Engine end emission SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 32 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-1

0A 6F1

0B

0B

6G

1A 6H

1B 6K

37A

3A 7A1

3B1 7B1

3C1 7C1

3D 7D

3E 7E

3F 7F

4A2 8A

4B 8B

8C

58D

5A 8E

5B

5C 9

5E

5E1 10

10A

610B

6-1

6A1

6A2

6A4

6B

6C

6E1

6E2

SECTION 0B

MAINTENANCE AND LUBRICATION

CONTENTS

Maintenance Schedule .................................. 0B-2

Maintenance Schedule Under Normal

Driving Conditions ........................................ 0B-2

Maintenance Recommended Under Severe

Driving Conditions ........................................ 0B-4

Maintenance Service...................................... 0B-5

Engine .......................................................... 0B-5

Drive Belt .................................................. 0B-5

Valve Lash................................................ 0B-6

Engine Oil and Filter ................................. 0B-6

Engine Coolant ......................................... 0B-8

Exhaust System ....................................... 0B-8

Ignition System ............................................. 0B-9

Spark Plugs .............................................. 0B-9

Fuel System ................................................. 0B-9

Air Cleaner Filter ...................................... 0B-9

Fuel Lines and Connections ................... 0B-10

Fuel Filter ............................................... 0B-10

Fuel Tank ............................................... 0B-10

Emission Control System ........................... 0B-10

Crankcase Ventilation Hoses and

Connections ........................................... 0B-10

PCV (Positive Crankcase Ventilation)

Valve ..................................................... 0B-11Fuel Evaporative Emission Control

System ................................................... 0B-11

Chassis and Body ...................................... 0B-11

Clutch ..................................................... 0B-11

Brake Discs and Pads ............................ 0B-11

Brake Drums and Shoes ........................ 0B-12

Brake Hoses and Pipes.......................... 0B-12

Brake Fluid ............................................. 0B-12

Parking Brake Lever and Cable ............. 0B-13

Tires/Wheels .......................................... 0B-13

Suspension System ............................... 0B-14

Propeller Shafts...................................... 0B-15

Manual Transmission Oil........................ 0B-16

Automatic Transmission Fluid ................ 0B-16

Transfer and Differential Oil ................... 0B-17

Steering System ..................................... 0B-18

Steering Knuckle Seal ............................ 0B-18

Power Steering (P/S) System

(if equipped) ........................................... 0B-19

All Hinges, Latches and Locks ............... 0B-19

Final Inspection............................................ 0B-20

Recommended Fluids and Lubricants ....... 0B-22

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 33 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-2 MAINTENANCE AND LUBRICATION

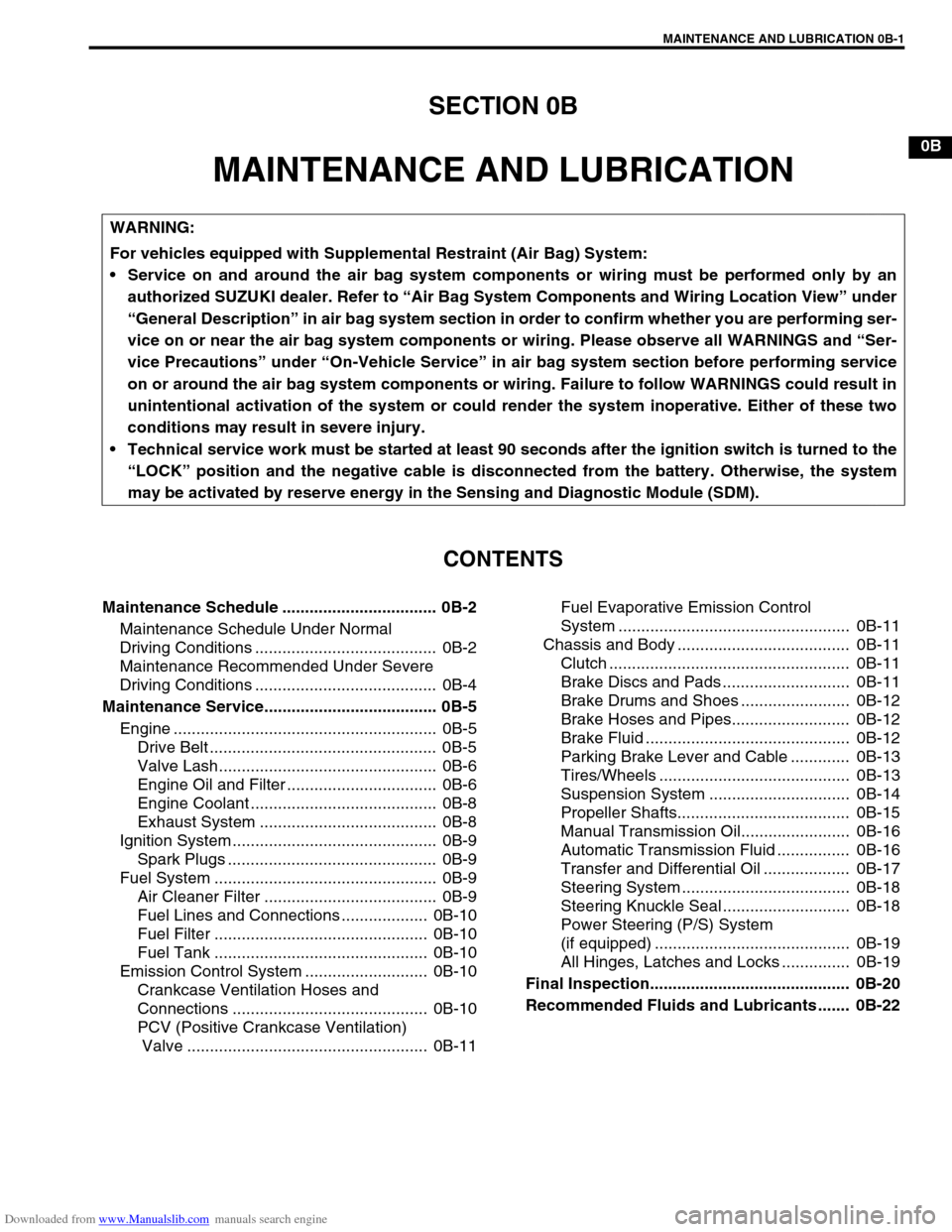

Maintenance Schedule

Maintenance Schedule Under Normal Driving Conditions

NOTE:

This interval should be judged by odometer reading or months, whichever comes first.

This table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km

(54,000 miles), carry out the same services at the same intervals respectively.

IntervalKm (x 1,000) 15 30 45 60 75 90

Miles (x 1,000) 9 1827364554

Months 12 24 36 48 60 72

ENGINE

Drive belt V-belt I R I R I R

V-rib belt (Flat type)––I––R

Valve lash (clearance) –I–I–I

Engine oil and oil filter R R R R R R

Engine coolant––R––R

Exhaust system–I–I–I

IGNITION SYSTEM

✱Spark plugs When

unleaded

fuel is usedVehicle without

HO2SNickel spark

plug–R–R–R

Iridium spark

plug––R––R

Vehicle with

HO2SNickel spark

plug––R––R

Iridium spark

plug–––R––

When leaded fuel is used, refer to “Maintenance Recommended Under Severe Driving Condi-

tions” in this section.

FUEL SYSTEM

Air cleaner filter I I R I I R

Fuel lines and connections–I–I–I

Fuel filter Replace every 210,000 km (126,000 miles).

Fuel tank––I––I

EMISSION CONTROL SYSTEM

Crankcase ventilation hoses and connections

(Vehicle without HO2S)––I––I

✱PCV valve Vehicle without HO2S––I––I

Vehicle with HO2S–––––I

✱Fuel evaporative emission

control systemVehicle without HO2S–I–I–I

Vehicle with HO2S–––––I

NOTE:

“R”: Replace or change

“I”: Inspect and correct, replace or lubricate if necessary

For Sweden, items with

✱

✱✱ ✱ (asterisk) should be performed by odometer reading only.

For spark plugs, replace every 50,000 km if the local law requires.

Nickel spark plug: BKR6E-11 (NGK) or K20PR-U11 (DENSO)

Iridium spark plug: IFR5E11 (NGK) or SK16PR-A11 (DENSO)

Page 42 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-11

PCV (Positive Crankcase Ventilation) Valve

INSPECTION

Check crankcase ventilation hose and PCV hose for leaks, cracks

or clog, and PCV valve for stick or clog. Refer to “PCV System” of

Section 6E for PCV valve checking procedure.

Fuel Evaporative Emission Control System

INSPECTION

1) Visually inspect hoses for cracks, damage, or excessive

bends. Inspect all clamps for damage and proper position.

2) Check EVAP canister for operation and clog, referring to

“Evaporative Emission (EVAP) Control System” in Section

6E.

If a malfunction is found, repair or replace.

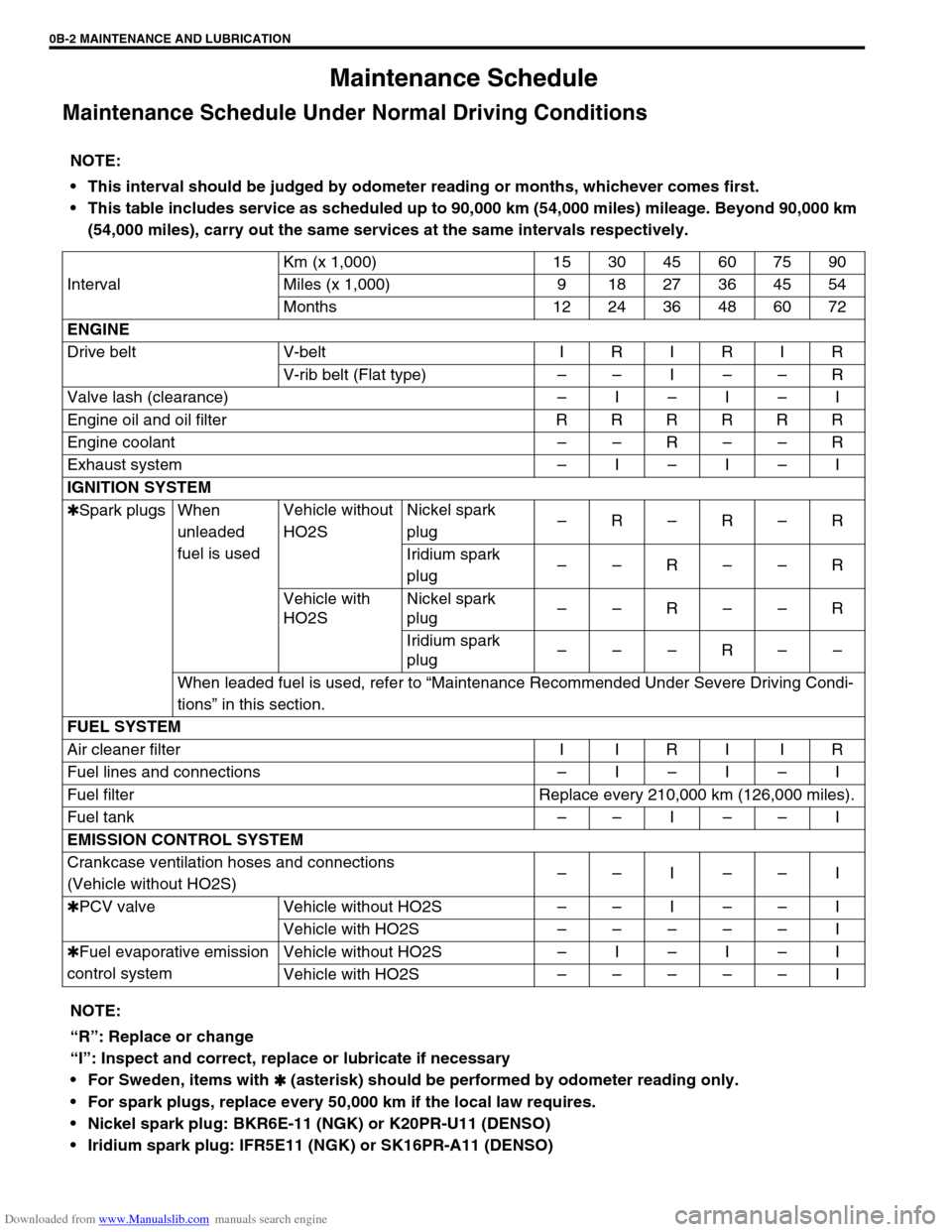

Chassis and Body

Clutch

INSPECTION

Check clutch pedal for height and free travel (1) referring to “Main-

tenance Service” in Section 7C. Adjust or correct if necessary.

Brake Discs and Pads

INSPECTION

1) Remove wheel and caliper but don’t disconnect brake hose

from caliper.

2) Check front disc brake pads and discs for excessive wear,

damage and deflection. Replace parts as necessary. For

details, refer to “Brake Pad” and “Brake Disc” in Section 5.

Be sure to torque caliper pin bolts to specification.

Page 358 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8B

6

8D

8E

8B

9

10A

10B

SECTION 6

ENGINE GENERAL INFORMATION AND

DIAGNOSIS

GENERAL INFORMATION AND ENGINE DIAGNOSIS ..............................................................................

6-1

ENGINE MECHANICAL ...........................................................................................................................

6A1-1

ENGINE COOLING.....................................................................................................................................

6B-1

ENGINE FUEL ............................................................................................................................................

6C-1

ENGINE AND EMISSION CONTROL SYSTEM ........................................................................................

6E-1

IGNITION SYSTEM ....................................................................................................................................

6F-1

CRANKING SYSTEM .................................................................................................................................

6G-1

CHARGING SYSTEM .................................................................................................................................

6H-1

EXHAUST SYSTEM ...................................................................................................................................

6K-1

CONTENTS

General Information .......................................... 6-3

Statement on Cleanliness and Care ............... 6-3

General Information on Engine Service .......... 6-3

Precaution on fuel system service............... 6-4

Fuel pressure relief procedure .................... 6-5

Fuel leakage check procedure .................... 6-5

Engine Diagnosis .............................................. 6-6

General Description ........................................ 6-6

On-Board Diagnostic System (Vehicle with

Immobilizer Indicator Lamp) ............................ 6-6On-Board Diagnostic System (Vehicle without

Immobilizer Indicator Lamp)............................ 6-9

Precaution in Diagnosing Trouble ................. 6-10

Engine Diagnostic Flow Table ...................... 6-11

Customer problem inspection form

(example) .................................................. 6-13

Malfunction indicator lamp (MIL) check..... 6-14

Diagnostic trouble code (DTC) check ....... 6-14

Diagnostic trouble code (DTC)

clearance................................................... 6-15 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Whether the following systems (parts) are used in the particular vehicle or not depends on vehicle

specifications. Be sure to bear this in mind when performing service work.

EGR valve

Heated oxygen sensor(s) or CO adjusting resistor

Three-way catalytic converter (TWC) and warm up three-way catalytic converter (WU-TWC)

Page 366 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-9

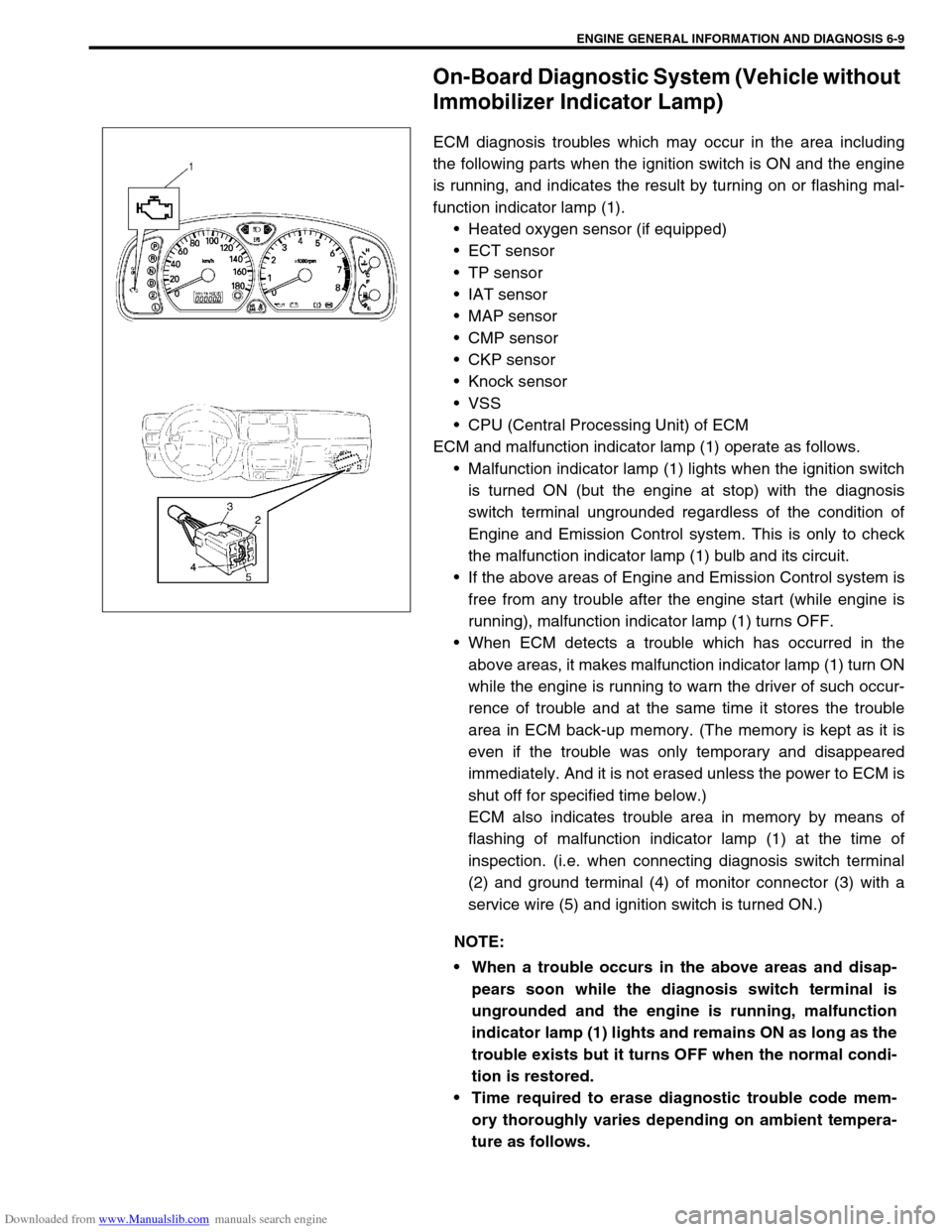

On-Board Diagnostic System (Vehicle without

Immobilizer Indicator Lamp)

ECM diagnosis troubles which may occur in the area including

the following parts when the ignition switch is ON and the engine

is running, and indicates the result by turning on or flashing mal-

function indicator lamp (1).

Heated oxygen sensor (if equipped)

ECT sensor

TP sensor

IAT sensor

MAP sensor

CMP sensor

CKP sensor

Knock sensor

VSS

CPU (Central Processing Unit) of ECM

ECM and malfunction indicator lamp (1) operate as follows.

Malfunction indicator lamp (1) lights when the ignition switch

is turned ON (but the engine at stop) with the diagnosis

switch terminal ungrounded regardless of the condition of

Engine and Emission Control system. This is only to check

the malfunction indicator lamp (1) bulb and its circuit.

If the above areas of Engine and Emission Control system is

free from any trouble after the engine start (while engine is

running), malfunction indicator lamp (1) turns OFF.

When ECM detects a trouble which has occurred in the

above areas, it makes malfunction indicator lamp (1) turn ON

while the engine is running to warn the driver of such occur-

rence of trouble and at the same time it stores the trouble

area in ECM back-up memory. (The memory is kept as it is

even if the trouble was only temporary and disappeared

immediately. And it is not erased unless the power to ECM is

shut off for specified time below.)

ECM also indicates trouble area in memory by means of

flashing of malfunction indicator lamp (1) at the time of

inspection. (i.e. when connecting diagnosis switch terminal

(2) and ground terminal (4) of monitor connector (3) with a

service wire (5) and ignition switch is turned ON.)

NOTE:

When a trouble occurs in the above areas and disap-

pears soon while the diagnosis switch terminal is

ungrounded and the engine is running, malfunction

indicator lamp (1) lights and remains ON as long as the

trouble exists but it turns OFF when the normal condi-

tion is restored.

Time required to erase diagnostic trouble code mem-

ory thoroughly varies depending on ambient tempera-

ture as follows.

Page 606 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-1

6F1

6F2

6G

7C1

7D

7E

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

6H

6E

10

10A

10B

SECTION 6E

ENGINE AND EMISSION CONTROL SYSTEM

CONTENTS

General Description ....................................... 6E-3

Air Intake System ......................................... 6E-5

Fuel Delivery System ................................... 6E-6

Fuel pump ................................................ 6E-6

Electronic Control System ............................ 6E-7

Engine & emission control input / output

table.......................................................... 6E-8

On-Vehicle Service....................................... 6E-15

Accelerator cable adjustment ................. 6E-15

Idle speed / idle air control (IAC) duty

inspection ............................................... 6E-15

Idle mixture inspection / adjustment

(vehicle without heated oxygen

sensor) ................................................... 6E-17

Air Intake System ....................................... 6E-18

Throttle body .......................................... 6E-18

Idle air control valve (IAC valve)............. 6E-21

Fuel Delivery System ................................. 6E-22

Fuel pressure inspection ........................ 6E-22

Fuel pump .............................................. 6E-23

Fuel pressure regulator .......................... 6E-24

Fuel injector ............................................ 6E-25

Electronic Control System .......................... 6E-29Engine control module (ECM) ................ 6E-29

Manifold absolute pressure sensor (MAP

sensor) ................................................... 6E-29

Throttle position sensor (TP sensor) ...... 6E-30

Intake air temperature sensor

(IAT sensor) ........................................... 6E-31

Engine coolant temperature sensor

(ECT sensor) .......................................... 6E-32

Heated oxygen sensor

(Sensor-1 and sensor-2) ........................ 6E-33

Camshaft position sensor....................... 6E-34

Crankshaft position sensor..................... 6E-35

Vehicle speed sensor (VSS) .................. 6E-36

Fuel level sensor (GAUGE).................... 6E-36

Knock sensor ......................................... 6E-36

Main relay, fuel pump relay and A/C

condenser fan control relay .................... 6E-36

Fuel cut operation .................................. 6E-37

A/C condenser fan control system ......... 6E-37

A/C condenser fan ................................. 6E-37

Output signals of throttle valve opening

and engine coolant temp.

(Vehicle with A/T only) ........................... 6E-38

Emission Control System ........................... 6E-38 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Whether following systems (parts) are used in the particular vehicle or not depends on specifications.

Be sure to bear this in mind when performing service work.

EGR valve

Heated oxygen sensor (s) or CO adjusting resistor

Three way catalytic converter (TWC) and warm up three-way catalytic converter (WU-TWC)

Page 611 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-6 ENGINE AND EMISSION CONTROL SYSTEM

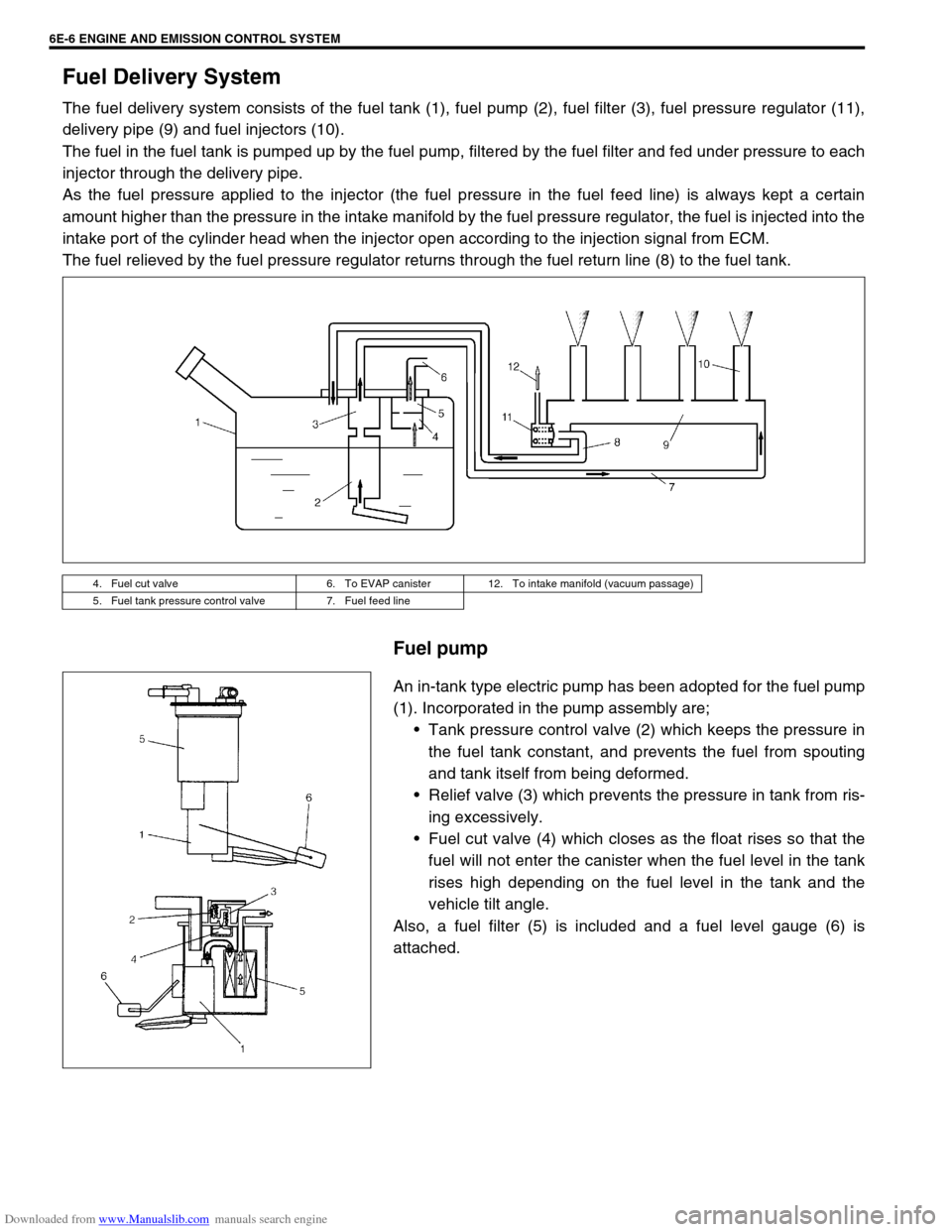

Fuel Delivery System

The fuel delivery system consists of the fuel tank (1), fuel pump (2), fuel filter (3), fuel pressure regulator (11),

delivery pipe (9) and fuel injectors (10).

The fuel in the fuel tank is pumped up by the fuel pump, filtered by the fuel filter and fed under pressure to each

injector through the delivery pipe.

As the fuel pressure applied to the injector (the fuel pressure in the fuel feed line) is always kept a certain

amount higher than the pressure in the intake manifold by the fuel pressure regulator, the fuel is injected into the

intake port of the cylinder head when the injector open according to the injection signal from ECM.

The fuel relieved by the fuel pressure regulator returns through the fuel return line (8) to the fuel tank.

Fuel pump

An in-tank type electric pump has been adopted for the fuel pump

(1). Incorporated in the pump assembly are;

Tank pressure control valve (2) which keeps the pressure in

the fuel tank constant, and prevents the fuel from spouting

and tank itself from being deformed.

Relief valve (3) which prevents the pressure in tank from ris-

ing excessively.

Fuel cut valve (4) which closes as the float rises so that the

fuel will not enter the canister when the fuel level in the tank

rises high depending on the fuel level in the tank and the

vehicle tilt angle.

Also, a fuel filter (5) is included and a fuel level gauge (6) is

attached.

4. Fuel cut valve 6. To EVAP canister 12. To intake manifold (vacuum passage)

5. Fuel tank pressure control valve 7. Fuel feed line

Page 612 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-7

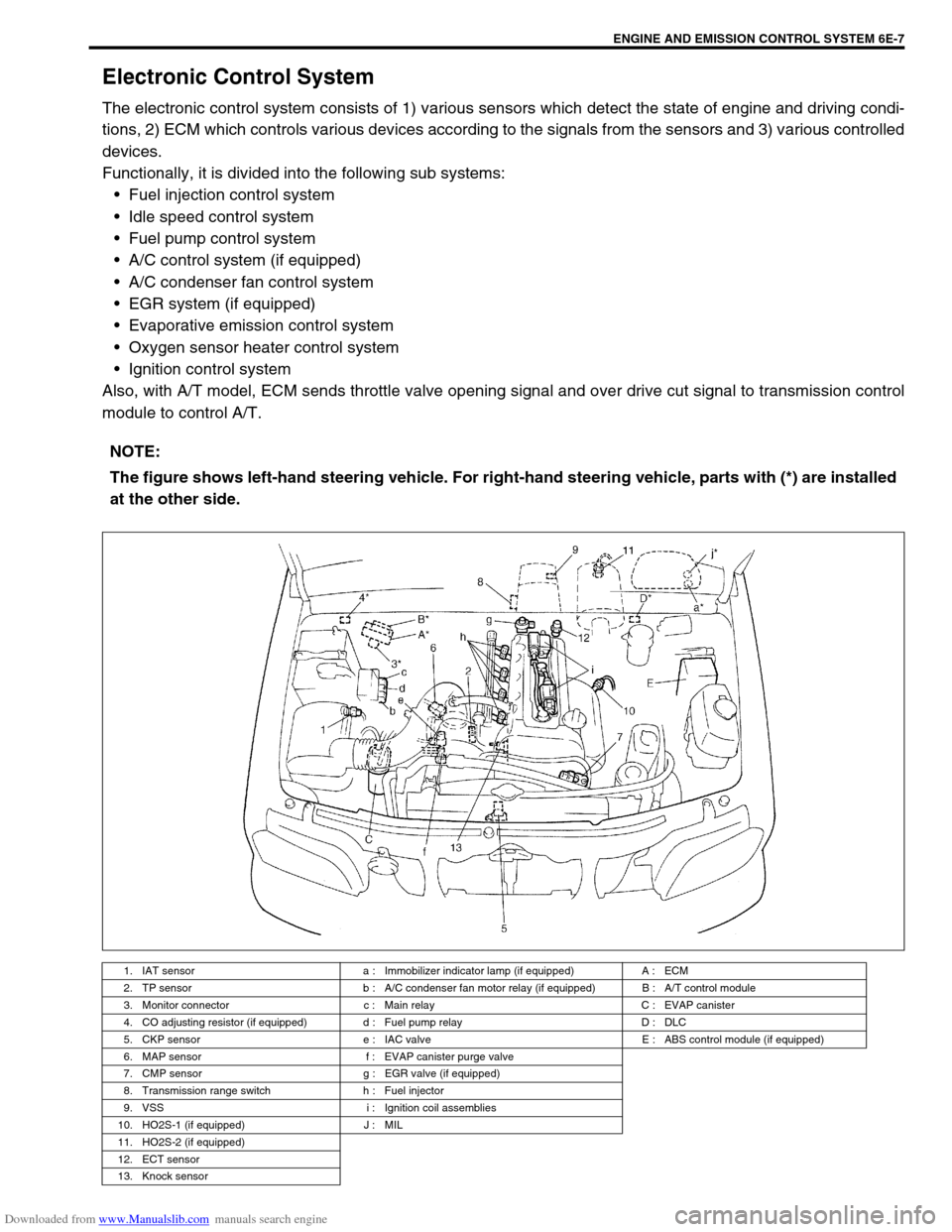

Electronic Control System

The electronic control system consists of 1) various sensors which detect the state of engine and driving condi-

tions, 2) ECM which controls various devices according to the signals from the sensors and 3) various controlled

devices.

Functionally, it is divided into the following sub systems:

Fuel injection control system

Idle speed control system

Fuel pump control system

A/C control system (if equipped)

A/C condenser fan control system

EGR system (if equipped)

Evaporative emission control system

Oxygen sensor heater control system

Ignition control system

Also, with A/T model, ECM sends throttle valve opening signal and over drive cut signal to transmission control

module to control A/T.

NOTE:

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the other side.

1. IAT sensor a : Immobilizer indicator lamp (if equipped) A : ECM

2. TP sensor b : A/C condenser fan motor relay (if equipped) B : A/T control module

3. Monitor connector c : Main relay C : EVAP canister

4. CO adjusting resistor (if equipped) d : Fuel pump relay D : DLC

5. CKP sensor e : IAC valve E : ABS control module (if equipped)

6. MAP sensor f : EVAP canister purge valve

7. CMP sensor g : EGR valve (if equipped)

8. Transmission range switch h : Fuel injector

9. VSS i : Ignition coil assemblies

10. HO2S-1 (if equipped) J : MIL

11. HO2S-2 (if equipped)

12. ECT sensor

13. Knock sensor

Page 643 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-38 ENGINE AND EMISSION CONTROL SYSTEM

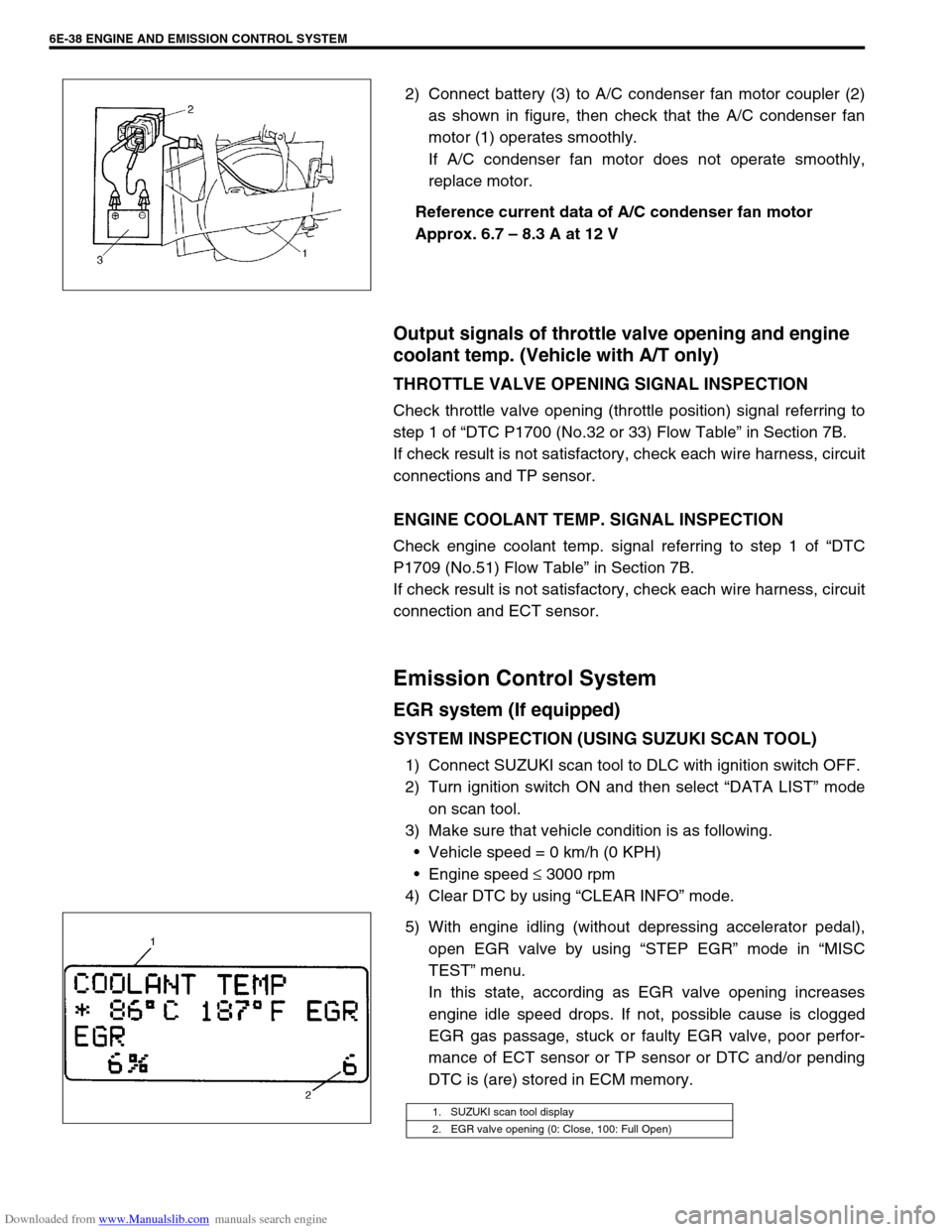

2) Connect battery (3) to A/C condenser fan motor coupler (2)

as shown in figure, then check that the A/C condenser fan

motor (1) operates smoothly.

If A/C condenser fan motor does not operate smoothly,

replace motor.

Reference current data of A/C condenser fan motor

Approx. 6.7 – 8.3 A at 12 V

Output signals of throttle valve opening and engine

coolant temp. (Vehicle with A/T only)

THROTTLE VALVE OPENING SIGNAL INSPECTION

Check throttle valve opening (throttle position) signal referring to

step 1 of “DTC P1700 (No.32 or 33) Flow Table” in Section 7B.

If check result is not satisfactory, check each wire harness, circuit

connections and TP sensor.

ENGINE COOLANT TEMP. SIGNAL INSPECTION

Check engine coolant temp. signal referring to step 1 of “DTC

P1709 (No.51) Flow Table” in Section 7B.

If check result is not satisfactory, check each wire harness, circuit

connection and ECT sensor.

Emission Control System

EGR system (If equipped)

SYSTEM INSPECTION (USING SUZUKI SCAN TOOL)

1) Connect SUZUKI scan tool to DLC with ignition switch OFF.

2) Turn ignition switch ON and then select “DATA LIST” mode

on scan tool.

3) Make sure that vehicle condition is as following.

Vehicle speed = 0 km/h (0 KPH)

Engine speed ≤ 3000 rpm

4) Clear DTC by using “CLEAR INFO” mode.

5) With engine idling (without depressing accelerator pedal),

open EGR valve by using “STEP EGR” mode in “MISC

TEST” menu.

In this state, according as EGR valve opening increases

engine idle speed drops. If not, possible cause is clogged

EGR gas passage, stuck or faulty EGR valve, poor perfor-

mance of ECT sensor or TP sensor or DTC and/or pending

DTC is (are) stored in ECM memory.

1. SUZUKI scan tool display

2. EGR valve opening (0: Close, 100: Full Open)

Page 644 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-39

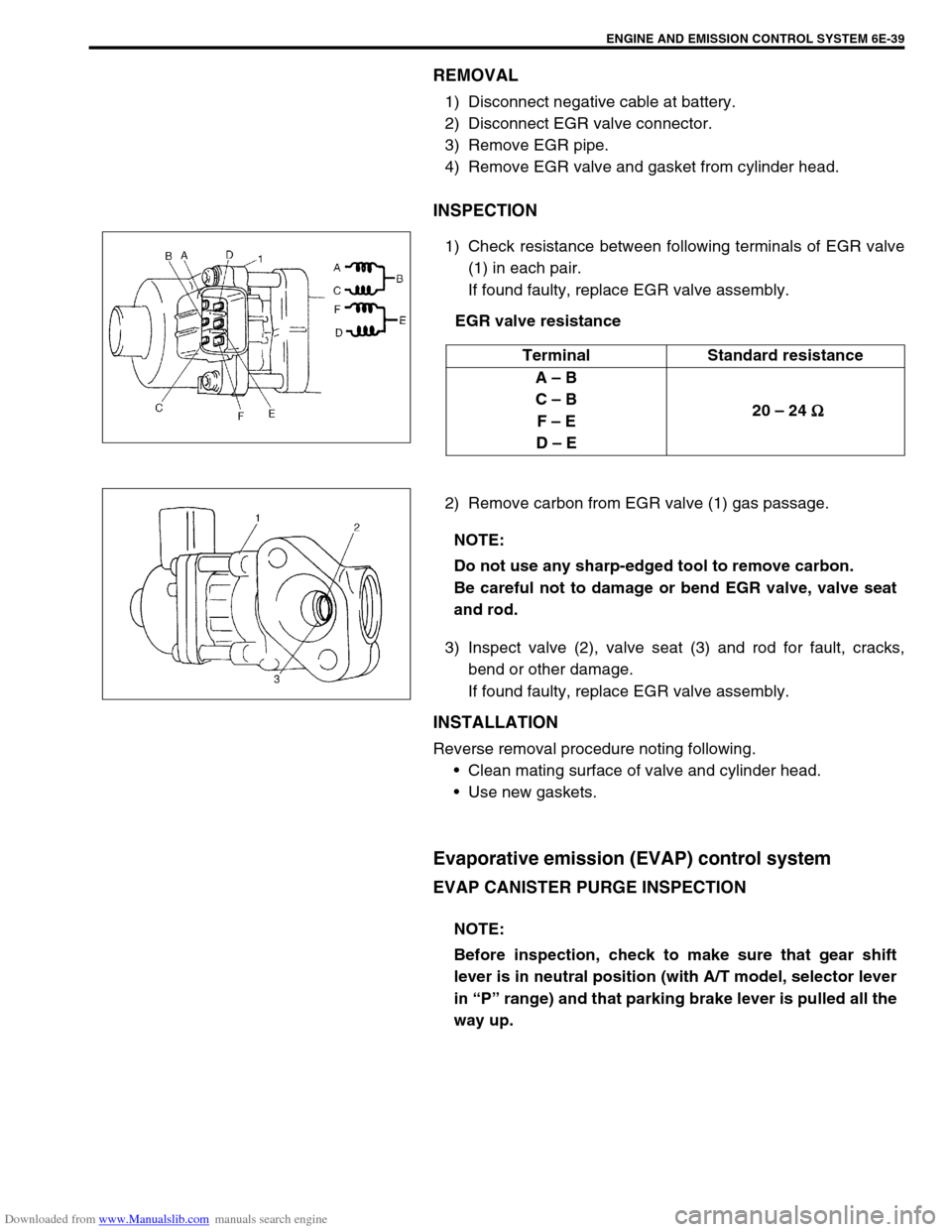

REMOVAL

1) Disconnect negative cable at battery.

2) Disconnect EGR valve connector.

3) Remove EGR pipe.

4) Remove EGR valve and gasket from cylinder head.

INSPECTION

1) Check resistance between following terminals of EGR valve

(1) in each pair.

If found faulty, replace EGR valve assembly.

EGR valve resistance

2) Remove carbon from EGR valve (1) gas passage.

3) Inspect valve (2), valve seat (3) and rod for fault, cracks,

bend or other damage.

If found faulty, replace EGR valve assembly.

INSTALLATION

Reverse removal procedure noting following.

Clean mating surface of valve and cylinder head.

Use new gaskets.

Evaporative emission (EVAP) control system

EVAP CANISTER PURGE INSPECTION

Terminal Standard resistance

A – B

C – B

F – E

D – E 20 – 24

Ω

ΩΩ Ω

NOTE:

Do not use any sharp-edged tool to remove carbon.

Be careful not to damage or bend EGR valve, valve seat

and rod.

NOTE:

Before inspection, check to make sure that gear shift

lever is in neutral position (with A/T model, selector lever

in “P” range) and that parking brake lever is pulled all the

way up.