TOYOTA PROACE CITY 2021 Owners Manual

Manufacturer: TOYOTA, Model Year: 2021, Model line: PROACE CITY, Model: TOYOTA PROACE CITY 2021Pages: 272, PDF Size: 60.75 MB

Page 171 of 272

171

In the event of a breakdown

8

After use, do not discard the bottle in standard waste, take it to a TOYOTA dealer or an authorised waste disposal site.Do not forget to obtain a new bottle of sealant, available from a TOYOTA dealer or a qualified workshop.

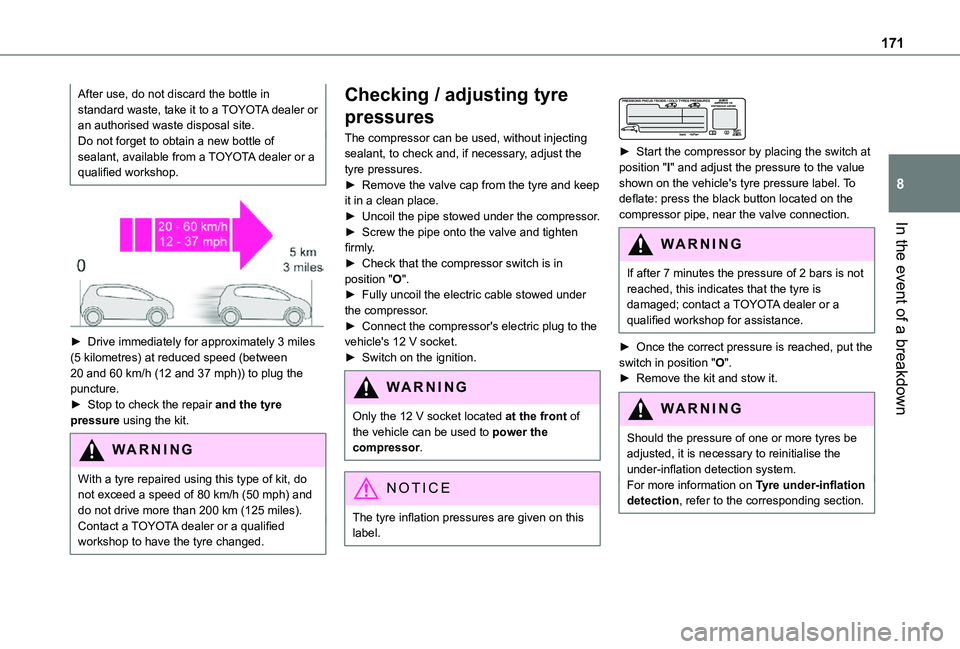

► Drive immediately for approximately 3 miles (5 kilometres) at reduced speed (between 20 and 60 km/h (12 and 37 mph)) to plug the puncture.► Stop to check the repair and the tyre pressure using the kit.

WARNI NG

With a tyre repaired using this type of kit, do not exceed a speed of 80 km/h (50 mph) and do not drive more than 200 km (125 miles).Contact a TOYOTA dealer or a qualified workshop to have the tyre changed.

Checking / adjusting tyre

pressures

The compressor can be used, without injecting sealant, to check and, if necessary, adjust the tyre pressures.► Remove the valve cap from the tyre and keep it in a clean place.► Uncoil the pipe stowed under the compressor.► Screw the pipe onto the valve and tighten firmly.► Check that the compressor switch is in position "O".► Fully uncoil the electric cable stowed under the compressor.► Connect the compressor's electric plug to the vehicle's 12 V socket.► Switch on the ignition.

WARNI NG

Only the 12 V socket located at the front of the vehicle can be used to power the compressor.

NOTIC E

The tyre inflation pressures are given on this label.

► Start the compressor by placing the switch at position "I" and adjust the pressure to the value shown on the vehicle's tyre pressure label. To deflate: press the black button located on the compressor pipe, near the valve connection.

WARNI NG

If after 7 minutes the pressure of 2 bars is not reached, this indicates that the tyre is damaged; contact a TOYOTA dealer or a qualified workshop for assistance.

► Once the correct pressure is reached, put the switch in position "O".► Remove the kit and stow it.

WARNI NG

Should the pressure of one or more tyres be adjusted, it is necessary to reinitialise the under-inflation detection system.For more information on Tyre under-inflation detection, refer to the corresponding section.

Page 172 of 272

172

Spare wheel

Procedure for changing a damaged wheel with the spare wheel using the tools provided with the vehicle.

NOTIC E

For more information on the Tool kit, refer to the corresponding section.

► Park the vehicle, taking care to avoid obstructing traffic, and apply the parking brake.► Follow the safety instructions (hazard warning lamps, warning triangle, wearing high visibility vest, etc.) according to the legislation in force in the country where you are driving.► Switch off the ignition.

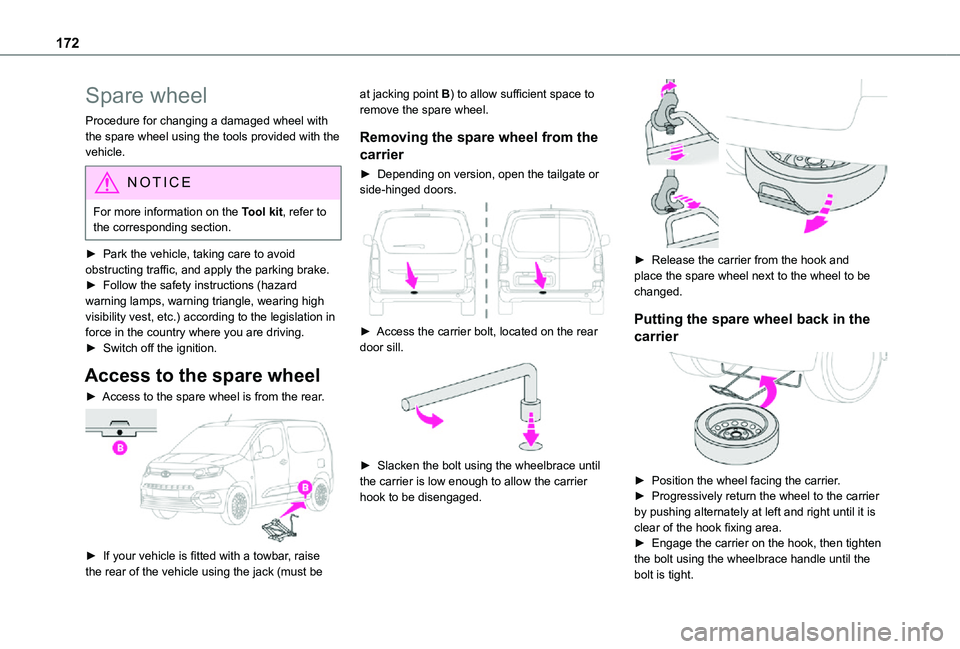

Access to the spare wheel

► Access to the spare wheel is from the rear.

► If your vehicle is fitted with a towbar, raise the rear of the vehicle using the jack (must be

at jacking point B) to allow sufficient space to remove the spare wheel.

Removing the spare wheel from the

carrier

► Depending on version, open the tailgate or side-hinged doors.

► Access the carrier bolt, located on the rear door sill.

► Slacken the bolt using the wheelbrace until the carrier is low enough to allow the carrier hook to be disengaged.

► Release the carrier from the hook and place the spare wheel next to the wheel to be changed.

Putting the spare wheel back in the

carrier

► Position the wheel facing the carrier.► Progressively return the wheel to the carrier by pushing alternately at left and right until it is clear of the hook fixing area.► Engage the carrier on the hook, then tighten the bolt using the wheelbrace handle until the bolt is tight.

Page 173 of 272

173

In the event of a breakdown

8

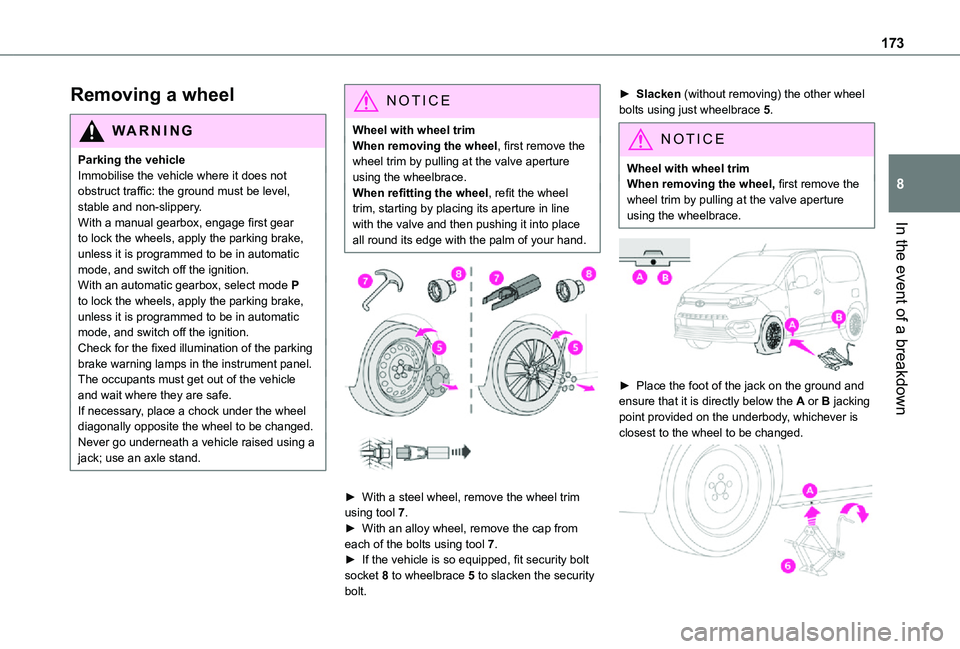

Removing a wheel

WARNI NG

Parking the vehicleImmobilise the vehicle where it does not obstruct traffic: the ground must be level, stable and non-slippery.With a manual gearbox, engage first gear to lock the wheels, apply the parking brake, unless it is programmed to be in automatic mode, and switch off the ignition.With an automatic gearbox, select mode P to lock the wheels, apply the parking brake, unless it is programmed to be in automatic mode, and switch off the ignition.Check for the fixed illumination of the parking brake warning lamps in the instrument panel.The occupants must get out of the vehicle and wait where they are safe.If necessary, place a chock under the wheel diagonally opposite the wheel to be changed.Never go underneath a vehicle raised using a

jack; use an axle stand.

NOTIC E

Wheel with wheel trimWhen removing the wheel, first remove the wheel trim by pulling at the valve aperture using the wheelbrace.When refitting the wheel, refit the wheel trim, starting by placing its aperture in line with the valve and then pushing it into place all round its edge with the palm of your hand.

► With a steel wheel, remove the wheel trim using tool 7.► With an alloy wheel, remove the cap from each of the bolts using tool 7.

► If the vehicle is so equipped, fit security bolt socket 8 to wheelbrace 5 to slacken the security bolt.

► Slacken (without removing) the other wheel bolts using just wheelbrace 5.

NOTIC E

Wheel with wheel trimWhen removing the wheel, first remove the wheel trim by pulling at the valve aperture using the wheelbrace.

► Place the foot of the jack on the ground and ensure that it is directly below the A or B jacking point provided on the underbody, whichever is closest to the wheel to be changed.

Page 174 of 272

174

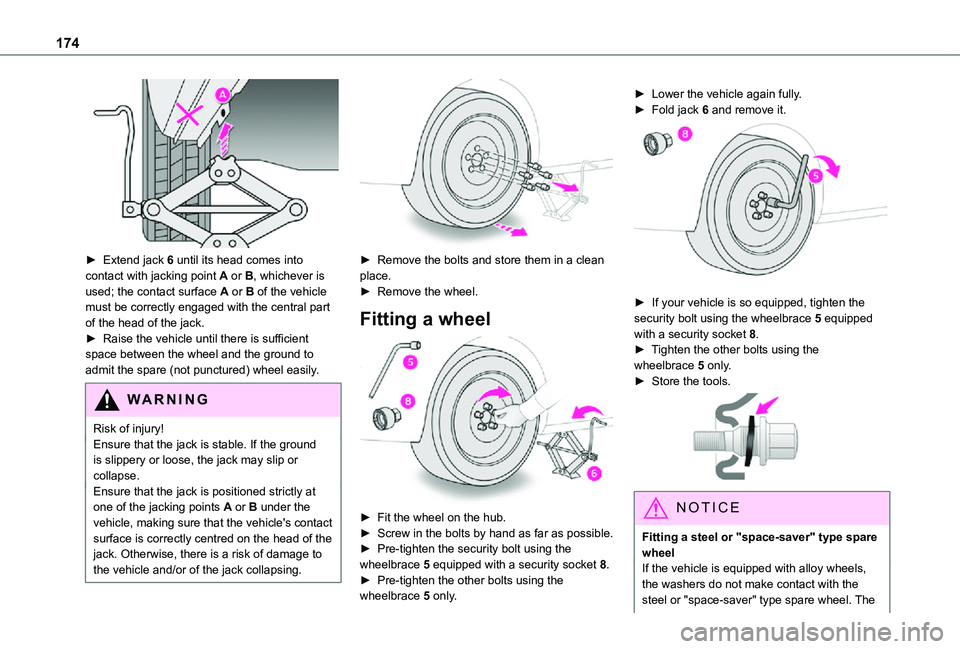

► Extend jack 6 until its head comes into contact with jacking point A or B, whichever is used; the contact surface A or B of the vehicle must be correctly engaged with the central part of the head of the jack.► Raise the vehicle until there is sufficient space between the wheel and the ground to admit the spare (not punctured) wheel easily.

WARNI NG

Risk of injury!

Ensure that the jack is stable. If the ground is slippery or loose, the jack may slip or collapse.Ensure that the jack is positioned strictly at one of the jacking points A or B under the vehicle, making sure that the vehicle's contact surface is correctly centred on the head of the jack. Otherwise, there is a risk of damage to the vehicle and/or of the jack collapsing.

► Remove the bolts and store them in a clean place.► Remove the wheel.

Fitting a wheel

► Fit the wheel on the hub.► Screw in the bolts by hand as far as possible.► Pre-tighten the security bolt using the wheelbrace 5 equipped with a security socket 8.► Pre-tighten the other bolts using the wheelbrace 5 only.

► Lower the vehicle again fully.► Fold jack 6 and remove it.

► If your vehicle is so equipped, tighten the security bolt using the wheelbrace 5 equipped with a security socket 8.► Tighten the other bolts using the wheelbrace 5 only.► Store the tools.

NOTIC E

Fitting a steel or "space-saver" type spare wheelIf the vehicle is equipped with alloy wheels, the washers do not make contact with the steel or "space-saver" type spare wheel. The

Page 175 of 272

175

In the event of a breakdown

8

wheel is secured by the conical contact of each bolt.

WARNI NG

After changing a wheelStow the punctured wheel in the carrier.Go to a TOYOTA dealer or a qualified workshop as soon as possible.Have the punctured tyre examined. After inspection, the technician will advise you on whether the tyre can be repaired or if it must be replaced.

NOTIC E

Some driving aid functions should be disabled, e.g. the Active Safety Brake.

NOTIC E

If your vehicle has tyre under-inflation detection, check the tyre pressures and reinitialise the system.For more information on Under-inflation detection, refer to the corresponding section.

NOTIC E

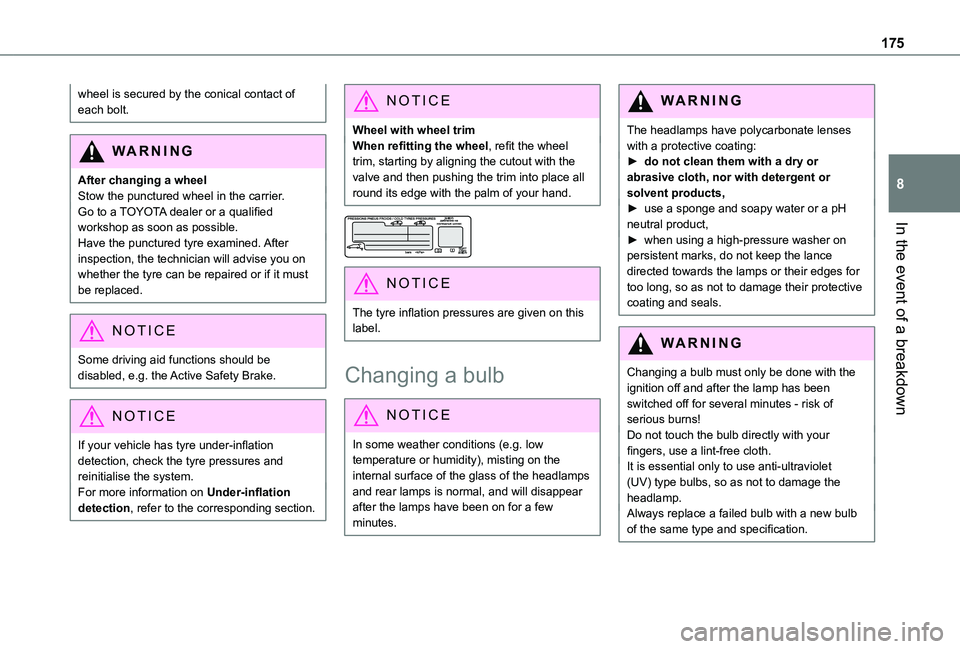

Wheel with wheel trimWhen refitting the wheel, refit the wheel trim, starting by aligning the cutout with the valve and then pushing the trim into place all round its edge with the palm of your hand.

NOTIC E

The tyre inflation pressures are given on this label.

Changing a bulb

NOTIC E

In some weather conditions (e.g. low temperature or humidity), misting on the internal surface of the glass of the headlamps and rear lamps is normal, and will disappear after the lamps have been on for a few minutes.

WARNI NG

The headlamps have polycarbonate lenses with a protective coating:► do not clean them with a dry or abrasive cloth, nor with detergent or solvent products,► use a sponge and soapy water or a pH neutral product,► when using a high-pressure washer on persistent marks, do not keep the lance directed towards the lamps or their edges for too long, so as not to damage their protective coating and seals.

WARNI NG

Changing a bulb must only be done with the ignition off and after the lamp has been switched off for several minutes - risk of serious burns!Do not touch the bulb directly with your fingers, use a lint-free cloth.It is essential only to use anti-ultraviolet (UV) type bulbs, so as not to damage the headlamp.Always replace a failed bulb with a new bulb of the same type and specification.

Page 176 of 272

176

WARNI NG

Opening the bonnet / Accessing the bulbsWith the engine warm, proceed with caution - risk of burns!Take care with objects or clothing that could be caught in the blades of the cooling fan - risk of strangulation!

NOTIC E

Halogen bulbs (Hx)To ensure good quality lighting, check that the bulb is correctly positioned in its housing.

WARNI NG

After changing a bulb

To refit, carry out the fitting operations in reverse order.Close the protective cover very carefully to guarantee the sealing of the lamps.

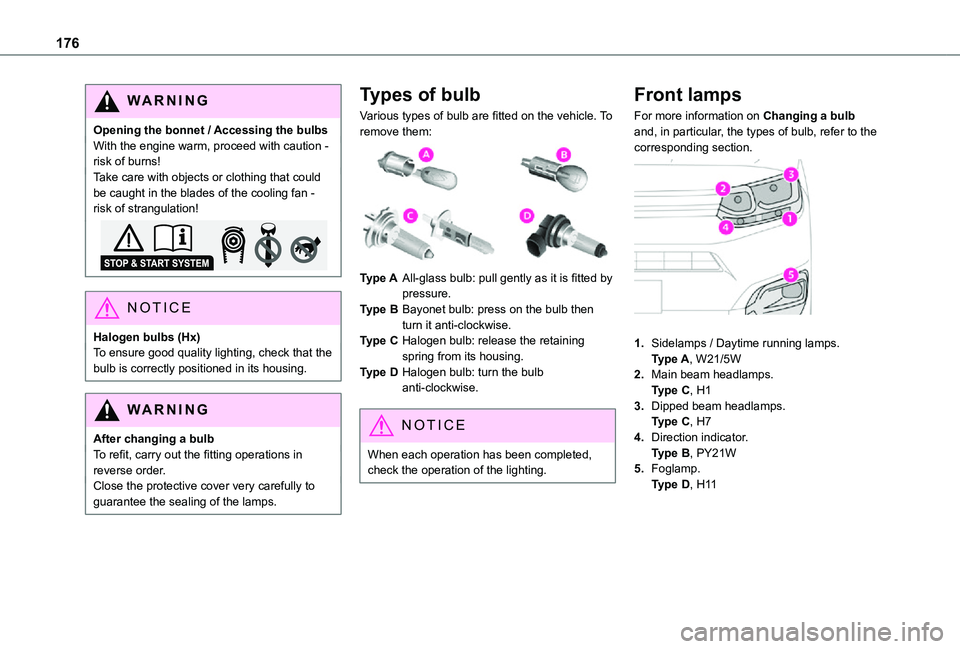

Types of bulb

Various types of bulb are fitted on the vehicle. To remove them:

Type AAll-glass bulb: pull gently as it is fitted by pressure.

Type BBayonet bulb: press on the bulb then turn it anti-clockwise.

Type CHalogen bulb: release the retaining spring from its housing.

Type DHalogen bulb: turn the bulb anti-clockwise.

NOTIC E

When each operation has been completed, check the operation of the lighting.

Front lamps

For more information on Changing a bulb and, in particular, the types of bulb, refer to the corresponding section.

1.Sidelamps / Daytime running lamps.Type A, W21/5W

2.Main beam headlamps.Type C, H1

3.Dipped beam headlamps.Type C, H7

4.Direction indicator.Type B, PY21W

5.Foglamp.Type D, H11

Page 177 of 272

177

In the event of a breakdown

8

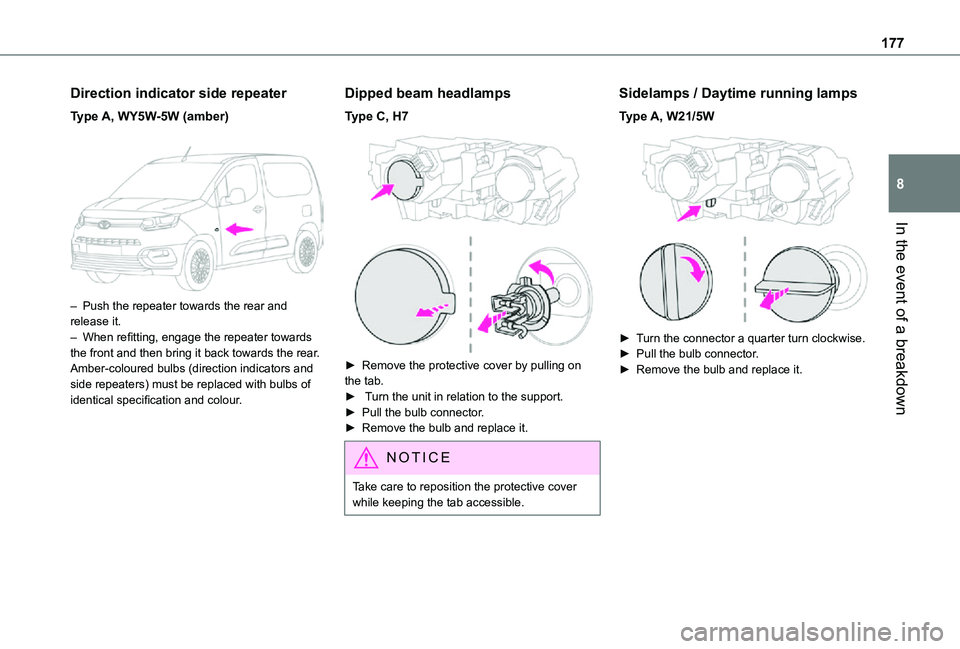

Direction indicator side repeater

Type A, WY5W-5W (amber)

– Push the repeater towards the rear and release it.– When refitting, engage the repeater towards the front and then bring it back towards the rear.Amber-coloured bulbs (direction indicators and side repeaters) must be replaced with bulbs of identical specification and colour.

Dipped beam headlamps

Type C, H7

► Remove the protective cover by pulling on the tab. ► Turn the unit in relation to the support.► Pull the bulb connector.► Remove the bulb and replace it.

NOTIC E

Take care to reposition the protective cover while keeping the tab accessible.

Sidelamps / Daytime running lamps

Type A, W21/5W

► Turn the connector a quarter turn clockwise.► Pull the bulb connector.► Remove the bulb and replace it.

Page 178 of 272

178

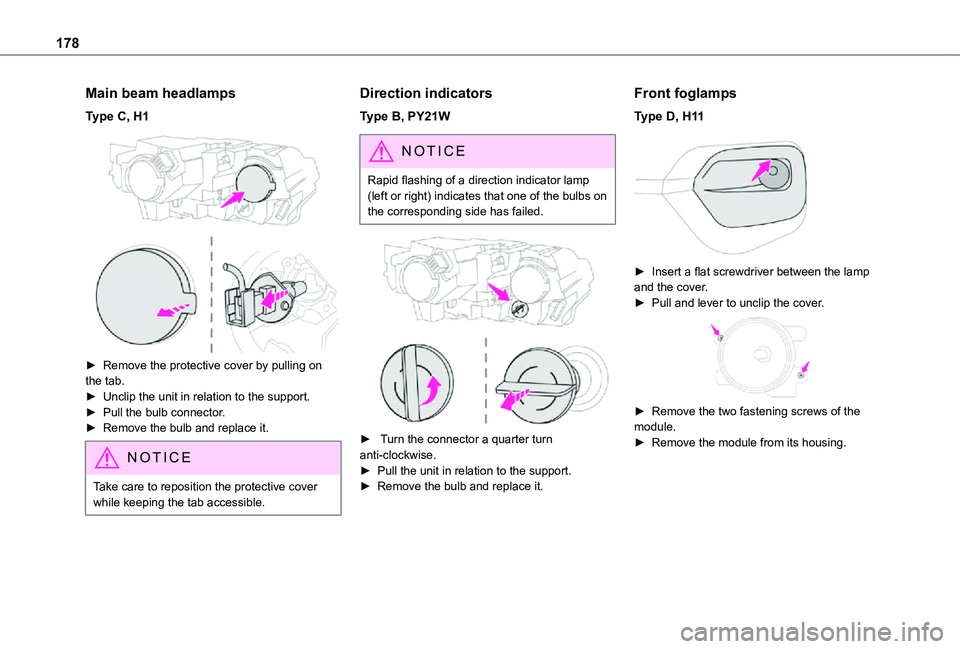

Main beam headlamps

Type C, H1

► Remove the protective cover by pulling on the tab.► Unclip the unit in relation to the support.► Pull the bulb connector.► Remove the bulb and replace it.

NOTIC E

Take care to reposition the protective cover while keeping the tab accessible.

Direction indicators

Type B, PY21W

NOTIC E

Rapid flashing of a direction indicator lamp (left or right) indicates that one of the bulbs on the corresponding side has failed.

► Turn the connector a quarter turn anti-clockwise.► Pull the unit in relation to the support.

► Remove the bulb and replace it.

Front foglamps

Type D, H11

► Insert a flat screwdriver between the lamp and the cover.► Pull and lever to unclip the cover.

► Remove the two fastening screws of the module.► Remove the module from its housing.

Page 179 of 272

179

In the event of a breakdown

8

► Press the locking clip and disconnect the connector.► Turn the bulb holder a quarter turn anti-clockwise.► Remove the bulb holder.► Replace the faulty bulb.

NOTIC E

To replace these bulbs, it is possible to contact a TOYOTA dealer or a qualified workshop.

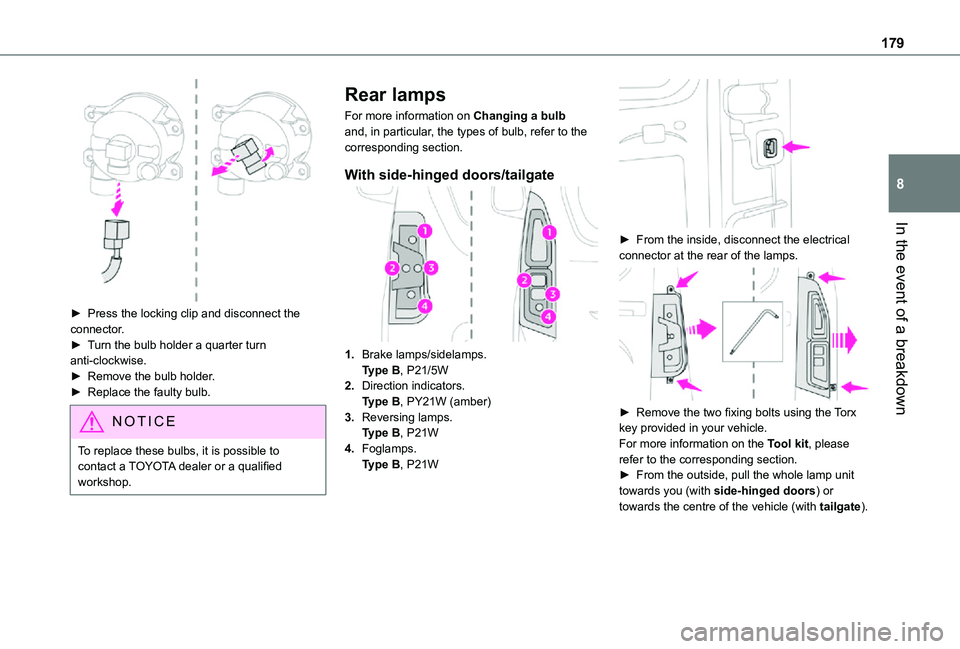

Rear lamps

For more information on Changing a bulb and, in particular, the types of bulb, refer to the corresponding section.

With side-hinged doors/tailgate

1.Brake lamps/sidelamps.Type B, P21/5W

2.Direction indicators.Type B, PY21W (amber)

3.Reversing lamps.Type B, P21W

4.Foglamps.Type B, P21W

► From the inside, disconnect the electrical connector at the rear of the lamps.

► Remove the two fixing bolts using the Torx key provided in your vehicle.For more information on the Tool kit, please refer to the corresponding section.► From the outside, pull the whole lamp unit towards you (with side-hinged doors) or towards the centre of the vehicle (with tailgate).

Page 180 of 272

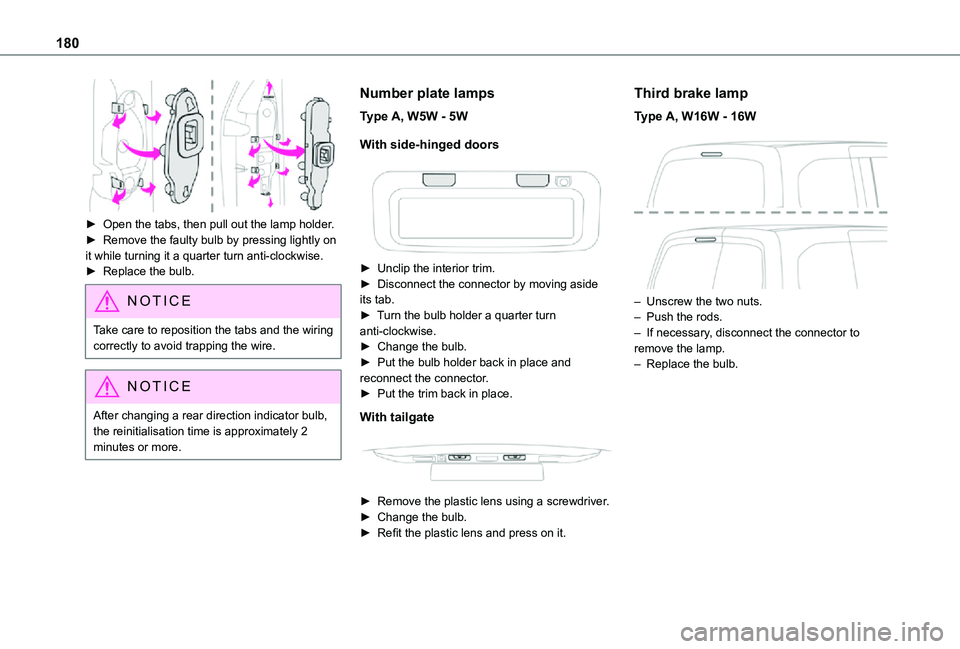

180

► Open the tabs, then pull out the lamp holder.► Remove the faulty bulb by pressing lightly on it while turning it a quarter turn anti-clockwise.► Replace the bulb.

NOTIC E

Take care to reposition the tabs and the wiring correctly to avoid trapping the wire.

NOTIC E

After changing a rear direction indicator bulb, the reinitialisation time is approximately 2

minutes or more.

Number plate lamps

Type A, W5W - 5W

With side-hinged doors

► Unclip the interior trim.► Disconnect the connector by moving aside its tab.► Turn the bulb holder a quarter turn anti-clockwise.► Change the bulb.► Put the bulb holder back in place and reconnect the connector.► Put the trim back in place.

With tailgate

► Remove the plastic lens using a screwdriver.► Change the bulb.► Refit the plastic lens and press on it.

Third brake lamp

Type A, W16W - 16W

– Unscrew the two nuts.– Push the rods.– If necessary, disconnect the connector to remove the lamp.– Replace the bulb.