TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: alternator belt, check oil, fuse chart, headlight aiming, dead battery, adding oil, cooling

Page 2051 of 2389

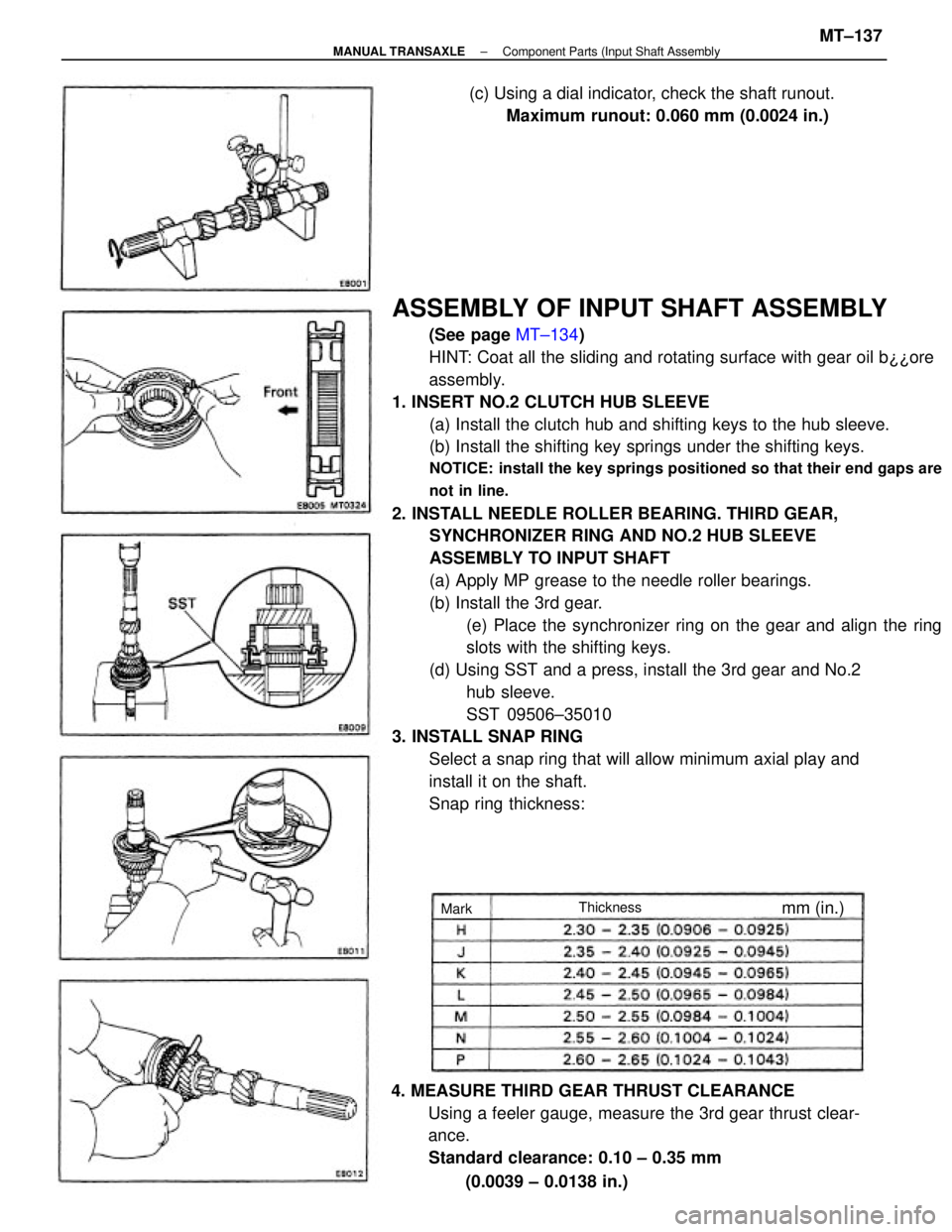

ASSEMBLY OF INPUT SHAFT ASSEMBLY

(See page MT±134)

HINT: Coat all the sliding and rotating surface with gear oil b¿¿ore

assembly.

1. INSERT NO.2 CLUTCH HUB SLEEVE

(a) Install the clutch hub and shifting keys to the hub sleeve.

(b) Install the shifting key springs under the shifting keys.

NOTICE: install the key springs positioned so that their end gaps are

not in line.

2. INSTALL NEEDLE ROLLER BEARING. THIRD GEAR,

SYNCHRONIZER RING AND NO.2 HUB SLEEVE

ASSEMBLY TO INPUT SHAFT

(a) Apply MP grease to the needle roller bearings.

(b) Install the 3rd gear.

(e) Place the synchronizer ring on the gear and align the ring

slots with the shifting keys.

(d) Using SST and a press, install the 3rd gear and No.2

hub sleeve.

SST 09506±35010

3. INSTALL SNAP RING

Select a snap ring that will allow minimum axial play and

install it on the shaft.

Snap ring thickness:

4. MEASURE THIRD GEAR THRUST CLEARANCE

Using a feeler gauge, measure the 3rd gear thrust clear-

ance.

Standard clearance: 0.10 ± 0.35 mm

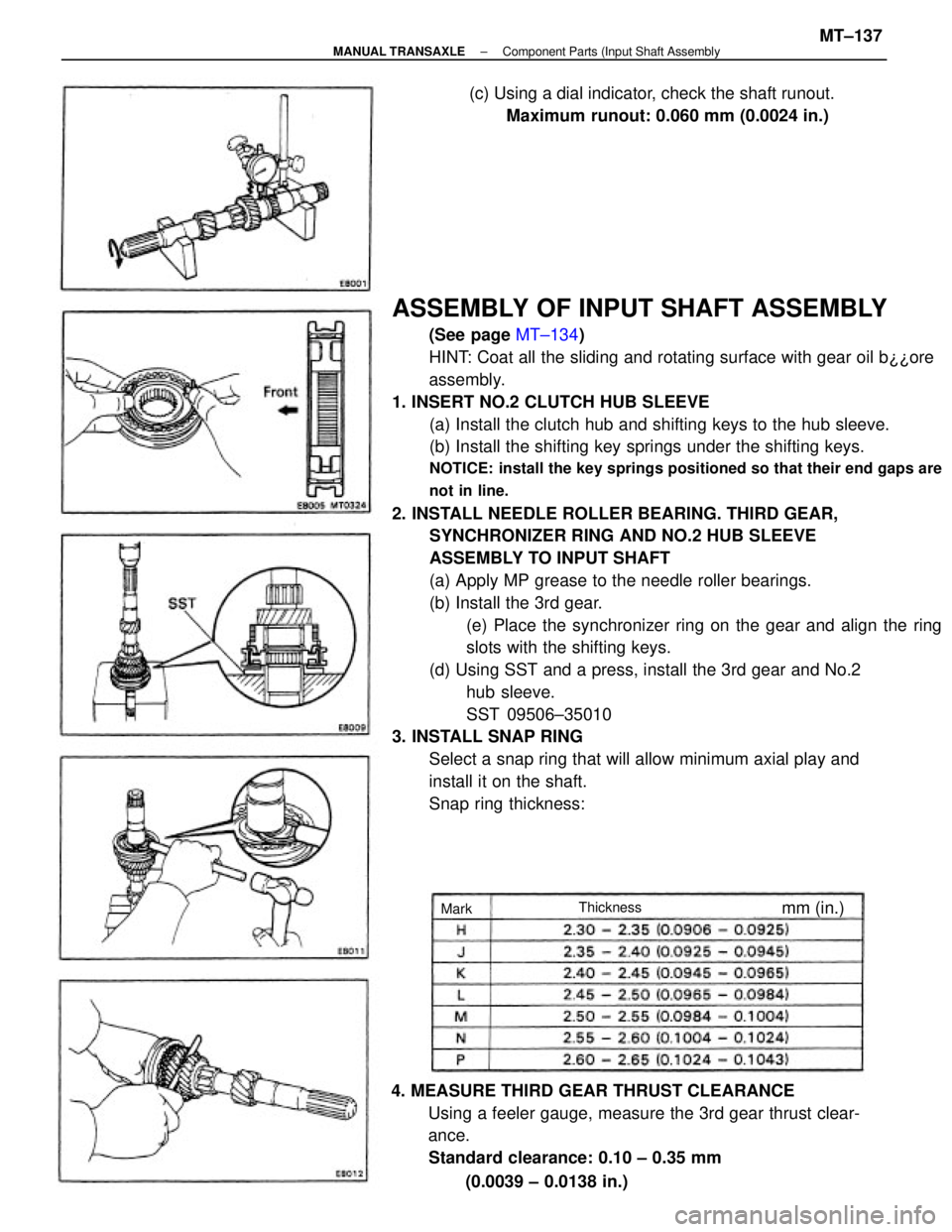

(0.0039 ± 0.0138 in.)(c) Using a dial indicator, check the shaft runout.

Maximum runout: 0.060 mm (0.0024 in.)

Thicknessmm (in.)Mark

± MANUAL TRANSAXLEComponent Parts (Input Shaft AssemblyMT±137

Page 2052 of 2389

5. INSTALL SPACER, SYNCHRONIZER RING, NEEDLE

ROLLER BEARINGS, FOURTH GEAR AND RADIAL

BALL BEARING

(a) Install the spacer.

(b) Apply MP grease to the needle roller bearings.

(c) Place the synchronizer ring on the gear and align the

the ring slots with the shifting keys.

(d) Install the 4th gear.

(e) Using SST and a press, install the radial ball bearing.

SST 09506±35010

6. INSTALL ±SNAP RING

Select a snap ring that will allow minimum axial play and

install it on the shaft.

Snap ring thickness:

7. MEASURE FOURTH GEAR THRUST CLEARANCE

Using a feeler gauge, measure the 4th gear thrust

clearance.

Standard clearance: 0.10 ± 0.55 mm

(0.0039 ± 0.0217 in.)

8. INSTALL INPUT SHAFT FRONT BEARING INNER

RACE

Using SST and a press, install the input shaft front

bearing inner race.

SST 09316±60010 (09316±00020)

Thicknessmm (in.)Mark

± MANUAL TRANSAXLEComponent Parts (Input. Shaft Assembly)MT±138

Page 2053 of 2389

DISASSEMBLY OF OUTPUT SHAFT

ASSEMBLY

1. MEASURE FIRST AND SECOND GEAR THRUST

CLEARANCE

Using a feeler gauge, measure the thrust clearance.

Standard clearance:

1 st gear 0.10 ± 0.35 mm

(0.0039 ± 0.0138 in.)2nd gear 0.10 ± 0.45 mm

(0.0038 ± 0.0177 in.)

Maximum clearance:

1 st gear 0.40 mm (0.0157 in.)

2nd gear 0.50 mm (0.0197 in.)

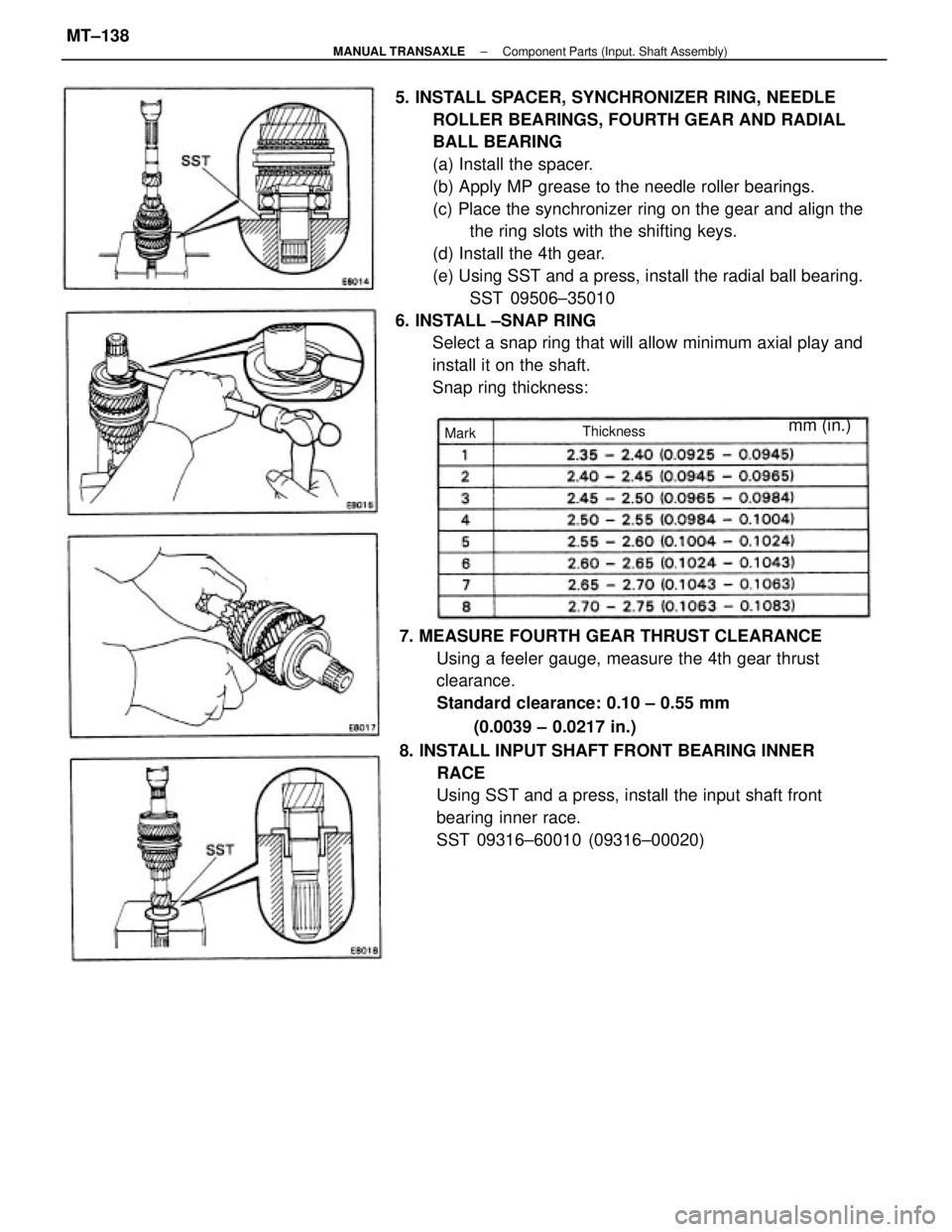

Output Shaft Assembly

± MANUAL TRANSAXLEComponent Parts (Output Shaft Assembly)MT±139

Page 2054 of 2389

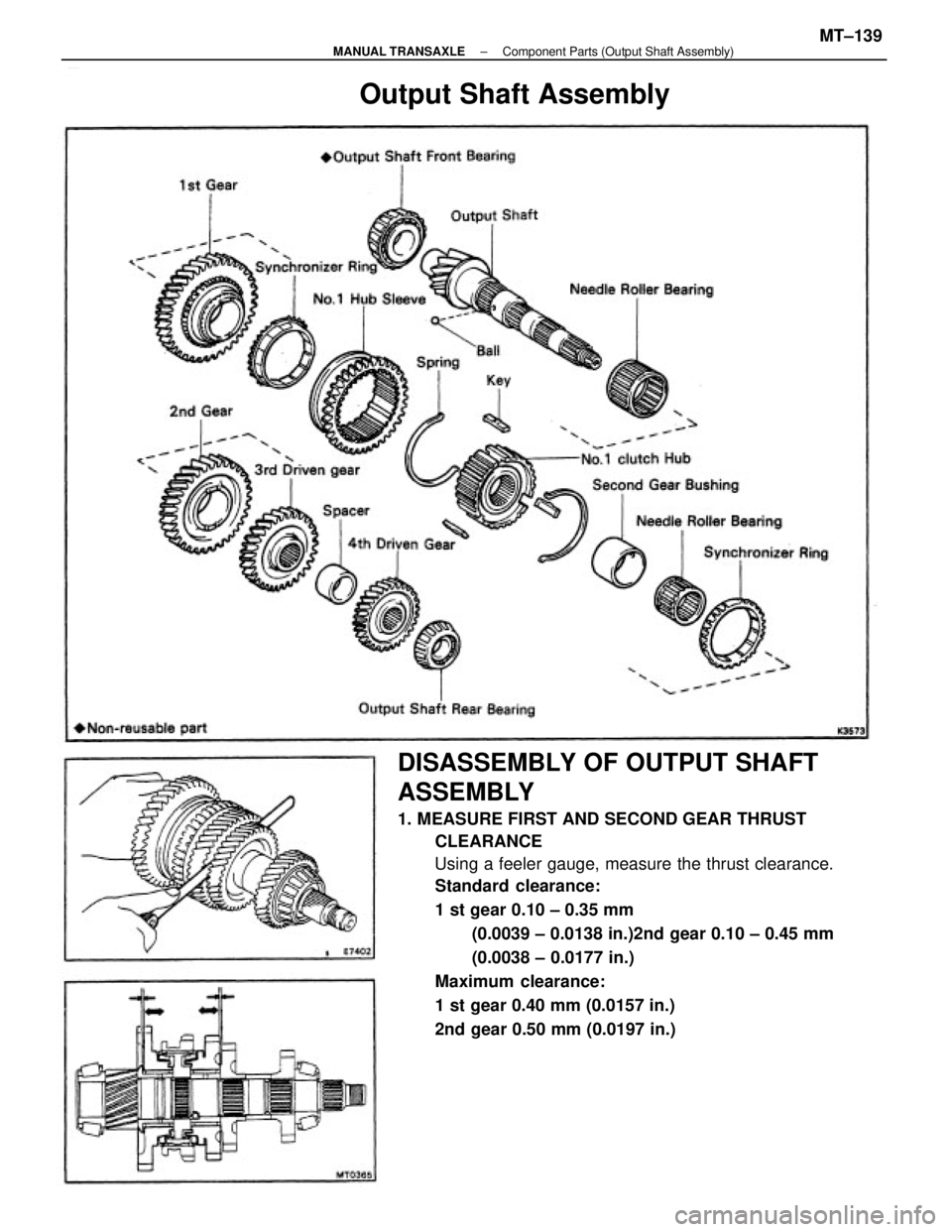

2. CHECK OIL CLEARANCE OF FIRST AND SECOND

GEAR

Using dial indicator, measure the oil clearance between

the gear and shaft.

Standard clearance:

1st gear 0.009 ± 0.051 mm

(0.0004 ± 0.0020 in.)

2nd gear, 0.009 ± 0.053 mm

(0.0004 ± 0.0020 in.)

Maximum clearance: 0.080 mm (0.0031 in.)

If the clearance exceeds the limit, replace the gear,

needle roller bearing or shaft.

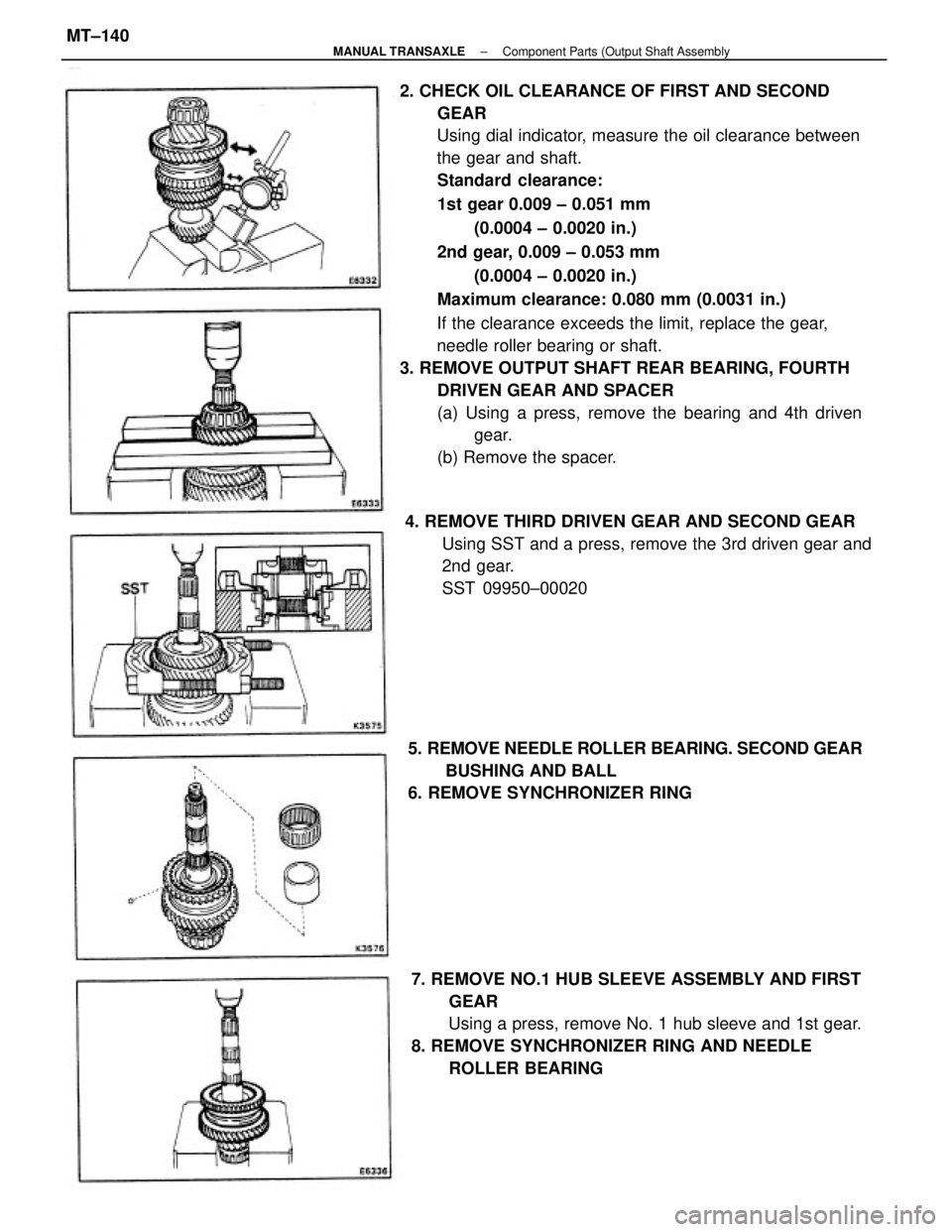

3. REMOVE OUTPUT SHAFT REAR BEARING, FOURTH

DRIVEN GEAR AND SPACER

(a) Using a press, remove the bearing and 4th driven

gear.

(b) Remove the spacer.

7. REMOVE NO.1 HUB SLEEVE ASSEMBLY AND FIRST

GEAR

Using a press, remove No. 1 hub sleeve and 1st gear.

8. REMOVE SYNCHRONIZER RING AND NEEDLE

ROLLER BEARING 4. REMOVE THIRD DRIVEN GEAR AND SECOND GEAR

Using SST and a press, remove the 3rd driven gear and

2nd gear.

SST 09950±00020

5. REMOVE NEEDLE ROLLER BEARING. SECOND GEAR

BUSHING AND BALL

6. REMOVE SYNCHRONIZER RING

± MANUAL TRANSAXLEComponent Parts (Output Shaft AssemblyMT±140

Page 2055 of 2389

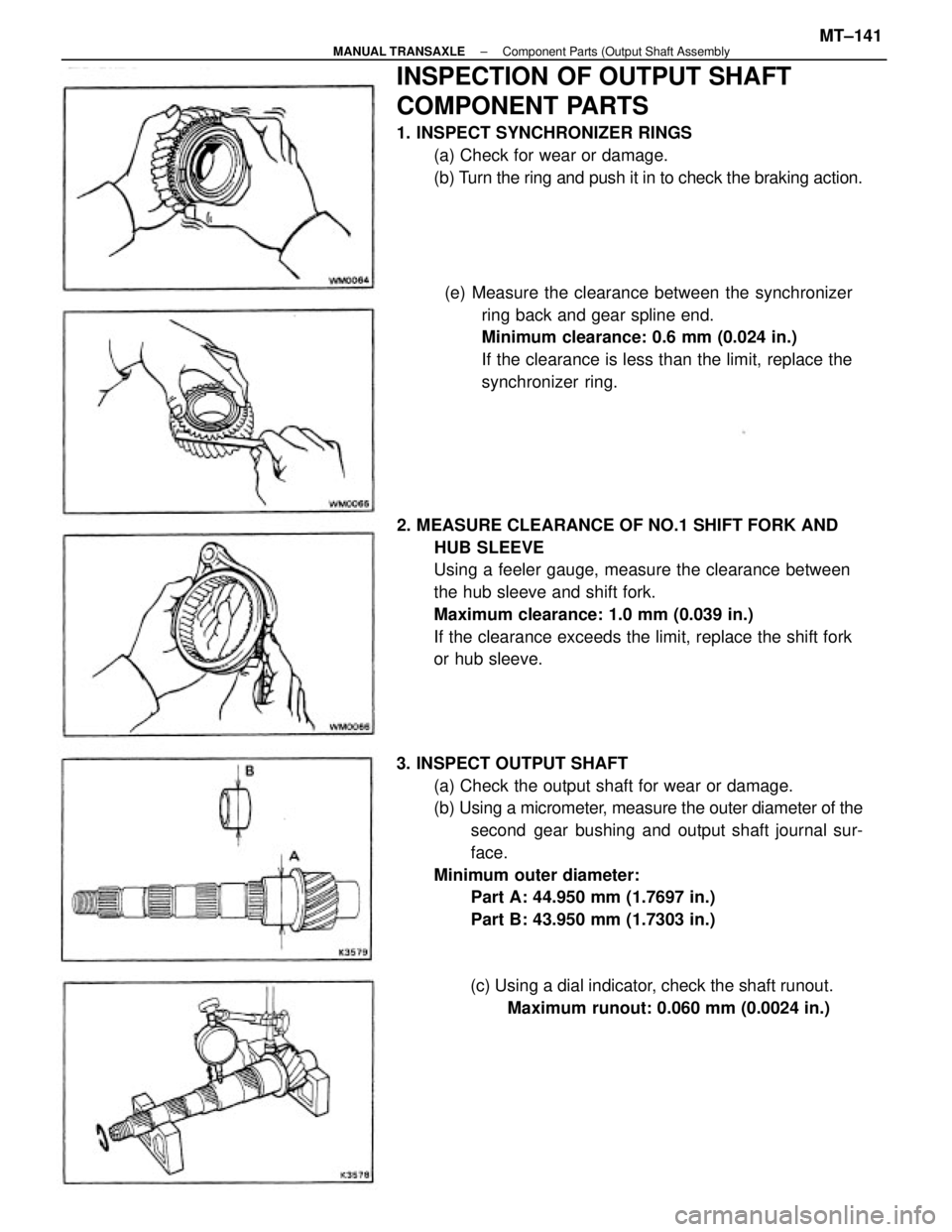

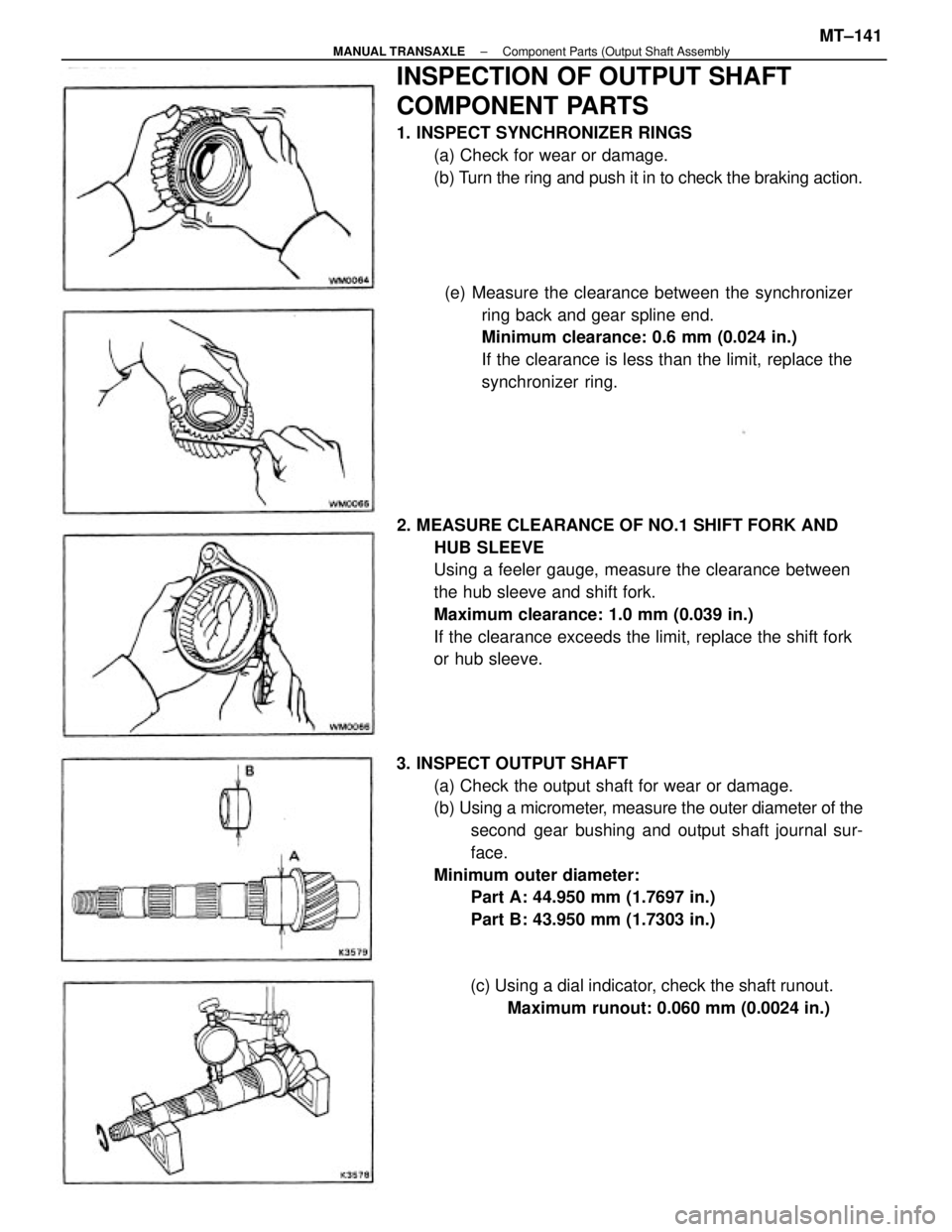

3. INSPECT OUTPUT SHAFT

(a) Check the output shaft for wear or damage.

(b) Using a micrometer, measure the outer diameter of the

second gear bushing and output shaft journal sur-

face.

Minimum outer diameter:

Part A: 44.950 mm (1.7697 in.)

Part B: 43.950 mm (1.7303 in.)

INSPECTION OF OUTPUT SHAFT

COMPONENT PARTS

1. INSPECT SYNCHRONIZER RINGS

(a) Check for wear or damage.

(b) Turn the ring and push it in to check the braking action.

2. MEASURE CLEARANCE OF NO.1 SHIFT FORK AND

HUB SLEEVE

Using a feeler gauge, measure the clearance between

the hub sleeve and shift fork.

Maximum clearance: 1.0 mm (0.039 in.)

If the clearance exceeds the limit, replace the shift fork

or hub sleeve.(e) Measure the clearance between the synchronizer

ring back and gear spline end.

Minimum clearance: 0.6 mm (0.024 in.)

If the clearance is less than the limit, replace the

synchronizer ring.

(c) Using a dial indicator, check the shaft runout.

Maximum runout: 0.060 mm (0.0024 in.)

± MANUAL TRANSAXLEComponent Parts (Output Shaft AssemblyMT±141

Page 2056 of 2389

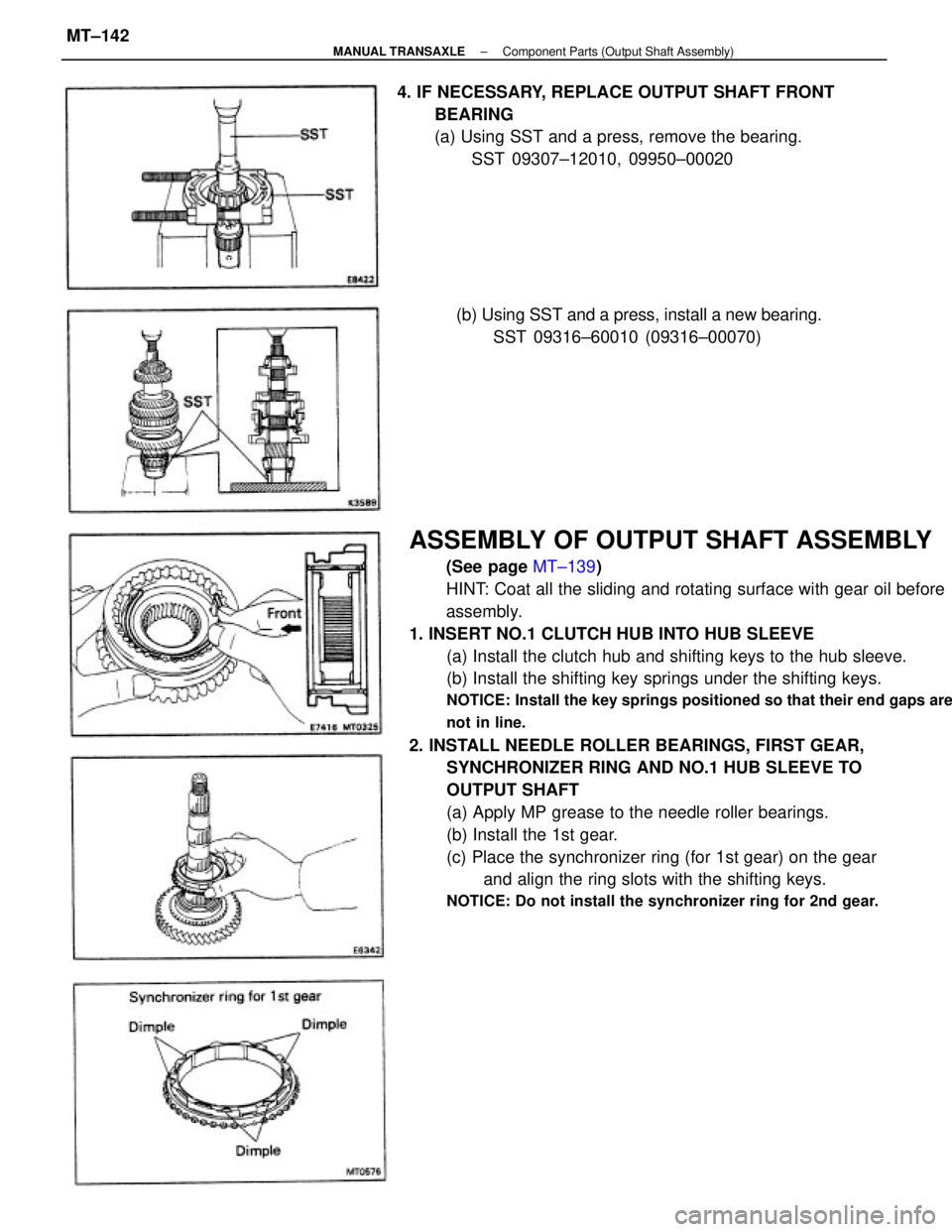

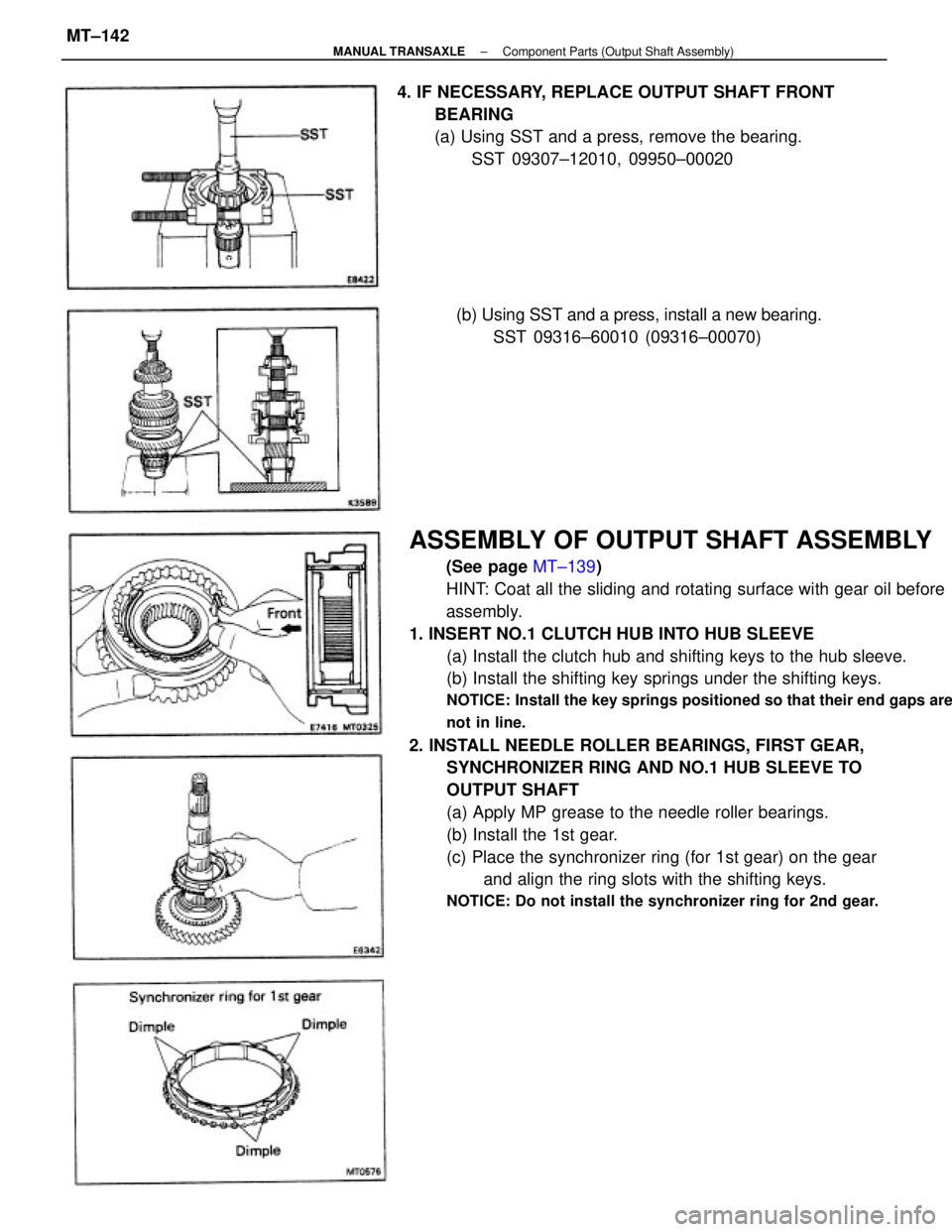

ASSEMBLY OF OUTPUT SHAFT ASSEMBLY

(See page MT±139)

HINT: Coat all the sliding and rotating surface with gear oil before

assembly.

1. INSERT NO.1 CLUTCH HUB INTO HUB SLEEVE

(a) Install the clutch hub and shifting keys to the hub sleeve.

(b) Install the shifting key springs under the shifting keys.

NOTICE: Install the key springs positioned so that their end gaps are

not in line.

2. INSTALL NEEDLE ROLLER BEARINGS, FIRST GEAR,

SYNCHRONIZER RING AND NO.1 HUB SLEEVE TO

OUTPUT SHAFT

(a) Apply MP grease to the needle roller bearings.

(b) Install the 1st gear.

(c) Place the synchronizer ring (for 1st gear) on the gear

and align the ring slots with the shifting keys.

NOTICE: Do not install the synchronizer ring for 2nd gear.

4. IF NECESSARY, REPLACE OUTPUT SHAFT FRONT

BEARING

(a) Using SST and a press, remove the bearing.

SST 09307±12010, 09950±00020

(b) Using SST and a press, install a new bearing.

SST 09316±60010 (09316±00070)

± MANUAL TRANSAXLEComponent Parts (Output Shaft Assembly)MT±142

Page 2057 of 2389

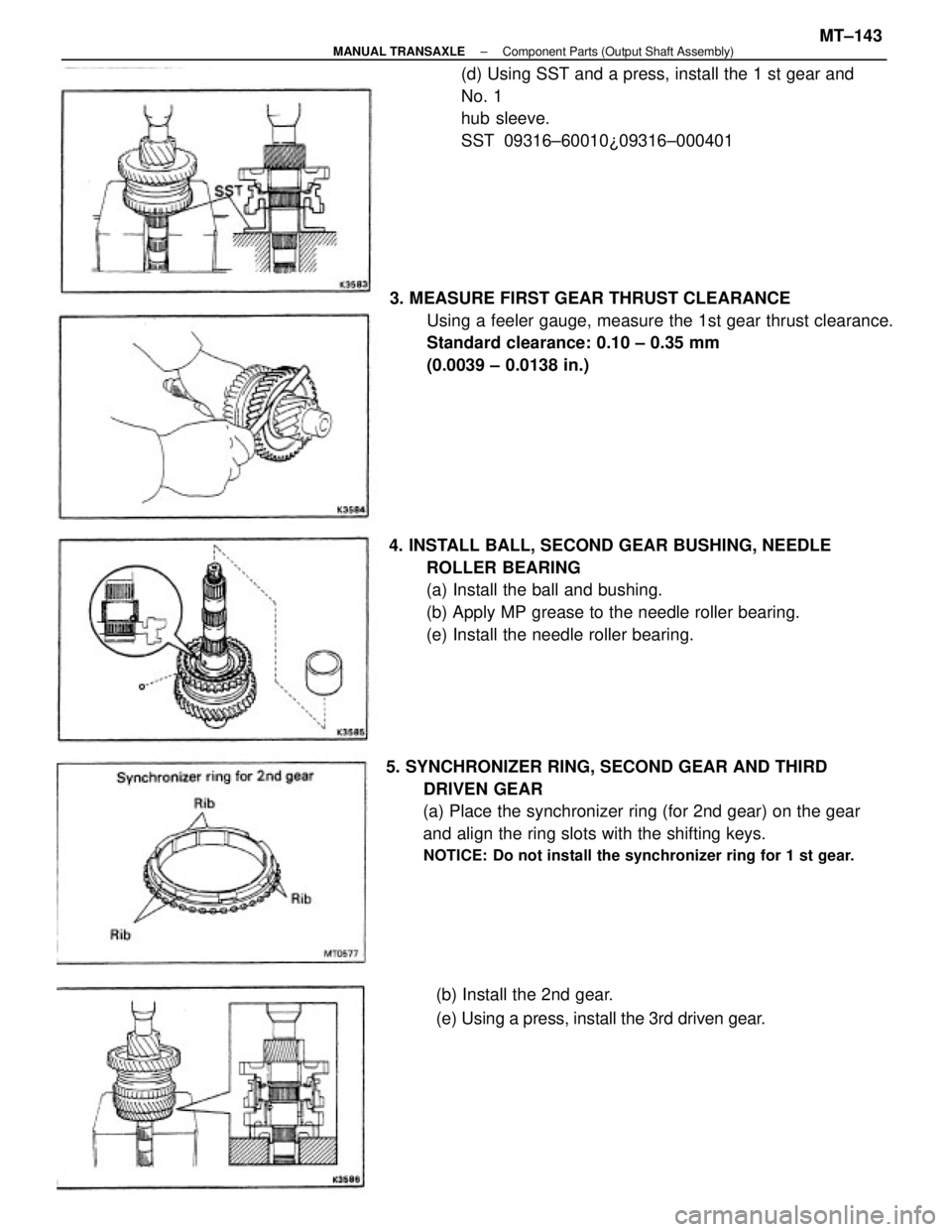

3. MEASURE FIRST GEAR THRUST CLEARANCE

Using a feeler gauge, measure the 1st gear thrust clearance.

Standard clearance: 0.10 ± 0.35 mm

(0.0039 ± 0.0138 in.)

5. SYNCHRONIZER RING, SECOND GEAR AND THIRD

DRIVEN GEAR

(a) Place the synchronizer ring (for 2nd gear) on the gear

and align the ring slots with the shifting keys.

NOTICE: Do not install the synchronizer ring for 1 st gear.

4. INSTALL BALL, SECOND GEAR BUSHING, NEEDLE

ROLLER BEARING

(a) Install the ball and bushing.

(b) Apply MP grease to the needle roller bearing.

(e) Install the needle roller bearing.(d) Using SST and a press, install the 1 st gear and

No. 1

hub sleeve.

SST 09316±60010¿09316±000401

(b) Install the 2nd gear.

(e) Using a press, install the 3rd driven gear.

± MANUAL TRANSAXLEComponent Parts (Output Shaft Assembly)MT±143

Page 2058 of 2389

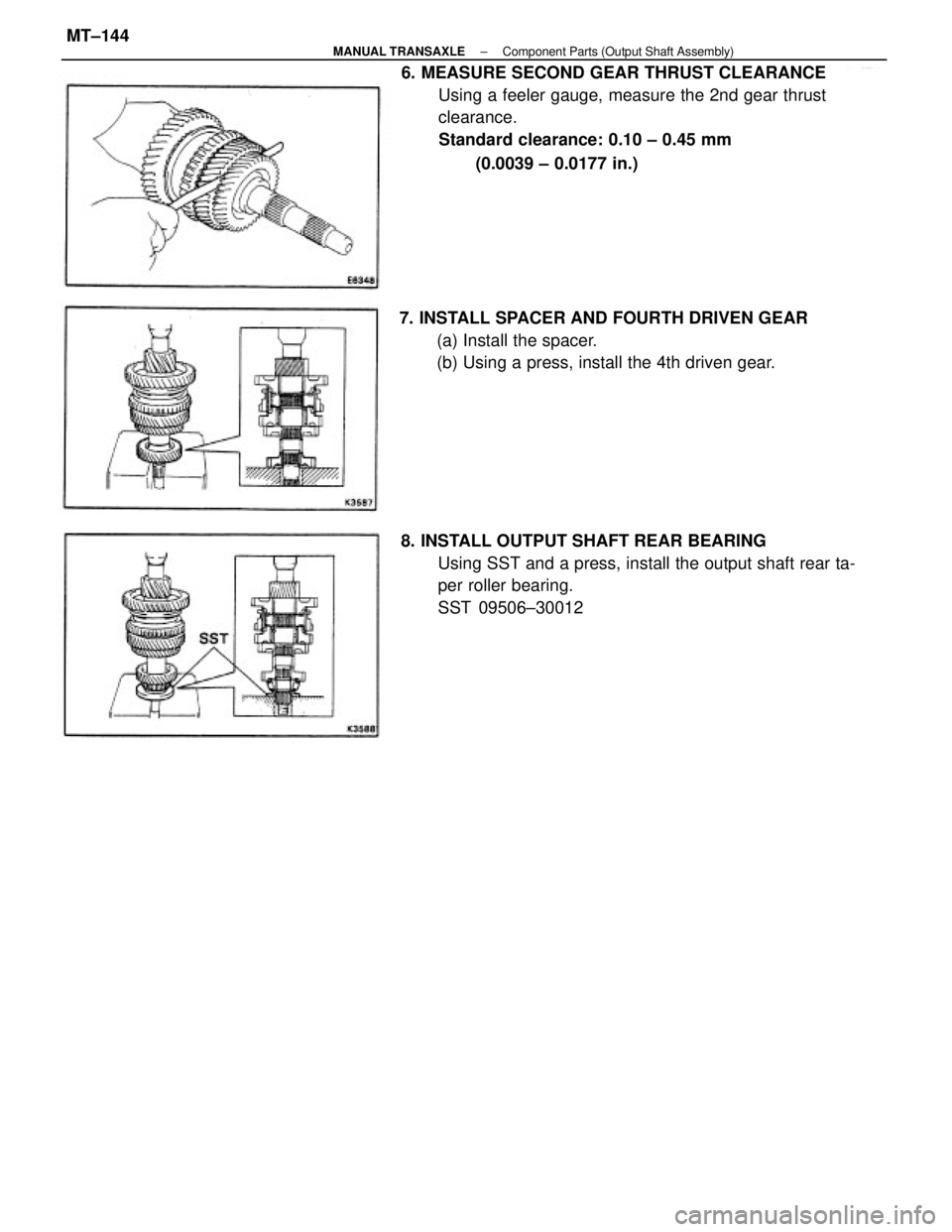

6. MEASURE SECOND GEAR THRUST CLEARANCE

Using a feeler gauge, measure the 2nd gear thrust

clearance.

Standard clearance: 0.10 ± 0.45 mm

(0.0039 ± 0.0177 in.)

8. INSTALL OUTPUT SHAFT REAR BEARING

Using SST and a press, install the output shaft rear ta-

per roller bearing.

SST 09506±30012 7. INSTALL SPACER AND FOURTH DRIVEN GEAR

(a) Install the spacer.

(b) Using a press, install the 4th driven gear.

± MANUAL TRANSAXLEComponent Parts (Output Shaft Assembly)MT±144

Page 2059 of 2389

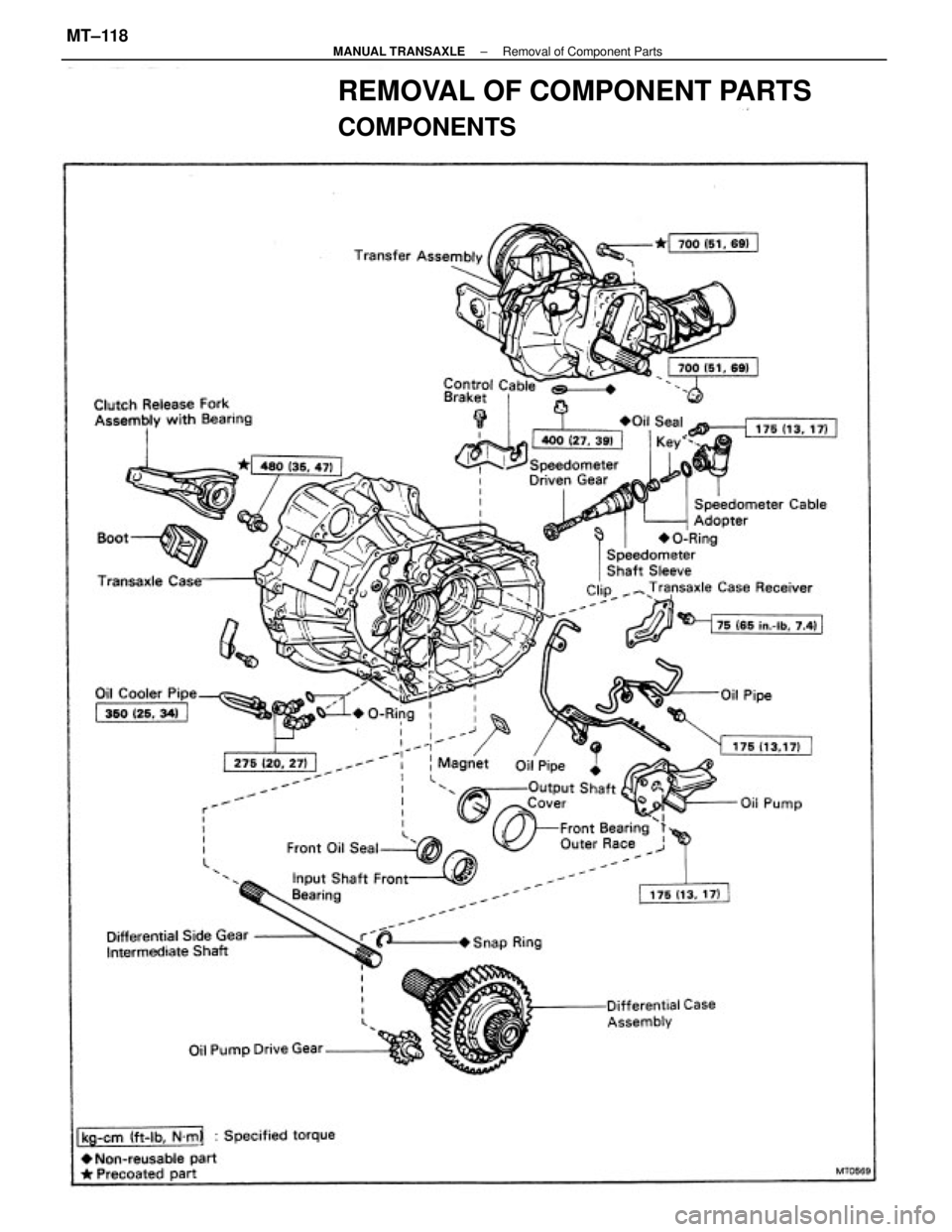

REMOVAL OF COMPONENT PARTS

COMPONENTS

± MANUAL TRANSAXLERemoval of Component PartsMT±118

Page 2060 of 2389

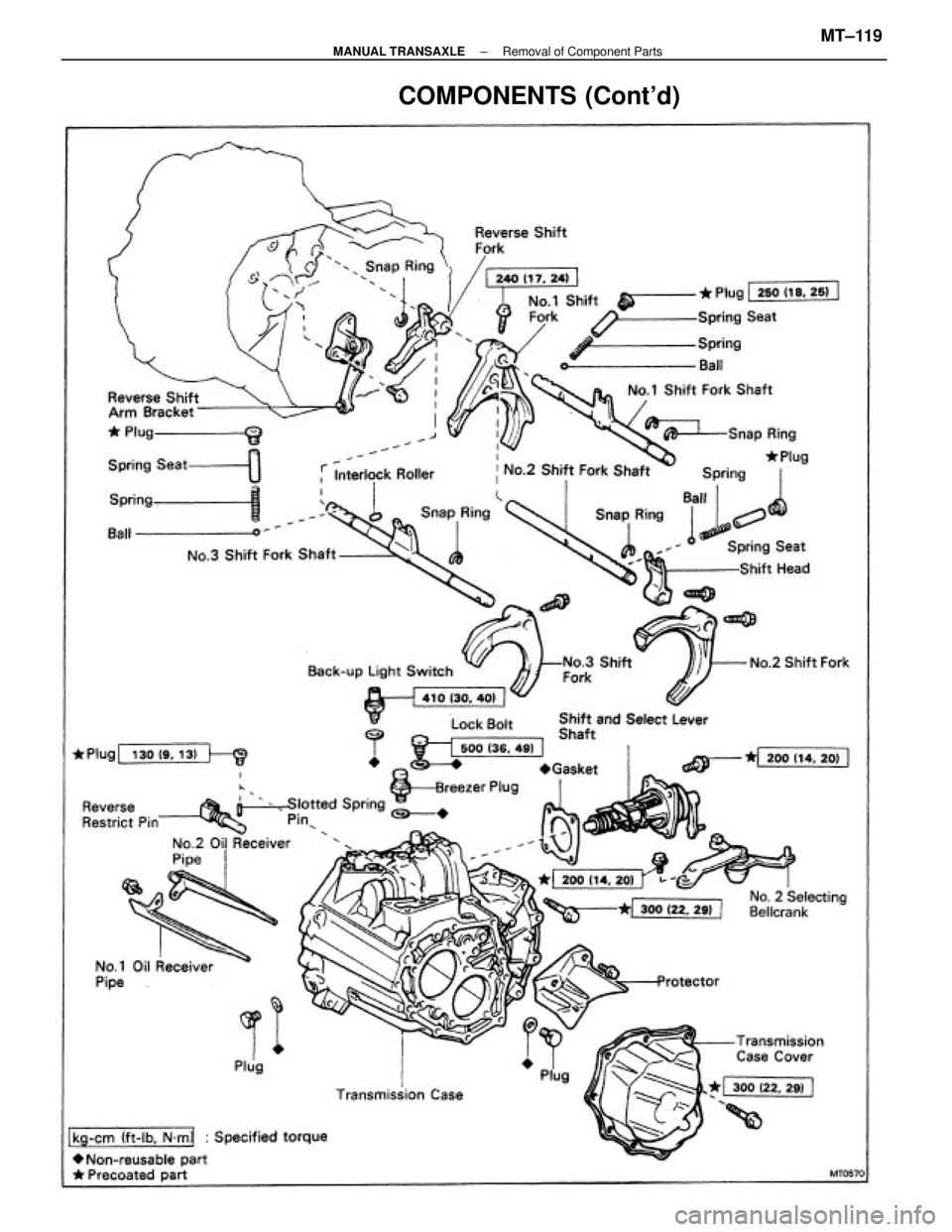

COMPONENTS (Cont'd)

± MANUAL TRANSAXLERemoval of Component PartsMT±119

Trending: roof rack, power steering fluid, set clock, key battery, alternator, radiator cap, automatic transmission