Automatic transaxle components SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 301 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-19

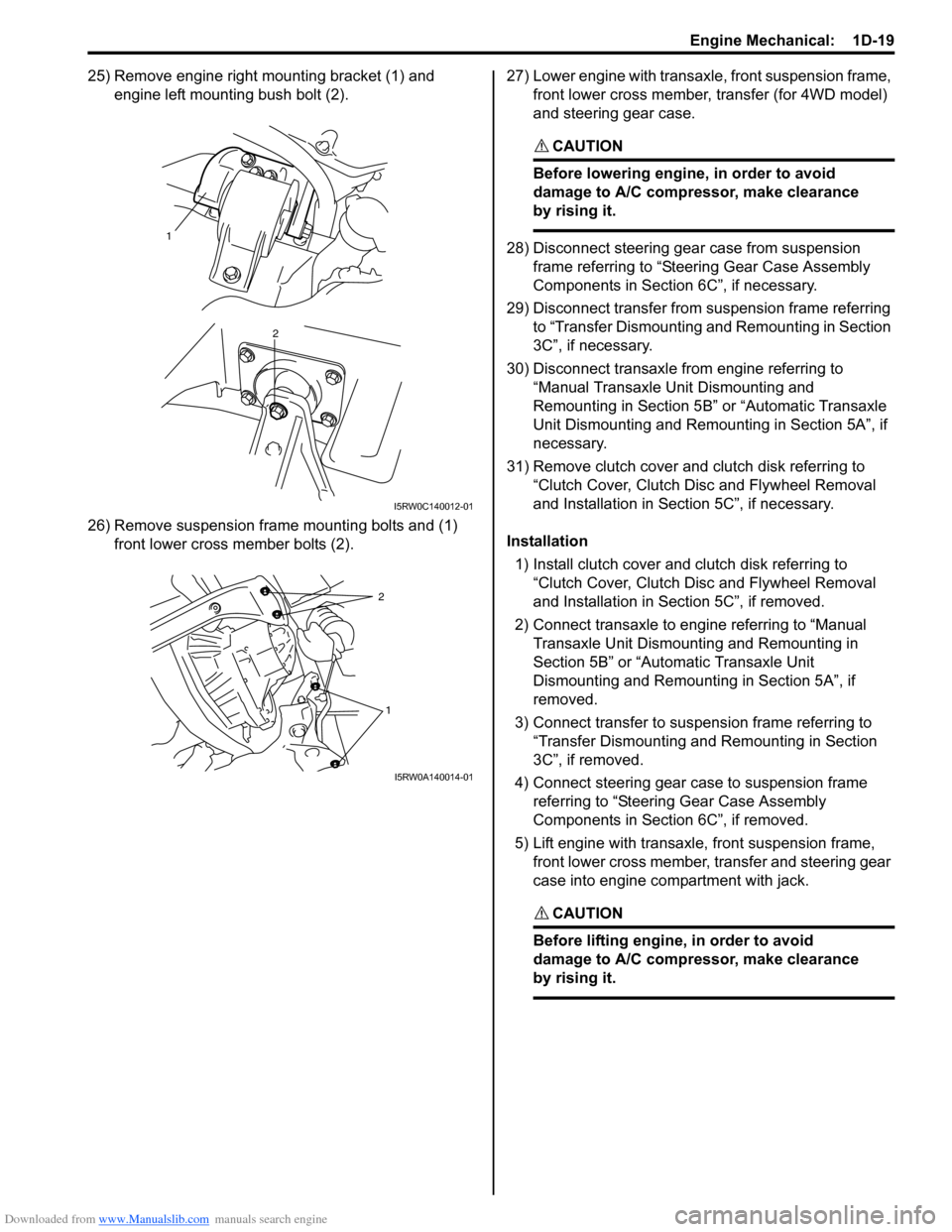

25) Remove engine right mounting bracket (1) and

engine left mounting bush bolt (2).

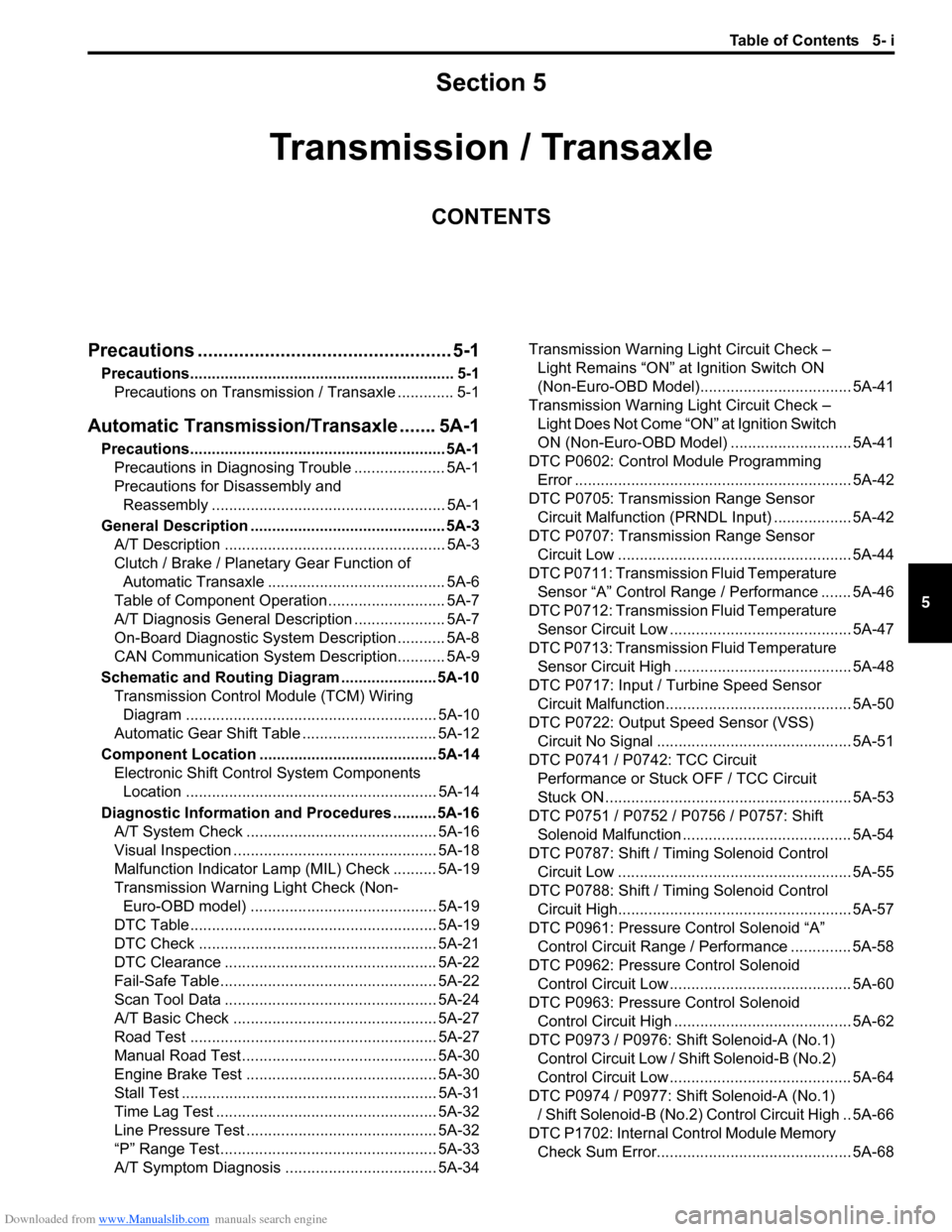

26) Remove suspension frame mounting bolts and (1)

front lower cross member bolts (2).27) Lower engine with transaxle, front suspension frame,

front lower cross member, transfer (for 4WD model)

and steering gear case.

CAUTION!

Before lowering engine, in order to avoid

damage to A/C compressor, make clearance

by rising it.

28) Disconnect steering gear case from suspension

frame referring to “Steering Gear Case Assembly

Components in Section 6C”, if necessary.

29) Disconnect transfer from suspension frame referring

to “Transfer Dismounting and Remounting in Section

3C”, if necessary.

30) Disconnect transaxle from engine referring to

“Manual Transaxle Unit Dismounting and

Remounting in Section 5B” or “Automatic Transaxle

Unit Dismounting and Remounting in Section 5A”, if

necessary.

31) Remove clutch cover and clutch disk referring to

“Clutch Cover, Clutch Disc and Flywheel Removal

and Installation in Section 5C”, if necessary.

Installation

1) Install clutch cover and clutch disk referring to

“Clutch Cover, Clutch Disc and Flywheel Removal

and Installation in Section 5C”, if removed.

2) Connect transaxle to engine referring to “Manual

Transaxle Unit Dismounting and Remounting in

Section 5B” or “Automatic Transaxle Unit

Dismounting and Remounting in Section 5A”, if

removed.

3) Connect transfer to suspension frame referring to

“Transfer Dismounting and Remounting in Section

3C”, if removed.

4) Connect steering gear case to suspension frame

referring to “Steering Gear Case Assembly

Components in Section 6C”, if removed.

5) Lift engine with transaxle, front suspension frame,

front lower cross member, transfer and steering gear

case into engine compartment with jack.

CAUTION!

Before lifting engine, in order to avoid

damage to A/C compressor, make clearance

by rising it.

1

2

I5RW0C140012-01

2

1

I5RW0A140014-01

Page 645 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5- i

5

Section 5

CONTENTS

Transmission / Transaxle

Precautions ................................................. 5-1

Precautions............................................................. 5-1

Precautions on Transmission / Transaxle ............. 5-1

Automatic Transmission/Transaxle ....... 5A-1

Precautions........................................................... 5A-1

Precautions in Diagnosing Trouble ..................... 5A-1

Precautions for Disassembly and

Reassembly ...................................................... 5A-1

General Description ............................................. 5A-3

A/T Description ................................................... 5A-3

Clutch / Brake / Planetary Gear Function of

Automatic Transaxle ......................................... 5A-6

Table of Component Operation ........................... 5A-7

A/T Diagnosis General Description ..................... 5A-7

On-Board Diagnostic System Description ........... 5A-8

CAN Communication System Description........... 5A-9

Schematic and Routing Diagram ...................... 5A-10

Transmission Control Module (TCM) Wiring

Diagram .......................................................... 5A-10

Automatic Gear Shift Table ............................... 5A-12

Component Location ......................................... 5A-14

Electronic Shift Control System Components

Location .......................................................... 5A-14

Diagnostic Information and Procedures .......... 5A-16

A/T System Check ............................................ 5A-16

Visual Inspection ............................................... 5A-18

Malfunction Indicator Lamp (MIL) Check .......... 5A-19

Transmission Warning Light Check (Non-

Euro-OBD model) ........................................... 5A-19

DTC Table ......................................................... 5A-19

DTC Check ....................................................... 5A-21

DTC Clearance ................................................. 5A-22

Fail-Safe Table .................................................. 5A-22

Scan Tool Data ................................................. 5A-24

A/T Basic Check ............................................... 5A-27

Road Test ......................................................... 5A-27

Manual Road Test ............................................. 5A-30

Engine Brake Test ............................................ 5A-30

Stall Test ........................................................... 5A-31

Time Lag Test ................................................... 5A-32

Line Pressure Test ............................................ 5A-32

“P” Range Test.................................................. 5A-33

A/T Symptom Diagnosis ................................... 5A-34Transmission Warning Light Circuit Check –

Light Remains “ON” at Ignition Switch ON

(Non-Euro-OBD Model)................................... 5A-41

Transmission Warning Light Circuit Check –

Light Does Not Come “ON” at Ignition Switch

ON (Non-Euro-OBD Model)............................ 5A-41

DTC P0602: Control Module Programming

Error ................................................................ 5A-42

DTC P0705: Transmission Range Sensor

Circuit Malfunction (PRNDL Input) .................. 5A-42

DTC P0707: Transmission Range Sensor

Circuit Low ...................................................... 5A-44

DTC P0711: Transmission Fluid Temperature

Sensor “A” Control Range / Performance ....... 5A-46

DTC P0712: Transmission Fluid Temperature

Sensor Circuit Low .......................................... 5A-47

DTC P0713: Transmission Fluid Temperature

Sensor Circuit High ......................................... 5A-48

DTC P0717: Input / Turbine Speed Sensor

Circuit Malfunction........................................... 5A-50

DTC P0722: Output Speed Sensor (VSS)

Circuit No Signal ............................................. 5A-51

DTC P0741 / P0742: TCC Circuit

Performance or Stuck OFF / TCC Circuit

Stuck ON ......................................................... 5A-53

DTC P0751 / P0752 / P0756 / P0757: Shift

Solenoid Malfunction ....................................... 5A-54

DTC P0787: Shift / Timing Solenoid Control

Circuit Low ...................................................... 5A-55

DTC P0788: Shift / Timing Solenoid Control

Circuit High...................................................... 5A-57

DTC P0961: Pressure Control Solenoid “A”

Control Circuit Range / Performance .............. 5A-58

DTC P0962: Pressure Control Solenoid

Control Circuit Low .......................................... 5A-60

DTC P0963: Pressure Control Solenoid

Control Circuit High ......................................... 5A-62

DTC P0973 / P0976: Shift Solenoid-A (No.1)

Control Circuit Low / Shift Solenoid-B (No.2)

Control Circuit Low .......................................... 5A-64

DTC P0974 / P0977: Shift Solenoid-A (No.1)

/ Shift Solenoid-B (No.2) Control Circuit High .. 5A-66

DTC P1702: Internal Control Module Memory

Check Sum Error............................................. 5A-68

Page 646 of 1556

Downloaded from www.Manualslib.com manuals search engine 5-ii Table of Contents

DTC P1723: Range Select Switch

Malfunction ...................................................... 5A-68

DTC P1878: Torque Converter Clutch

Shudder .......................................................... 5A-69

DTC P2762: Torque Converter Clutch (TCC)

Pressure Control Solenoid Control Circuit

Range / Performance ...................................... 5A-70

DTC P2763: Torque Converter Clutch (TCC)

Pressure Control Solenoid Control Circuit

High ................................................................. 5A-72

DTC P2764: Torque Converter Clutch (TCC)

Circuit Pressure Control Solenoid Control

Circuit Low ...................................................... 5A-74

DTC U0073: Control Module Communication

Bus Off ............................................................ 5A-76

DTC U0100: Lost Communication with ECM /

PCM “A” .......................................................... 5A-76

Inspection of TCM and Its Circuits .................... 5A-76

TCM Power and Ground Circuit Check ............. 5A-80

Brake Interlock System Inspection .................... 5A-81

Repair Instructions ............................................5A-82

Learning Control Initialization ............................ 5A-82

A/T Fluid Level Check ....................................... 5A-82

A/T Fluid Change .............................................. 5A-83

Select Lever Components ................................. 5A-84

Select Lever Assembly Removal and

Installation ....................................................... 5A-84

Select Lever Knob Installation........................... 5A-84

Select Lever Inspection ..................................... 5A-85

“3” Position Switch Inspection ........................... 5A-85

Shift Lock Solenoid Inspection .......................... 5A-85

Shift Lock Solenoid Replacement ..................... 5A-85

Select Cable Components ................................ 5A-86

Select Cable Removal and Installation ............. 5A-86

Select Cable Adjustment ................................... 5A-86

Key Interlock Cable Removal and Installation... 5A-87

Transmission Range Sensor Inspection and

Adjustment ...................................................... 5A-89

Output Shaft Speed Sensor (VSS) Removal

and Installation ................................................ 5A-90

Output Shaft Speed Sensor (VSS) Inspection .. 5A-90

Input Shaft Speed Sensor Removal and

Installation ....................................................... 5A-91

Input Shaft Speed Sensor Inspection................ 5A-91

Transmission Fluid Temperature Sensor

Removal and Installation ................................. 5A-91

Transmission Fluid Temperature Sensor

Inspection ........................................................ 5A-92

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Removal and

Installation ....................................................... 5A-92

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Inspection .................. 5A-94

Pressure Control Solenoid Valves (Pressure

Control Solenoid and TCC Solenoid)

Removal and Installation ................................. 5A-95

Pressure Control Solenoid Valves Inspection ... 5A-96

Transmission Control Module (TCM)

Removal and Installation ................................. 5A-97

A/T Relay Inspection ......................................... 5A-97Differential Side Oil Seal Replacement ............. 5A-98

A/T Fluid Cooler Hoses Replacement ............... 5A-98

Automatic Transaxle Unit Components............. 5A-99

Automatic Transaxle Unit Dismounting and

Remounting ................................................... 5A-100

Automatic Transaxle Assembly Components . 5A-102

Automatic Transaxle Unit Disassembly........... 5A-104

Oil Pump Assembly Components ................... 5A-116

Oil Pump Assembly Disassembly and

Reassembly .................................................. 5A-116

Oil Pump Assembly Inspection ....................... 5A-117

Direct Clutch Assembly Components.............. 5A-119

Direct Clutch Assembly Preliminary Check ..... 5A-119

Direct Clutch Assembly Disassembly and

Reassembly .................................................. 5A-120

Direct Clutch Assembly Inspection.................. 5A-122

Forward and Reverse Clutch Assembly

Components .................................................. 5A-123

Forward and Reverse Clutch Assembly

Preliminary Check ......................................... 5A-123

Forward and Reverse Clutch Assembly

Disassembly and Reassembly ...................... 5A-124

Forward and Reverse Clutch Assembly

Inspection ...................................................... 5A-127

2nd Brake Piston Assembly Components ....... 5A-128

2nd Brake Piston Assembly Disassembly and

Reassembly .................................................. 5A-128

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Components........... 5A-129

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Disassembly and

Reassembly .................................................. 5A-130

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Inspection............... 5A-131

Countershaft Assembly Components.............. 5A-132

Countershaft Assembly Disassembly and

Reassembly .................................................. 5A-132

Valve Body Assembly Components ................ 5A-133

Valve Body Assembly Disassembly and

Reassembly .................................................. 5A-134

Differential Assembly Components ................. 5A-135

Differential Assembly Disassembly and

Reassembly .................................................. 5A-136

Differential Assembly Inspection ..................... 5A-137

Torque Converter Housing Disassembly and

Reassembly .................................................. 5A-138

Transaxle Case Disassembly and

Reassembly .................................................. 5A-140

Automatic Transaxle Unit Inspection and

Adjustment .................................................... 5A-141

Automatic Transaxle Unit Assembly ............... 5A-144

Specifications ...................................................5A-161

Tightening Torque Specifications .................... 5A-161

Special Tools and Equipment .........................5A-162

Recommended Service Material ..................... 5A-162

Special Tool .................................................... 5A-162

Manual Transmission/Transaxle ............ 5B-1

General Description .............................................5B-1

Manual Transaxle Construction .......................... 5B-1

Page 662 of 1556

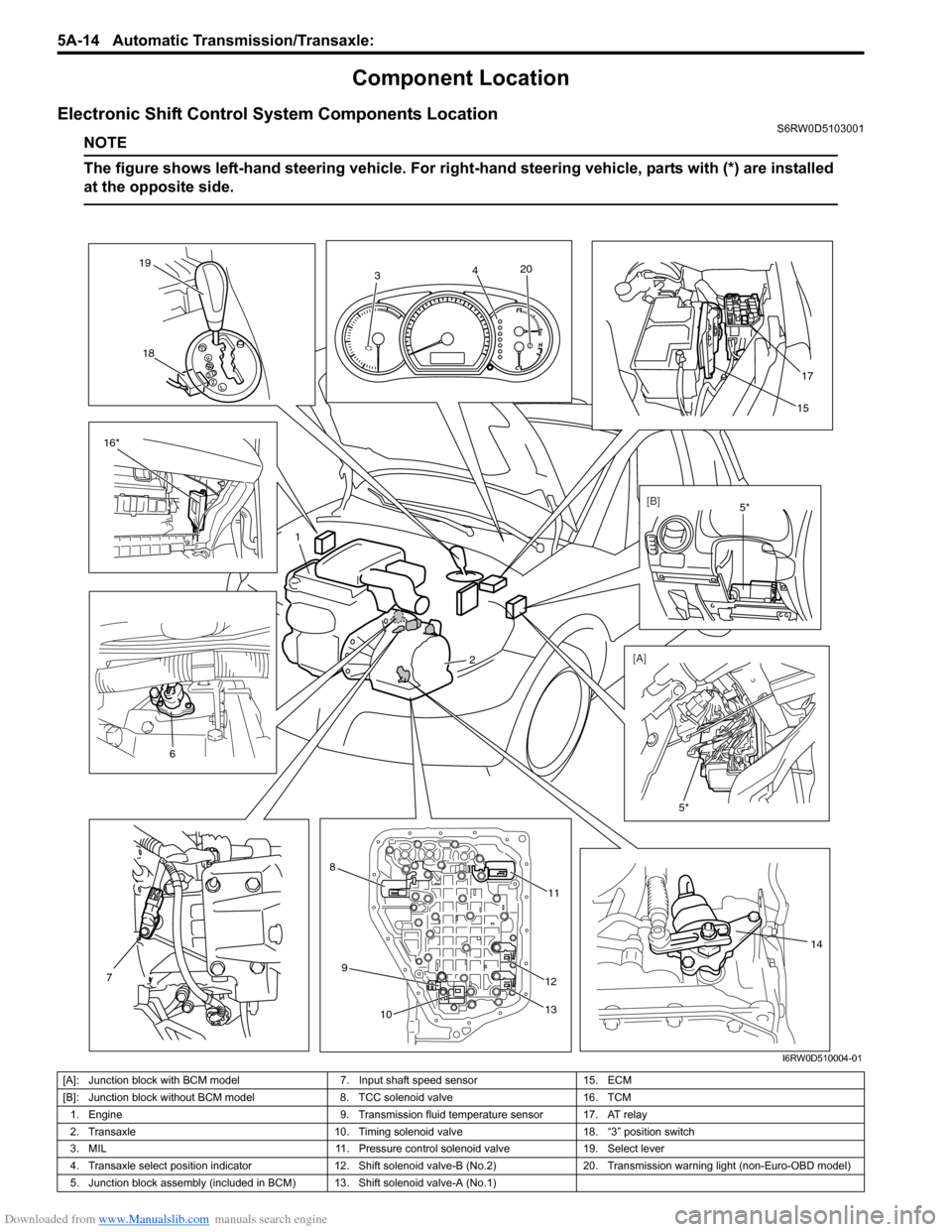

Downloaded from www.Manualslib.com manuals search engine 5A-14 Automatic Transmission/Transaxle:

Component Location

Electronic Shift Control System Components LocationS6RW0D5103001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

5*

17

15

1

2

8

9

1011

12

13

16*18 19

14

7

6

3420

[B]

[A]5*

I6RW0D510004-01

[A]: Junction block with BCM model 7. Input shaft speed sensor 15. ECM

[B]: Junction block without BCM model 8. TCC solenoid valve 16. TCM

1. Engine 9. Transmission fluid temperature sensor 17. AT relay

2. Transaxle 10. Timing solenoid valve 18. “3” position switch

3. MIL 11. Pressure control solenoid valve 19. Select lever

4. Transaxle select position indicator 12. Shift solenoid valve-B (No.2) 20. Transmission warning light (non-Euro-OBD model)

5. Junction block assembly (included in BCM) 13. Shift solenoid valve-A (No.1)

Page 666 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

Step 2. DTC / Freeze Frame Data Check, Record and

Clearance

First, referring to “DTC Check”, check DTC and pending

DTC. If DTC exists, print or write down DTC and freeze

frame data and then clear malfunction DTC(s) by

referring to “DTC Clearance”. Malfunction DTC indicates

malfunction in the system but it is not possible to know

from it whether the malfunction is occurring now or it

occurred in the past and normal condition has been

restored. In order to know that, check symptom in

question according to Step 5 and then recheck DTC

according to Step 6.

Diagnosing a trouble based on the DTC in this step only

or failure to clear the DTC in this step may result in an

faulty diagnosis, trouble diagnosis of a normal circuit or

difficulty in troubleshooting which is otherwise

unnecessary.

Step 3 and 4. Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine and

automatic transaxle referring to “Visual Inspection”.

Step 5. Trouble Symptom Confirmation

Check trouble symptoms based on information obtained

in “Step 1. Customer Complaint Analysis: ” and “Step 2.

DTC / Freeze Frame Data Check, Record and

Clearance: ”.

Also, reconfirm DTC according to “DTC Confirmation

Procedure” described in each DTC flow.

Step 6 and 7. Rechecking and Record of DTC and

Freeze Frame Data

Refer to “DTC Check” for checking procedure.Step 8. A/T Basic Check and A/T Symptom

Diagnosis

Perform basic check of A/T according to “A/T Basic

Check” first. When the end of the flow has been reached,

check the parts of the system suspected as a possible

cause referring to “A/T Symptom Diagnosis” and based

on symptoms appearing on the vehicle (symptoms

obtained through steps of customer complaint analysis,

trouble symptom confirmation and/or A/T basic check)

and repair or replace faulty parts, if any.

Step 9. Troubleshooting for DTC

Based on the DTC indicated in Step 6 / 7 and referring to

“applicable DTC flow”, locate the cause of the trouble,

namely in a sensor, switch, wire harness, connector,

actuator, TCM or other part and repair or replace faulty

parts.

Step 10. Check for Intermittent Problem

Check parts where an intermittent trouble is easy to

occur (e.g. wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11. Final Confirmation Test

Confirm that the problem symptom has gone and the

vehicle is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear

the DTC once and check to ensure that no malfunction

DTC is indicated.

Visual InspectionS6RW0D5104002

Visually check the following parts and systems.

Inspection item Referring

• A/T fluid ----- level, leakage, color “Automatic Transaxle Fluid Level Inspection in

Section 0B”

• A/T fluid hoses ----- disconnection, looseness, deterioration “A/T Fluid Cooler Hoses Replacement”

• Throttle cable (if equipped) ----- play (under warm engine),

installation

• A/T select cable ----- installation “Select Cable Removal and Installation”

• Engine oil ----- level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant ----- level, leakage “Engine Coolant Change in Section 0B”

• Engine mountings ----- play, looseness, damage “Engine Assembly Removal and Installation in

Section 1D”

• Suspension ----- play, looseness “Suspension, Wheels and Tires Symptom

Diagnosis in Section 2A”

• Drive shafts ----- damage “Front Drive Shaft Assembly On-Vehicle Inspection

in Section 3A”

• Battery ----- indicator condition, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ----- disconnection, friction “Electronic Shift Control System Components

Location”

• Fuses ----- burning

• Parts ----- installation, damage

• Bolts ----- looseness

• Other parts that can be checked visually

Page 732 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-84 Automatic Transmission/Transaxle:

5) Lower vehicle and pour proper amount of SUZUKI

ATF 3317 or Mobil ATF 3309.

6) Check fluid level referring to “A/T Fluid Level Check”.

Automatic transaxle fluid

: SUZUKI ATF 3317 or Mobil ATF 3309

Automatic transaxle fluid capacity

When draining from drain plug hole: 2.6 liters

(5.49 / 4.58 US/Imp. pt.)

When overhauling: 5.8 liters (12.26 / 10.21 US/

Imp. pt.)

Select Lever ComponentsS6RW0D5106004

Select Lever Assembly Removal and

Installation

S6RW0D5106059

Remove and install select lever referring to “Select Lever

Components”.

When installing select lever nothing the following.

• After installing select lever assembly, adjust select

cable referring to “Select Cable Adjustment”.

Select Lever Knob InstallationS6RW0D5106060

Screw select lever knob onto select lever by specified

numbers of rotation below.

Rotation numbers for select lever knob installation

(a): 11 – 12 rotations

CAUTION!

When installing select lever knob, do not turn

more than specified numbers of rotation.

Otherwise select lever knob is damaged.

1. Fluid level gauge 4. “FULL COLD” mark

2. “FULL HOT” mark 5. “LOW COLD” mark

3. “LOW HOT” mark

1. Shift lock solenoid 3. Connector

2. Select lever assembly 4. “3” position switch

1

54 321

I5RW0C510027-01

1

2 3 4

I5RW0C510028-04

1, (a)

I5RW0C510030-01

Page 733 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-85

Select Lever InspectionS6RW0D5106005

Check select lever for smooth and clear-cut movement

individually. If a malfunction is found, replace select lever

assembly.

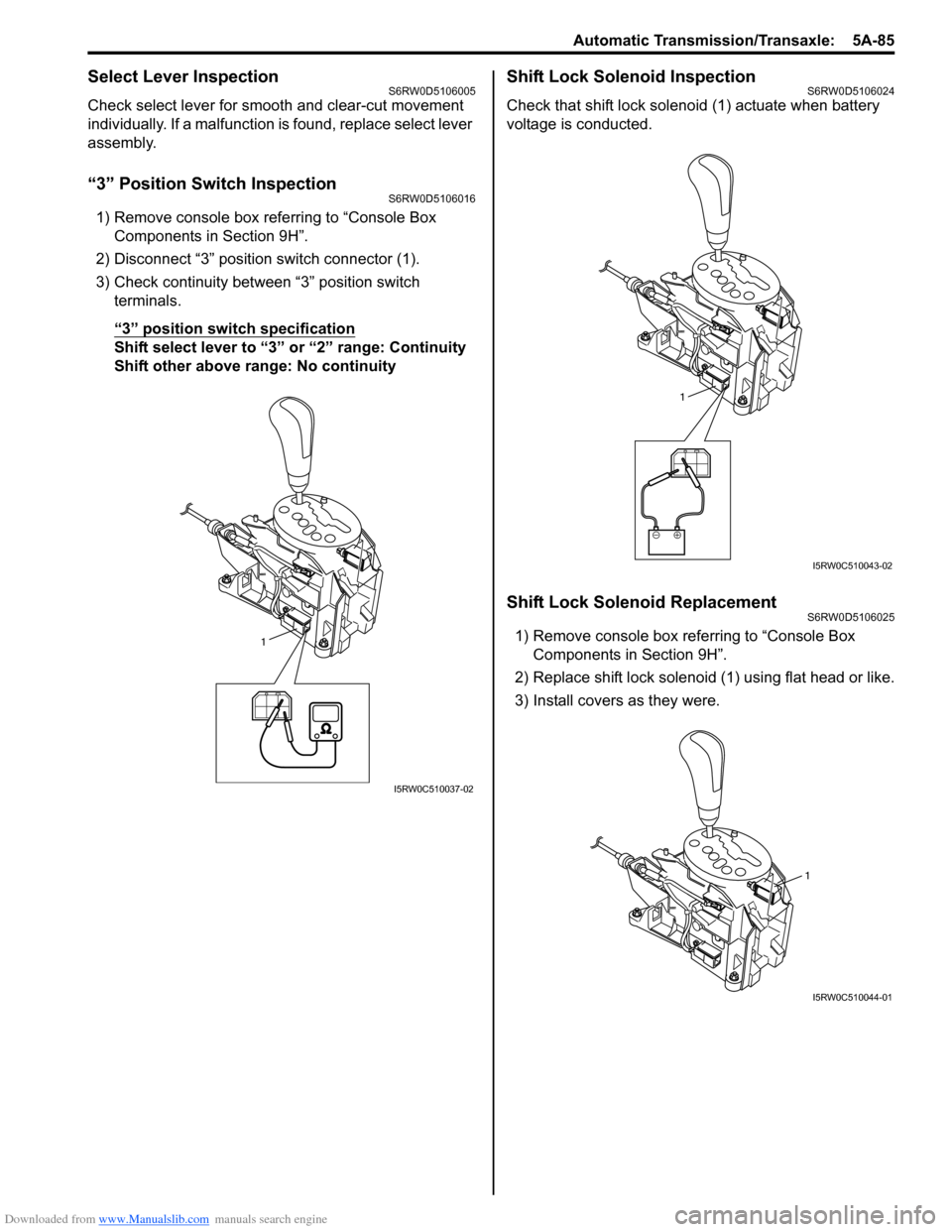

“3” Position Switch InspectionS6RW0D5106016

1) Remove console box referring to “Console Box

Components in Section 9H”.

2) Disconnect “3” position switch connector (1).

3) Check continuity between “3” position switch

terminals.

“3” position switch specification

Shift select lever to “3” or “2” range: Continuity

Shift other above range: No continuity

Shift Lock Solenoid InspectionS6RW0D5106024

Check that shift lock solenoid (1) actuate when battery

voltage is conducted.

Shift Lock Solenoid ReplacementS6RW0D5106025

1) Remove console box referring to “Console Box

Components in Section 9H”.

2) Replace shift lock solenoid (1) using flat head or like.

3) Install covers as they were.1

I5RW0C510037-02

1

I5RW0C510043-02

1

I5RW0C510044-01

Page 734 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-86 Automatic Transmission/Transaxle:

Select Cable ComponentsS6RW0D5106006

Select Cable Removal and InstallationS6RW0D5106007

Removal

1) Remove console box referring to “Console Box

Components in Section 9H”.

2) Disconnect select cable from select lever and then

detach from bracket.

3) Remove clip and disconnect select cable from

manual select lever.

4) Remove select cable retainer from dash panel.

Installation

Install select cable by reversing removal procedure.

The important steps in installation are as follows.

• Apply grease to pin and cable joint.

• Tighten bolts to specified torque referring to “Select

Cable Components”.• Adjusting procedure is as follows. Refer to “Select

Cable Adjustment”.Select Cable AdjustmentS6RW0D5106008

1) Shift manual shift lever to “N” range (transmission

range sensor “N” range).

(a)

(b)

(c)

6

7A

112

[B]

[B] [A]

[A]

34

5

9

8

101

A

I5RW0C510031-01

[A]: View [A] 5. Clip 11. Radiator inlet hose

[B]: View [B] 6. Manual select lever pin

: Apply lithium grease 99000-25011 to all around pin (0.15 g):23 N⋅m (2.0 kgf-m, 17.0 lb-ft)

1. Select lever assembly 7. Select lever pin

: Apply lithium grease 99000-25011 to all around pin (0.15 g):6.5 N⋅m (0.65 kgf-m, 5.0 lb-ft)

2. Select cable 8. Adjuster case : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

3. Cable bracket 9. Lock

4. Manual select lever 10. P/S control module

“P”“R”“N”

“D”

“2”

“L”

I2RH0B510040-01

Page 735 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-87

2) Remove adjuster (cable end) from select lever pin of

select lever assembly.

3) Remove adjuster (cable end) from select lever pin of

select lever assembly.

4) Release lock plate (1) which restrict moving of cable

end holder (2).

5) Push cable end holder (1) out from eye-end (2) using

an appropriate tool (3) to disengage cable.

6) Shift select lever to “N” position.

7) Apply grease to select lever pin and install adjuster

(cable end) to it.

: Grease 99000–25011 (SUZUKI Super Grease

A)

8) With both select lever and transmission range

sensor kept each “N” position, drive cable end holder

(1) in until it locks cable.

9) Slide lock plate (2) to secure cable end holder in

position.

10) After select cable was installed, check for the

following.

• Push vehicle with select lever shifted to “P” range.

Vehicle should not move.

• Vehicle can not be driven in “N” range.• Vehicle can be driven in “D”, “3”, “2” and “L”

ranges.

• Vehicle can be backed in “R” range.

Key Interlock Cable Removal and InstallationS6RW0D5106026

NOTE

Don’t bend interlock cable excessively when

removing and installing it, or system will not

operate correctly.

Removal

1) If the vehicle is equipped with air bag system,

disconnect negative cable at battery and disable air

bag system, referring to “Disabling Air Bag System in

Section 8B”.

2) Remove steering column cover.

3) Turn ignition switch to ACC position.

4) Pull out key interlock cable (1) from key cylinder

cover (2) while pressing checkhook with slotted

screwdriver (3) or the like.

5) Turn ignition switch to LOCK position.

6) Remove console box referring to “Console Box

Components in Section 9H”.

7) Detach cable end (1) from interlock cam (2) while

pressing claws (3) of interlock cam boss.

At this time, be careful not to cause damage to its

claws.

Detach cable casing cap (4) from bracket (5) while

pressing checkhook.

8) Remove interlock cable.

I2RH01510046-01

I2RH01510047-01

I3RM0B510037-01

2

13I5RW0C510045-01

4

5 3 12

4

I5RW0C510046-01

Page 747 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-99

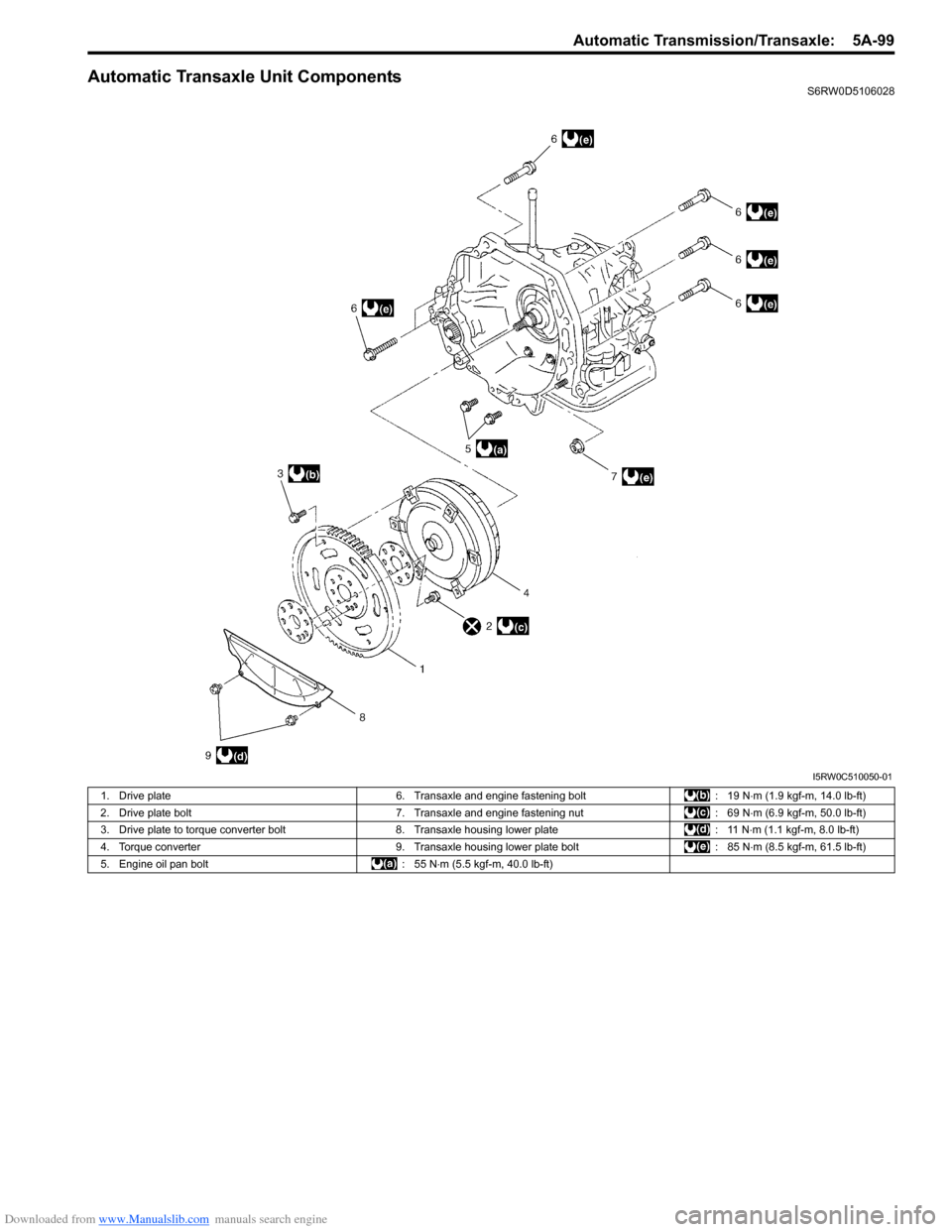

Automatic Transaxle Unit ComponentsS6RW0D5106028

I5RW0C510050-01

1. Drive plate 6. Transaxle and engine fastening bolt : 19 N⋅m (1.9 kgf-m, 14.0 lb-ft)

2. Drive plate bolt 7. Transaxle and engine fastening nut : 69 N⋅m (6.9 kgf-m, 50.0 lb-ft)

3. Drive plate to torque converter bolt 8. Transaxle housing lower plate : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

4. Torque converter 9. Transaxle housing lower plate bolt : 85 N⋅m (8.5 kgf-m, 61.5 lb-ft)

5. Engine oil pan bolt : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)