•

Children should also never stand up in

a vehicle or kneel on the seats when

the vehicle is moving. In the event of an accident the child will be thrown through the vehicle and may as a result

suffer fatal injuries

, and also injure

other occupants.•

Children are exposed to an increased risk

of injury in the event of an acci-

dent if they lean forward or adopt an in

correct seated position when the vehicle

is moving. This particularly applies to children who are transported on the front

sgg.6.book Page 156 Thursday, September 24, 2009 2:32 PM

Page 188 of 271

Driving and the Environment

187

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

roof should be removed and secured, as the

vehicle could tilt by

a sudden shifting of

the luggage. A passenger, seated at the rear, should always

remain seated on the seat facing up the

hill during such a journey. In an extreme ca

se, the passenger on the relevant side must

exit the vehicle until you have

safely crossed the hillside.

Exiting the vehicle on a hillside If the vehicle comes to a standstill at a steep angle on a hillside and you and your passengers must exit the vehicle, then all th

e occupants should exit on the side facing

up the hill

⇒page 186, fig. 166

on the right.

WARNING

•

Never attempt to drive uphill or downhill if it is too steep for your vehicle.

The vehicle could slip, tilt or roll over - risk of accident!•

When driving at an angle on a hillside,

the vehicle can lose its grip and slide

sideways. The vehicle can tilt or roll over

and then roll down the hillside. This

can lead to serious injuries.•

Always make sure that when the vehicle

is at an angle, the wheels on the low

side do not sink deeply into the ground or into troughs and do not drive over stones, tree stumps or other obstructions

with the alternate ra

ised wheels - risk

of accident!•

Before you drive at an angle on a hillside

⇒page 186, fig. 166

, make sure

that you can steer and maintain your trajectory. If this is not possible, choose a different path. If you drive at an angle

on a hillside and there is a risk your

vehicle may tilt, steer imme

diately downhill on your trajectory and lightly

depress the accelerator.•

If the vehicle is stationary on a hillside

with a too great angle of lateral incli-

nation, avoid sudden and uncontrolled movements in the vehicle. The vehicle can roll over and then roll down the hillside. This can lead to serious injuries.•

If the vehicle is stationary on a hillside

with a too great angle of lateral incli-

nation, neither you nor your occupants must exit the vehicle through the doors facing downhill. This can lead to a shift of the overall centre of gravity. The vehicle can tilt or roll over and then roll down the hillside. This can lead to serious injuries. To avoid this, you and your occupants must exit the vehicle only on the side facing uphill

⇒page 186, fig. 166

.

•

When you exit the vehicle, make sure

that the door which faces uphill does

not close by its own weight or by carelessness - risk of injury!•

Observe the important guidelines

⇒page 180.

Driving over rutted roads and troughsYou will always encounter ruts when drivin

g on forest roads, through wet meadows

and fields as well as on rutted stretches of terrain. If the ruts and troughs are on firm and soft ground, you can simply follow the ruts.Do not drive over ruts and troughs which are

too deep. If you cannot avoid this, it is

better that you turn back.

Caution

If the ruts or troughs become too deep,

the underbody of the vehicle can touch the

ground, which might cause the

underbody to get damaged. Therefore, avoid driving in

deep ruts and troughs.Crossing a trenchIf possible, drive through the trench at an acute angle. Make sure when driving through the trench that the tilt angle is not too steep.

WARNING

Never attempt to drive through a trench if its embankment is too steep. The vehicle could slip, tilt or roll over - risk of accident!

Caution

If you drive into the trench at a right angle,

the front wheels will sink into the trench.

There is also the danger that the underbod

y of the vehicle touches the ground and is

damaged. For these reasons (even with four-wheel drive) it is rarely possible to get out of the trench.

WARNING (continued)

sgg.6.book Page 187 Thursday, September 24, 2009 2:32 PM

Page 191 of 271

Towing a trailer

190

Towing a trailerTo w i n g a t r a i l e rTechnical requirements The towing device must satisfy certain technical requirements.Your vehicle is designed primarily for tr

ansporting persons and luggage. It can,

however, also be used for towing a traile

r - provided certain technical equipment is

fitted. If your vehicle has already been supplied with a

factory-fitted

towing device then

everything that is nece

ssary for towing a trailer in technical terms, and in terms of the

law, has already been taken into account. Your vehicle is fitted with a 13-pin power so

cket for the electrical connection between

the vehicle and trailer. If the tr

ailer which you wish to tow has a

7-pin connector

, you

can use a suitable adapter

14) from Škoda original accessories.

This work must be carried out in accordance

with the manufacturer's specifications if

a towing device is retrofitted. Authorised Škoda Service Partners are familiar with details relating to retrofitting a towing device and for any necessary

modifications to the cooling system.

WARNING

We recommend that you have the towing device from Škoda original accesso- ries installed by an authorised Škoda Serv

ice Partner. He is familiar with all the

relevant details relating to retrofitting such equipment. There is a risk of an accident if the towing device is not properly fitted!

General Maintenance There are a number of points to pay attention to when towing a trailer.Trailer load The permissible trailer load must on no account be exceeded. You can negotiate appropriately steeper inclin

es and descents if you do not make full

use of the permissible trailer load. The trailer loads specified only apply for

altitudes

up to 1 000 metres above mean sea

level. The fact that the engi

ne power output drops with increasing height due to a

lowering of air pressure and thus the abil

ity to climb, means that the towed weight

must be reduced by 10% for every further increase of 1 000 metres in height above sea level. The towed weight is the weight of the (laden) vehicle and the (laden) trailer together. One should take this into account

before driving up to higher altitudes.

The trailer and drawbar load information on the type plate of the towing device are merely test data for the towing device. The data relating to your vehicle, which is often less than this test data, can be found in your vehicle registration documents. Distribution of the load Distribute the load in the trailer in such a

way that any heavy items are located as close

as possible to the axle. Secure th

e items to preven

t them slipping.

Tyre pressure Correct the tyre inflation pressure on yo

ur vehicle for that of “fully laden”,

⇒page 215.

The inflation pressure of the tyres fitted to

the trailer adjust in accordance with the

manufacturer's recommendation. Exterior mirrors You have to have additional ex

terior mirrors fitted if you are not able to see the traffic

behind the trailer with the standard rear-view mirrors. Both exterior mirrors should be attached to folding arms. Adjust the mirrors so that they provide you with an adequate field of view to the rear.

14)In some countries the adapter is supplied with the towing device.sgg.6.book Page 190 Thursday, September 24, 2009 2:32 PM

Page 202 of 271

Fuel

201

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

It is therefore the case that EN 590 prescribes diesel fuel class for certain periods of the year which can also be purchased at the co

rresponding time during the year. “Winter-

grade diesel fuel” will still operate properly even at a temperature of -20°C. It is often the case in countries with different climatic conditions that diesel fuels avail- able have a different temperature characte

ristic. The authorised Škoda Service Part-

ners and filling stations in the country concer

ned will be able to provide you with infor-

mation regarding the diesel fuels available. Prewarming fuel The vehicle is fitted with a fuel filter prewarming system. This secures operation of a vehicle using diesel fuel down to an environmental temperature of -25°C.

Caution

It is not permitted to add the various fuel

additives on the market, including petrol, to

diesel fuel in order to im

prove its flow properties.

RefuellingFig. 168 Right rear side of the vehicle: Fuel fi

ller flap / fuel filler

flap with cap unscrewed

The filler flap is automatically unlocke

d or locked* with the central locking.

Opening the fuel filler cap– Press in the middle of the left area of

the fuel filler flap in direction of arrow

⇒ fig. 168

.

– The fuel filler cap on the fuel filler tube

must be unlocked to the left using the

vehicle key (only valid for vehicles which

do not have automatic unlocking of the

fuel filler flap).

– Unscrew the fuel filler ca

p anti-clockwise and place the fuel filler cap from above

on the fuel filler flap

⇒fig. 168

on the right.

Closing fuel filler cap– Screw on the cap by turning it to the right until it is heard to lock. – The fuel filler cap on the fuel filler tube

must be locked to the right using the vehicle

key (only valid for vehicles which do not

have automatic locking of the fuel filler

flap).

– Close the fuel filler flap until it locks. The correct grade of fuel for your vehicle as well as the tyre size and inflation pressures are stated on a sticker affixed to the inside of the fuel filler flap. Further information on fuel

⇒page 200.

The fuel tank has a capacity of about 60 litres.

WARNING

Pay attention to any legal requirements if

you do carry a spare canister in the

vehicle. We do not recommend carrying any fuel canisters in your vehicle for safety reasons. The canister can be damaged

in the event of an accident and fuel

may leak out.

Caution

•

Before refuelling it is necessary to switch off the auxiliary heating system (auxiliary

heating and ventilation) *.•

Remove any fuel which has spilled onto th

e paintwork of your vehicle immediately

- risk of paint damage!•

On vehicles fitted with a ca

talytic converter, never let the fuel tank run completely

empty. An irregular supply of fuel to the engine can result in misfiring and unburnt fuel may get into the exhaust system, which may result in overheating and damage to the catalytic converter.

A1

sgg.6.book Page 201 Thursday, September 24, 2009 2:32 PM

Page 204 of 271

Inspecting and replenishing

203

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

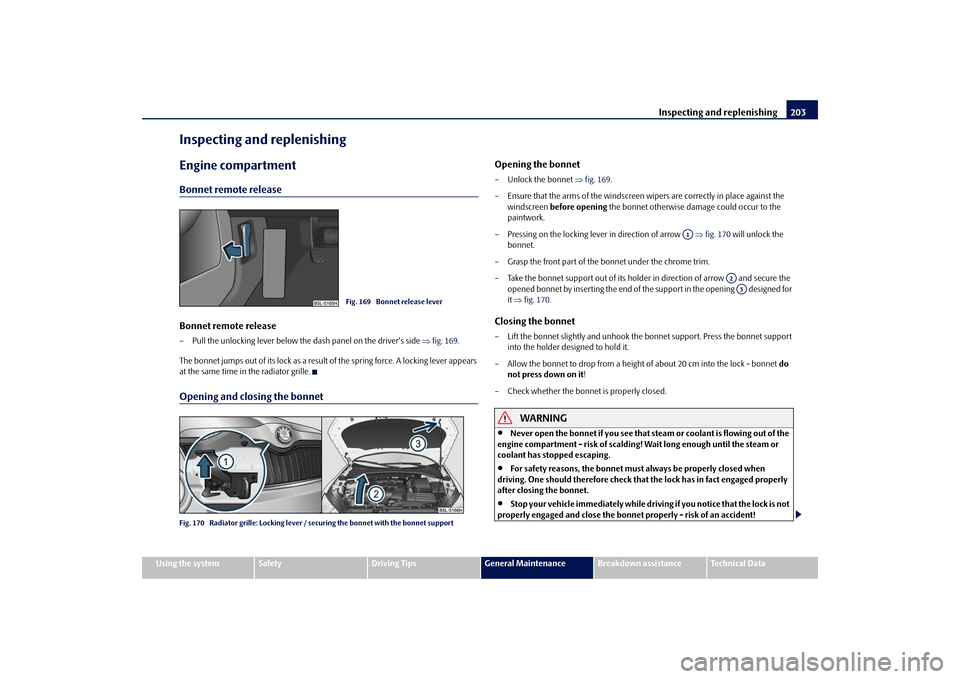

Inspecting and replenishingEngine compartmentBonnet remote releaseBonnet remote release– Pull the unlocking lever below the

dash panel on the driver's side

⇒fig. 169

.

The bonnet jumps out of its lock as a result of the spring force. A locking lever appears at the same time in the radiator grille.Opening and closing the bonnetFig. 170 Radiator grille: Locking lever / se

curing the bonnet with the bonnet support

Opening the bonnet– Unlock the bonnet

⇒fig. 169

.

– Ensure that the arms of the windscreen wipers are correctly in place against the

windscreen

before opening

the bonnet otherwise damage could occur to the

paintwork.

– Pressing on the locking lever in direction of arrow

⇒fig. 170

will unlock the

bonnet.

– Grasp the front part of the bonnet under the chrome trim. – Take the bonnet support out of its holder in direction of arrow and secure the

opened bonnet by inserting the end of the support in the opening designed for it ⇒fig. 170

.

Closing the bonnet– Lift the bonnet slightly and unhook the bonnet support. Press the bonnet support

into the holder designed to hold it.

– Allow the bonnet to drop from a height

of about 20 cm into the lock - bonnet

do

not press down on it

!

– Check whether the bonnet is properly closed.

WARNING

•

Never open the bonnet if you see that steam or coolant is flowing out of the

engine compartment - risk of scalding!

Wait long enough until the steam or

coolant has stopped escaping.•

For safety reasons, the bonnet must always be properly closed when

driving. One should therefore check that

the lock has in fact engaged properly

after closing the bonnet.•

Stop your vehicle immediately while driving if you notice that the lock is not

properly engaged and close the bonnet

properly - risk of an accident!

Fig. 169 Bonnet release lever

A1

A2A3

sgg.6.book Page 203 Thursday, September 24, 2009 2:32 PM

Page 205 of 271

Inspecting and replenishing

204

Caution

Never open the bonnet using the locking lever - danger of causing damage.Working in the engine compartment Particular care is required when carrying out any work in the engine compartment!There is a risk of injuries, scalding, acci

dents and fire when working in the engine

compartment, e.g. inspecting and replenishing oil and other fluids. For this reason, it is essential to comply with the warning instructions stated below and with the general applicable rules of safe

ty. The engine compartment of your car

is a hazardous area

⇒

.

WARNING

•

Never open the bonnet if

you see that steam or coolant is flowing out of the

engine compartment - risk of scalding!

Wait long enough until the steam or

coolant has stopped escaping.•

Switch off the engine and pull out the ignition key.

•

Apply the handbrake firmly.

•

If your vehicle is fitted with a manual

gearbox, move the gearshift lever into

Neutral, or if it is fitted with automatic gearbox, move the selector lever into position P.•

Allow the engine to cool down.

•

Keep children clear of the engine compartment.

•

Never spill oil and other fluids over the hot engine. Such fluids (e.g. the anti-

freeze contained in the coolant) may ignite!•

Avoid short circuits in the electrical system - particularly on the battery.

•

Never place your hand into the radiator fan as long as the engine is still

warm. The fan might suddenly start running!•

Never open the cap of the coolant expans

ion bottle as long as the engine is

still warm. The cooling

system is pressurized!

•

Cover over the cap of the coolant expansion reservoir with a large cloth

when opening it as protection for your

face, hands and arms from hot steam or

hot coolant.•

Do not let objects, such as e.g cleaning cloth or tools lie in the engine

compartment.•

If you wish to work under the vehicl

e, you must secure the vehicle from

rolling away and support it with suitable supporting blocks: the car jack is not sufficient for this - risk of injury!•

In cases where it be necessary to carry out inspection work when the engine

is running there is an additional risk fr

om rotating parts (e.g. the V-ribbed belt,

alternator, radiator fan) and from the high-voltage ignition system. Please observe in addition the following:

− Never touch the electrical cabl

es of the ignition system.

− Absolutely avoid any jewellery, loose it

ems of clothing or long hair from

getting into the rotating parts of the

engine - Hazard! Therefore remove any

jewellery beforehand, tie up your hair and wear tight fitting clothing.

•

Please also comply with the warnin

g instructions st

ated below when

carrying out any essential work on the fu

el system or on th

e electrical system:

− Always separate the car battery from the electrical system. − Do not smoke. − Never carry out any work close to naked flames. − Always keep a working fire

extinguisher at hand.

Caution

When replenishing fluids in the engine, always

ensure that the fluids are on no account

mixed up. This may result in major oper

ating problems and also vehicle damage!

WARNING (continued)

sgg.6.book Page 204 Thursday, September 24, 2009 2:32 PM

Page 225 of 271

Breakdown assistance

224

The vehicle tool kit and the lifting jack*, on which a sign is affixed, are stowed in a box in the luggage compartment

⇒page 223, fig. 182

; there is also space here for the

detachable ball head of the towing devi

ce*. The box is secured with a strap.

The vehicle tool kit contains the following

parts (depending on equipment fitted):

•

Wire clamps for removing the full wheel trims,

•

Wheel wrench*,

•

To w i n g e y e ,

•

Adapter for the wheel bolts lock*,

•

Replacement bulb set*

15),

•

To r x s c r e w d r i v e r.

Before placing the lifting jack back in its storage area, screw in the arm of the lifting jack fully.

WARNING

•

The factory-supplied lifting jack is only intended for your model of vehicle.

On no account attempt to lift a heavier vehicle or other loads - risk of injury!•

Ensure that the vehicle tool kit is safely attached in the luggage compart-

ment.

Note

Ensure that the box is always secured with the strap.Tyre repair kitThe tyre repair kit is intended for the repair

of minor tyre defects. The tyre repair kit

contains a compressor, inflation bottle,

operating instructions and accessories.

The repair with the tyre repair kit is

not at all intended to replace

a permanent repair

on the tyre, this repair only serves to reach the next specialist garage. The repair can be undertaken on the vehicle immediately.

Please read the attached instructions care-

fully before the repair.

The tyre repair kit is located in

a box in the luggage compartment

⇒page 223,

fig. 182

.

Spare wheel*The spare wheel is stowed in the luggage compartment in the area below the variable loading floor* and is secured with a special screw

⇒fig. 183

.

One should check the inflation pressure in

the spare wheel (at best when generally

checking the tyre air pressures - see sign on the fuel filler flap

⇒page 215) to ensure

that the spare wheel is always ready to use. Temporary spare wheel A yellow warning label is displayed on the rim of the temporary spare wheel. Please observe the following notes when driving with a temporary spare wheel:•

The warning label must not be covered after installing the wheel.

•

Do not drive faster than 80 km/h with this spare wheel and pay particular attention

while driving. Avoid accelerating at full throttle, sharp braking and fast cornering.•

The inflation pressure for this spare wheel is identical to the maximum inflation

pressure of the standard tyres.•

Use this spare wheel only to reach the nearest specialist garage as it is not intended

for continuous use.

15)Depending on the vehicle equipment.

Fig. 183 Luggage compartment: Spare wheel

sgg.6.book Page 224 Thursday, September 24, 2009 2:32 PM

Page 226 of 271

Breakdown assistance

225

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Changing a wheelPreliminary workThe following steps should be carried ou

t before actually changing the wheel.

– If it is necessary to change a wheel, park

the vehicle as far aw

ay as possible from

the traffic flow. The place you choose should be

level

.

–Have

all the occupants get out.

While changing a wheel, the occupants of the

vehicle should not stand on the ro

ad (e.g. behind a crash barrier).

– Apply the

handbrake

firmly.

–Engage

1st gear

or if your vehicle is fitted with

an automatic gearbox, position the

selector lever into position P

.

– If a trailer is coupled, uncouple it. –Take the

vehicle tool kit

⇒page 223 and the

spare wheel*

⇒page 224 out of the

luggage compartment.

WARNING

•

If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle on

the side of the road at the prescribed

distance from your vehicle while observing all national legal provisions. In this way you are protecting not only yourself but also other road users.•

Never start the engine with the vehicle si

tting on the raised

jack - danger of

suffering injury.

Caution

If you have to change a wheel on a slope first block the opposite wheel with a stone or similar object in order to secure the

vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.

Changing a wheelAlways change a wheel on a level surface as far as possible. – Take off the full wheel trim*

⇒page 226 or the caps

⇒page 226.

– In the case of light alloy wheels remove the wheel trim cap

⇒page 227.

– First of all slacken the safety wheel bolt * and afterwards the other wheel bolts

⇒ page 227.

– Jack up the vehicle until the wheel to

be changed is clear of the ground

⇒ page 227.

– Unscrew the wheel bolts and place them

on a clean surface (cloth, paper etc.).

– Take off the wheel. – Fit on the spare wheel and tighten the wheel bolts slightly.– Lower the car. – Tighten the wheel bolts firmly, alternatel

y and diagonally using the wheel wrench

(crosswise) and last the safety wheel bolt*

⇒page 227.

Note

•

All bolts must be clean and must turn easily.

•

You must never grease or oil the wheel bolts!

•

When fitting on unidirectiona

l tyres, ensure that the tyres rotate in the correct

direction

⇒page 215.

Subsequent stepsAfter changing the wheel, you mu

st perform the following steps.

– Stow the vehicle tool kit in the space provided.– Stow the replaced wheel in the luggage compartment. –

Check

the

tyre pressure

on the spare wheel just mounted as soon as possible.

sgg.6.book Page 225 Thursday, September 24, 2009 2:32 PM

Page 229 of 271

Breakdown assistance

228

– Align the lifting jack* so that its claw grasps the web of the lower sill at the height

of the marking on the plasti

c cover and the base plate

is resting flat with its

complete surface ag

ainst firm ground.

– Turn the lifting jack* up further until

the wheel is just cl

ear of the ground.

Ground below the lifting jack which is soft and slippery

can cause the vehicle to slip

off the jack. It is therefore always necessary

to place the lifting jack* on a solid surface

or use a wide and stable base. Use a non-sl

ip base (e.g. a rubber foot mat) if the

surface is smooth

, such as cobbled stones, a tiled floor, etc.

WARNING

•

Always raise the vehicle with the doors closed - risk of injury!

•

Take suitable measures to prevent the base of the lifting jack from slipping

off - risk of injury!•

Not positioning the lifting jack at the specified points can result in damage

to the vehicle. The jack can also slip off if it does not have sufficient grip - risk of injury!•

It is important to support the vehicle with suitable supporting blocks if you

wish to work under the lifted vehicle - risk of injury!Securing wheels against being stolen* You need a special adapter for sl

ackening the safety wheel bolts.

– Pull off the full wheel trim/cap from the wheel hub or cap from the safety wheel

bolt.

– Insert the adapter with its toothed side into the inner toothing of the head of

the safety wheel bolt

⇒fig. 188

.

– Insert the wheel wrench fully onto the adapter .– Slacken the wheel bolt, or tighten it firmly

⇒page 227.

– Reinstall the full wheel trim/wheel cap after removing the adapter or place the cap

onto the safety wheel bolt.

– Have the

tightening torque

checked

with a torque wrench as soon as possible.

Steel and light alloy wheels must be tightened to a tightening torque of

120 Nm

.

The safety wheel bolts on vehicles fitted with them (one safety wheel bolt per wheel) can only be loosened or tighten

up by using the adapter provided.

It is meaningful to note th

e code number hammered into the rear side of the adapter

or the rear side of the safety wheel bolts.

You can obtain a replacement adapter from

an authorised Škoda Service Partner, if necessary, by quoting this number. We recommend that you always carry the ad

apter for the wheel bolts with you in the

vehicle. It should be stow

ed in the vehicle tool kit.

Caution

Damage can occur to the adapter and safety wh

eel bolt if the safety wheel bolt is tight-

ened up too much.

Note

The set of safety wheel bolts can be obta

ined from an authorised Škoda Service

Par tner.

AAAB

Fig. 188 Safety wheel bolt with adapter

ABAA

AB

sgg.6.book Page 228 Thursday, September 24, 2009 2:32 PM