cylinder SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1721 of 2453

GD(H6DO)-109

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

BO:DTC P0302 CYLINDER 2 MISFIRE DETECTED

1. OUTLINE OF DIAGNOSIS

NOTE:

For the diagnostic procedure, refer to DTC P0301.

BP:DTC P0303 CYLINDER 3 MISFIRE DETECTED

1. OUTLINE OF DIAGNOSIS

NOTE:

For the diagnostic procedure, refer to DTC P0301.

BQ:DTC P0304 CYLINDER 4 MISFIRE DETECTED

1. OUTLINE OF DIAGNOSIS

NOTE:

For the diagnostic procedure, refer to DTC P0301.

BR:DTC P0305 CYLINDER 5 MISFIRE DETECTED

1. OUTLINE OF DIAGNOSIS

NOTE:

For the diagnostic procedure, refer to DTC P0301.

BS:DTC P0306 CYLINDER 6 MISFIRE DETECTED

1. OUTLINE OF DIAGNOSIS

NOTE:

For the diagnostic procedure, refer to DTC P0301.

Page 1729 of 2453

GD(H6DO)-117

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform the diagnosis continuously under 3000 rpm engine RPM.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when all the malfunction criteria below are completed more than 10 times in a row.

Time Needed for Diagnosis: 10 engine rotations

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

None

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Secondary Parameters Enable Conditions

Battery voltage≥ 8 V

Engine speed < 3000 rpm

Judgment Value

Malfunction Criteria Threshold Value

Cylinder number identification Completed

Amount of crank sensor signal during 1

rev.

Not = 30

Judgment Value

Malfunction Criteria Threshold Value

Cylinder number distinction Completed

Amount of crank sensor signal during 1

rev.

= 30

Page 1781 of 2453

GD(H6DO)-169

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

CW:DTC P0519 IDLE CONTROL SYSTEM MALFUNCTION (FAIL-SAFE)

1. OUTLINE OF DIAGNOSIS

Detect malfunctions in which the engine RPM continues to rise during idling.

2. ENABLE CONDITIONS

3. GENERAL DRIVING CYCLE

Perform the diagnosis continuously if the vehicle speed at less than 4 km/h (2.49 MPH).

4. DIAGNOSTIC METHOD

Judge as NG when the continuous time until completing the all malfunction criteria below becomes more than

the time needed for diagnosis (2 seconds).

Time Needed for Diagnosis: 2 seconds

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK and clear NG when the continuous time until completing the malfunction criteria below be-

comes more than the time needed for diagnosis (5 seconds).

5. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

6. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

7. FAIL SAFE

Fuel cut: Cuts off fuel only #1 and #2 cylinders, or for all cylinders according to vehicle speed, engine RPM,

and throttle position.

8. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Secondary Parameters Enable Conditions

Battery voltage≥ 10.9 V

Feedback in ISC In operation

Ve h i c l e s p e e d < 4 k m / h ( 2 . 4 9 M P H )

After engine starting 1 second or more

Judgment Value

Malfunction Criteria Threshold Value

Engine RPM - Targeted engine RPM≥ 1500 rpm

Feedback value for ISC≤ 0

Change of engine RPM for every engine

120 °CA

≥ –5 rpm

Judgment Value

Malfunction Criteria Threshold Value

Engine RPM - Targeted engine RPM < 1500 rpm

Page 1860 of 2453

LU(H6DO)-11

Oil Pan and Strainer

LUBRICATION

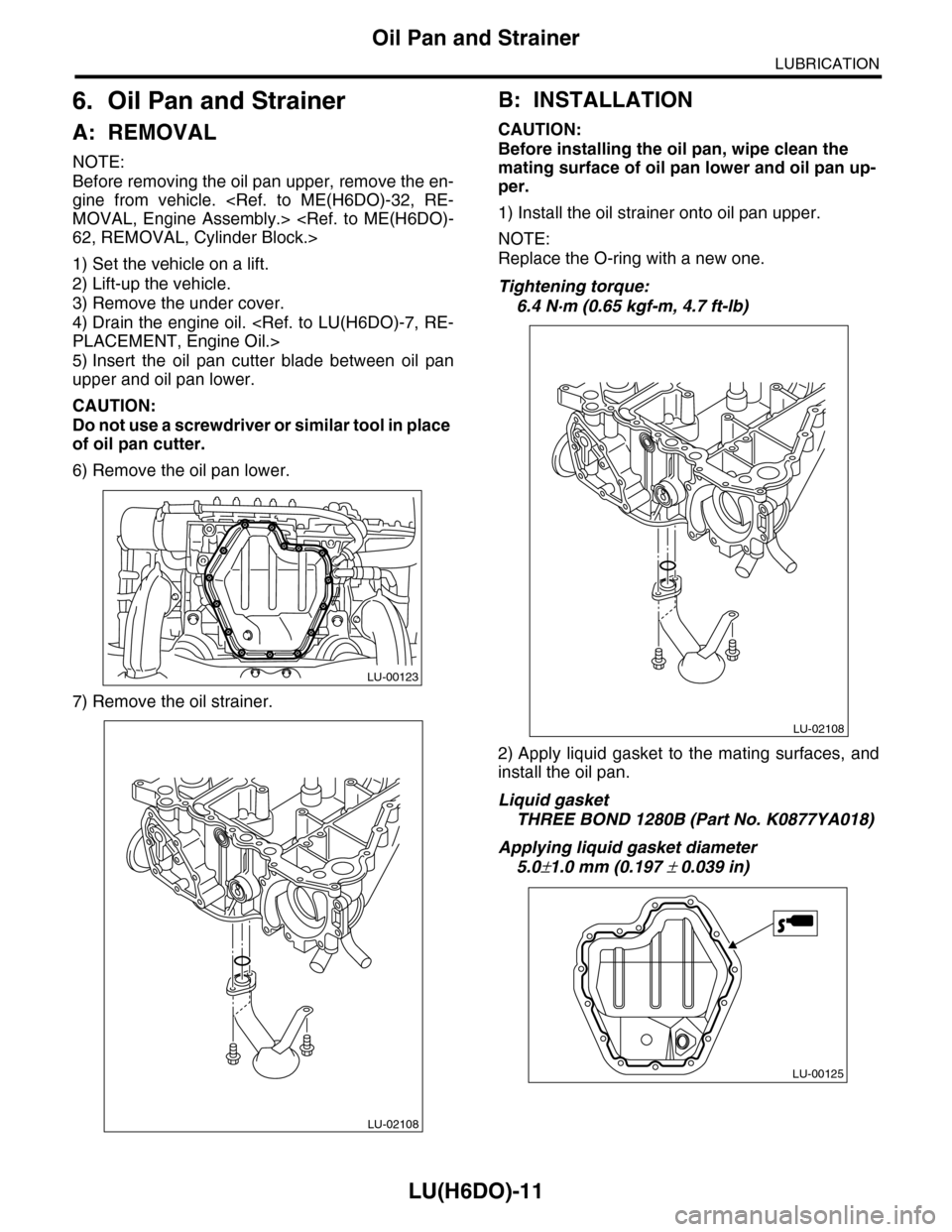

6. Oil Pan and Strainer

A: REMOVAL

NOTE:

Before removing the oil pan upper, remove the en-

gine from vehicle.

1) Set the vehicle on a lift.

2) Lift-up the vehicle.

3) Remove the under cover.

4) Drain the engine oil.

5) Insert the oil pan cutter blade between oil pan

upper and oil pan lower.

CAUTION:

Do not use a screwdriver or similar tool in place

of oil pan cutter.

6) Remove the oil pan lower.

7) Remove the oil strainer.

B: INSTALLATION

CAUTION:

Before installing the oil pan, wipe clean the

mating surface of oil pan lower and oil pan up-

per.

1) Install the oil strainer onto oil pan upper.

NOTE:

Replace the O-ring with a new one.

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

2) Apply liquid gasket to the mating surfaces, and

install the oil pan.

Liquid gasket

THREE BOND 1280B (Part No. K0877YA018)

Applying liquid gasket diameter

5.0±1.0 mm (0.197 ± 0.039 in)

LU-00123

LU-02108

LU-02108

LU-00125

Page 1868 of 2453

ME(H6DO)-2

General Description

MECHANICAL

1. General Description

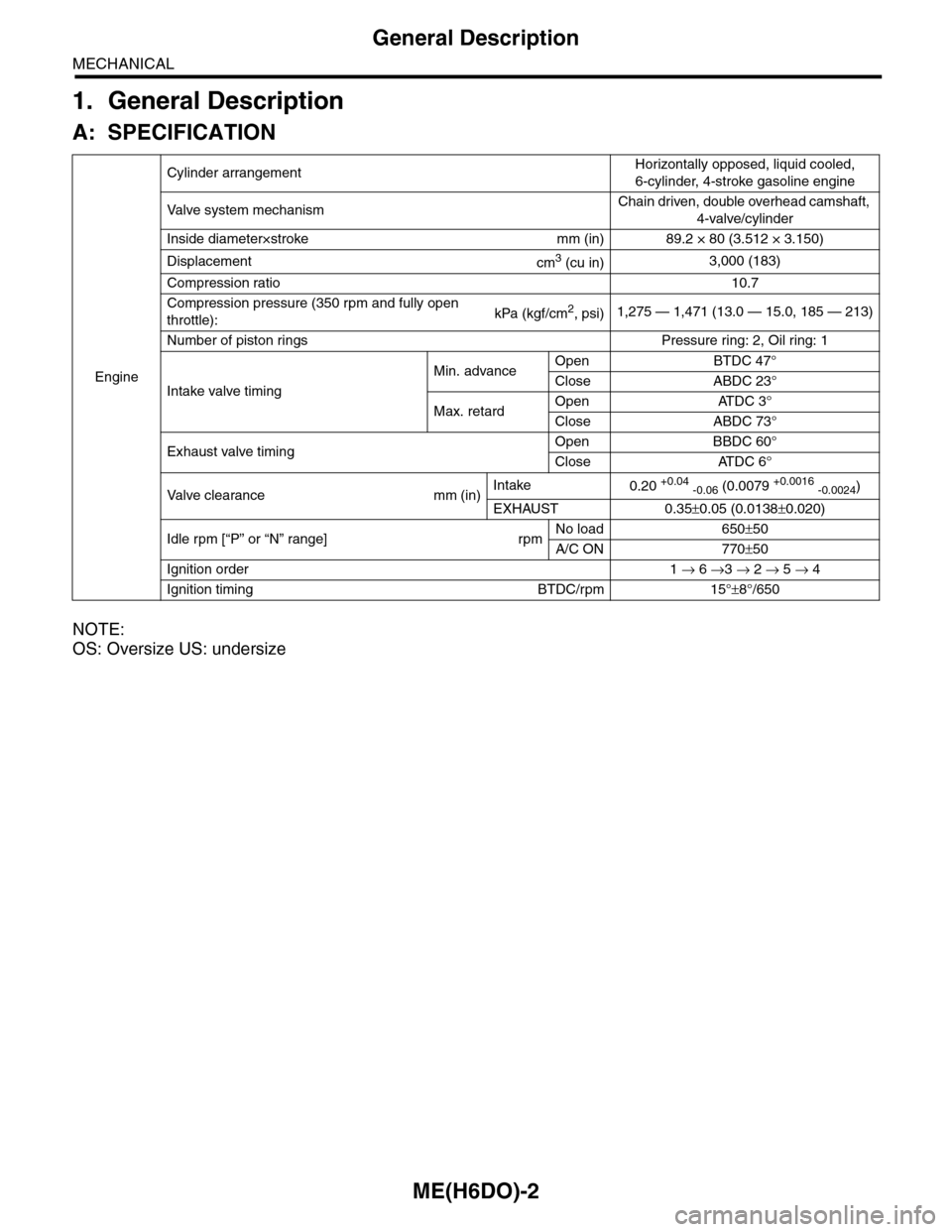

A: SPECIFICATION

NOTE:

OS: Oversize US: undersize

Engine

Cylinder arrangementHorizontally opposed, liquid cooled,

6-cylinder, 4-stroke gasoline engine

Va l ve s y s t e m m e c h a n i s mChain driven, double overhead camshaft,

4-valve/cylinder

Inside diameter×stroke mm (in) 89.2 × 80 (3.512 × 3.150)

Displacementcm3 (cu in)3,000 (183)

Compression ratio10.7

Compression pressure (350 rpm and fully open

throttle):kPa (kgf/cm2, psi)1,275 — 1,471 (13.0 — 15.0, 185 — 213)

Number of piston rings Pressure ring: 2, Oil ring: 1

Intake valve timing

Min. advanceOpen BTDC 47°

Close ABDC 23°

Max. retardOpen ATDC 3°

Close ABDC 73°

Exhaust valve timingOpen BBDC 60°

Close ATDC 6°

Va l ve c l e a r a n c e m m ( i n )Intake0.20 +0.04 -0.06 (0.0079 +0.0016 -0.0024)

EXHAUST 0.35±0.05 (0.0138±0.020)

Idle rpm [“P” or “N” range] rpmNo load 650±50

A/C ON 770±50

Ignition order 1 → 6 →3 → 2 → 5 → 4

Ignition timing BTDC/rpm 15°±8°/650

Page 1869 of 2453

ME(H6DO)-3

General Description

MECHANICAL

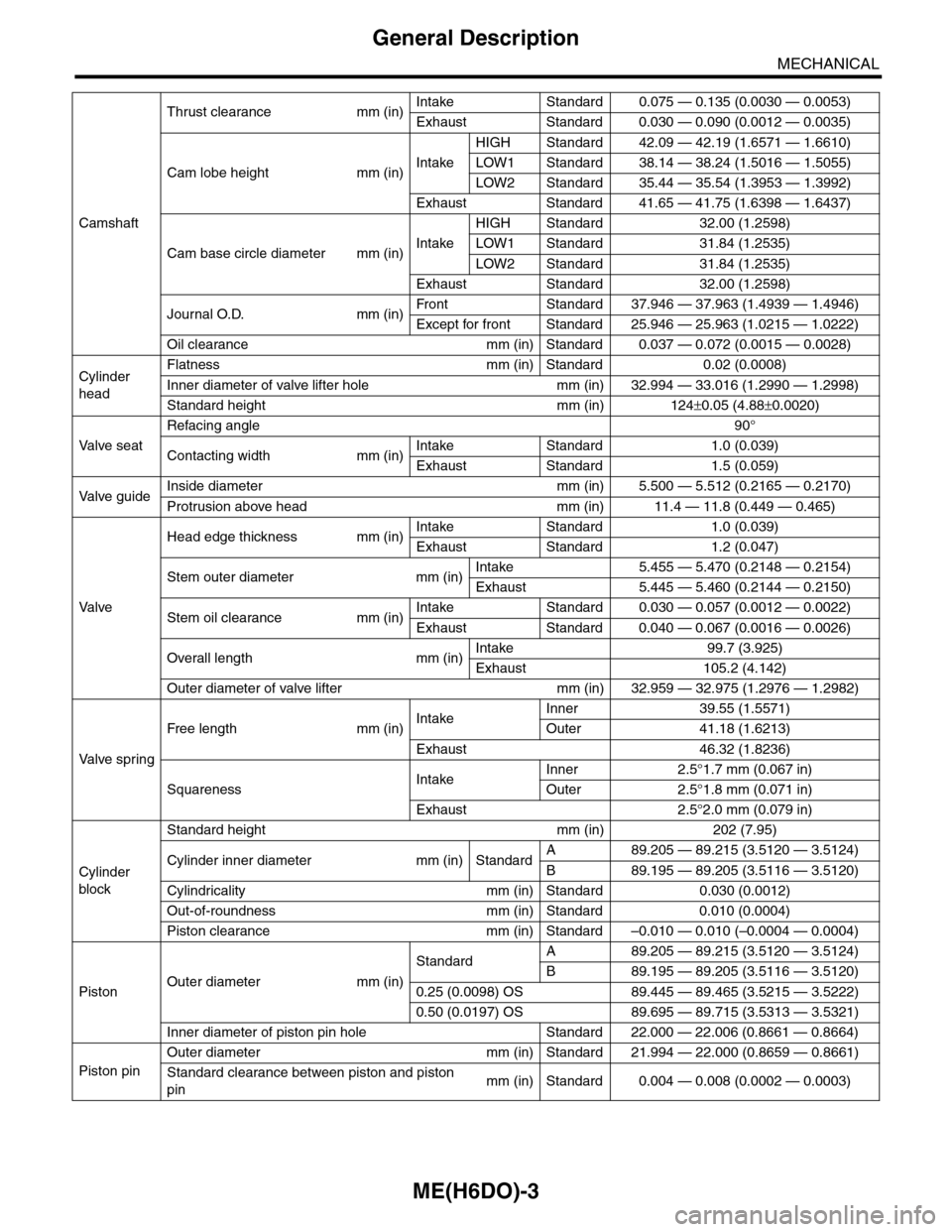

Camshaft

Thrust clearance mm (in)Intake Standard 0.075 — 0.135 (0.0030 — 0.0053)

Exhaust Standard 0.030 — 0.090 (0.0012 — 0.0035)

Cam lobe height mm (in)Intake

HIGH Standard 42.09 — 42.19 (1.6571 — 1.6610)

LOW1 Standard 38.14 — 38.24 (1.5016 — 1.5055)

LOW2 Standard 35.44 — 35.54 (1.3953 — 1.3992)

Exhaust Standard 41.65 — 41.75 (1.6398 — 1.6437)

Cam base circle diameter mm (in)Intake

HIGH Standard 32.00 (1.2598)

LOW1 Standard 31.84 (1.2535)

LOW2 Standard 31.84 (1.2535)

Exhaust Standard 32.00 (1.2598)

Journal O.D. mm (in)Fr o nt S ta n da r d 3 7. 9 46 — 3 7 . 96 3 ( 1 . 49 3 9 — 1. 4 9 46 )

Except for front Standard 25.946 — 25.963 (1.0215 — 1.0222)

Oil clearance mm (in) Standard 0.037 — 0.072 (0.0015 — 0.0028)

Cylinder

head

Flatness mm (in) Standard 0.02 (0.0008)

Inner diameter of valve lifter hole mm (in) 32.994 — 33.016 (1.2990 — 1.2998)

Standard height mm (in) 124±0.05 (4.88±0.0020)

Va l ve s e a t

Refacing angle90°

Contacting width mm (in)Intake Standard 1.0 (0.039)

Exhaust Standard 1.5 (0.059)

Va l ve g u i d eInside diameter mm (in) 5.500 — 5.512 (0.2165 — 0.2170)

Protrusion above head mm (in) 11.4 — 11.8 (0.449 — 0.465)

Va l ve

Head edge thickness mm (in)Intake Standard 1.0 (0.039)

Exhaust Standard 1.2 (0.047)

Stem outer diameter mm (in)Intake 5.455 — 5.470 (0.2148 — 0.2154)

Exhaust 5.445 — 5.460 (0.2144 — 0.2150)

Stem oil clearance mm (in)Intake Standard 0.030 — 0.057 (0.0012 — 0.0022)

Exhaust Standard 0.040 — 0.067 (0.0016 — 0.0026)

Overall length mm (in)Intake 99.7 (3.925)

Exhaust 105.2 (4.142)

Outer diameter of valve lifter mm (in) 32.959 — 32.975 (1.2976 — 1.2982)

Va l ve s p r i n g

Free length mm (in)IntakeInner 39.55 (1.5571)

Outer 41.18 (1.6213)

Exhaust 46.32 (1.8236)

SquarenessIntakeInner 2.5°1.7 mm (0.067 in)

Outer 2.5°1.8 mm (0.071 in)

Exhaust 2.5°2.0 mm (0.079 in)

Cylinder

block

Standard height mm (in) 202 (7.95)

Cylinder inner diameter mm (in) StandardA89.205 — 89.215 (3.5120 — 3.5124)

B89.195 — 89.205 (3.5116 — 3.5120)

Cylindricality mm (in) Standard 0.030 (0.0012)

Out-of-roundness mm (in) Standard 0.010 (0.0004)

Piston clearance mm (in) Standard –0.010 — 0.010 (–0.0004 — 0.0004)

PistonOuter diameter mm (in)

StandardA89.205 — 89.215 (3.5120 — 3.5124)

B89.195 — 89.205 (3.5116 — 3.5120)

0.25 (0.0098) OS 89.445 — 89.465 (3.5215 — 3.5222)

0.50 (0.0197) OS 89.695 — 89.715 (3.5313 — 3.5321)

Inner diameter of piston pin hole Standard 22.000 — 22.006 (0.8661 — 0.8664)

Piston pin

Outer diameter mm (in) Standard 21.994 — 22.000 (0.8659 — 0.8661)

Standard clearance between piston and piston

pinmm (in) Standard 0.004 — 0.008 (0.0002 — 0.0003)

Page 1874 of 2453

ME(H6DO)-8

General Description

MECHANICAL

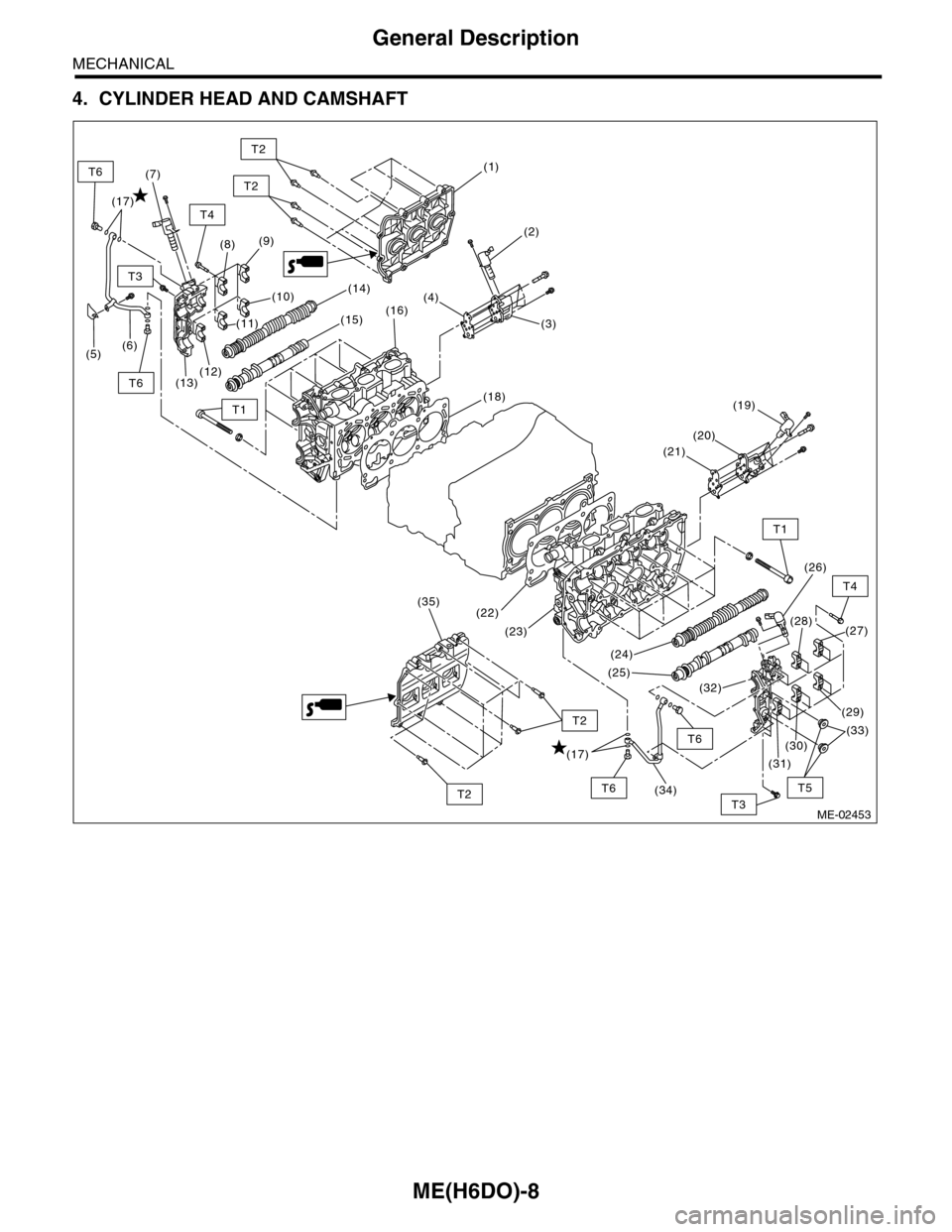

4. CYLINDER HEAD AND CAMSHAFT

ME-02453

(1)

(2)

(3)

(4)

(9)

(10)

(22)

(23)

(24)

(26)

(27)(28)

(25)

(32)

(8)

(18)

(16)

(13)(12)

(6)(5)

(14)

(15)

(19)

(20)

(21)

(7)

(11)

(31)

(34)

(35)

(30)

(29)

(33)

T3

T1

T4

T2

T2

T1

T4

T5

T2

T2T3

T6

T6

T6

T6

(17)

(17)

Page 1875 of 2453

ME(H6DO)-9

General Description

MECHANICAL

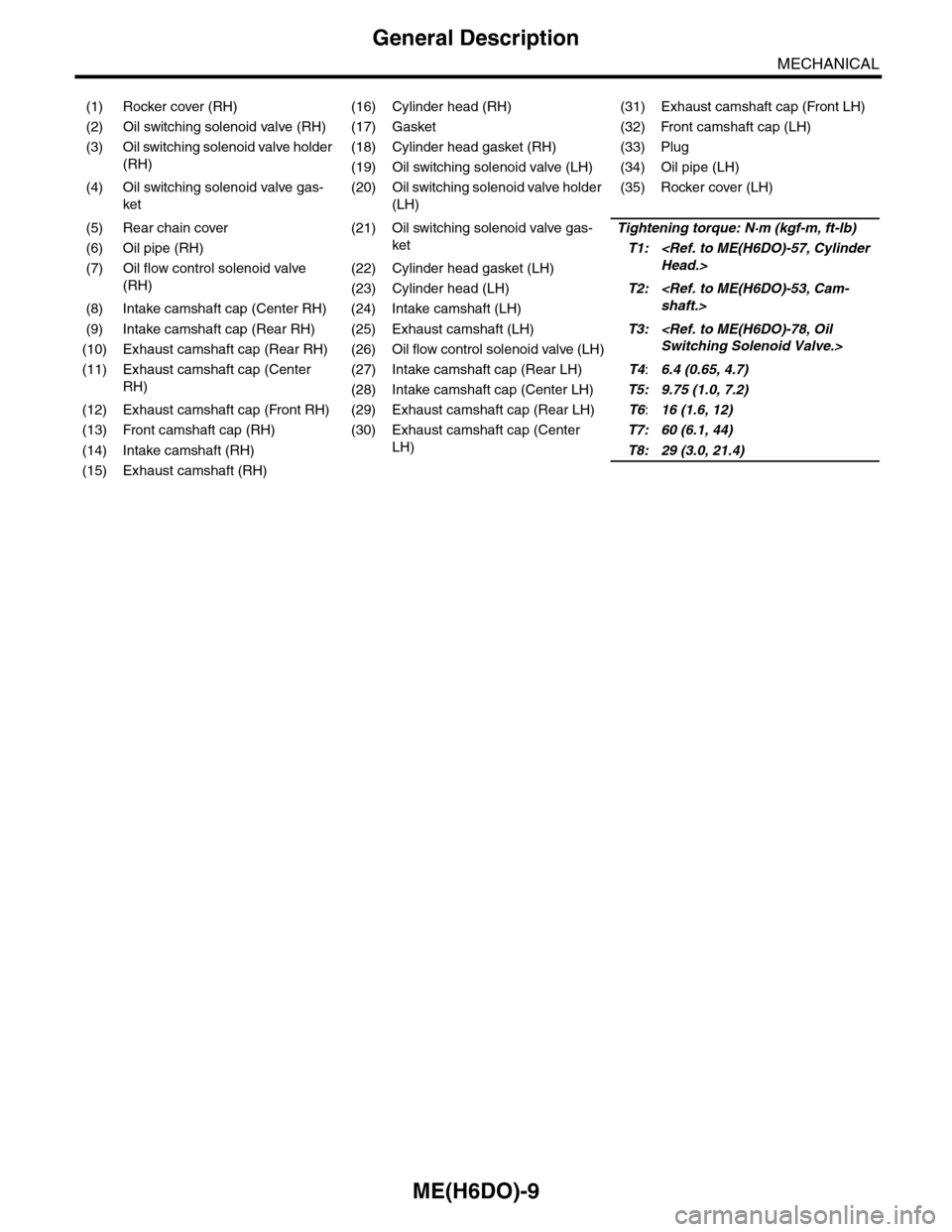

(1) Rocker cover (RH) (16) Cylinder head (RH) (31) Exhaust camshaft cap (Front LH)

(2) Oil switching solenoid valve (RH) (17) Gasket (32) Front camshaft cap (LH)

(3) Oil switching solenoid valve holder

(RH)

(18) Cylinder head gasket (RH) (33) Plug

(19) Oil switching solenoid valve (LH) (34) Oil pipe (LH)

(4) Oil switching solenoid valve gas-

ket

(20) Oil switching solenoid valve holder

(LH)

(35) Rocker cover (LH)

(5) Rear chain cover (21) Oil switching solenoid valve gas-

ket

Tightening torque: N·m (kgf-m, ft-lb)

(6) Oil pipe (RH)T1:

(RH)

(22) Cylinder head gasket (LH)

(23) Cylinder head (LH)T2:

(9) Intake camshaft cap (Rear RH) (25) Exhaust camshaft (LH)T3:

(11) Exhaust camshaft cap (Center

RH)

(27) Intake camshaft cap (Rear LH)T4:6.4 (0.65, 4.7)

(28) Intake camshaft cap (Center LH)T5: 9.75 (1.0, 7.2)

(12) Exhaust camshaft cap (Front RH) (29) Exhaust camshaft cap (Rear LH)T6:16 (1.6, 12)

(13) Front camshaft cap (RH) (30) Exhaust camshaft cap (Center

LH)

T7: 60 (6.1, 44)

(14) Intake camshaft (RH)T8: 29 (3.0, 21.4)

(15) Exhaust camshaft (RH)

Page 1876 of 2453

ME(H6DO)-10

General Description

MECHANICAL

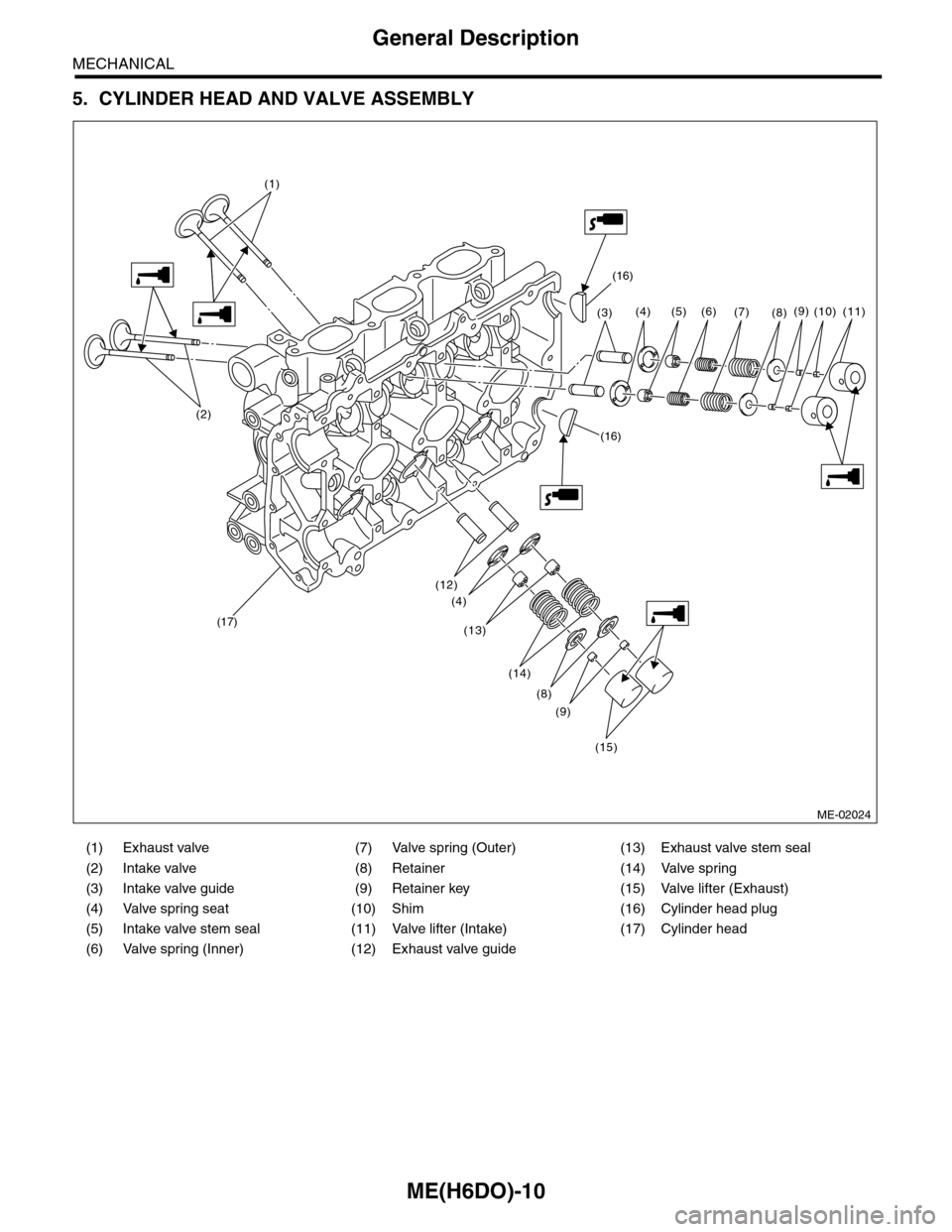

5. CYLINDER HEAD AND VALVE ASSEMBLY

(1) Exhaust valve (7) Valve spring (Outer) (13) Exhaust valve stem seal

(2) Intake valve (8) Retainer (14) Valve spring

(3) Intake valve guide (9) Retainer key (15) Valve lifter (Exhaust)

(4) Valve spring seat (10) Shim (16) Cylinder head plug

(5) Intake valve stem seal (11) Valve lifter (Intake) (17) Cylinder head

(6) Valve spring (Inner) (12) Exhaust valve guide

ME-02024

(16)

(16)

(17)

(3)

(12)

(13)

(4)

(14)

(8)

(9)

(15)

(4) (5) (6)(7)(8)(9)(11)(10)

(1)

(2)

Page 1877 of 2453

ME(H6DO)-11

General Description

MECHANICAL

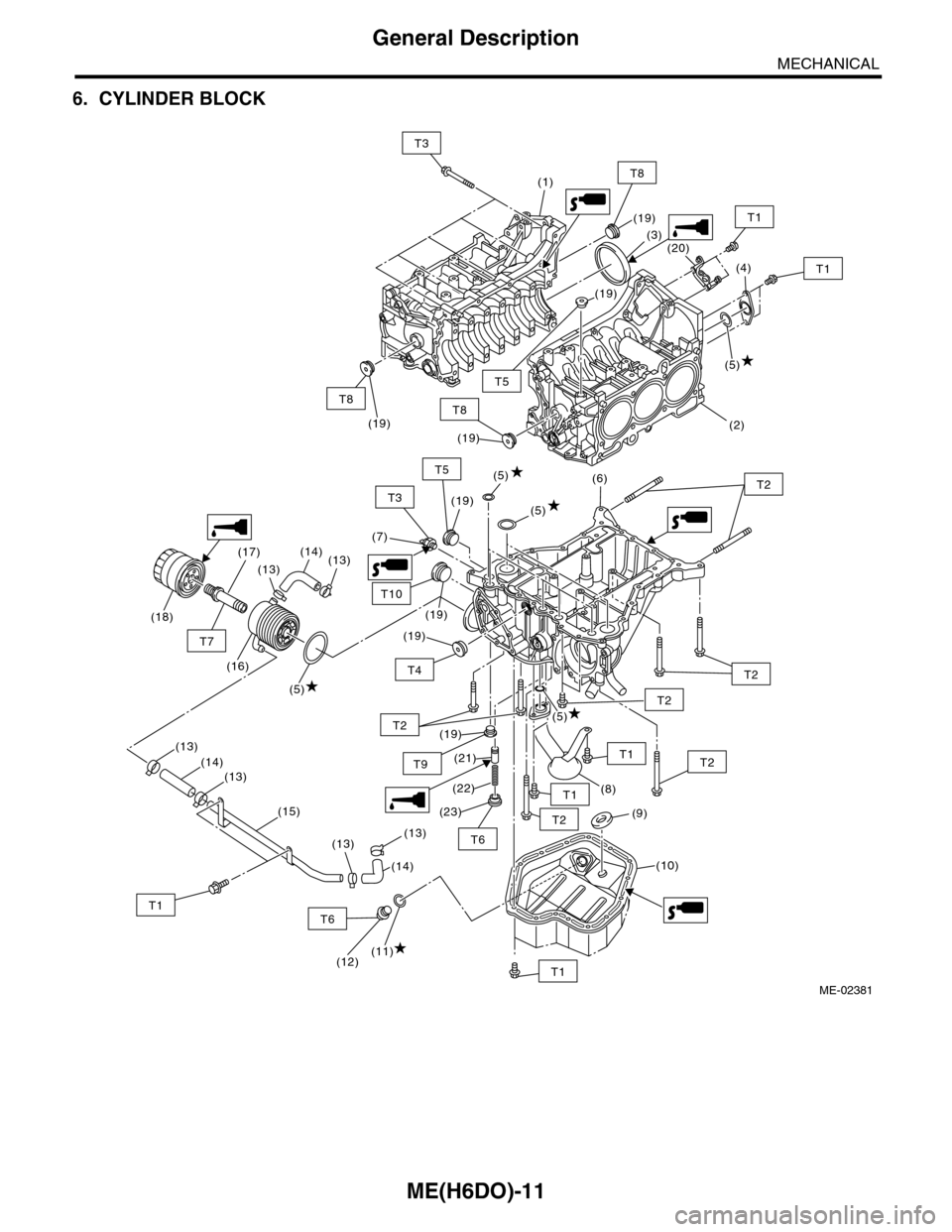

6. CYLINDER BLOCK

(5)

(6)

(7)

(9)

(5)

(8)

(19)

(19)

(10)

(19)

(19)

(21)

(22)

(23)

T1

T2

T2

T2

T1

T2

T2T5

T2

T9

ME-02381

T4

T6

T10

(5)

(1)

(3)

(4)

(5)

(2)

(19)

(19)

(20)

(19)(19)

T1

T1

T8

T3

T5

T8T8

(5)

(18)

(17)

(13)

(14)(13)

(16)

(13)

(14)(13)

(15)

(13)(13)

(11)(12)

(14)

T6T1

T7

T3

T1