ABS SSANGYONG NEW ACTYON SPORTS 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 31 of 751

01-14

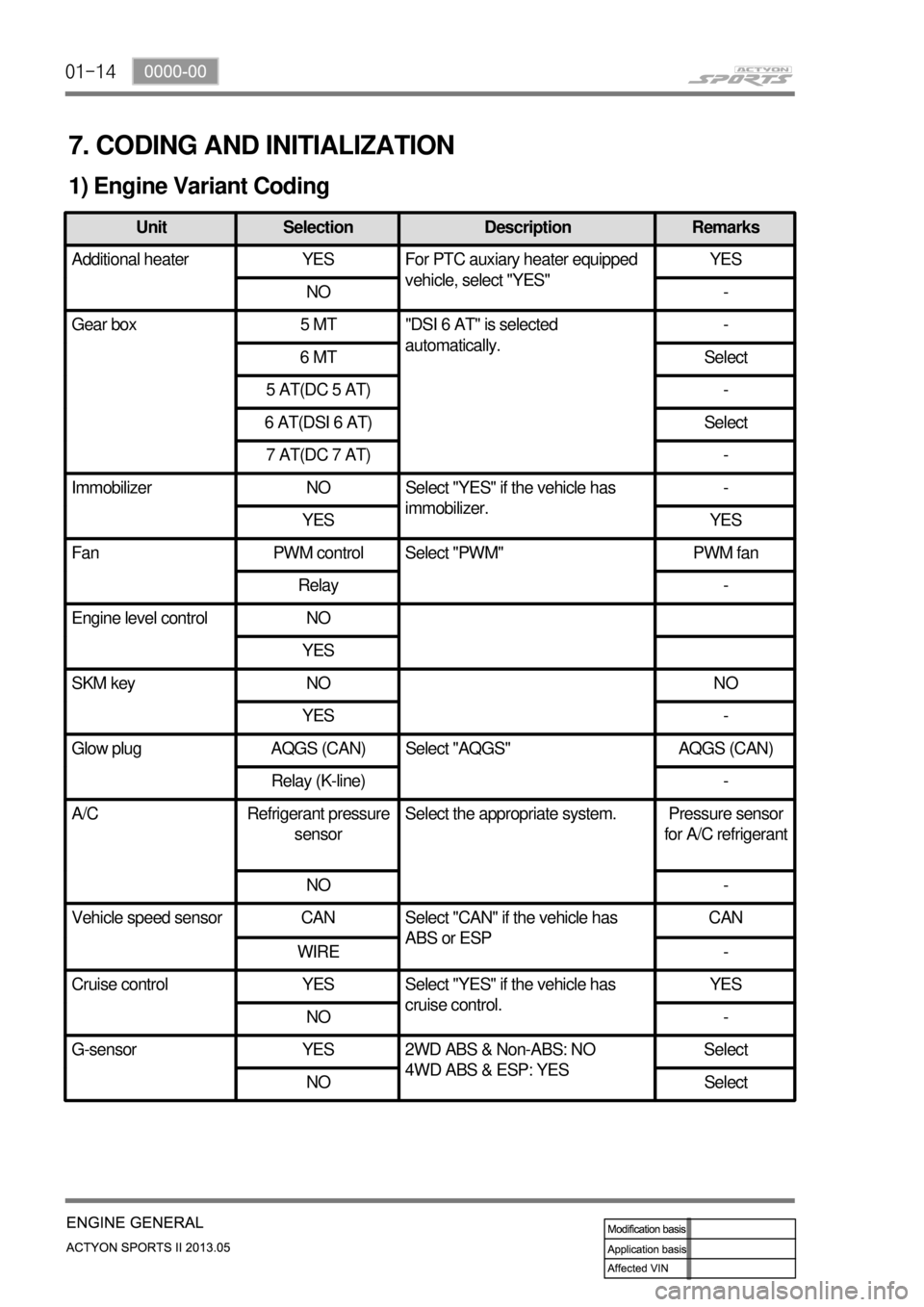

7. CODING AND INITIALIZATION

1) Engine Variant Coding

Unit Selection Description Remarks

Additional heater YES For PTC auxiary heater equipped

vehicle, select "YES"YES

NO -

Gear box 5 MT "DSI 6 AT" is selected

automatically.-

6 MT Select

5 AT(DC 5 AT) -

6 AT(DSI 6 AT) Select

7 AT(DC 7 AT) -

Immobilizer NO Select "YES" if the vehicle has

immobilizer.-

YES YES

Fan PWM control Select "PWM" PWM fan

Relay -

Engine level control NO

YES

SKM key NO NO

YES -

Glow plug AQGS (CAN) Select "AQGS" AQGS (CAN)

Relay (K-line) -

A/C Refrigerant pressure

sensorSelect the appropriate system. Pressure sensor

for A/C refrigerant

NO -

Vehicle speed sensor CAN Select "CAN" if the vehicle has

ABS or ESPCAN

WIRE -

Cruise control YES Select "YES" if the vehicle has

cruise control.YES

NO -

G-sensor YES 2WD ABS & Non-ABS: NO

4WD ABS & ESP: YESSelect

NO Select

Page 33 of 751

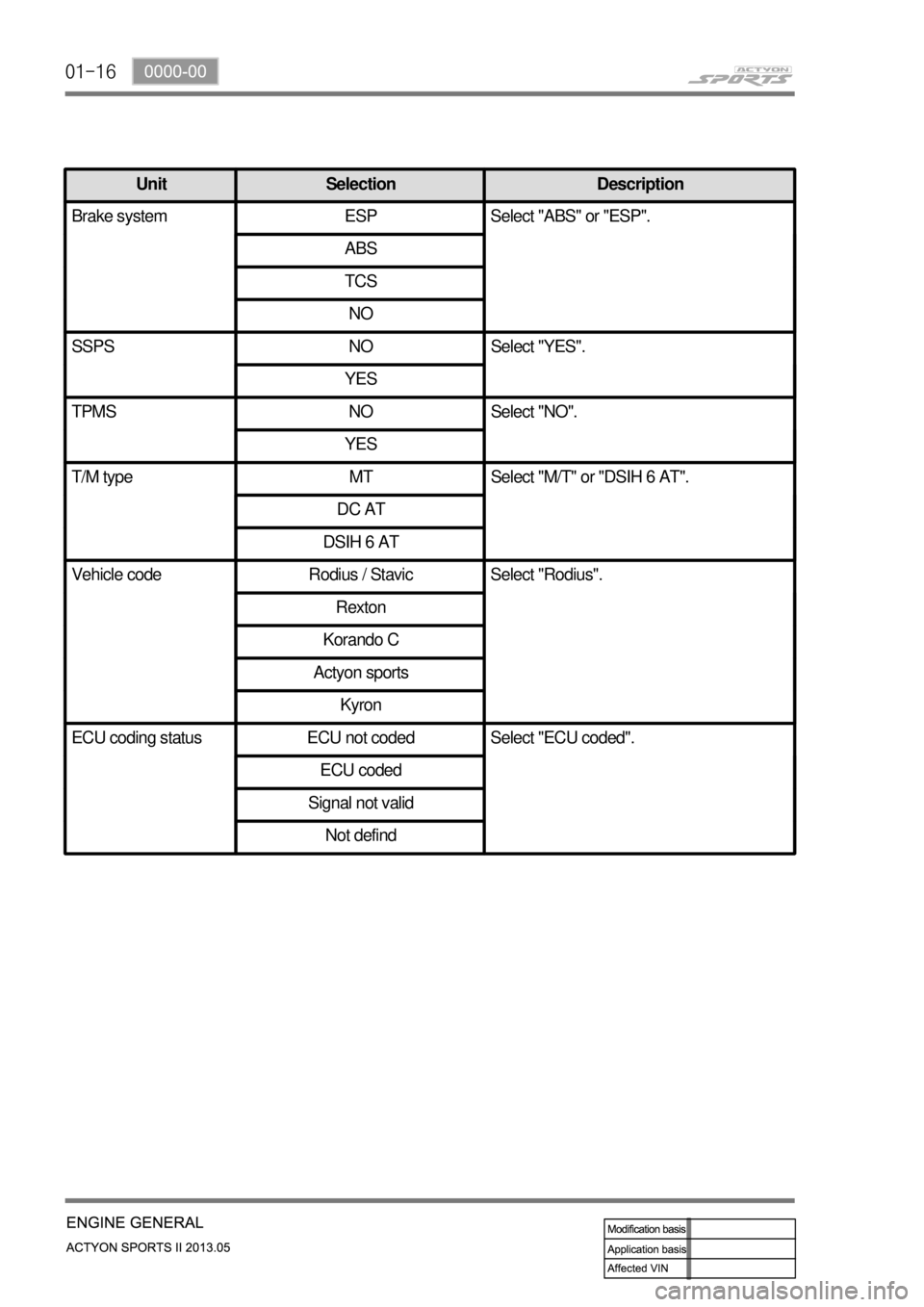

01-16

Unit Selection Description

Brake system ESP Select "ABS" or "ESP".

ABS

TCS

NO

SSPS NO Select "YES".

YES

TPMS NO Select "NO".

YES

T/M type MT Select "M/T" or "DSIH 6 AT".

DC AT

DSIH 6 AT

Vehicle code Rodius / Stavic Select "Rodius".

Rexton

Korando C

Actyon sports

Kyron

ECU coding status ECU not coded Select "ECU coded".

ECU coded

Signal not valid

Not defind

Page 61 of 751

02-30

2) Timing Chain and Gear

(1) Timing chain

Simple layout: optimized timing, enhanced

NVH

Single stage layout: minimized chain load -

-

Chain upper bush

- Single bush type (112 EA)

Chain lower bush

- Single bush type (60 EA)

(2) Tensioner

Tensioner adjusts the chain tension to keep it tight during engine running. This reduces the wear in

guide rail and spoke.

Operating principle

- Use the spring tension in tensioner and hydraulic pressure

Tensioner type

- Compensation and impact absorbing

Static and dynamic force

- Spring + Hydraulic pressure 1.

2.

3.

Plunger

HousingSpring

Check valve

Hydraulic tensioner assembly ▶

Page 62 of 751

02-310000-00

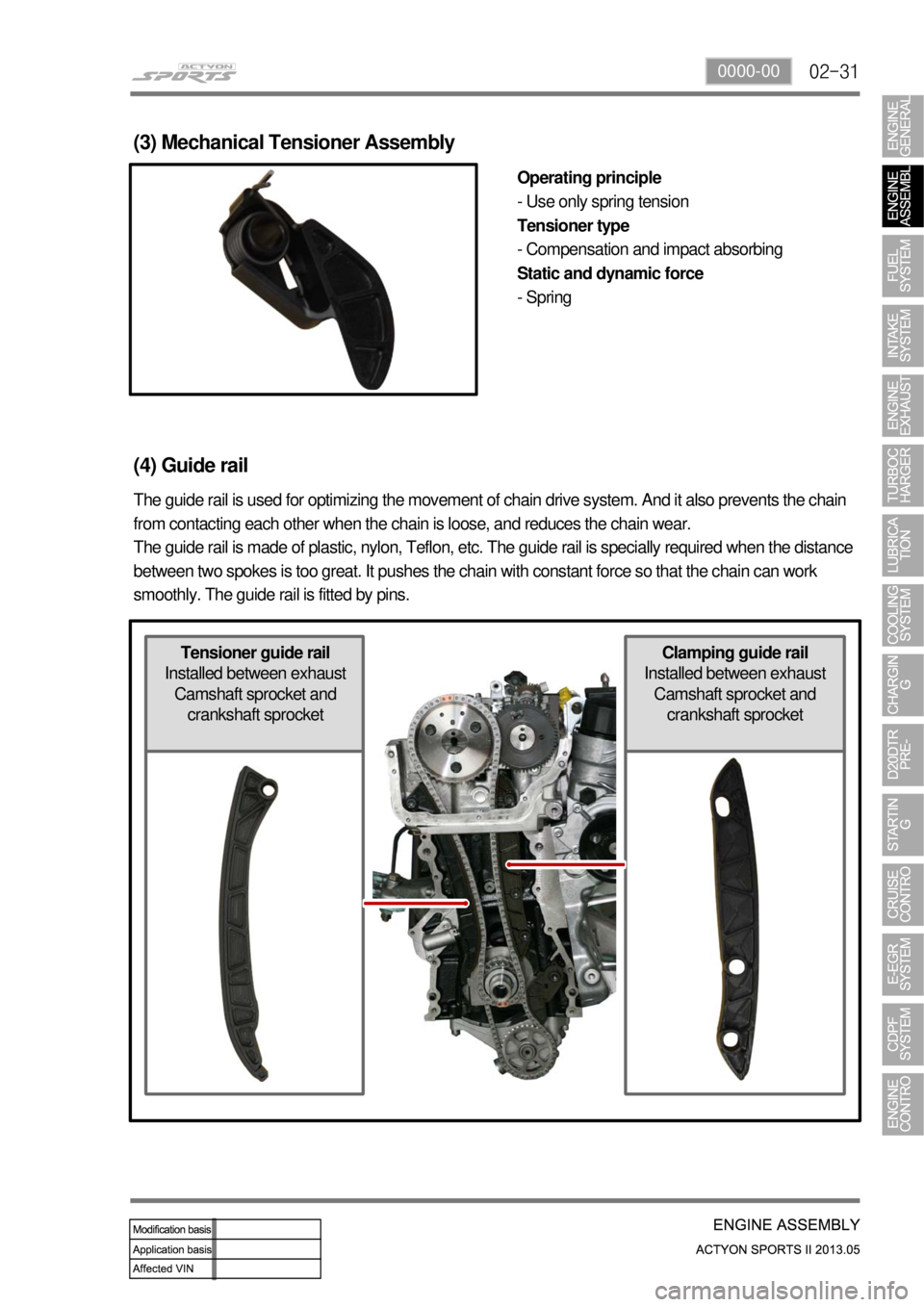

Clamping guide rail

Installed between exhaust

Camshaft sprocket and

crankshaft sprocketTensioner guide rail

Installed between exhaust

Camshaft sprocket and

crankshaft sprocket

(3) Mechanical Tensioner Assembly

Operating principle

- Use only spring tension

Tensioner type

- Compensation and impact absorbing

Static and dynamic force

- Spring

(4) Guide rail

The guide rail is used for optimizing the movement of chain drive system. And it also prevents the chain

from contacting each other when the chain is loose, and reduces the chain wear.

The guide rail is made of plastic, nylon, Teflon, etc. The guide rail is specially required when the distance

between two spokes is too great. It pushes the chain with constant force so that the chain can work

smoothly. The guide rail is fitted by pins.

Page 67 of 751

02-36

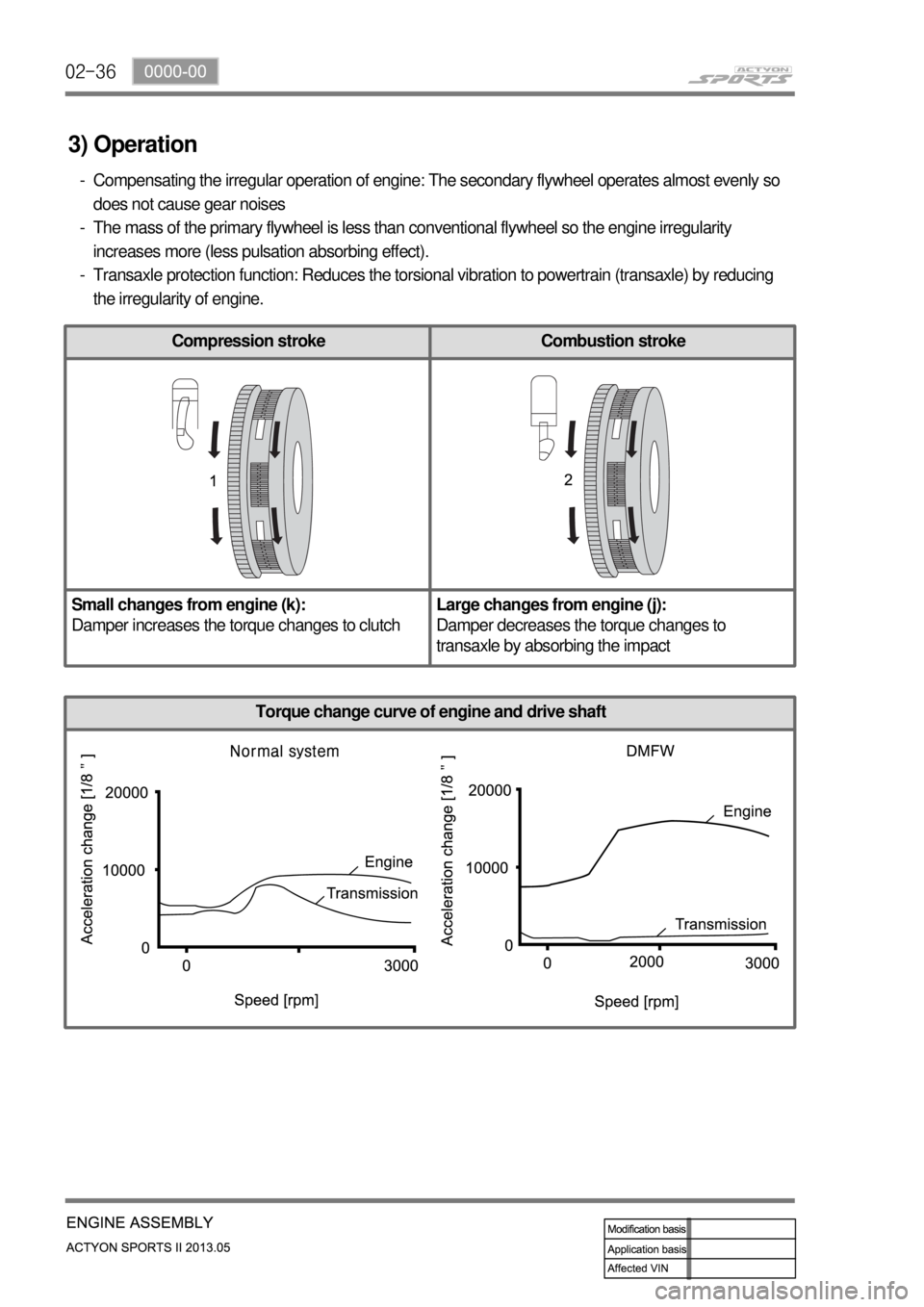

Torque change curve of engine and drive shaft

Compression stroke Combustion stroke

Small changes from engine (k):

Damper increases the torque changes to clutchLarge changes from engine (j):

Damper decreases the torque changes to

transaxle by absorbing the impact

3) Operation

Compensating the irregular operation of engine: The secondary flywheel operates almost evenly so

does not cause gear noises

The mass of the primary flywheel is less than conventional flywheel so the engine irregularity

increases more (less pulsation absorbing effect).

Transaxle protection function: Reduces the torsional vibration to powertrain (transaxle) by reducing

the irregularity of engine. -

-

-

Page 120 of 751

06-6

3) Inspection of Turbine

Thoroughly check the followings.

Must absolutely not operate the turbocharger with the compressor outlet and inlet opened as it could

damage the turbocharger or be hazardous during inspection.

Interference: In case where is trace of interference or smallest damage on the compressor wheel

means, most of times, that abrasion has occurred on the journal bearing. Must inspect after the

overhaul.

Oil Leakage: The reason for oil leakage at the compressor section is the air cleaner, clogged by

substances such as dust, causes the compressor inlet negative pressure. -

-

Rotating in high speed at no-load for extended period of time can cause oil leakage to the

compressor section as oil pressure within the center housing gets higher than pressure within the

compressor housing.

Overuse of engine break (especially in low gear) in down hill makes significantly low exhaust gas

energy compared to the time where great amount of air is required during idling conditions of the

engine. Therefore, amount of air in the compressor inlet increases but the turbocharge pressure is

not high, which makes negative a.

b.

No problem will occur with the turbocharger if above conditions are found in early stage but oil

leaked over long period of time will solidify at each section causing to breakout secondary defects.

Damages by foreign materials: In case where the compressor wheel is damaged by foreign materials

requires having an overhaul. At this time, it's necessary to check whether the foreign materials have

contaminated intake/exhaust manifold or inside of engine.

Page 209 of 751

15-90000-00

Fuel rail pressure

sensor

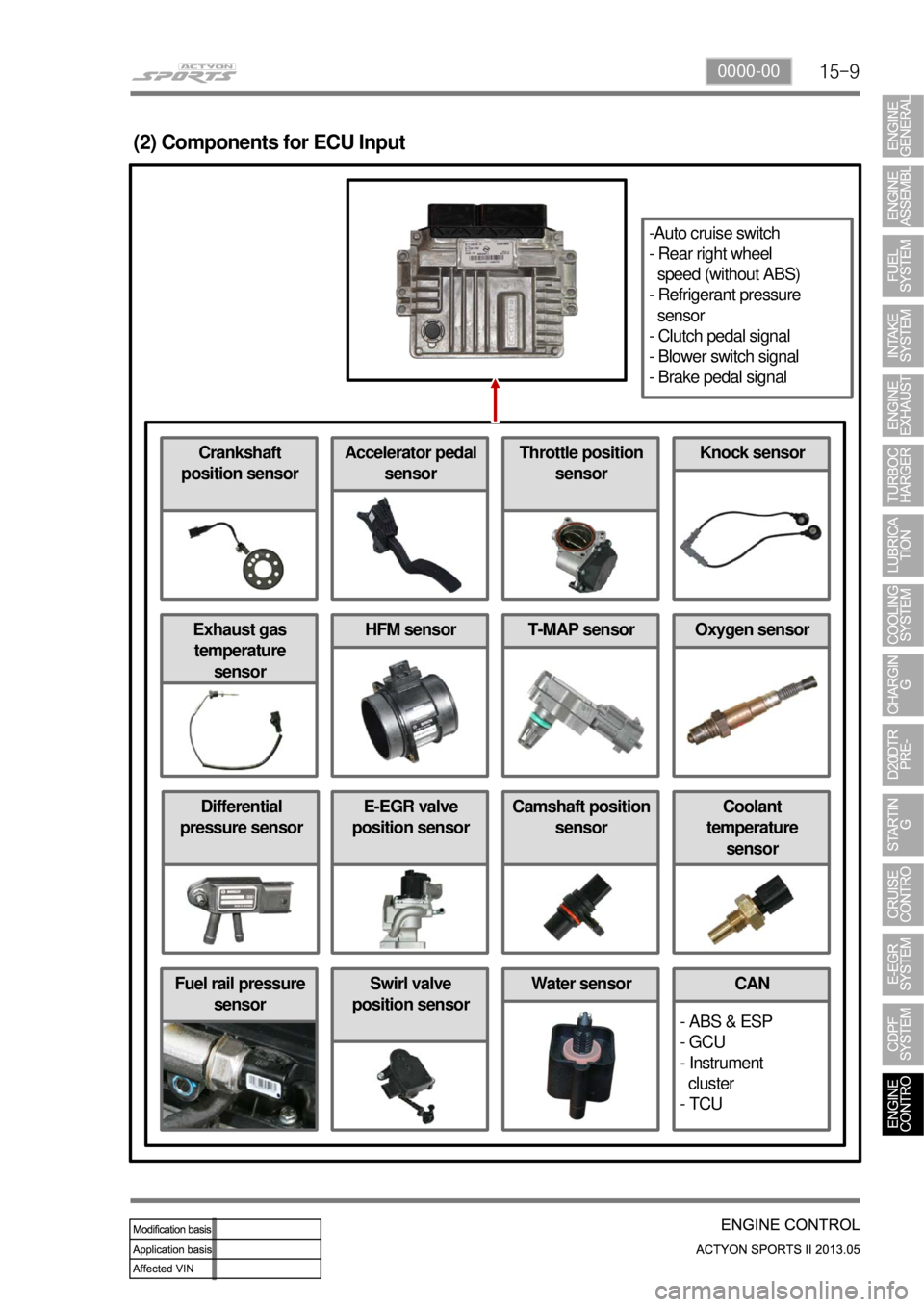

(2) Components for ECU Input

CAN

- ABS & ESP

- GCU

- Instrument

cluster

- TCUSwirl valve

position sensor

Differential

pressure sensorE-EGR valve

position sensorCamshaft position

sensorCoolant

temperature

sensor

Exhaust gas

temperature

sensorHFM sensorOxygen sensorT-MAP sensor

Crankshaft

position sensorAccelerator pedal

sensorThrottle position

sensorKnock sensor

-Auto cruise switch

- Rear right wheel

speed (without ABS)

- Refrigerant pressure

sensor

- Clutch pedal signal

- Blower switch signal

- Brake pedal signal

Water sensor

Page 210 of 751

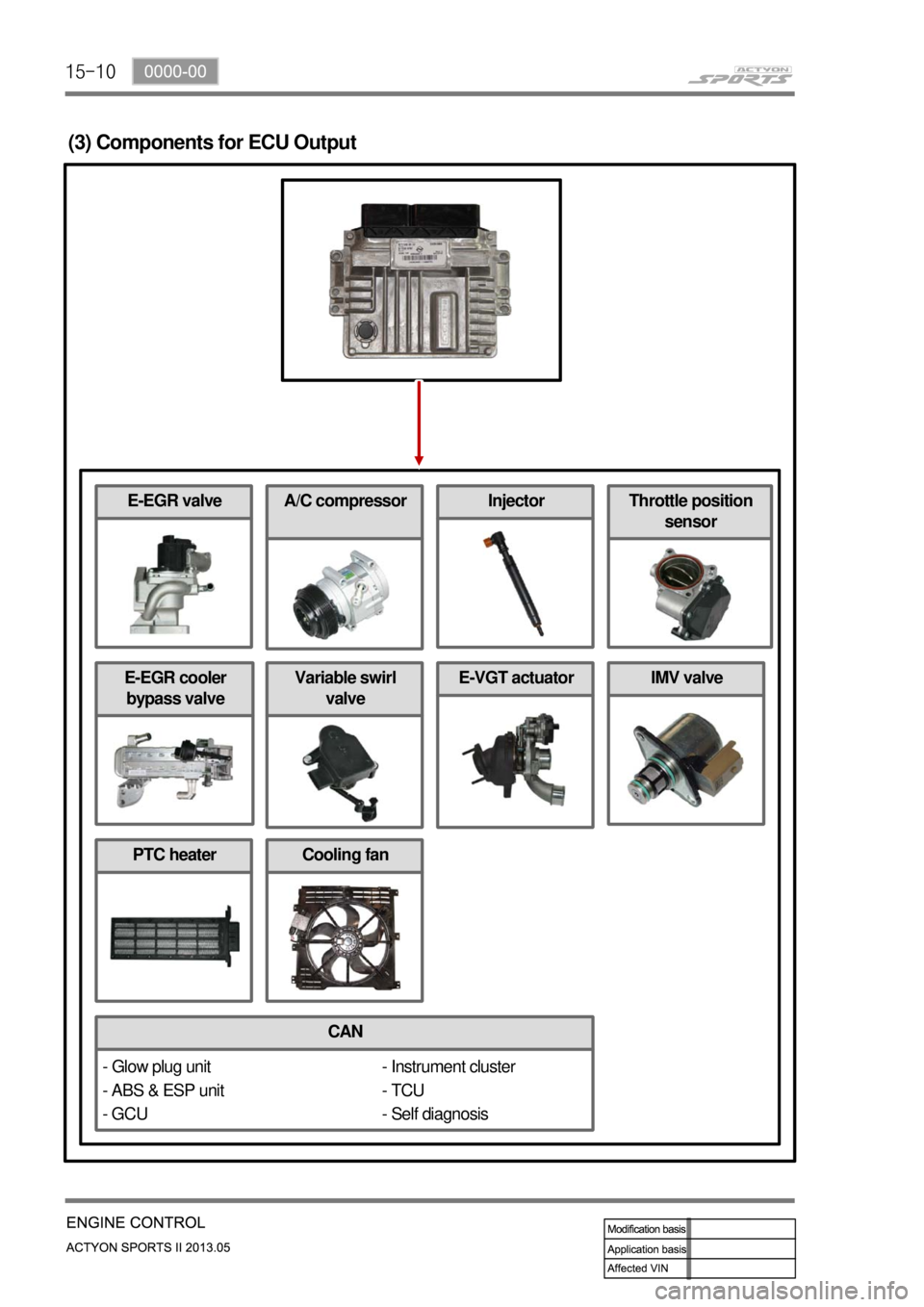

15-10

(3) Components for ECU Output

CAN

E-EGR cooler

bypass valve

- Instrument cluster

- TCU

- Self diagnosis

PTC heaterCooling fan

E-EGR valve

Variable swirl

valveE-VGT actuatorIMV valve

A/C compressorInjectorThrottle position

sensor

- Glow plug unit

- ABS & ESP unit

- GCU

Page 274 of 751

02-52211-06

1. FUEL SYSTEM

The function of the fuel metering system is to deliver the correct amount of fuel to the engine under all

operating conditions.

The fuel is delivered to the engine by the individual fuel injectors mounted into the intake manifold nea

r

each cylinder.

The main fuel control sensors are the Mass Air Flow (MAF) sensor and the oxygen (O2) sensors.

The MAF sensor monitors the mass flow of the air being drawn into the engine. An electrically heated

element is mounted in the intake air stream, where it is cooled by the flow of incoming air. Engine Control

Module (ECM) modulates the flow of heating current to maintain the temperature differential between the

heated film and the intake air at a constant level. The amount of heating current required to maintain the

temperature thus provides an index for the mass air flow. This

concept automatically compensates for variations in air density, as this is one of the factors that

determines the amount of warmth that the surrounding air absorbs from the heated element. MAF

sensor is located between the air filter and the throttle valve.

Under high fuel demands, the MAF sensor reads a high mass flow condition, such as wide open throttle.

The ECM uses this information to enrich the mixture, thus increasing the fuel injector on-time, to provide

the correct amount of fuel. When decelerating, the mass flow decreases. This mass flow change is

sensed by the MAF sensor and read by the ECM, which then decreases the fuel injector on-time due to

the low fuel demand conditions.

The O2 sensors are located in the exhaust pipe before catalytic converter. The O2 sensors indicate to

the ECM the amount of oxygen in the exhaust gas, and the ECM changes the air/fuel ratio to the engine

by controlling the fuel injectors. The best air/fuel ratio to minimize exhaust emissions is 14.7 to 1, which

allows the catalytic converter to operate most efficiently. Because

of the constant measuring and adjusting of the air/fuel ratio, the fuel injection system is called a "closed

loop" system.

The ECM uses voltage inputs from several sensors to determine how much fuel to provide to the engine.

The fuel is delivered under one of several conditions, called "modes".

Page 388 of 751

04-58210-01

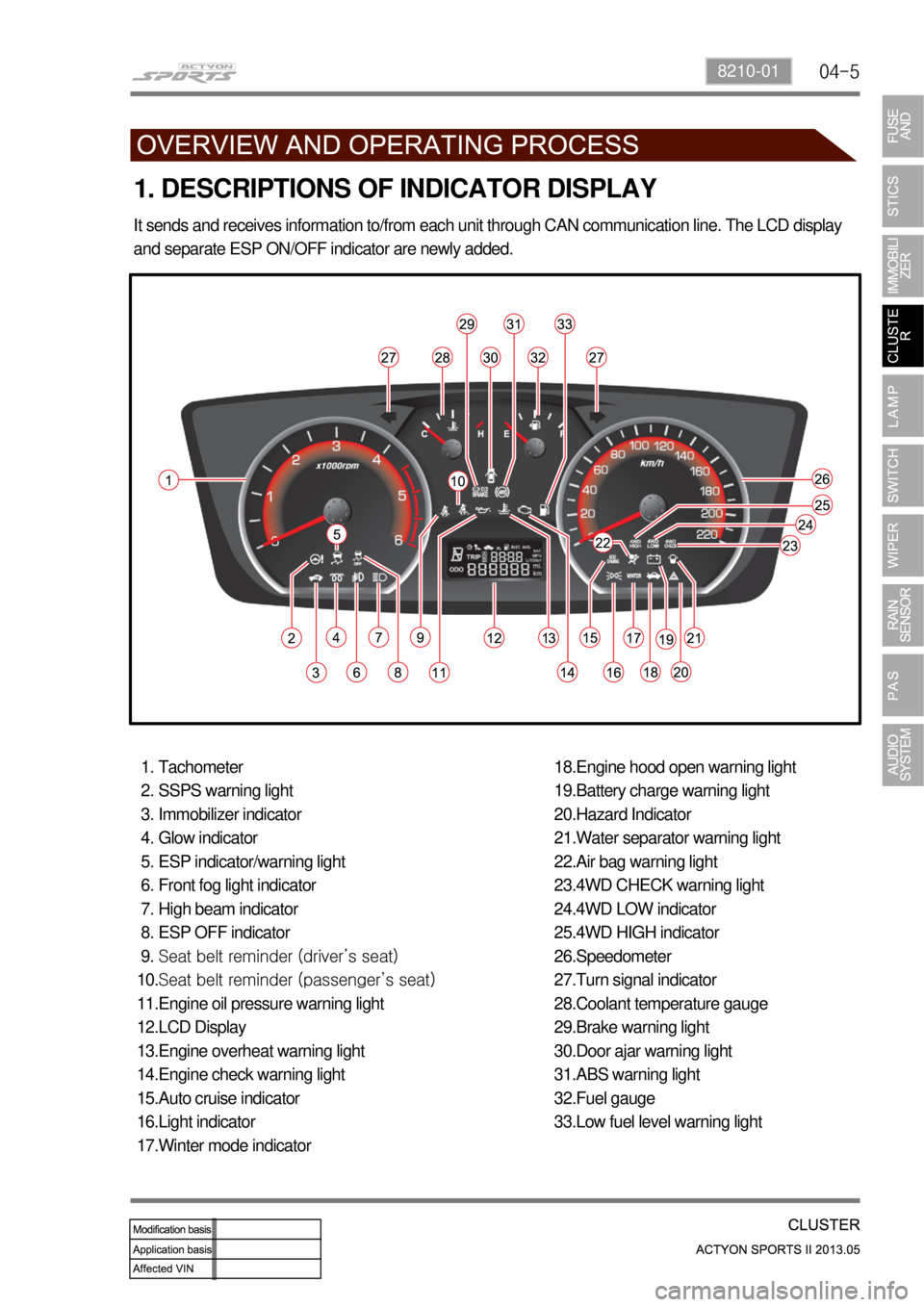

1. DESCRIPTIONS OF INDICATOR DISPLAY

Tachometer

SSPS warning light

Immobilizer indicator

Glow indicator

ESP indicator/warning light

Front fog light indicator

High beam indicator

ESP OFF indicator

Seat belt reminder (driver’s seat)

Seat belt reminder (passenger’s seat)

Engine oil pressure warning light

LCD Display

Engine overheat warning light

Engine check warning light

Auto cruise indicator

Light indicator

Winter mode indicator 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.Engine hood open warning light

Battery charge warning light

Hazard Indicator

Water separator warning light

Air bag warning light

4WD CHECK warning light

4WD LOW indicator

4WD HIGH indicator

Speedometer

Turn signal indicator

Coolant temperature gauge

Brake warning light

Door ajar warning light

ABS warning light

Fuel gauge

Low fuel level warning light 18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33. It sends and receives information to/from each unit through CAN communication line. The LCD display

and separate ESP ON/OFF indicator are newly added.