relay SUZUKI GRAND VITARA 1999 2.G Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1999, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1999 2.GPages: 656, PDF Size: 14.31 MB

Page 341 of 656

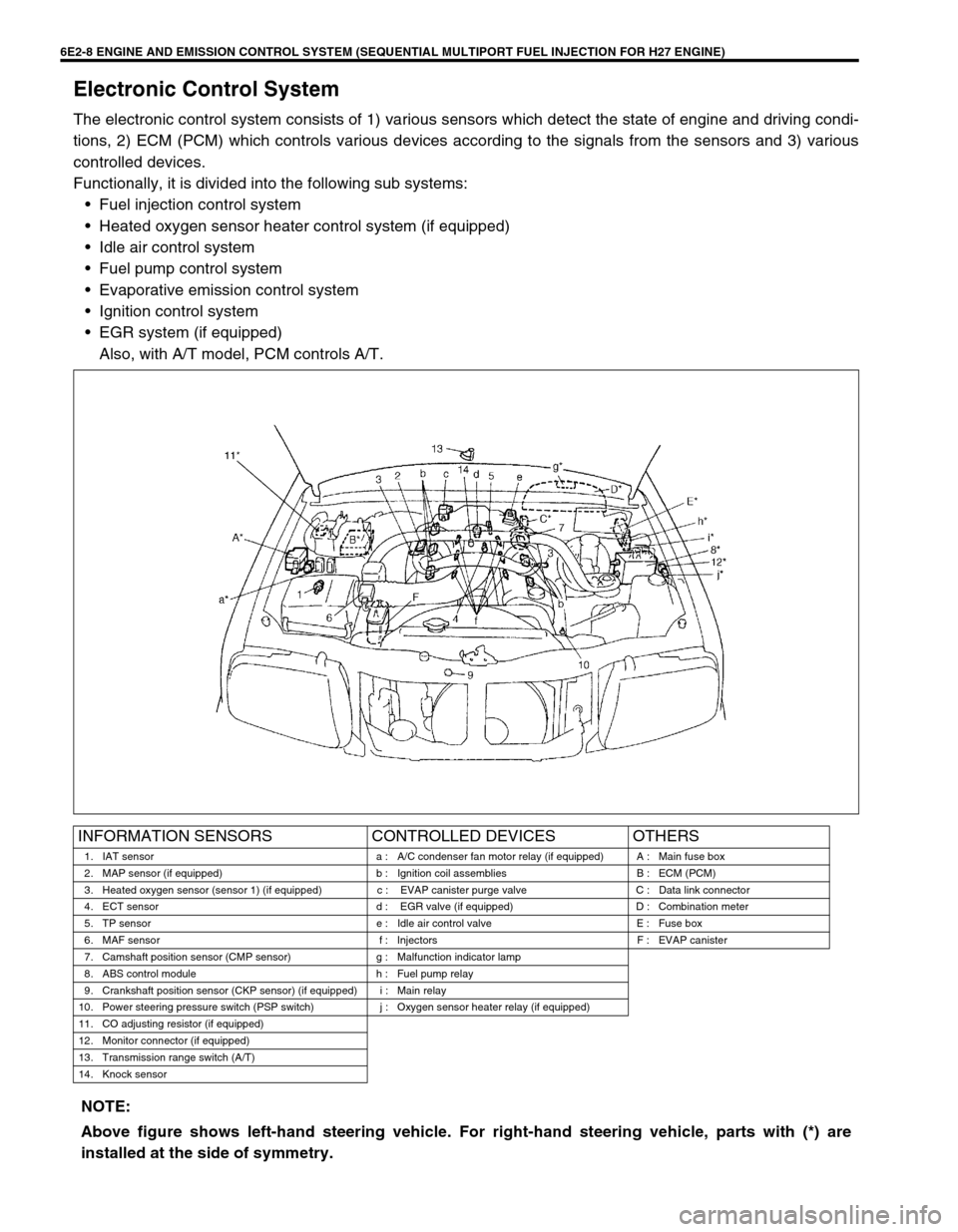

6E2-8 ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE)

Electronic Control System

The electronic control system consists of 1) various sensors which detect the state of engine and driving condi-

tions, 2) ECM (PCM) which controls various devices according to the signals from the sensors and 3) various

controlled devices.

Functionally, it is divided into the following sub systems:

•Fuel injection control system

•Heated oxygen sensor heater control system (if equipped)

•Idle air control system

•Fuel pump control system

•Evaporative emission control system

•Ignition control system

•EGR system (if equipped)

Also, with A/T model, PCM controls A/T.

INFORMATION SENSORS CONTROLLED DEVICES OTHERS

1. IAT sensor a : A/C condenser fan motor relay (if equipped) A : Main fuse box

2. MAP sensor (if equipped) b : Ignition coil assemblies B : ECM (PCM)

3. Heated oxygen sensor (sensor 1) (if equipped) c : EVAP canister purge valve C : Data link connector

4. ECT sensor d : EGR valve (if equipped) D : Combination meter

5. TP sensor e : Idle air control valve E : Fuse box

6. MAF sensor f : Injectors F : EVAP canister

7. Camshaft position sensor (CMP sensor) g : Malfunction indicator lamp

8. ABS control module h : Fuel pump relay

9. Crankshaft position sensor (CKP sensor) (if equipped) i : Main relay

10. Power steering pressure switch (PSP switch) j : Oxygen sensor heater relay (if equipped)

11. CO adjusting resistor (if equipped)

12. Monitor connector (if equipped)

13. Transmission range switch (A/T)

14. Knock sensor

NOTE:

Above figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are

installed at the side of symmetry.

Page 343 of 656

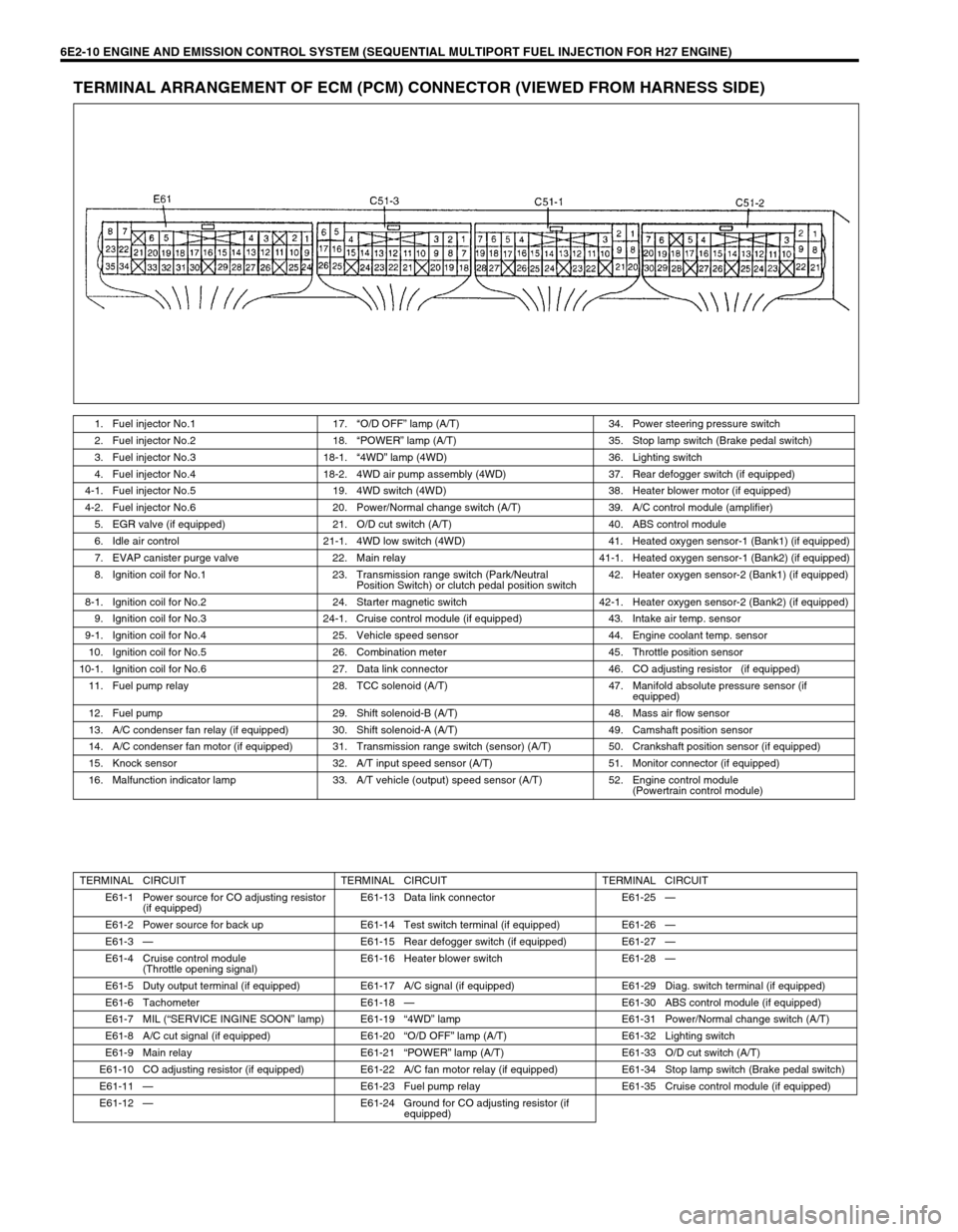

6E2-10 ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE)

TERMINAL ARRANGEMENT OF ECM (PCM) CONNECTOR (VIEWED FROM HARNESS SIDE)

1. Fuel injector No.1 17.“O/D OFF” lamp (A/T) 34. Power steering pressure switch

2. Fuel injector No.2 18.“POWER” lamp (A/T) 35. Stop lamp switch (Brake pedal switch)

3. Fuel injector No.3 18-1.“4WD” lamp (4WD) 36. Lighting switch

4. Fuel injector No.4 18-2. 4WD air pump assembly (4WD) 37. Rear defogger switch (if equipped)

4-1. Fuel injector No.5 19. 4WD switch (4WD) 38. Heater blower motor (if equipped)

4-2. Fuel injector No.6 20. Power/Normal change switch (A/T) 39. A/C control module (amplifier)

5. EGR valve (if equipped) 21. O/D cut switch (A/T) 40. ABS control module

6. Idle air control 21-1. 4WD low switch (4WD) 41. Heated oxygen sensor-1 (Bank1) (if equipped)

7. EVAP canister purge valve 22. Main relay 41-1. Heated oxygen sensor-1 (Bank2) (if equipped)

8. Ignition coil for No.1 23. Transmission range switch (Park/Neutral

Position Switch) or clutch pedal position switch42. Heater oxygen sensor-2 (Bank1) (if equipped)

8-1. Ignition coil for No.2 24. Starter magnetic switch 42-1. Heater oxygen sensor-2 (Bank2) (if equipped)

9. Ignition coil for No.3 24-1. Cruise control module (if equipped) 43. Intake air temp. sensor

9-1. Ignition coil for No.4 25. Vehicle speed sensor 44. Engine coolant temp. sensor

10. Ignition coil for No.5 26. Combination meter 45. Throttle position sensor

10-1. Ignition coil for No.6 27. Data link connector 46. CO adjusting resistor (if equipped)

11. Fuel pump relay 28. TCC solenoid (A/T) 47. Manifold absolute pressure sensor (if

equipped)

12. Fuel pump 29. Shift solenoid-B (A/T) 48. Mass air flow sensor

13. A/C condenser fan relay (if equipped) 30. Shift solenoid-A (A/T) 49. Camshaft position sensor

14. A/C condenser fan motor (if equipped) 31. Transmission range switch (sensor) (A/T) 50. Crankshaft position sensor (if equipped)

15. Knock sensor 32. A/T input speed sensor (A/T) 51. Monitor connector (if equipped)

16. Malfunction indicator lamp 33. A/T vehicle (output) speed sensor (A/T) 52. Engine control module

(Powertrain control module)

TERMINAL CIRCUIT TERMINAL CIRCUIT TERMINAL CIRCUIT

E61-1 Power source for CO adjusting resistor

(if equipped)E61-13 Data link connector E61-25—

E61-2 Power source for back up E61-14 Test switch terminal (if equipped) E61-26—

E61-3—E61-15 Rear defogger switch (if equipped) E61-27—

E61-4 Cruise control module

(Throttle opening signal)E61-16 Heater blower switch E61-28—

E61-5 Duty output terminal (if equipped) E61-17 A/C signal (if equipped) E61-29 Diag. switch terminal (if equipped)

E61-6 Tachometer E61-18—E61-30 ABS control module (if equipped)

E61-7 MIL (“SERVICE INGINE SOON” lamp) E61-19“4WD” lamp E61-31 Power/Normal change switch (A/T)

E61-8 A/C cut signal (if equipped) E61-20“O/D OFF” lamp (A/T) E61-32 Lighting switch

E61-9 Main relay E61-21“POWER” lamp (A/T) E61-33 O/D cut switch (A/T)

E61-10 CO adjusting resistor (if equipped) E61-22 A/C fan motor relay (if equipped) E61-34 Stop lamp switch (Brake pedal switch)

E61-11—E61-23 Fuel pump relay E61-35 Cruise control module (if equipped)

E61-12—E61-24 Ground for CO adjusting resistor (if

equipped)

Page 345 of 656

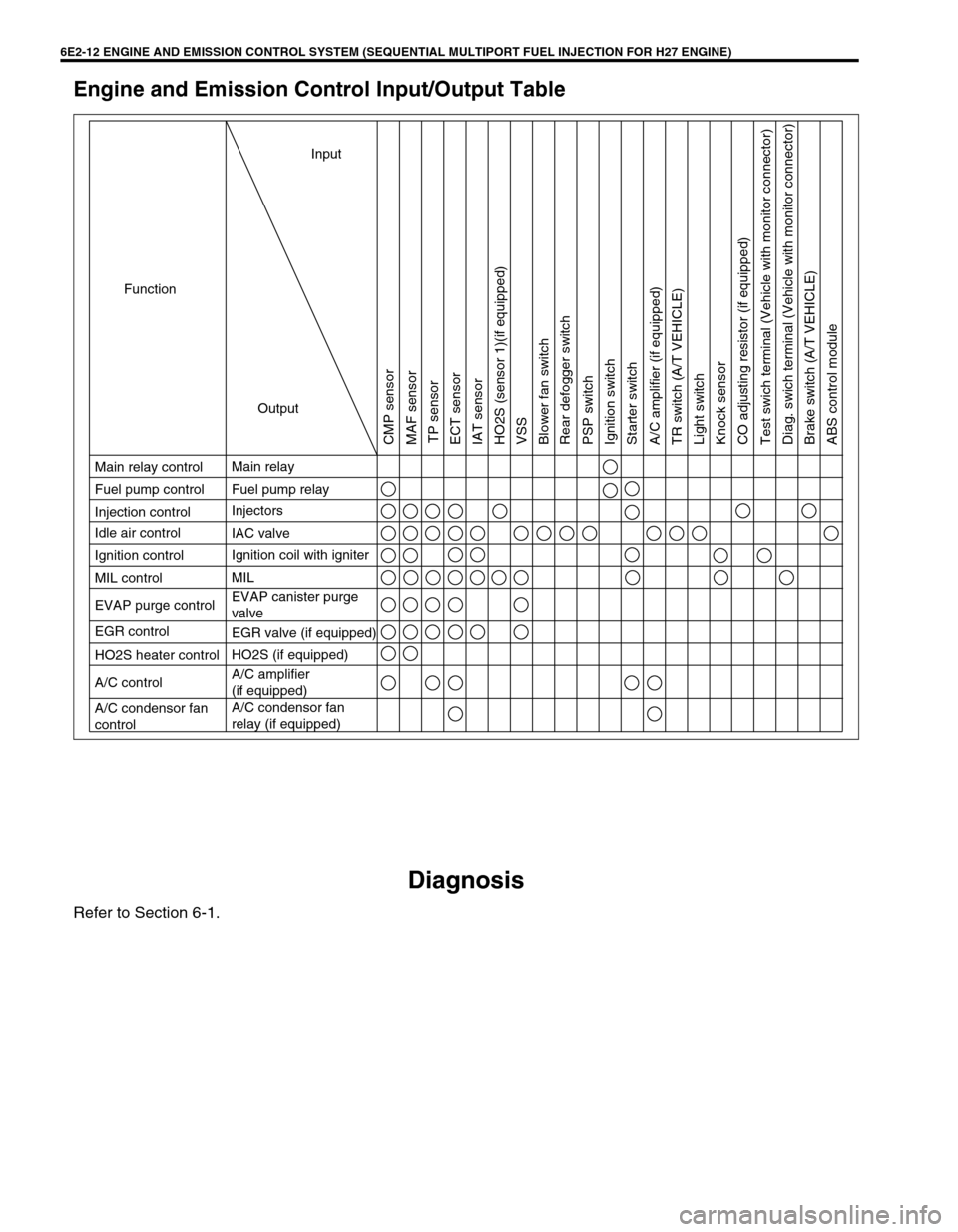

6E2-12 ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE)

Engine and Emission Control Input/Output Table

Diagnosis

Refer to Section 6-1.

Ignition coil with igniter

HO2S heater control

Input

Output Function

Main relay control

Fuel pump control

Injection control

Ignition control

MIL control Idle air control

EVAP purge control

EGR control

A/C control

A/C condensor fan

controlMain relay

Fuel pump relay

Injectors

MIL

EVAP canister purge

valve IAC valve

EGR valve (if equipped)

HO2S (if equipped)

A/C amplifier

(if equipped)

A/C condensor fan

relay (if equipped)

CMP sensor

MAF sensor

TP sensor

ECT sensor

IAT sensor

HO2S (sensor 1)(if equipped)

VSS

Blower fan switch

Rear defogger switch

PSP switch

Ignition switch

Starter switch

A/C amplifier (if equipped)

TR switch (A/T VEHICLE)

Light switch

Knock sensor

CO adjusting resistor (if equipped)

Test swich terminal (Vehicle with monitor connector)

Diag. swich terminal (Vehicle with monitor connector)

Brake switch (A/T VEHICLE)

ABS control module

Page 361 of 656

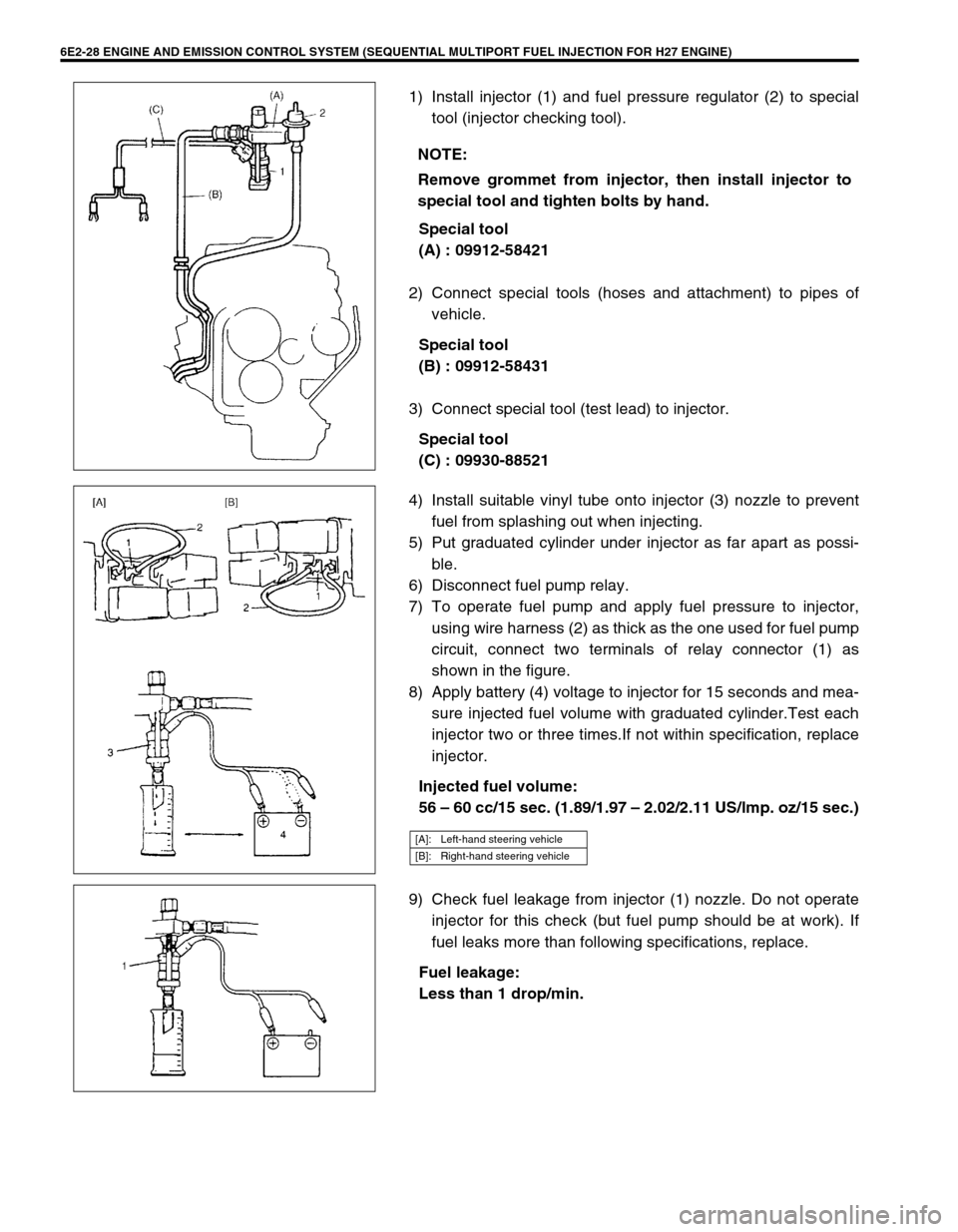

6E2-28 ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE)

1) Install injector (1) and fuel pressure regulator (2) to special

tool (injector checking tool).

Special tool

(A) : 09912-58421

2) Connect special tools (hoses and attachment) to pipes of

vehicle.

Special tool

(B) : 09912-58431

3) Connect special tool (test lead) to injector.

Special tool

(C) : 09930-88521

4) Install suitable vinyl tube onto injector (3) nozzle to prevent

fuel from splashing out when injecting.

5) Put graduated cylinder under injector as far apart as possi-

ble.

6) Disconnect fuel pump relay.

7) To operate fuel pump and apply fuel pressure to injector,

using wire harness (2) as thick as the one used for fuel pump

circuit, connect two terminals of relay connector (1) as

shown in the figure.

8) Apply battery (4) voltage to injector for 15 seconds and mea-

sure injected fuel volume with graduated cylinder.Test each

injector two or three times.If not within specification, replace

injector.

Injected fuel volume:

56 – 60 cc/15 sec. (1.89/1.97 – 2.02/2.11 US/lmp. oz/15 sec.)

9) Check fuel leakage from injector (1) nozzle. Do not operate

injector for this check (but fuel pump should be at work). If

fuel leaks more than following specifications, replace.

Fuel leakage:

Less than 1 drop/min. NOTE:

Remove grommet from injector, then install injector to

special tool and tighten bolts by hand.

[A]: Left-hand steering vehicle

[B]: Right-hand steering vehicle

Page 374 of 656

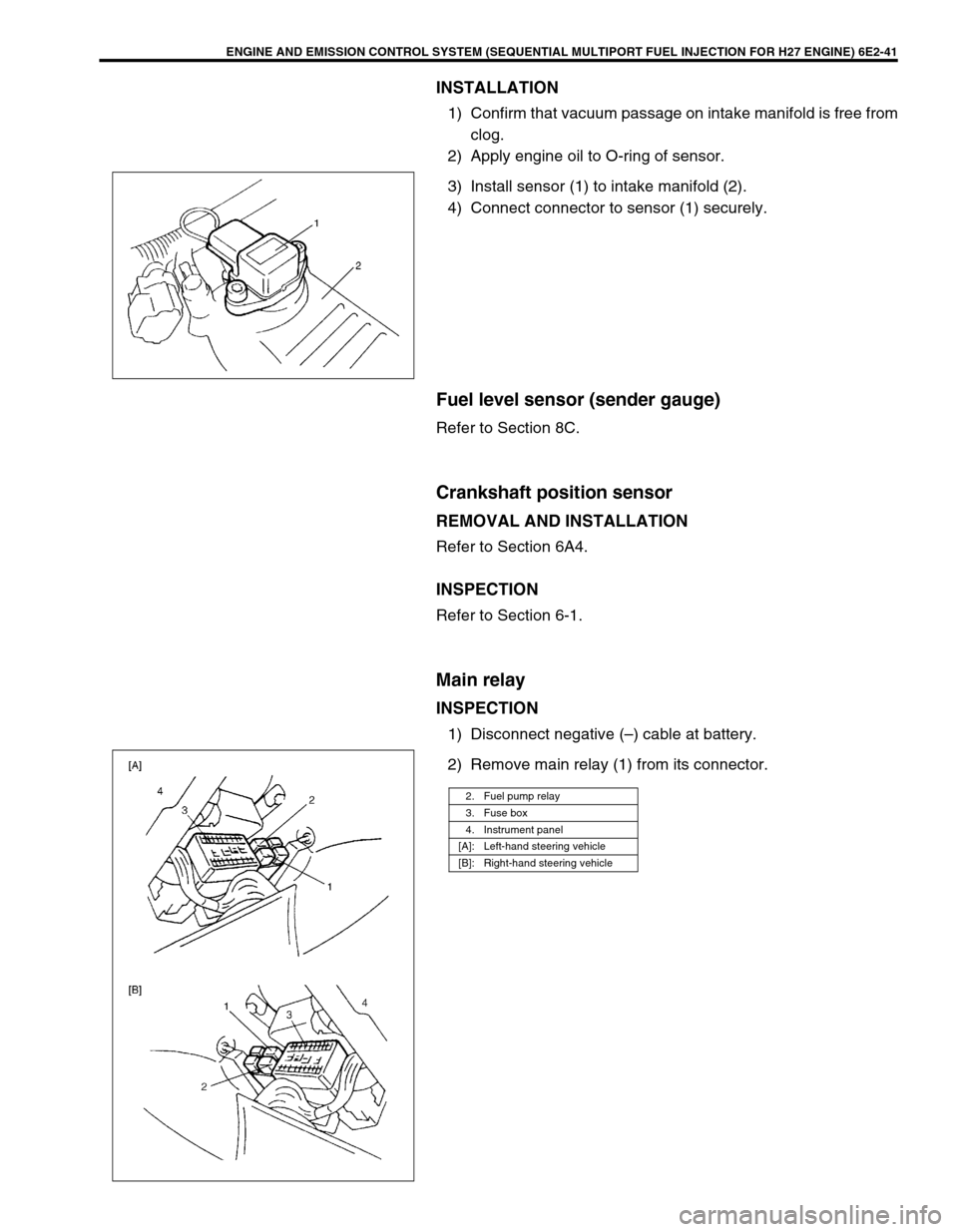

ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE) 6E2-41

INSTALLATION

1) Confirm that vacuum passage on intake manifold is free from

clog.

2) Apply engine oil to O-ring of sensor.

3) Install sensor (1) to intake manifold (2).

4) Connect connector to sensor (1) securely.

Fuel level sensor (sender gauge)

Refer to Section 8C.

Crankshaft position sensor

REMOVAL AND INSTALLATION

Refer to Section 6A4.

INSPECTION

Refer to Section 6-1.

Main relay

INSPECTION

1) Disconnect negative (–) cable at battery.

2) Remove main relay (1) from its connector.

2. Fuel pump relay

3. Fuse box

4. Instrument panel

[A]: Left-hand steering vehicle

[B]: Right-hand steering vehicle

Page 375 of 656

6E2-42 ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE)

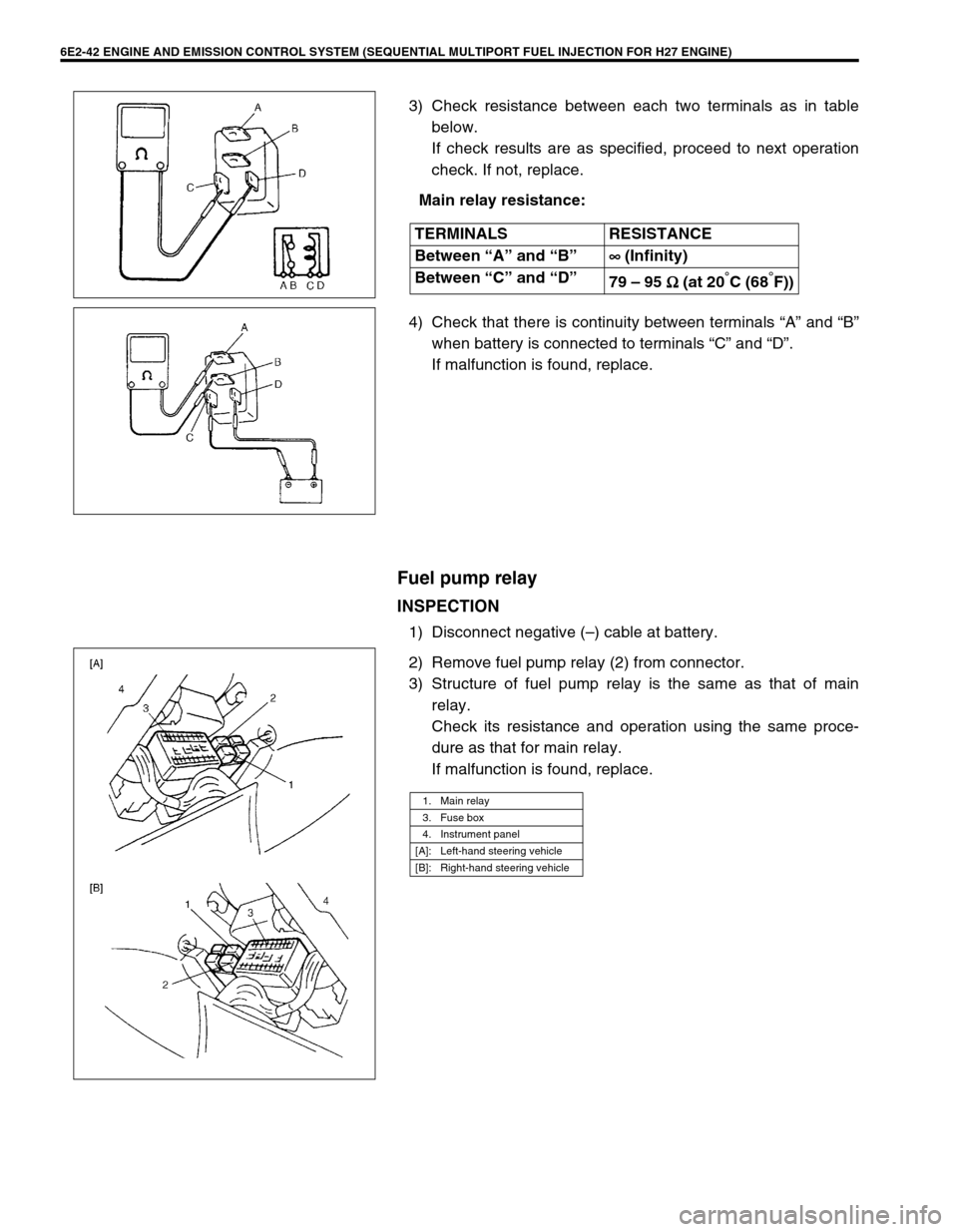

3) Check resistance between each two terminals as in table

below.

If check results are as specified, proceed to next operation

check. If not, replace.

Main relay resistance:

4) Check that there is continuity between terminals “A” and “B”

when battery is connected to terminals “C” and “D”.

If malfunction is found, replace.

Fuel pump relay

INSPECTION

1) Disconnect negative (–) cable at battery.

2) Remove fuel pump relay (2) from connector.

3) Structure of fuel pump relay is the same as that of main

relay.

Check its resistance and operation using the same proce-

dure as that for main relay.

If malfunction is found, replace. TERMINALS RESISTANCE

Between “A” and “B”∞

∞∞ ∞ (Infinity)

Between “C” and “D”

79 – 95 Ω

ΩΩ Ω (at 20

°C (68°F))

1. Main relay

3. Fuse box

4. Instrument panel

[A]: Left-hand steering vehicle

[B]: Right-hand steering vehicle

Page 386 of 656

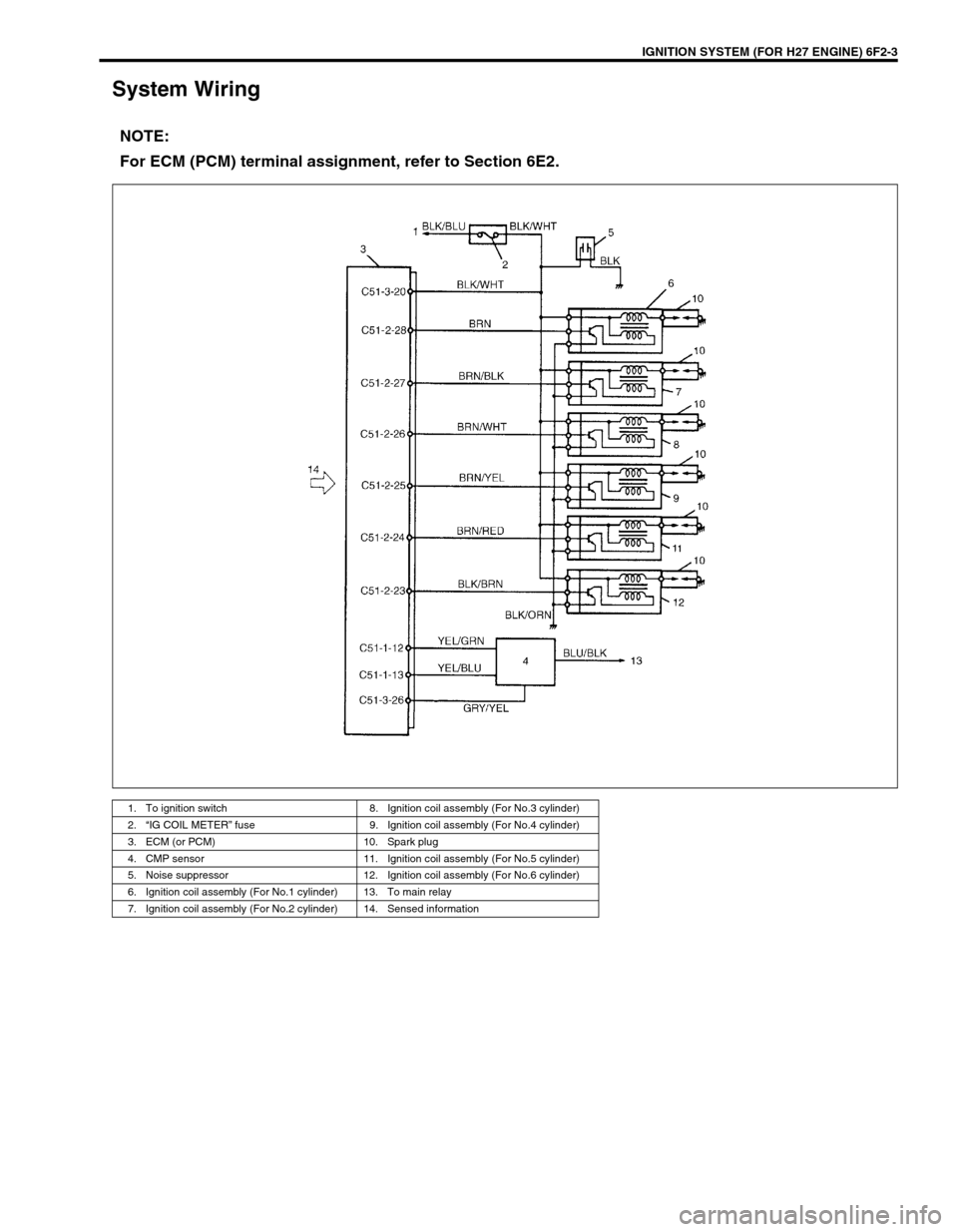

IGNITION SYSTEM (FOR H27 ENGINE) 6F2-3

System Wiring

NOTE:

For ECM (PCM) terminal assignment, refer to Section 6E2.

1. To ignition switch 8. Ignition coil assembly (For No.3 cylinder)

2.“IG COIL METER” fuse 9. Ignition coil assembly (For No.4 cylinder)

3. ECM (or PCM) 10. Spark plug

4. CMP sensor 11. Ignition coil assembly (For No.5 cylinder)

5. Noise suppressor 12. Ignition coil assembly (For No.6 cylinder)

6. Ignition coil assembly (For No.1 cylinder) 13. To main relay

7. Ignition coil assembly (For No.2 cylinder) 14. Sensed information

Page 413 of 656

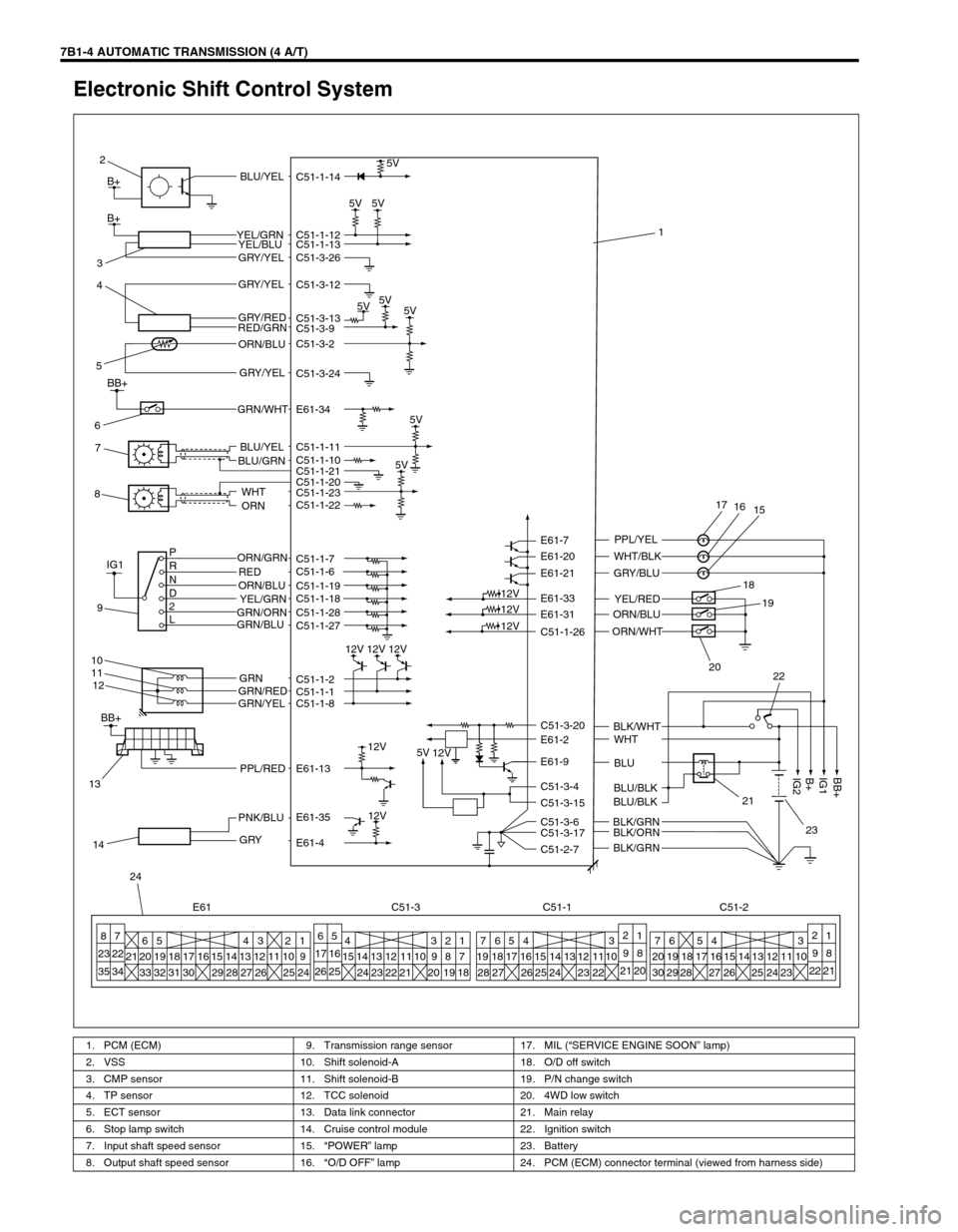

7B1-4 AUTOMATIC TRANSMISSION (4 A/T)

Electronic Shift Control System

1. PCM (ECM) 9. Transmission range sensor 17. MIL (“SERVICE ENGINE SOON” lamp)

2. VSS 10. Shift solenoid-A 18. O/D off switch

3. CMP sensor 11. Shift solenoid-B 19. P/N change switch

4. TP sensor 12. TCC solenoid 20. 4WD low switch

5. ECT sensor 13. Data link connector 21. Main relay

6. Stop lamp switch 14. Cruise control module 22. Ignition switch

7. Input shaft speed sensor 15.“POWER” lamp 23. Battery

8. Output shaft speed sensor 16.“O/D OFF” lamp 24. PCM (ECM) connector terminal (viewed from harness side)

5V

5V5V

5V5V

5V

5V 5V C51-1-14

C51-1-12

C51-1-13

C51-3-26

C51-3-12

C51-3-13

C51-3-9

C51-3-2

C51-3-24

C51-1-11

C51-1-10

C51-1-20 C51-1-21

C51-1-23

C51-1-22

C51-1-7

C51-1-6

C51-1-19

C51-1-18

C51-1-28

C51-1-27

C51-1-2

C51-1-1

C51-1-8

E61-13

E61-35

E61-4C51-1-26 E61-31 E61-33 E61-21 E61-20 E61-7

C51-3-20

E61-2

E61-9

C51-3-4

C51-3-15

C51-3-6

C51-3-17

C51-2-7

12V

12V 12V 12V

12V

12V

12V

12V

5V

12V

BLU/YEL

YEL/GRN

YEL/BLU

GRY/YEL

GRY/YEL

GRY/RED

RED/GRN

ORN/BLU

GRY/YEL

BLU/YEL

BLU/GRN

WHT

ORN

ORN/GRN

RED P

R

N

D

2

LORN/BLU

YEL/GRN

GRN/ORN

GRN/BLU

GRN

GRN/RED

GRN/YEL

PPL/RED

PNK/BLU

GRY

PPL/YEL

WHT/BLK

GRY/BLU

YEL/RED

ORN/BLU

WHT

BLU

BLU/BLK

BLU/BLK

BLK/GRN

BLK/ORN

BLK/GRNBLK/WHT ORN/WHT

8

7

23 22

35 346

20 21

335

19

3218

3117

3016 15

2914

284

13

273

12

26112

10

256

5

17 16

26 252

1

98

21 202

1

98

22 21 1

9

247

20

306

19

2918

27 17

2816 15

2614

25 5

13 4

12

24113

10

23 7

19

28654 3

18

2717 16

2615 14

2513

2412

2311

2210 4

15 14

2413

2312

2211 10 9 8 7

213

202

191

18

24

E61 C51-3 C51-1 C51-2 14

13

B+

B+

17

16

15

18

19

20

22

21

23

BB+

IG1

B+

IG2

1 2

3

4

5

7 6

8

IG1

9

10

11

12

BB+

E61-34 GRN/WHT

BB+

Page 418 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-9

Precaution in Diagnosing Trouble

•Don’t disconnect couplers from PCM (ECM), battery cable

from battery, PCM ground wire harness from engine or main

fuse before checking the diagnosis information (DTC, freeze

frame data, etc.) stored in PCM memory. Such disconnec-

tion will clear memorized information in PCM memory.

•Using SUZUKI scan tool or also generic scan tool for vehicle

without monitor connector, the diagnostic information stored

in PCM memory can be checked and cleared as well. Before

its use, be sure to read Operator’s (Instruction) Manual sup-

plied with it carefully to have good understanding of its func-

tions and usage.

•Priorities for diagnosing troubles

If two or more diagnostic trouble codes (DTCs) are stored,

proceed to the flow table of the DTC which was detected

earliest in the order and follow the instruction in that table.

If no instructions are given, troubleshoot diagnostic trouble

codes according to the following priorities.

–Diagnostic trouble codes (DTCs) other than DTC P0171/

P0172/P0174/P0175 (Fuel system too lean/too rich), DTC

P0300/P0301/P0302/P0303/P0304/P0305/P0306 (Misfire

detected) and DTC P0400 (EGR flow malfunction)

–DTC P0171/P0172/P0174/P0175 (Fuel system too lean/too

rich) and DTC P0400 (EGR flow malfunction)

–DTC P0300/P0301/P0302/P0303/P0304/P0305/P0306

(Misfire detected)

•Be sure to read “PRECAUTIONS FOR ELECTRICAL CIR-

CUIT SERVICE” in Section 0A before inspection and

observe what is written there.

•PCM replacement

When substituting a known-good PCM, check for following

conditions.

Neglecting this check may result in damage to a good PCM.

–All relays and actuators have resistance of specified value.

–MAF sensor, MDP sensor, TP sensor and fuel tank pres-

sure sensor are in good condition. Also, the power circuit of

these sensors is not shorted to the ground.

Page 510 of 656

BODY ELECTRICAL SYSTEM 8-1

6F1

6F2

6G

6H

6K

7A

8

6K

7C1

7D

7E

7F

8A

8D

8E

9

10

10A

10B

SECTION 8

BODY ELECTRICAL SYSTEM

Wiring System

(Harnesses, Connectors, Fuses, Relay, Switches, Grounds, System Circuit Diagram) .......... Section 8A

Lighting System .............................................................................................................................. Section 8B

Instrumententation and Driver Information .................................................................................. Section 8C

Windows, Mirrors, Security and Locks ......................................................................................... Section 8D

Immobilizer Control System............................................................................................................Section 8F

CONTENTS

General Description .......................................... 8-3

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Manual

mentioned in FOREWORD of this manual.