battery replacement SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1320 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-1 Lighting Systems:

Body, Cab and Accessories

Lighting Systems

Precautions

Precautions for Discharge Headlight Service (If Equipped)S6RW0D9200001

WARNING!

• Do not touch igniter or ballast when lighting switch is at “HEAD” position to avoid possible electric

shock.

• Do not measure voltage or resistance with tester connected to output connector of ballast or igniter

to avoid possible electric shock.

• Do not perform work where exposed to water including rain or with wet hands to avoid possible

electric shock.

• Disassembling igniter or ballast is strictly prohibited as it may cause an electric shock.

• Before inspecting or repairing discharge headlight or its peripheral parts, make sure that lighting

switch is at OFF position and battery is disconnected at negative terminal to avoid possible

electrical shock.

• Do not set lighting switch to “HEAD” position with connector disconnected or any part removed to

avoid possible electric shock.

• Do not touch glass surface of headlight bulb. Oil or grease attached on it may not only make bulb

service life shorter but also cause bulb to burst when lighting switch is turned on.

• Mercury, metal iodide and xenon gas are sealed in discharge headlight bulb. Be sure to dispose of

used discharge headlight bulb properly according to applicable rules or regulations.

Precautions in Diagnosing Troubles (Headlight Auto Leveling System)S6RW0D9200002

• Be sure to read “Air Bag Warning in Section 00” before inspection and observe what is written there.

• Replacement of height sensor and headlight leveling control module. When height sensor and/or headlight leveling

control module is replaced with new one, perform initialization of headlight auto leveling system according to

“Initialization of Headlight Auto Leveling System”.

General Description

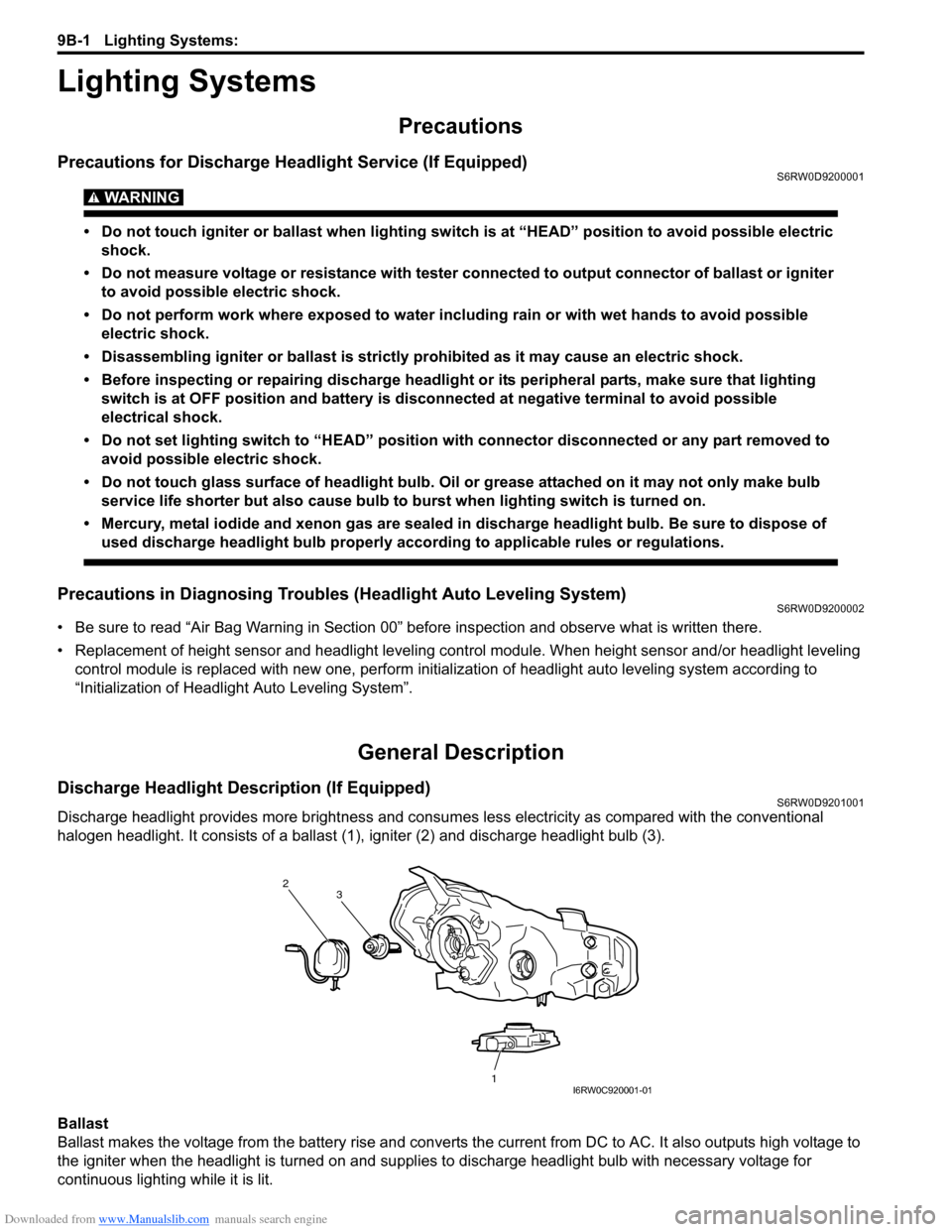

Discharge Headlight Description (If Equipped)S6RW0D9201001

Discharge headlight provides more brightness and consumes less electricity as compared with the conventional

halogen headlight. It consists of a ballast (1), igniter (2) and discharge headlight bulb (3).

Ballast

Ballast makes the voltage from the battery rise and converts the current from DC to AC. It also outputs high voltage to

the igniter when the headlight is turned on and supplies to discharge headlight bulb with necessary voltage for

continuous lighting while it is lit.

2

1 3

I6RW0C920001-01

Page 1338 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-19 Lighting Systems:

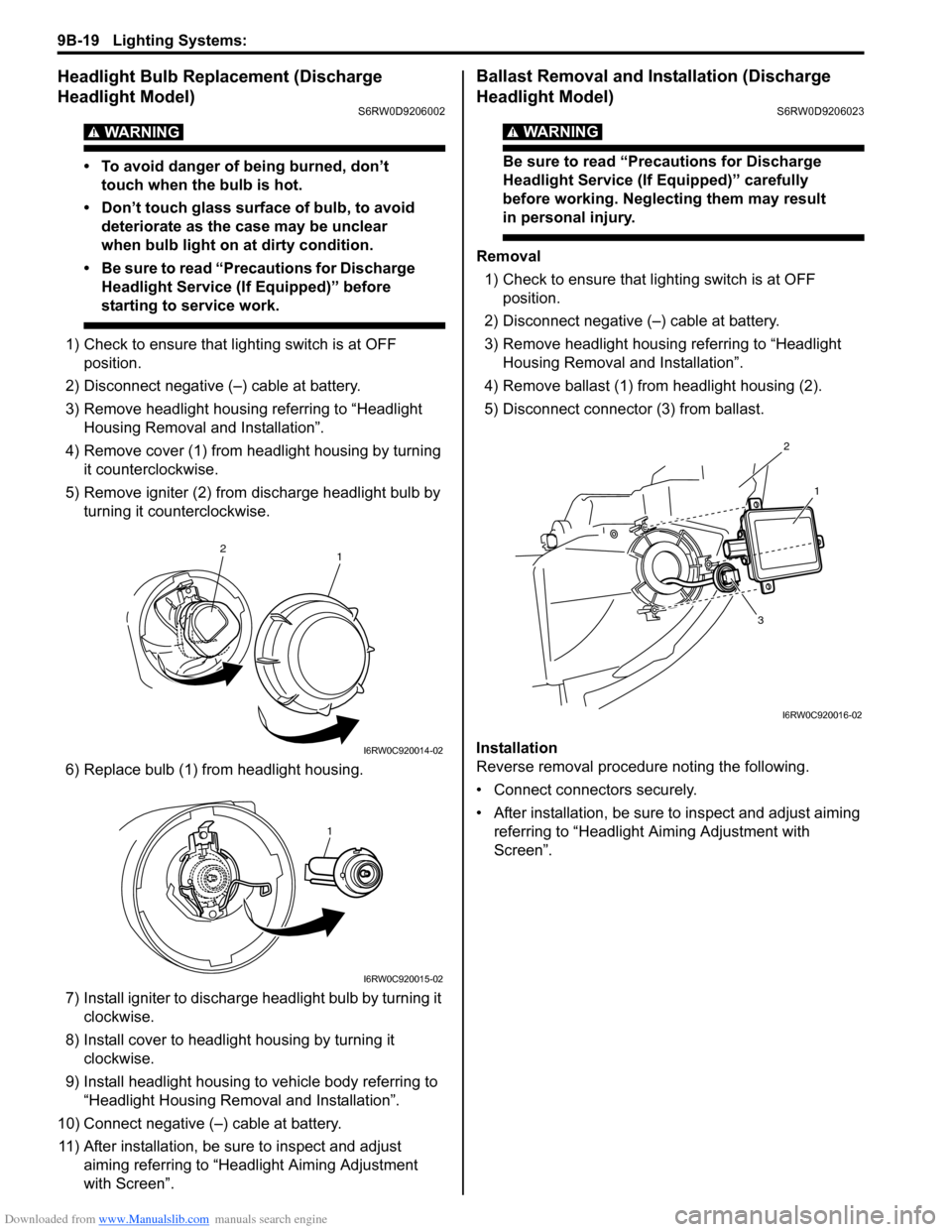

Headlight Bulb Replacement (Discharge

Headlight Model)

S6RW0D9206002

WARNING!

• To avoid danger of being burned, don’t

touch when the bulb is hot.

• Don’t touch glass surface of bulb, to avoid

deteriorate as the case may be unclear

when bulb light on at dirty condition.

• Be sure to read “Precautions for Discharge

Headlight Service (If Equipped)” before

starting to service work.

1) Check to ensure that lighting switch is at OFF

position.

2) Disconnect negative (–) cable at battery.

3) Remove headlight housing referring to “Headlight

Housing Removal and Installation”.

4) Remove cover (1) from headlight housing by turning

it counterclockwise.

5) Remove igniter (2) from discharge headlight bulb by

turning it counterclockwise.

6) Replace bulb (1) from headlight housing.

7) Install igniter to discharge headlight bulb by turning it

clockwise.

8) Install cover to headlight housing by turning it

clockwise.

9) Install headlight housing to vehicle body referring to

“Headlight Housing Removal and Installation”.

10) Connect negative (–) cable at battery.

11) After installation, be sure to inspect and adjust

aiming referring to “Headlight Aiming Adjustment

with Screen”.

Ballast Removal and Installation (Discharge

Headlight Model)

S6RW0D9206023

WARNING!

Be sure to read “Precautions for Discharge

Headlight Service (If Equipped)” carefully

before working. Neglecting them may result

in personal injury.

Removal

1) Check to ensure that lighting switch is at OFF

position.

2) Disconnect negative (–) cable at battery.

3) Remove headlight housing referring to “Headlight

Housing Removal and Installation”.

4) Remove ballast (1) from headlight housing (2).

5) Disconnect connector (3) from ballast.

Installation

Reverse removal procedure noting the following.

• Connect connectors securely.

• After installation, be sure to inspect and adjust aiming

referring to “Headlight Aiming Adjustment with

Screen”.

1 2

I6RW0C920014-02

1

I6RW0C920015-02

2

1

3

I6RW0C920016-02

Page 1349 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-30

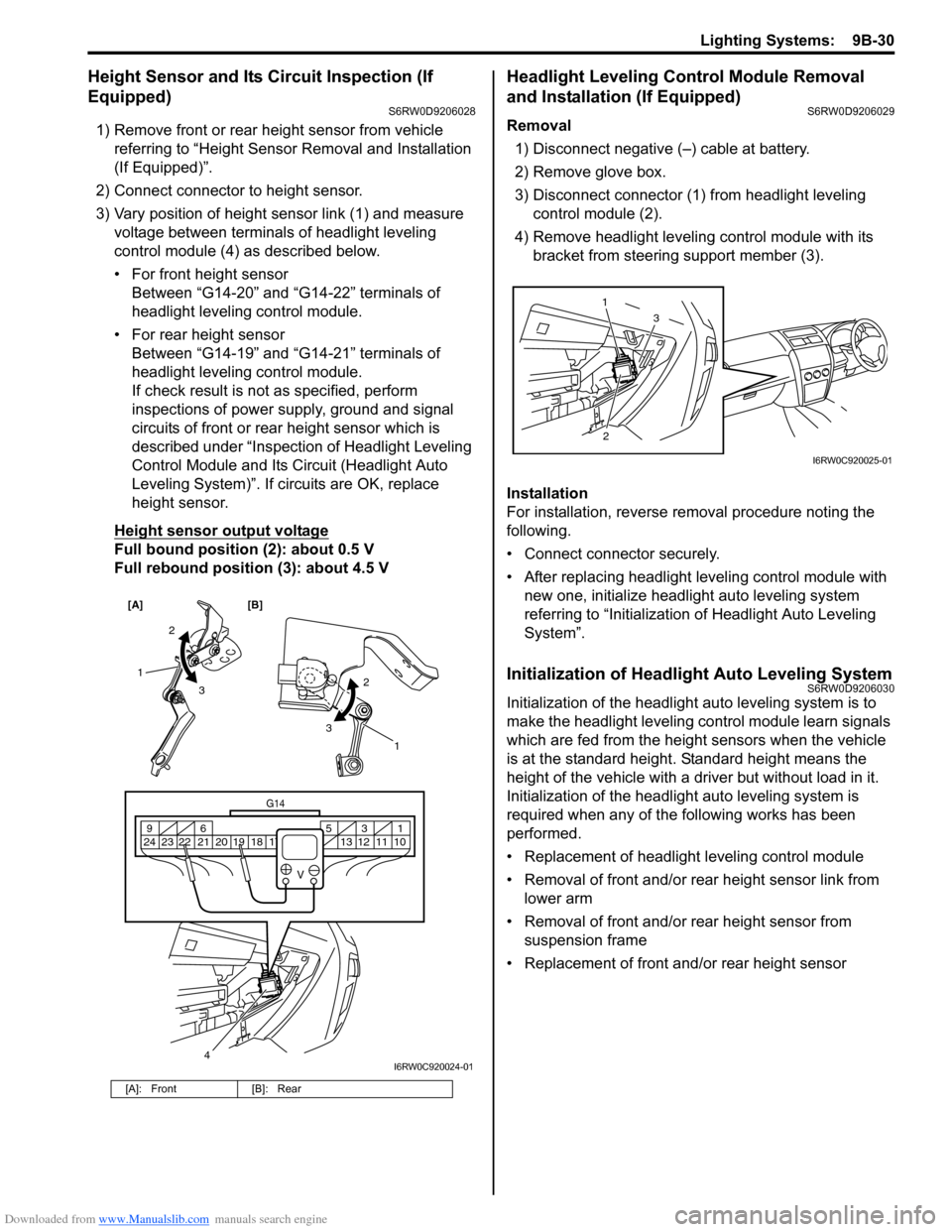

Height Sensor and Its Circuit Inspection (If

Equipped)

S6RW0D9206028

1) Remove front or rear height sensor from vehicle

referring to “Height Sensor Removal and Installation

(If Equipped)”.

2) Connect connector to height sensor.

3) Vary position of height sensor link (1) and measure

voltage between terminals of headlight leveling

control module (4) as described below.

• For front height sensor

Between “G14-20” and “G14-22” terminals of

headlight leveling control module.

• For rear height sensor

Between “G14-19” and “G14-21” terminals of

headlight leveling control module.

If check result is not as specified, perform

inspections of power supply, ground and signal

circuits of front or rear height sensor which is

described under “Inspection of Headlight Leveling

Control Module and Its Circuit (Headlight Auto

Leveling System)”. If circuits are OK, replace

height sensor.

Height sensor output voltage

Full bound position (2): about 0.5 V

Full rebound position (3): about 4.5 V

Headlight Leveling Control Module Removal

and Installation (If Equipped)

S6RW0D9206029

Removal

1) Disconnect negative (–) cable at battery.

2) Remove glove box.

3) Disconnect connector (1) from headlight leveling

control module (2).

4) Remove headlight leveling control module with its

bracket from steering support member (3).

Installation

For installation, reverse removal procedure noting the

following.

• Connect connector securely.

• After replacing headlight leveling control module with

new one, initialize headlight auto leveling system

referring to “Initialization of Headlight Auto Leveling

System”.

Initialization of Headlight Auto Leveling SystemS6RW0D9206030

Initialization of the headlight auto leveling system is to

make the headlight leveling control module learn signals

which are fed from the height sensors when the vehicle

is at the standard height. Standard height means the

height of the vehicle with a driver but without load in it.

Initialization of the headlight auto leveling system is

required when any of the following works has been

performed.

• Replacement of headlight leveling control module

• Removal of front and/or rear height sensor link from

lower arm

• Removal of front and/or rear height sensor from

suspension frame

• Replacement of front and/or rear height sensor

[A]: Front [B]: Rear

[A] [B]

4

G14

10 11 12 13 16 17 18 19 2031 5 6 9

21 22 23 24

V

2

3 1

2

3

1

I6RW0C920024-01

23 1

I6RW0C920025-01

Page 1415 of 1556

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-4

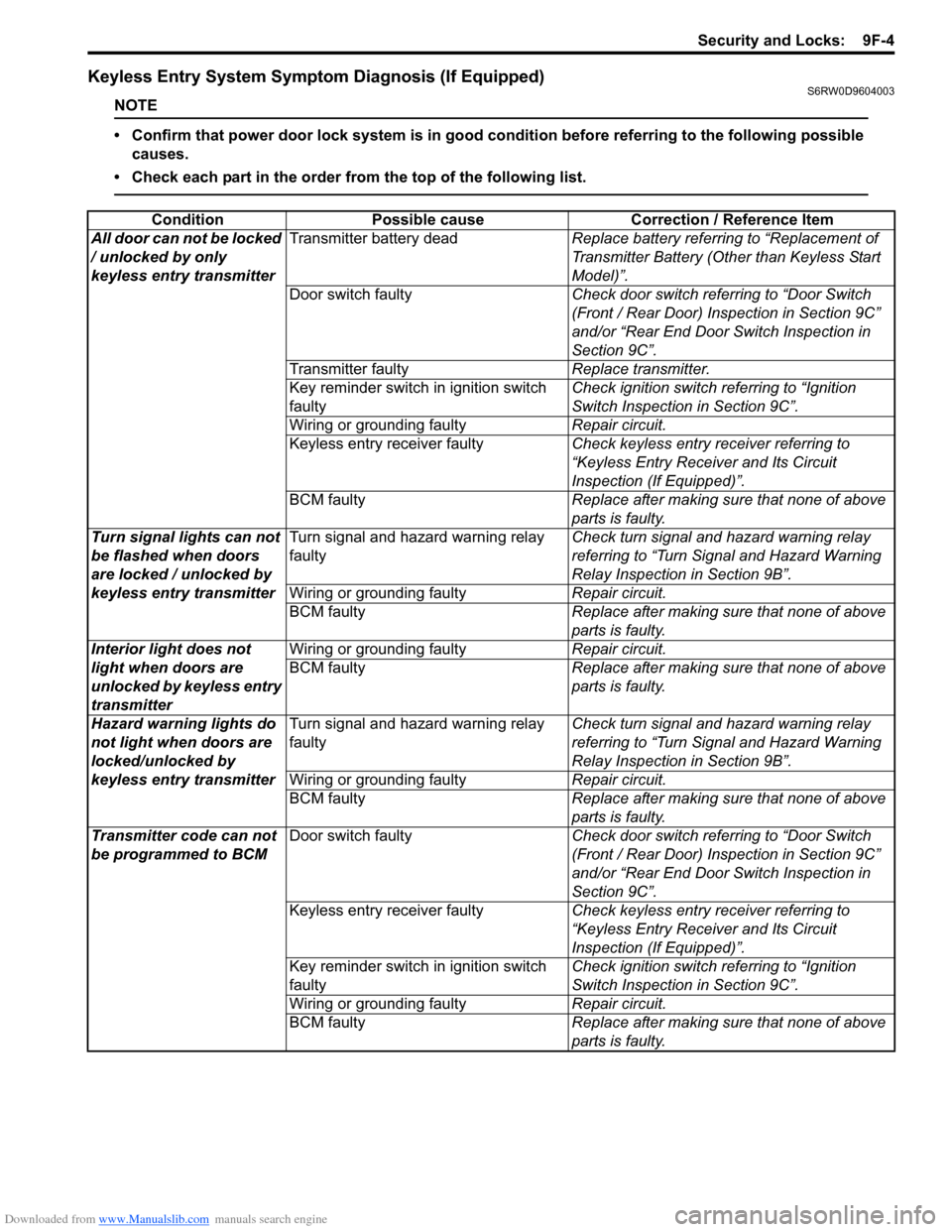

Keyless Entry System Symptom Diagnosis (If Equipped)S6RW0D9604003

NOTE

• Confirm that power door lock system is in good condition before referring to the following possible

causes.

• Check each part in the order from the top of the following list.

Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by only

keyless entry transmitterTransmitter battery deadReplace battery referring to “Replacement of

Transmitter Battery (Other than Keyless Start

Model)”.

Door switch faultyCheck door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Transmitter faultyReplace transmitter.

Key reminder switch in ignition switch

faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

Keyless entry receiver faultyCheck keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection (If Equipped)”.

BCM faultyReplace after making sure that none of above

parts is faulty.

Turn signal lights can not

be flashed when doors

are locked / unlocked by

keyless entry transmitterTurn signal and hazard warning relay

faultyCheck turn signal and hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection in Section 9B”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Interior light does not

light when doors are

unlocked by keyless entry

transmitterWiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Hazard warning lights do

not light when doors are

locked/unlocked by

keyless entry transmitterTurn signal and hazard warning relay

faultyCheck turn signal and hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection in Section 9B”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Transmitter code can not

be programmed to BCMDoor switch faultyCheck door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Keyless entry receiver faultyCheck keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection (If Equipped)”.

Key reminder switch in ignition switch

faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1424 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-13 Security and Locks:

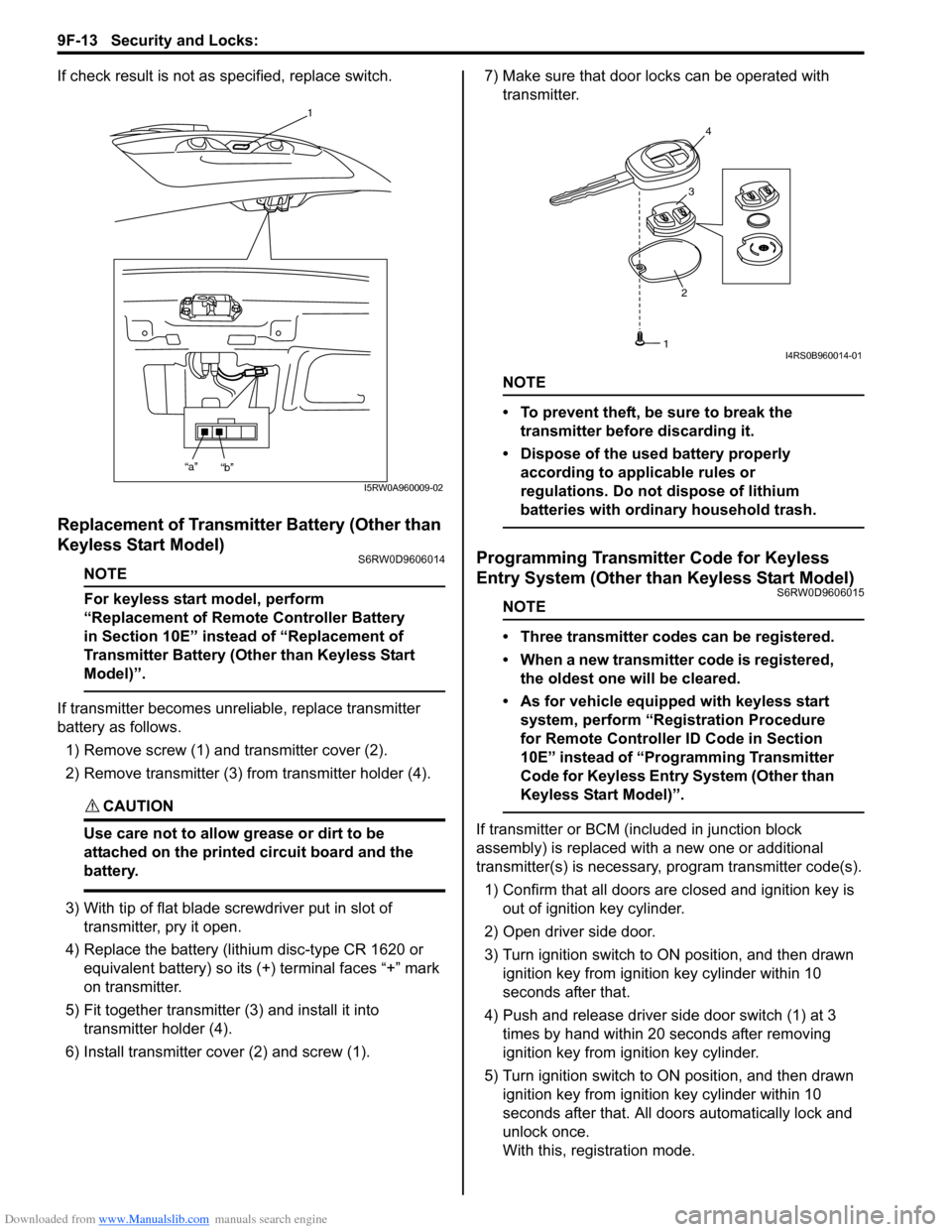

If check result is not as specified, replace switch.

Replacement of Transmitter Battery (Other than

Keyless Start Model)

S6RW0D9606014

NOTE

For keyless start model, perform

“Replacement of Remote Controller Battery

in Section 10E” instead of “Replacement of

Transmitter Battery (Other than Keyless Start

Model)”.

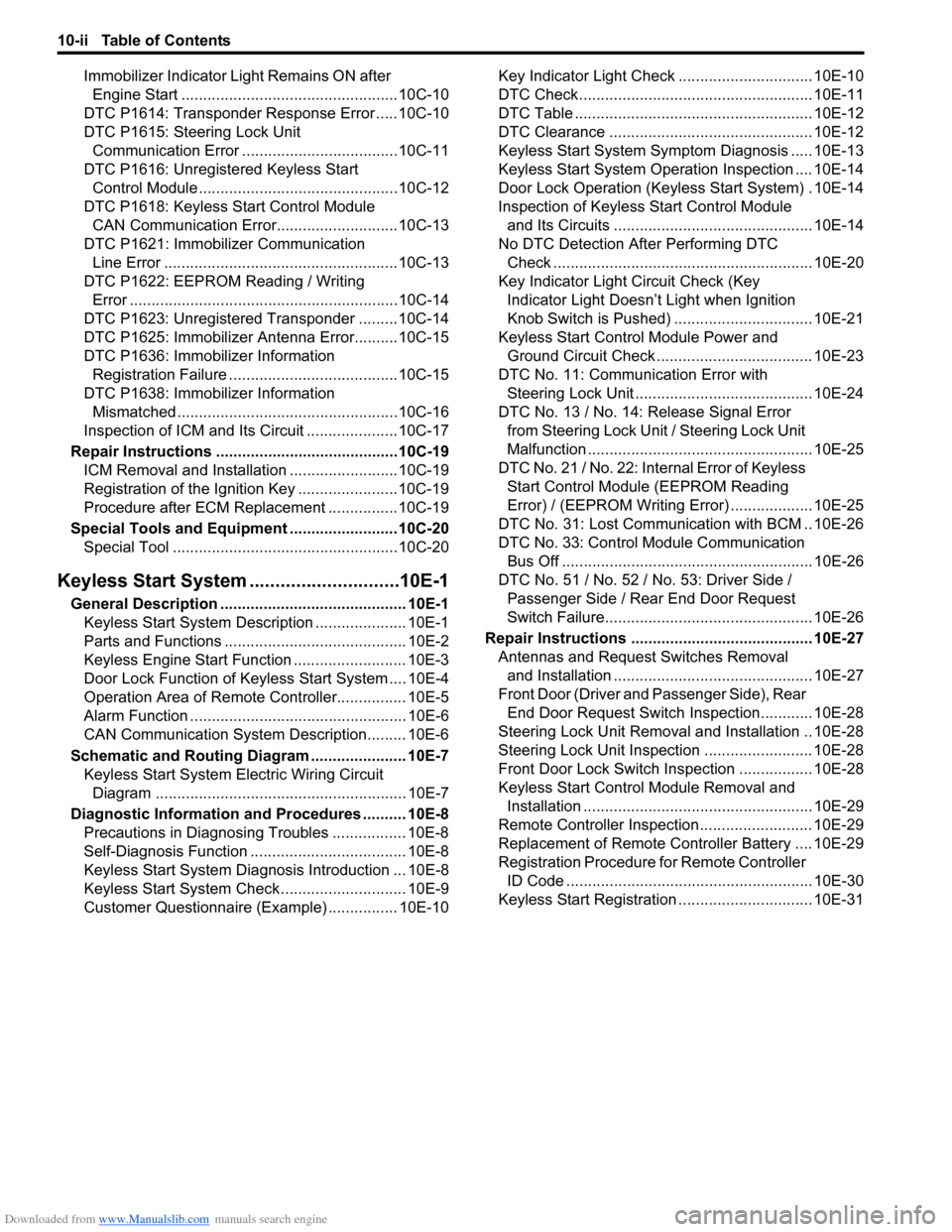

If transmitter becomes unreliable, replace transmitter

battery as follows.

1) Remove screw (1) and transmitter cover (2).

2) Remove transmitter (3) from transmitter holder (4).

CAUTION!

Use care not to allow grease or dirt to be

attached on the printed circuit board and the

battery.

3) With tip of flat blade screwdriver put in slot of

transmitter, pry it open.

4) Replace the battery (lithium disc-type CR 1620 or

equivalent battery) so its (+) terminal faces “+” mark

on transmitter.

5) Fit together transmitter (3) and install it into

transmitter holder (4).

6) Install transmitter cover (2) and screw (1).7) Make sure that door locks can be operated with

transmitter.

NOTE

• To prevent theft, be sure to break the

transmitter before discarding it.

• Dispose of the used battery properly

according to applicable rules or

regulations. Do not dispose of lithium

batteries with ordinary household trash.

Programming Transmitter Code for Keyless

Entry System (Other than Keyless Start Model)

S6RW0D9606015

NOTE

• Three transmitter codes can be registered.

• When a new transmitter code is registered,

the oldest one will be cleared.

• As for vehicle equipped with keyless start

system, perform “Registration Procedure

for Remote Controller ID Code in Section

10E” instead of “Programming Transmitter

Code for Keyless Entry System (Other than

Keyless Start Model)”.

If transmitter or BCM (included in junction block

assembly) is replaced with a new one or additional

transmitter(s) is necessary, program transmitter code(s).

1) Confirm that all doors are closed and ignition key is

out of ignition key cylinder.

2) Open driver side door.

3) Turn ignition switch to ON position, and then drawn

ignition key from ignition key cylinder within 10

seconds after that.

4) Push and release driver side door switch (1) at 3

times by hand within 20 seconds after removing

ignition key from ignition key cylinder.

5) Turn ignition switch to ON position, and then drawn

ignition key from ignition key cylinder within 10

seconds after that. All doors automatically lock and

unlock once.

With this, registration mode.

1

“a”

“b”

I5RW0A960009-02

234

1I4RS0B960014-01

Page 1472 of 1556

Downloaded from www.Manualslib.com manuals search engine 10-ii Table of Contents

Immobilizer Indicator Light Remains ON after

Engine Start ..................................................10C-10

DTC P1614: Transponder Response Error .....10C-10

DTC P1615: Steering Lock Unit

Communication Error ....................................10C-11

DTC P1616: Unregistered Keyless Start

Control Module ..............................................10C-12

DTC P1618: Keyless Start Control Module

CAN Communication Error............................10C-13

DTC P1621: Immobilizer Communication

Line Error ......................................................10C-13

DTC P1622: EEPROM Reading / Writing

Error ..............................................................10C-14

DTC P1623: Unregistered Transponder .........10C-14

DTC P1625: Immobilizer Antenna Error..........10C-15

DTC P1636: Immobilizer Information

Registration Failure .......................................10C-15

DTC P1638: Immobilizer Information

Mismatched ...................................................10C-16

Inspection of ICM and Its Circuit .....................10C-17

Repair Instructions ..........................................10C-19

ICM Removal and Installation .........................10C-19

Registration of the Ignition Key .......................10C-19

Procedure after ECM Replacement ................10C-19

Special Tools and Equipment .........................10C-20

Special Tool ....................................................10C-20

Keyless Start System .............................10E-1

General Description ........................................... 10E-1

Keyless Start System Description ..................... 10E-1

Parts and Functions .......................................... 10E-2

Keyless Engine Start Function .......................... 10E-3

Door Lock Function of Keyless Start System .... 10E-4

Operation Area of Remote Controller................ 10E-5

Alarm Function .................................................. 10E-6

CAN Communication System Description......... 10E-6

Schematic and Routing Diagram ...................... 10E-7

Keyless Start System Electric Wiring Circuit

Diagram .......................................................... 10E-7

Diagnostic Information and Procedures .......... 10E-8

Precautions in Diagnosing Troubles ................. 10E-8

Self-Diagnosis Function .................................... 10E-8

Keyless Start System Diagnosis Introduction ... 10E-8

Keyless Start System Check ............................. 10E-9

Customer Questionnaire (Example) ................ 10E-10Key Indicator Light Check ............................... 10E-10

DTC Check...................................................... 10E-11

DTC Table ....................................................... 10E-12

DTC Clearance ............................................... 10E-12

Keyless Start System Symptom Diagnosis ..... 10E-13

Keyless Start System Operation Inspection .... 10E-14

Door Lock Operation (Keyless Start System) . 10E-14

Inspection of Keyless Start Control Module

and Its Circuits .............................................. 10E-14

No DTC Detection After Performing DTC

Check ............................................................ 10E-20

Key Indicator Light Circuit Check (Key

Indicator Light Doesn’t Light when Ignition

Knob Switch is Pushed) ................................ 10E-21

Keyless Start Control Module Power and

Ground Circuit Check .................................... 10E-23

DTC No. 11: Communication Error with

Steering Lock Unit ......................................... 10E-24

DTC No. 13 / No. 14: Release Signal Error

from Steering Lock Unit / Steering Lock Unit

Malfunction .................................................... 10E-25

DTC No. 21 / No. 22: Internal Error of Keyless

Start Control Module (EEPROM Reading

Error) / (EEPROM Writing Error) ................... 10E-25

DTC No. 31: Lost Communication with BCM .. 10E-26

DTC No. 33: Control Module Communication

Bus Off .......................................................... 10E-26

DTC No. 51 / No. 52 / No. 53: Driver Side /

Passenger Side / Rear End Door Request

Switch Failure................................................ 10E-26

Repair Instructions .......................................... 10E-27

Antennas and Request Switches Removal

and Installation .............................................. 10E-27

Front Door (Driver and Passenger Side), Rear

End Door Request Switch Inspection............ 10E-28

Steering Lock Unit Removal and Installation .. 10E-28

Steering Lock Unit Inspection ......................... 10E-28

Front Door Lock Switch Inspection ................. 10E-28

Keyless Start Control Module Removal and

Installation ..................................................... 10E-29

Remote Controller Inspection.......................... 10E-29

Replacement of Remote Controller Battery .... 10E-29

Registration Procedure for Remote Controller

ID Code ......................................................... 10E-30

Keyless Start Registration ............................... 10E-31

Page 1503 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-1

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing TroublesS6RW0DA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well

as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” before inspection.

• Communication of ECM, BCM, ABS control module,

TCM (if equipped), 4WD control module (if equipped),

keyless start control module (if equipped),

combination meter and DLC is established by CAN

(Controller Area Network). Therefore, handle CAN

communication lines with care referring to “Precaution

for CAN Communication System in Section 00”.

For CAN communication system, refer to description

on “CAN Communication System Description in

Section 1A”.

Precaution in Replacing ECMS6RW0DA300002

• If ECM is replaced with new or used one without

Immobilizer control function, the engine will not be

started. In case of the above, check if the newly

installed ECM has Immobilizer control function.

• After ECM is replaced with new one or used one, the

transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

Precaution in Replacing Ignition KeyS6RW0DA300003

To register ignition key in case of replacing key(s) and/or

making spare key(s), the transponder code in the ignition

key is registered with ECM. Or the engine can not be

started up. For the registration procedure, refer to

“Registration of the Ignition Key”.

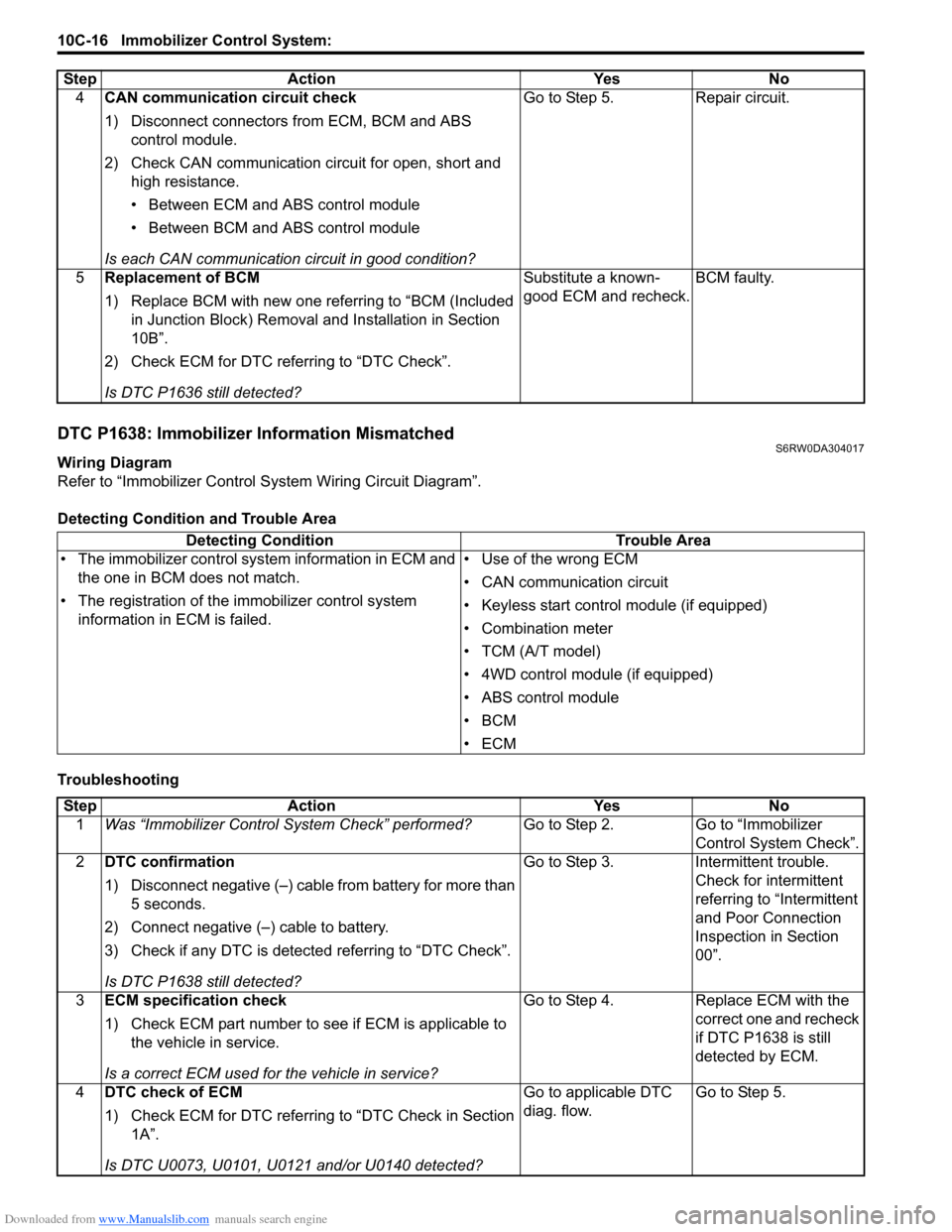

Precautions in Handling Immobilizer Control

System

S6RW0DA300004

• Do not turn ON ignition switch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer control system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key

with any type of metal (1) wrapped its grip or in

contact with it. Or, the immobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

I3RH0AA30001-01

1

I3RH0AA30002-01

Page 1518 of 1556

Downloaded from www.Manualslib.com manuals search engine 10C-16 Immobilizer Control System:

DTC P1638: Immobilizer Information MismatchedS6RW0DA304017

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Detecting Condition and Trouble Area

Troubleshooting4CAN communication circuit check

1) Disconnect connectors from ECM, BCM and ABS

control module.

2) Check CAN communication circuit for open, short and

high resistance.

• Between ECM and ABS control module

• Between BCM and ABS control module

Is each CAN communication circuit in good condition?Go to Step 5. Repair circuit.

5Replacement of BCM

1) Replace BCM with new one referring to “BCM (Included

in Junction Block) Removal and Installation in Section

10B”.

2) Check ECM for DTC referring to “DTC Check”.

Is DTC P1636 still detected?Substitute a known-

good ECM and recheck.BCM faulty. Step Action Yes No

Detecting Condition Trouble Area

• The immobilizer control system information in ECM and

the one in BCM does not match.

• The registration of the immobilizer control system

information in ECM is failed.• Use of the wrong ECM

• CAN communication circuit

• Keyless start control module (if equipped)

• Combination meter

• TCM (A/T model)

• 4WD control module (if equipped)

• ABS control module

•BCM

•ECM

Step Action Yes No

1Was “Immobilizer Control System Check” performed?Go to Step 2. Go to “Immobilizer

Control System Check”.

2DTC confirmation

1) Disconnect negative (–) cable from battery for more than

5 seconds.

2) Connect negative (–) cable to battery.

3) Check if any DTC is detected referring to “DTC Check”.

Is DTC P1638 still detected?Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3ECM specification check

1) Check ECM part number to see if ECM is applicable to

the vehicle in service.

Is a correct ECM used for the vehicle in service?Go to Step 4. Replace ECM with the

correct one and recheck

if DTC P1638 is still

detected by ECM.

4DTC check of ECM

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is DTC U0073, U0101, U0121 and/or U0140 detected?Go to applicable DTC

diag. flow.Go to Step 5.

Page 1519 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-17

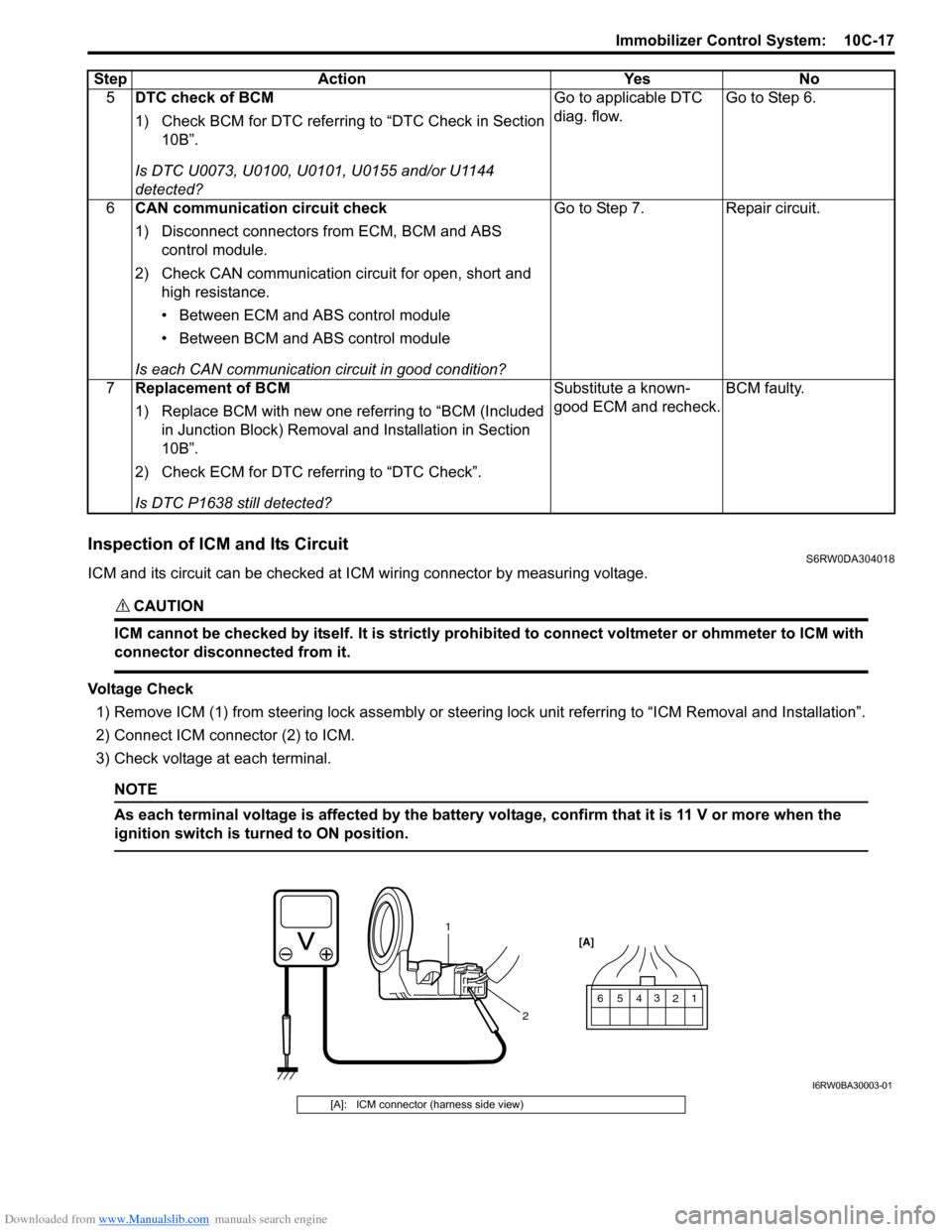

Inspection of ICM and Its CircuitS6RW0DA304018

ICM and its circuit can be checked at ICM wiring connector by measuring voltage.

CAUTION!

ICM cannot be checked by itself. It is strictly prohibited to connect voltmeter or ohmmeter to ICM with

connector disconnected from it.

Voltage Check

1) Remove ICM (1) from steering lock assembly or steering lock unit referring to “ICM Removal and Installation”.

2) Connect ICM connector (2) to ICM.

3) Check voltage at each terminal.

NOTE

As each terminal voltage is affected by the battery voltage, confirm that it is 11 V or more when the

ignition switch is turned to ON position.

5DTC check of BCM

1) Check BCM for DTC referring to “DTC Check in Section

10B”.

Is DTC U0073, U0100, U0101, U0155 and/or U1144

detected?Go to applicable DTC

diag. flow.Go to Step 6.

6CAN communication circuit check

1) Disconnect connectors from ECM, BCM and ABS

control module.

2) Check CAN communication circuit for open, short and

high resistance.

• Between ECM and ABS control module

• Between BCM and ABS control module

Is each CAN communication circuit in good condition?Go to Step 7. Repair circuit.

7Replacement of BCM

1) Replace BCM with new one referring to “BCM (Included

in Junction Block) Removal and Installation in Section

10B”.

2) Check ECM for DTC referring to “DTC Check”.

Is DTC P1638 still detected?Substitute a known-

good ECM and recheck.BCM faulty. Step Action Yes No

1 2 3

4

1

25

6 [A]

I6RW0BA30003-01

[A]: ICM connector (harness side view)

Page 1521 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-19

Repair Instructions

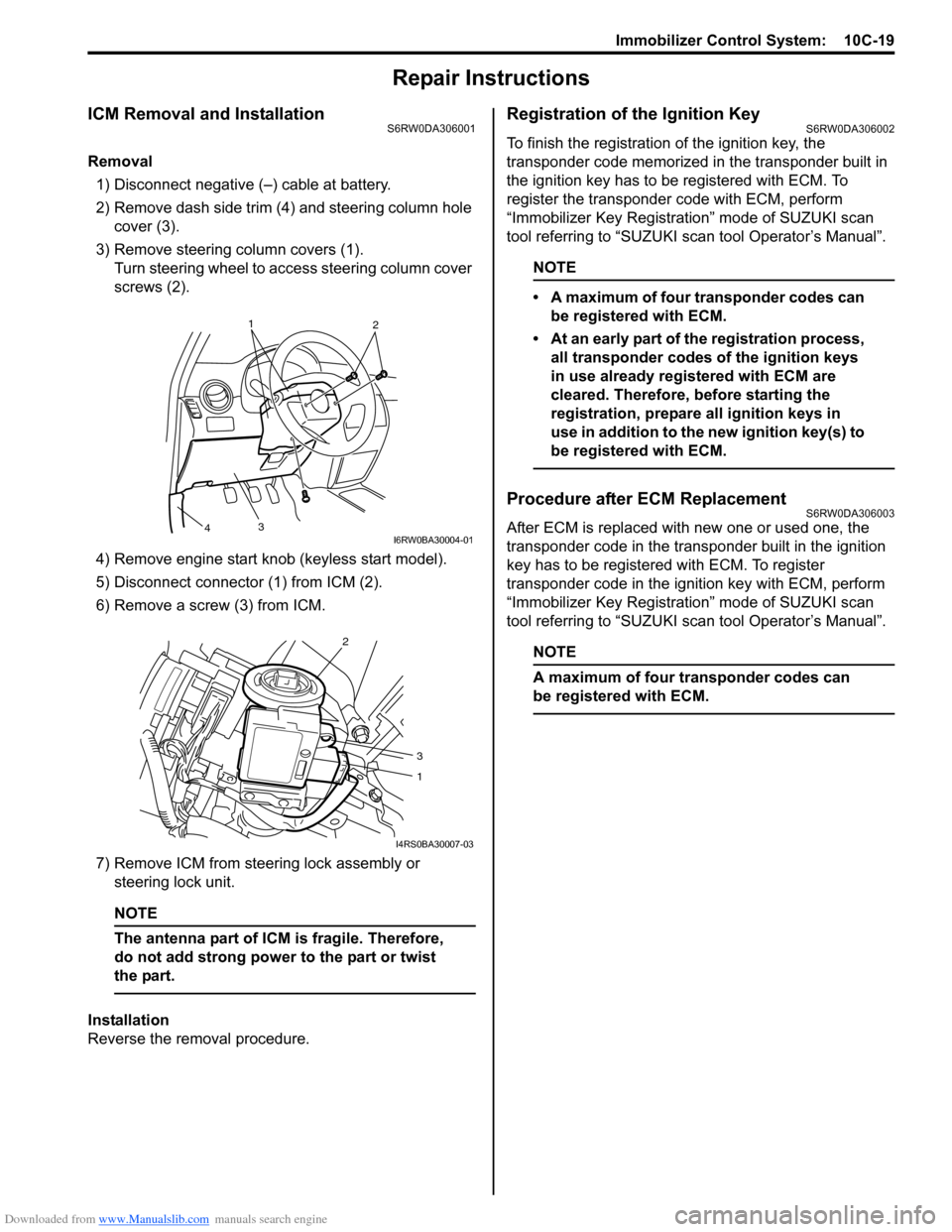

ICM Removal and InstallationS6RW0DA306001

Removal

1) Disconnect negative (–) cable at battery.

2) Remove dash side trim (4) and steering column hole

cover (3).

3) Remove steering column covers (1).

Turn steering wheel to access steering column cover

screws (2).

4) Remove engine start knob (keyless start model).

5) Disconnect connector (1) from ICM (2).

6) Remove a screw (3) from ICM.

7) Remove ICM from steering lock assembly or

steering lock unit.

NOTE

The antenna part of ICM is fragile. Therefore,

do not add strong power to the part or twist

the part.

Installation

Reverse the removal procedure.

Registration of the Ignition KeyS6RW0DA306002

To finish the registration of the ignition key, the

transponder code memorized in the transponder built in

the ignition key has to be registered with ECM. To

register the transponder code with ECM, perform

“Immobilizer Key Registration” mode of SUZUKI scan

tool referring to “SUZUKI scan tool Operator’s Manual”.

NOTE

• A maximum of four transponder codes can

be registered with ECM.

• At an early part of the registration process,

all transponder codes of the ignition keys

in use already registered with ECM are

cleared. Therefore, before starting the

registration, prepare all ignition keys in

use in addition to the new ignition key(s) to

be registered with ECM.

Procedure after ECM ReplacementS6RW0DA306003

After ECM is replaced with new one or used one, the

transponder code in the transponder built in the ignition

key has to be registered with ECM. To register

transponder code in the ignition key with ECM, perform

“Immobilizer Key Registration” mode of SUZUKI scan

tool referring to “SUZUKI scan tool Operator’s Manual”.

NOTE

A maximum of four transponder codes can

be registered with ECM.

1

2

3

4I6RW0BA30004-01

2

3

1

I4RS0BA30007-03