tow TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 79 of 2389

AT4304

AT0193

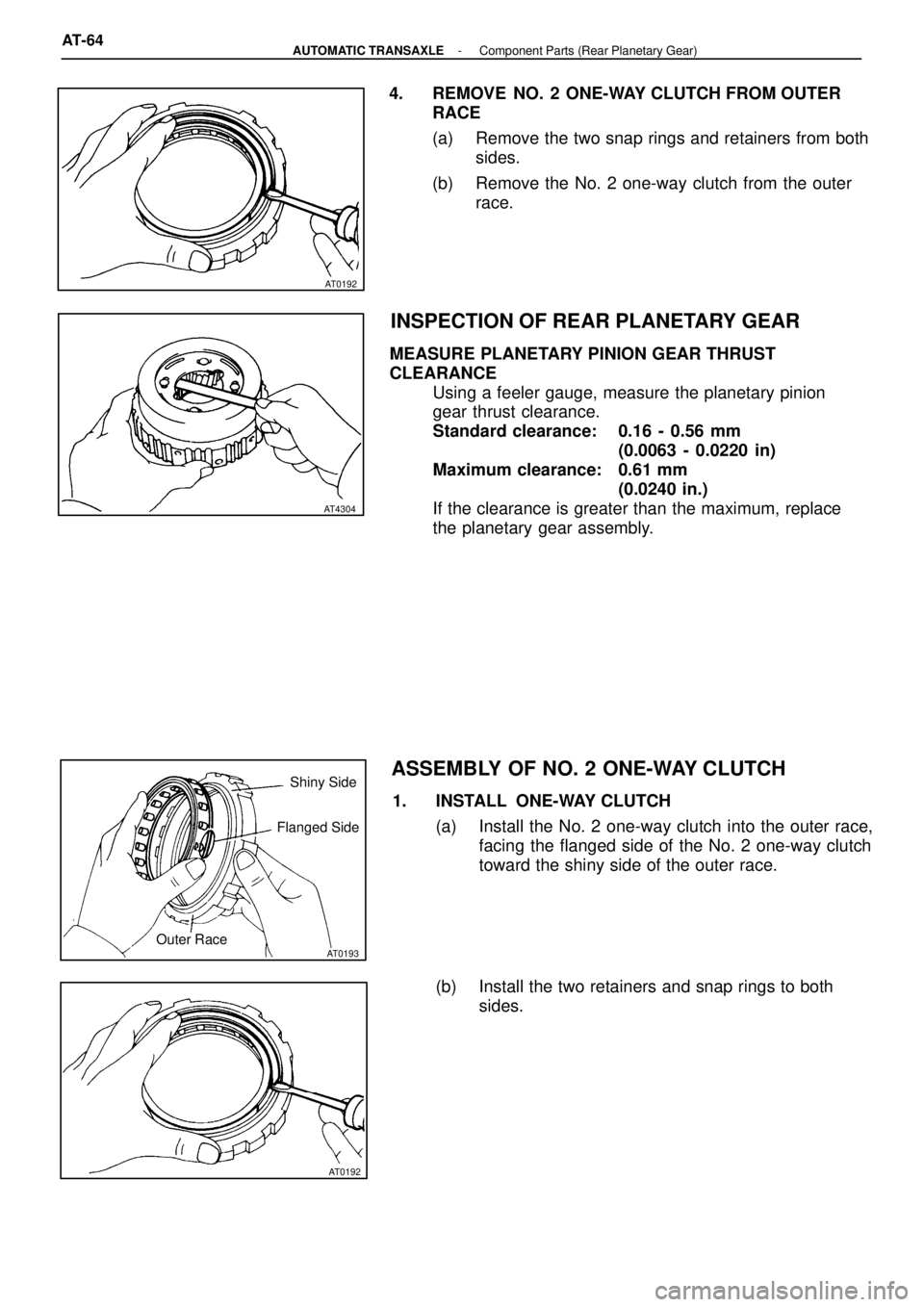

Outer RaceFlanged SideShiny Side

AT0192 AT0192

4. REMOVE NO. 2 ONE-WAY CLUTCH FROM OUTER

RACE

(a) Remove the two snap rings and retainers from both

sides.

(b) Remove the No. 2 one-way clutch from the outer

race.

INSPECTION OF REAR PLANETARY GEAR

MEASURE PLANETARY PINION GEAR THRUST

CLEARANCE

Using a feeler gauge, measure the planetary pinion

gear thrust clearance.

Standard clearance: 0.16 - 0.56 mm

(0.0063 - 0.0220 in)

Maximum clearance: 0.61 mm

(0.0240 in.)

If the clearance is greater than the maximum, replace

the planetary gear assembly.

ASSEMBLY OF NO. 2 ONE-WAY CLUTCH

1. INSTALL ONE-WAY CLUTCH

(a) Install the No. 2 one-way clutch into the outer race,

facing the flanged side of the No. 2 one-way clutch

toward the shiny side of the outer race.

(b) Install the two retainers and snap rings to both

sides.

AT-64- AUTOMATIC TRANSAXLEComponent Parts (Rear Planetary Gear)

Page 80 of 2389

Black Side

AT0191

Turn HoldFreeLock

AT0323

Align

AT4235 AT7717

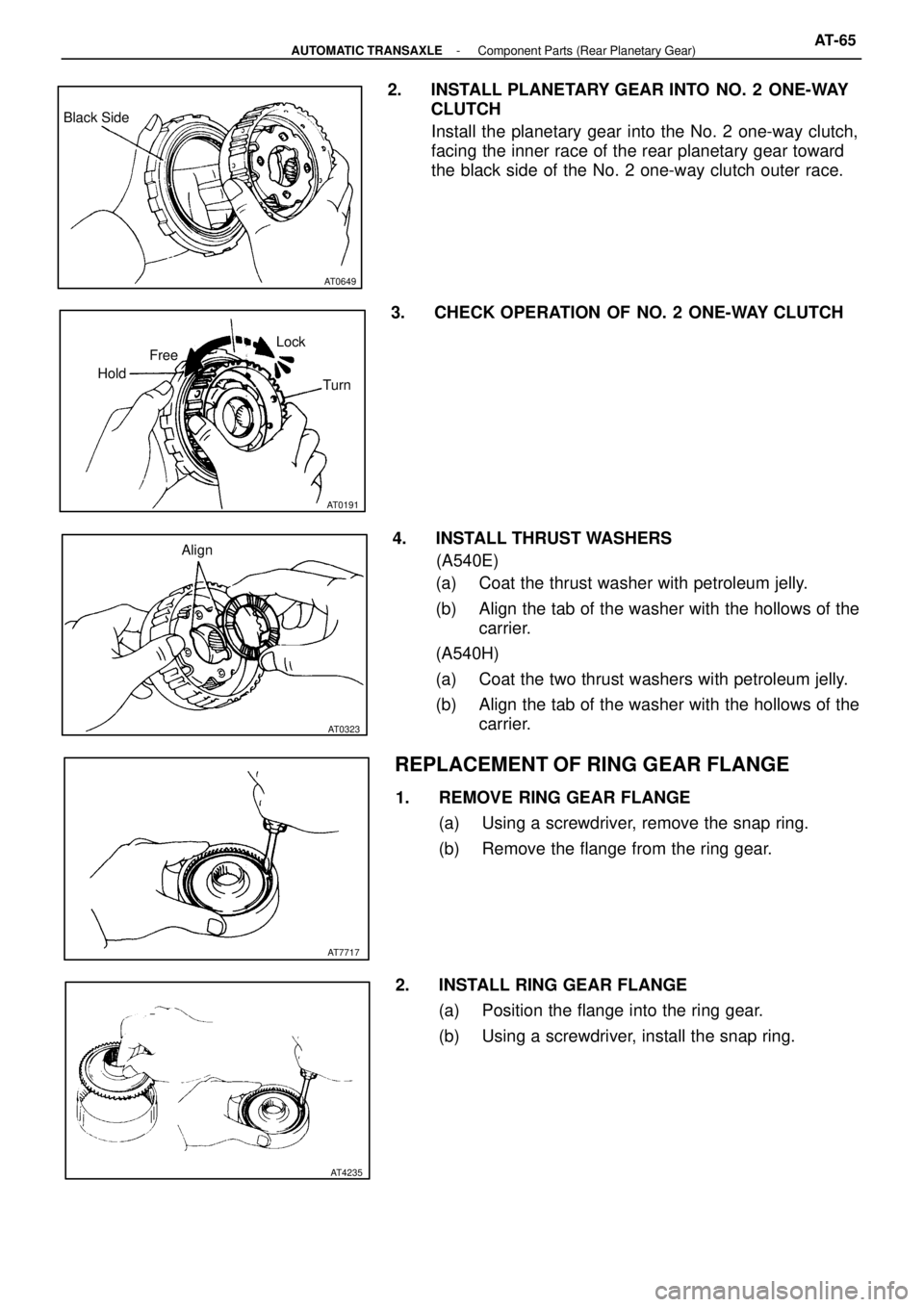

2. INSTALL PLANETARY GEAR INTO NO. 2 ONE-WAY

CLUTCH

Install the planetary gear into the No. 2 one-way clutch,

facing the inner race of the rear planetary gear toward

the black side of the No. 2 one-way clutch outer race.

AT0649

3. CHECK OPERATION OF NO. 2 ONE-WAY CLUTCH

4. INSTALL THRUST WASHERS

(A540E)

(a) Coat the thrust washer with petroleum jelly.

(b) Align the tab of the washer with the hollows of the

carrier.

(A540H)

(a) Coat the two thrust washers with petroleum jelly.

(b) Align the tab of the washer with the hollows of the

carrier.

REPLACEMENT OF RING GEAR FLANGE

1. REMOVE RING GEAR FLANGE

(a) Using a screwdriver, remove the snap ring.

(b) Remove the flange from the ring gear.

2. INSTALL RING GEAR FLANGE

(a) Position the flange into the ring gear.

(b) Using a screwdriver, install the snap ring.

- AUTOMATIC TRANSAXLEComponent Parts (Rear Planetary Gear)AT-65

Page 155 of 2389

AT3735

AT7700

AT3545

AT3736 AT3547

(e) Install the direct clutch and forward clutch into the

case.

HINT: Hold the direct clutch toward the forward clutch to

prevent the thrust washer from getting out of place.

(f) Check the distance between the direct clutch

drum and the sun gear input drum.

Distance: Approx. 3 mm (0.12 in.)

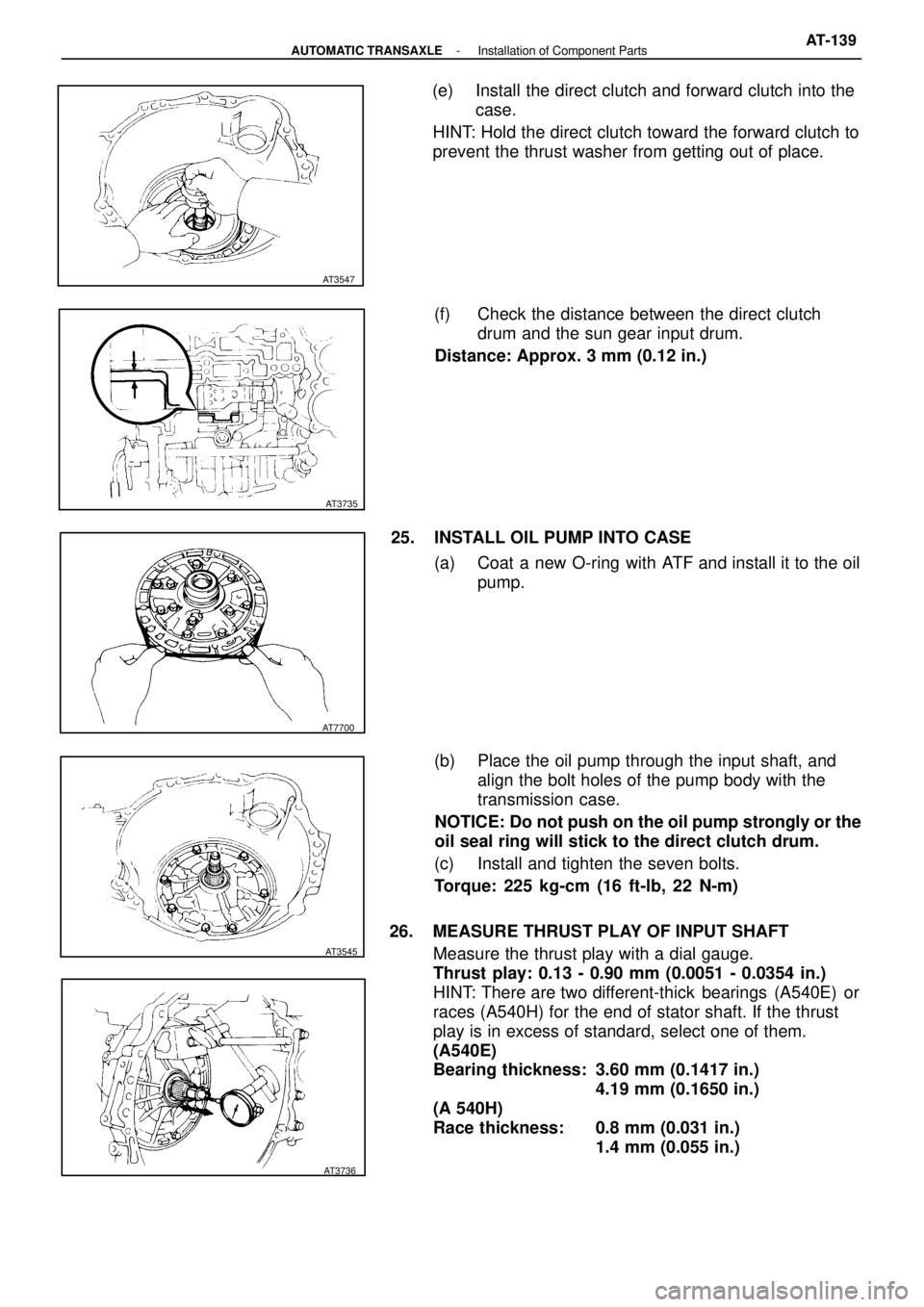

25. INSTALL OIL PUMP INTO CASE

(a) Coat a new O-ring with ATF and install it to the oil

pump.

(b) Place the oil pump through the input shaft, and

align the bolt holes of the pump body with the

transmission case.

NOTICE: Do not push on the oil pump strongly or the

oil seal ring will stick to the direct clutch drum.

(c) Install and tighten the seven bolts.

Torque: 225 kg-cm (16 ft-lb, 22 N-m)

26. MEASURE THRUST PLAY OF INPUT SHAFT

Measure the thrust play with a dial gauge.

Thrust play: 0.13 - 0.90 mm (0.0051 - 0.0354 in.)

HINT: There are two different-thick bearings (A540E) or

races (A540H) for the end of stator shaft. If the thrust

play is in excess of standard, select one of them.

(A540E)

Bearing thickness: 3.60 mm (0.1417 in.)

4.19 mm (0.1650 in.)

(A 540H)

Race thickness: 0.8 mm (0.031 in.)

1.4 mm (0.055 in.)

- AUTOMATIC TRANSAXLEInstallation of Component PartsAT-139

Page 181 of 2389

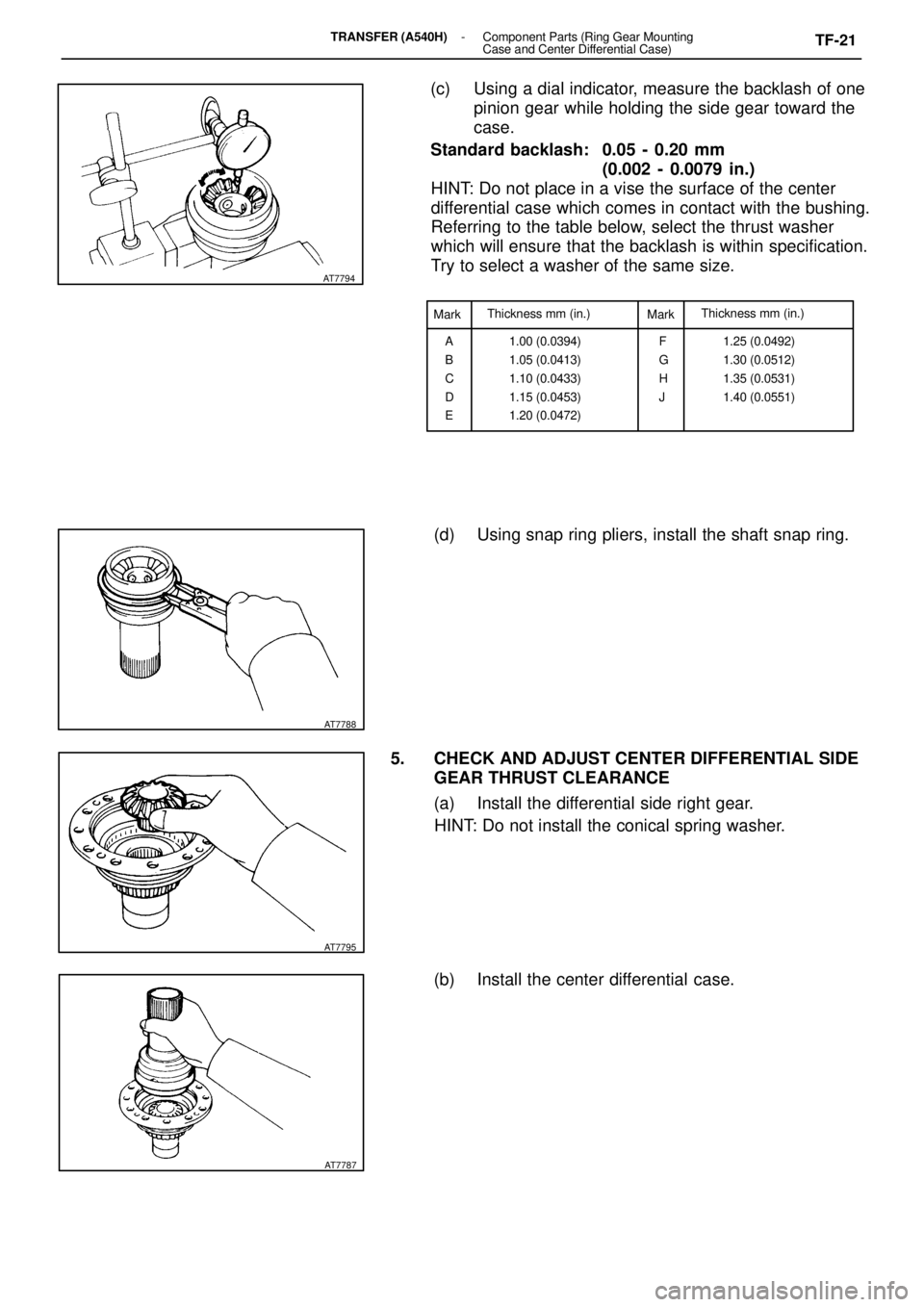

MarkThickness mm (in.)

MarkThickness mm (in.)

A

B

C

D

E1.00 (0.0394)

1.05 (0.0413)

1.10 (0.0433)

1.15 (0.0453)

1.20 (0.0472)F

G

H

J1.25 (0.0492)

1.30 (0.0512)

1.35 (0.0531)

1.40 (0.0551)

AT7788

AT7795

AT7787 AT7794

(c) Using a dial indicator, measure the backlash of one

pinion gear while holding the side gear toward the

case.

Standard backlash: 0.05 - 0.20 mm

(0.002 - 0.0079 in.)

HINT: Do not place in a vise the surface of the center

differential case which comes in contact with the bushing.

Referring to the table below, select the thrust washer

which will ensure that the backlash is within specification.

Try to select a washer of the same size.

(d) Using snap ring pliers, install the shaft snap ring.

5. CHECK AND ADJUST CENTER DIFFERENTIAL SIDE

GEAR THRUST CLEARANCE

(a) Install the differential side right gear.

HINT: Do not install the conical spring washer.

(b) Install the center differential case.

- TRANSFER (A540H)Component Parts (Ring Gear Mounting

Case and Center Differential Case)TF-21

Page 219 of 2389

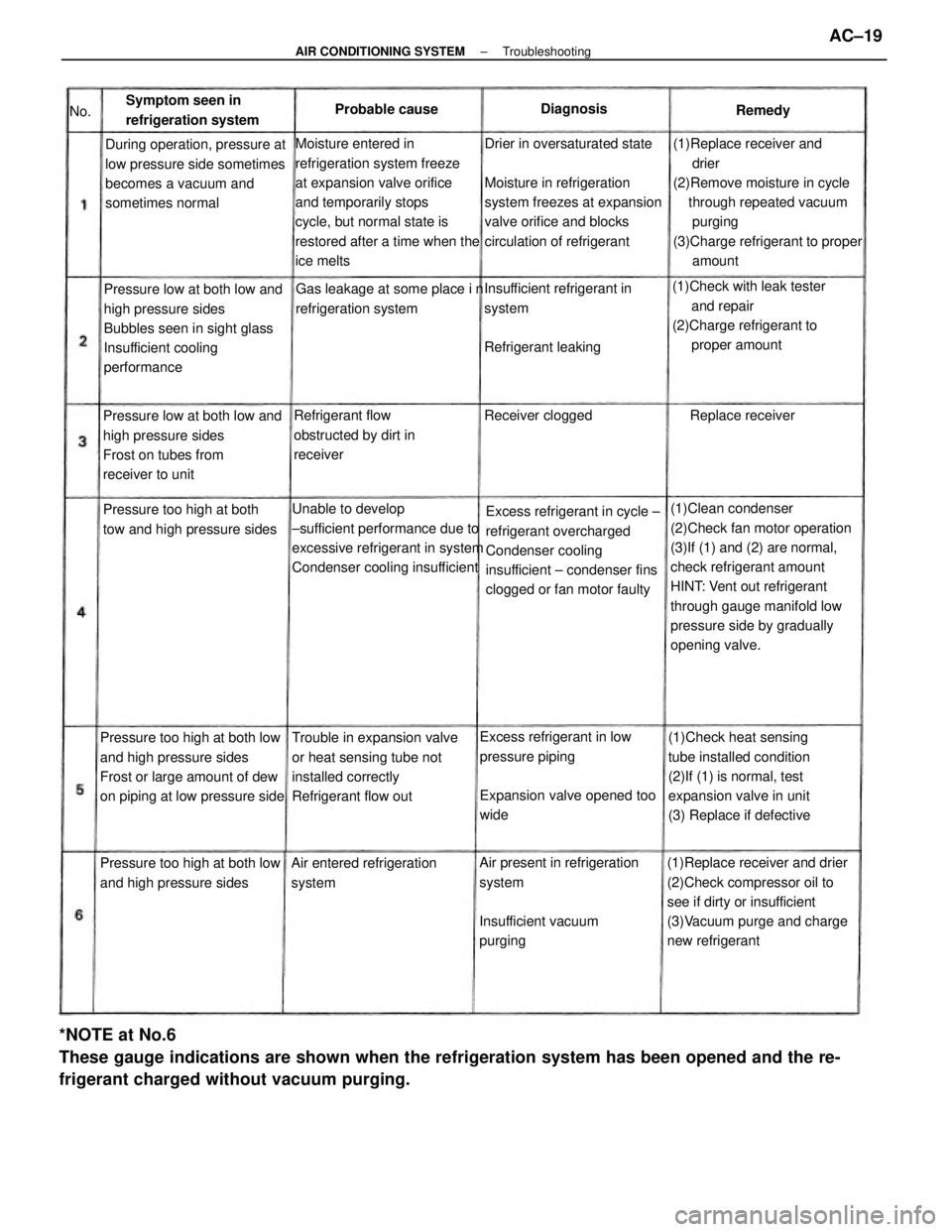

*NOTE at No.6

These gauge indications are shown when the refrigeration system has been opened and the re-

frigerant charged without vacuum purging.

(1)Clean condenser

(2)Check fan motor operation

(3)If (1) and (2) are normal,

check refrigerant amount

HINT: Vent out refrigerant

through gauge manifold low

pressure side by gradually

opening valve.

(1)Replace receiver and drier

(2)Check compressor oil to

see if dirty or insufficient

(3)Vacuum purge and charge

new refrigerant Drier in oversaturated state

Moisture in refrigeration

system freezes at expansion

valve orifice and blocks

circulation of refrigerant(1)Replace receiver and

drier

(2)Remove moisture in cycle

through repeated vacuum

purging

(3)Charge refrigerant to proper

amount

Excess refrigerant in cycle ±

refrigerant overcharged

Condenser cooling

insufficient ± condenser fins

clogged or fan motor faulty Unable to develop

±sufficient performance due to

excessive refrigerant in system

Condenser cooling insufficientMoisture entered in

refrigeration system freeze

at expansion valve orifice

and temporarily stops

cycle, but normal state is

restored after a time when the

ice melts

Pressure too high at both low

and high pressure sides

Frost or large amount of dew

on piping at low pressure side(1)Check heat sensing

tube installed condition

(2)If (1) is normal, test

expansion valve in unit

(3) Replace if defective Pressure low at both low and

high pressure sides

Bubbles seen in sight glass

Insufficient cooling

performance

Air present in refrigeration

system

Insufficient vacuum

purging During operation, pressure at

low pressure side sometimes

becomes a vacuum and

sometimes normal

Trouble in expansion valve

or heat sensing tube not

installed correctly

Refrigerant flow out Pressure low at both low and

high pressure sides

Frost on tubes from

receiver to unit(1)Check with leak tester

and repair

(2)Charge refrigerant to

proper amount

Excess refrigerant in low

pressure piping

Expansion valve opened too

wideInsufficient refrigerant in

system

Refrigerant leaking

Pressure too high at both low

and high pressure sidesPressure too high at both

tow and high pressure sidesGas leakage at some place i n

refrigeration system

Refrigerant flow

obstructed by dirt in

receiver

Air entered refrigeration

system Symptom seen in

refrigeration system

Receiver clogged Replace receiver Probable causeDiagnosis

Remedy

No.

± AIR CONDITIONING SYSTEMTroubleshootingAC±19

Page 277 of 2389

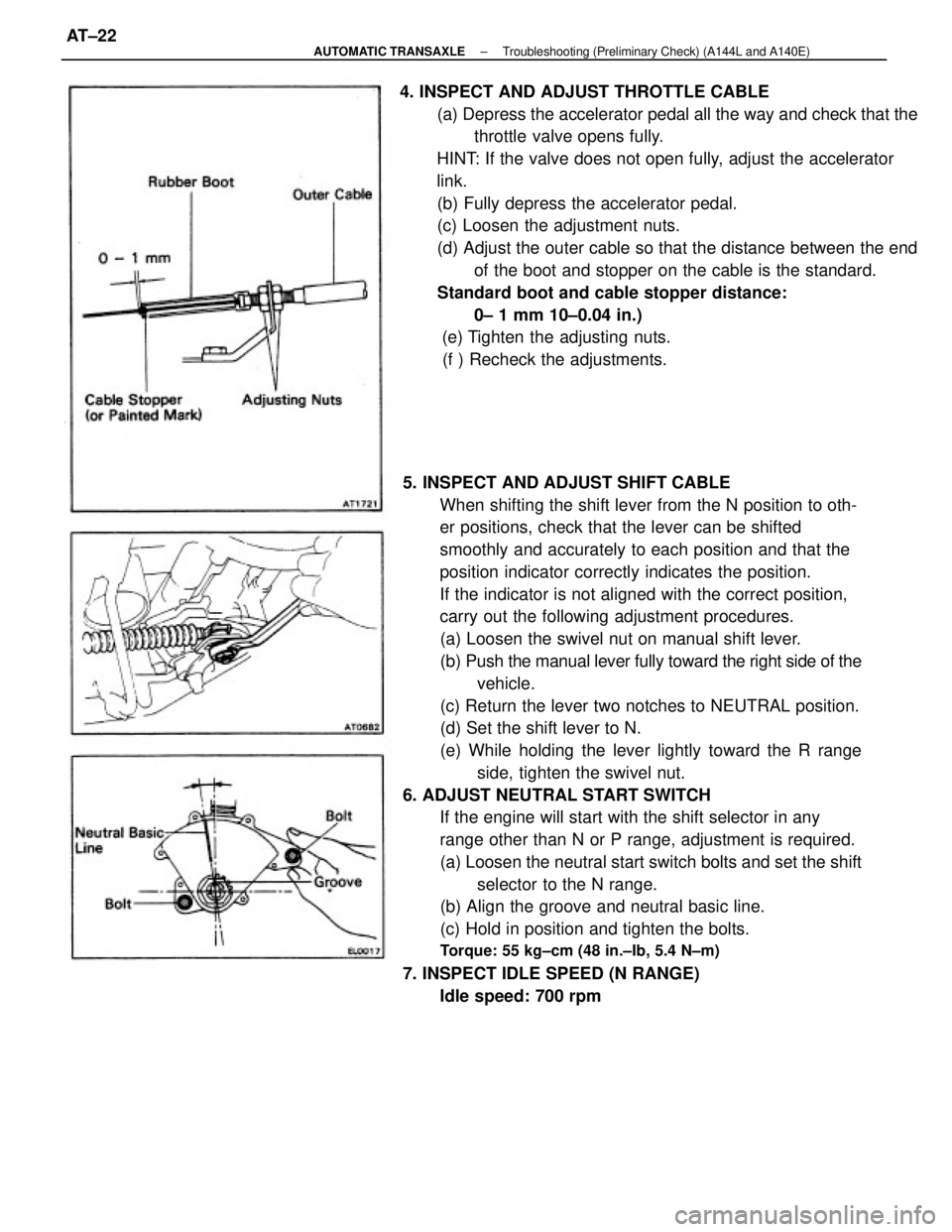

5. INSPECT AND ADJUST SHIFT CABLE

When shifting the shift lever from the N position to oth-

er positions, check that the lever can be shifted

smoothly and accurately to each position and that the

position indicator correctly indicates the position.

If the indicator is not aligned with the correct position,

carry out the following adjustment procedures.

(a) Loosen the swivel nut on manual shift lever.

(b) Push the manual lever fully toward the right side of the

vehicle.

(c) Return the lever two notches to NEUTRAL position.

(d) Set the shift lever to N.

(e) While holding the lever lightly toward the R range

side, tighten the swivel nut.

6. ADJUST NEUTRAL START SWITCH

If the engine will start with the shift selector in any

range other than N or P range, adjustment is required.

(a) Loosen the neutral start switch bolts and set the shift

selector to the N range.

(b) Align the groove and neutral basic line.

(c) Hold in position and tighten the bolts.

Torque: 55 kg±cm (48 in.±Ib, 5.4 N±m)

7. INSPECT IDLE SPEED (N RANGE)

Idle speed: 700 rpm 4. INSPECT AND ADJUST THROTTLE CABLE

(a) Depress the accelerator pedal all the way and check that the

throttle valve opens fully.

HINT: If the valve does not open fully, adjust the accelerator

link.

(b) Fully depress the accelerator pedal.

(c) Loosen the adjustment nuts.

(d) Adjust the outer cable so that the distance between the end

of the boot and stopper on the cable is the standard.

Standard boot and cable stopper distance:

0± 1 mm 10±0.04 in.)

(e) Tighten the adjusting nuts.

(f ) Recheck the adjustments.

± AUTOMATIC TRANSAXLETroubleshooting (Preliminary Check) (A144L and A140E)AT±22

Page 337 of 2389

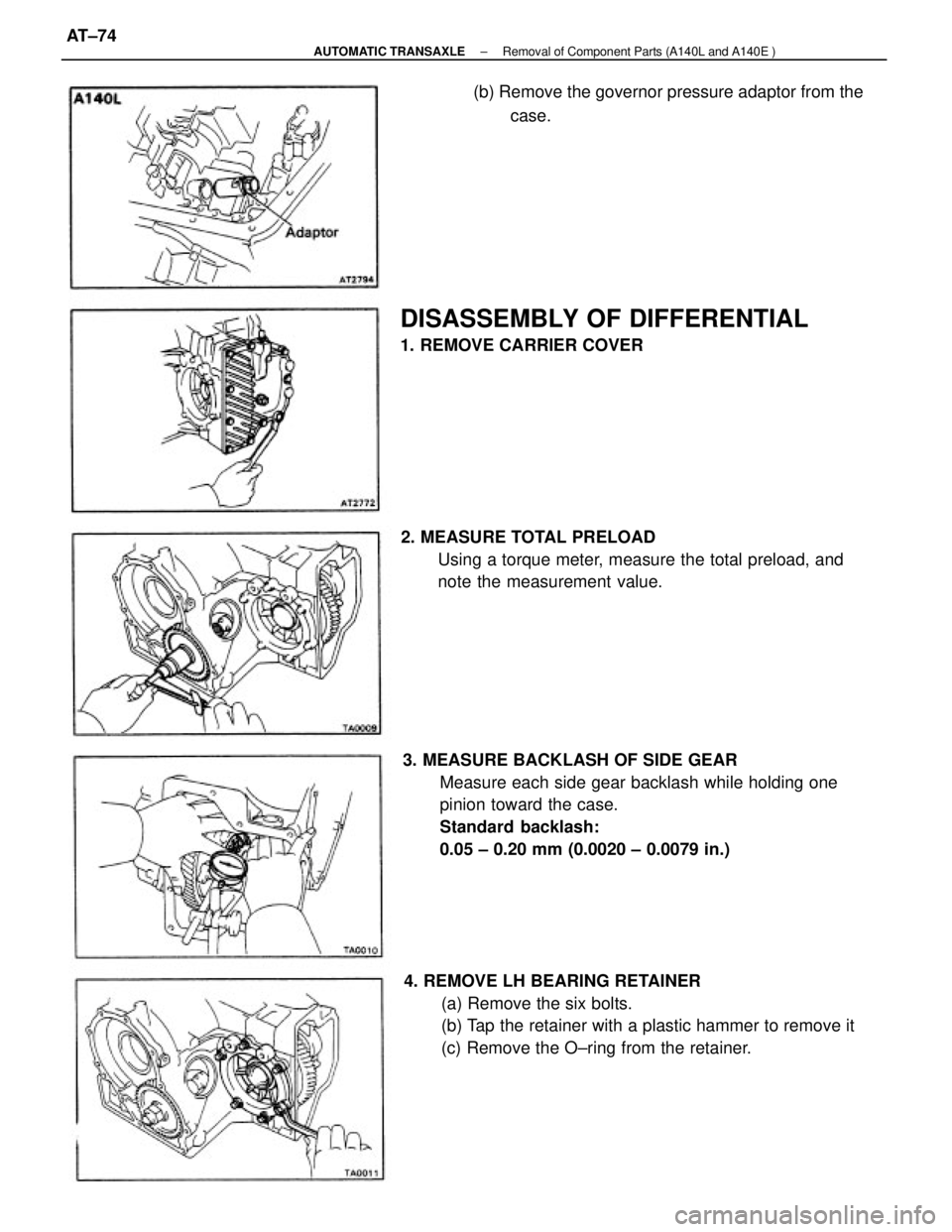

3. MEASURE BACKLASH OF SIDE GEAR

Measure each side gear backlash while holding one

pinion toward the case.

Standard backlash:

0.05 ± 0.20 mm (0.0020 ± 0.0079 in.)

4. REMOVE LH BEARING RETAINER

(a) Remove the six bolts.

(b) Tap the retainer with a plastic hammer to remove it

(c) Remove the O±ring from the retainer. 2. MEASURE TOTAL PRELOAD

Using a torque meter, measure the total preload, and

note the measurement value.

DISASSEMBLY OF DIFFERENTIAL

1. REMOVE CARRIER COVER(b) Remove the governor pressure adaptor from the

case.

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E )AT±74

Page 357 of 2389

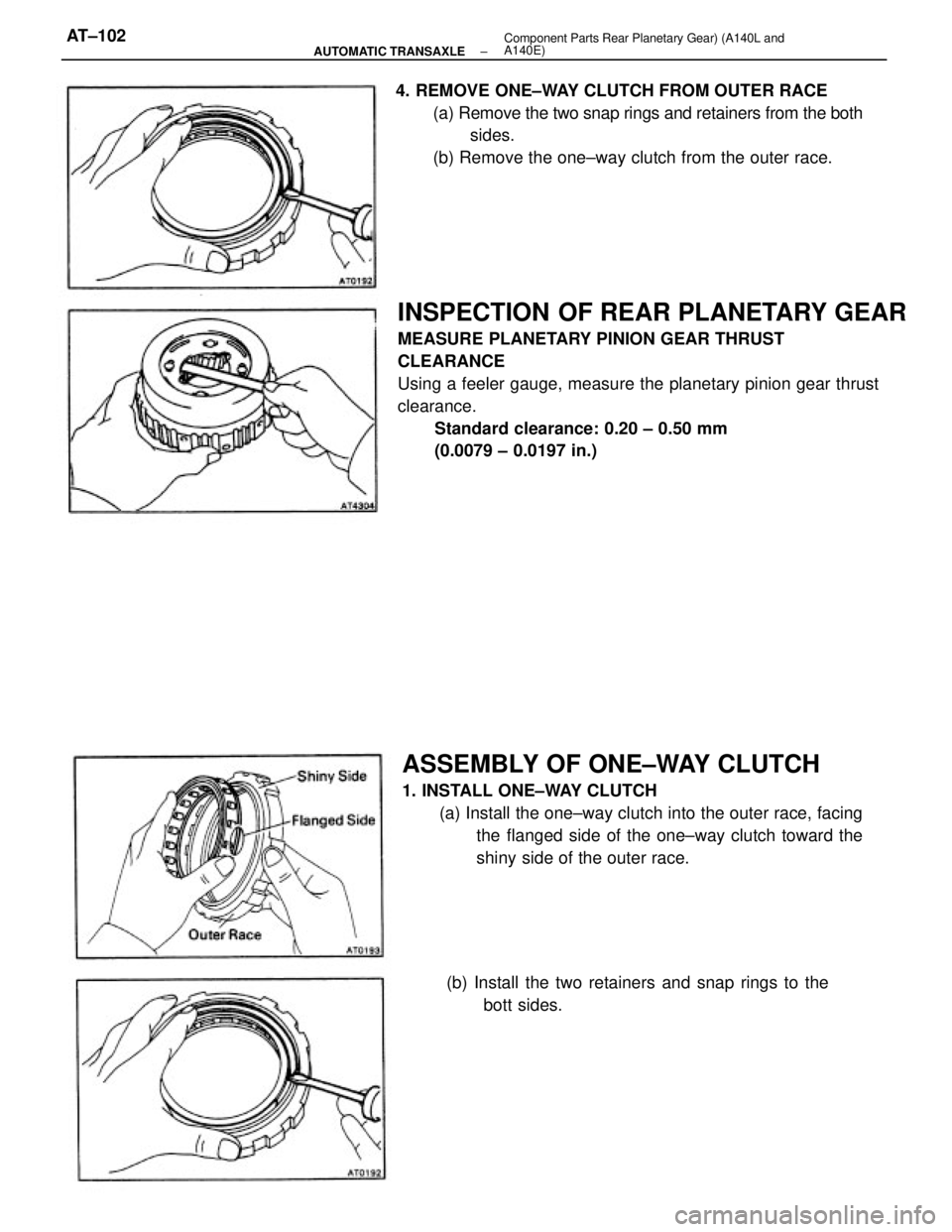

INSPECTION OF REAR PLANETARY GEAR

MEASURE PLANETARY PINION GEAR THRUST

CLEARANCE

Using a feeler gauge, measure the planetary pinion gear thrust

clearance.

Standard clearance: 0.20 ± 0.50 mm

(0.0079 ± 0.0197 in.) 4. REMOVE ONE±WAY CLUTCH FROM OUTER RACE

(a) Remove the two snap rings and retainers from the both

sides.

(b) Remove the one±way clutch from the outer race.

ASSEMBLY OF ONE±WAY CLUTCH

1. INSTALL ONE±WAY CLUTCH

(a) Install the one±way clutch into the outer race, facing

the flanged side of the one±way clutch toward the

shiny side of the outer race.

(b) Install the two retainers and snap rings to the

bott sides.

± AUTOMATIC TRANSAXLEComponent Parts Rear Planetary Gear) (A140L and

A140E)AT±102

Page 358 of 2389

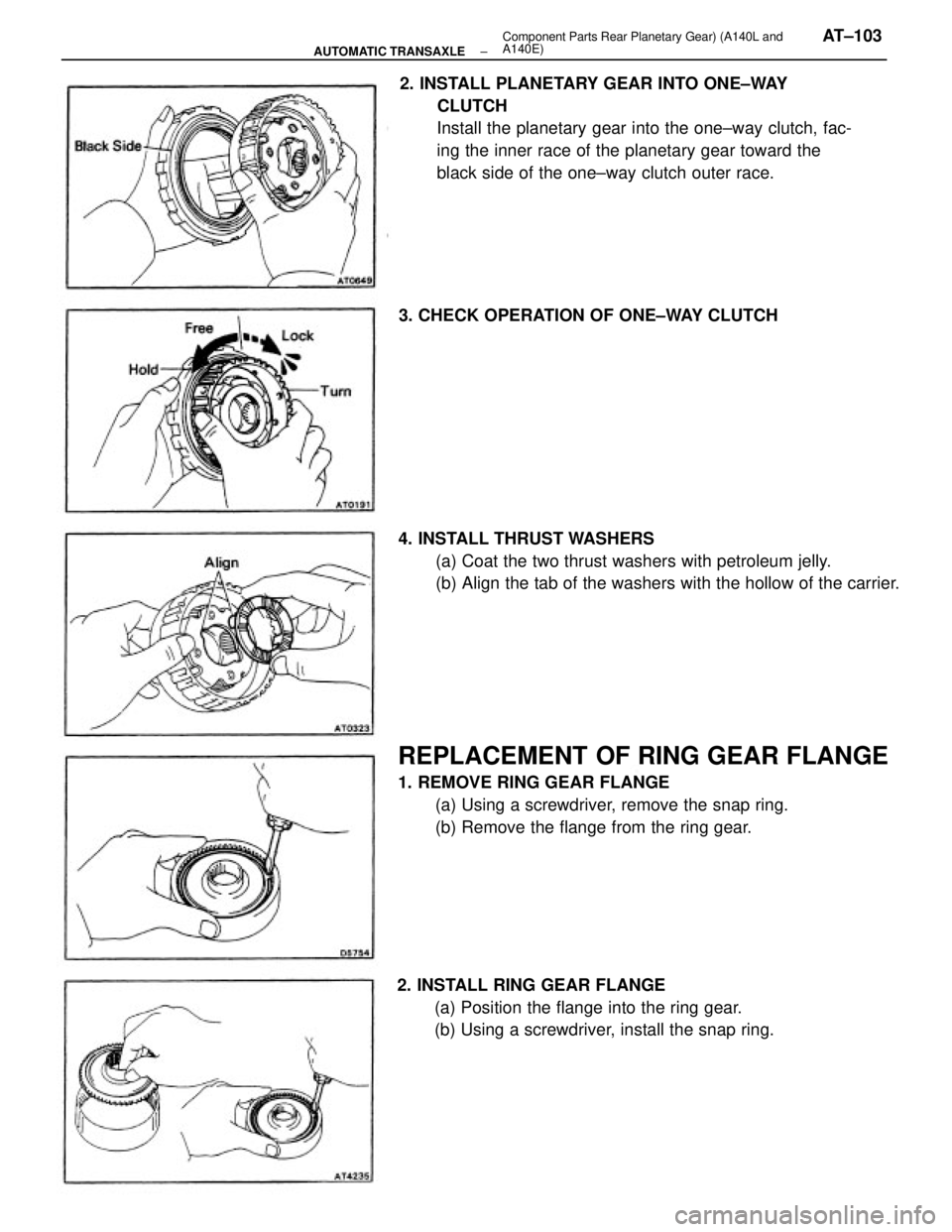

2. INSTALL PLANETARY GEAR INTO ONE±WAY

CLUTCH

Install the planetary gear into the one±way clutch, fac-

ing the inner race of the planetary gear toward the

black side of the one±way clutch outer race.

REPLACEMENT OF RING GEAR FLANGE

1. REMOVE RING GEAR FLANGE

(a) Using a screwdriver, remove the snap ring.

(b) Remove the flange from the ring gear. 4. INSTALL THRUST WASHERS

(a) Coat the two thrust washers with petroleum jelly.

(b) Align the tab of the washers with the hollow of the carrier.

2. INSTALL RING GEAR FLANGE

(a) Position the flange into the ring gear.

(b) Using a screwdriver, install the snap ring. 3. CHECK OPERATION OF ONE±WAY CLUTCH

± AUTOMATIC TRANSAXLEComponent Parts Rear Planetary Gear) (A140L and

A140E)AT±103

Page 371 of 2389

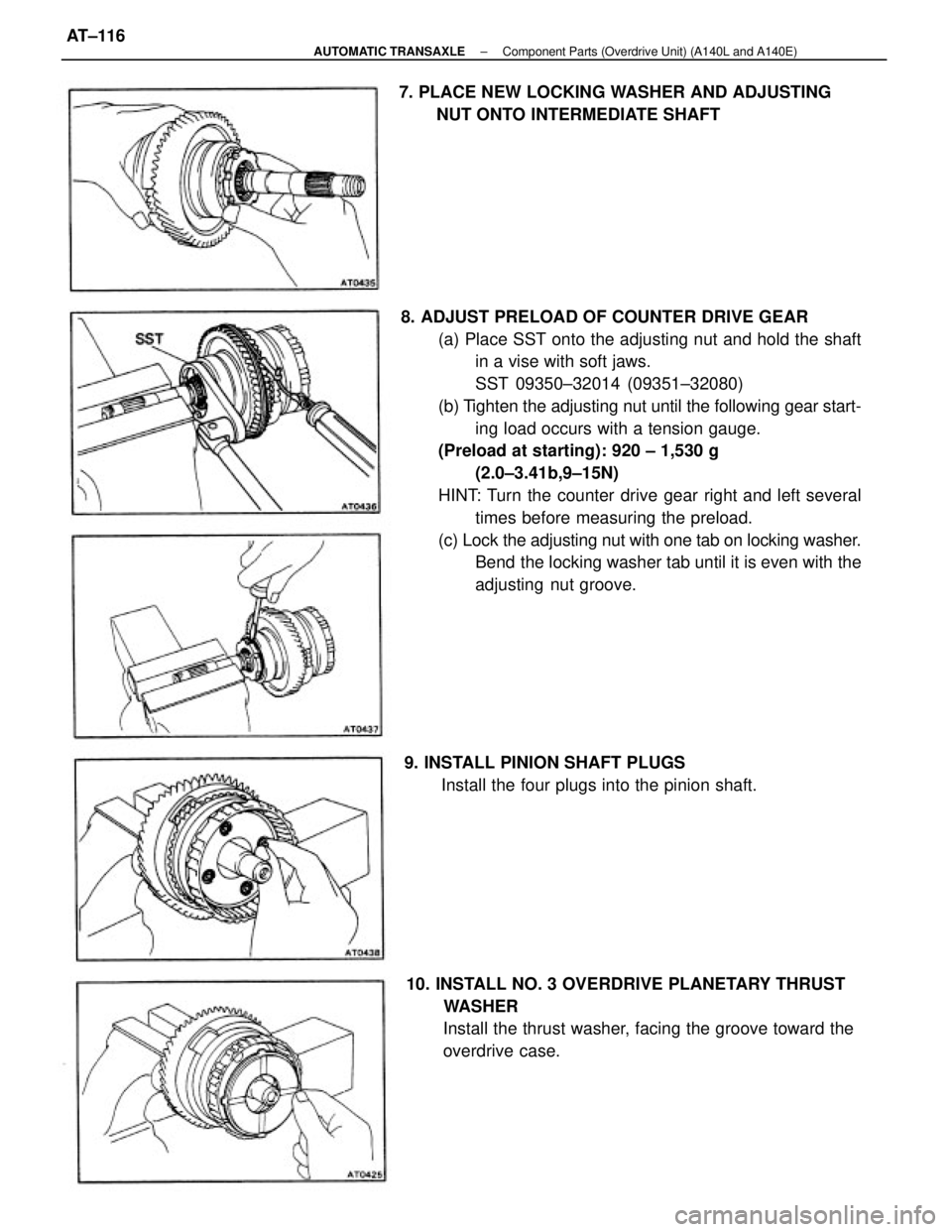

8. ADJUST PRELOAD OF COUNTER DRIVE GEAR

(a) Place SST onto the adjusting nut and hold the shaft

in a vise with soft jaws.

SST 09350±32014 (09351±32080)

(b) Tighten the adjusting nut until the following gear start-

ing load occurs with a tension gauge.

(Preload at starting): 920 ± 1,530 g

(2.0±3.41b,9±15N)

HINT: Turn the counter drive gear right and left several

times before measuring the preload.

(c) Lock the adjusting nut with one tab on locking washer.

Bend the locking washer tab until it is even with the

adjusting nut groove.

10. INSTALL NO. 3 OVERDRIVE PLANETARY THRUST

WASHER

Install the thrust washer, facing the groove toward the

overdrive case. 7. PLACE NEW LOCKING WASHER AND ADJUSTING

NUT ONTO INTERMEDIATE SHAFT

9. INSTALL PINION SHAFT PLUGS

Install the four plugs into the pinion shaft.

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit) (A140L and A140E)AT±116