engine TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1283 of 2389

25. INSTALL EGR PIPE

Install a new gasket and the EGR pipe with the two bolts and

union nut.

Torque:

Bolt 185 kg±cm (13 f t±lb, 18 N±m)

Nut 800 kg±cm (58 ft±Ib, 78 N±m)

26. INSTALL THROTTLE BODY

(See steps 1 and 2 on page Fl±115)

27. INSTALL ISC VALVE

(See steps 1 to 3 on page FI±119)

28. INSTALL ALTERNATOR (See page CH±15)

29. INSTALL FRONT EXHAUST PIPE

(See step 14 on page EM±172)

30. INSTALL ENGINE RH UNDER COVER

31. INSTALL AIR CLEANER HOSE

32. INSTALL CRUISE CONTROL ACTUATOR

(See step 27 on page EM±173)

33. INSTALL ACCELERATOR CABLE, AND ADJUST IT

34. (A/T)

CONNECT THROTTLE CABLE, AND ADJUST IT

35. FILL WITH ENGINE COOLANT (See page CO±5)

Capacity (w/ Heater):

M/T 9.5 liters (110.0 US qts, 8.4 Imp. qts)

A/T 9.4 liters ( 9.9 US qts, 8.3 Imp. qts)

36. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY

37. START ENGINE AND CHECK FOR LEAKS

38. ADJUST IGNITION TIMING (See on page IG±21)

Ignition timing:

10° BTDC @ idle

(w/ Terminals TE1 and E1 connected)

39. PERFORM ROAD TEST

Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

40. RECHECK ENGINE COOLANT LEVEL AND OIL LEVEL

,

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±106

Page 1284 of 2389

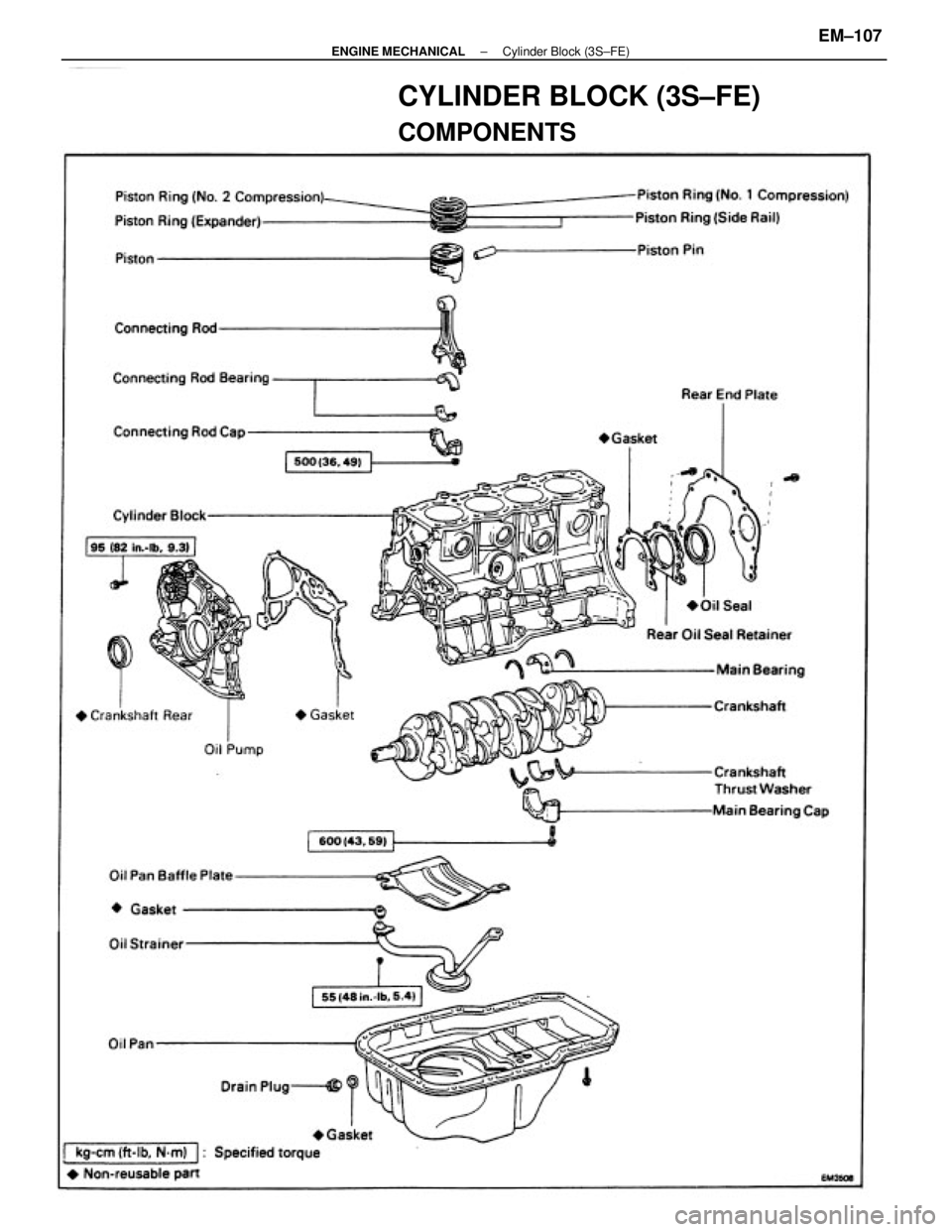

CYLINDER BLOCK (3S±FE)

COMPONENTS

± ENGINE MECHANICALCylinder Block (3S±FE)EM±107

Page 1285 of 2389

REMOVAL OF ENGINE

1. REMOVE BATTERY

2. DRAIN ENGINE COOLANT (See page CO±4)

3. REMOVE HOOD

4. REMOVE IGNITER AND BRACKET ASSEMBLY

(a) Disconnect the igniter connector.

(b) Disconnect the ground strap from the bracket.

(c) Remove the two bolts, the igniter and bracket assembly.

5. REMOVE RADIATOR (See page CO±16)

6. REMOVE RADIATOR RESERVOIR TANK

7. (A/T)

DISCONNECT THROTTLE CABLE FROM THROTTLE

BODY

8. DISCONNECT ACCELERATOR CABLE FROM

THROTTLE BODY

9. (w/ CRUISE CONTROL SYSTEM)

REMOVE CRUISE CONTROL ACTUATOR

(a) Disconnect the actuator vacuum hose.

(b) Disconnect the actuator connector.

(c) Remove the bolts, actuator and bracket.

10. REMOVE AIR CLEANER ASSEMBLY

(a) Disconnect the air flow meter connector.

(b) Disconnect the four air cleaner cap clips.

(c) Disconnect the air cleaner hose, and air flow meter

assembly.

(d) Remove the air cleaner element.

(e) Remove the three bolts and air cleaner case.

11. (M/T)

REMOVE CLUTCH RELEASE CYLINDER AND TUBE

BRACKET WITHOUT DISCONNECTING TUBE

12. DISCONNECT SPEEDOMETER CABLE

13. DISCONNECT TRANSAXLE CONTROL CABLES

± ENGINE MECHANICALCylinder Block (3S±FE)EM±108

Page 1286 of 2389

15. DISCONNECT HOSES

(a) Two heater water by±pass hoses

(b) Two fuel hoses

NOTICE: Catch leaking fuel in a container.

(c) Brake booster vacuum hose

(d) A/C control valve vacuum hoses

(e) Charcoal canister vacuum hose

16. DISCONNECT WIRES AND CONNECTORS

(a) Check connector

(b) Ground straps from LH fender apron

(e) Connectors from relay box

(d) Engine room wire connector

17. RAISE VEHICLE

NOTICE: Be sure the vehicle is securely supported.

18. REMOVE ENGINE UNDER COVERS

19. DRAIN ENGINE OIL (See page LU±7)

20. REMOVE SUSPENSION LOWER CROSSMEMBER

Remove the four bolts, two nuts and crossmember.

21. REMOVE DRIVE SHAFTS

22. (4WD) .

REMOVE PROPELLER SHAFT

23. (4WD)

REMOVE DEFECTOR FROM TRANSFER EXTENSION

HOUSING

24. REMOVE PS PUMP WITHOUT DISCONNECTING

HOSES

HINT: Put aside the pump and suspend it to the cowl with a

string.14. (w/ A/C)

REMOVE A/C COMPRESSOR WITHOUT

DISCONNECTING HOSES

(a) Disconnect the two connectors.

(b) Remove the four compressor bolts.

HINT: Put aside the compressor, and suspend it to the radia-

tor support with a string.

± ENGINE MECHANICALCylinder Block (3S±FE)EM±109

Page 1287 of 2389

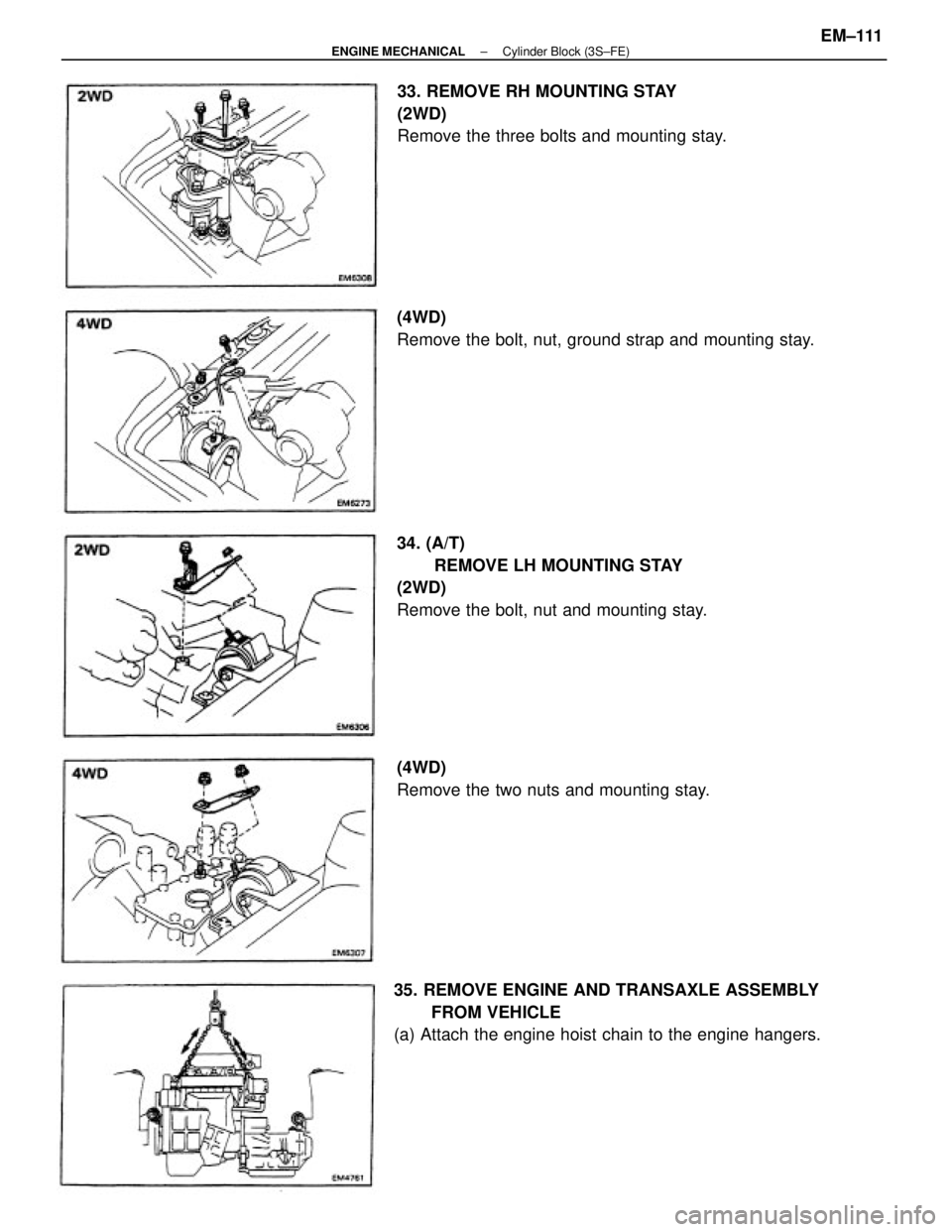

26. REMOVE ENGINE MOUNTING CENTER MEMBER

(2WD)

Remove the eight bolts, two nuts and center member.

(4WD )

Remove the eight bolts, two nuts and center member.

27. REMOVE ENGINE FRONT MOUNTING INSULATOR

AND BRACKET

28. (2WD)

REMOVE ENGINE CENTER MOUNTING INSULATOR

AND BRACKET ASSEMBLY

29. REMOVE ENGINE REAR MOUNTING INSULATOR

AND BRACKET

30. LOWER VEHICLE

31. DISCONNECT ENGINE WIRE

(a) Remove the glove compartment box.

(b) Disconnect the following connectors:

(1) Three TCCS ECU connectors

(2) Circuit opening relay connector

(3) Cowl wire connector

(4) Instrument panel wire connector

(c) Pull out the engine wire from the cowl panel.

32. REMOVE PS OIL RESERVOIR TANK WITHOUT

DISCONNECTING HOSES

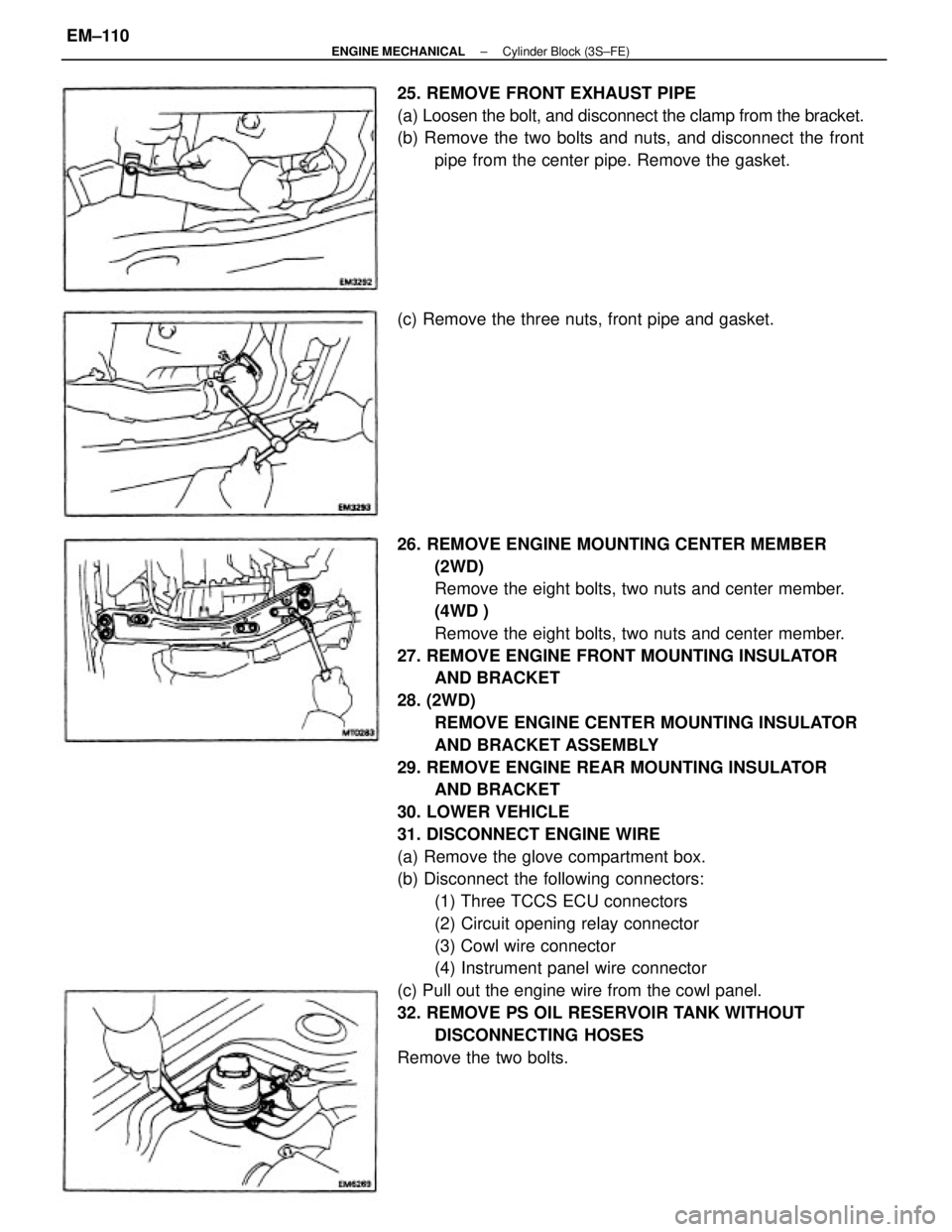

Remove the two bolts. 25. REMOVE FRONT EXHAUST PIPE

(a) Loosen the bolt, and disconnect the clamp from the bracket.

(b) Remove the two bolts and nuts, and disconnect the front

pipe from the center pipe. Remove the gasket.

(c) Remove the three nuts, front pipe and gasket.

± ENGINE MECHANICALCylinder Block (3S±FE)EM±110

Page 1288 of 2389

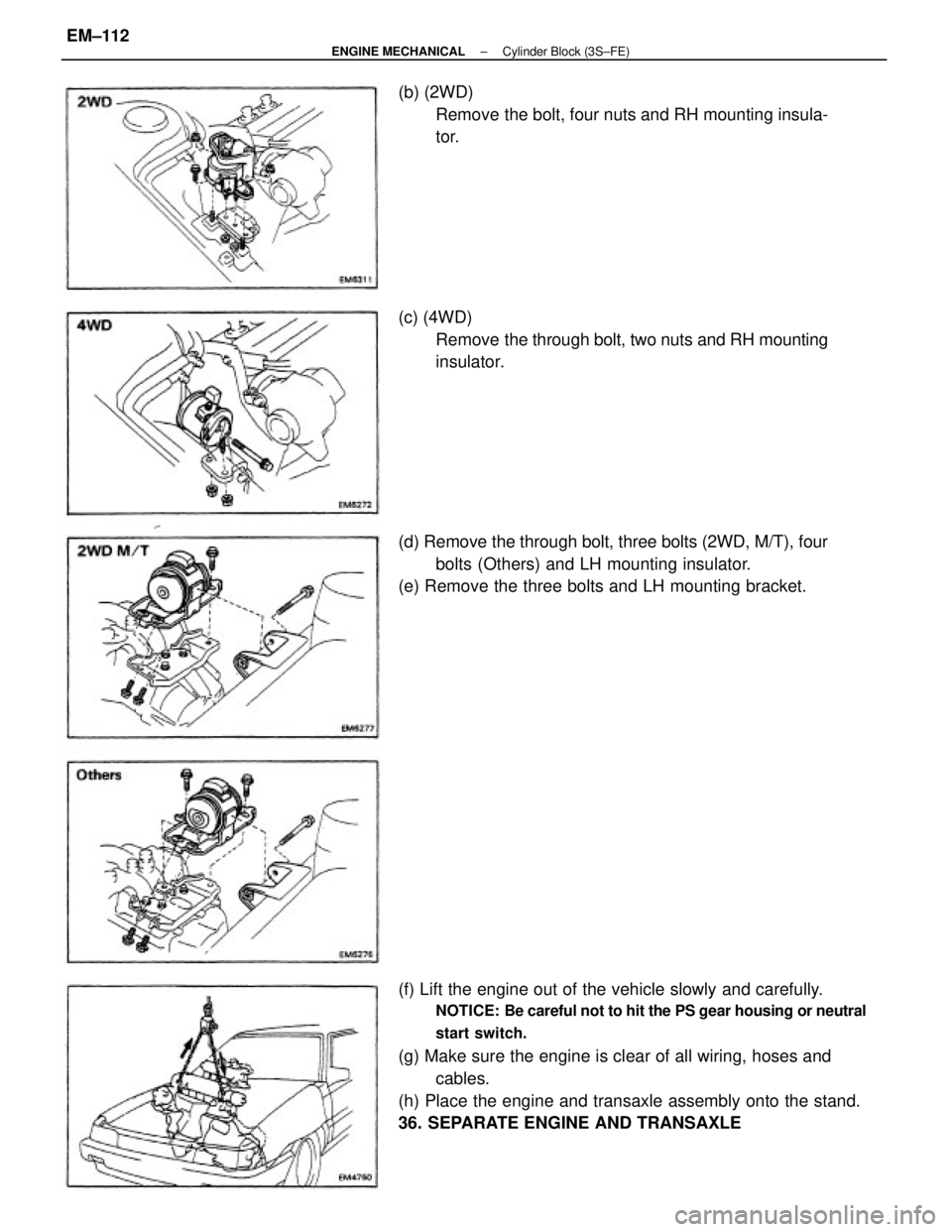

35. REMOVE ENGINE AND TRANSAXLE ASSEMBLY

FROM VEHICLE

(a) Attach the engine hoist chain to the engine hangers.34. (A/T)

REMOVE LH MOUNTING STAY

(2WD)

Remove the bolt, nut and mounting stay.33. REMOVE RH MOUNTING STAY

(2WD)

Remove the three bolts and mounting stay.

(4WD)

Remove the bolt, nut, ground strap and mounting stay.

(4WD)

Remove the two nuts and mounting stay.

± ENGINE MECHANICALCylinder Block (3S±FE)EM±111

Page 1289 of 2389

(f) Lift the engine out of the vehicle slowly and carefully.

NOTICE: Be careful not to hit the PS gear housing or neutral

start switch.

(g) Make sure the engine is clear of all wiring, hoses and

cables.

(h) Place the engine and transaxle assembly onto the stand.

36. SEPARATE ENGINE AND TRANSAXLE (d) Remove the through bolt, three bolts (2WD, M/T), four

bolts (Others) and LH mounting insulator.

(e) Remove the three bolts and LH mounting bracket. (b) (2WD)

Remove the bolt, four nuts and RH mounting insula-

tor.

(c) (4WD)

Remove the through bolt, two nuts and RH mounting

insulator.

± ENGINE MECHANICALCylinder Block (3S±FE)EM±112

Page 1290 of 2389

PREPARATION FOR DISASSEMBLY

1. ( M /T)

REMOVE CLUTCH COVER AND DISC

2. ( M /T)

REMOVE FLYWHEEL

3. 1A/T)

REMOVE DRIVE PLATE

4. REMOVE REAR END PLATE

5. INSTALL ENGINE TO ENGINE STAND FOR

DISASSEMBLY

6. REMOVE ALTERNATOR (See page CH±6)

7 REMOVE DISTRIBUTOR (See page IG±13)

8. REMOVE TIMING BELT AND PULLEYS

(See page EM±23)

9. REMOVE CYLINDER HEAD (See page EM±48)

10. REMOVE WATER PUMP (See page CO±6)

11. REMOVE OIL PAN AND OIL PUMP

(See page LU±9)

± ENGINE MECHANICALCylinder Block (3S±FE)EM±113

Page 1291 of 2389

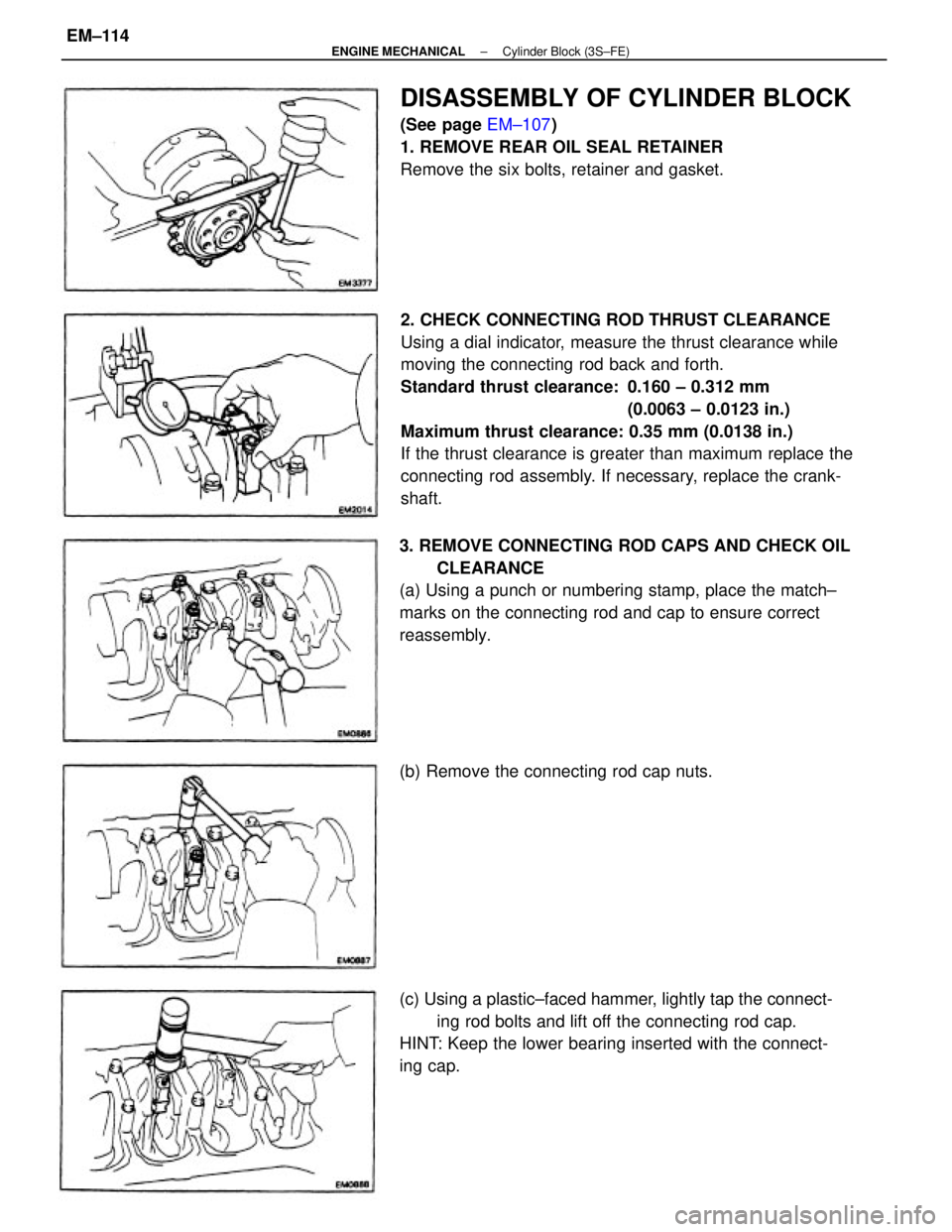

2. CHECK CONNECTING ROD THRUST CLEARANCE

Using a dial indicator, measure the thrust clearance while

moving the connecting rod back and forth.

Standard thrust clearance: 0.160 ± 0.312 mm

(0.0063 ± 0.0123 in.)

Maximum thrust clearance: 0.35 mm (0.0138 in.)

If the thrust clearance is greater than maximum replace the

connecting rod assembly. If necessary, replace the crank-

shaft.

3. REMOVE CONNECTING ROD CAPS AND CHECK OIL

CLEARANCE

(a) Using a punch or numbering stamp, place the match±

marks on the connecting rod and cap to ensure correct

reassembly.

(c) Using a plastic±faced hammer, lightly tap the connect-

ing rod bolts and lift off the connecting rod cap.

HINT: Keep the lower bearing inserted with the connect-

ing cap.

DISASSEMBLY OF CYLINDER BLOCK

(See page EM±107)

1. REMOVE REAR OIL SEAL RETAINER

Remove the six bolts, retainer and gasket.

(b) Remove the connecting rod cap nuts.

± ENGINE MECHANICALCylinder Block (3S±FE)EM±114

Page 1292 of 2389

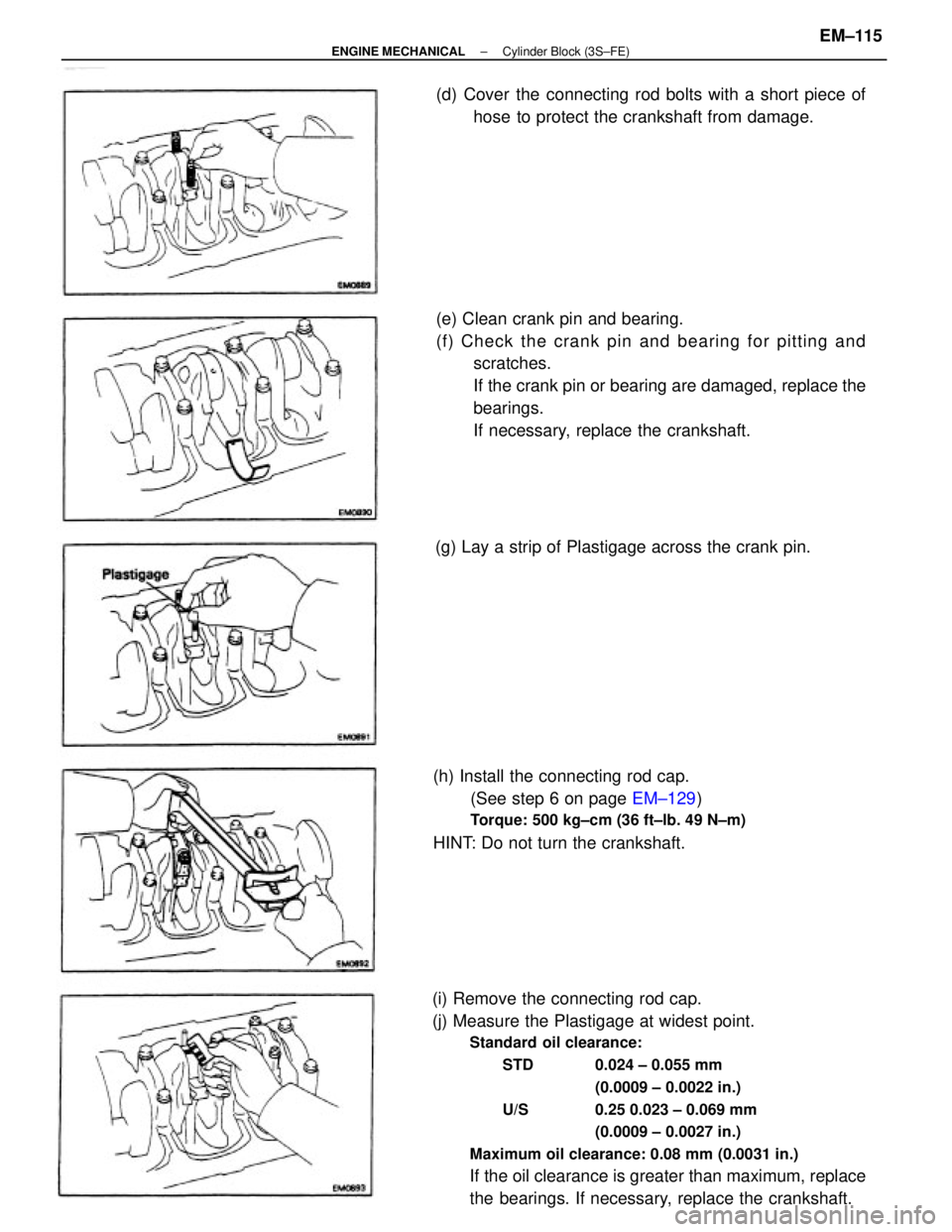

(i) Remove the connecting rod cap.

(j) Measure the Plastigage at widest point.

Standard oil clearance:

STD 0.024 ± 0.055 mm

(0.0009 ± 0.0022 in.)

U/S 0.25 0.023 ± 0.069 mm

(0.0009 ± 0.0027 in.)

Maximum oil clearance: 0.08 mm (0.0031 in.)

If the oil clearance is greater than maximum, replace

the bearings. If necessary, replace the crankshaft. (e) Clean crank pin and bearing.

(f) Check the crank pin and bearing for pitting and

scratches.

If the crank pin or bearing are damaged, replace the

bearings.

If necessary, replace the crankshaft.

(h) Install the connecting rod cap.

(See step 6 on page EM±129)

Torque: 500 kg±cm (36 ft±lb. 49 N±m)

HINT: Do not turn the crankshaft.(d) Cover the connecting rod bolts with a short piece of

hose to protect the crankshaft from damage.

(g) Lay a strip of Plastigage across the crank pin.

± ENGINE MECHANICALCylinder Block (3S±FE)EM±115