SSANGYONG KORANDO 2012 Owner's Manual

KORANDO 2012

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57504/w960_57504-0.png

SSANGYONG KORANDO 2012 Owner's Manual

Page 521 of 1082

14-150000-00

8. DTC SETTING CONDITIONS

Charge warning lamp ON condition ▶

Turn the ignition ON (Engine stopped)

Open or short circuit of L terminal wiring, open or short internal circuit of alternator (fixed control of

13.8V)

Open or short circuit of F terminal wiring, no feedback output signal 1.

2.

3.

Page 534 of 1082

01-10

4. SCHEMATIC DIAGRAM FOR WIRING AND ELECTRICAL

DEVICES

1) Wiring Harness Arrangement

Page 539 of 1082

01-150000-00

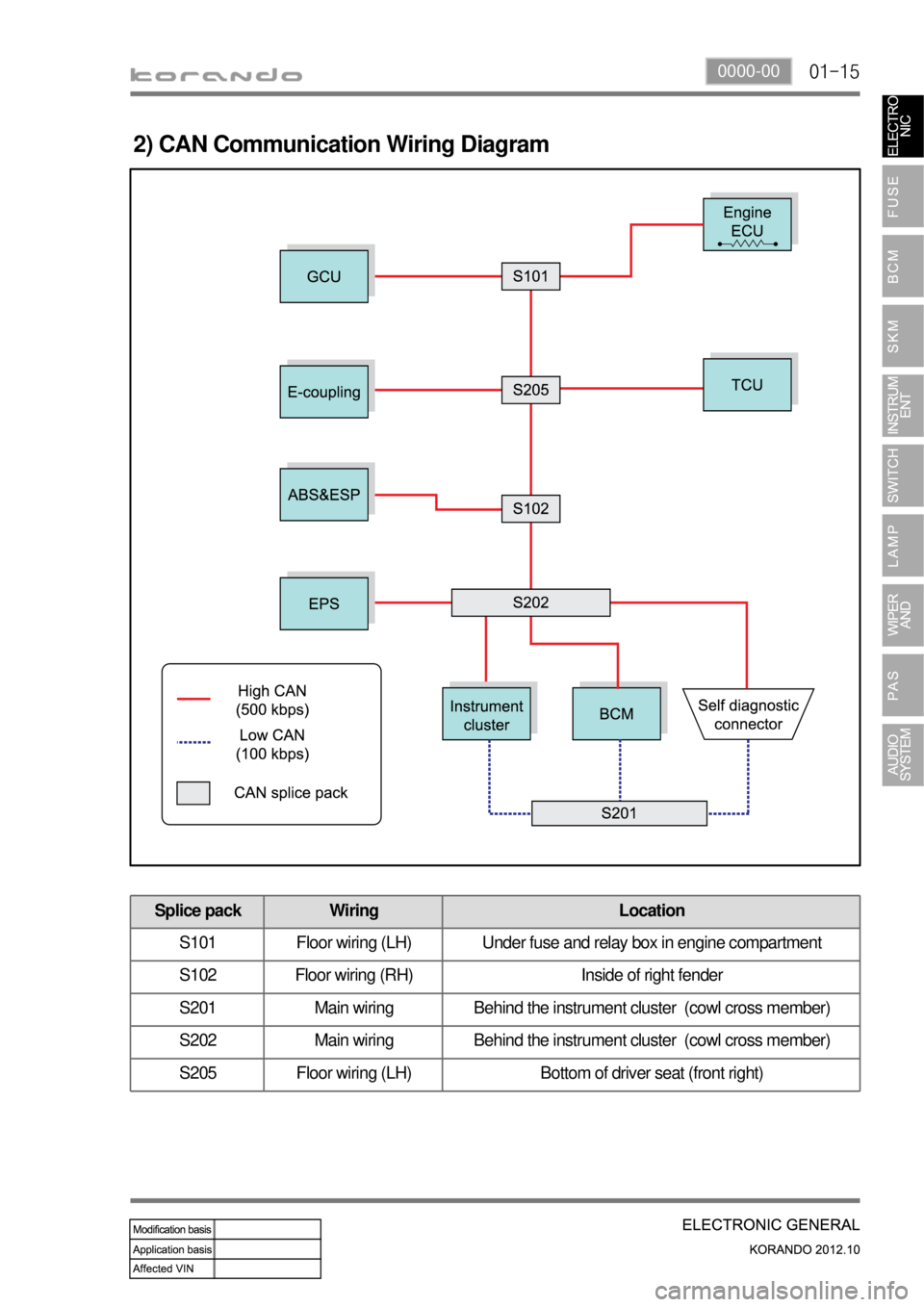

2) CAN Communication Wiring Diagram

Splice pack Wiring Location

S101 Floor wiring (LH) Under fuse and relay box in engine compartment

S102 Floor wiring (RH) Inside of right fender

S201 Main wiring Behind the instrument cluster (cowl cross member)

S202 Main wiring Behind the instrument cluster (cowl cross member)

S205 Floor wiring (LH) Bottom of driver seat (front right)

Page 542 of 1082

02-4

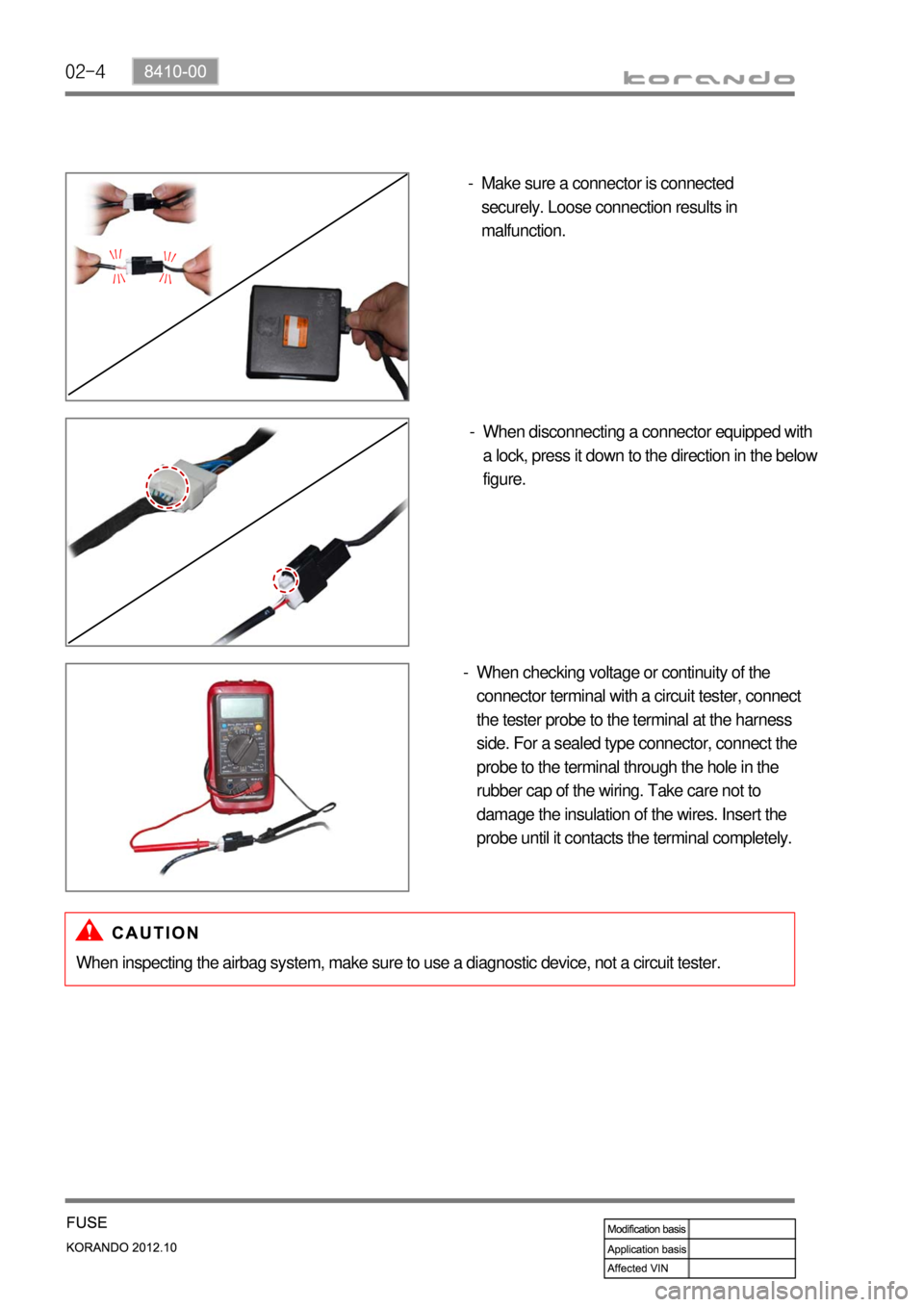

Make sure a connector is connected

securely. Loose connection results in

malfunction. -

When disconnecting a connector equipped with

a lock, press it down to the direction in the below

figure. -

When checking voltage or continuity of the

connector terminal with a circuit tester, connect

the tester probe to the terminal at the harness

side. For a sealed type connector, connect the

probe to the terminal through the hole in the

rubber cap of the wiring. Take care not to

damage the insulation of the wires. Insert the

probe until it contacts the terminal completely. -

When inspecting the airbag system, make sure to use a diagnostic device, not a circuit tester.

Page 543 of 1082

02-58410-00

2. CHECKING CABLES AND WIRES

Check for loose connection or rust.

Check terminals and wires for corrosion due to electrolyte leakage.

Check terminals and wires for open circuit.

Check the wire insulation and coat for damage, cracks or deterioration.

Check if the conductive parts of the terminals do not contact with vehicle body or other metal parts.

Check that the grounding part has continuity with mounting bolts and vehicle body.

Check that wires are properly routed.

Make sure that wires are securely fixed to avoid contact with sharp body parts and high-temperature

parts, such as the exhaust manifold and exhaust pipes.

The rotating parts, such as fan pulley and fan belt, perturbative parts and wiring should be secured

tightly at regular intervals.

Secure the wiring between the fixed parts, such as the vehicle body, and vibrating parts, such as the

engine, after slackening it slightly to prevent it from being damaged. -

-

-

-

-

-

-

-

-

-

Page 554 of 1082

02-16

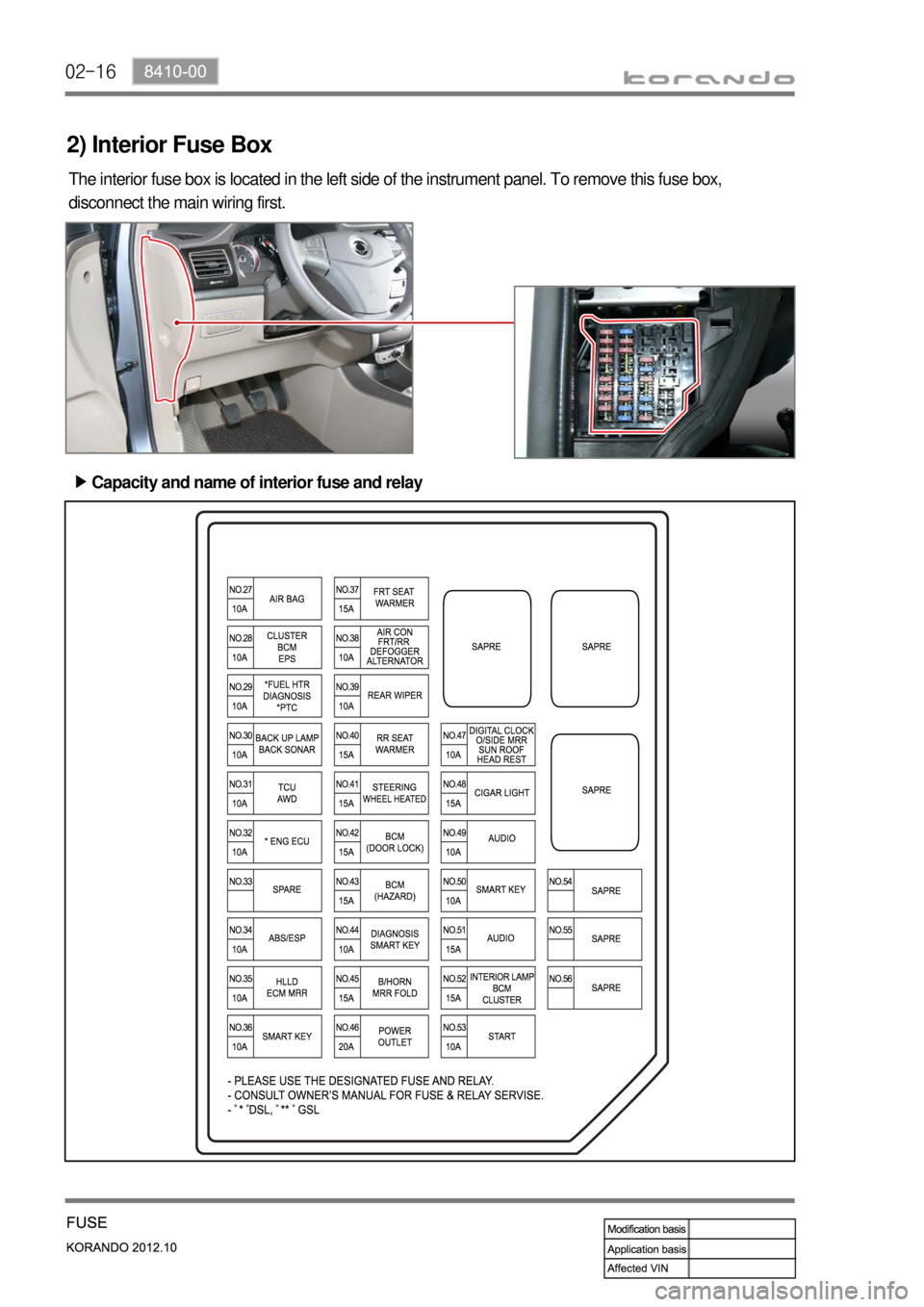

2) Interior Fuse Box

The interior fuse box is located in the left side of the instrument panel. To remove this fuse box,

disconnect the main wiring first.

Capacity and name of interior fuse and relay ▶

Page 742 of 1082

06-318510-00

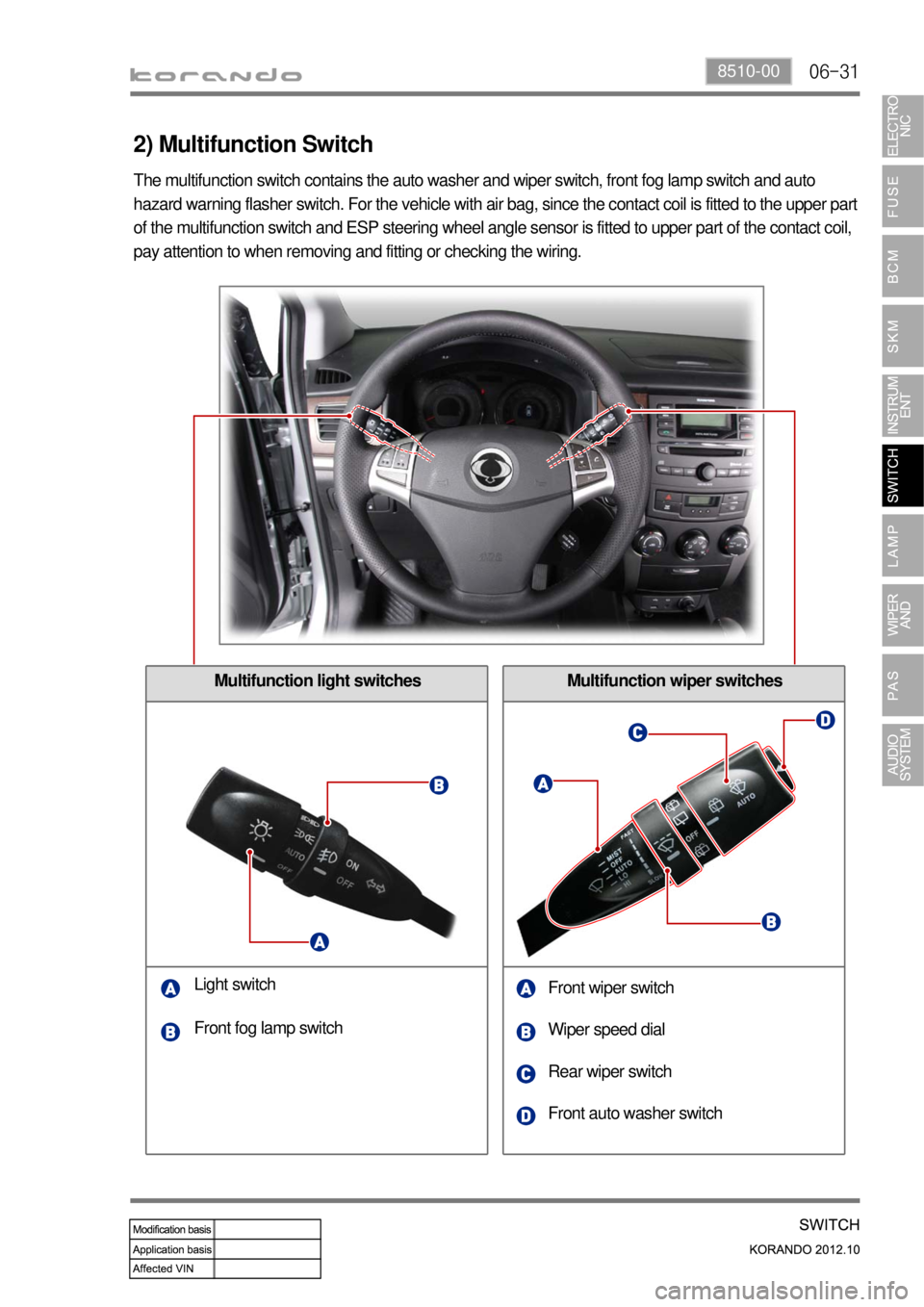

Multifunction wiper switches

2) Multifunction Switch

Multifunction light switches

Light switch

Front wiper switch

Wiper speed dial

Rear wiper switch Front fog lamp switch

Front auto washer switch The multifunction switch contains the auto washer and wiper switch, front fog lamp switch and auto

hazard warning flasher switch. For the vehicle with air bag, since the contact coil is fitted to the upper part

of the multifunction switch and ESP steering wheel angle sensor is fitted to upper part of the contact coil,

pay attention to when removing and fitting or checking the wiring.

Page 893 of 1082

03-8

1) Characteristics of WM6F1 M/T

Both Forward and Reverse gears use the helical gear and are made of high-strength material.

Drives the clutch with a concentric slave cylinder mounting bolt.

Shifting the transmission gears is performed through the remote control cable.

A pull type clutch is used for Reverse gear shifting.

Features triple/double/single synchronization. -

-

-

-

-

Clutch housing

Transmission case

Input shaft

Concentric slave cylinder

Shift lever

Selector lever

Wiring bracket

Neutral switch

Backup lamp switch

Reverse idle shaft mounting bolt 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.Control guide bolt

Oil filler plug (for servicing)

Oil drain plug

Oil filler plug (for manufacturing)

Air breather

Detent pin (for securing shift fork)

Oil seal (RH)

Oil seal (LH)

Control housing 11.

12.

13.

14.

15.

16.

17.

18.

19.

Page 1005 of 1082

01-4

2. MAJOR CHANGES

1) Heater & Evaporator Module (Wiring Specification)

The driving circuit for the manual A/C ambient temperature sensor is added, giving the change to the

heater and evaporator module.

Ambient temperature sensor signal wiring

added to vehicle wiring connecting

connector (2 circuits)

: manual A/CBlower max signal wiring added to

vehicle wiring connecting connector

(1 circuit)

: manual A/C & FATC

Manual A/C: Wiring pin added to controller assembly connector

FATC: Wiring pin added to existing connector of controller assembly

Page 1019 of 1082

02-38810-00

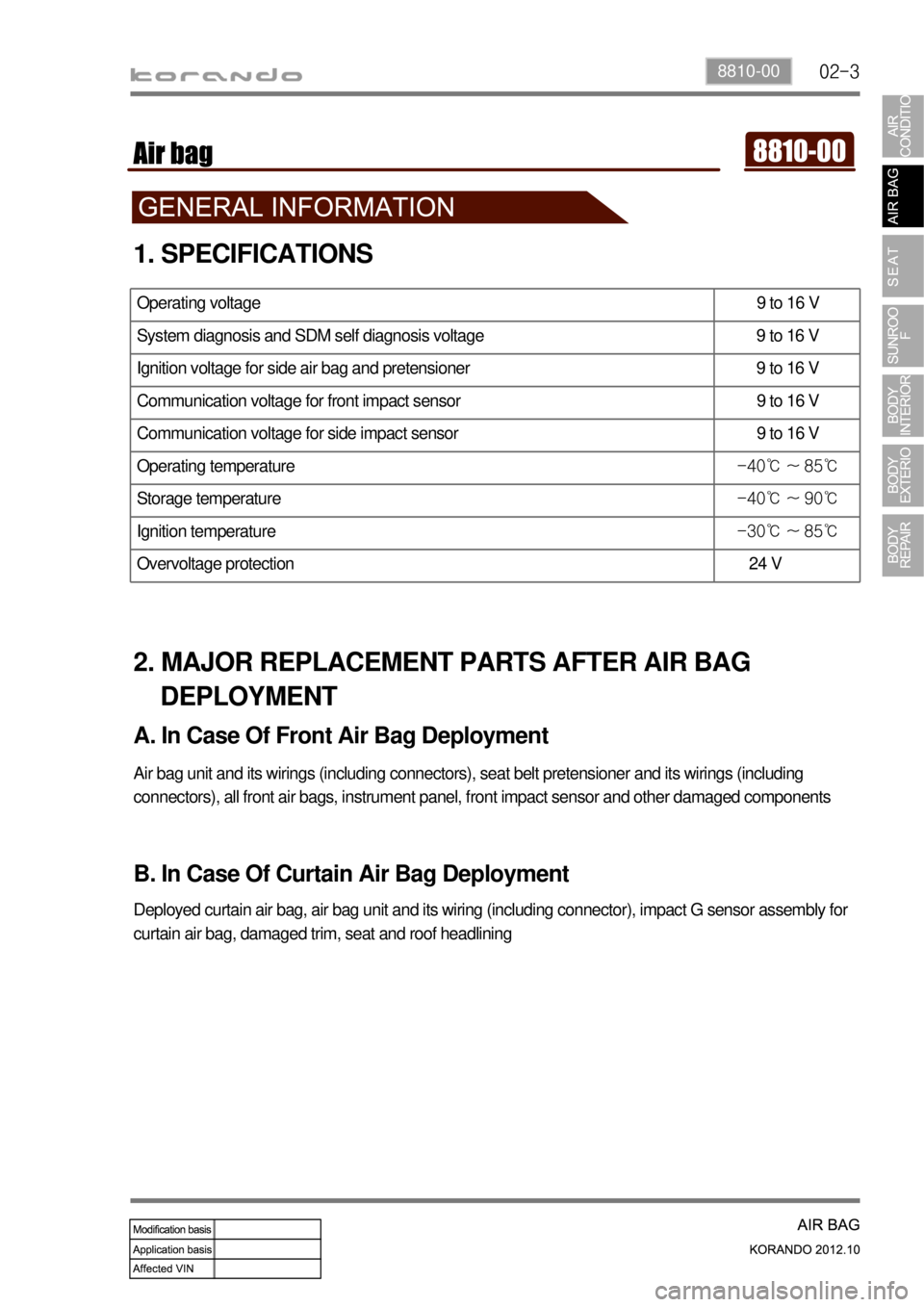

1. SPECIFICATIONS

Operating voltage 9 to 16 V

System diagnosis and SDM self diagnosis voltage 9 to 16 V

Ignition voltage for side air bag and pretensioner 9 to 16 V

Communication voltage for front impact sensor 9 to 16 V

Communication voltage for side impact sensor 9 to 16 V

Operating temperature -40℃ ~ 85℃

Storage temperature -40℃ ~ 90℃

Ignition temperature -30℃ ~ 85℃

Overvoltage protection 24 V

2. MAJOR REPLACEMENT PARTS AFTER AIR BAG

DEPLOYMENT

A. In Case Of Front Air Bag Deployment

Air bag unit and its wirings (including connectors), seat belt pretensioner and its wirings (including

connectors), all front air bags, instrument panel, front impact sensor and other damaged components

B. In Case Of Curtain Air Bag Deployment

Deployed curtain air bag, air bag unit and its wiring (including connector), impact G sensor assembly for

curtain air bag, damaged trim, seat and roof headlining