hot air SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 448 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-15 Front Suspension:

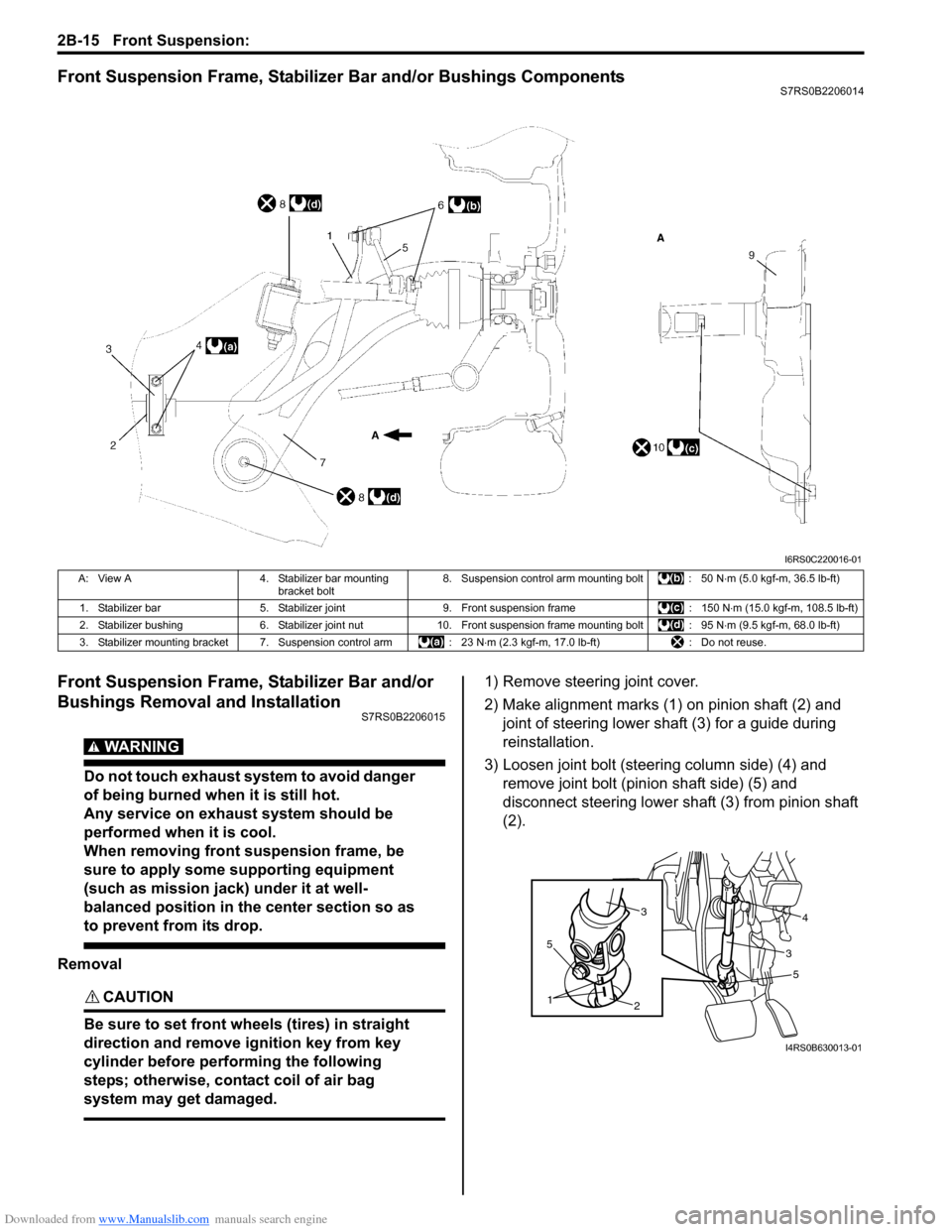

Front Suspension Frame, Stabilizer Bar and/or Bushings ComponentsS7RS0B2206014

Front Suspension Frame, Stabilizer Bar and/or

Bushings Removal and Installation

S7RS0B2206015

WARNING!

Do not touch exhaust system to avoid danger

of being burned when it is still hot.

Any service on exhaust system should be

performed when it is cool.

When removing front suspension frame, be

sure to apply some supporting equipment

(such as mission jack) under it at well-

balanced position in the center section so as

to prevent from its drop.

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps; otherwise, contact coil of air bag

system may get damaged.

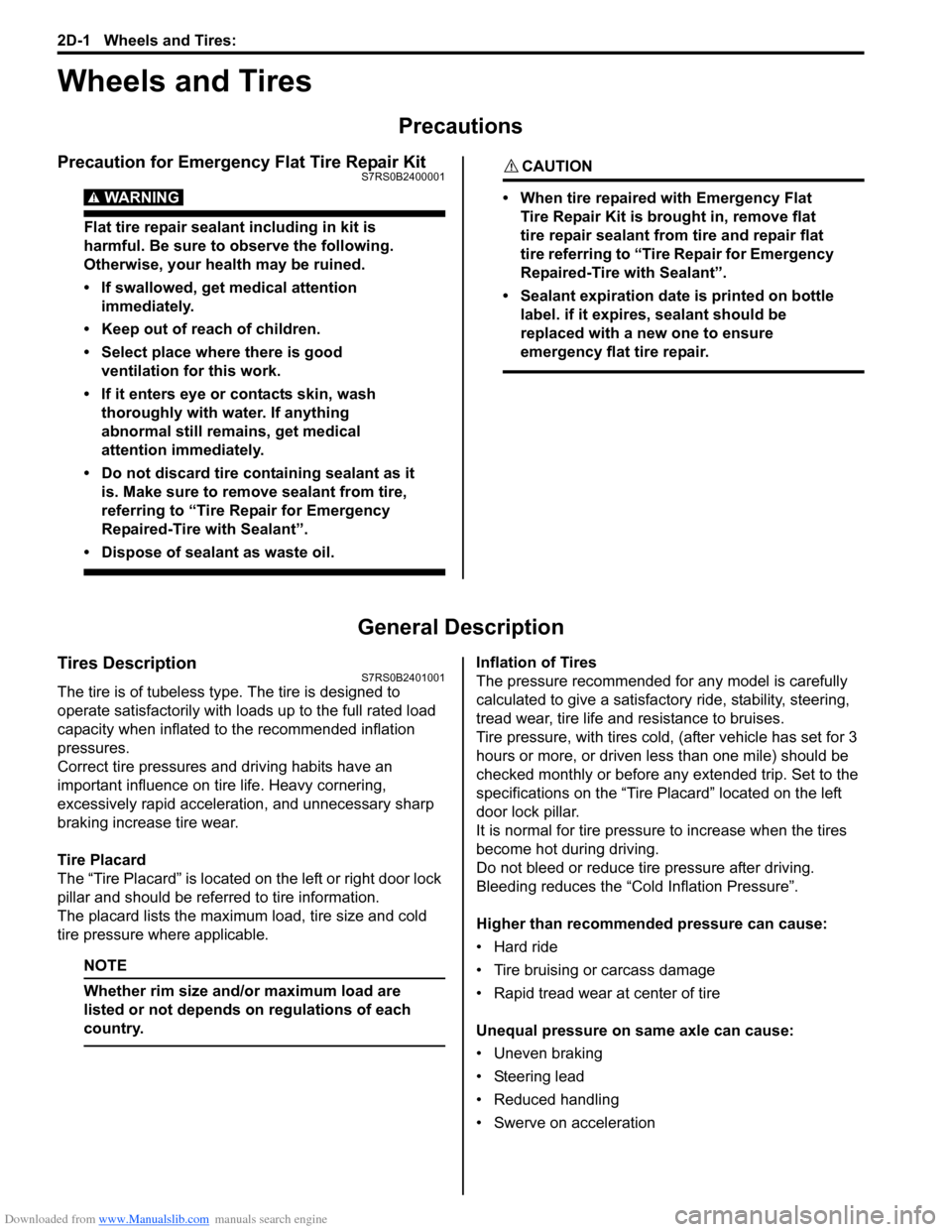

1) Remove steering joint cover.

2) Make alignment marks (1) on pinion shaft (2) and joint of steering lower shaft (3) for a guide during

reinstallation.

3) Loosen joint bolt (steering column side) (4) and remove joint bolt (pin ion shaft side) (5) and

disconnect steering lower shaft (3) from pinion shaft

(2).

I6RS0C220016-01

A: View A 4. Stabilizer bar mounting

bracket bolt 8. Suspension control arm mounting bolt : 50 N

⋅m (5.0 kgf-m, 36.5 lb-ft)

1. Stabilizer bar 5. Stabilizer joint 9. Front suspension frame : 150 N⋅m (15.0 kgf-m, 108.5 lb-ft)

2. Stabilizer bushing 6. Stabilizer joint nut10. Front suspension frame mounting bolt : 95 N ⋅m (9.5 kgf-m, 68.0 lb-ft)

3. Stabilizer mounting bracket 7. Suspension control arm : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft) : Do not reuse.

5

2

1

5

34

3

I4RS0B630013-01

Page 468 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-1 Wheels and Tires:

Suspension

Wheels and Tires

Precautions

Precaution for Emergency Flat Tire Repair KitS7RS0B2400001

WARNING!

Flat tire repair sealant including in kit is

harmful. Be sure to observe the following.

Otherwise, your health may be ruined.

• If swallowed, get medical attention immediately.

• Keep out of reach of children.

• Select place where there is good ventilation for this work.

• If it enters eye or contacts skin, wash thoroughly with water. If anything

abnormal still rema ins, get medical

attention immediately.

• Do not discard tire containing sealant as it is. Make sure to remove sealant from tire,

referring to “Tire Repair for Emergency

Repaired-Tire with Sealant”.

• Dispose of sealant as waste oil.

CAUTION!

• When tire repaired with Emergency Flat Tire Repair Kit is brought in, remove flat

tire repair sealant from tire and repair flat

tire referring to “Tire Repair for Emergency

Repaired-Tire with Sealant”.

• Sealant expiration date is printed on bottle label. if it expires, sealant should be

replaced with a new one to ensure

emergency flat tire repair.

General Description

Tires DescriptionS7RS0B2401001

The tire is of tubeless type. The tire is designed to

operate satisfactorily with loads up to the full rated load

capacity when inflated to the recommended inflation

pressures.

Correct tire pressures and driving habits have an

important influence on tire life. Heavy cornering,

excessively rapid acceleration, and unnecessary sharp

braking increase tire wear.

Tire Placard

The “Tire Placard” is located on the left or right door lock

pillar and should be referred to tire information.

The placard lists the maximum load, tire size and cold

tire pressure where applicable.

NOTE

Whether rim size and/or maximum load are

listed or not depends on regulations of each

country.

Inflation of Tires

The pressure recommended for any model is carefully

calculated to give a satisfacto ry ride, stability, steering,

tread wear, tire life and resistance to bruises.

Tire pressure, with tires cold, (after vehicle has set for 3

hours or more, or driven less than one mile) should be

checked monthly or before any extended trip. Set to the

specifications on the “Tire Placard” located on the left

door lock pillar.

It is normal for tire pressure to increase when the tires

become hot during driving.

Do not bleed or reduce tire pressure after driving.

Bleeding reduces the “Cold Inflation Pressure”.

Higher than recommended pressure can cause:

• Hard ride

• Tire bruising or carcass damage

• Rapid tread wear at center of tire

Unequal pressure on same axle can cause:

• Uneven braking

• Steering lead

• Reduced handling

• Swerve on acceleration

Page 943 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-7

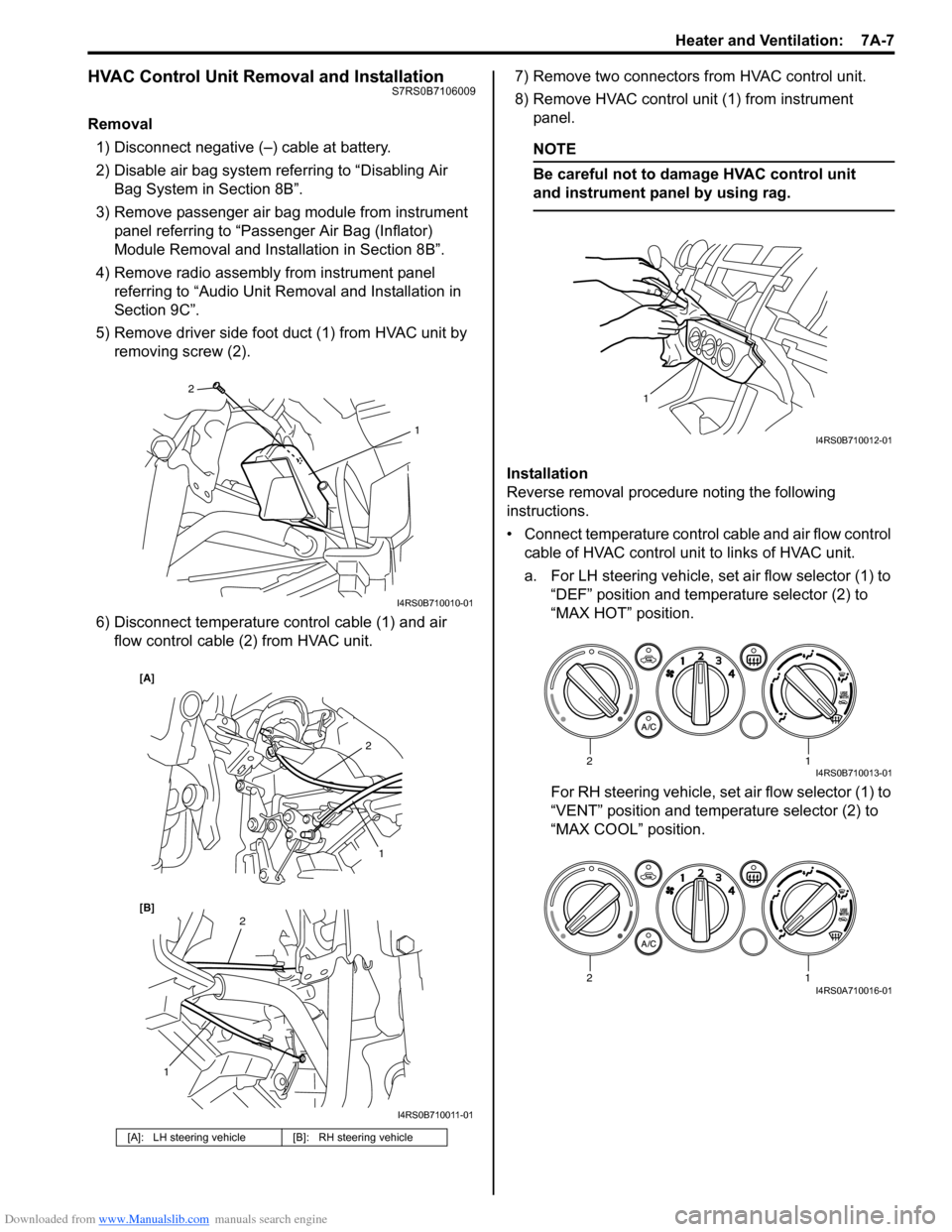

HVAC Control Unit Removal and InstallationS7RS0B7106009

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Audio Unit Re moval and Installation in

Section 9C”.

5) Remove driver side foot duct (1) from HVAC unit by removing screw (2).

6) Disconnect temperature control cable (1) and air flow control cable (2) from HVAC unit. 7) Remove two connectors from HVAC control unit.

8) Remove HVAC control unit (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control unit

and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

• Connect temperature control cable and air flow control

cable of HVAC control unit to links of HVAC unit.

a. For LH steering vehicle, set air flow selector (1) to “DEF” position and temperature selector (2) to

“MAX HOT” position.

For RH steering vehicle, set air flow selector (1) to

“VENT” position and temperature selector (2) to

“MAX COOL” position.

[A]: LH steering vehicle [B]: RH steering vehicle

2

1

I4RS0B710010-01

2

1

1

2

[B] [A]

I4RS0B710011-01

1

I4RS0B710012-01

12I4RS0B710013-01

12I4RS0A710016-01

Page 967 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-19

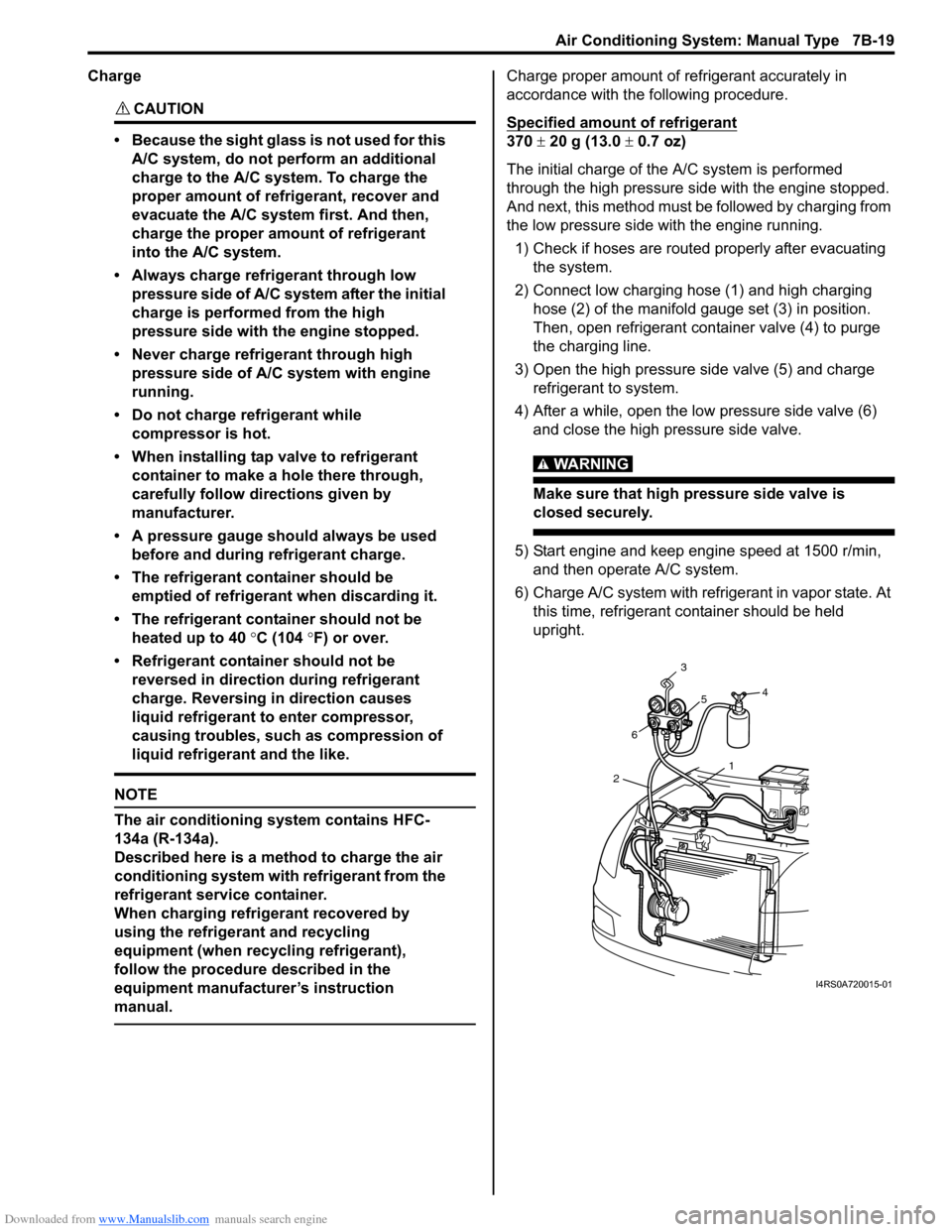

Charge

CAUTION!

• Because the sight glass is not used for this A/C system, do not perform an additional

charge to the A/C system. To charge the

proper amount of refrigerant, recover and

evacuate the A/C system first. And then,

charge the proper amount of refrigerant

into the A/C system.

• Always charge refrigerant through low pressure side of A/C system after the initial

charge is performed from the high

pressure side with the engine stopped.

• Never charge refrigerant through high pressure side of A/C system with engine

running.

• Do not charge refrigerant while compressor is hot.

• When installing tap valve to refrigerant container to make a hole there through,

carefully follow dire ctions given by

manufacturer.

• A pressure gauge should always be used before and during refrigerant charge.

• The refrigerant container should be emptied of refrigerant when discarding it.

• The refrigerant container should not be heated up to 40 °C (104 °F) or over.

• Refrigerant container should not be reversed in direction during refrigerant

charge. Reversing in direction causes

liquid refrigerant to enter compressor,

causing troubles, such as compression of

liquid refrigerant and the like.

NOTE

The air conditioning system contains HFC-

134a (R-134a).

Described here is a method to charge the air

conditioning system with refrigerant from the

refrigerant service container.

When charging refrigerant recovered by

using the refrigerant and recycling

equipment (when recycling refrigerant),

follow the procedure described in the

equipment manufacturer’s instruction

manual.

Charge proper amount of refrigerant accurately in

accordance with the following procedure.

Specified amount of refrigerant

370 ± 20 g (13.0 ± 0.7 oz)

The initial charge of the A/C system is performed

through the high pressure side with the engine stopped.

And next, this method must be followed by charging from

the low pressure side with the engine running.

1) Check if hoses are routed properly after evacuating the system.

2) Connect low charging hose (1) and high charging hose (2) of the manifold gauge set (3) in position.

Then, open refrigerant container valve (4) to purge

the charging line.

3) Open the high pressure side valve (5) and charge refrigerant to system.

4) After a while, open the low pressure side valve (6) and close the high pressure side valve.

WARNING!

Make sure that high pressure side valve is

closed securely.

5) Start engine and keep engine speed at 1500 r/min, and then operate A/C system.

6) Charge A/C system with refrigerant in vapor state. At this time, refrigerant container should be held

upright.

1

2 6 3

5 4

I4RS0A720015-01

Page 994 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-46 Air Conditioning System: Automatic Type

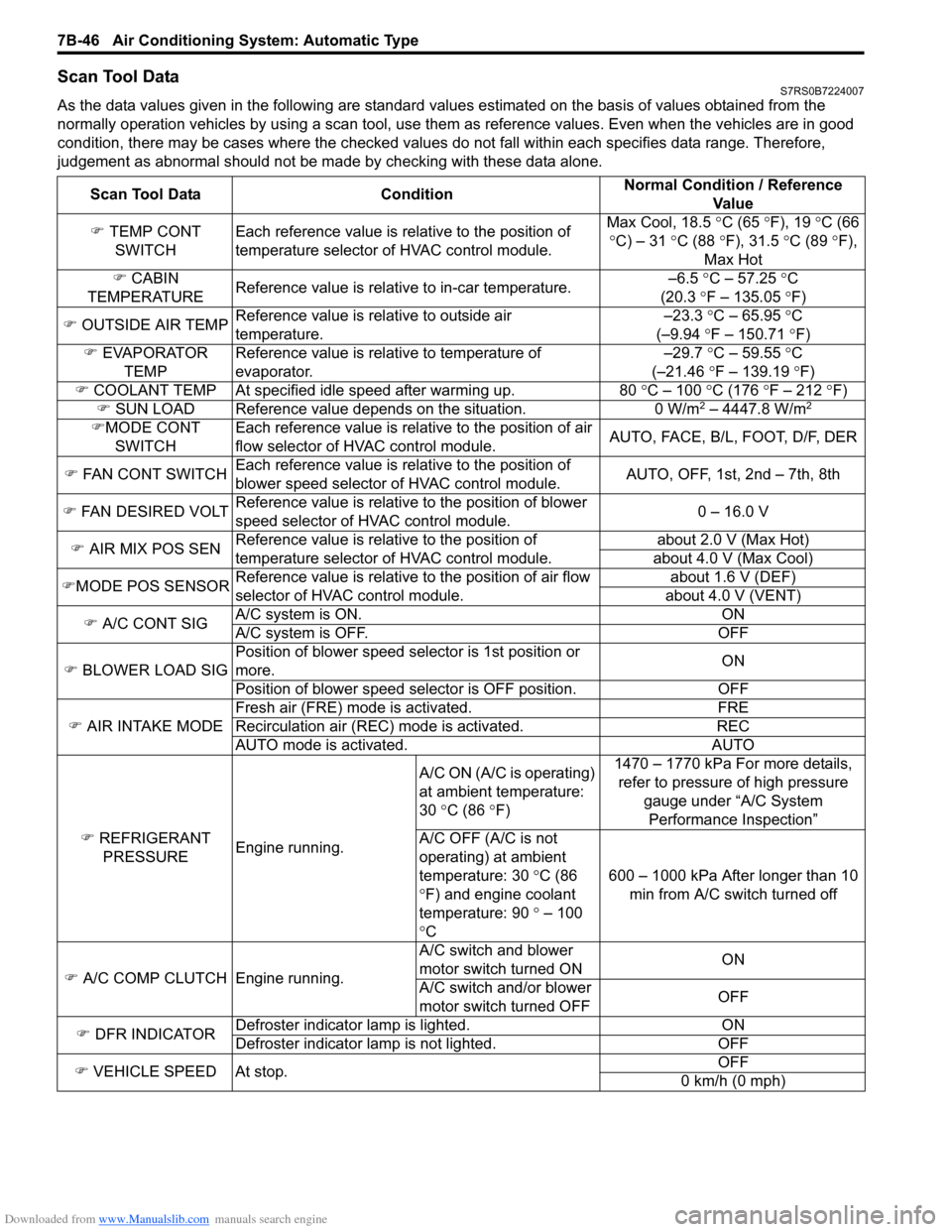

Scan Tool DataS7RS0B7224007

As the data values given in the following are standard values estimated on the basis of values obtained from the

normally operation vehicles by using a scan tool, use them as reference values. Even when the vehicles are in good

condition, there may be cases where the checked values do not fall within each specifies data range. Therefore,

judgement as abnormal should not be ma de by checking with these data alone.

Scan Tool Data Condition Normal Condition / Reference

Va l u e

�) TEMP CONT

SWITCH Each reference value is relative to the position of

temperature selector of HVAC control module. Max Cool, 18.5

°C (65 ° F), 19 °C (66

° C) – 31 °C (88 °F), 31.5 °C (89 °F),

Max Hot

�) CABIN

TEMPERATURE Reference value is relative to in-car temperature. –6.5

°C – 57.25 ° C

(20.3 °F – 135.05 °F)

�) OUTSIDE AIR TEMP Reference value is relative to outside air

temperature. –23.3

°C – 65.95 °C

(–9.94 °F – 150.71 °F)

�) EVAPORATOR

TEMP Reference value is relative to temperature of

evaporator. –29.7

°C – 59.55 °C

(–21.46 °F – 139.19 °F)

�) COOLANT TEMP At specified id le speed after warming up. 80 °C – 100 °C (176 ° F – 212 ° F)

�) SUN LOAD Reference value depends on the situation. 0 W/m

2 – 4447.8 W/m2

�)MODE CONT

SWITCH Each reference value is relative to the position of air

flow selector of HVAC control module.

AUTO, FACE, B/L, FOOT, D/F, DER

�) FAN CONT SWITCH Each reference value is relative to the position of

blower speed selector of HVAC control module. AUTO, OFF, 1st, 2nd – 7th, 8th

�) FAN DESIRED VOLT Reference value is relative to the position of blower

speed selector of HVAC control module. 0 – 16.0 V

�) AIR MIX POS SEN Reference value is relative to the position of

temperature selector of HVAC control module. about 2.0 V (Max Hot)

about 4.0 V (Max Cool)

�) MODE POS SENSOR Reference value is relative to the position of air flow

selector of HVAC control module. about 1.6 V (DEF)

about 4.0 V (VENT)

�) A/C CONT SIG A/C system is ON. ON

A/C system is OFF. OFF

�) BLOWER LOAD SIG Position of blower speed selector is 1st position or

more.

ON

Position of blower speed selector is OFF position. OFF

�) AIR INTAKE MODE Fresh air (FRE) mode is activated. FRE

Recirculation air (REC) mode is activated. REC

AUTO mode is activated. AUTO

�) REFRIGERANT

PRESSURE Engine running. A/C ON (A/C is operating)

at ambient temperature:

30

°C (86 °F) 1470 – 1770 kPa For more details,

refer to pressure of high pressure

gauge under “A/C System Performance Inspection”

A/C OFF (A/C is not

operating) at ambient

temperature: 30 °C (86

° F) and engine coolant

temperature: 90 ° – 100

° C 600 – 1000 kPa After longer than 10

min from A/C switch turned off

�) A/C COMP CLUTCH Engine running. A/C switch and blower

motor switch turned ON

ON

A/C switch and/or blower

motor switch turned OFF OFF

�) DFR INDICATOR Defroster indicator

lamp is lighted. ON

Defroster indicator la mp is not lighted. OFF

�) VEHICLE SPEED At stop. OFF

0 km/h (0 mph)

Page 1007 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-59

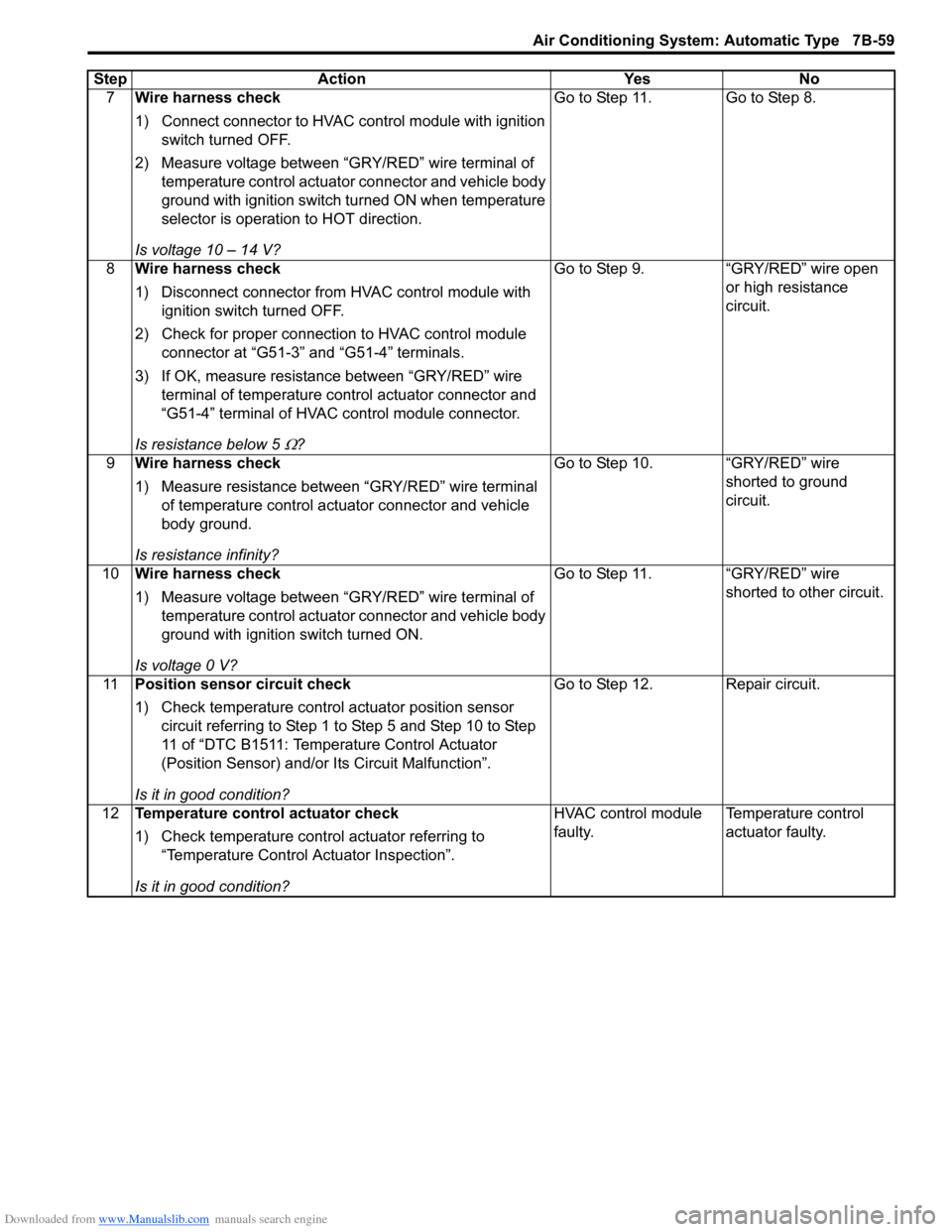

7Wire harness check

1) Connect connector to HVAC control module with ignition

switch turned OFF.

2) Measure voltage between “GRY/RED” wire terminal of temperature control actuator connector and vehicle body

ground with ignition switch turned ON when temperature

selector is operation to HOT direction.

Is voltage 10 – 14 V? Go to Step 11. Go to Step 8.

8 Wire harness check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G51-3” and “G51-4” terminals.

3) If OK, measure resistance between “GRY/RED” wire terminal of temperature control actuator connector and

“G51-4” terminal of HVAC control module connector.

Is resistance below 5

Ω? Go to Step 9. “GRY/RED” wire open

or high resistance

circuit.

9 Wire harness check

1) Measure resistance between “GRY/RED” wire terminal

of temperature control actuator connector and vehicle

body ground.

Is resistance infinity? Go to Step 10. “GRY/RED” wire

shorted to ground

circuit.

10 Wire harness check

1) Measure voltage between “GRY/RED” wire terminal of

temperature control actuator connector and vehicle body

ground with ignition switch turned ON.

Is voltage 0 V? Go to Step 11. “GRY/RED” wire

shorted to other circuit.

11 Position sensor circuit check

1) Check temperature control actuator position sensor

circuit referring to Step 1 to Step 5 and Step 10 to Step

11 of “DTC B1511: Temperature Control Actuator

(Position Sensor) and/or Its Circuit Malfunction”.

Is it in good condition? Go to Step 12. Repair circuit.

12 Temperature control actuator check

1) Check temperature control actuator referring to

“Temperature Control Actuator Inspection”.

Is it in good condition? HVAC control module

faulty.

Temperature control

actuator faulty.

Step Action Yes No

Page 1015 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-67

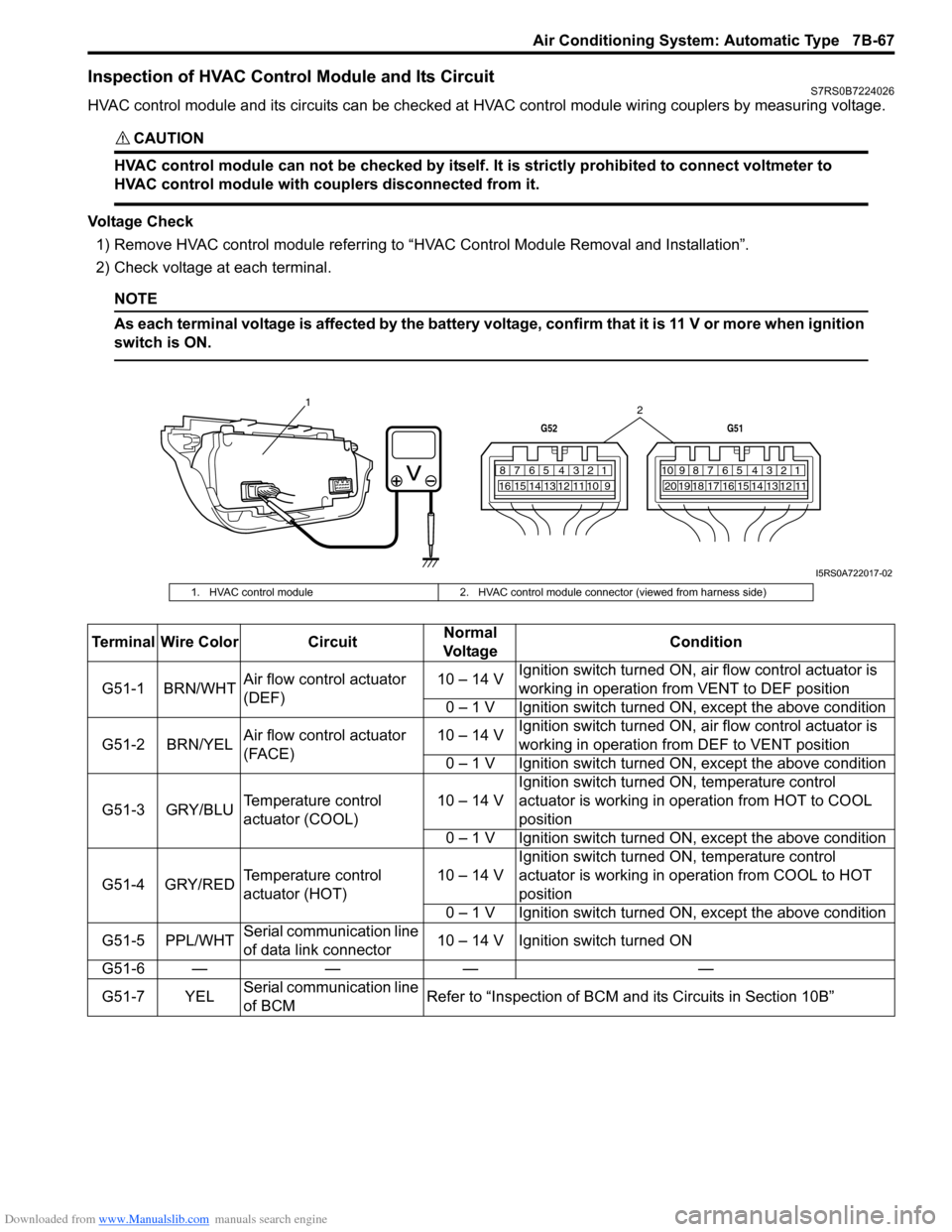

Inspection of HVAC Control Module and Its CircuitS7RS0B7224026

HVAC control module and its circuits can be checked at HVAC control module wiring couplers by measuring voltage.

CAUTION!

HVAC control module can not be checked by itself. It is strictly prohibited to connect voltmeter to

HVAC control module with couplers disconnected from it.

Voltage Check

1) Remove HVAC control module referring to “HVAC Control Module Removal and Installation”.

2) Check voltage at each terminal.

NOTE

As each terminal voltage is affected by the battery voltage, confirm that it is 11 V or more when ignition

switch is ON.

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

1

2

I5RS0A722017-02

1. HVAC control module2. HVAC control module connector (viewed from harness side)

Terminal Wire Color CircuitNormal

Vo l ta g e Condition

G51-1 BRN/WHT Air flow control actuator

(DEF) 10 – 14 V

Ignition switch turned ON, ai

r flow control actuator is

working in operation fr om VENT to DEF position

0 – 1 V Ignition switch turned ON, except the above condition

G51-2 BRN/YEL Air flow control actuator

(FACE) 10 – 14 V

Ignition switch turned ON, ai

r flow control actuator is

working in operation fr om DEF to VENT position

0 – 1 V Ignition switch turned ON, except the above condition

G51-3 GRY/BLU Temperature control

actuator (COOL) 10 – 14 VIgnition switch turned ON, temperature control

actuator is working in ope

ration from HOT to COOL

position

0 – 1 V Ignition switch turned ON, except the above condition

G51-4 GRY/RED Temperature control

actuator (HOT) 10 – 14 VIgnition switch turned ON, temperature control

actuator is working in operation from COOL to HOT

position

0 – 1 V Ignition switch turned ON, except the above condition

G51-5 PPL/WHT Serial communication line

of data link connector 10 – 14 V Ignition switch turned ON

G51-6 — — — —

G51-7 YEL Serial communication line

of BCM Refer to “Inspection of BCM a

nd its Circuits in Section 10B”

Page 1017 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-69

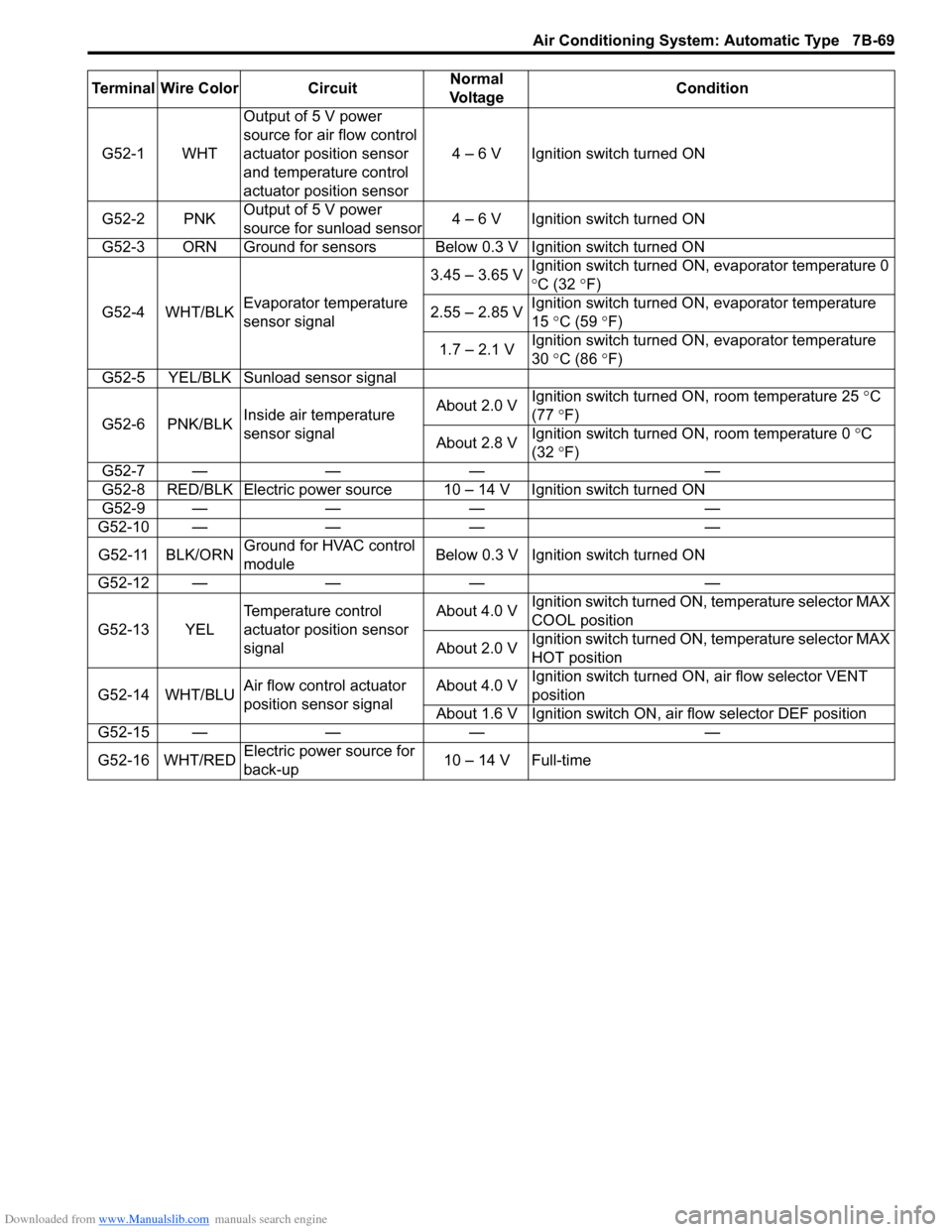

Terminal Wire Color CircuitNormal

Vo l ta g e Condition

G52-1 WHT Output of 5 V power

source for air flow control

actuator position sensor

and temperature control

actuator position sensor 4 – 6 V Ignition switch turned ON

G52-2 PNK Output of 5 V power

source for sunload sensor 4 – 6 V Ignition switch turned ON

G52-3 ORN Ground for sensors Below 0.3 V Ignition switch turned ON

G52-4 WHT/BLK Evaporator temperature

sensor signal 3.45 – 3.65 V

Ignition switch turned ON, evaporator temperature 0

°

C (32 °F)

2.55 – 2.85 V Ignition switch turned ON, evaporator temperature

15

°C (59 ° F)

1.7 – 2.1 V Ignition switch turned ON, evaporator temperature

30

°C (86 ° F)

G52-5 YEL/BLK Sunload sensor signal

G52-6 PNK/BLK Inside air temperature

sensor signal About 2.0 V

Ignition switch turned ON, room temperature 25

°C

(77 °F)

About 2.8 V Ignition switch turned ON, room temperature 0

°C

(32 °F)

G52-7 — — — —

G52-8 RED/BLK Electric power source 10 – 14 V Ignition switch turned ON

G52-9 — — — —

G52-10 — — — —

G52-11 BLK/ORN Ground for HVAC control

module Below 0.3 V Ignition

switch turned ON

G52-12 — — — —

G52-13 YEL Temperature control

actuator position sensor

signal About 4.0 V

Ignition switch turned ON, temperature selector MAX

COOL position

About 2.0 V Ignition switch turned ON, temperature selector MAX

HOT position

G52-14 WHT/BLU Air flow control actuator

position sensor signal About 4.0 V

Ignition switch turned ON

, air flow selector VENT

position

About 1.6 V Ignition switch ON, air flow selector DEF position

G52-15 — — — —

G52-16 WHT/RED Electric power source for

back-up 10 – 14 V Full-time

Page 1021 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-73

HVAC Unit Removal and InstallationS7RS0B7226003

Refer to “HVAC Unit Removal and Installation”.

Temperature Control Actuator Removal and

Installation

S7RS0B7226004

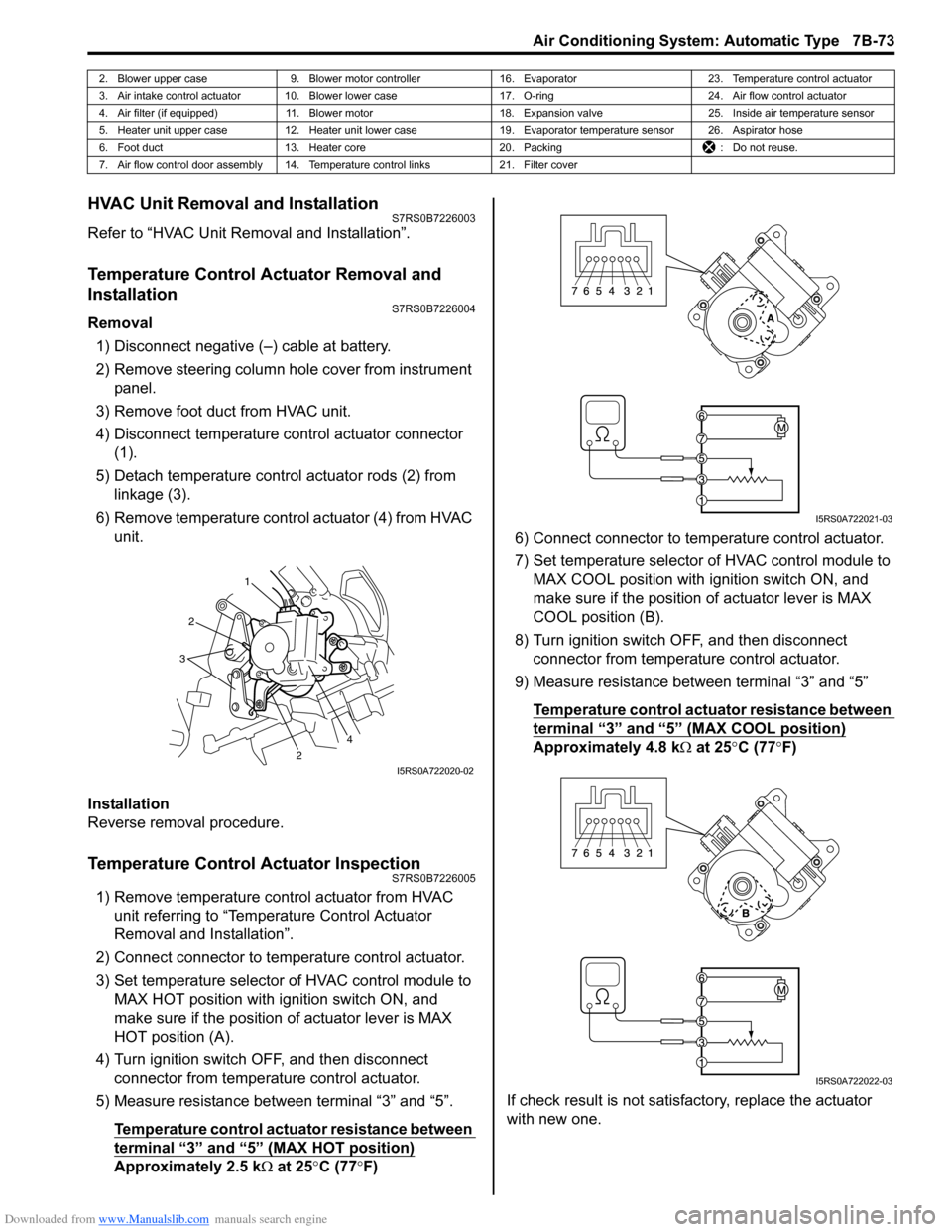

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hol e cover from instrument

panel.

3) Remove foot duct from HVAC unit.

4) Disconnect temperature control actuator connector (1).

5) Detach temperature control actuator rods (2) from linkage (3).

6) Remove temperature control actuator (4) from HVAC unit.

Installation

Reverse removal procedure.

Temperature Control Actuator InspectionS7RS0B7226005

1) Remove temperature control actuator from HVAC unit referring to “Temperature Control Actuator

Removal and Installation”.

2) Connect connector to temperature control actuator.

3) Set temperature selector of HVAC control module to MAX HOT position with ignition switch ON, and

make sure if the position of actuator lever is MAX

HOT position (A).

4) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

5) Measure resistance between terminal “3” and “5”.

Temperature control actuator resistance between

terminal “3” and “5” (MAX HOT position)

Approximately 2.5 k Ω at 25 °C (77 °F) 6) Connect connector to tem

perature control actuator.

7) Set temperature selector of HVAC control module to MAX COOL position with ignition switch ON, and

make sure if the position of actuator lever is MAX

COOL position (B).

8) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

9) Measure resistance between terminal “3” and “5”

Temperature control actuator resistance between

terminal “3” and “5” (MAX COOL position)

Approximately 4.8 k Ω at 25 °C (77 °F)

If check result is not satisfactory, replace the actuator

with new one.

2. Blower upper case 9. Blower motor controller 16. Evaporator 23. Temperature control actuator

3. Air intake control actuator 10. Blower lower case 17. O-ring24. Air flow control actuator

4. Air filter (if equipped) 11. Blower motor 18. Expansion valve25. Inside air temperature sensor

5. Heater unit upper case 12. Heater unit lower case 19. Evaporator temperature sensor 26. Aspirator hose

6. Foot duct 13. Heater core 20. Packing : Do not reuse.

7. Air flow control door assembly 14. Temperature control links 21. Filter cover

1

2

2

3

4

I5RS0A722020-02

I5RS0A722021-03

I5RS0A722022-03

Page 1039 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-1

Restraint

Air Bag System

Precautions

Precautions on Service and Diagnosis of Air

Bag System

S7RS0B8200001

WARNING!

• If the air bag system and another vehicle system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel, dashboard, both front seat or any other on

or around air bag system components.

Modifications can adversely affect air bag

system performance and lead to injury.

• Be sure to follow the procedures described in this section. Failure to follow

procedures could result in possible air bag

system activation, personal injury or

unneeded air bag system repairs.

• WARNING / CAUTION labels are attached on each

part of air bag system components (SDM, air bag

(inflator) modules and seat belt pretensioners). Be

sure to follow the instructions.

• Many of service procedures require disconnection of

“A/BAG” fuse and air bag (inflator) module(s) (driver,

passenger, side of both si des and curtain of both

sides) from initiator circuit to avoid an accidental

deployment.

• Do not apply power to the air bag system unless all components are connected or a diagnostic flow

requests it, as this will set a DTC.

• The “Air Bag Diagnostic S ystem Check” must be the

starting point of any air bag diagnostics. The “Air Bag

Diagnostic System Check” will verify proper “AIR

BAG” warning right operatio n and will lead you to the

correct flow to diagnose any air bag malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements. • Never use air bag component parts from another

vehicle.

• If the vehicle will be exposed to temperatures over 93

° C (200 °F) (for example, during a paint baking

process), remove the air bag system components

beforehand to avoid component damage or

unintended system activation.

• When handling the air bag (inflator) modules (driver, passenger, side of both si des and curtain of both

sides), seat belt pretensio ners (driver and passenger),

SDM, forward-sensor or side-sensor, be careful not to

drop it or apply an impact to it. If an excessive impact

was applied (e.g., SDM, forward-sensor and side-

sensor are dropped, air bag (inflator) module is

dropped from a height of 90 cm (3 ft) or more, seat

belt pretensioner (retractor assembly) is dropped from

a height of 30 cm (1 ft) or more), never attempt

disassembly or repair but replace it with a new one.

• When using electric welding, be sure to disconnect air bag (inflator) module connectors (driver, passenger,

side of both sides and curtain of both sides) and seat

belt pretensioner connectors (driver and passenger)

respectively.

• When applying paint around the air bag system related parts, use care so that the harness or

connector will not be expo sed to the paint mist.

• Never expose air bag system component parts directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING!

When performing service on or around air

bag system components or air bag wiring,

follow the procedures listed in “Disabling Air

Bag System” to temporarily disable the air

bag system.

Failure to follow procedures could result in

possible air bag system activation, personal

injury or unneeded air bag system repairs.