Hvac SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 931 of 1556

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-3

Diagnostic Information and Procedures

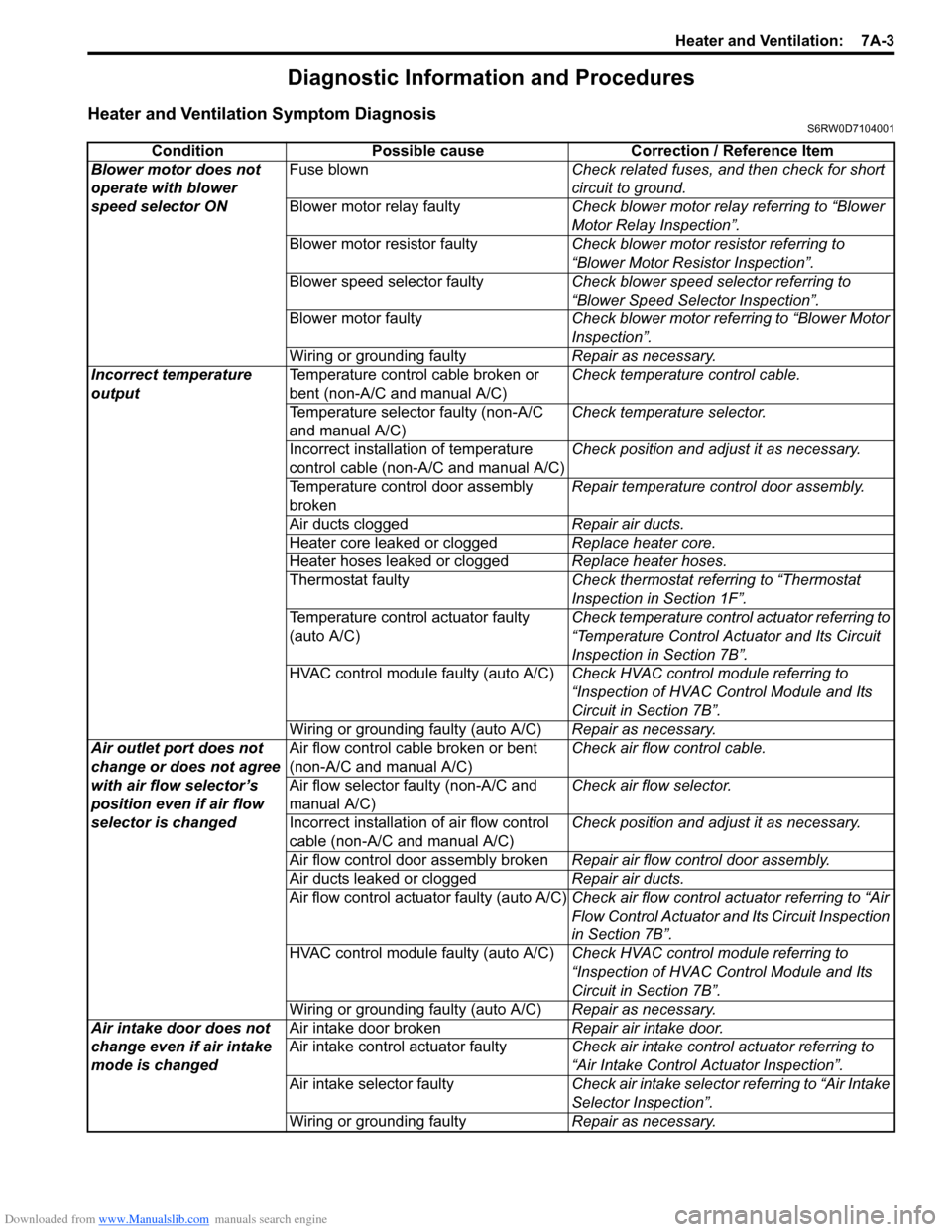

Heater and Ventilation Symptom DiagnosisS6RW0D7104001

Condition Possible cause Correction / Reference Item

Blower motor does not

operate with blower

speed selector ONFuse blownCheck related fuses, and then check for short

circuit to ground.

Blower motor relay faultyCheck blower motor relay referring to “Blower

Motor Relay Inspection”.

Blower motor resistor faultyCheck blower motor resistor referring to

“Blower Motor Resistor Inspection”.

Blower speed selector faultyCheck blower speed selector referring to

“Blower Speed Selector Inspection”.

Blower motor faultyCheck blower motor referring to “Blower Motor

Inspection”.

Wiring or grounding faultyRepair as necessary.

Incorrect temperature

outputTemperature control cable broken or

bent (non-A/C and manual A/C)Check temperature control cable.

Temperature selector faulty (non-A/C

and manual A/C)Check temperature selector.

Incorrect installation of temperature

control cable (non-A/C and manual A/C)Check position and adjust it as necessary.

Temperature control door assembly

brokenRepair temperature control door assembly.

Air ducts cloggedRepair air ducts.

Heater core leaked or cloggedReplace heater core.

Heater hoses leaked or cloggedReplace heater hoses.

Thermostat faultyCheck thermostat referring to “Thermostat

Inspection in Section 1F”.

Temperature control actuator faulty

(auto A/C)Check temperature control actuator referring to

“Temperature Control Actuator and Its Circuit

Inspection in Section 7B”.

HVAC control module faulty (auto A/C)Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit in Section 7B”.

Wiring or grounding faulty (auto A/C)Repair as necessary.

Air outlet port does not

change or does not agree

with air flow selector’s

position even if air flow

selector is changedAir flow control cable broken or bent

(non-A/C and manual A/C)Check air flow control cable.

Air flow selector faulty (non-A/C and

manual A/C)Check air flow selector.

Incorrect installation of air flow control

cable (non-A/C and manual A/C)Check position and adjust it as necessary.

Air flow control door assembly brokenRepair air flow control door assembly.

Air ducts leaked or cloggedRepair air ducts.

Air flow control actuator faulty (auto A/C)Check air flow control actuator referring to “Air

Flow Control Actuator and Its Circuit Inspection

in Section 7B”.

HVAC control module faulty (auto A/C)Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit in Section 7B”.

Wiring or grounding faulty (auto A/C)Repair as necessary.

Air intake door does not

change even if air intake

mode is changedAir intake door brokenRepair air intake door.

Air intake control actuator faultyCheck air intake control actuator referring to

“Air Intake Control Actuator Inspection”.

Air intake selector faultyCheck air intake selector referring to “Air Intake

Selector Inspection”.

Wiring or grounding faultyRepair as necessary.

Page 932 of 1556

Downloaded from www.Manualslib.com manuals search engine 7A-4 Heater and Ventilation:

Repair Instructions

HVAC Unit ComponentsS6RW0D7106001

For non-A/C and manual A/C, refer to “HVAC Unit

Components in Section 7B”.

For auto A/C, refer to “HVAC Unit Components in

Section 7B”.

HVAC Unit Removal and Installation (Non-A/C)S6RW0D7106002

For manual A/C and auto A/C, refer to “HVAC Unit

Removal and Installation in Section 7B”.

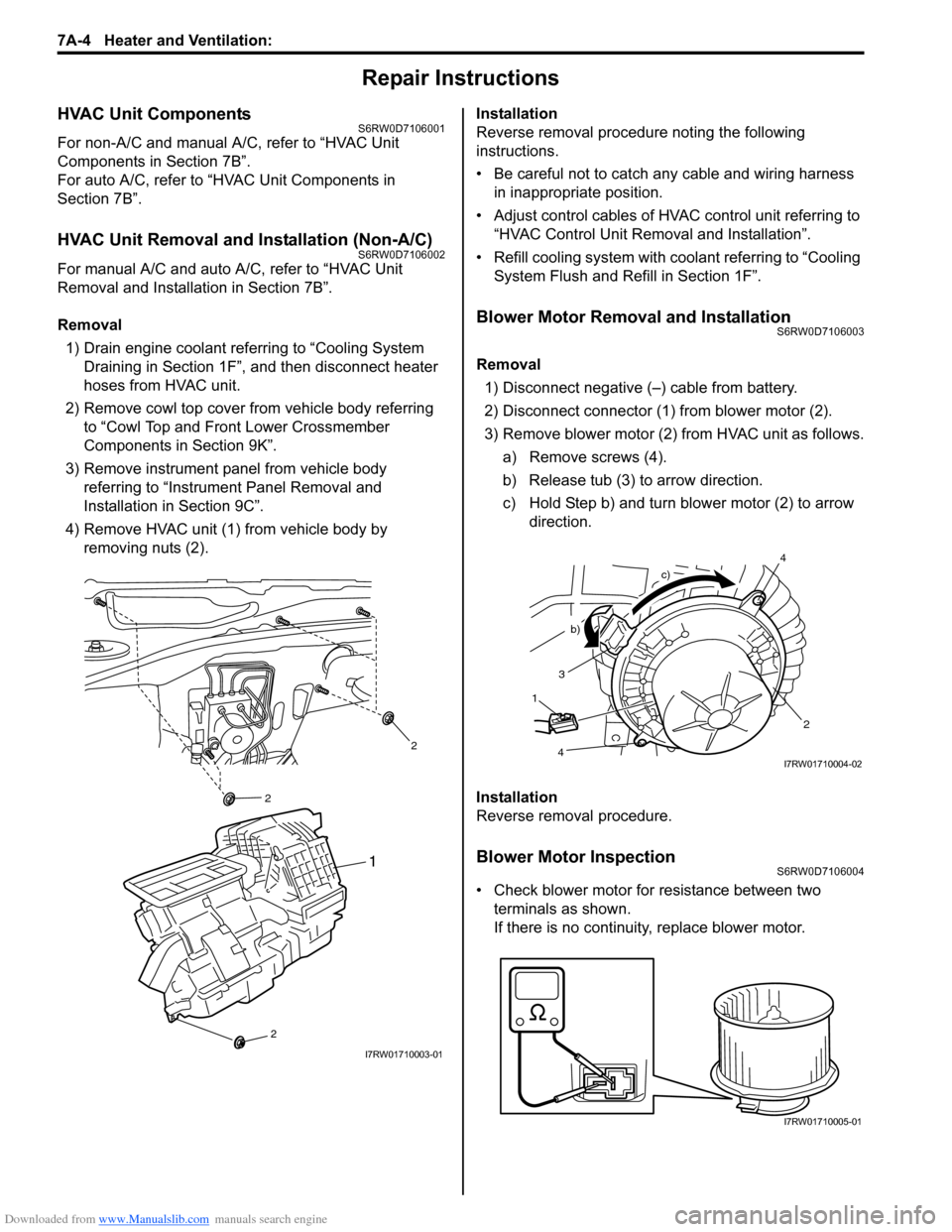

Removal

1) Drain engine coolant referring to “Cooling System

Draining in Section 1F”, and then disconnect heater

hoses from HVAC unit.

2) Remove cowl top cover from vehicle body referring

to “Cowl Top and Front Lower Crossmember

Components in Section 9K”.

3) Remove instrument panel from vehicle body

referring to “Instrument Panel Removal and

Installation in Section 9C”.

4) Remove HVAC unit (1) from vehicle body by

removing nuts (2).Installation

Reverse removal procedure noting the following

instructions.

• Be careful not to catch any cable and wiring harness

in inappropriate position.

• Adjust control cables of HVAC control unit referring to

“HVAC Control Unit Removal and Installation”.

• Refill cooling system with coolant referring to “Cooling

System Flush and Refill in Section 1F”.

Blower Motor Removal and InstallationS6RW0D7106003

Removal

1) Disconnect negative (–) cable from battery.

2) Disconnect connector (1) from blower motor (2).

3) Remove blower motor (2) from HVAC unit as follows.

a) Remove screws (4).

b) Release tub (3) to arrow direction.

c) Hold Step b) and turn blower motor (2) to arrow

direction.

Installation

Reverse removal procedure.

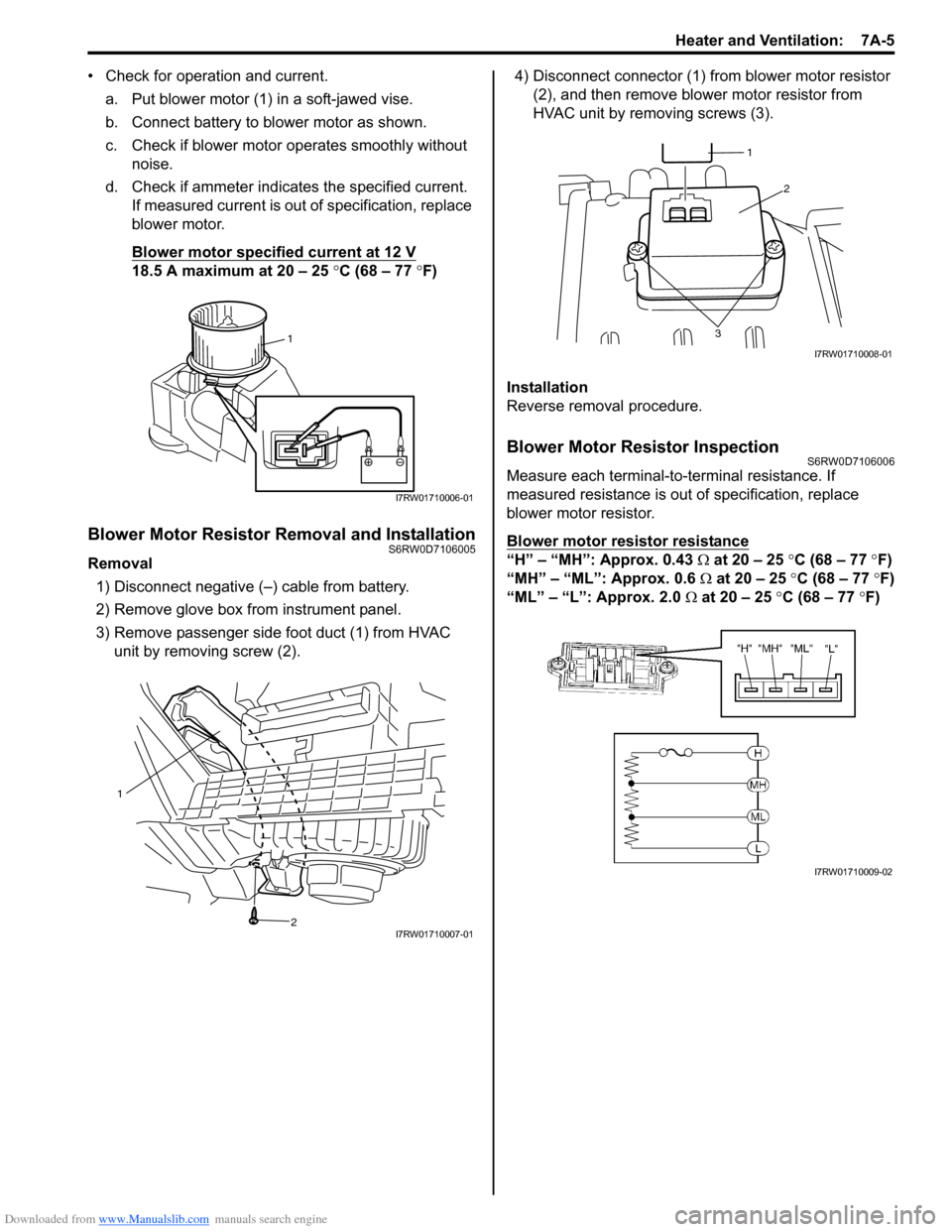

Blower Motor InspectionS6RW0D7106004

• Check blower motor for resistance between two

terminals as shown.

If there is no continuity, replace blower motor.

2

2

2

1

I7RW01710003-01

3

2

b)

c)

1

4

4I7RW01710004-02

I7RW01710005-01

Page 933 of 1556

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-5

• Check for operation and current.

a. Put blower motor (1) in a soft-jawed vise.

b. Connect battery to blower motor as shown.

c. Check if blower motor operates smoothly without

noise.

d. Check if ammeter indicates the specified current.

If measured current is out of specification, replace

blower motor.

Blower motor specified current at 12 V

18.5 A maximum at 20 – 25 °C (68 – 77 °F)

Blower Motor Resistor Removal and InstallationS6RW0D7106005

Removal

1) Disconnect negative (–) cable from battery.

2) Remove glove box from instrument panel.

3) Remove passenger side foot duct (1) from HVAC

unit by removing screw (2).4) Disconnect connector (1) from blower motor resistor

(2), and then remove blower motor resistor from

HVAC unit by removing screws (3).

Installation

Reverse removal procedure.

Blower Motor Resistor InspectionS6RW0D7106006

Measure each terminal-to-terminal resistance. If

measured resistance is out of specification, replace

blower motor resistor.

Blower motor resistor resistance

“H” – “MH”: Approx. 0.43 Ω at 20 – 25 °C (68 – 77 °F)

“MH” – “ML”: Approx. 0.6 Ω at 20 – 25 °C (68 – 77 °F)

“ML” – “L”: Approx. 2.0 Ω at 20 – 25 °C (68 – 77 °F)

1

I7RW01710006-01

1

2

I7RW01710007-01

2

3

1

I7RW01710008-01

I7RW01710009-02

Page 934 of 1556

Downloaded from www.Manualslib.com manuals search engine 7A-6 Heater and Ventilation:

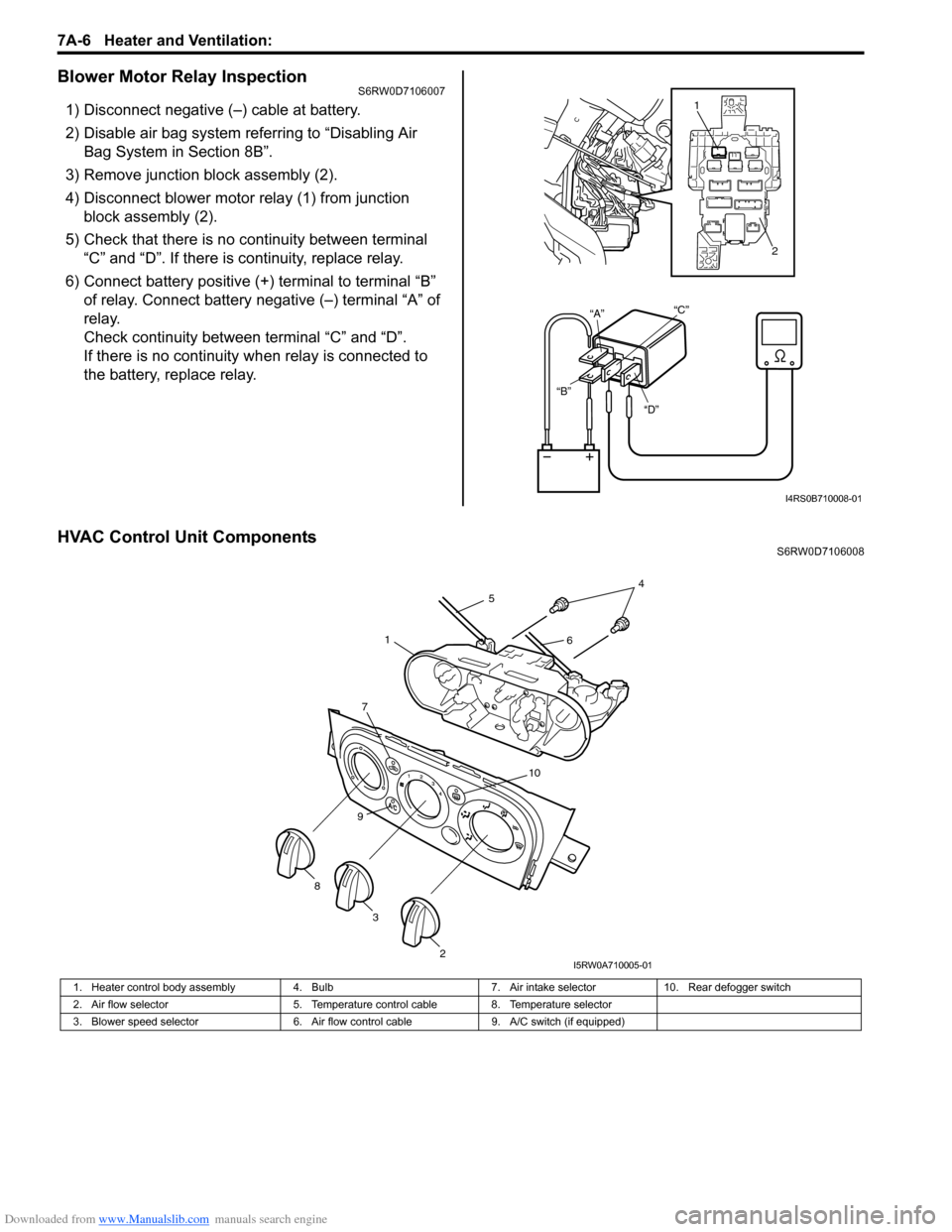

Blower Motor Relay InspectionS6RW0D7106007

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove junction block assembly (2).

4) Disconnect blower motor relay (1) from junction

block assembly (2).

5) Check that there is no continuity between terminal

“C” and “D”. If there is continuity, replace relay.

6) Connect battery positive (+) terminal to terminal “B”

of relay. Connect battery negative (–) terminal “A” of

relay.

Check continuity between terminal “C” and “D”.

If there is no continuity when relay is connected to

the battery, replace relay.

HVAC Control Unit ComponentsS6RW0D7106008

“D” “B”“A”“C”

1

2

I4RS0B710008-01

1. Heater control body assembly 4. Bulb 7. Air intake selector 10. Rear defogger switch

2. Air flow selector 5. Temperature control cable 8. Temperature selector

3. Blower speed selector 6. Air flow control cable 9. A/C switch (if equipped)

7

10

9

2

3 8

45

61

I5RW0A710005-01

Page 935 of 1556

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-7

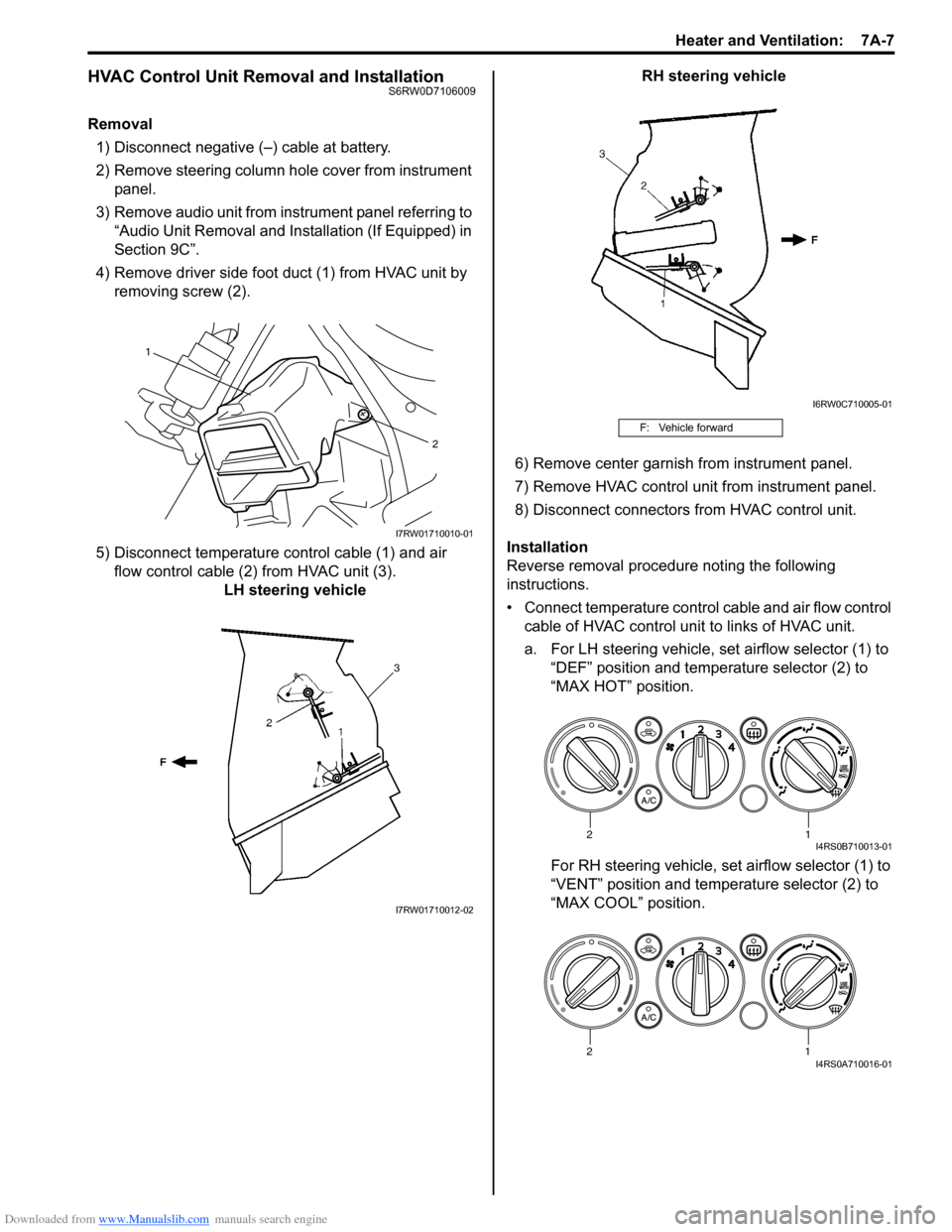

HVAC Control Unit Removal and InstallationS6RW0D7106009

Removal

1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover from instrument

panel.

3) Remove audio unit from instrument panel referring to

“Audio Unit Removal and Installation (If Equipped) in

Section 9C”.

4) Remove driver side foot duct (1) from HVAC unit by

removing screw (2).

5) Disconnect temperature control cable (1) and air

flow control cable (2) from HVAC unit (3).

LH steering vehicleRH steering vehicle

6) Remove center garnish from instrument panel.

7) Remove HVAC control unit from instrument panel.

8) Disconnect connectors from HVAC control unit.

Installation

Reverse removal procedure noting the following

instructions.

• Connect temperature control cable and air flow control

cable of HVAC control unit to links of HVAC unit.

a. For LH steering vehicle, set airflow selector (1) to

“DEF” position and temperature selector (2) to

“MAX HOT” position.

For RH steering vehicle, set airflow selector (1) to

“VENT” position and temperature selector (2) to

“MAX COOL” position.

1

2

I7RW01710010-01

I7RW01710012-02

F: Vehicle forward

I6RW0C710005-01

12I4RS0B710013-01

12I4RS0A710016-01

Page 937 of 1556

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-9

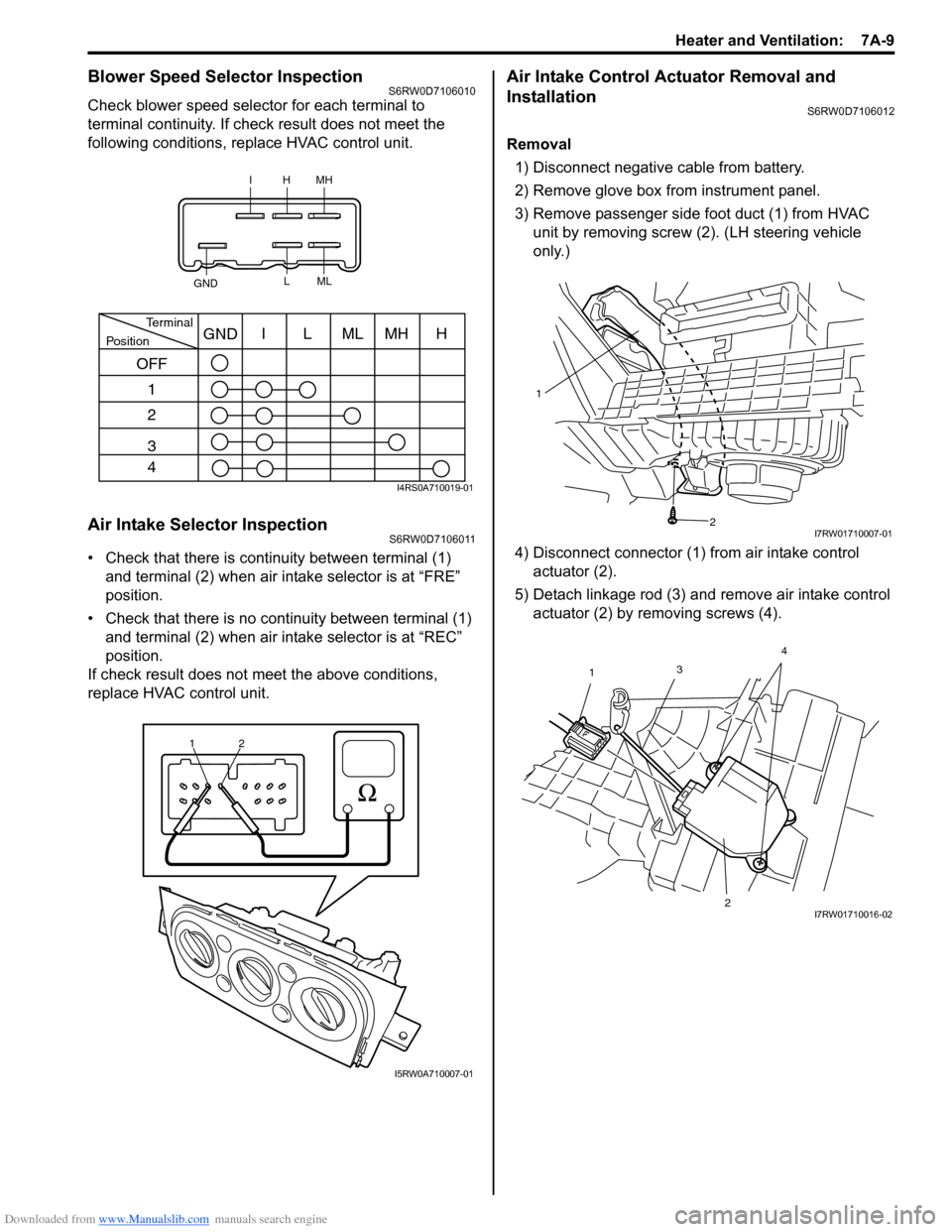

Blower Speed Selector InspectionS6RW0D7106010

Check blower speed selector for each terminal to

terminal continuity. If check result does not meet the

following conditions, replace HVAC control unit.

Air Intake Selector InspectionS6RW0D7106011

• Check that there is continuity between terminal (1)

and terminal (2) when air intake selector is at “FRE”

position.

• Check that there is no continuity between terminal (1)

and terminal (2) when air intake selector is at “REC”

position.

If check result does not meet the above conditions,

replace HVAC control unit.

Air Intake Control Actuator Removal and

Installation

S6RW0D7106012

Removal

1) Disconnect negative cable from battery.

2) Remove glove box from instrument panel.

3) Remove passenger side foot duct (1) from HVAC

unit by removing screw (2). (LH steering vehicle

only.)

4) Disconnect connector (1) from air intake control

actuator (2).

5) Detach linkage rod (3) and remove air intake control

actuator (2) by removing screws (4).

IHMH

GNDLML

PositionTerminalI

OFF

1

2

3

4LMLMHHGND

I4RS0A710019-01

1

2

I5RW0A710007-01

1

2

I7RW01710007-01

3

1

24I7RW01710016-02

Page 940 of 1556

Downloaded from www.Manualslib.com manuals search engine 7A-12 Heater and Ventilation:

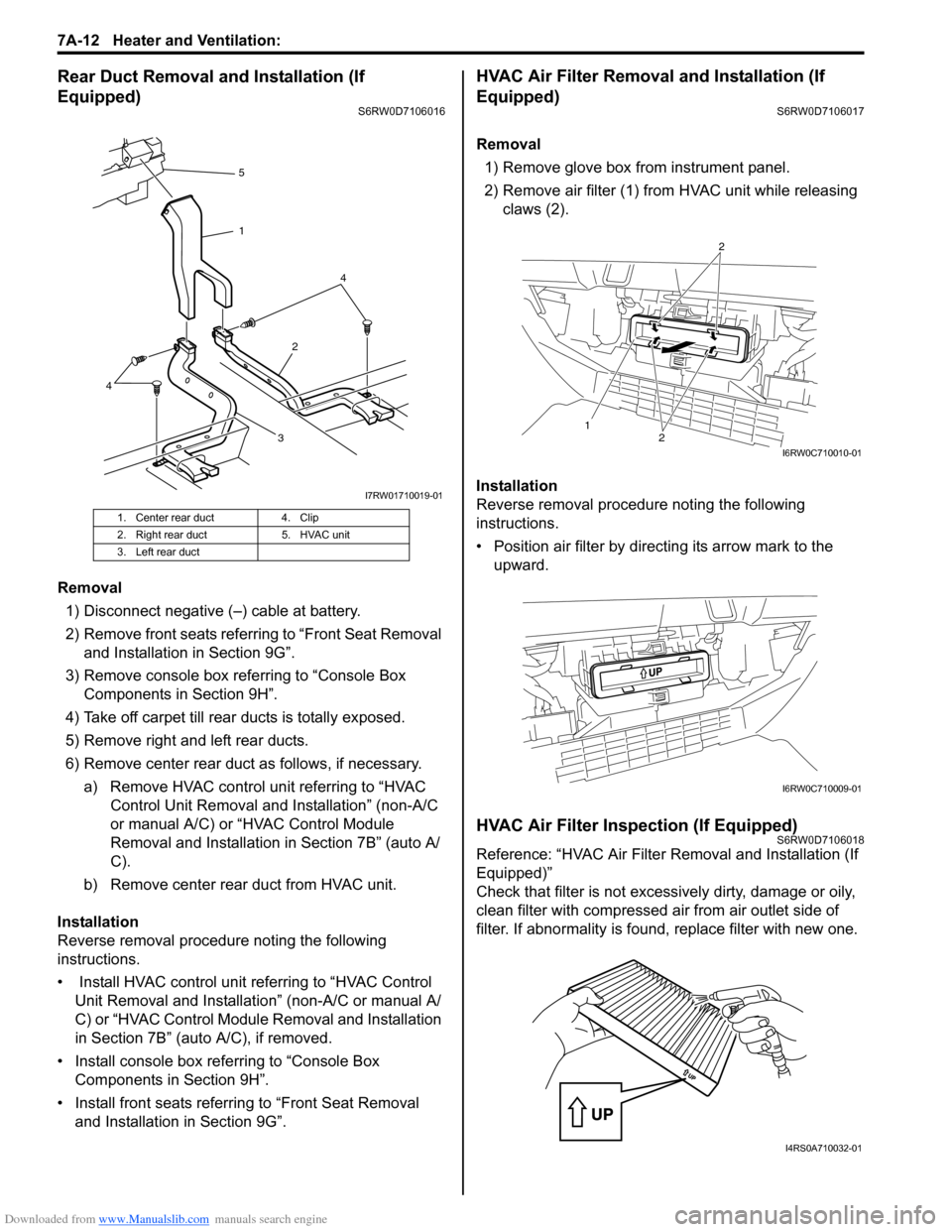

Rear Duct Removal and Installation (If

Equipped)

S6RW0D7106016

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front seats referring to “Front Seat Removal

and Installation in Section 9G”.

3) Remove console box referring to “Console Box

Components in Section 9H”.

4) Take off carpet till rear ducts is totally exposed.

5) Remove right and left rear ducts.

6) Remove center rear duct as follows, if necessary.

a) Remove HVAC control unit referring to “HVAC

Control Unit Removal and Installation” (non-A/C

or manual A/C) or “HVAC Control Module

Removal and Installation in Section 7B” (auto A/

C).

b) Remove center rear duct from HVAC unit.

Installation

Reverse removal procedure noting the following

instructions.

• Install HVAC control unit referring to “HVAC Control

Unit Removal and Installation” (non-A/C or manual A/

C) or “HVAC Control Module Removal and Installation

in Section 7B” (auto A/C), if removed.

• Install console box referring to “Console Box

Components in Section 9H”.

• Install front seats referring to “Front Seat Removal

and Installation in Section 9G”.

HVAC Air Filter Removal and Installation (If

Equipped)

S6RW0D7106017

Removal

1) Remove glove box from instrument panel.

2) Remove air filter (1) from HVAC unit while releasing

claws (2).

Installation

Reverse removal procedure noting the following

instructions.

• Position air filter by directing its arrow mark to the

upward.

HVAC Air Filter Inspection (If Equipped)S6RW0D7106018

Reference: “HVAC Air Filter Removal and Installation (If

Equipped)”

Check that filter is not excessively dirty, damage or oily,

clean filter with compressed air from air outlet side of

filter. If abnormality is found, replace filter with new one.

1. Center rear duct 4. Clip

2. Right rear duct 5. HVAC unit

3. Left rear duct

324 5

1

4

I7RW01710019-01

12

2

I6RW0C710010-01

I6RW0C710009-01

I4RS0A710032-01

Page 941 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-1

HVAC

Air Conditioning System

Manual Type

Precautions

A/C System CautionS6RW0D7210001

CAUTION!

The A/C system of this vehicle uses HFC-134a (R-134a) refrigerant, specified compressor oil and

specified parts.

Do not use CFC-12 (R-12) refrigerant, R-12 exclusive use compressor oil and R-12 exclusive parts in

this A/C system, do not attempt to use R-12 servicing equipment. Otherwise, use of it will result in

leakage of refrigerant, damage or other faulty condition of A/C system and damage or other faulty

condition of servicing equipment.

When replenishing or changing refrigerant and compressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

Precautions on Servicing A/C SystemS6RW0D7210002

WARNING!

Should refrigerant HFC-134a (R-134a) is exposed to your eye(s), consult a doctor immediately.

• Do not reuse your hand to rub affected eye(s). Instead, use fresh cold water to splash it over

affected area to thus gradually raise its temperature above the freezing point.

• Obtain proper treatment as soon as possible from a doctor or eye specialist. Should liquid

refrigerant HFC-134a (R-134a) is exposed to your skin, such affected part should be treated in the

same manner as when skin is frostbitten or frozen.

Handling Refrigerant HFC-134a (R-134a)

• Always wear goggles to protect your eyes.

• Avoid direct contact to liquid refrigerant.

• Do not heat refrigerant container higher than 40 °C (104 °F).

• Do not discharge refrigerant into atmosphere.

• Do not expose bright metals to liquid refrigerant. Refrigerant combined with moisture is corrosive and tarnishes

surfaces of bright metals including chrome.

• Never use heat for bending pipes. When bending a pipe, try to make its bending angle as smooth as possible.

• Keep internal parts of air conditioning free from moisture and dirt. When disconnecting any line from system, install

a blind plug or cap to the fitting immediately.

• When handling recovery and recycling equipment, be sure to follow the instruction manual for the equipment.

• Check local governmental regulations regarding working with refrigerator systems and its tooling.

• When connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to O-ring.

• Replace O-ring with new one once hoses, pipes and parts disconnected.

• When tightening or loosening a fitting, use two wrenches, one for turning and the other for support.

• Route drain hose so that drained water does not make any contact to vehicle components.

• If pipes or hoses are replaced, replenish specified amount of compressor oil to compressor suction side referring to

“Replenishing Compressor Oil” in “Operation Procedure for Refrigerant Charge”.

Page 943 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-3

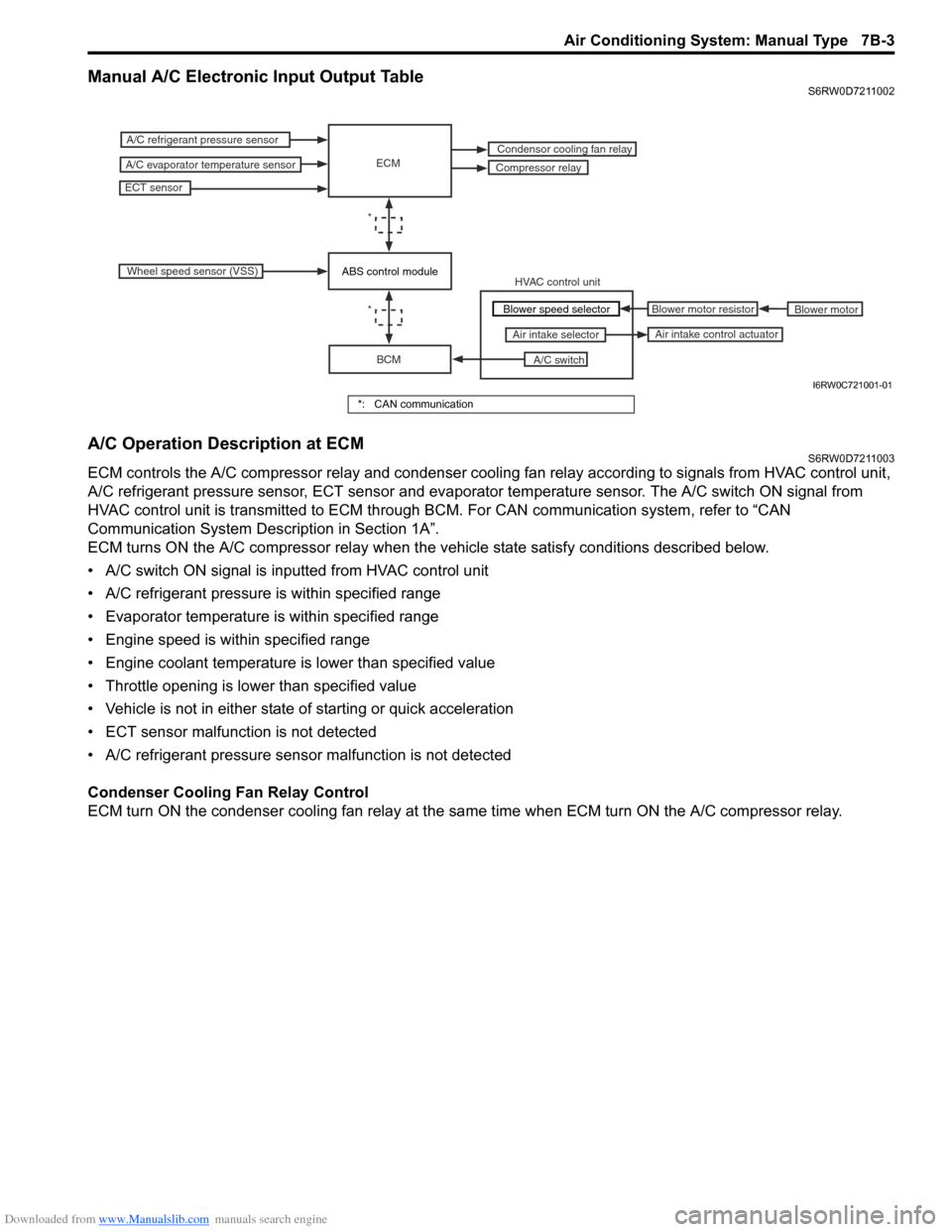

Manual A/C Electronic Input Output TableS6RW0D7211002

A/C Operation Description at ECMS6RW0D7211003

ECM controls the A/C compressor relay and condenser cooling fan relay according to signals from HVAC control unit,

A/C refrigerant pressure sensor, ECT sensor and evaporator temperature sensor. The A/C switch ON signal from

HVAC control unit is transmitted to ECM through BCM. For CAN communication system, refer to “CAN

Communication System Description in Section 1A”.

ECM turns ON the A/C compressor relay when the vehicle state satisfy conditions described below.

• A/C switch ON signal is inputted from HVAC control unit

• A/C refrigerant pressure is within specified range

• Evaporator temperature is within specified range

• Engine speed is within specified range

• Engine coolant temperature is lower than specified value

• Throttle opening is lower than specified value

• Vehicle is not in either state of starting or quick acceleration

• ECT sensor malfunction is not detected

• A/C refrigerant pressure sensor malfunction is not detected

Condenser Cooling Fan Relay Control

ECM turn ON the condenser cooling fan relay at the same time when ECM turn ON the A/C compressor relay.

ECM

BCM

A/C switch Air intake selector

A/C refrigerant pressure sensor

A/C evaporator temperature sensorCompressor relay

ECT sensor

Condensor cooling fan relay

*

Wheel speed sensor (VSS)

HVAC control unit

Blower motor Blower motor resistor

Air intake control actuator

*Blower speed selector

ABS control module

I6RW0C721001-01

*: CAN communication

Page 944 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-4 Air Conditioning System: Manual Type

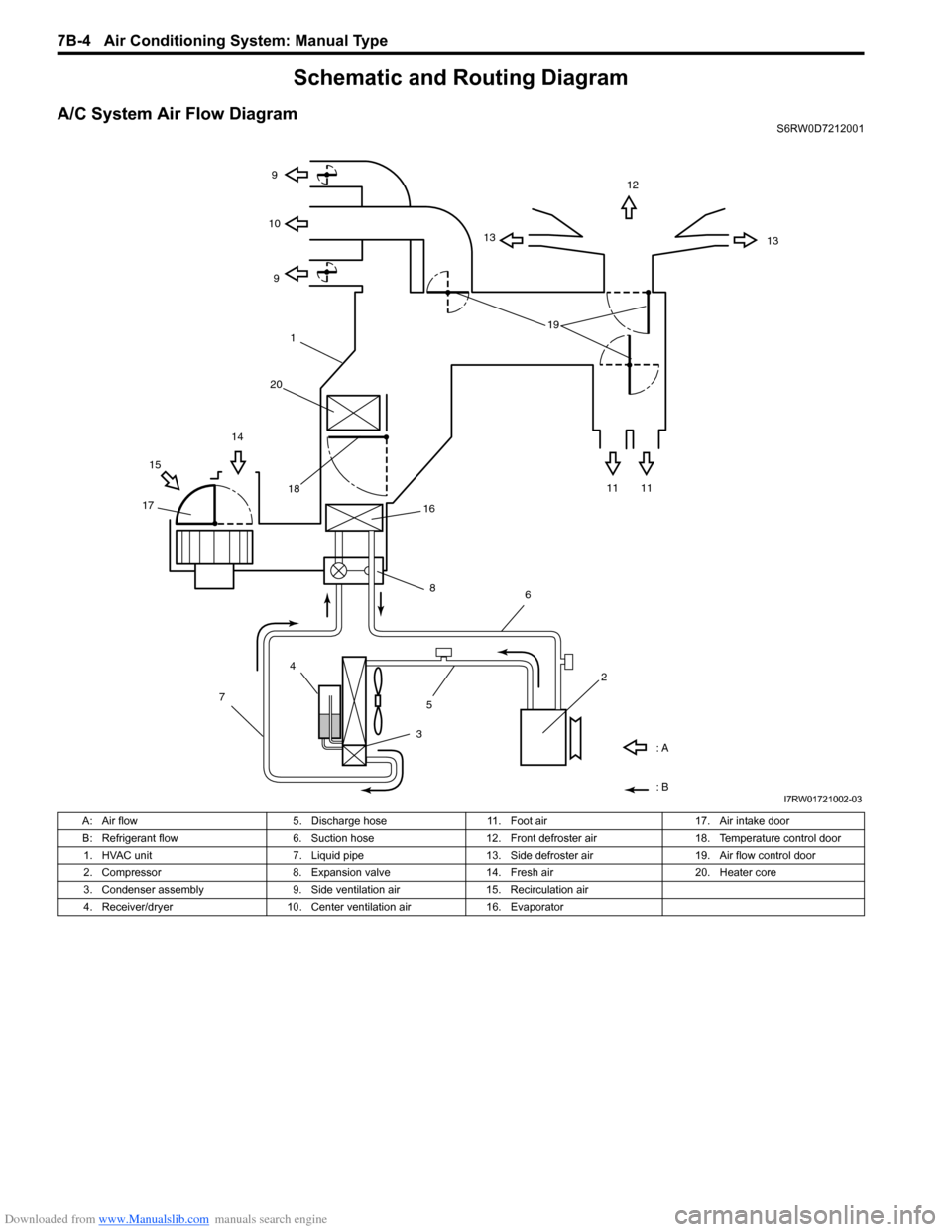

Schematic and Routing Diagram

A/C System Air Flow DiagramS6RW0D7212001

1312

13 9

9 10

11 11 1514

1718

: A

: B

4

7

356

2 16

8

191

20

I7RW01721002-03

A: Air flow 5. Discharge hose 11. Foot air 17. Air intake door

B: Refrigerant flow 6. Suction hose 12. Front defroster air 18. Temperature control door

1. HVAC unit 7. Liquid pipe 13. Side defroster air 19. Air flow control door

2. Compressor 8. Expansion valve 14. Fresh air 20. Heater core

3. Condenser assembly 9. Side ventilation air 15. Recirculation air

4. Receiver/dryer 10. Center ventilation air 16. Evaporator