roller SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 579 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-5

Yaw rate / G sensor

The yaw rate / G sensor consists of the yaw rate (angular velocity in the vehicle turning direction) sensor and right-left

G (acceleration in right-left direction) sensor and is mounted to the P/S controller B/K at the lower part of the center

console. It detects the angular velocity in the vehicle turn ing direction and movement in the right-left direction, and

then it sends that information to ESP ® control module.

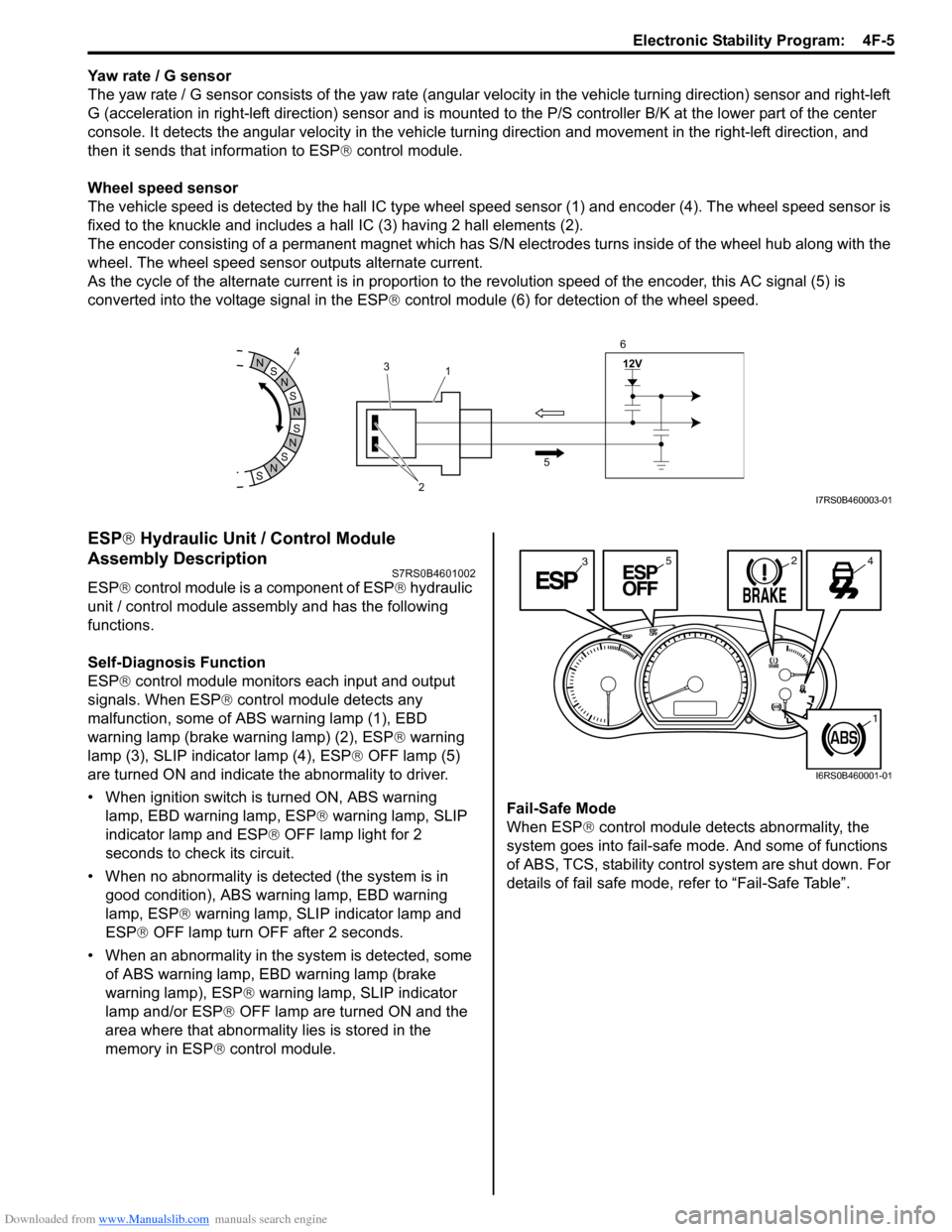

Wheel speed sensor

The vehicle speed is detected by the hall IC type wheel speed sensor (1) and encoder (4). The wheel speed sensor is

fixed to the knuckle and includes a hall IC (3) having 2 hall elements (2).

The encoder consisting of a permanent ma gnet which has S/N electrodes turns inside of the wheel hub along with the

wheel. The wheel speed sensor outputs alternate current.

As the cycle of the alternate current is in proportion to the revolution speed of the encoder, this AC signal (5) is

converted into the voltage signal in the ESP ® control module (6) for detection of the wheel speed.

ESP ® Hydraulic Unit / Control Module

Assembly Description

S7RS0B4601002

ESP ® control module is a component of ESP ® hydraulic

unit / control module assembly and has the following

functions.

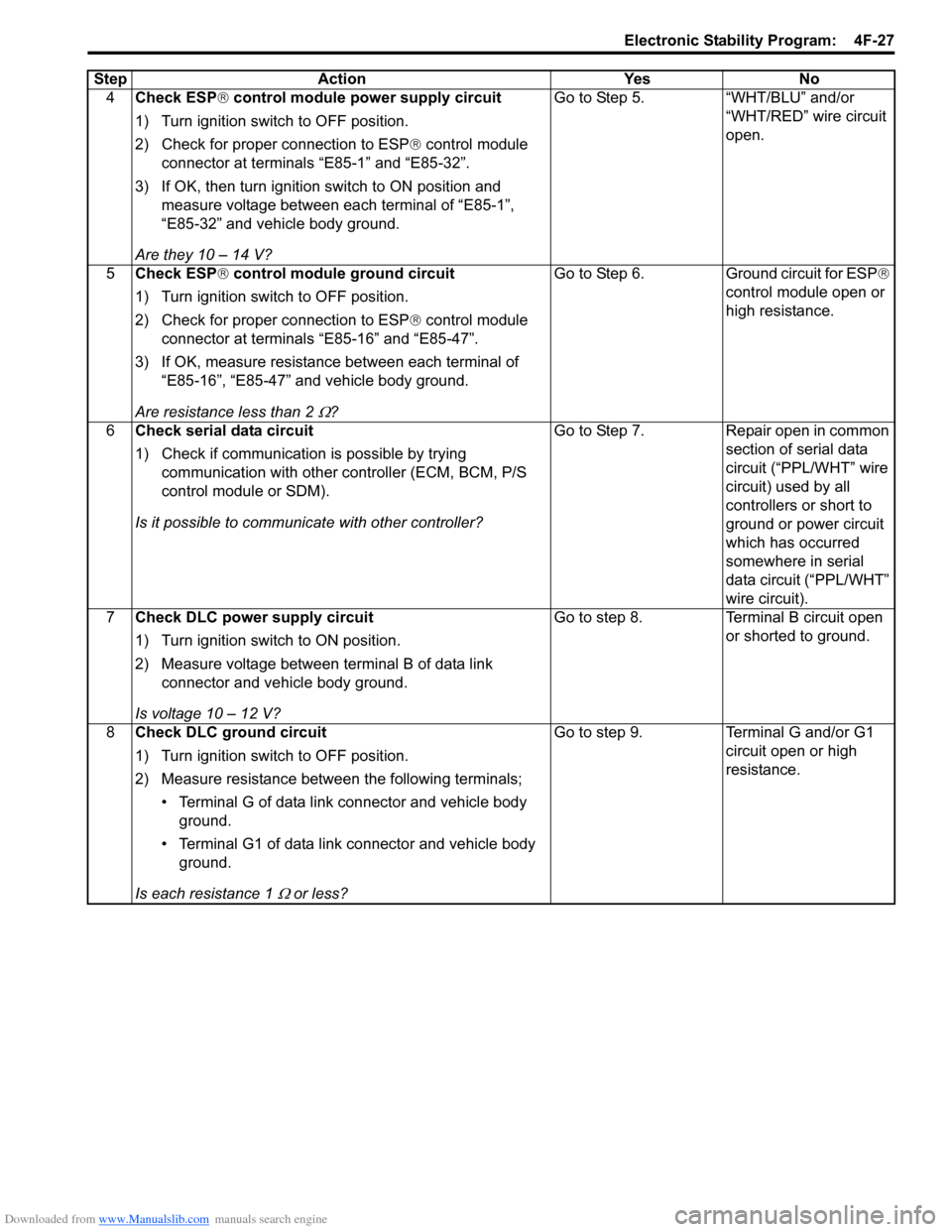

Self-Diagnosis Function

ESP ® control module monitors each input and output

signals. When ESP ® control module detects any

malfunction, some of ABS warning lamp (1), EBD

warning lamp (brake warning lamp) (2), ESP ® warning

lamp (3), SLIP indicator lamp (4), ESP ® OFF lamp (5)

are turned ON and indicate the abnormality to driver.

• When ignition switch is turned ON, ABS warning lamp, EBD warning lamp, ESP ® warning lamp, SLIP

indicator lamp and ESP ® OFF lamp light for 2

seconds to check its circuit.

• When no abnormality is detected (the system is in good condition), ABS warning lamp, EBD warning

lamp, ESP ® warning lamp, SLIP indicator lamp and

ESP ® OFF lamp turn OFF after 2 seconds.

• When an abnormality in the system is detected, some of ABS warning lamp, EBD warning lamp (brake

warning lamp), ESP ® warning lamp, SLIP indicator

lamp and/or ESP ® OFF lamp are turned ON and the

area where that abnormality lies is stored in the

memory in ESP ® control module. Fail-Safe Mode

When ESP

® control module detects abnormality, the

system goes into fail-safe mode. And some of functions

of ABS, TCS, stability control system are shut down. For

details of fail safe mode, re fer to “Fail-Safe Table”.

S

N

S

N

S

N

N

S

N

S

12V

2

3

1

5

4

6I7RS0B460003-01

3245

1

I6RS0B460001-01

Page 601 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-27

4Check ESP ® control module power supply circuit

1) Turn ignition switch to OFF position.

2) Check for proper connection to ESP ® control module

connector at terminals “E85-1” and “E85-32”.

3) If OK, then turn ignition switch to ON position and measure voltage between each terminal of “E85-1”,

“E85-32” and vehicle body ground.

Are they 10 – 14 V? Go to Step 5. “WHT/BLU” and/or

“WHT/RED” wire circuit

open.

5 Check ESP ® control module ground circuit

1) Turn ignition switch to OFF position.

2) Check for proper connection to ESP ® control module

connector at terminals “E85-16” and “E85-47”.

3) If OK, measure resistance between each terminal of “E85-16”, “E85-47” and vehicle body ground.

Are resistance less than 2

Ω? Go to Step 6. Ground circuit for ESP

®

control module open or

high resistance.

6 Check serial data circuit

1) Check if communication is possible by trying

communication with other c ontroller (ECM, BCM, P/S

control module or SDM).

Is it possible to commun icate with other controller? Go to Step 7. Repair open in common

section of serial data

circuit (“PPL/WHT” wire

circuit) used by all

controllers or short to

ground or power circuit

which has occurred

somewhere in serial

data circuit (“PPL/WHT”

wire circuit).

7 Check DLC power supply circuit

1) Turn ignition switch to ON position.

2) Measure voltage between terminal B of data link

connector and vehicle body ground.

Is voltage 10 – 12 V? Go to step 8. Terminal B circuit open

or shorted to ground.

8 Check DLC ground circuit

1) Turn ignition switch to OFF position.

2) Measure resistance between the following terminals;

• Terminal G of data link connector and vehicle body ground.

• Terminal G1 of data link connector and vehicle body ground.

Is each resistance 1

Ω or less? Go to step 9. Terminal G and/or G1

circuit open or high

resistance.

Step Action Yes No

Page 645 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-1

Transmission / Transaxle

Automatic Transmission/Transaxle

Precautions

Precautions in Diagnosing TroubleS7RS0B5100001

• Do not disconnect couplers from TCM, battery cable from battery, TCM ground wire harness from engine or

main fuse before checking the diagnostic information

(DTC, freeze frame data, etc.) stored in TCM memory.

Such disconnection will clea r memorized information

in TCM memory.

• Diagnostic information stored in TCM memory can be cleared as well as checked by using SUZUKI scan

tool or generic scan tool. Before using scan tool, read

its Operator’s (Instruction) Manual carefully to have

good understanding as to what functions are available

and how to use it.

It is indistinguishable wh ich module turns on MIL

because not only ECM but also TCM turns on MIL.

Therefore, check both ECM and TCM for DTC when

MIL lights on.

When checking TCM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by TCM.

– Generic scan tool displays DTC detected by each of ECM and TCM simultaneously.

• Using SUZUKI scan tool the diagnostic information stored in TCM memory can be checked and cleared

as well. Before its use, be sure to read Operator’s

Manual supplied with it carefully to have good

understanding of its functions and usage.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• TCM replacement

– When substituting a known-good TCM, check that all relays and actuators have resistance of

specified value.

Neglecting this check may result in damage to good

TCM.

• Communication of ECUs , ECM, TCM, ABS control

module, keyless start control module and BCM is

established by CAN (Controller Area Network).

Therefore, handle CAN communication line with care

referring to “Precaution for CAN Communication

System in Section 00”.

Precautions for Disassembly and ReassemblyS7RS0B5100002

When repairing automatic transaxle, it is necessary to

conduct the on-vehicle test to investigate where the

cause of the trouble lies first.

Then whether overhaul should be done or not is

determined. If the transaxle is disassembled without

such preliminary procedure, not only the cause of the

trouble would be unknown, but also a secondary trouble

may occur and often time would be wasted.

As the automatic transaxle consists of high precision

component, the following cautions should be strictly

observed when handling its parts in disassembly and

reassembly.

• Disassembling valve body assembly is prohibited

essentially. However, a few parts can be

disassembled. When disassembling valve body

component parts, confirm whether their parts are

allowed to disassemble or not referring to “Valve Body

Assembly Disassembly and Reassembly”.

• When component part of forward clutch, direct clutch, 2nd brake and/or O/D and 2nd coast brake, namely

clutch disc, brake disc, retaining plate and/or

separator plate, have been replaced, all learned

contents, which have been stored in TCM memory by

executing learning control, should be initialized

referring to “Learning Control Initialization”.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

dismounting and remounting.

• Select a clean place free from dust and dirt for overhauling.

• Place a rubber mat on the work bench to protect parts from damage.

• Work gloves or shop cloth should not be used. (Use a nylon cloth or a paper towel.)

• When separating the case joint, do not pry with a screwdriver or such but tap with a plastic hammer

lightly.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

disassembly and reassembly.

• Wash the disassembled parts in ATF (Automatic Transaxle Fluid) or kerosene (using care not to allow

ATF or kerosene to get on your face, etc.) and confirm

that each fluid passage is not clogged by blowing air

into it. But use kerosene to wash the discs, resin

washers and rubber parts.

• Replace each gasket, oil seal and O-ring with a new one.

• Apply ATF to sliding or rotating parts before

reassembly.

Page 815 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-1

Transmission / Transaxle

Manual Transmission/Transaxle

General Description

Manual Transaxle Construction and ServicingS7RS0B5201001

The transaxle provides five forward speeds and one reverse speed by means of three synchromeshs and three shafts

(input shaft, countershaft and reverse gear shaft). All forward gears are in constant mesh, and reverse uses a sliding

idler gear arrangement.

The low speed synchronizer sleeve & hub is mounted on countershaft and engaged with countershaft 1st gear or 2nd

gear, while the high speed synchronizer sleeve & hub is don e on input shaft and engaged with input shaft 3rd gear or

4th gear. The 5th speed synchronizer sleev e & hub on input shaft is engaged with input shaft fifth gear mounted on the

input shaft.

To prevent the cracking noise from the reverse gear when shifting transaxle gear into the reverse gear, the reverse

shift braking device is used.

The device utilizes the 5th synchromesh, which is the lever synchro type, to appl y the brake on the input shaft rotation.

The double cone synchronizing mechanism is provided to 2nd gear synchromesh device for high performance of

shifting to 2nd gear.

The countershaft turns the final gear and differential assembly, thereby turning the front drive shafts which are

attached to the front wheels.

For servicing, it is ne cessary to use genuine sealant or its equivalent on mating surfaces of transaxle case which is

made of aluminum. The case fastening bolts must be tight ened to specified torque by means of torque wrench. It is

also important that all parts are thoroughly cleaned with cleaning fluid and air dried before reassembling.

Further, care must be taken to adjust preload of count ershaft taper roller bearings. New synchronizer rings are

prohibited from being lapped with respective gear cones by using lapping compound before they are assembled.

Page 896 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-14 Power Assisted Steering System:

TroubleshootingStep Action Yes No 1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 1) Make sure that SUZUKI scan tool is free from malfunction and that correct program card (software) for

P/S system is used.

2) Turn ignition switch to OFF position.

3) Check proper connection of SUZUKI scan tool to DLC.

Is connection in good condition? Go to Step 3. Connect SUZUKI scan

tool to DLC properly.

3 1) Check if communication is possible by making communication with other controllers (ECM, BCM, ABS

or SDM) or other vehicles.

Is it possible to communic ate with the other controllers? Go to Step 4. Repair open in common

section of “serial data

circuit” (“PPL/WHT” wire

circuit) used by all

controllers or short to

ground or power circuit

which has occurred

somewhere in serial

data circuit (“PPL/WHT”

wire circuit).

4 1) Check power supply circuit and ground circuit for P/S control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition? Go to Step 5. Repair or replace

defective circuit.

5 1) With ignition switch turned OFF, disconnect “E52” connector from P/S control module and check for

terminal to P/S control module connector.

2) If connections are OK, check t hat “Serial data circuit” is

as following.

• Insulation resistance of “Serial data circuit” wire is infinity between its terminal and other terminals at P/S

control module connector.

• Wiring resistance of “Seria l data circuit” wire is less

than 1 Ω.

• Insulation resistance of “Serial data circuit” wire is infinity between its terminal and vehicle body ground.

Is circuit in good condition? Substitute a known-

good P/S control

module and recheck.

Repair or replace

defective circuit.

Page 934 of 1496

Downloaded from www.Manualslib.com manuals search engine 7-ii Table of Contents

Recommended Service Material ....................... 7B-33

Special Tool ...................................................... 7B-33

Automatic Type .................... .................................7B-34

Precautions.........................................................7B-34 A/C System Caution .......................................... 7B-34

Precautions in Diagnosing Trouble ................... 7B-34

Precautions on Servicing A/C System .............. 7B-34

General Description .......... .................................7B-34

Auto A/C System Descript ion ............................ 7B-34

HVAC Control Module Operation Description ... 7B-36

Refrigerant Type Identifica tion .......................... 7B-36

Sub-Cool A/C System Description .................... 7B-36

A/C Operation Description ................................ 7B-36

On-Board Diagnostic System Description ......... 7B-37

Schematic and Routing Diagram ......................7B-37 Major Components of A/C System .................... 7B-37

A/C System Wiring Diagra m ............................. 7B-38

Diagnostic Information and Procedures ..........7B-39 A/C System Symptom Diagnosis ...................... 7B-39

Abnormal Noise Sympto m Diagnosis of A/C

System ............................................................ 7B-42

DTC Check........................................................ 7B-42

DTC Clearance ................................................. 7B-43

DTC Table ......................................................... 7B-44

Fail-Safe Table ................. ................................. 7B-45

Scan Tool Data ................................................. 7B-46

Air Conditioning System Check......................... 7B-47

Visual Inspection ............................................... 7B-49

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit Malfunction .......................... 7B-49

DTC B1503: A/C Evaporator Air Temperature Sensor and/or Its Circuit Malfunction .............. 7B-50

DTC B1504: Sunload Sensor and/or Its Circuit Malfunction ......... ................................. 7B-52

DTC B1511: Temperature Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-53

DTC B1512: Air flow Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-55

DTC B1513: Temperature Control Actuator and/or Its Circuit Malfunction .......................... 7B-57

DTC B1514: Air Flow Co ntrol Actuator and/or

Its Circuit Malfunction ...................................... 7B-60

DTC B1541: HVAC Control Module Back-Up Power Supply Malfunction .............................. 7B-62

DTC B1546: A/C Refrigerant Pressure Malfunction ...................................................... 7B-63

DTC B1551: Serial Communication Circuit Malfunction ...................................................... 7B-63

DTC B1552: Serial Communication Signal Malfunction ...................................................... 7B-64

DTC B1553: CAN Communication Signal Malfunction ...................................................... 7B-65

DTC B1557: Vehicle Speed Sensor Signal Malfunction ...................................................... 7B-65

DTC B1561: Engine Coolant Temperature Sensor Signal Malfunctio n .............................. 7B-66 DTC B1562: Outside Air Temperature Sensor

Signal Malfunction ........................................... 7B-66

DTC B1563: A/C Refr igerant Pressure

Sensor Signal Malfunction .............................. 7B-66

Inspection of HVAC Control Module and Its Circuit .............................................................. 7B-67

A/C System Performance Inspection ................ 7B-70

A/C System Inspection at ECM ......................... 7B-70

Repair Instructions ............ ................................7B-71

Operation Procedure for Refrigerant Charge .... 7B-71

HVAC Unit Components ................................... 7B-72

HVAC Unit Removal and In stallation ................ 7B-73

Temperature Control Actuator Removal and Installation ....................................................... 7B-73

Temperature Control Actuat or Inspection ......... 7B-73

Air Flow Control Actuator Removal and Installation ....................................................... 7B-74

Air Flow Control Actuator Inspection ................. 7B-74

Air Intake Control Actuator Removal and Installation ....................................................... 7B-75

Air Intake Control Actuator Inspection............... 7B-75

Actuator Linkage Inspection .............................. 7B-76

Blower Motor Controller Removal and Installation ....................................................... 7B-76

Blower Motor Controller Inspection ................... 7B-76

HVAC Control Module Removal and Installation ....................................................... 7B-77

Sunload Sensor Removal and Installation ........ 7B-77

Sunload Sensor Inspection ............................... 7B-77

Outside Air Temperature Sensor Removal and Installation ................................................ 7B-77

Outside Air Temperature Sensor Inspection ..... 7B-77

Inside Air Temperature Sensor Removal and Installation ....................................................... 7B-78

Inside Air Temperature Sens or Inspection ........ 7B-78

Condenser Assembly On-Vehicle Inspection .... 7B-78

Condenser Assembly Removal and Installation ....................................................... 7B-78

Receiver/Dryer Removal and Installation .......... 7B-78

Evaporator Inspection ....................................... 7B-78

Evaporator Temperature Sensor Removal and Installation ................................................ 7B-78

Evaporator Temperature Se nsor Inspection ..... 7B-78

Expansion Valve Removal an d Installation ....... 7B-78

Expansion Valve Inspection .............................. 7B-78

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-78

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-78

Compressor Relay Inspection .

.......................... 7B-78

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-78

Compressor Drive Belt Removal and Installation ....................................................... 7B-79

Compressor Assembly Removal and Installation ....................................................... 7B-79

Compressor Assembly Components................. 7B-79

Magnet Clutch Removal and Installation........... 7B-79

Magnet Clutch Inspection.................................. 7B-79

Relief Valve Inspection...................................... 7B-79

Page 983 of 1496

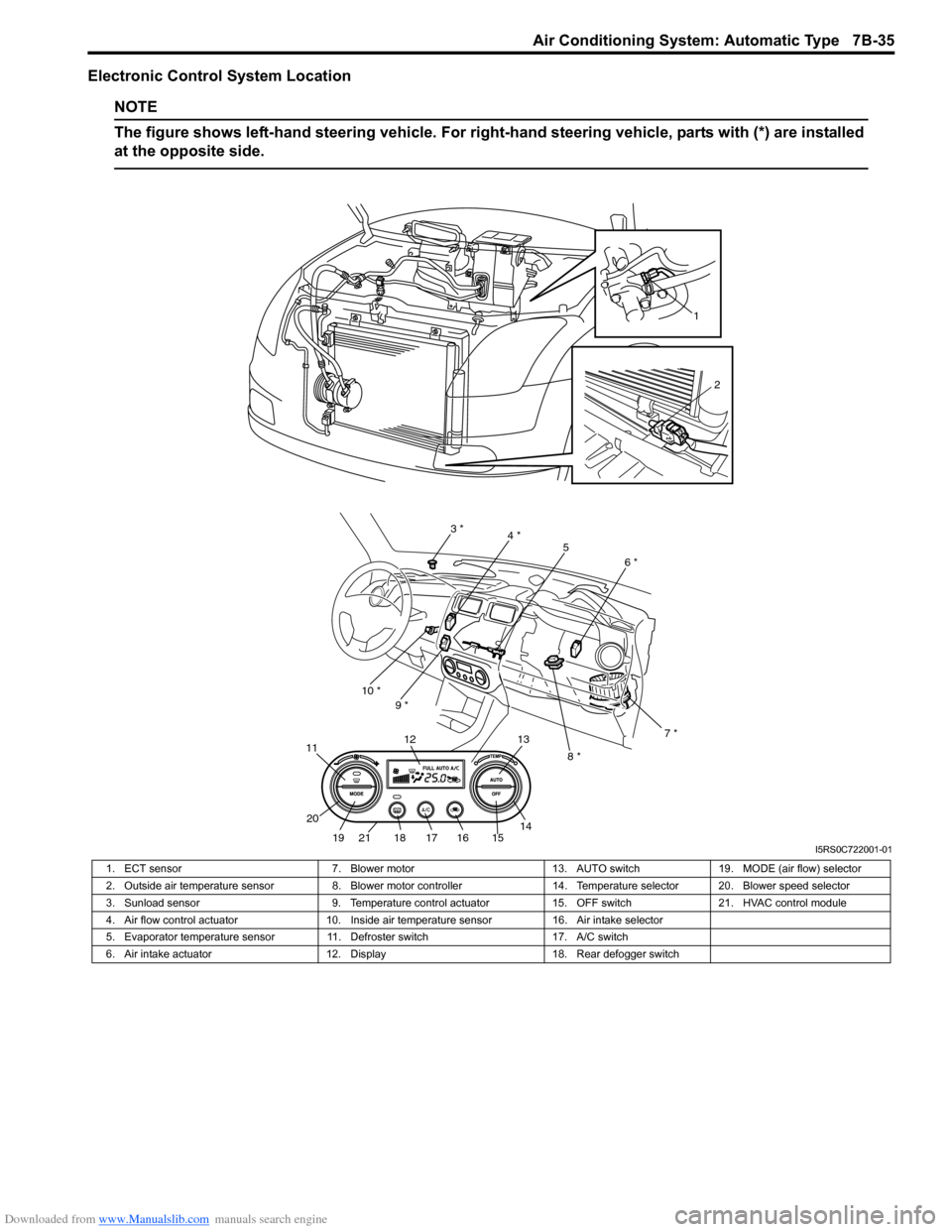

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-35

Electronic Control System Location

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

1

2

3 * 4 *

5

6 *

7 *

8 *

9 *

10 *

21

11

12 13

14

15161718

19

20

I5RS0C722001-01

1. ECT sensor

7. Blower motor13. AUTO switch19. MODE (air flow) selector

2. Outside air temperature sensor 8. Blower motor controller 14. Temperature selector 20. Blower speed selector

3. Sunload sensor 9. Temperature control actuator15. OFF switch21. HVAC control module

4. Air flow control actuator 10. Inside air temperature sensor 16. Air intake selector

5. Evaporator temperature sensor 11. Defroster switch 17. A/C switch

6. Air intake actuator 12. Display 18. Rear defogger switch

Page 984 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-36 Air Conditioning System: Automatic Type

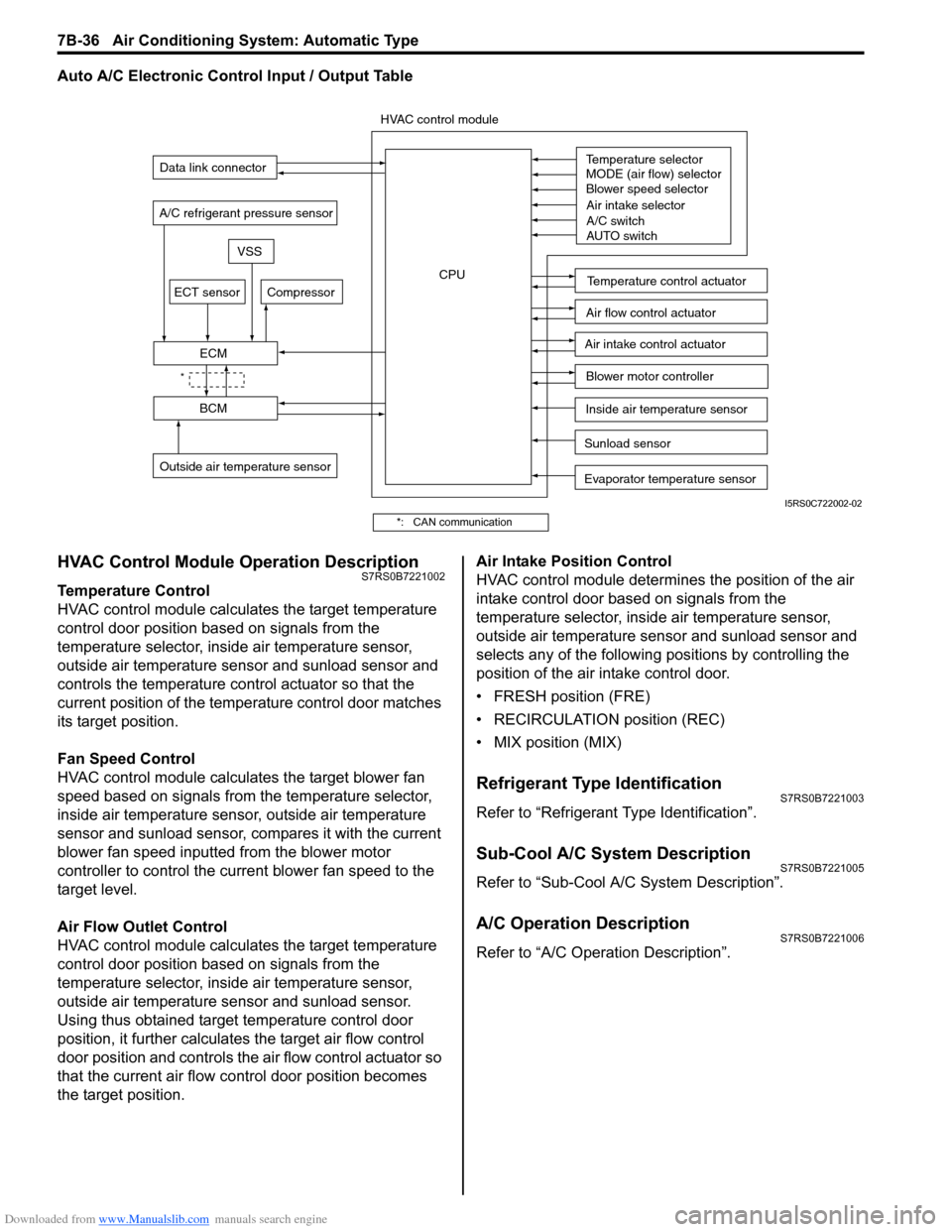

Auto A/C Electronic Control Input / Output Table

HVAC Control Module Operation DescriptionS7RS0B7221002

Temperature Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

controls the temperature control actuator so that the

current position of the temperature control door matches

its target position.

Fan Speed Control

HVAC control module calculates the target blower fan

speed based on signals from the temperature selector,

inside air temperature sensor, outside air temperature

sensor and sunload sensor, compares it with the current

blower fan speed inputted from the blower motor

controller to control the current blower fan speed to the

target level.

Air Flow Outlet Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor.

Using thus obtained target temperature control door

position, it further calculates the target air flow control

door position and controls the ai r flow control actuator so

that the current air flow c ontrol door position becomes

the target position. Air Intake Position Control

HVAC control module determines the position of the air

intake control door based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

selects any of the following positions by controlling the

position of the air intake control door.

• FRESH position (FRE)

• RECIRCULATION position (REC)

• MIX position (MIX)

Refrigerant Type IdentificationS7RS0B7221003

Refer to “Refrigerant Type Identification”.

Sub-Cool A/C System DescriptionS7RS0B7221005

Refer to “Sub-Cool A/C System Description”.

A/C Operation DescriptionS7RS0B7221006

Refer to “A/C Operation Description”.

Sunload sensor

Outside air temperature sensor Evaporator temperature sensor

A/C refrigerant pressure sensor

Temperature selector

MODE (air flow) selector

Blower speed selector

Air intake selector

AUTO switch

A/C switch

Compressor

Blower motor controller

Temperature control actuator

Air flow control actuator

Air intake control actuator

BCM

ECM

Data link connector

HVAC control module

CPU

ECT sensor

Inside air temperature sensor

VSS

*

I5RS0C722002-02

*: CAN communication

Page 987 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-39

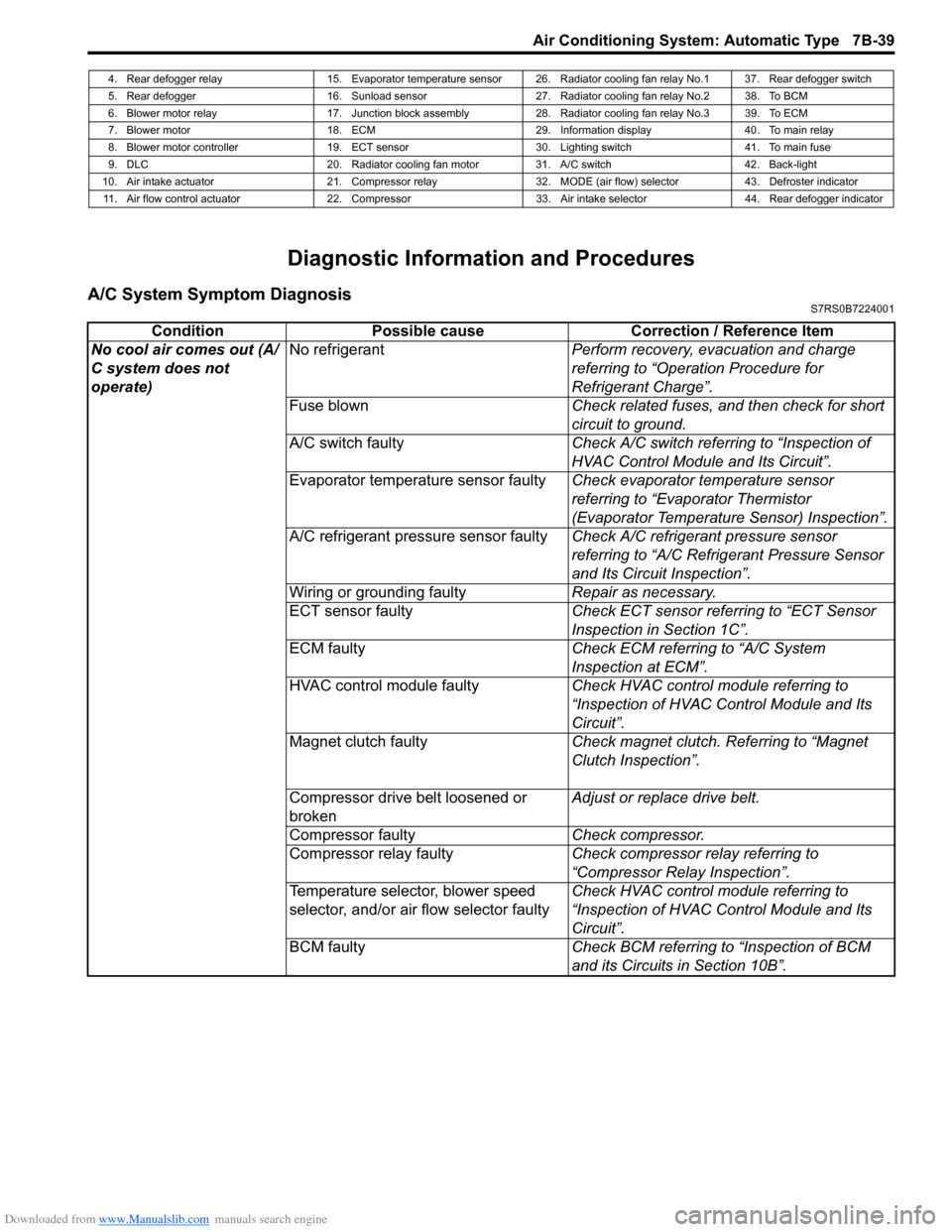

Diagnostic Information and Procedures

A/C System Symptom DiagnosisS7RS0B7224001

4. Rear defogger relay 15. Evaporator temperature sensor 26. Radiator cooling fan relay No.1 37. Rear defogger switch

5. Rear defogger 16. Sunload sensor 27. Radiator cooling fan relay No.2 38. To BCM

6. Blower motor relay 17. Junction block assembly 28. Radiator cooling fan relay No.3 39. To ECM

7. Blower motor 18. ECM 29. Information display 40. To main relay

8. Blower motor controller 19. ECT sensor 30. Lighting switch 41. To main fuse

9. DLC 20. Radiator cooling fan motor 31. A/C switch 42. Back-light

10. Air intake actuator 21. Compressor relay 32. MODE (air flow) selector 43. Defroster indicator 11. Air flow control actuator 22. Compressor 33. Air intake selector 44. Rear defogger indicator

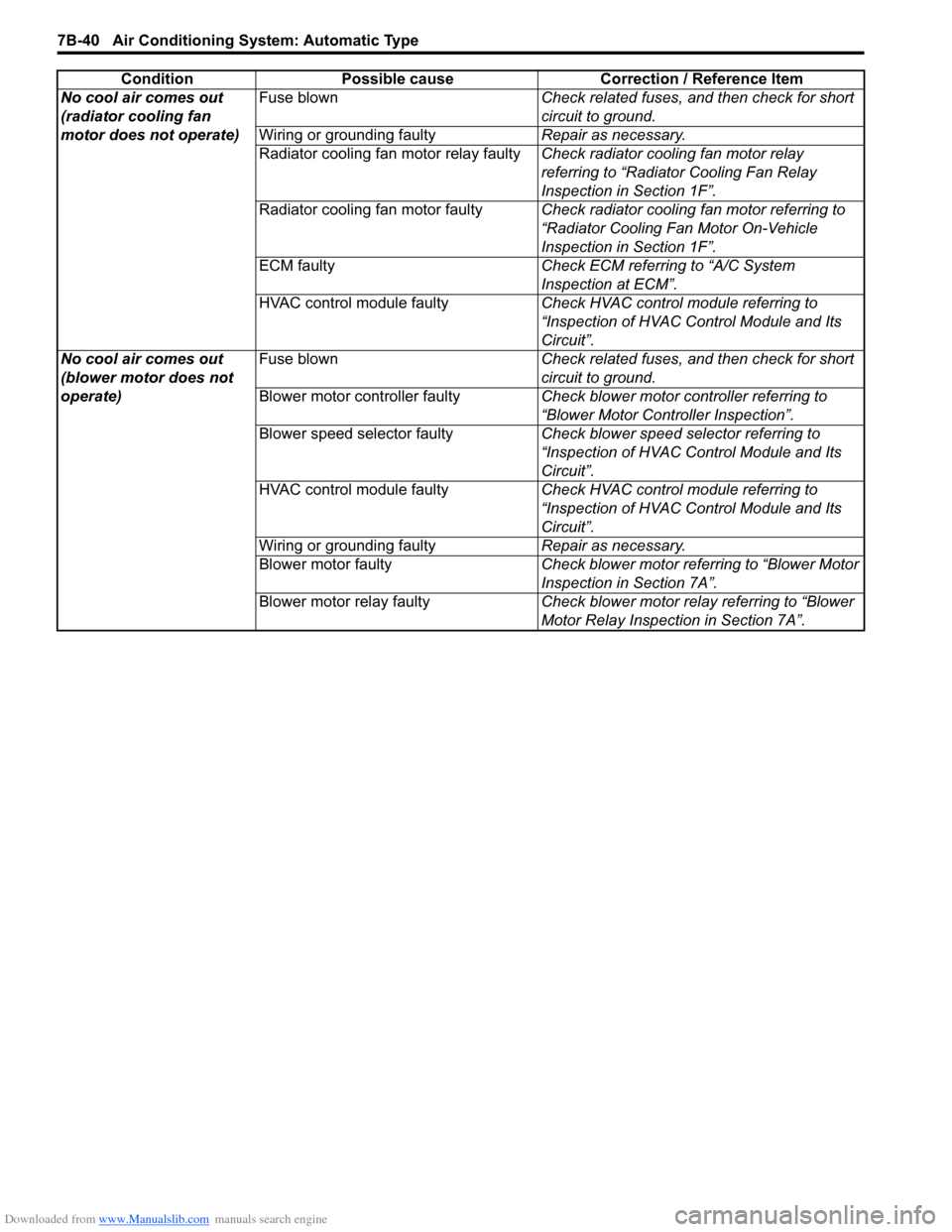

Condition Possible cause Correction / Reference Item

No cool air comes out (A/

C system does not

operate) No refrigerant

Perform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blown Check related fuses, and then check for short

circuit to ground.

A/C switch faulty Check A/C switch referring to “Inspection of

HVAC Control Module and Its Circuit”.

Evaporator temperature sensor faulty Check evaporator temperature sensor

referring to “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

A/C refrigerant pressure sensor faulty Check A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faulty Repair as necessary.

ECT sensor faulty Check ECT sensor referring to “ECT Sensor

Inspection in Section 1C”.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Compressor relay faulty Check compressor relay referring to

“Compressor Relay Inspection”.

Temperature selector, blower speed

selector, and/or air flow selector faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

BCM faulty Check BCM referring to “Inspection of BCM

and its Circuits in Section 10B”.

Page 988 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-40 Air Conditioning System: Automatic Type

No cool air comes out

(radiator cooling fan

motor does not operate)Fuse blown

Check related fuses, and then check for short

circuit to ground.

Wiring or grounding faulty Repair as necessary.

Radiator cooling fan motor relay faulty Check radiator cooling fan motor relay

referring to “Radiator Cooling Fan Relay

Inspection in Section 1F”.

Radiator cooling fan motor faulty Check radiator cooling fan motor referring to

“Radiator Cooling Fan Motor On-Vehicle

Inspection in Section 1F”.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

No cool air comes out

(blower motor does not

operate) Fuse blown

Check related fuses, and then check for short

circuit to ground.

Blower motor controller faulty Check blower motor controller referring to

“Blower Motor Controller Inspection”.

Blower speed selector faulty Check blower speed selector referring to

“Inspection of HVAC Control Module and Its

Circuit”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Wiring or grounding faulty Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Blower motor relay faulty Check blower motor relay referring to “Blower

Motor Relay Inspection in Section 7A”.

Condition Possible cause Correction / Reference Item