Fuel line TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 72 of 2000

ENGINE - 2GR-FE ENGINE

285EG12

Liner

Cylinder

Block

Irregularly shaped

outer casting

surface of liner A

A

A - A Cross Section

285EG13

Front MarkResin CoatingTaper Squish Shape

Alumite

Coating EG-76

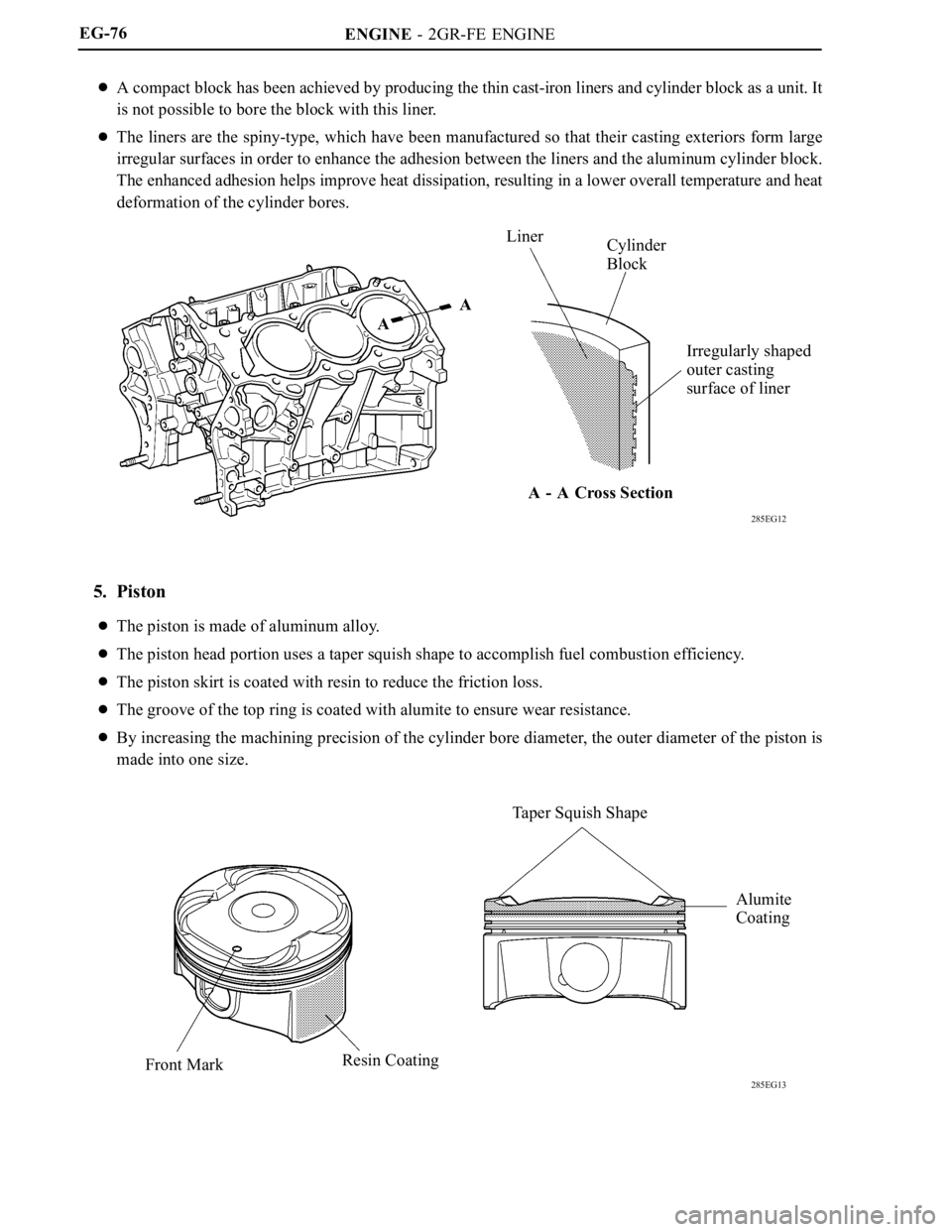

A compact block has been achieved by producing the thin cast-iron liners and cylinder block as a unit. It

is not possible to bore the block with this liner.

The liners are the spiny-type, which have been manufactured so that their casting exteriors form large

irregular surfaces in order to enhance the adhesion between the liners and the aluminum cylinder block.

The enhanced adhesion helps improve heat dissipation, resulting in a lower overall temperature and heat

deformation of the cylinder bores.

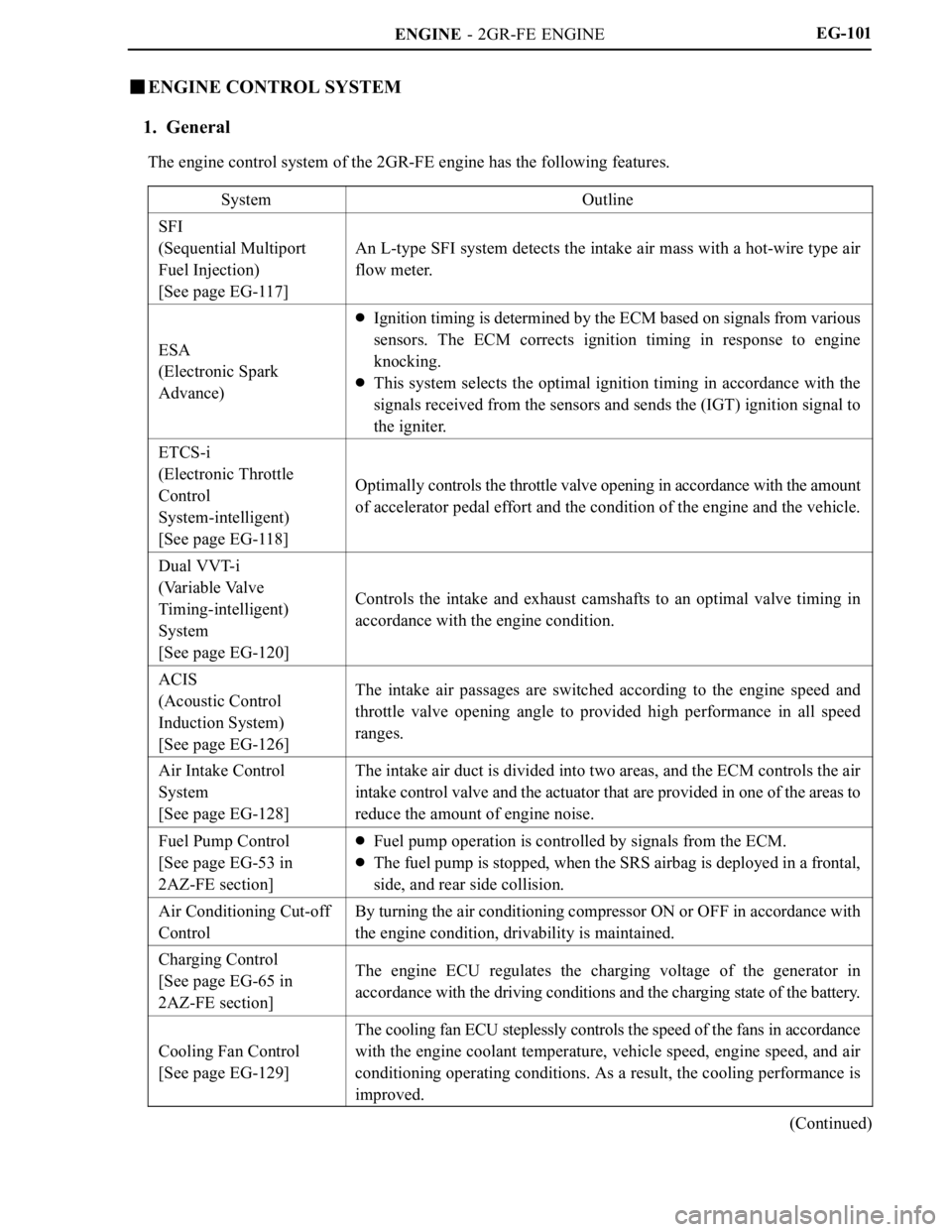

5. Piston

The piston is made of aluminum alloy.

The piston head portion uses a taper squish shape to accomplish fuel combustion efficiency.

The piston skirt is coated with resin to reduce the friction loss.

The groove of the top ring is coated with alumite to ensure wear resistance.

By increasing the machining precision of the cylinder bore diameter, the outer diameter of the piston is

made into one size.

Page 97 of 2000

ENGINE - 2GR-FE ENGINEEG-101

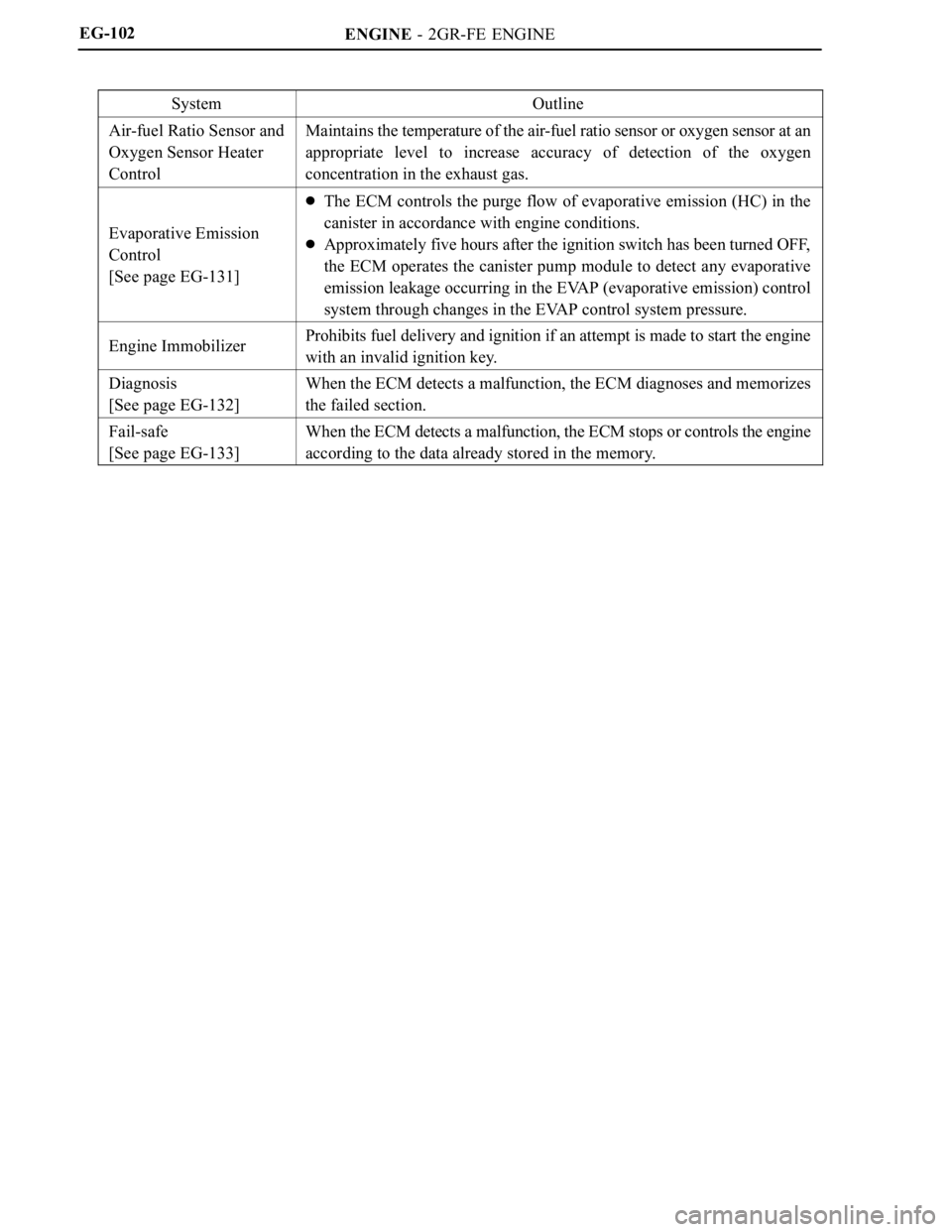

ENGINE CONTROL SYSTEM

1. General

The engine control system of the 2GR-FE engine has the following features.

System

Outline

SFI

(Sequential Multiport

Fuel Injection)

[See page EG-117]

An L-type SFI system detects the intake air mass with a hot-wire type air

flow meter.

ESA

(Electronic Spark

Advance)

Ignition timing is determined by the ECM based on signals from various

sensors. The ECM corrects ignition timing in response to engine

knocking.

This system selects the optimal ignition timing in accordance with the

signals received from the sensors and sends the (IGT) ignition signal to

the igniter.

ETCS-i

(Electronic Throttle

Control

System-intelligent)

[See page EG-118]

Optimally controls the throttle valve opening in accordance with the amount

of accelerator pedal effort and the condition of the engine and the vehicle.

Dual VVT-i

(Variable Valve

Timing-intelligent)

System

[See page EG-120]

Controls the intake and exhaust camshafts to an optimal valve timing in

accordance with the engine condition.

ACIS

(Acoustic Control

Induction System)

[See page EG-126]The intake air passages are switched according to the engine speed and

throttle valve opening angle to provided high performance in all speed

ranges.

Air Intake Control

System

[See page EG-128]The intake air duct is divided into two areas, and the ECM controls the air

intake control valve and the actuator that are provided in one of the areas to

reduce the amount of engine noise.

Fuel Pump Control

[See page EG-53 in

2AZ-FE section]Fuel pump operation is controlled by signals from the ECM.

The fuel pump is stopped, when the SRS airbag is deployed in a frontal,

side, and rear side collision.

Air Conditioning Cut-off

ControlBy turning the air conditioning compressor ON or OFF in accordance with

the engine condition, drivability is maintained.

Charging Control

[See page EG-65 in

2AZ-FE section]The engine ECU regulates the charging voltage of the generator in

accordance with the driving conditions and the charging state of the battery.

Cooling Fan Control

[See page EG-129]

The cooling fan ECU steplessly controls the speed of the fans in accordance

with the engine coolant temperature, vehicle speed, engine speed, and air

conditioning operating conditions. As a result, the cooling performance is

improved.

(Continued)

Page 98 of 2000

ENGINE - 2GR-FE ENGINE EG-102

System

Outline

Air-fuel Ratio Sensor and

Oxygen Sensor Heater

ControlMaintains the temperature of the air-fuel ratio sensor or oxygen sensor at an

appropriate level to increase accuracy of detection of the oxygen

concentration in the exhaust gas.

Evaporative Emission

Control

[See page EG-131]

The ECM controls the purge flow of evaporative emission (HC) in the

canister in accordance with engine conditions.

Approximately five hours after the ignition switch has been turned OFF,

the ECM operates the canister pump module to detect any evaporative

emission leakage occurring in the EVAP (evaporative emission) control

system through changes in the EVAP control system pressure.

Engine ImmobilizerProhibits fuel delivery and ignition if an attempt is made to start the engine

with an invalid ignition key.

Diagnosis

[See page EG-132]When the ECM detects a malfunction, the ECM diagnoses and memorizes

the failed section.

Fail-safe

[See page EG-133]When the ECM detects a malfunction, the ECM stops or controls the engine

according to the data already stored in the memory.

Page 105 of 2000

ENGINE - 2GR-FE ENGINEEG-109

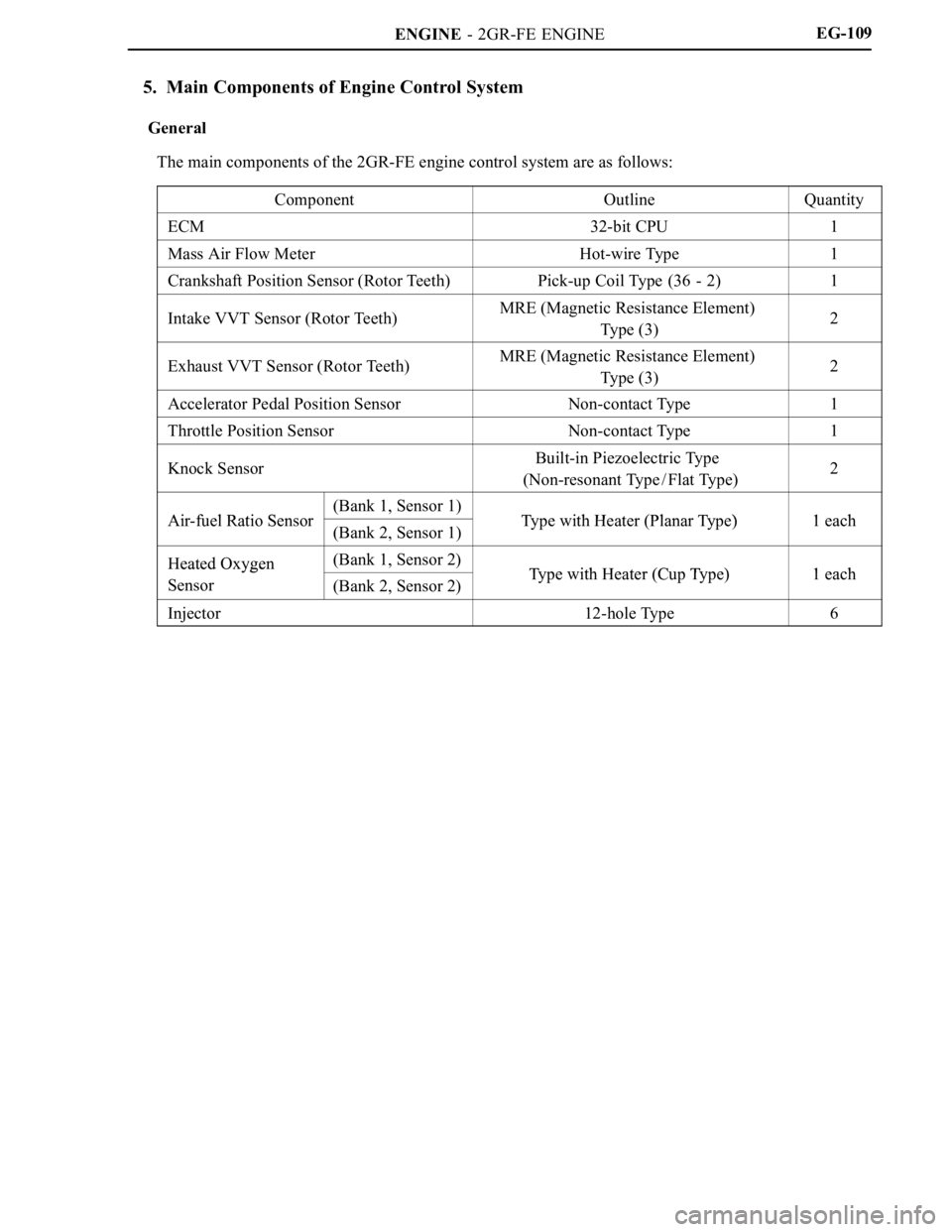

5. Main Components of Engine Control System

General

The main components of the 2GR-FE engine control system are as follows:

Component

OutlineQuantity

ECM32-bit CPU1

Mass Air Flow MeterHot-wire Type1

Crankshaft Position Sensor (Rotor Teeth)Pick-up Coil Type (36 - 2)1

Intake VVT Sensor (Rotor Teeth)MRE (Magnetic Resistance Element)

Ty p e ( 3 )2

Exhaust VVT Sensor (Rotor Teeth)MRE (Magnetic Resistance Element)

Ty p e ( 3 )2

Accelerator Pedal Position SensorNon-contact Type1

Throttle Position SensorNon-contact Type1

Knock SensorBuilt-in Piezoelectric Type

(Non-resonant Type / Flat Type)2

Air fuel Ratio Sensor(Bank 1, Sensor 1)Type with Heater (Planar Type)1 eachAir-fuel Ratio Sensor(Bank 2, Sensor 1)Type with Heater (Planar Type)1 each

Heated Oxygen (Bank 1, Sensor 2)Type with Heater (Cup Type)1 eachHeated Oxygen

Sensor

(Bank 2, Sensor 2)Type with Heater (Cup Type)1 each

Injector12-hole Type6

Page 114 of 2000

ENGINE - 2GR-FE ENGINE

01MEG18Y

Accelerator Pedal

Position SensorThrottle ValveThrottle Position Sensor

Throttle Control

Motor

Mass Air

Flow Meter

Cruise Control

Switch

Skid Control

ECUECMIgnition Coil

Fuel Injection EG-118

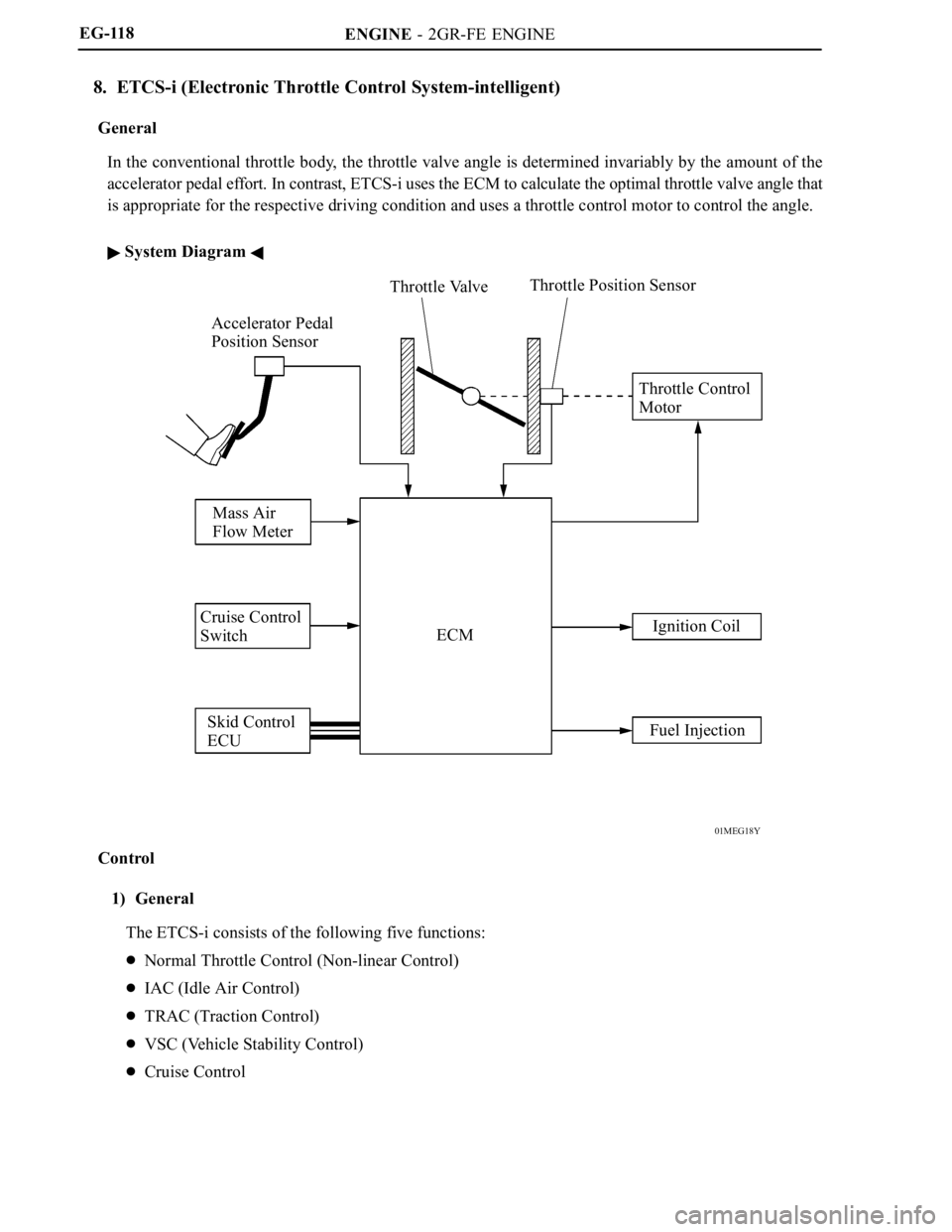

8. ETCS-i (Electronic Throttle Control System-intelligent)

General

In the conventional throttle body, the throttle valve angle is determined invariably by the amount of the

accelerator pedal effort. In contrast, ETCS-i uses the ECM to calculate the optimal throttle valve angle that

is appropriate for the respective driving condition and uses a throttle control motor to control the angle.

System Diagram

Control

1) General

The ETCS-i consists of the following five functions:

Normal Throttle Control (Non-linear Control)

IAC (Idle Air Control)

TRAC (Traction Control)

VSC (Vehicle Stability Control)

Cruise Control

Page 127 of 2000

ENGINE - 2GR-FE ENGINE

01MEG23Y

Purge Line

Purge VSV

Fuel Tank

Canister Pump Module

Canister Pressure Sensor

Leak Detection Pump

Vent Valve

Front

Fresh Air Line

Air Filter

Refueling Valve CanisterEG-131

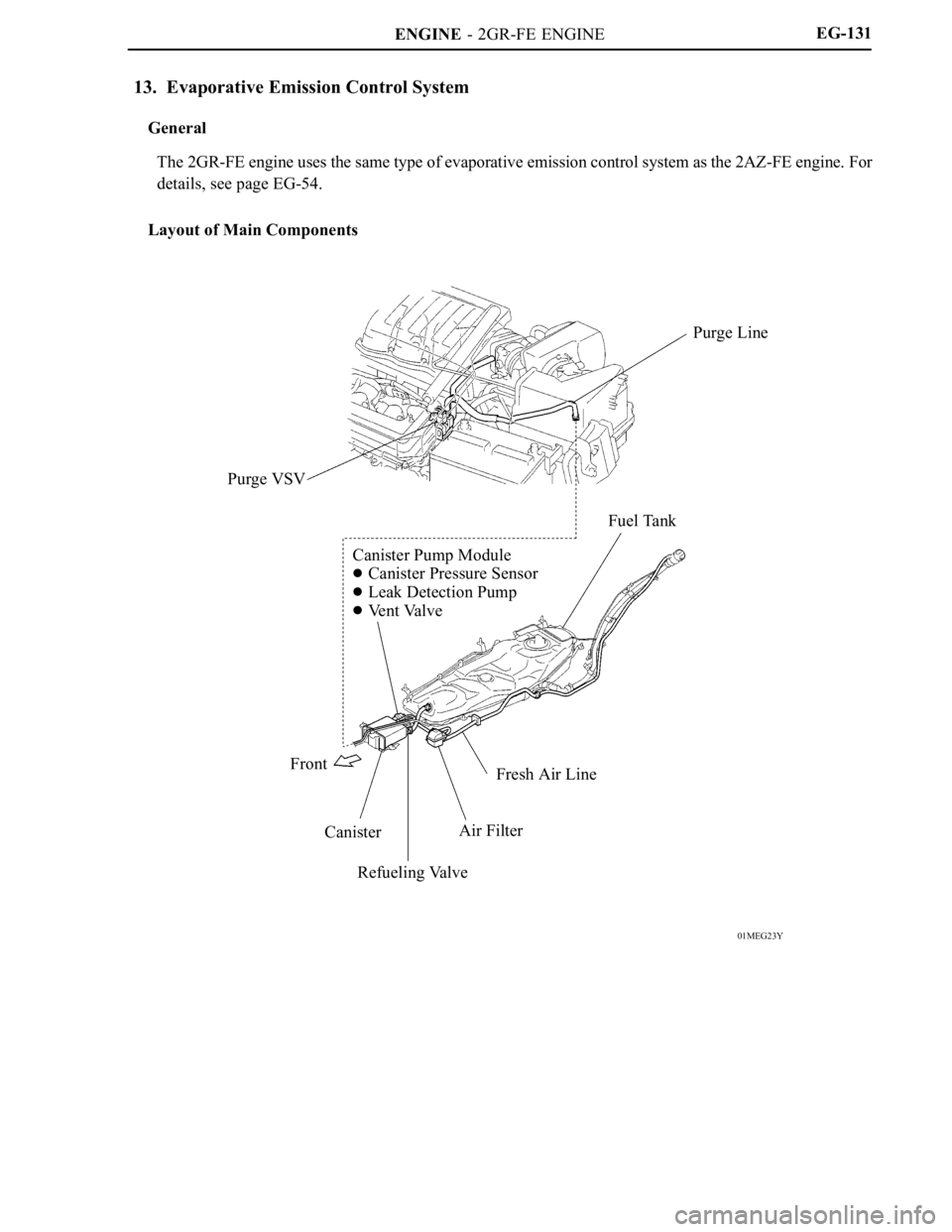

13. Evaporative Emission Control System

General

The 2GR-FE engine uses the same type of evaporative emission control system as the 2AZ-FE engine. For

details, see page EG-54.

Layout of Main Components

Page 133 of 2000

CHASSIS - 4WD SYSTEM CH-66

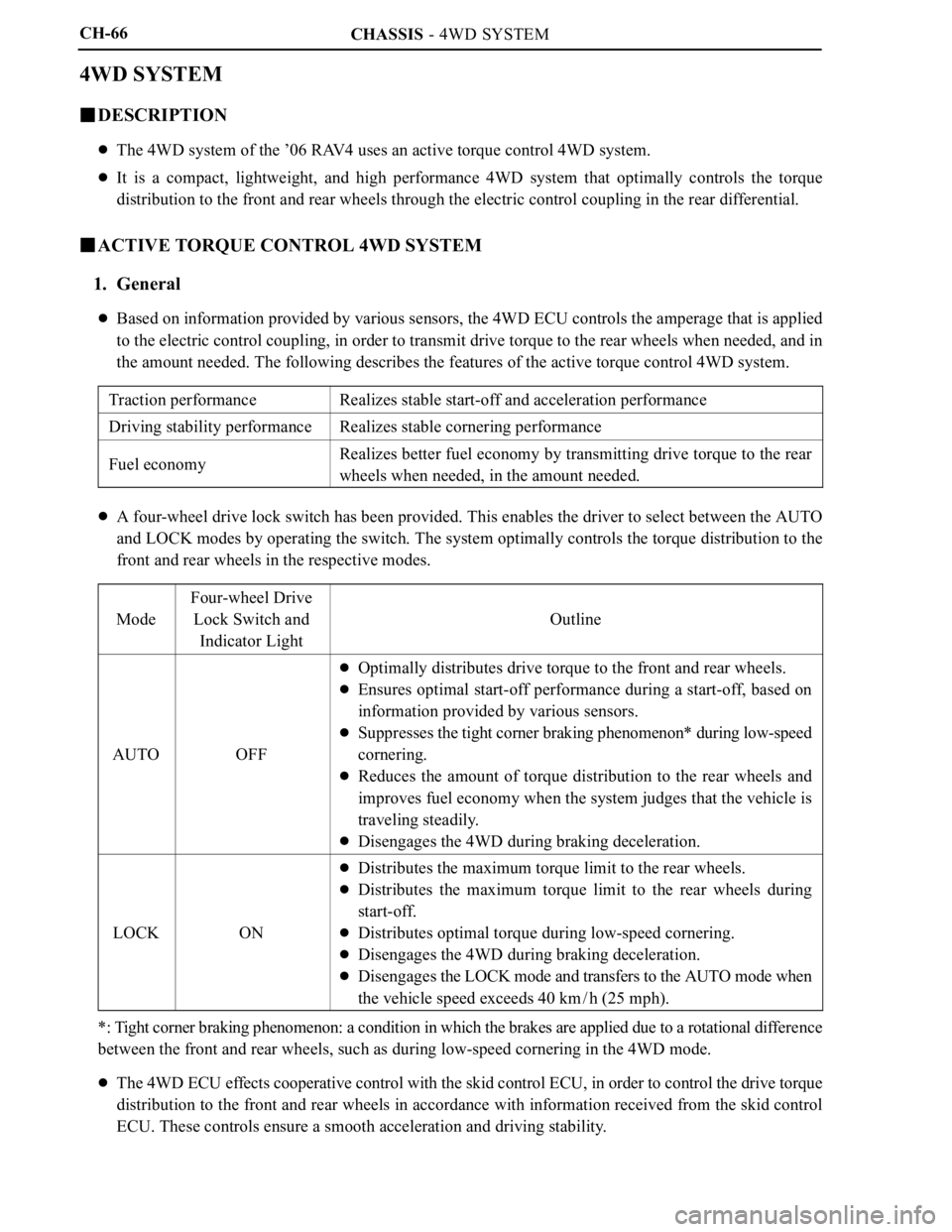

4WD SYSTEM

DESCRIPTION

The 4WD system of the ’06 RAV4 uses an active torque control 4WD system.

It is a compact, lightweight, and high performance 4WD system that optimally controls the torque

distribution to the front and rear wheels through the electric control coupling in the rear differential.

ACTIVE TORQUE CONTROL 4WD SYSTEM

1. General

Based on information provided by various sensors, the 4WD ECU controls the amperage that is applied

to the electric control coupling, in order to transmit drive torque to the rear wheels when needed, and in

the amount needed. The following describes the features of the active torque control 4WD system.

Traction performance

Realizes stable start-off and acceleration performance

Driving stability performanceRealizes stable cornering performance

Fuel economyRealizes better fuel economy by transmitting drive torque to the rear

wheels when needed, in the amount needed.

A four-wheel drive lock switch has been provided. This enables the driver to select between the AUTO

and LOCK modes by operating the switch. The system optimally controls the torque distribution to the

front and rear wheels in the respective modes.

Mode

Four-wheel Drive

Lock Switch and

Indicator Light

Outline

AUTOOFF

Optimally distributes drive torque to the front and rear wheels.

Ensures optimal start-off performance during a start-off, based on

information provided by various sensors.

Suppresses the tight corner braking phenomenon* during low-speed

cornering.

Reduces the amount of torque distribution to the rear wheels and

improves fuel economy when the system judges that the vehicle is

traveling steadily.

Disengages the 4WD during braking deceleration.

LOCKON

Distributes the maximum torque limit to the rear wheels.

Distributes the maximum torque limit to the rear wheels during

start-off.

Distributes optimal torque during low-speed cornering.

Disengages the 4WD during braking deceleration.

Disengages the LOCK mode and transfers to the AUTO mode when

the vehicle speed exceeds 40 km / h (25 mph).

*: Tight corner braking phenomenon: a condition in which the brakes are applied due to a rotational difference

between the front and rear wheels, such as during low-speed cornering in the 4WD mode.

The 4WD ECU effects cooperative control with the skid control ECU, in order to control the drive torque

distribution to the front and rear wheels in accordance with information received from the skid control

ECU. These controls ensure a smooth acceleration and driving stability.

Page 137 of 2000

CHASSIS - 4WD SYSTEM

01NCH38Y

Torque Distribution

to Rear WheelsTorque Distribution

to Rear Wheels

Straightline Driving Low-Speed Cornering

01NCH39Y

Torque Distribution

to Rear WheelsTorque Distribution

to Rear Wheels

Steady Driving Straightline Acceleration

NOTICE

In the LOCK mode after the four-wheel drive lock switch is pressed, the system starts control upon

judging that the vehicle is operating in a stable manner. During this judgment, the 4WD LOCK

indicator light blinks.

CH-70

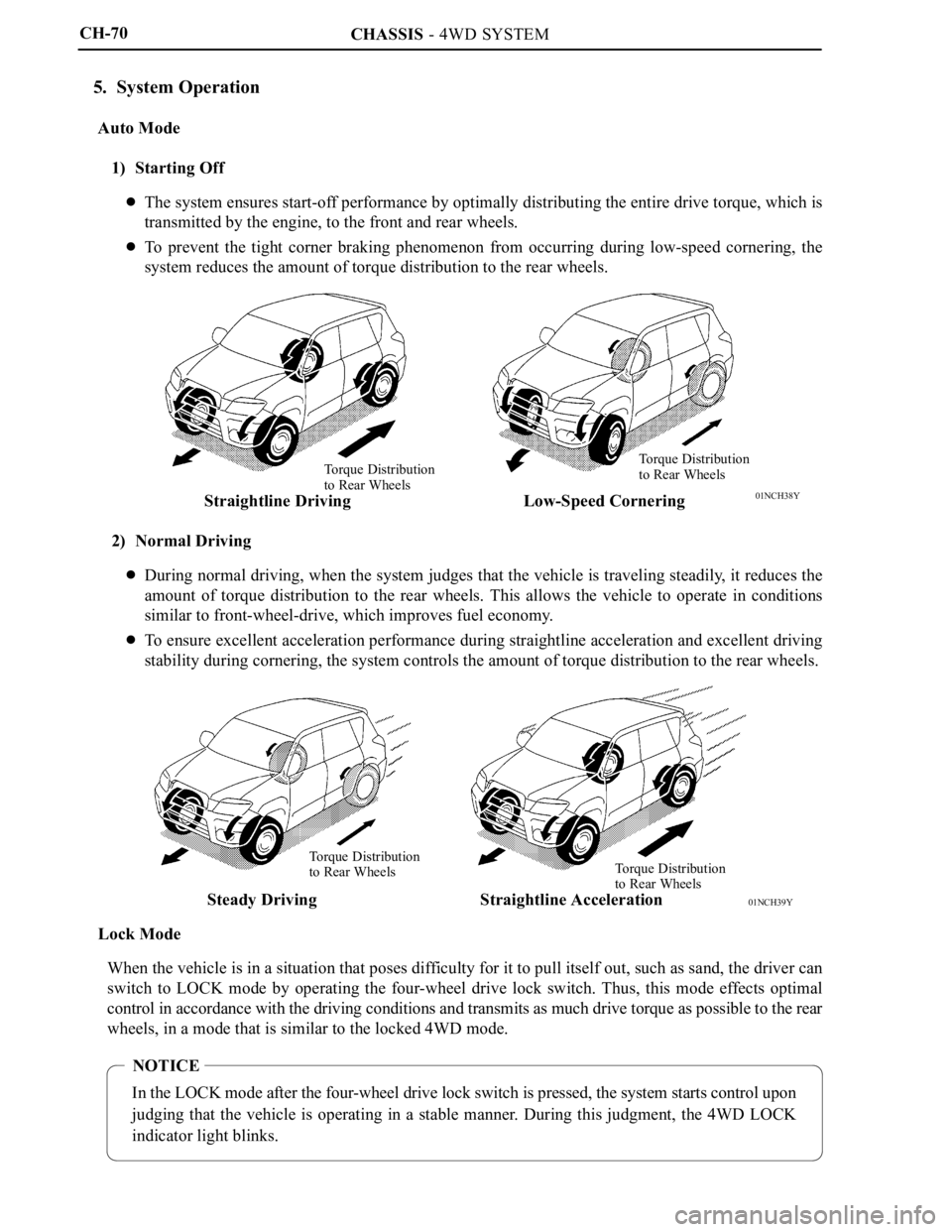

5. System Operation

Auto Mode

1) Starting Off

The system ensures start-off performance by optimally distributing the entire drive torque, which is

transmitted by the engine, to the front and rear wheels.

To prevent the tight corner braking phenomenon from occurring during low-speed cornering, the

system reduces the amount of torque distribution to the rear wheels.

2) Normal Driving

During normal driving, when the system judges that the vehicle is traveling steadily, it reduces the

amount of torque distribution to the rear wheels. This allows the vehicle to operate in conditions

similar to front-wheel-drive, which improves fuel economy.

To ensure excellent acceleration performance during straightline acceleration and excellent driving

stability during cornering, the system controls the amount of torque distribution to the rear wheels.

Lock Mode

When the vehicle is in a situation that poses difficulty for it to pull itself out, such as sand, the driver can

switch to LOCK mode by operating the four-wheel drive lock switch. Thus, this mode effects optimal

control in accordance with the driving conditions and transmits as much drive torque as possible to the rear

wheels, in a mode that is similar to the locked 4WD mode.

Page 208 of 2000

FU–62AZ-FE FUEL – FUEL SYSTEM

FU

ON-VEHICLE INSPECTION

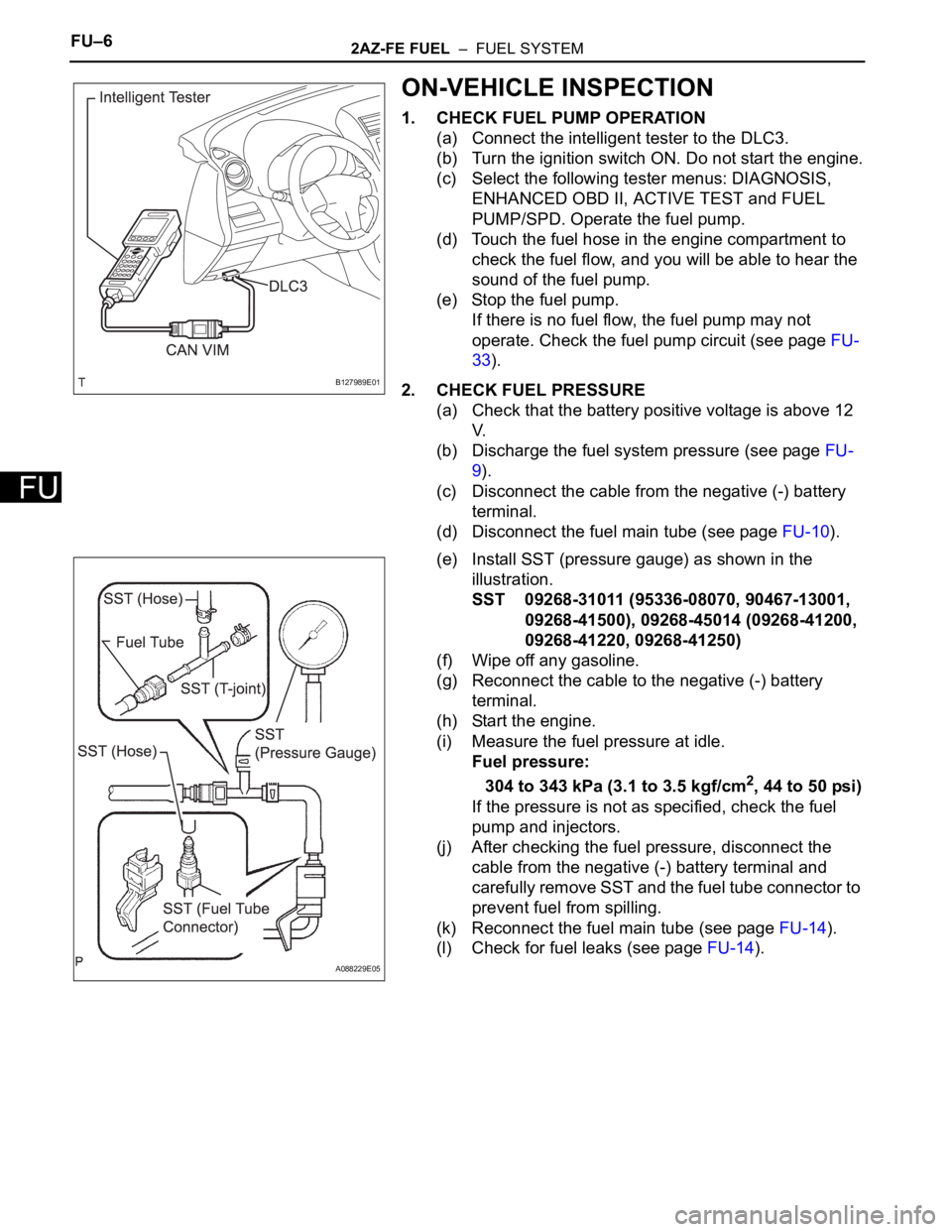

1. CHECK FUEL PUMP OPERATION

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch ON. Do not start the engine.

(c) Select the following tester menus: DIAGNOSIS,

ENHANCED OBD II, ACTIVE TEST and FUEL

PUMP/SPD. Operate the fuel pump.

(d) Touch the fuel hose in the engine compartment to

check the fuel flow, and you will be able to hear the

sound of the fuel pump.

(e) Stop the fuel pump.

If there is no fuel flow, the fuel pump may not

operate. Check the fuel pump circuit (see page FU-

33).

2. CHECK FUEL PRESSURE

(a) Check that the battery positive voltage is above 12

V.

(b) Discharge the fuel system pressure (see page FU-

9).

(c) Disconnect the cable from the negative (-) battery

terminal.

(d) Disconnect the fuel main tube (see page FU-10).

(e) Install SST (pressure gauge) as shown in the

illustration.

SST 09268-31011 (95336-08070, 90467-13001,

09268-41500), 09268-45014 (09268-41200,

09268-41220, 09268-41250)

(f) Wipe off any gasoline.

(g) Reconnect the cable to the negative (-) battery

terminal.

(h) Start the engine.

(i) Measure the fuel pressure at idle.

Fuel pressure:

304 to 343 kPa (3.1 to 3.5 kgf/cm

2, 44 to 50 psi)

If the pressure is not as specified, check the fuel

pump and injectors.

(j) After checking the fuel pressure, disconnect the

cable from the negative (-) battery terminal and

carefully remove SST and the fuel tube connector to

prevent fuel from spilling.

(k) Reconnect the fuel main tube (see page FU-14).

(l) Check for fuel leaks (see page FU-14).

B127989E01

A088229E05

Page 227 of 2000

2AZ-FE EMISSION CONTROL – EMISSION CONTROL SYSTEMEC–7

EC

ON-VEHICLE INSPECTION

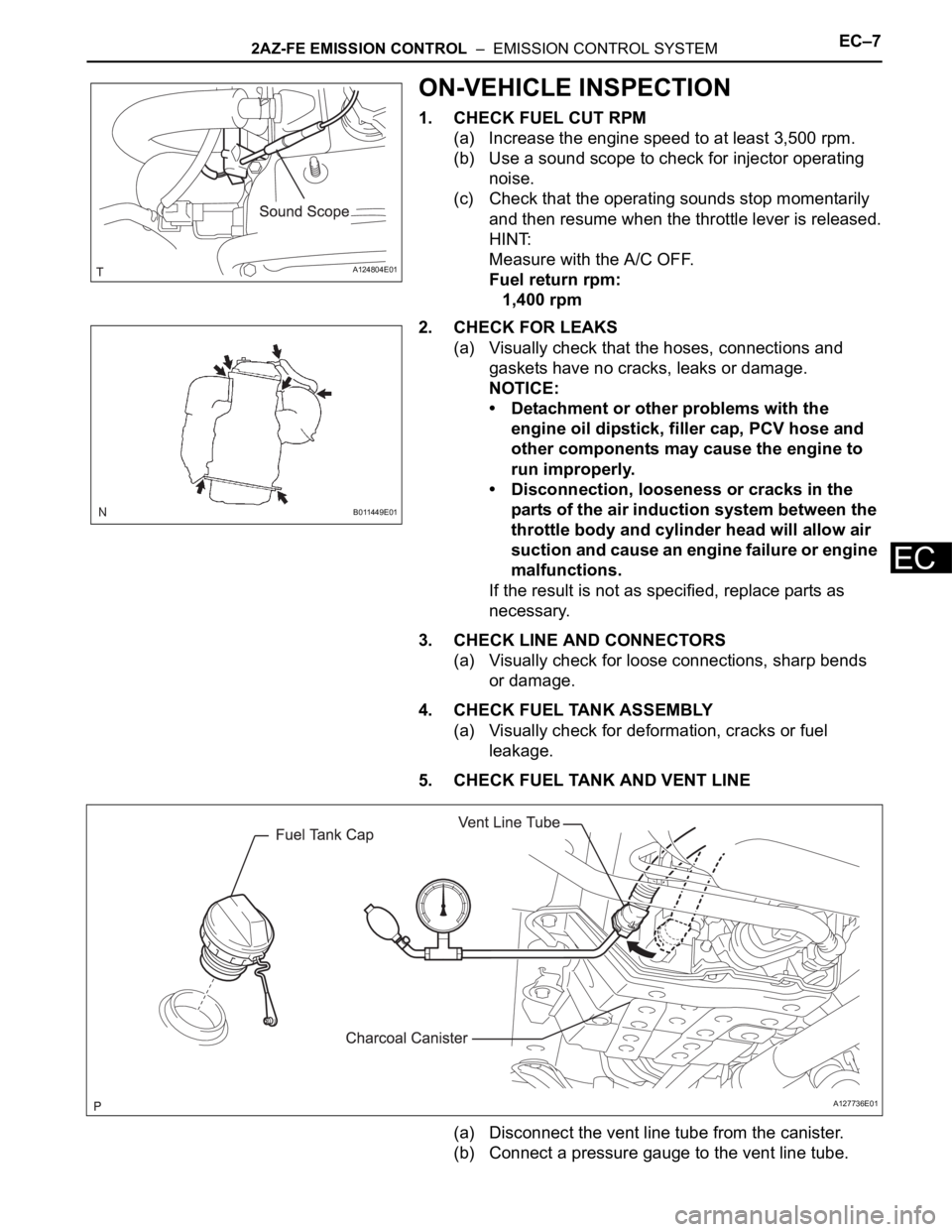

1. CHECK FUEL CUT RPM

(a) Increase the engine speed to at least 3,500 rpm.

(b) Use a sound scope to check for injector operating

noise.

(c) Check that the operating sounds stop momentarily

and then resume when the throttle lever is released.

HINT:

Measure with the A/C OFF.

Fuel return rpm:

1,400 rpm

2. CHECK FOR LEAKS

(a) Visually check that the hoses, connections and

gaskets have no cracks, leaks or damage.

NOTICE:

• Detachment or other problems with the

engine oil dipstick, filler cap, PCV hose and

other components may cause the engine to

run improperly.

• Disconnection, looseness or cracks in the

parts of the air induction system between the

throttle body and cylinder head will allow air

suction and cause an engine failure or engine

malfunctions.

If the result is not as specified, replace parts as

necessary.

3. CHECK LINE AND CONNECTORS

(a) Visually check for loose connections, sharp bends

or damage.

4. CHECK FUEL TANK ASSEMBLY

(a) Visually check for deformation, cracks or fuel

leakage.

5. CHECK FUEL TANK AND VENT LINE

(a) Disconnect the vent line tube from the canister.

(b) Connect a pressure gauge to the vent line tube.

A124804E01

B011449E01

A127736E01