boot TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 891 of 2389

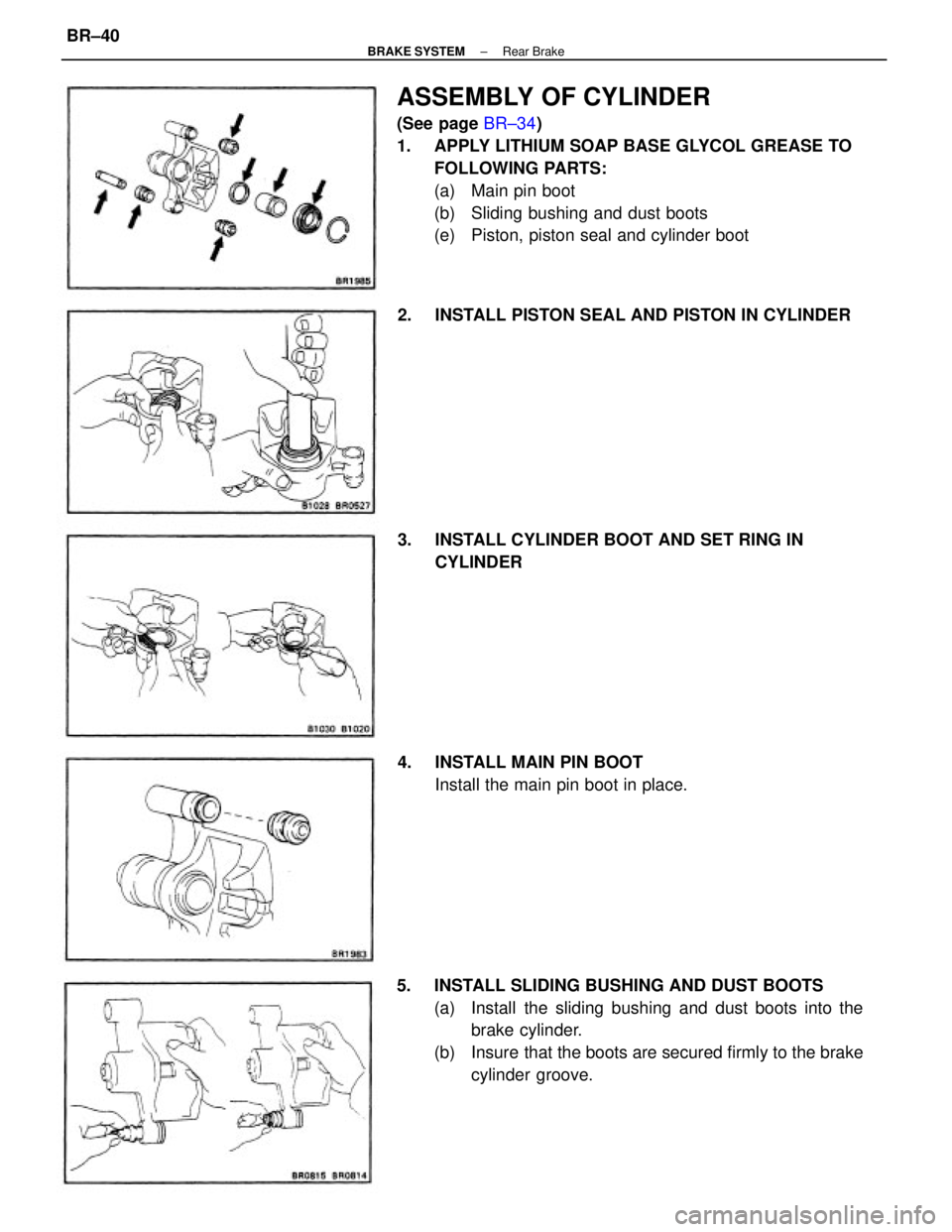

ASSEMBLY OF CYLINDER

(See page BR±34)

1. APPLY LITHIUM SOAP BASE GLYCOL GREASE TO

FOLLOWING PARTS:

(a) Main pin boot

(b) Sliding bushing and dust boots

(e) Piston, piston seal and cylinder boot

5. INSTALL SLIDING BUSHING AND DUST BOOTS

(a) Install the sliding bushing and dust boots into the

brake cylinder.

(b) Insure that the boots are secured firmly to the brake

cylinder groove. 3. INSTALL CYLINDER BOOT AND SET RING IN

CYLINDER

4. INSTALL MAIN PIN BOOT

Install the main pin boot in place. 2. INSTALL PISTON SEAL AND PISTON IN CYLINDER

± BRAKE SYSTEMRear BrakeBR±40

Page 979 of 2389

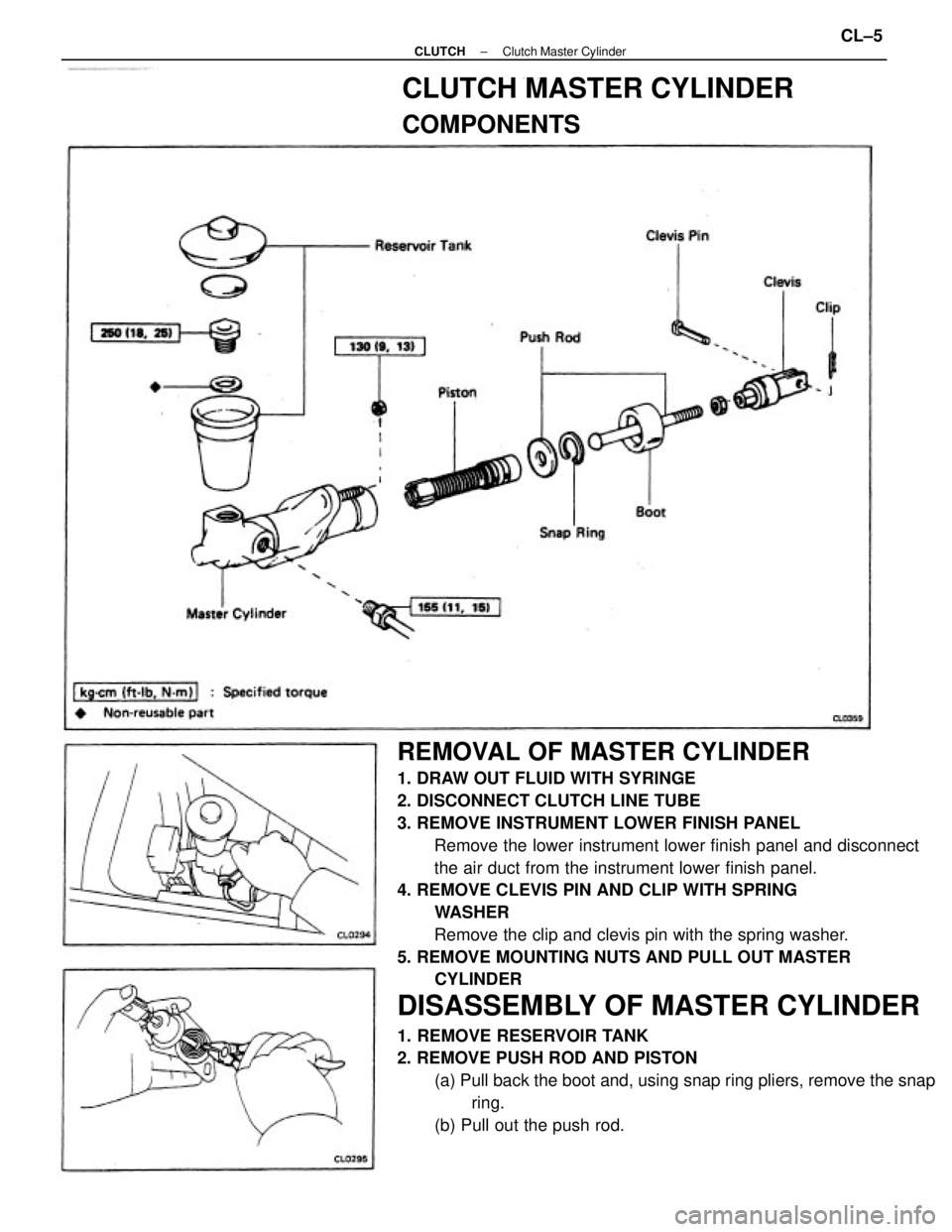

REMOVAL OF MASTER CYLINDER

1. DRAW OUT FLUID WITH SYRINGE

2. DISCONNECT CLUTCH LINE TUBE

3. REMOVE INSTRUMENT LOWER FINISH PANEL

Remove the lower instrument lower finish panel and disconnect

the air duct from the instrument lower finish panel.

4. REMOVE CLEVIS PIN AND CLIP WITH SPRING

WASHER

Remove the clip and clevis pin with the spring washer.

5. REMOVE MOUNTING NUTS AND PULL OUT MASTER

CYLINDER

DISASSEMBLY OF MASTER CYLINDER

1. REMOVE RESERVOIR TANK

2. REMOVE PUSH ROD AND PISTON

(a) Pull back the boot and, using snap ring pliers, remove the snap

ring.

(b) Pull out the push rod.

CLUTCH MASTER CYLINDER

COMPONENTS

± CLUTCHClutch Master CylinderCL±5

Page 981 of 2389

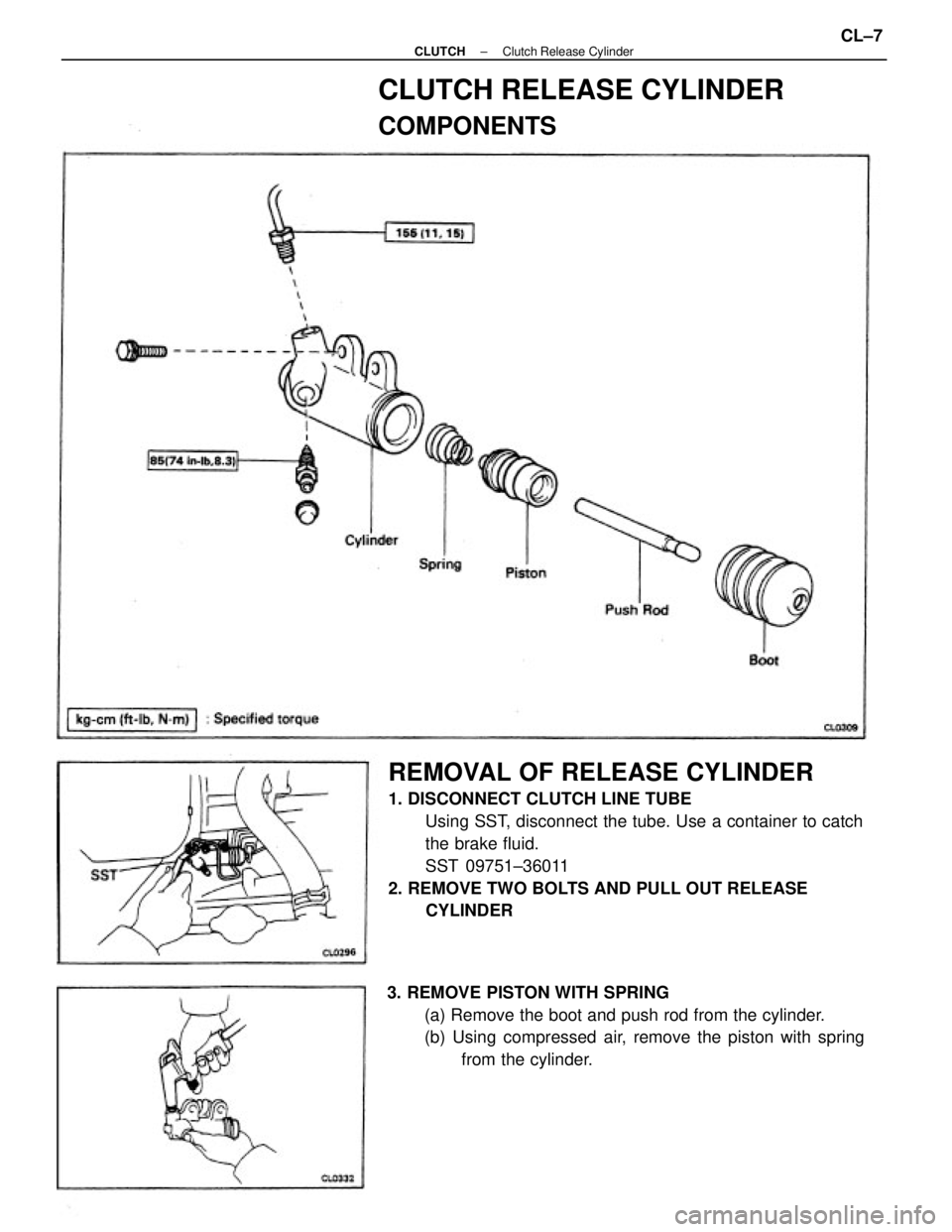

REMOVAL OF RELEASE CYLINDER

1. DISCONNECT CLUTCH LINE TUBE

Using SST, disconnect the tube. Use a container to catch

the brake fluid.

SST 09751±36011

2. REMOVE TWO BOLTS AND PULL OUT RELEASE

CYLINDER

3. REMOVE PISTON WITH SPRING

(a) Remove the boot and push rod from the cylinder.

(b) Using compressed air, remove the piston with spring

from the cylinder.

CLUTCH RELEASE CYLINDER

COMPONENTS

± CLUTCHClutch Release CylinderCL±7

Page 982 of 2389

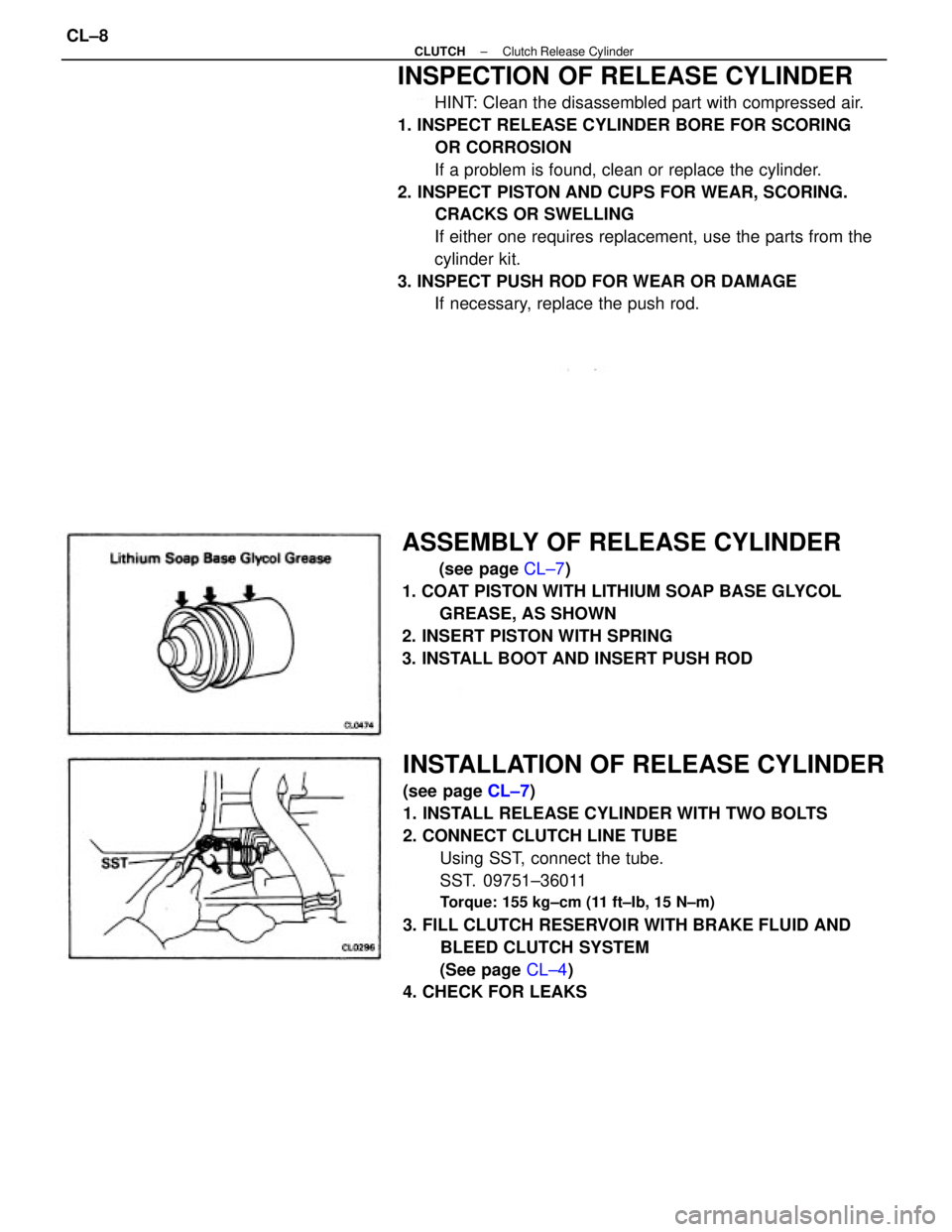

INSPECTION OF RELEASE CYLINDER

HINT: Clean the disassembled part with compressed air.

1. INSPECT RELEASE CYLINDER BORE FOR SCORING

OR CORROSION

If a problem is found, clean or replace the cylinder.

2. INSPECT PISTON AND CUPS FOR WEAR, SCORING.

CRACKS OR SWELLING

If either one requires replacement, use the parts from the

cylinder kit.

3. INSPECT PUSH ROD FOR WEAR OR DAMAGE

If necessary, replace the push rod.

INSTALLATION OF RELEASE CYLINDER

(see page CL±7)

1. INSTALL RELEASE CYLINDER WITH TWO BOLTS

2. CONNECT CLUTCH LINE TUBE

Using SST, connect the tube.

SST. 09751±36011

Torque: 155 kg±cm (11 ft±Ib, 15 N±m)

3. FILL CLUTCH RESERVOIR WITH BRAKE FLUID AND

BLEED CLUTCH SYSTEM

(See page CL±4)

4. CHECK FOR LEAKS

ASSEMBLY OF RELEASE CYLINDER

(see page CL±7)

1. COAT PISTON WITH LITHIUM SOAP BASE GLYCOL

GREASE, AS SHOWN

2. INSERT PISTON WITH SPRING

3. INSTALL BOOT AND INSERT PUSH ROD

± CLUTCHClutch Release CylinderCL±8

Page 984 of 2389

4. INSPECT DIAPHRAGM SPRING FOR WEAR

Using calipers, measure the diaphragm spring for depth

and width of wear.

Maximum: Depth 0.6 mm (0.024 in.)

Width 5.0 mm (0.197 in.)

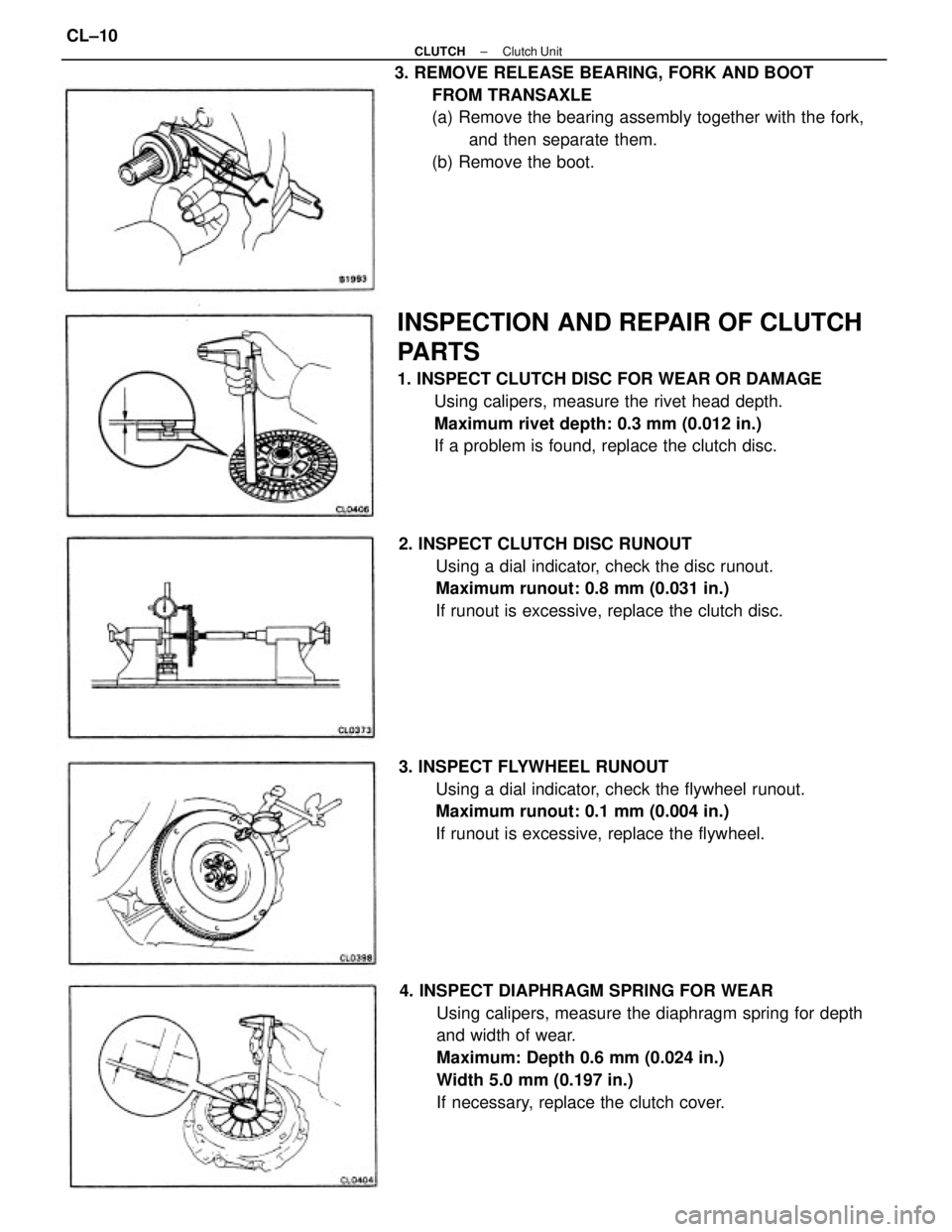

If necessary, replace the clutch cover. 3. REMOVE RELEASE BEARING, FORK AND BOOT

FROM TRANSAXLE

(a) Remove the bearing assembly together with the fork,

and then separate them.

(b) Remove the boot.

INSPECTION AND REPAIR OF CLUTCH

PARTS

1. INSPECT CLUTCH DISC FOR WEAR OR DAMAGE

Using calipers, measure the rivet head depth.

Maximum rivet depth: 0.3 mm (0.012 in.)

If a problem is found, replace the clutch disc.

3. INSPECT FLYWHEEL RUNOUT

Using a dial indicator, check the flywheel runout.

Maximum runout: 0.1 mm (0.004 in.)

If runout is excessive, replace the flywheel. 2. INSPECT CLUTCH DISC RUNOUT

Using a dial indicator, check the disc runout.

Maximum runout: 0.8 mm (0.031 in.)

If runout is excessive, replace the clutch disc.

± CLUTCHClutch UnitCL±10

Page 986 of 2389

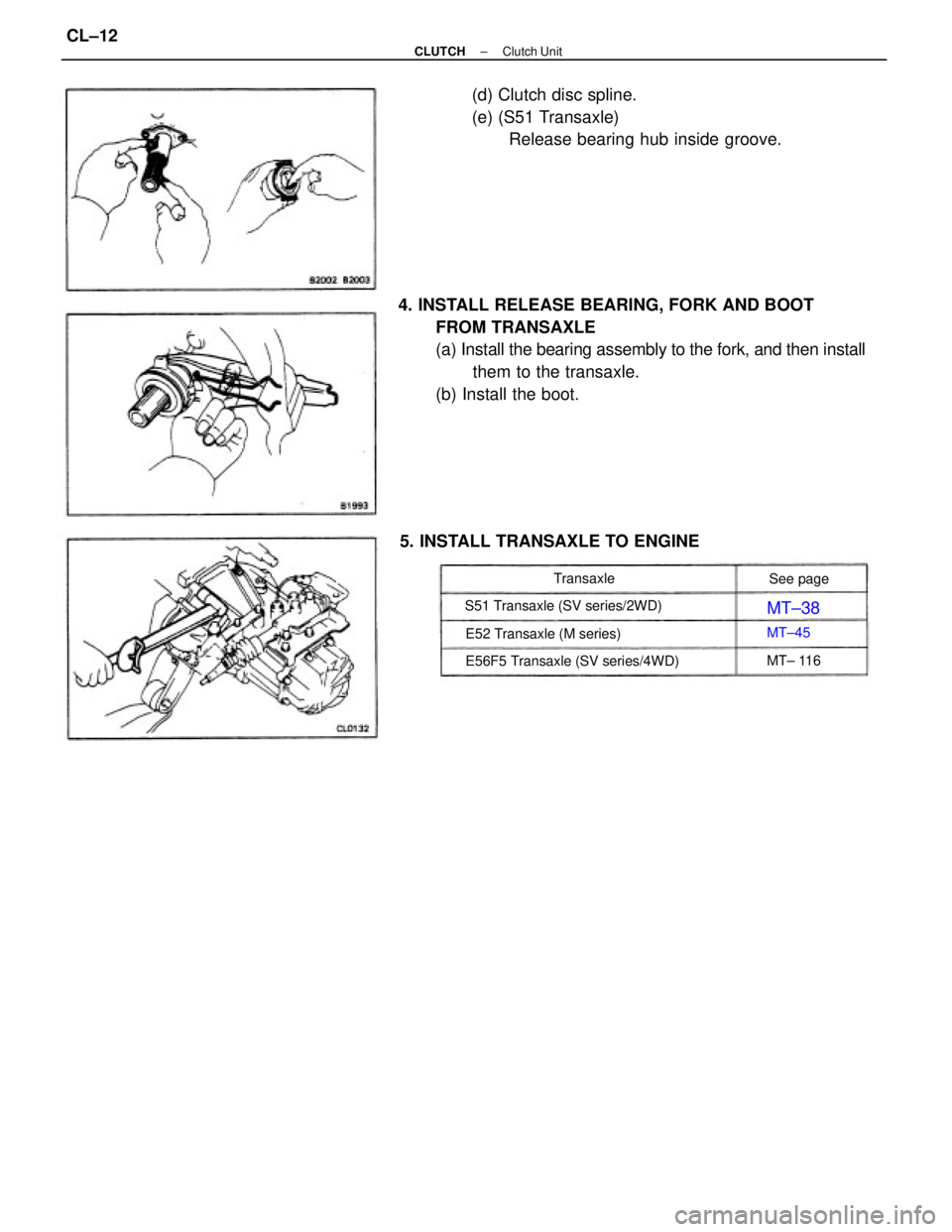

4. INSTALL RELEASE BEARING, FORK AND BOOT

FROM TRANSAXLE

(a) Install the bearing assembly to the fork, and then install

them to the transaxle.

(b) Install the boot.(d) Clutch disc spline.

(e) (S51 Transaxle)

Release bearing hub inside groove.

5. INSTALL TRANSAXLE TO ENGINE

E56F5 Transaxle (SV series/4WD) S51 Transaxle (SV series/2WD)

E52 Transaxle (M series)Transaxle

See page

MT± 116 MT±45

MT±38

± CLUTCHClutch UnitCL±12

Page 1213 of 2389

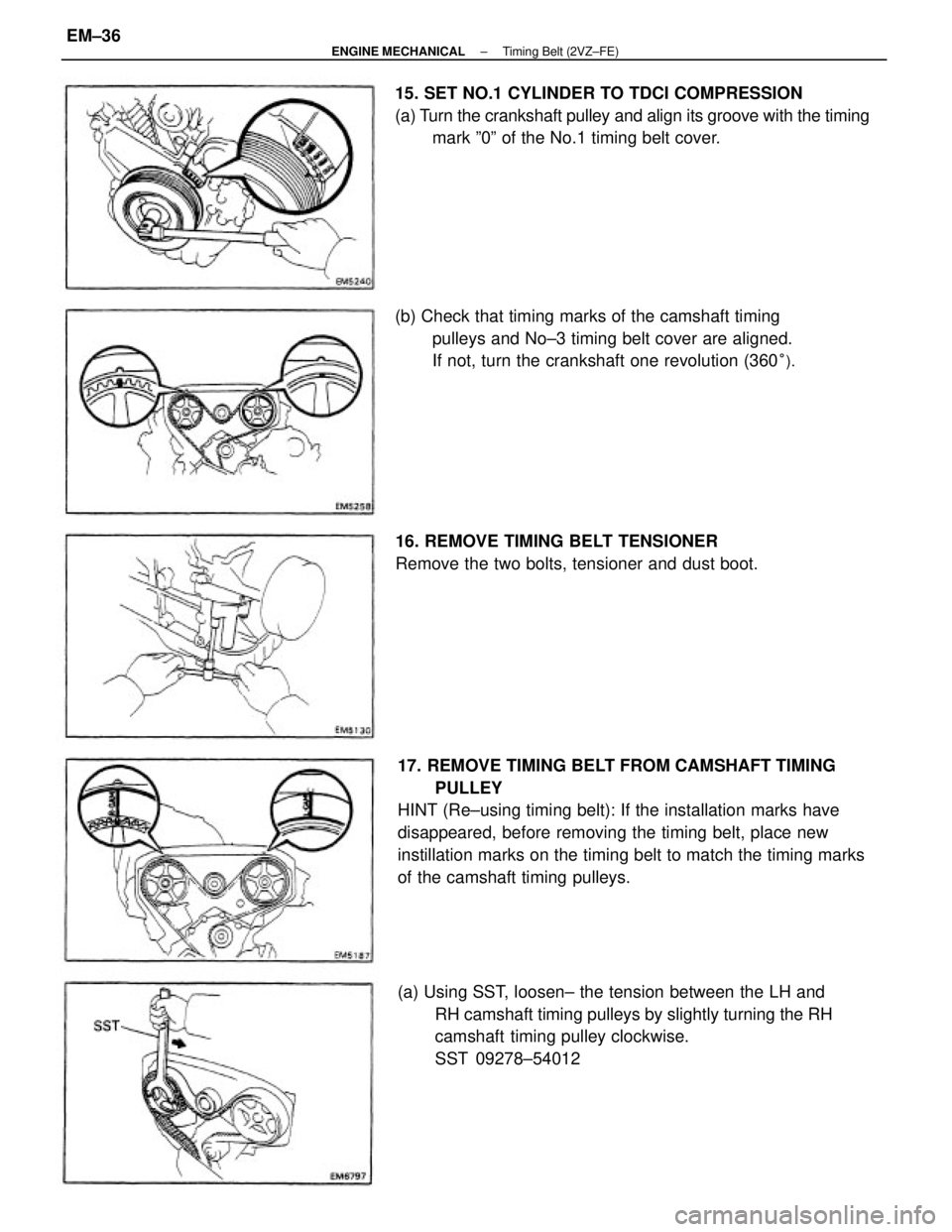

17. REMOVE TIMING BELT FROM CAMSHAFT TIMING

PULLEY

HINT (Re±using timing belt): If the installation marks have

disappeared, before removing the timing belt, place new

instillation marks on the timing belt to match the timing marks

of the camshaft timing pulleys.

(a) Using SST, loosen± the tension between the LH and

RH camshaft timing pulleys by slightly turning the RH

camshaft timing pulley clockwise.

SST 09278±54012 15. SET NO.1 CYLINDER TO TDCI COMPRESSION

(a) Turn the crankshaft pulley and align its groove with the timing

mark º0º of the No.1 timing belt cover.

(b) Check that timing marks of the camshaft timing

pulleys and No±3 timing belt cover are aligned.

If not, turn the crankshaft one revolution (360

°).

16. REMOVE TIMING BELT TENSIONER

Remove the two bolts, tensioner and dust boot.

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±36

Page 1222 of 2389

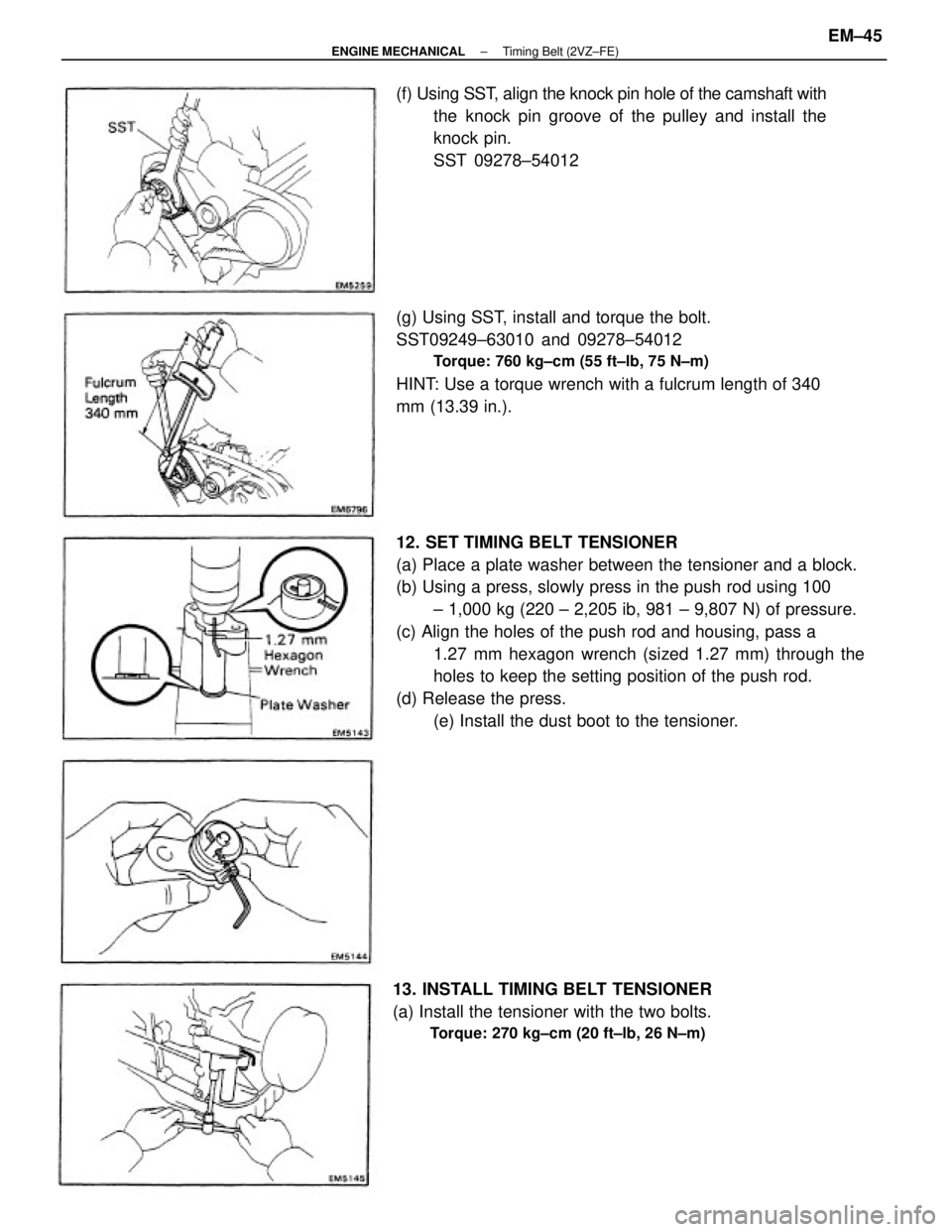

12. SET TIMING BELT TENSIONER

(a) Place a plate washer between the tensioner and a block.

(b) Using a press, slowly press in the push rod using 100

± 1,000 kg (220 ± 2,205 ib, 981 ± 9,807 N) of pressure.

(c) Align the holes of the push rod and housing, pass a

1.27 mm hexagon wrench (sized 1.27 mm) through the

holes to keep the setting position of the push rod.

(d) Release the press.

(e) Install the dust boot to the tensioner. (g) Using SST, install and torque the bolt.

SST09249±63010 and 09278±54012

Torque: 760 kg±cm (55 ft±lb, 75 N±m)

HINT: Use a torque wrench with a fulcrum length of 340

mm (13.39 in.). (f) Using SST, align the knock pin hole of the camshaft with

the knock pin groove of the pulley and install the

knock pin.

SST 09278±54012

13. INSTALL TIMING BELT TENSIONER

(a) Install the tensioner with the two bolts.

Torque: 270 kg±cm (20 ft±lb, 26 N±m)

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±45

Page 1362 of 2389

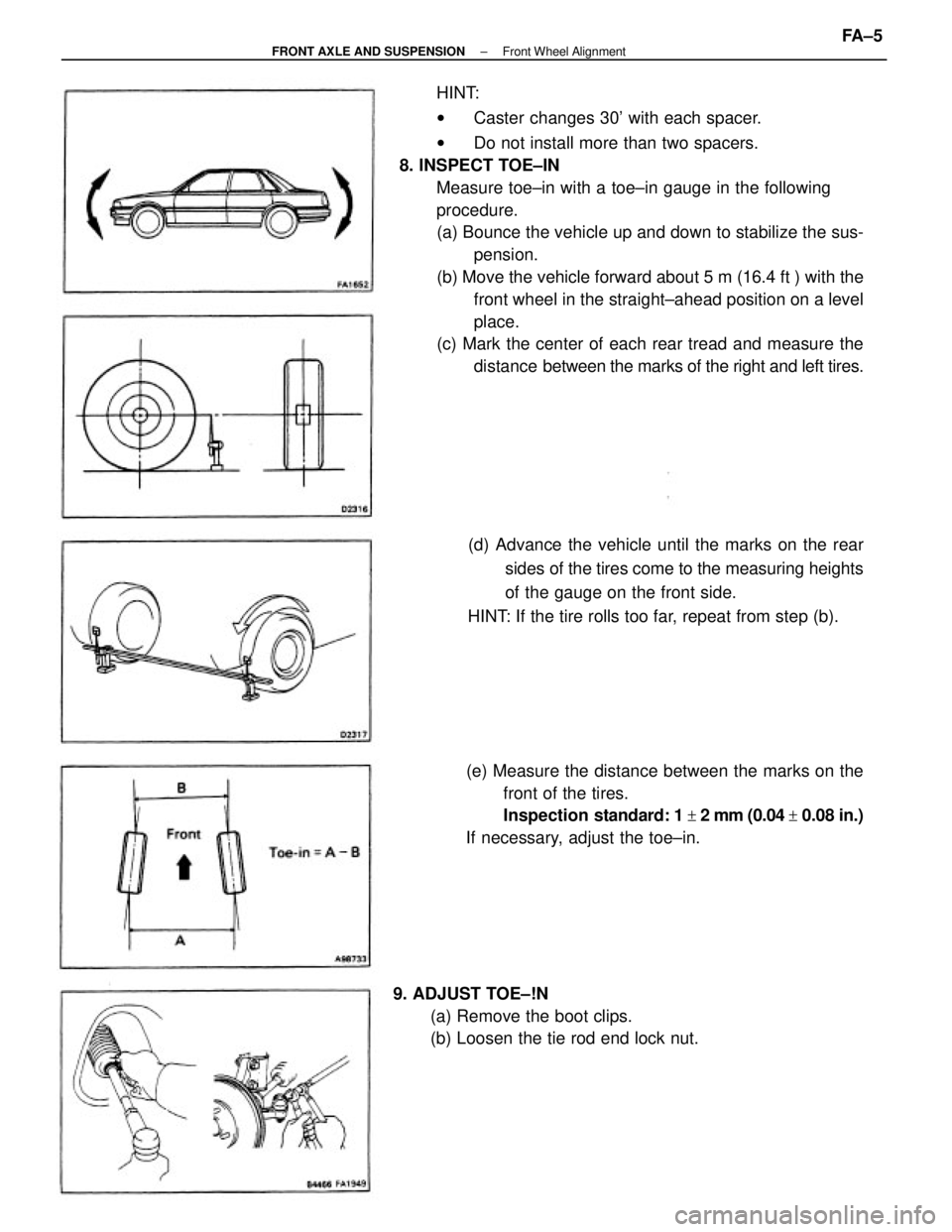

HINT:

wCaster changes 30' with each spacer.

wDo not install more than two spacers.

8. INSPECT TOE±IN

Measure toe±in with a toe±in gauge in the following

procedure.

(a) Bounce the vehicle up and down to stabilize the sus-

pension.

(b) Move the vehicle forward about 5 m (16.4 ft ) with the

front wheel in the straight±ahead position on a level

place.

(c) Mark the center of each rear tread and measure the

distance between the marks of the right and left tires.

(e) Measure the distance between the marks on the

front of the tires.

Inspection standard: 1

+ 2 mm (0.04 + 0.08 in.)

If necessary, adjust the toe±in.(d) Advance the vehicle until the marks on the rear

sides of the tires come to the measuring heights

of the gauge on the front side.

HINT: If the tire rolls too far, repeat from step (b).

9. ADJUST TOE±!N

(a) Remove the boot clips.

(b) Loosen the tie rod end lock nut.

± FRONT AXLE AND SUSPENSIONFront Wheel AlignmentFA ± 5

Page 1363 of 2389

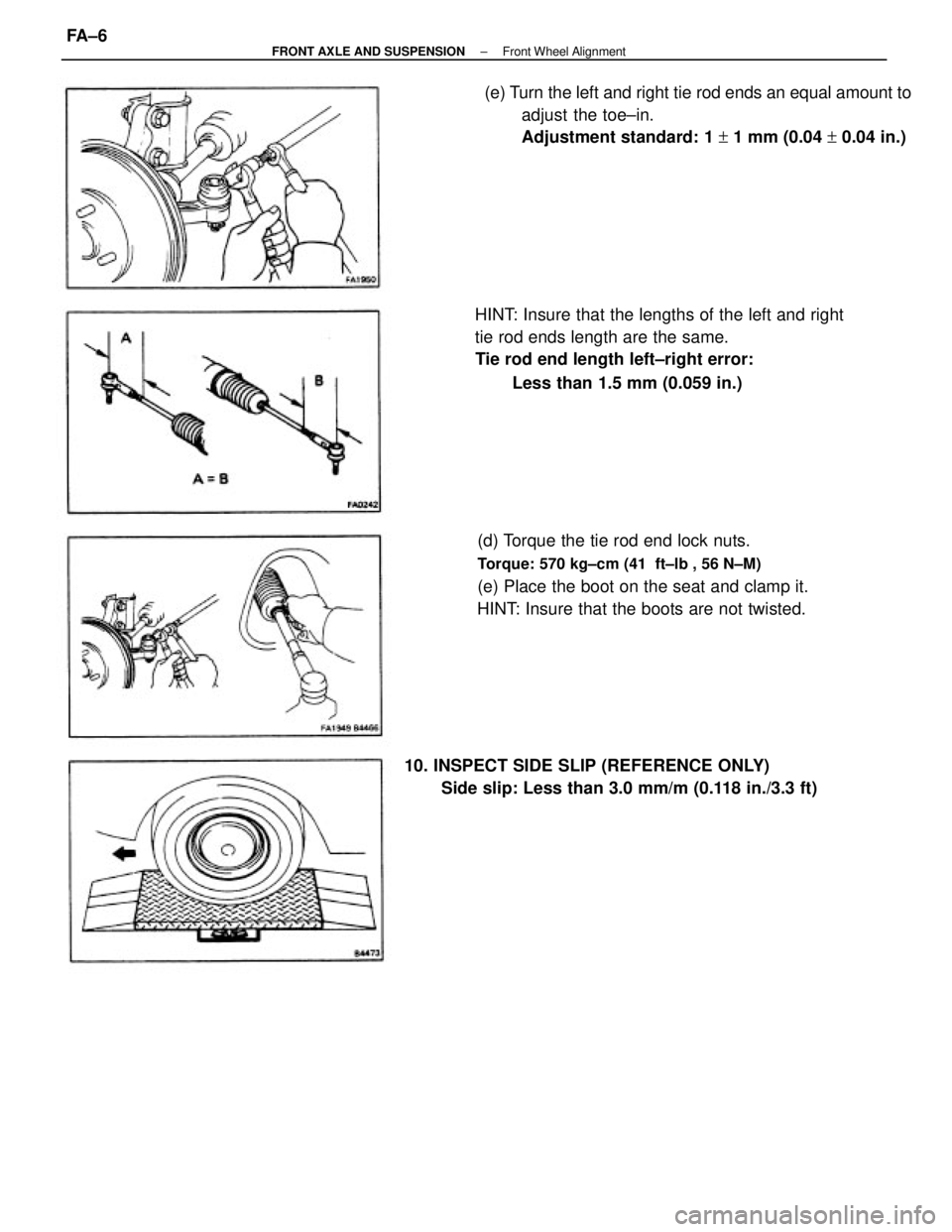

HINT: Insure that the lengths of the left and right

tie rod ends length are the same.

Tie rod end length left±right error:

Less than 1.5 mm (0.059 in.)

(d) Torque the tie rod end lock nuts.

Torque: 570 kg±cm (41 ft±lb , 56 N±M)

(e) Place the boot on the seat and clamp it.

HINT: Insure that the boots are not twisted.(e) Turn the left and right tie rod ends an equal amount to

adjust the toe±in.

Adjustment standard: 1 + 1 mm (0.04 + 0.04 in.)

10. INSPECT SIDE SLIP (REFERENCE ONLY)

Side slip: Less than 3.0 mm/m (0.118 in./3.3 ft)

± FRONT AXLE AND SUSPENSIONFront Wheel AlignmentFA ± 6