transmission TOYOTA CAMRY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1999, Model line: CAMRY, Model: TOYOTA CAMRY 1999Pages: 4592, PDF Size: 55.16 MB

Page 3954 of 4592

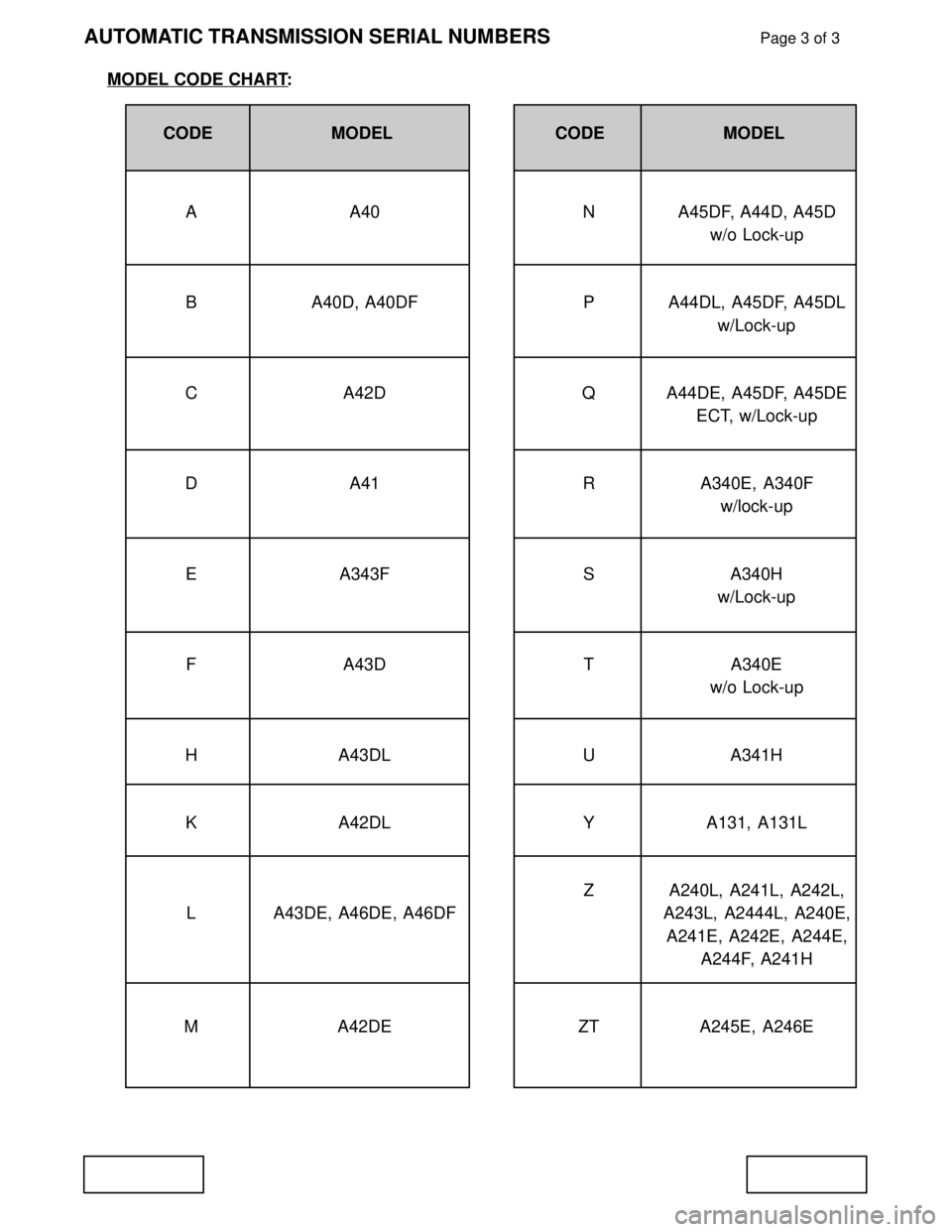

AUTOMATIC TRANSMISSION SERIAL NUMBERSPage 3 of 3

MODEL CODE CHART:

CODE MODEL CODE MODEL

A A40 N A45DF, A44D, A45D

w/o Lock-up

B A40D, A40DF P A44DL, A45DF, A45DL

w/Lock-up

C A42D Q A44DE, A45DF, A45DE

ECT, w/Lock-up

D A41 R A340E, A340F

w/lock-up

E A343F S A340H

w/Lock-up

F A43D T A340E

w/o Lock-up

H A43DL U A341H

K A42DL Y A131, A131L

Z A240L, A241L, A242L,

L A43DE, A46DE, A46DF A243L, A2444L, A240E,

A241E, A242E, A244E,

A244F, A241H

M A42DE ZT A245E, A246E

Page 3955 of 4592

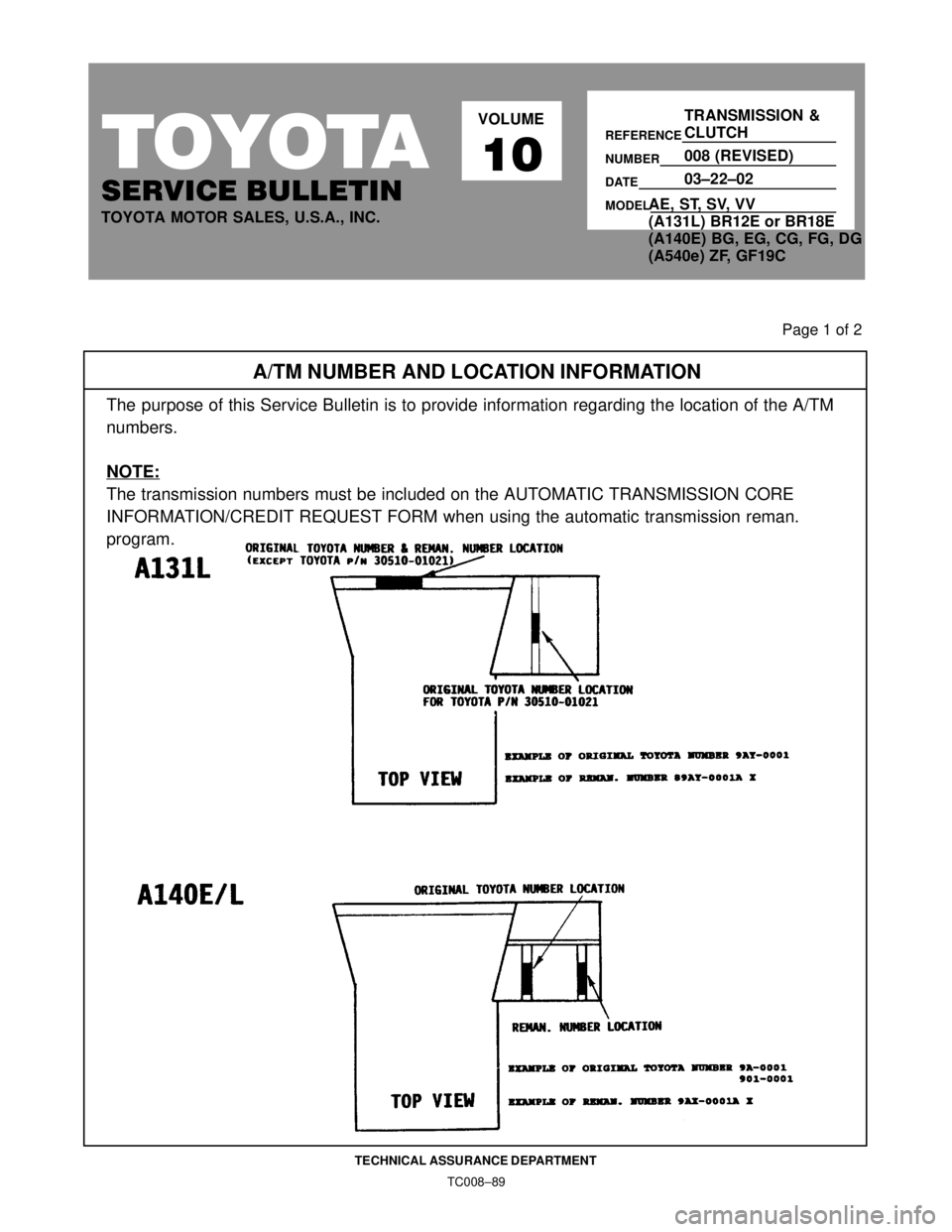

TC008±89 TECHNICAL ASSURANCE DEPARTMENT

TOYOTA

SERVICE BULLETIN

TOYOTA MOTOR SALES, U.S.A., INC.VOLUME

10

REFERENCE

NUMBER

DATE

MODEL

TRANSMISSION &

CLUTCH

008 (REVISED)

03±22±02

Page 1 of 2

A/TM NUMBER AND LOCATION INFORMATION

The purpose of this Service Bulletin is to provide information regarding the location of the A/TM

numbers.

NOTE:

The transmission numbers must be included on the AUTOMATIC TRANSMISSION CORE

INFORMATION/CREDIT REQUEST FORM when using the automatic transmission reman.

program.

AE, ST, SV, VV

(A131L) BR12E or BR18E

(A140E) BG, EG, CG, FG, DG

(A540e) ZF, GF19C

Page 4018 of 4592

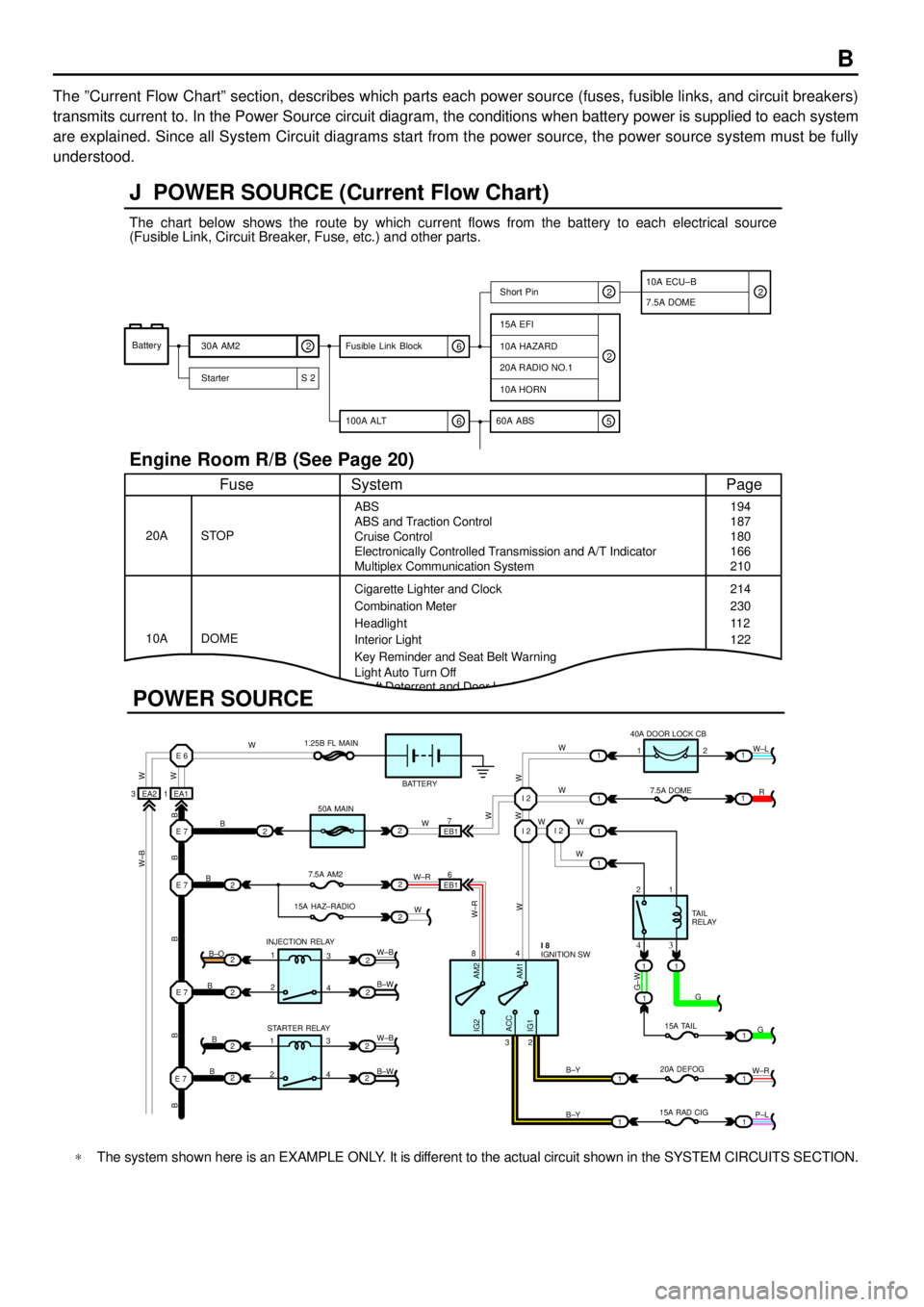

B

The ºCurrent Flow Chartº section, describes which parts each power source (fuses, fusible links, and circuit breakers)

transmits current to. In the Power Source circuit diagram, the conditions when battery power is supplied to each system

are explained. Since all System Circuit diagrams start from the power source, the power source system must be fully

understood.

Theft Deterrent and Door Lock Control

J POWER SOURCE (Current Flow Chart)

11

1

EA1 1EA2 3

7

EB16

E 6

E 7I 2I 2

I 2

E 7

E 7

E 7

2

1

1

2

2

2

2

2

B

B

W W

B B B B BW±B

B

B

B B±O

B±W

W±B

B±W STARTER RELAY INJECTION RELAY15A HAZ±RADIO7.5A AM250A MAIN 1.25B FL MAIN

BATTERY

WWW

W W W

R W±L

W

W

G±W

G

15A TAIL

20A DEFOG

15A RAD CIGTA I L

RELAY 7.5A DOME 40A DOOR LOCK CB

2 1

1 2

4 8

2 3

3 4

G

W±R

P±L B±Y

B±Y

W±R

AM2 IG2

ACC

IG1AM1W W

W±R

W W

W±B

21

1

1

1

1

2

2

2

2

3

4

3

4 1

2

1

22

1

11

1

IGNITION SW I 8

Battery

30A AM2

2

Starter S 220A RADIO NO.1

10A HORN

15A EFI

7.5A DOMEShort Pin

10A HAZARD

The chart below shows the route by which current flows from the battery to each electrical source

(Fusible Link, Circuit Breaker, Fuse, etc.) and other parts.

Engine Room R/B (See Page 20)

ABS

ABS and Traction Control

Cruise Control

Electronically Controlled Transmission and A/T Indicator

Multiplex Communication System

Cigarette Lighter and Clock

Key Reminder and Seat Belt Warning STOP

Fuse Page

194

214

11 2

System

DOME 20A

10ACombination Meter

Headlight

Interior Light

2

2

6 100A ALT

EB1

POWER SOURCE

Light Auto Turn Off187

180

166

210

230

122

10A ECU±B

5 60A ABS

2

6 Fusible Link Block2

*The system shown here is an EXAMPLE ONLY. It is different to the actual circuit shown in the SYSTEM CIRCUITS SECTION.

Page 4037 of 4592

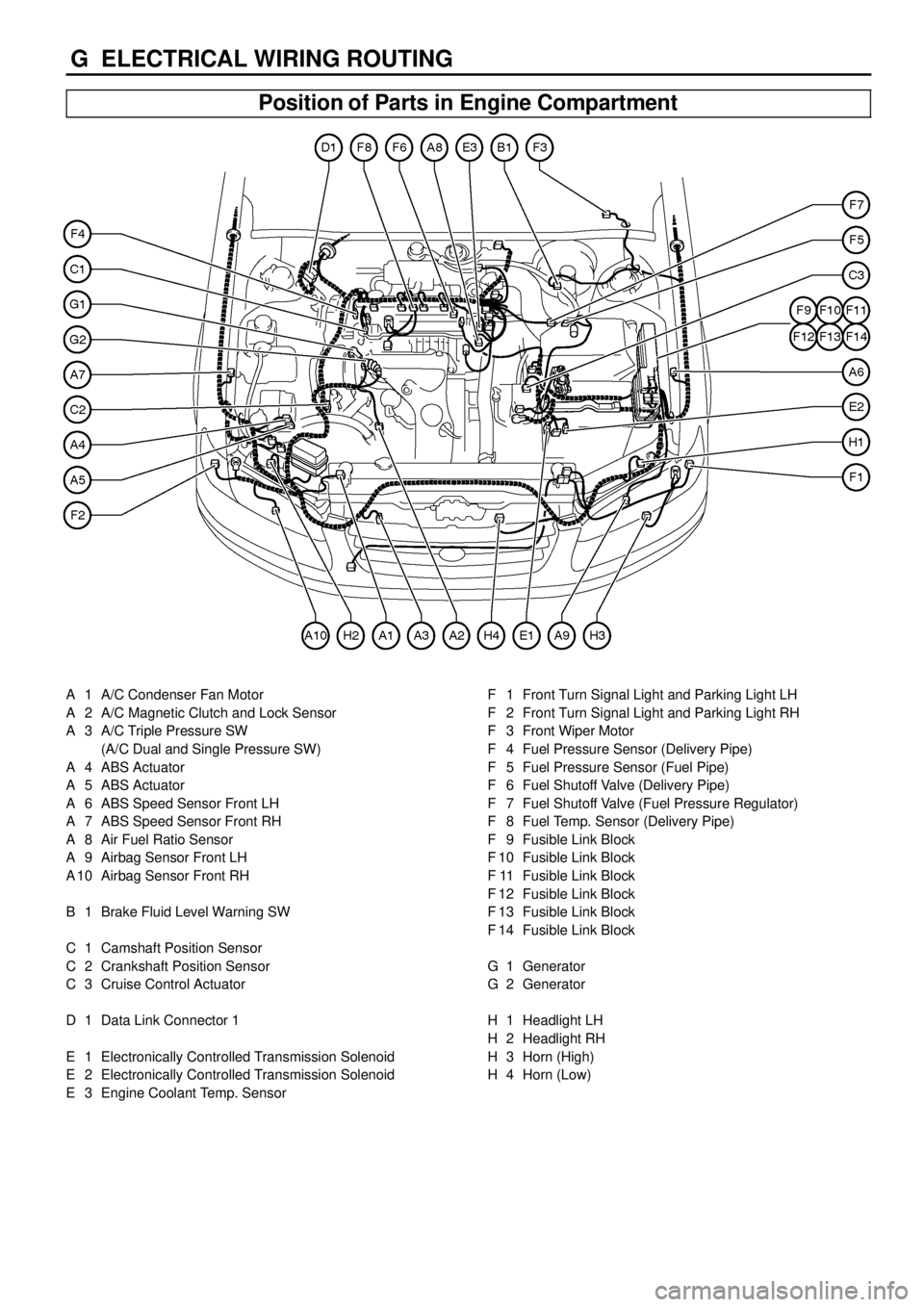

G ELECTRICAL WIRING ROUTING

Position of Parts in Engine Compartment

A 1 A/C Condenser Fan Motor

A 2 A/C Magnetic Clutch and Lock Sensor

A 3 A/C Triple Pressure SW

(A/C Dual and Single Pressure SW)

A 4 ABS Actuator

A 5 ABS Actuator

A 6 ABS Speed Sensor Front LH

A 7 ABS Speed Sensor Front RH

A 8 Air Fuel Ratio Sensor

A 9 Airbag Sensor Front LH

A 10 Airbag Sensor Front RH

B 1 Brake Fluid Level Warning SW

C 1 Camshaft Position Sensor

C 2 Crankshaft Position Sensor

C 3 Cruise Control Actuator

D 1 Data Link Connector 1

E 1 Electronically Controlled Transmission Solenoid

E 2 Electronically Controlled Transmission Solenoid

E 3 Engine Coolant Temp. SensorF 1 Front Turn Signal Light and Parking Light LH

F 2 Front Turn Signal Light and Parking Light RH

F 3 Front Wiper Motor

F 4 Fuel Pressure Sensor (Delivery Pipe)

F 5 Fuel Pressure Sensor (Fuel Pipe)

F 6 Fuel Shutoff Valve (Delivery Pipe)

F 7 Fuel Shutoff Valve (Fuel Pressure Regulator)

F 8 Fuel Temp. Sensor (Delivery Pipe)

F 9 Fusible Link Block

F 10 Fusible Link Block

F 11 Fusible Link Block

F 12 Fusible Link Block

F 13 Fusible Link Block

F 14 Fusible Link Block

G 1 Generator

G 2 Generator

H 1 Headlight LH

H 2 Headlight RH

H 3 Horn (High)

H 4 Horn (Low)

Page 4068 of 4592

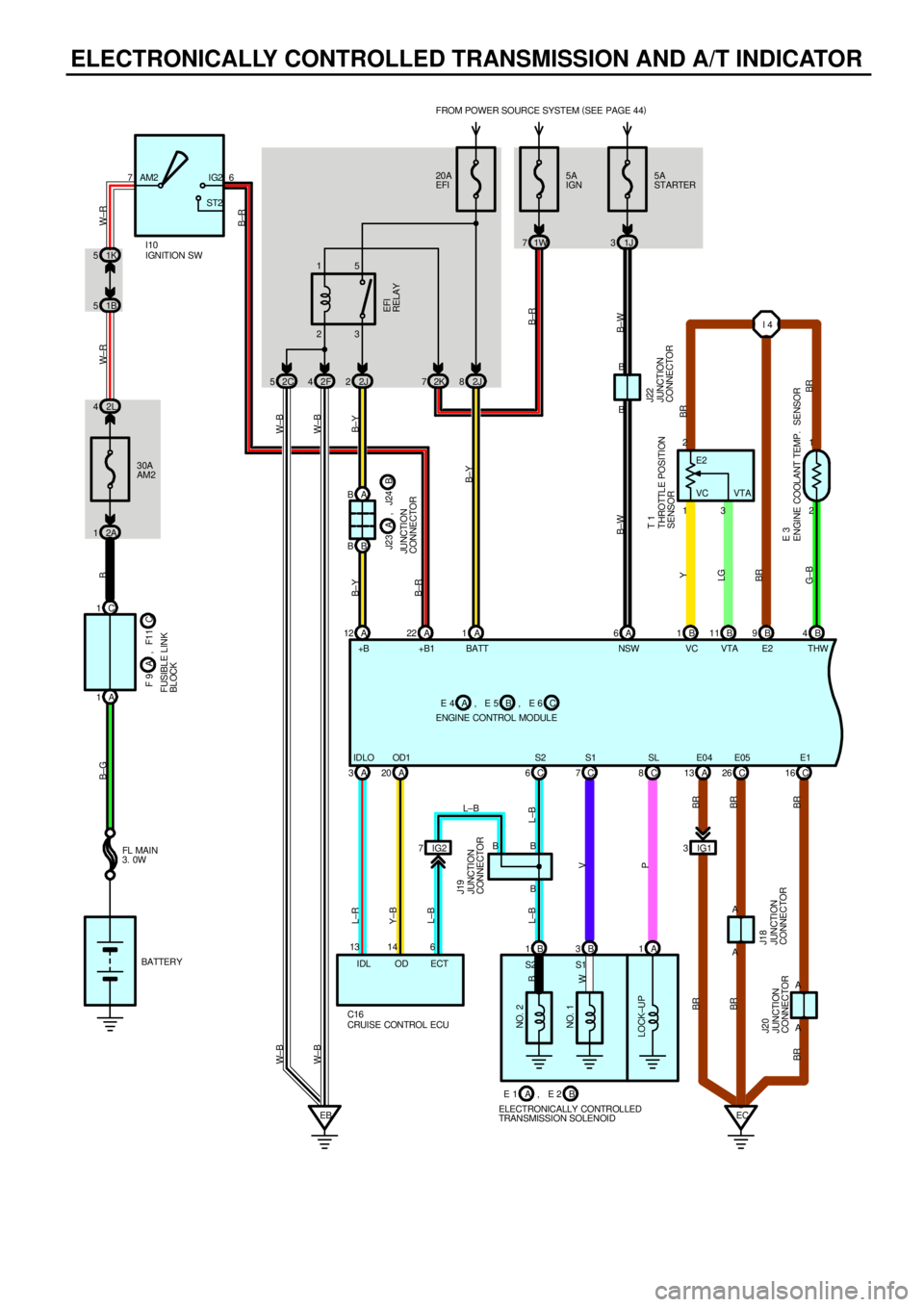

This system utilizes an engine control module and maintains overall control of the engine, transmission and so on. An outline

of the engine control is explained here.

1. INPUT SIGNALS

(1) Engine coolant temp. signal circuit

The engine coolant temp. sensor detects the engine coolant temp. and has a built±in thermistor with a resistance which

varies according to the engine coolant temp. thus the engine coolant temp. is input in the form of a control signal into

TERMINAL THW of the engine control module.

(2) Intake air temp. signal circuit

The intake air temp. sensor detects the intake air temp. , which is input as a control signal into TERMINAL THA of the

engine control module.

(3) Oxygen sensor signal circuit

The oxygen density in the exhaust gases is detected and input as a control signal into TERMINAL OX2 of the engine

control module.

(4) RPM signal circuit

Camshaft position and crankshaft position are detected by the camshaft position sensor and crankshaft position sensor.

Camshaft position is input as a control signal to TERMINAL G of the engine control module, and engine RPM is input

into TERMINAL NE.

(5) Throttle signal circuit

The throttle position sensor detects the throttle valve opening angle, which is input as a control signal into TERMINAL

VTA of the engine control module.

(6) Vehicle speed signal circuit

The vehicle speed sensor, installed inside the transmission, detects the vehicle speed and inputs a control signal into

TERMINAL SPD of the engine control module.

(7) Park/Neutral position SW signal circuit

The Park/Neutral position SW detects whether the shift position are in neutral, parking or not, and inputs a control signal

into TERMINAL STA of the engine control module.

(8) A/C SW signal circuit

The A/C amplifier is built in the engine control module. The signal from the A/C SW is input into TERMINAL A/CS of the

engine control module.

(9) Battery signal circuit

Voltage is constantly applied to TERMINAL BATT of the engine control module. When the ignition SW is turned on, the

voltage for engine control module start±up power supply is applied to TERMINAL +B of engine control module via EFI

relay.

(10) Intake air volume signal circuit

Intake air volume is detected by the manifold absolute pressure sensor (for manifold pressure) and is input as a control

signal into TERMINAL PIM of the engine control module.

(11) Starter signal circuit

To confirm whether the engine is cranking, the voltage applied to the starter motor during cranking is detected and the

signal is input into TERMINAL NSW of the engine control module as a control signal.

(12) Electrical load signal circuit

The signal when systems such as the rear window defogger, headlights, etc. Which cause a high electrical burden are

on is input to TERMINAL ELS as a control signal.

(13) Air fuel ratio signal circuit

The air fuel ratio is detected and input as a control signal into TERMINAL AF+ of the engine control module.

SYSTEM OUTLINE

Page 4109 of 4592

ELECTRONICALLY CONTROLLED TRANSMISSION AND A/T INDICATOR

72K

NO. 2

LOCK±UPNO. 1

B E 1

ELECTRONICALLY CONTROLLED

TRANSMISSION SOLENOIDAB 20A

EFI FROM POWER SOURCE SYSTEM (

SEE PAGE 44)

2J 8 3 15

2F 42J2

1 2

2 1

A 1B1B11 B4 B 9

C 6C7C8C16 A B

B B

EBEC B

A B3

A

B±YB±Y W±B W± B

BR

BR G±BLGY

BR L±B L±B

V

P

BR BREFI

RELAY

E 2

THROTTLE POSITION

SENSOR

ENGINE COOLANT TEMP. SENSORT 1

E 3 B

W

S2 S1 IG2 7 A 3A20

CRUISE CONTROL ECU C166 13 14

L±B L±R

Y±B

ECT IDL ODB ENGINE CONTROL MODULEB AC A 12

B±Y

B±R

JUNCTION

CONNECTOR J20JUNCTION

CONNECTOR J19

L±B5A

IGN

1W 7

1A 3B 1B

, E 4 , E 5 , E 6

J23

JUNCTION

CONNECTORB A, J24

A 65A

STARTER

1J 3

B±W B±W

JUNCTION

CONNECTOR J22

C 26

BR

B 2C 5

W±B

VC E2

VTA

+B BATT NSW VC VTA E2 THW

IDLO OD1 S2 S1 SL E05 E1

A 13

IG1 3

A A

JUNCTION

CONNECTOR J18 BRBR BR

2L 4

2A 1

B±G B

IGNITION SW

30A

AM2

BATTERY FL MAIN

3. 0WI10 7AM2 IG2

ST2

1B 51K 5

W± R W±R

C 1

A 1

F 9

FUSIBLE LINK

BLOCKC A, F11

A 22

B±R

6

W± B

2

B±R

+B1

E04I 4

Page 4111 of 4592

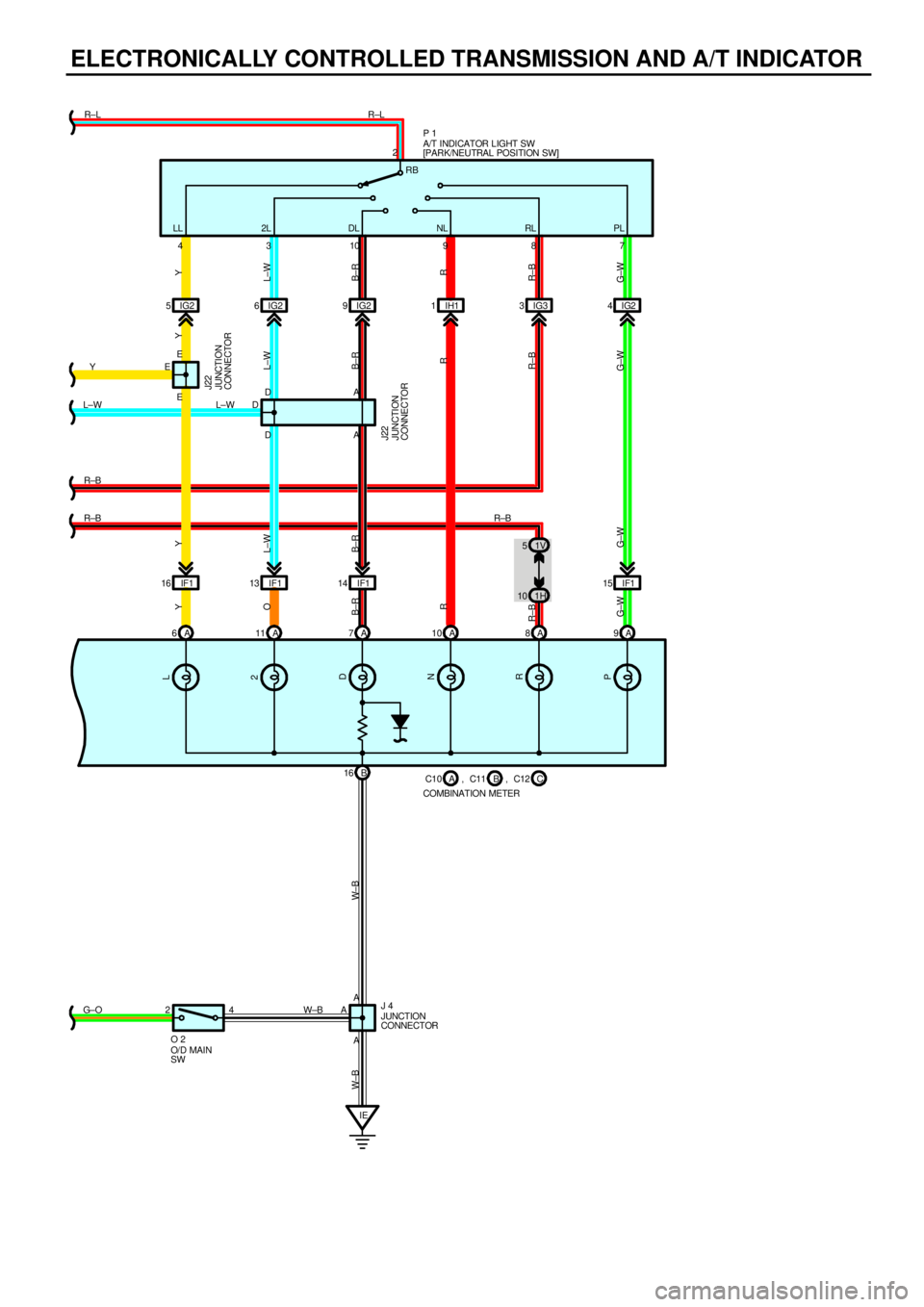

ELECTRONICALLY CONTROLLED TRANSMISSION AND A/T INDICATOR

A 6A11 A7A10 A8A9

B 16

IE IG2 5IG26IG29IH11IG33IG24

IF1 16 IF113 IF114 IF115 LL 2L DL NL RL PL

43109872

1V 5

1H 10 EE

DDA

AA E

DA

A L±WR±L

W±B

Y

O

B±R

R

R±B

G±WY

L±W

B±RY

L±W

B±R

R

R±B

G±W W± B W±B

COMBINATION METERB C10 C11ACC12

JUNCTION

CONNECTOR J 4A/T INDICATOR LIGHT SW

[PARK/NEUTRAL POSITION SW] P 1

JUNCTION

CONNECTOR J22JUNCTION

CONNECTOR J22 L

2

D

N

R

PY

L±W

B±R

R

R±B

G±W

G± OR±B R±B L±WY R±L

G±W

4 2

O/ D MAI N

SW O 2, , R±B RB

Page 4112 of 4592

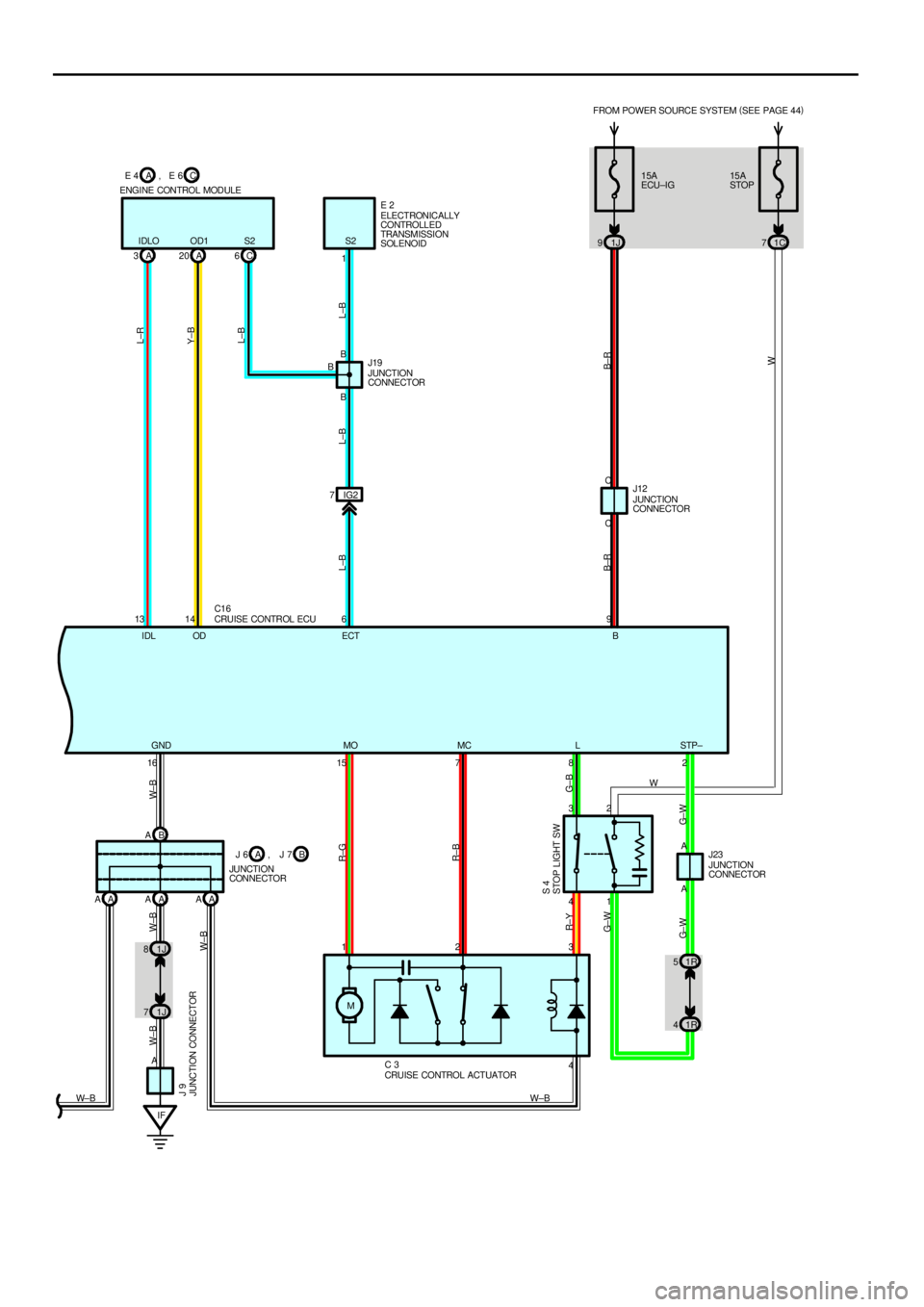

The electronically controlled transmission, however, electrically controls the line pressure and lock±up pressure etc., through

the solenoid valve. Engine control module controls of the solenoid valve based on the input signals from each sensor which

makes smooth driving possible by shift selection for each gear which is most appropriate to the driving conditions at that

time.

1. GEAR SHIFT OPERATION

During driving, the engine control module selects the shift for each gear which is most appropriate to the driving conditions,

based on input signals from the engine coolant temp. sensor to TERMINAL THW of the engine control module, and also the

input signals to TERMINAL SPD of the engine control module from the vehicle speed sensor devoted to the electronically

controlled transmission. Current is then output to the electronically controlled transmission solenoid. When shifting to 1st

gear, current flows from TERMINAL S1 of the engine control module to TERMINAL (B) 3 of the solenoid to GROUND, and

continuity to the No.1 solenoid causes the shift.

For 2nd gear, current flows from TERMINAL S1 of the engine control module to TERMINAL (B) 3 of the solenoid to

GROUND, and from TERMINAL S2 of the engine control module to TERMINAL (B) 1 of the solenoid to GROUND, and

continuity to solenoids No.1 and No.2 causes the shift.

For 3rd gear, there is no continuity to No.1 solenoid, only to No.2, causing the shift.

Shifting into 4th gear (Overdrive) takes place when there is no continuity to either No.1 or No.2 solenoid.

2. LOCK±UP OPERATION

When the engine control module judges from each signal that lock±up operation conditions have been met, current flows

from TERMINAL SL of the engine control module to TERMINAL (A) 1 of the electronically controlled transmission solenoid to

GROUND, causing continuity to the lock±up solenoid and causing lock±up operation.

3. STOP LIGHT SW CIRCUIT

If the brake pedal is depressed (Stop light SW on) when driving in lock±up condition, a signal is input to TERMINAL STP of

the engine control module, the engine control module operates and continuity to the lock±up solenoid is cut.

4. OVERDRIVE CIRCUIT

*O/D main SW on

When the O/D main SW is turned on (O/D off indicator light turns off), a signal is input into TERMINAL OD2 of the engine

control module and engine control module operation causes gear shift when the conditions for overdrive are met.

*O/D main SW off

When the O/D main SW is turned to off, the current through the O/D off indicator light flows through the O/D main SW to

GROUND, causing the indicator light to light up. At the same time, a signal is input into TERMINAL OD2 of the engine

control module and engine control module operation prevents shift into overdrive.

E4 (A), E5 (B), E6 (C) ENGINE CONTROL MODULE

S1, S2±E1 :9.0±14.0 volts with the solenoid on

0±1.5 volts with the solenoid off

L±E1 :7.5±14.0 volts with the shift lever at L position

2±E1 :7.5±14.0 volts with the shift lever at 2 position

R±E1 :7.5±14.0 volts with the shift lever at R position

STP±E1 :9.0±14.0 volts with the brake pedal depressed

THW±E2 :0.2±1.0 volts with the ignition SW on and coolant temp. 80°C (176°F)

VTA±E2 :0.3±0.8 volts with the throttle valve fully closed

3.2±4.9 volts with the throttle valve fully opened

VC±E2 :4.5±5.5 volts

OD2±E1 :9.0±14.0 volts with the O/D main SW turned on

0±3.0 volts with the O/D main SW turned off

+B±E1 :9.0±14.0 volts

O2 O/D MAIN SW

2±4 : Closed with the O/D main SW off, open with the O/D main SW on

SYSTEM OUTLINE

SERVICE HINTS

Page 4113 of 4592

ELECTRONICALLY CONTROLLED TRANSMISSION AND A/T INDICATOR

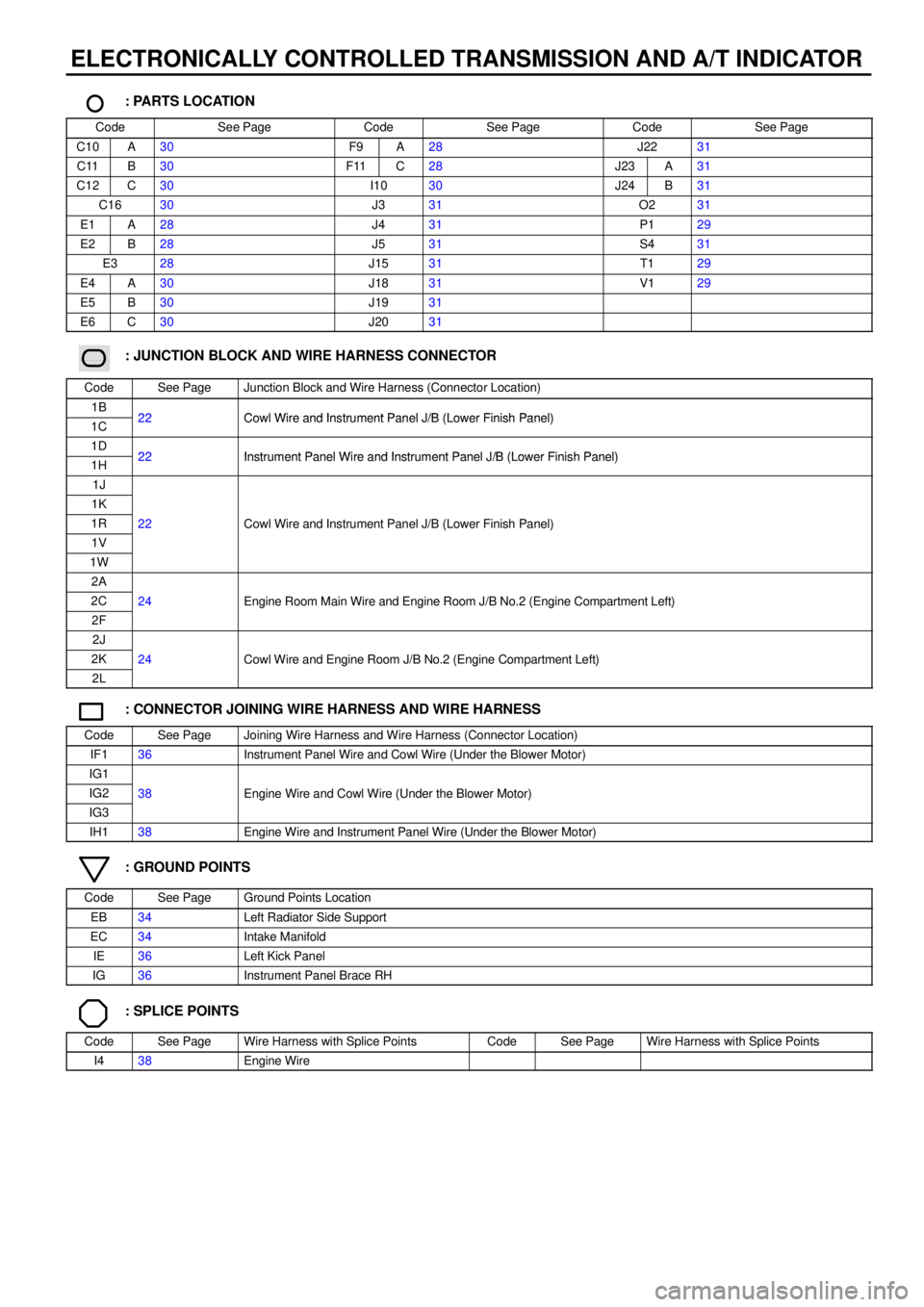

: PARTS LOCATION

CodeSee PageCodeSee PageCodeSee Page

C10A30F9A28J2231

C11B30F11C28J23A31

C12C30I1030J24B31

C1630J331O231

E1A28J431P129

E2B28J531S431

E328J1531T129

E4A30J1831V129

E5B30J1931

E6C30J2031

������ ���: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CodeSee PageJunction Block and Wire Harness (Connector Location)

1B22Cowl Wire and Instrument Panel J/B (Lower Finish Panel)1C22Cowl Wire and Instrument Panel J/B (Lower Finish Panel)

1D22Instrument Panel Wire and Instrument Panel J/B (Lower Finish Panel)1H22Instrument Panel Wire and Instrument Panel J/B (Lower Finish Panel)

1J

1K

1R22Cowl Wire and Instrument Panel J/B (Lower Finish Panel)

1V

()

1W

2A

2C24Engine Room Main Wire and Engine Room J/B No.2 (Engine Compartment Left)

2F

gg(g)

2J

2K24Cowl Wire and Engine Room J/B No.2 (Engine Compartment Left)

2L

g(g )

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CodeSee PageJoining Wire Harness and Wire Harness (Connector Location)

IF136Instrument Panel Wire and Cowl Wire (Under the Blower Motor)

IG1

IG238Engine Wire and Cowl Wire (Under the Blower Motor)

IG3

g()

IH138Engine Wire and Instrument Panel Wire (Under the Blower Motor)

: GROUND POINTS

CodeSee PageGround Points Location

EB34Left Radiator Side Support

EC34Intake Manifold

IE36Left Kick Panel

IG36Instrument Panel Brace RH

: SPLICE POINTS

CodeSee PageWire Harness with Splice PointsCodeSee PageWire Harness with Splice Points

I438Engine Wire

Page 4116 of 4592

15A

ECU±IG

1J 9

C 6 A 20 A 315A

STOP FROM POWER SOURCE SYSTEM (

SEE PAGE 44)

1C 7

A AAAAA B A

IF1R 5

1R 4 16 15 8 2

41

4 B

C

12332

ABB

C

W± BGND IDLO OD1 S2

7 13 14 6 9

L±B L±B Y±BL±R

L±B

B±RL±B

B±R

W W± B

R±G

R±B

G±B R±Y W±B

G± W

W

W±B JUNCTION

CONNECTOR J19

JUNCTION

CONNECTOR J12

STOP LIGHT SW S 4

ENGINE CONTROL MODULE

JUNCTION

CONNECTOR

CRUISE CONTROL ACTUATOR C 3

G± W G± W

CRUISE CONTROL ECU

C16

1J 8

1J 7

W±B W±B

M

JUNCTION CONNECTOR J 9

IG2 7S2

B J 6 A , J 7 E 4 CA, E 6

1

IDL OD ECT B

MO MC L STP±

A A

JUNCTION

CONNECTOR J23 ELECTRONICALLY

CONTROLLED

TRANSMISSION

SOLENOID E 2