light TOYOTA CAMRY 1999 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1999, Model line: CAMRY, Model: TOYOTA CAMRY 1999Pages: 4592, PDF Size: 55.16 MB

Page 159 of 4592

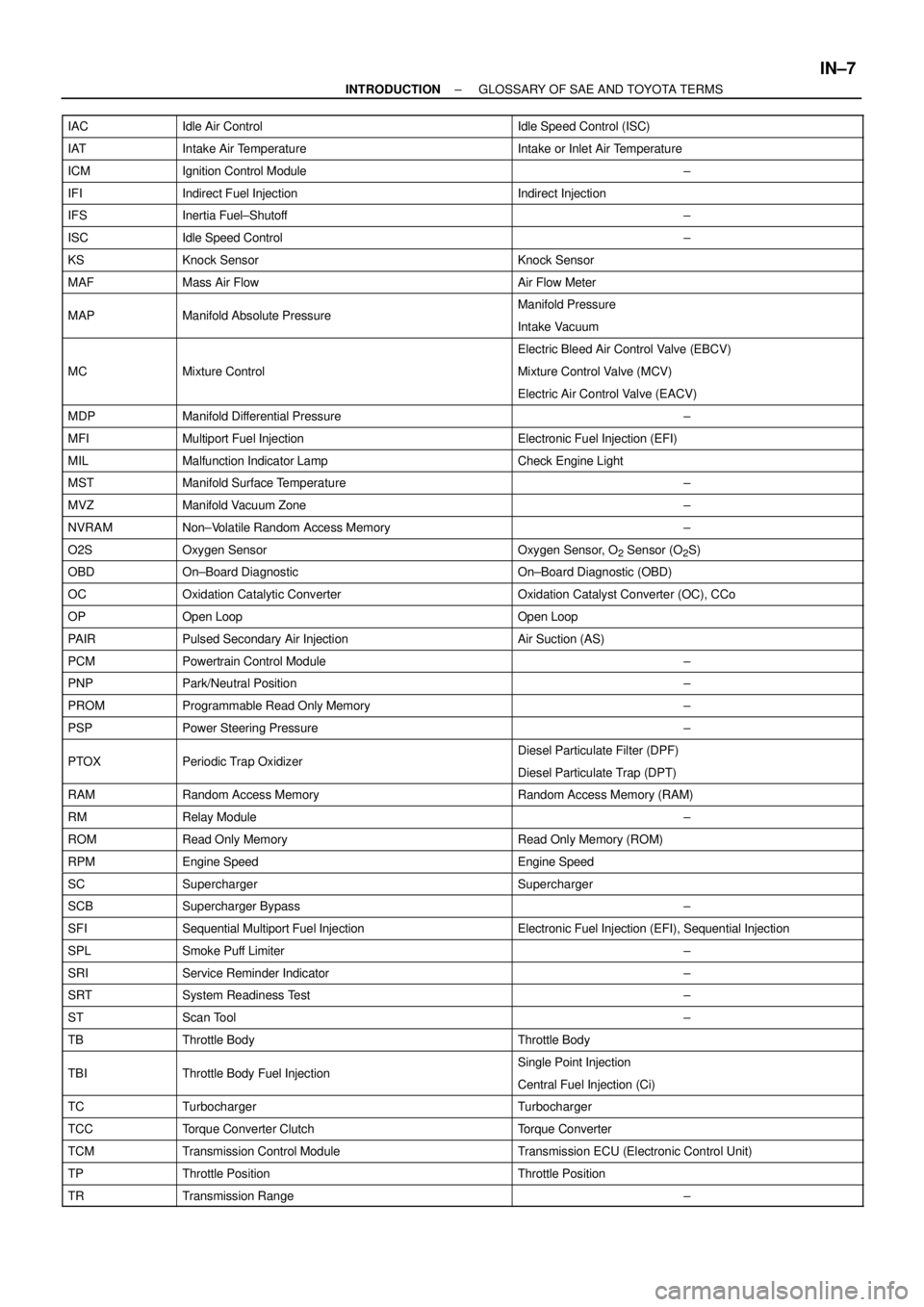

INTRODUCTIONGLOSSARY OF SAE AND TOYOTA TERMS ±

IN±7

IACIdle Air ControlIdle Speed Control (ISC)

IATIntake Air TemperatureIntake or Inlet Air Temperature

ICMIgnition Control Module±

IFIIndirect Fuel InjectionIndirect Injection

IFSInertia Fuel±Shutoff±

ISCIdle Speed Control±

KSKnock SensorKnock Sensor

MAFMass Air FlowAir Flow Meter

MAPManifold Absolute PressureManifold Pressure

Intake Vacuum

MCMixture Control

Electric Bleed Air Control Valve (EBCV)

Mixture Control Valve (MCV)

Electric Air Control Valve (EACV)

MDPManifold Differential Pressure±

MFIMultiport Fuel InjectionElectronic Fuel Injection (EFI)

MILMalfunction Indicator LampCheck Engine Light

MSTManifold Surface Temperature±

MVZManifold Vacuum Zone±

NVRAMNon±Volatile Random Access Memory±

O2SOxygen SensorOxygen Sensor, O2 Sensor (O2S)

OBDOn±Board DiagnosticOn±Board Diagnostic (OBD)

OCOxidation Catalytic ConverterOxidation Catalyst Converter (OC), CCo

OPOpen LoopOpen Loop

PAIRPulsed Secondary Air InjectionAir Suction (AS)

PCMPowertrain Control Module±

PNPPark/Neutral Position±

PROMProgrammable Read Only Memory±

PSPPower Steering Pressure±

PTOXPeriodic Trap OxidizerDiesel Particulate Filter (DPF)

Diesel Particulate Trap (DPT)

RAMRandom Access MemoryRandom Access Memory (RAM)

RMRelay Module±

ROMRead Only MemoryRead Only Memory (ROM)

RPMEngine SpeedEngine Speed

SCSuperchargerSupercharger

SCBSupercharger Bypass±

SFISequential Multiport Fuel InjectionElectronic Fuel Injection (EFI), Sequential Injection

SPLSmoke Puff Limiter±

SRIService Reminder Indicator±

SRTSystem Readiness Test±

STScan Tool±

TBThrottle BodyThrottle Body

TBIThrottle Body Fuel InjectionSingle Point Injection

Central Fuel Injection (Ci)

TCTurbochargerTurbocharger

TCCTorque Converter ClutchTorque Converter

TCMTransmission Control ModuleTransmission ECU (Electronic Control Unit)

TPThrottle PositionThrottle Position

TRTransmission Range±

Page 166 of 4592

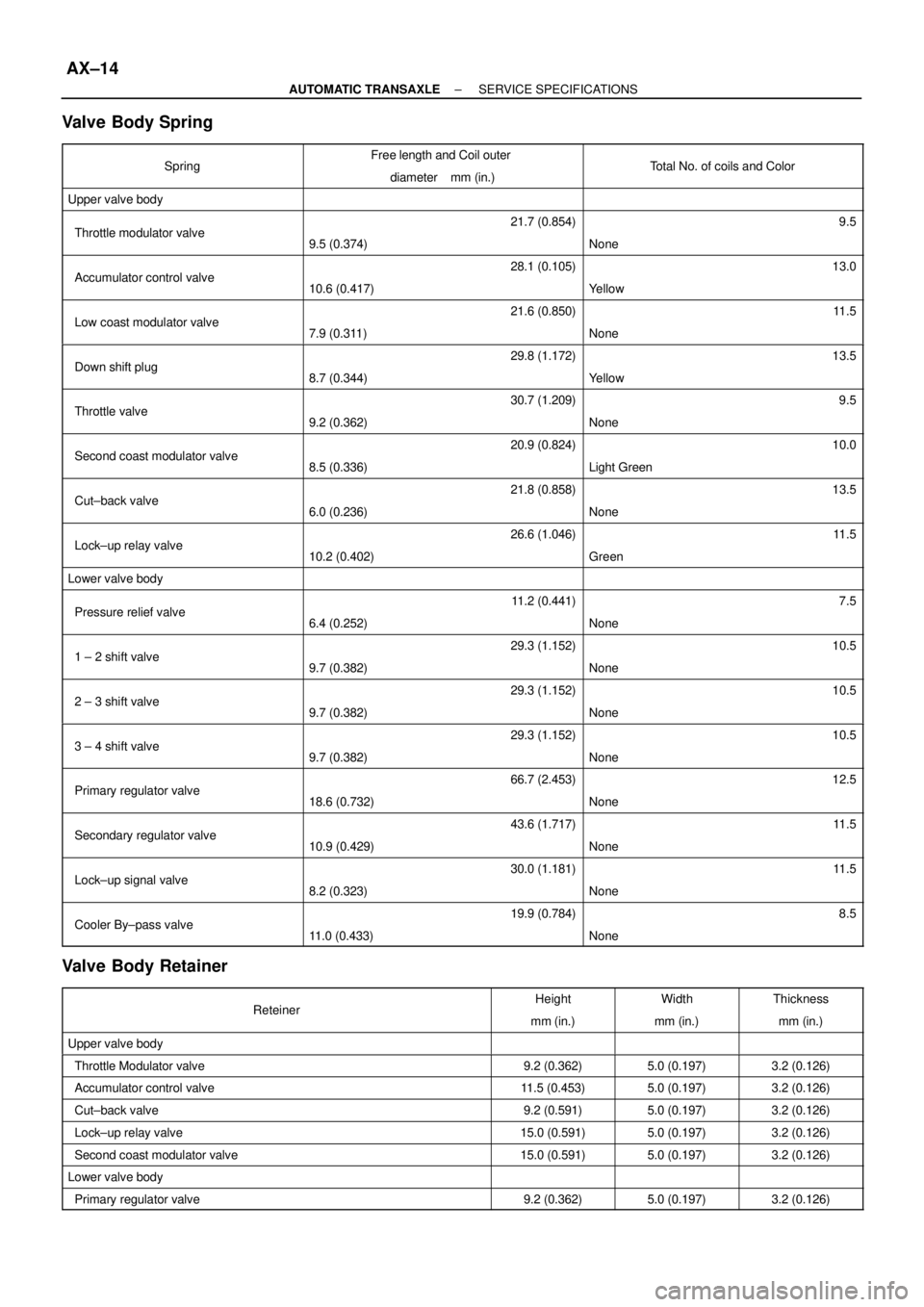

AUTOMATIC TRANSAXLESERVICE SPECIFICATIONS ±

AX±14

Valve Body Spring

SpringFree length and Coil outer

diameter mm (in.)Total No. of coils and Color

Upper valve body

Throttle modulator valve21.7 (0.854)

9.5 (0.374)9.5

None

Accumulator control valve28.1 (0.105)

10.6 (0.417)13.0

Yellow

Low coast modulator valve21.6 (0.850)

7.9 (0.311)11.5

None

Down shift plug29.8 (1.172)

8.7 (0.344)13.5

Yellow

Throttle valve30.7 (1.209)

9.2 (0.362)9.5

None

Second coast modulator valve20.9 (0.824)

8.5 (0.336)10.0

Light Green

Cut±back valve21.8 (0.858)

6.0 (0.236)13.5

None

Lock±up relay valve26.6 (1.046)

10.2 (0.402)11.5

Green

Lower valve body

Pressure relief valve11.2 (0.441)

6.4 (0.252)7.5

None

1 ± 2 shift valve29.3 (1.152)

9.7 (0.382)10.5

None

2 ± 3 shift valve29.3 (1.152)

9.7 (0.382)10.5

None

3 ± 4 shift valve29.3 (1.152)

9.7 (0.382)10.5

None

Primary regulator valve66.7 (2.453)

18.6 (0.732)12.5

None

Secondary regulator valve43.6 (1.717)

10.9 (0.429)11.5

None

Lock±up signal valve30.0 (1.181)

8.2 (0.323)11.5

None

Cooler By±pass valve19.9 (0.784)

11.0 (0.433)8.5

None

Valve Body Retainer

ReteinerHeight

mm (in.)Width

mm (in.)Thickness

mm (in.)

Upper valve body

Throttle Modulator valve9.2 (0.362)5.0 (0.197)3.2 (0.126)

Accumulator control valve11.5 (0.453)5.0 (0.197)3.2 (0.126)

Cut±back valve9.2 (0.591)5.0 (0.197)3.2 (0.126)

Lock±up relay valve15.0 (0.591)5.0 (0.197)3.2 (0.126)

Second coast modulator valve15.0 (0.591)5.0 (0.197)3.2 (0.126)

Lower valve body

Primary regulator valve9.2 (0.362)5.0 (0.197)3.2 (0.126)

Page 192 of 4592

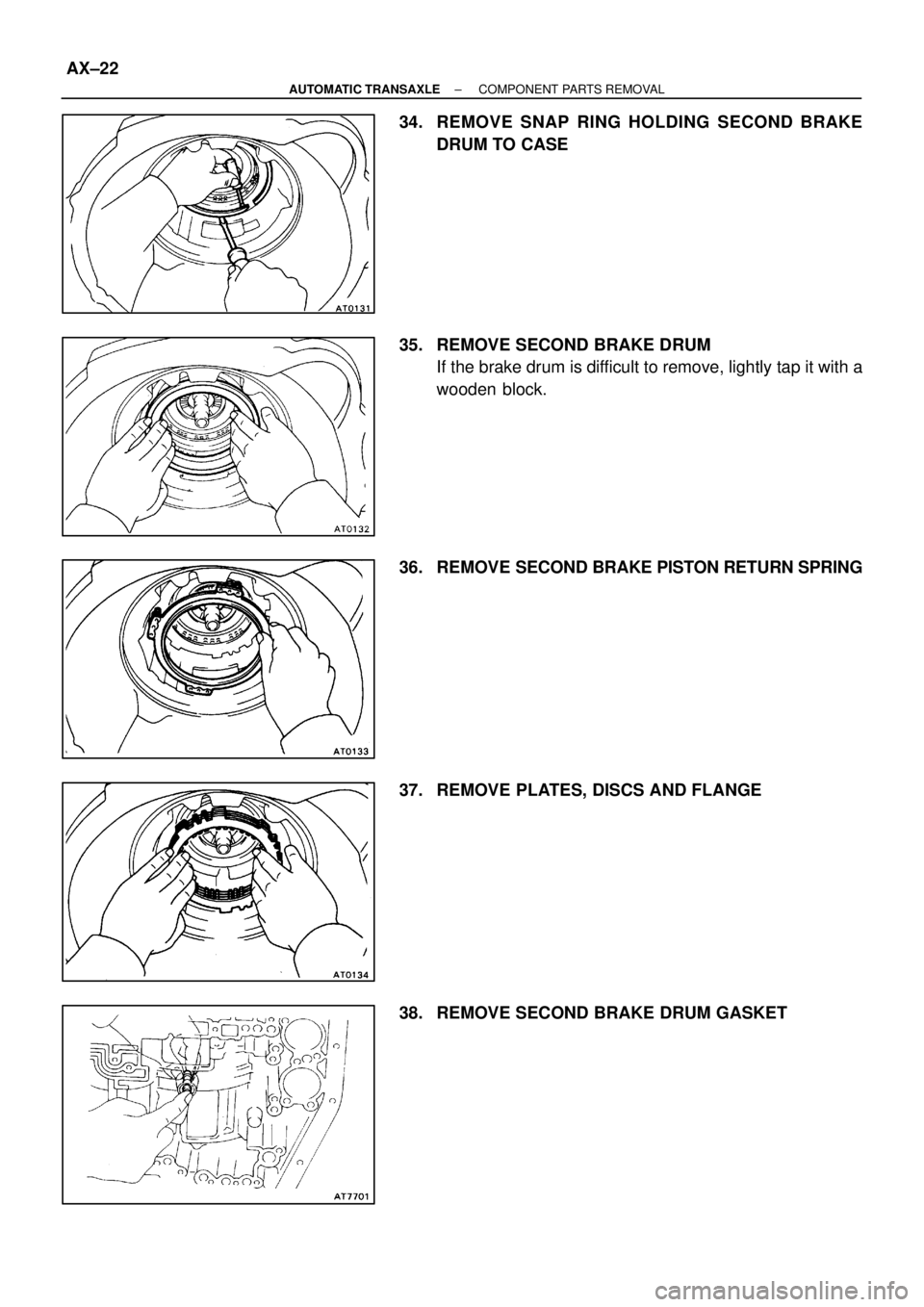

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±22

34. REMOVE SNAP RING HOLDING SECOND BRAKE

DRUM TO CASE

35. REMOVE SECOND BRAKE DRUM

If the brake drum is difficult to remove, lightly tap it with a

wooden block.

36. REMOVE SECOND BRAKE PISTON RETURN SPRING

37. REMOVE PLATES, DISCS AND FLANGE

38. REMOVE SECOND BRAKE DRUM GASKET

Page 196 of 4592

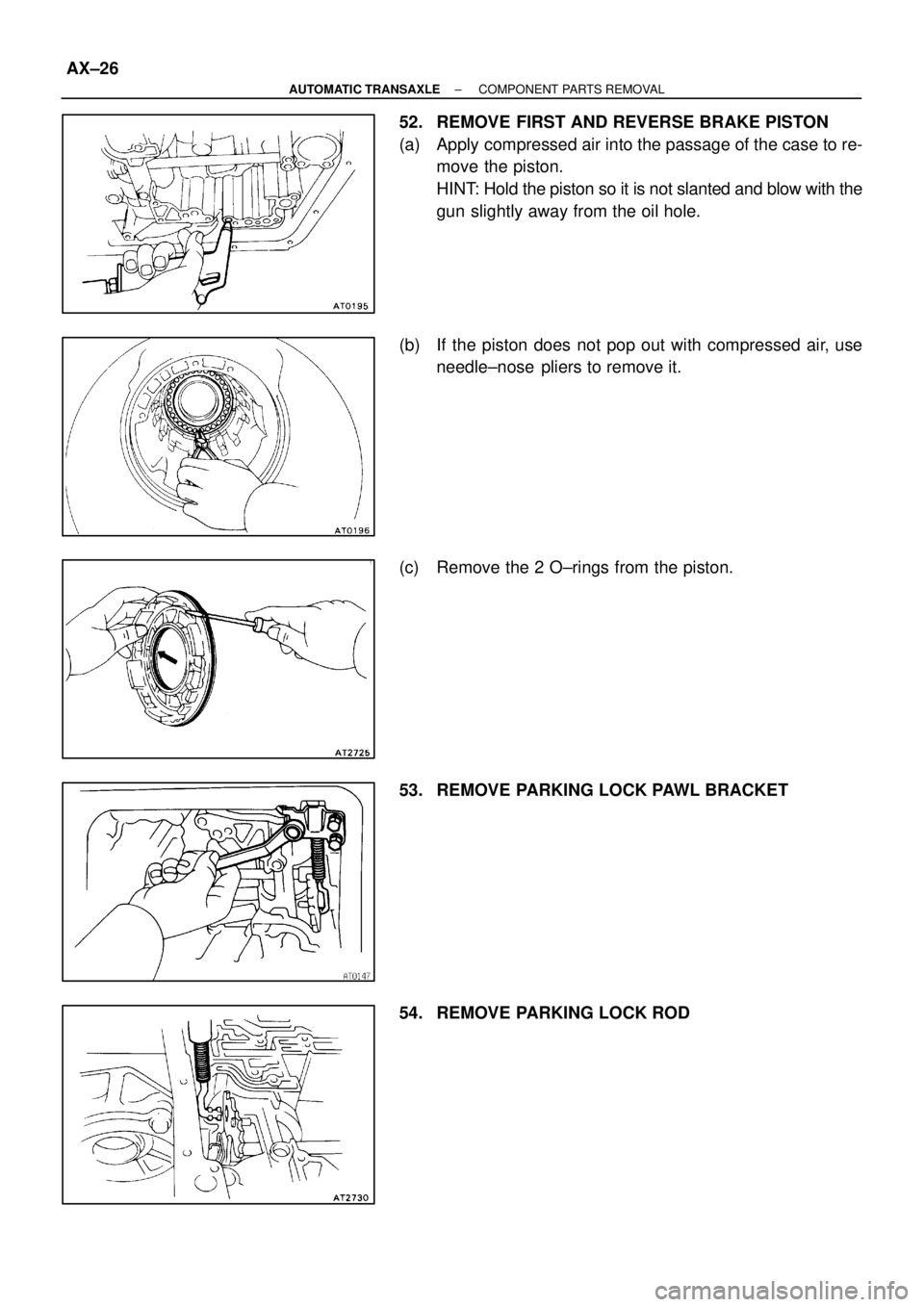

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±26

52. REMOVE FIRST AND REVERSE BRAKE PISTON

(a) Apply compressed air into the passage of the case to re-

move the piston.

HINT: Hold the piston so it is not slanted and blow with the

gun slightly away from the oil hole.

(b) If the piston does not pop out with compressed air, use

needle±nose pliers to remove it.

(c) Remove the 2 O±rings from the piston.

53. REMOVE PARKING LOCK PAWL BRACKET

54. REMOVE PARKING LOCK ROD

Page 230 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±60

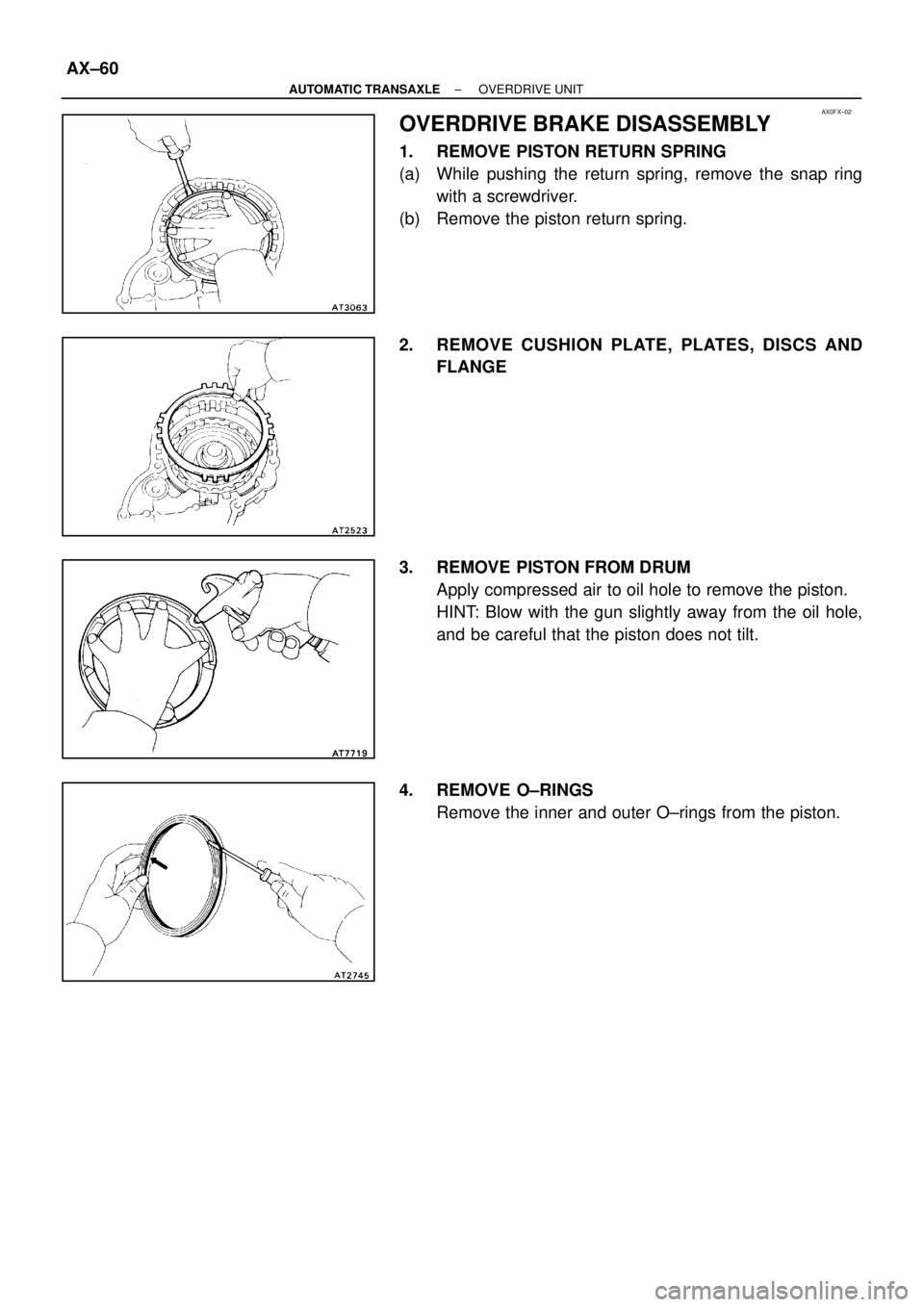

OVERDRIVE BRAKE DISASSEMBLY

1. REMOVE PISTON RETURN SPRING

(a) While pushing the return spring, remove the snap ring

with a screwdriver.

(b) Remove the piston return spring.

2. REMOVE CUSHION PLATE, PLATES, DISCS AND

FLANGE

3. REMOVE PISTON FROM DRUM

Apply compressed air to oil hole to remove the piston.

HINT: Blow with the gun slightly away from the oil hole,

and be careful that the piston does not tilt.

4. REMOVE O±RINGS

Remove the inner and outer O±rings from the piston.

AX0FX±02

Page 240 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±70

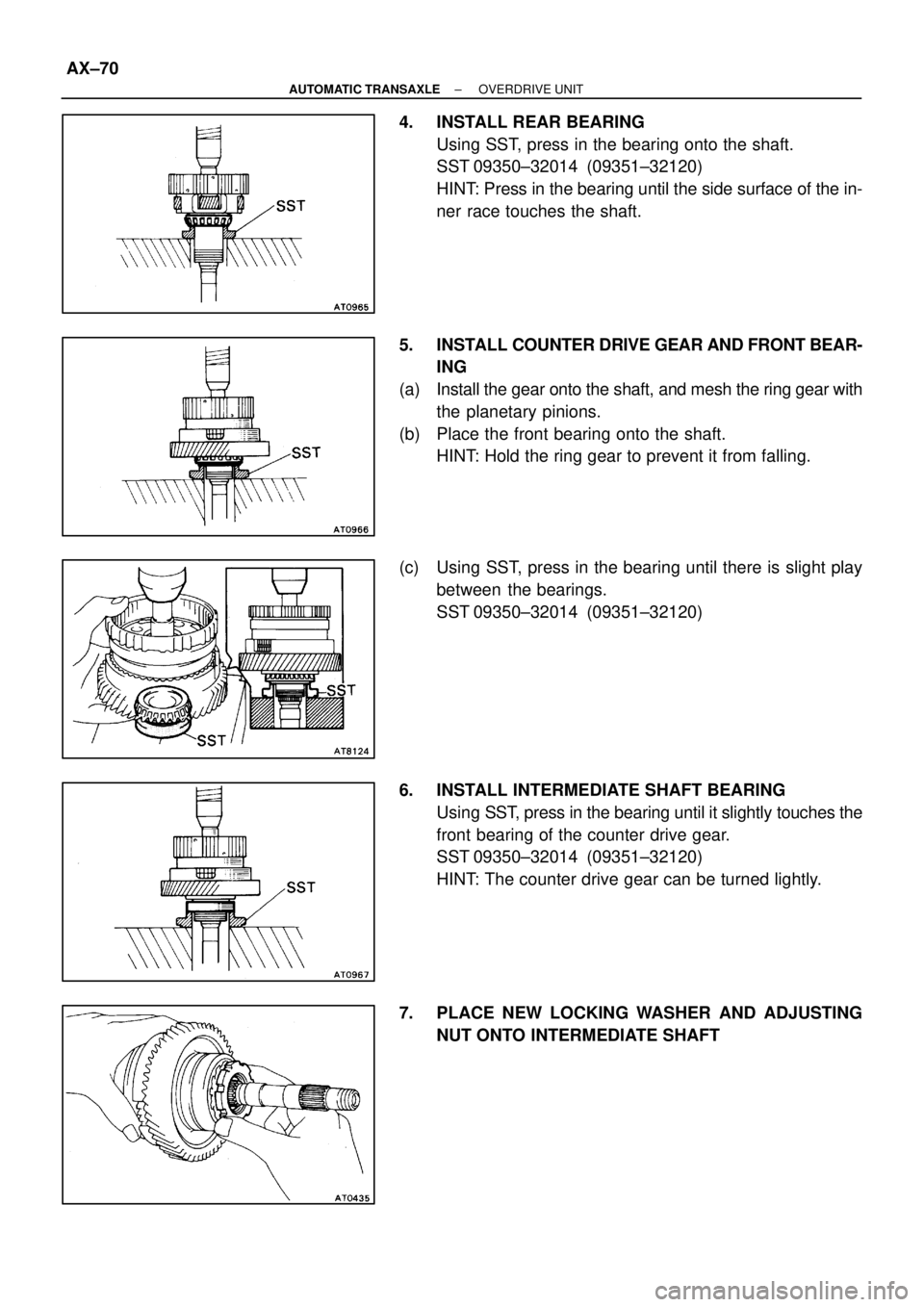

4. INSTALL REAR BEARING

Using SST, press in the bearing onto the shaft.

SST 09350±32014 (09351±32120)

HINT: Press in the bearing until the side surface of the in-

ner race touches the shaft.

5. INSTALL COUNTER DRIVE GEAR AND FRONT BEAR-

ING

(a) Install the gear onto the shaft, and mesh the ring gear with

the planetary pinions.

(b) Place the front bearing onto the shaft.

HINT: Hold the ring gear to prevent it from falling.

(c) Using SST, press in the bearing until there is slight play

between the bearings.

SST 09350±32014 (09351±32120)

6. INSTALL INTERMEDIATE SHAFT BEARING

Using SST, press in the bearing until it slightly touches the

front bearing of the counter drive gear.

SST 09350±32014 (09351±32120)

HINT: The counter drive gear can be turned lightly.

7. PLACE NEW LOCKING WASHER AND ADJUSTING

NUT ONTO INTERMEDIATE SHAFT

Page 253 of 4592

![TOYOTA CAMRY 1999 Service User Guide AUTOMATIC TRANSAXLEUPPER VALVE BODY ±

AX±83

@@

@@

@:

[c E]

Throttle Valve Spring (None)30.70 / 9.20 (1.2087 / 0.3622)9.5

@@

@@

@:

[c F]

Second Coast Modulator Valve Spring

(Light Green)20.93 / 8.50 TOYOTA CAMRY 1999 Service User Guide AUTOMATIC TRANSAXLEUPPER VALVE BODY ±

AX±83

@@

@@

@:

[c E]

Throttle Valve Spring (None)30.70 / 9.20 (1.2087 / 0.3622)9.5

@@

@@

@:

[c F]

Second Coast Modulator Valve Spring

(Light Green)20.93 / 8.50](/img/14/57448/w960_57448-252.png)

AUTOMATIC TRANSAXLEUPPER VALVE BODY ±

AX±83

@@

@@

@:

[c E]

Throttle Valve Spring (None)30.70 / 9.20 (1.2087 / 0.3622)9.5

@@

@@

@:

[c F]

Second Coast Modulator Valve Spring

(Light Green)20.93 / 8.50 (0.8240 / 0.3364)10.0

@@

@@

@:

[c G]

Lock±up Relay Valve spring (Green)26.56 / 10.20 (1.0457 / 0.4016)11.5

@@

@@

@:

[c H]

Cut±back Valve Spring (None)21.80 / 6.00 (0.8583 / 0.2362)13.5

Page 271 of 4592

![TOYOTA CAMRY 1999 Service User Guide AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±101

@@

@@

@:

[c B]

37.9 / 22.0 (1.492 / 0.866)36.1 / 22.2 (1.421 / 0.874)35.7 / 23.0 (1.406 / 0.906)

@@

@@

@:

[c C]

37.9 / 22.0 (1.492 / 0.866)36 TOYOTA CAMRY 1999 Service User Guide AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±101

@@

@@

@:

[c B]

37.9 / 22.0 (1.492 / 0.866)36.1 / 22.2 (1.421 / 0.874)35.7 / 23.0 (1.406 / 0.906)

@@

@@

@:

[c C]

37.9 / 22.0 (1.492 / 0.866)36](/img/14/57448/w960_57448-270.png)

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±101

@@

@@

@:

[c B]

37.9 / 22.0 (1.492 / 0.866)36.1 / 22.2 (1.421 / 0.874)35.7 / 23.0 (1.406 / 0.906)

@@

@@

@:

[c C]

37.9 / 22.0 (1.492 / 0.866)36.1 / 22.2 (1.421 / 0.874)35.0 / 19.0 (1.378 / 0.748)

@@

@@

@:

[c D]

45.0 / 28.0 (1.772 / 1.102)45.0 / 30.0 (1.772 / 1.181)±

@@

@@

@:

[c E]

37.3 / 24.1 (1.469 / 0.949)37.6 / 24.0 (1.480 / 0.945)37.6 / 22.2 (1.480 / 0.874)

@@

@@

@:

[c F]

±46.3 / 26.2 (1.823 / 1.031)43.0 / 24.5 (1.693 / 0.965)

DRIVE PINION ASSEMBLY INSTALLATION

1. INSTALL NEW O±RING ONTO BEARING CAGE

2. INSTALL DRIVE PINION SHAFT INTO CASE

Slightly tap the cage into the case until the groove with the

bore can be see.

HINT: Drive in the bearing cage until the surface of the

bearing cage passes through the groove with the bore.

AX0GM±02

Page 272 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±102

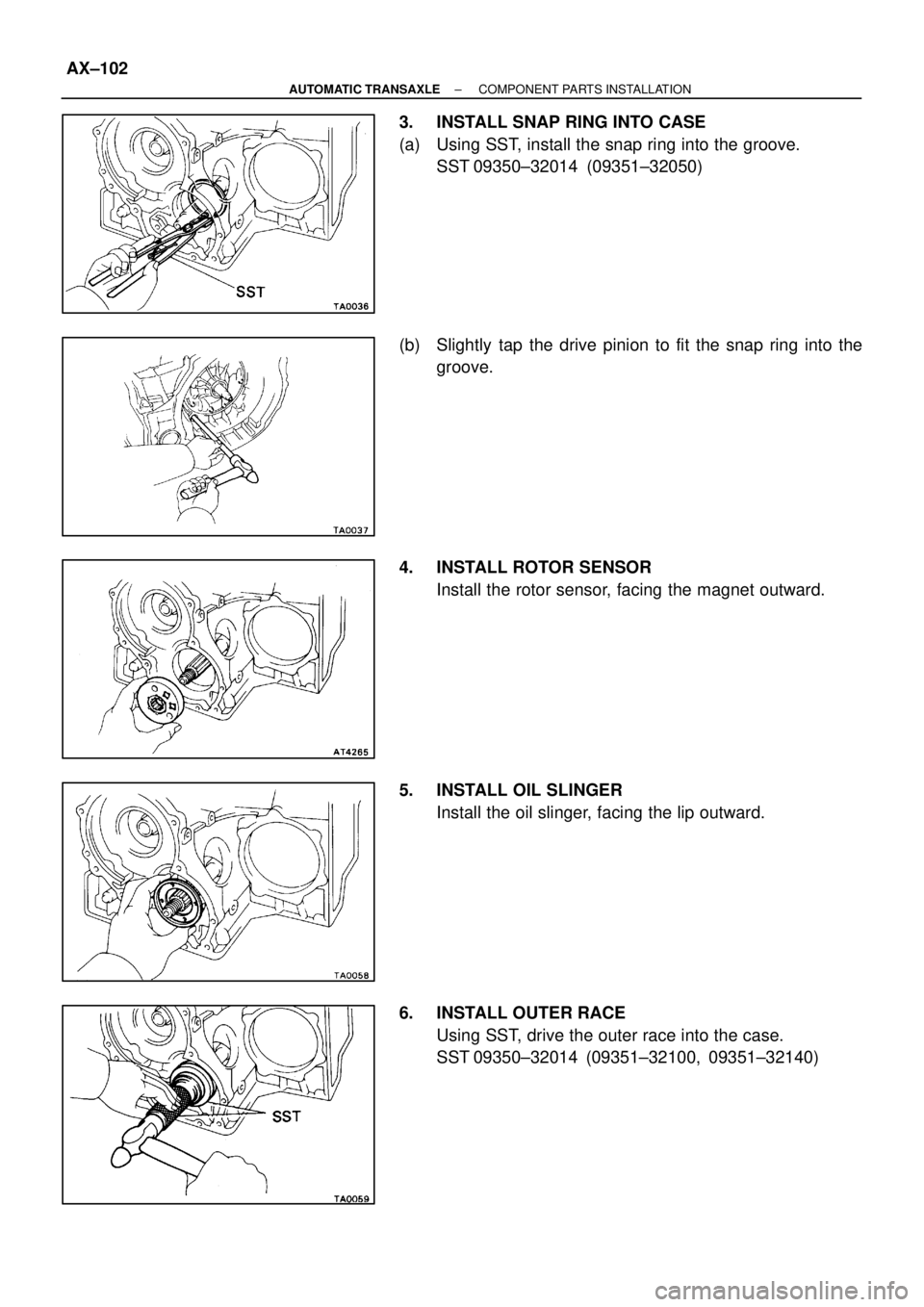

3. INSTALL SNAP RING INTO CASE

(a) Using SST, install the snap ring into the groove.

SST 09350±32014 (09351±32050)

(b) Slightly tap the drive pinion to fit the snap ring into the

groove.

4. INSTALL ROTOR SENSOR

Install the rotor sensor, facing the magnet outward.

5. INSTALL OIL SLINGER

Install the oil slinger, facing the lip outward.

6. INSTALL OUTER RACE

Using SST, drive the outer race into the case.

SST 09350±32014 (09351±32100, 09351±32140)

Page 288 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±118

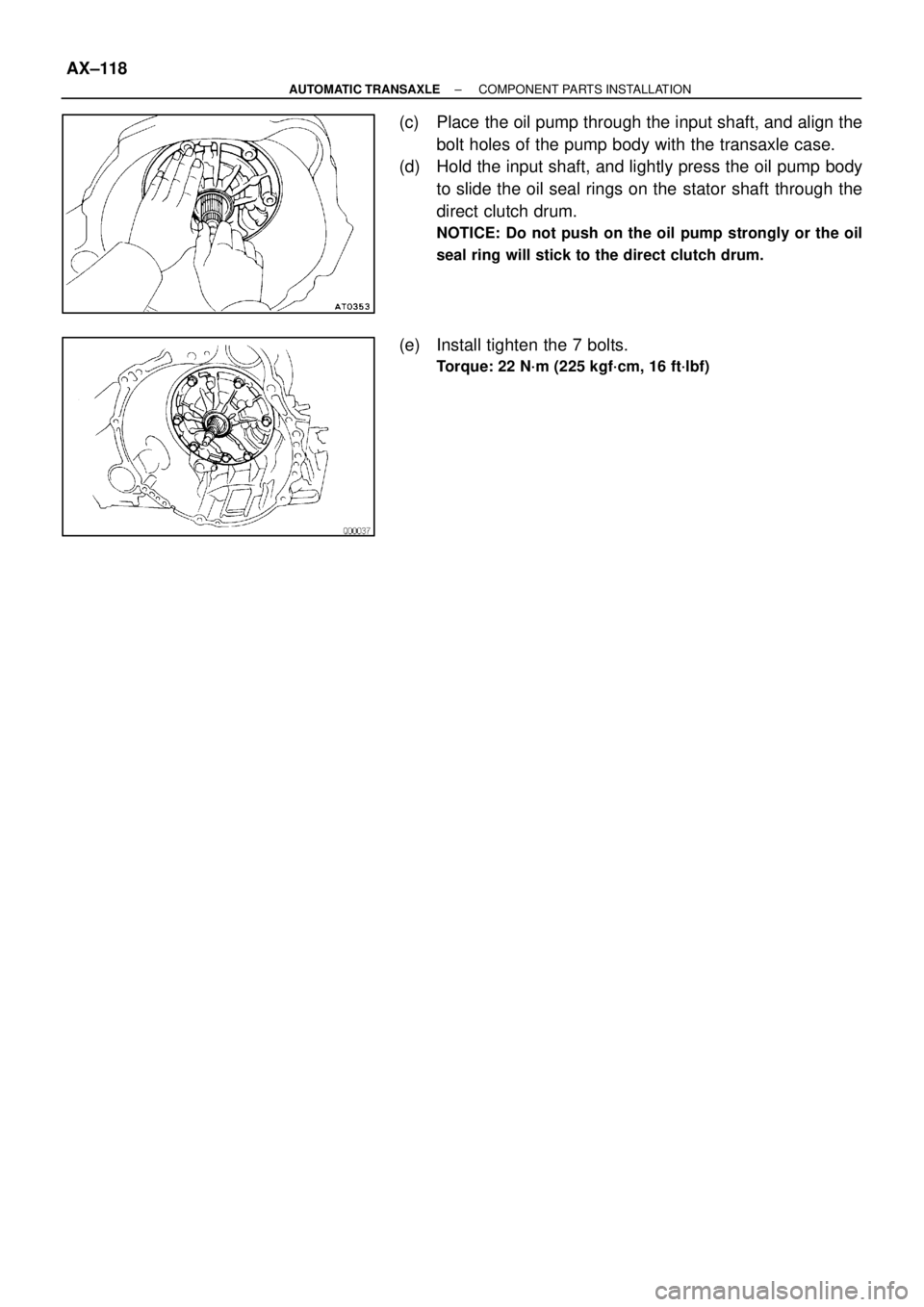

(c) Place the oil pump through the input shaft, and align the

bolt holes of the pump body with the transaxle case.

(d) Hold the input shaft, and lightly press the oil pump body

to slide the oil seal rings on the stator shaft through the

direct clutch drum.

NOTICE: Do not push on the oil pump strongly or the oil

seal ring will stick to the direct clutch drum.

(e) Install tighten the 7 bolts.

Torque: 22 N´m (225 kgf´cm, 16 ft´lbf)