belt SSANGYONG MUSSO 2003 Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 201 of 1574

M161 ENGINE MECHANICAL 1B2-49

BELT PULLEY AND VIBRATION DAMPER Preceding Work : Removal of cooling fan and viscous clutchRemoval of fan shroud Removal of drive belt

1 Center Bolt(M18 X 55) ....................... 1st step 200-220 Nm

2nd step 90° + 10 ° rotation added

2 Vibration Damper Disk 5 Vibration Damper Assembly

6 Key

Page 204 of 1574

1B2-52 M161 ENGINE MECHANICAL CRANKSHAFT FRONT RADIAL SEAL Preceding Work : Removal of belt pulley and vibration damper

1 Center Bolt (M18 x 50)............................... 1st step 200-220 Nm

2nd step 90° +10 °

2 Center Bolt Washer

3 Sleeve (Special Tool)

4 Crankshaft Front Seal

5 Key

Tools Required

601 589 03 14 00 Sleeve Replacement Procedure

1. Remove the radial seal with a screw driver.

Notice Use a clean cloth not to damage the radial seal mounting hole and the crankshaft.

5. Remove the sleeve and install the belt pulley and thevibration damper.

6. Check for leaks while operating the engine.

2. Coat the radial sealing lip with engine oil.

3. Using the sleeve, assemble the radial seal .

4. Align the sleeve groove and the woodruff key and tighten

the center bolt until the center bolt and the damper disk stop in the movement. Installation Notice

Tightening Torque 1st step 200 - 220Nm

2nd step 90

° + 10 °

Page 266 of 1574

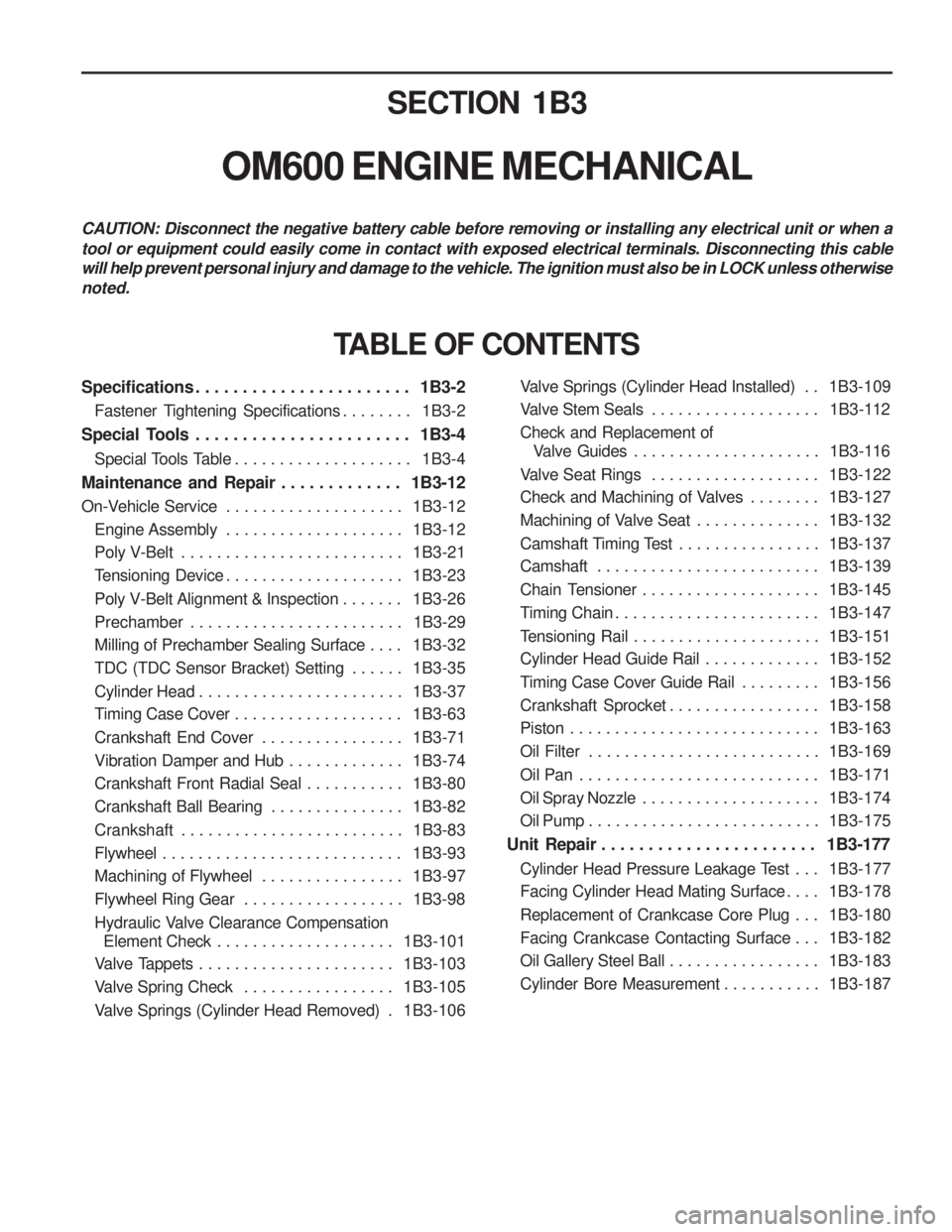

SECTION 1B3

OM600 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1B3-2Fastener Tightening Specifications . . . . . . . . 1B3-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1B3-4 Special Tools Table . . . . . . . . . . . . . . . . . . . . 1B3-4

Maintenance and Repair . . . . . . . . . . . . . 1B3-12

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1B3-12

Engine Assembly . . . . . . . . . . . . . . . . . . . . 1B3-12

Poly V-Belt . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-21

Tensioning Device . . . . . . . . . . . . . . . . . . . . 1B3-23

Poly V-Belt Alignment & Inspection . . . . . . . 1B3-26

Prechamber . . . . . . . . . . . . . . . . . . . . . . . . 1B3-29

Milling of Prechamber Sealing Surface . . . . 1B3-32

TDC (TDC Sensor Bracket) Setting . . . . . . 1B3-35

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 1B3-37

Timing Case Cover . . . . . . . . . . . . . . . . . . . 1B3-63

Crankshaft End Cover . . . . . . . . . . . . . . . . 1B3-71

Vibration Damper and Hub . . . . . . . . . . . . . 1B3-74

Crankshaft Front Radial Seal . . . . . . . . . . . 1B3-80

Crankshaft Ball Bearing . . . . . . . . . . . . . . . 1B3-82

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-83

Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-93

Machining of Flywheel . . . . . . . . . . . . . . . . 1B3-97

Flywheel Ring Gear . . . . . . . . . . . . . . . . . . 1B3-98

Hydraulic Valve Clearance Compensation

Element Check . . . . . . . . . . . . . . . . . . . . 1B3-101

Valve Tappets . . . . . . . . . . . . . . . . . . . . . . 1B3-103

Valve Spring Check . . . . . . . . . . . . . . . . . 1B3-105

Valve Springs (Cylinder Head Removed) . 1B3-106

TABLE OF CONTENTS

Valve Springs (Cylinder Head Installed) . . 1B3-109

Valve Stem Seals . . . . . . . . . . . . . . . . . . . 1B3-112

Check and Replacement of Valve Guides . . . . . . . . . . . . . . . . . . . . . 1B3-116

Valve Seat Rings . . . . . . . . . . . . . . . . . . . 1B3-122

Check and Machining of Valves . . . . . . . . 1B3-127

Machining of Valve Seat . . . . . . . . . . . . . . 1B3-132

Camshaft Timing Test . . . . . . . . . . . . . . . . 1B3-137

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-139

Chain Tensioner . . . . . . . . . . . . . . . . . . . . 1B3-145

Timing Chain . . . . . . . . . . . . . . . . . . . . . . . 1B3-147

Tensioning Rail . . . . . . . . . . . . . . . . . . . . . 1B3-151

Cylinder Head Guide Rail . . . . . . . . . . . . . 1B3-152

Timing Case Cover Guide Rail . . . . . . . . . 1B3-156

Crankshaft Sprocket . . . . . . . . . . . . . . . . . 1B3-158

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-163

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-169

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-171

Oil Spray Nozzle . . . . . . . . . . . . . . . . . . . . 1B3-174

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-175

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 1B3-177

Cylinder Head Pressure Leakage Test . . . 1B3-177

Facing Cylinder Head Mating Surface . . . . 1B3-178

Replacement of Crankcase Core Plug . . . 1B3-180

Facing Crankcase Contacting Surface . . . 1B3-182

Oil Gallery Steel Ball . . . . . . . . . . . . . . . . . 1B3-183

Cylinder Bore Measurement . . . . . . . . . . . 1B3-187

Page 267 of 1574

1B3-2 OM600 ENGINE MECHANICALSPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

N

m

28 - 47 30

3 - 7

8 - 18

20 - 34 30

70 - 80 81 - 8450 - 75

N

m

10 23

200 / 90 °

10

55 / 90 °

45 / 90 °

25 / 90 °

25

N

m

35 / 90 °

N

m

45 / 90 °

Application

Skid Plate Bolt Drain Plug Bolt Coolong Fan Shroud BoltControl Linkage NutClutch Linkage Cylinder NutExhaust Manifold Bolt

Propeller Shaft Bolt & Nut (Axle) Propeller Shaft Bolt & Nut (T/C)

Engine Mounting Nut

Application

Cooling Fan Belt Pulley Bolt Socket Bolt

Tighten The BoltEnd Cover BoltCrankshaft Bearing Cap Bolt Ball Bearing Camshaft Sprocket BoltOil Pump Sprocket Bolt

Application

Connecting Rod Bolt

Application

12-Sided Stretch Bolt

Engine Assembly

Crankshaft Assembly Piston

Flywheel

Cylinder Head

Application

Prechamber Threaded Ring Cylinder Head Cover Bolt Fuel Injsction Pipe NutSocket BoltFuel Filter Pipe BoltIdle Pulley Bolt Damper Bolt N

m

130 10 18252523 21

Page 268 of 1574

OM600 ENGINE MECHANICAL 1B3-3

N

m

12 2525

25 / 90 °

N

m

1010 23 32 4

2380 23Application

Stud Bolt Exhaust Manifold Not CamShaft Bearing Cap Bolt

12-Sided Bolt (M11)

Application

Oil Pan Bolt-Socket Bolt

Oil Pan Bolt- M6

Oil Pan Bolt- M23Belt Pulley Bolt Guide Pulley Bolt Guide Pulley Bracket Nut

Chain Tensioner

Tesioning Lever Bolt

Cylinder Head

Application

Camshaft Bearing Cap Bolt Camshaft Sprocket Bolt Exhaust Pipe Bolt& Nut

Chain TensionerInjection NozzleIntake Manifold Not Injection Nozzle Pipe Not

Oil Dipstick Tube BoltScrew Plug M18 x 15 N

m

25

25 / 90 °

25804025 18 1050

Cam Support & Shaft

Timing Cover

Page 286 of 1574

OM600 ENGINE MECHANICAL 1B3-21

POLY V-BELT

1 Nut .............................................................23Nm

2 Tensioning Lever

3 Bolt 4 Spring

5 Tensioning Lever

6 Poly V-Belt

Page 287 of 1574

1B3-22 OM600 ENGINE MECHANICALWith Air Conditioner

Removal & Installation Procedure

1. Remove the nut.

2. Push the tensioning lever in direction of arrow with a rod

(F12 ´ 180mm) and pull out the bolt to the rear.

3. Push back the tensioning lever (arrow direction) to release the spring tension and remove the belt.

4. Install the poly V-belt beginning at the tensioning pulley (7). 7 Tensioning Pulley

8 Crankshaft

9 Alternator

10 Coolant Pump 11 Guide Pulley

12 Power Steering Pump

13 Aircon. Compressor

Lengthe of Belt

Length (L)

Without Air Conditioner 2,100 mm 2,040 mm

Page 288 of 1574

OM600 ENGINE MECHANICAL 1B3-23

TENSIONING DEVICE Preceding Work : Removal of cooling fan

1 Bolt............................................................ 21Nm

2 Damper

3 Nut ............................................................. 21Nm

4 Tensioning Lever

5 Guide Rail Pin

6 Bolt

7 Poly V-Belt

8 Belt Pulley

9 Bolt ............................................................ 10Nm10 Tensioning Pulley

11 Socket Bolt ................................................ 29Nm

12 Closing Cover

13 Washer

14 Tensioning Lever

15 Fit Bolt ..................................................... 100Nm

16 Closing Cover

17 Spring

18 Bolt ............................................................ 20Nm

Page 289 of 1574

1B3-24 OM600 ENGINE MECHANICAL Removal & Installation Procedure

1. Remove the nut.Installation Notice

Tightening Torque 10 Nm

2. Push the tensioning lever in direction of arrow with a rod ( F12 ´ 180mm ) and push out the bolt to the rear.

3. Push back the tensioning lever to release the spring tension and remove the belt.

4. Remove the bolt (9) and then remove the belt pulley (8).

5. Remove the bolt (1, 18) and take off the damper (2). Notice

Pay attention to installation position of the damper.

Page 291 of 1574

1B3-26 OM600 ENGINE MECHANICAL

POLY V-BELT ALIGNMENT & INSPECTION Without Air Conditioner

With Air Conditioner