low oil pressure TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 120 of 2000

ENGINE - 2GR-FE ENGINE

238EG63

Va n e

Rotational Direction

Oil Pressure

IN DrainECM

281EG48

Va n e

Rotational DirectionECM

Oil Pressure

IN Drain EG-124

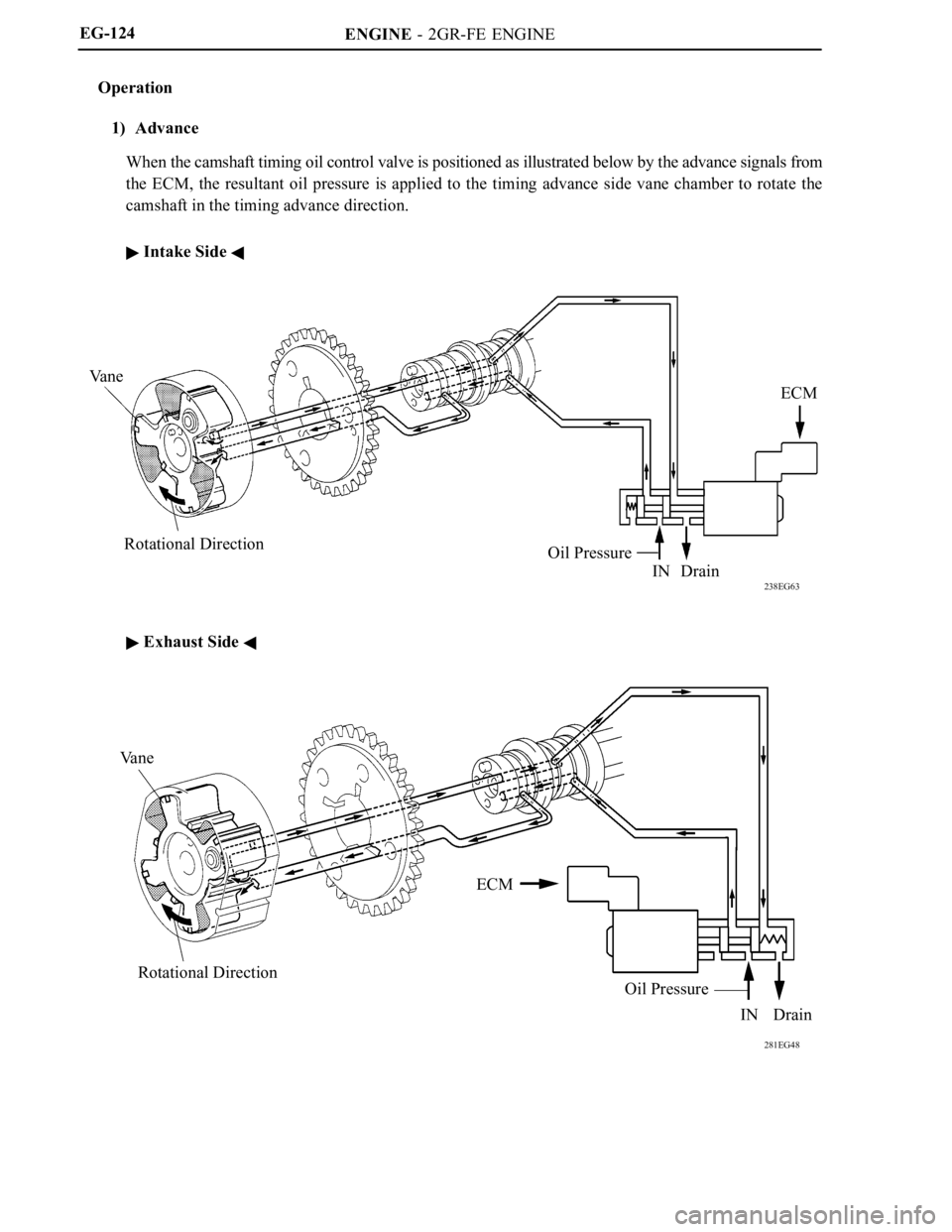

Operation

1) Advance

When the camshaft timing oil control valve is positioned as illustrated below by the advance signals from

the ECM, the resultant oil pressure is applied to the timing advance side vane chamber to rotate the

camshaft in the timing advance direction.

Intake Side

Exhaust Side

Page 121 of 2000

ENGINE - 2GR-FE ENGINE

238EG64

Rotational Direction

Va n e

Drain INOil PressureECM

281EG49

Rotational Direction

Va n eECM

Drain INOil Pressure

EG-125

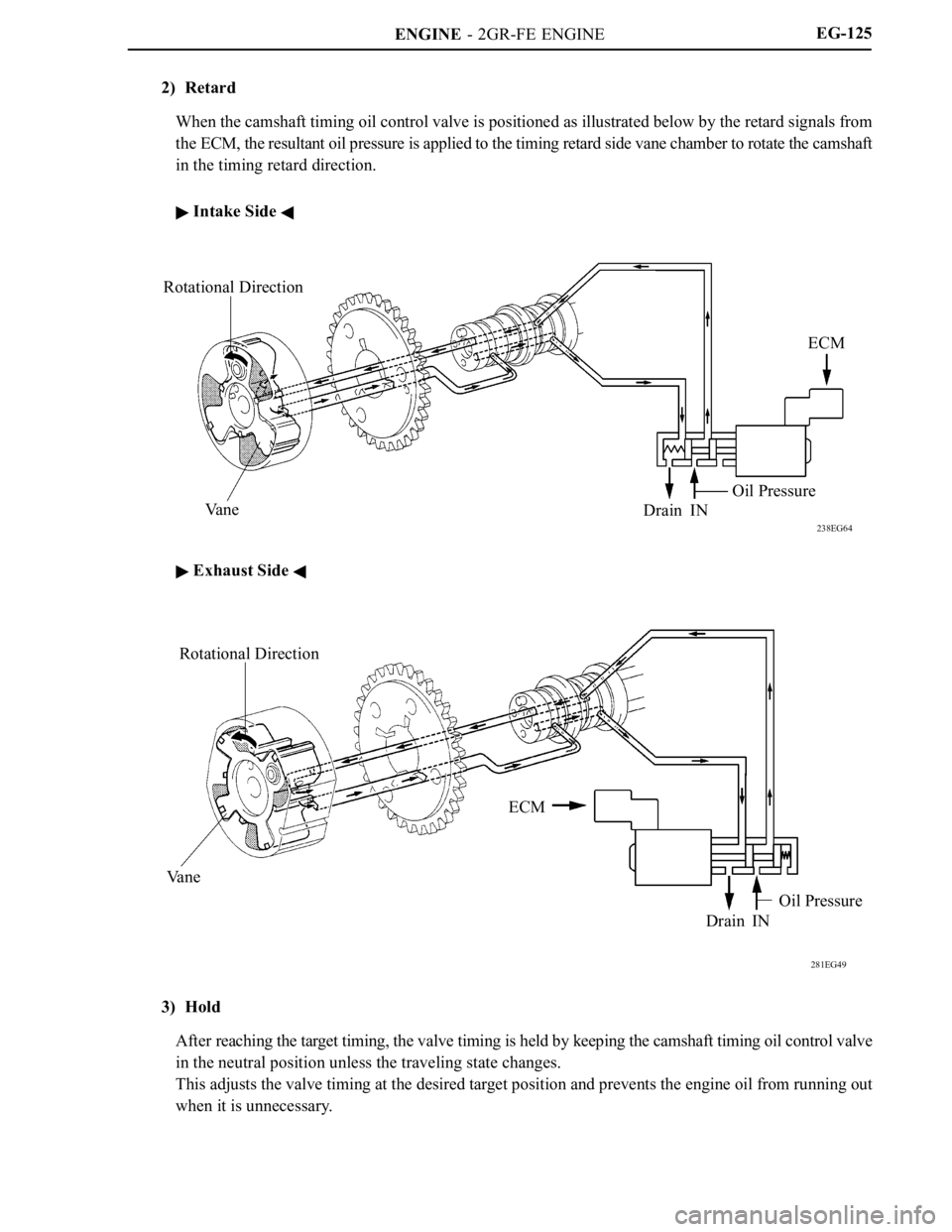

2) Retard

When the camshaft timing oil control valve is positioned as illustrated below by the retard signals from

the ECM, the resultant oil pressure is applied to the timing retard side vane chamber to rotate the camshaft

in the timing retard direction.

Intake Side

Exhaust Side

3) Hold

After reaching the target timing, the valve timing is held by keeping the camshaft timing oil control valve

in the neutral position unless the traveling state changes.

This adjusts the valve timing at the desired target position and prevents the engine oil from running out

when it is unnecessary.

Page 227 of 2000

2AZ-FE EMISSION CONTROL – EMISSION CONTROL SYSTEMEC–7

EC

ON-VEHICLE INSPECTION

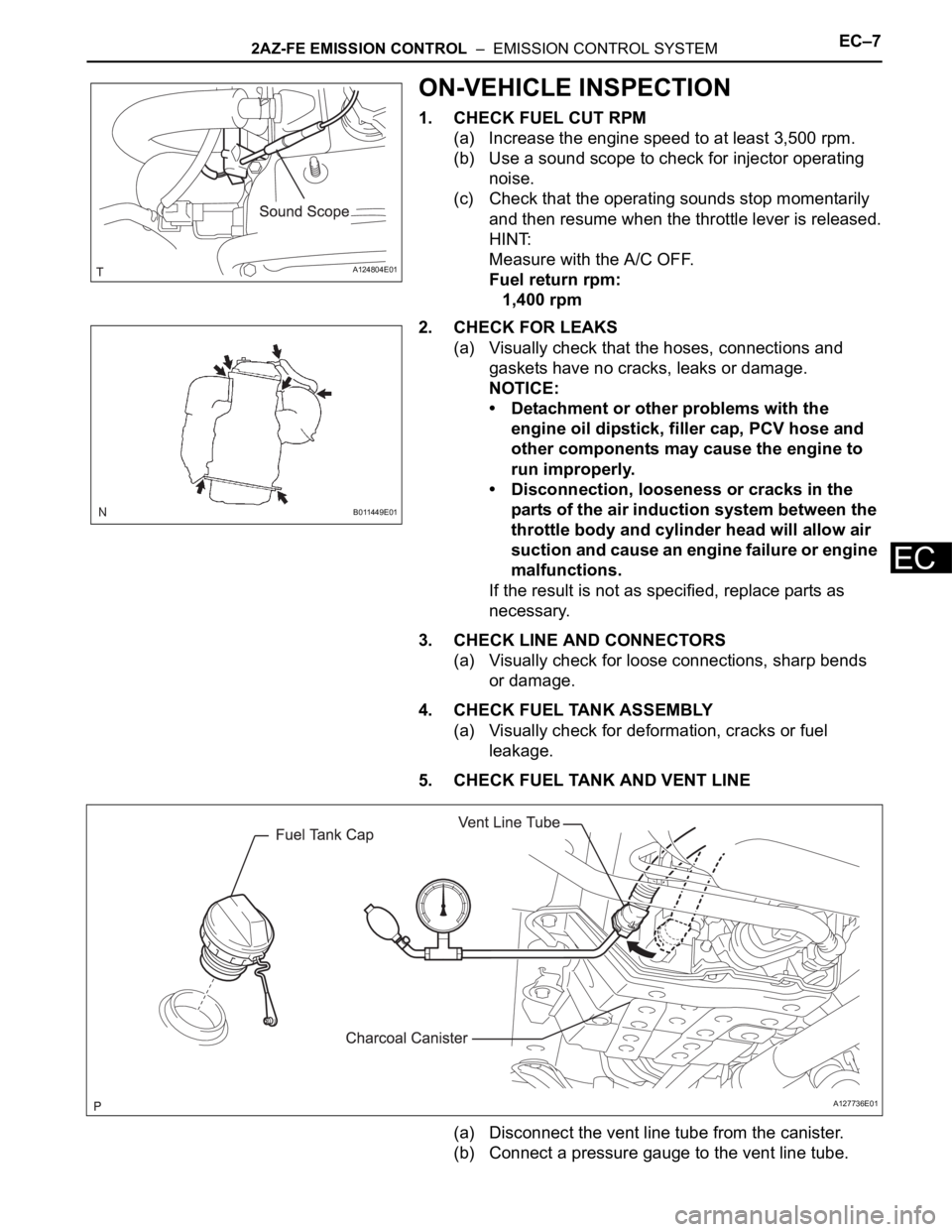

1. CHECK FUEL CUT RPM

(a) Increase the engine speed to at least 3,500 rpm.

(b) Use a sound scope to check for injector operating

noise.

(c) Check that the operating sounds stop momentarily

and then resume when the throttle lever is released.

HINT:

Measure with the A/C OFF.

Fuel return rpm:

1,400 rpm

2. CHECK FOR LEAKS

(a) Visually check that the hoses, connections and

gaskets have no cracks, leaks or damage.

NOTICE:

• Detachment or other problems with the

engine oil dipstick, filler cap, PCV hose and

other components may cause the engine to

run improperly.

• Disconnection, looseness or cracks in the

parts of the air induction system between the

throttle body and cylinder head will allow air

suction and cause an engine failure or engine

malfunctions.

If the result is not as specified, replace parts as

necessary.

3. CHECK LINE AND CONNECTORS

(a) Visually check for loose connections, sharp bends

or damage.

4. CHECK FUEL TANK ASSEMBLY

(a) Visually check for deformation, cracks or fuel

leakage.

5. CHECK FUEL TANK AND VENT LINE

(a) Disconnect the vent line tube from the canister.

(b) Connect a pressure gauge to the vent line tube.

A124804E01

B011449E01

A127736E01

Page 560 of 2000

ES–362GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

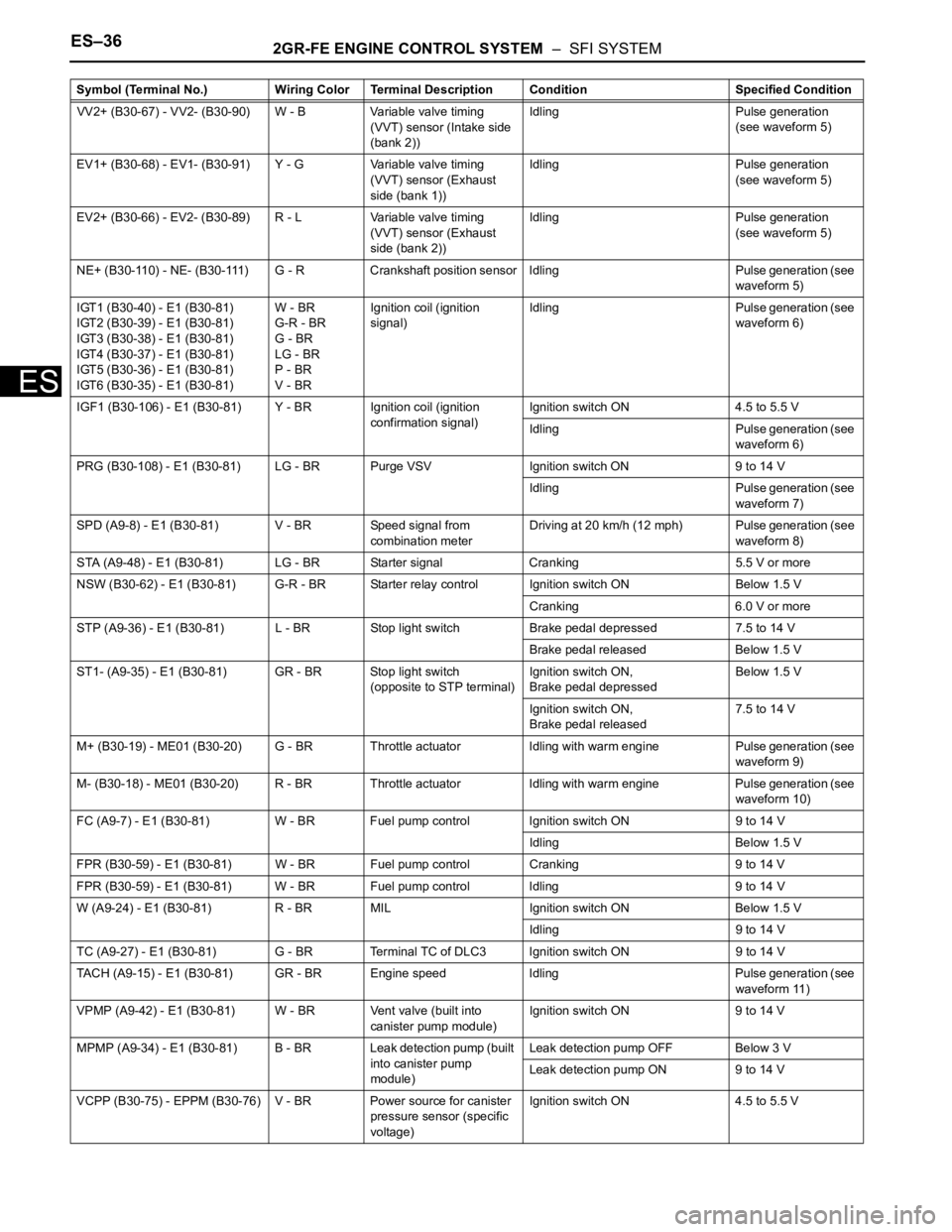

VV2+ (B30-67) - VV2- (B30-90) W - B Variable valve timing

(VVT) sensor (Intake side

(bank 2))Idling Pulse generation

(see waveform 5)

EV1+ (B30-68) - EV1- (B30-91) Y - G Variable valve timing

(VVT) sensor (Exhaust

side (bank 1))Idling Pulse generation

(see waveform 5)

EV2+ (B30-66) - EV2- (B30-89) R - L Variable valve timing

(VVT) sensor (Exhaust

side (bank 2))Idling Pulse generation

(see waveform 5)

NE+ (B30-110) - NE- (B30-111) G - R Crankshaft position sensor Idling Pulse generation (see

waveform 5)

IGT1 (B30-40) - E1 (B30-81)

IGT2 (B30-39) - E1 (B30-81)

IGT3 (B30-38) - E1 (B30-81)

IGT4 (B30-37) - E1 (B30-81)

IGT5 (B30-36) - E1 (B30-81)

IGT6 (B30-35) - E1 (B30-81)W - BR

G-R - BR

G - BR

LG - BR

P - BR

V - BRIgnition coil (ignition

signal)Idling Pulse generation (see

waveform 6)

IGF1 (B30-106) - E1 (B30-81) Y - BR Ignition coil (ignition

confirmation signal)Ignition switch ON 4.5 to 5.5 V

Idling Pulse generation (see

waveform 6)

PRG (B30-108) - E1 (B30-81) LG - BR Purge VSV Ignition switch ON 9 to 14 V

Idling Pulse generation (see

waveform 7)

SPD (A9-8) - E1 (B30-81) V - BR Speed signal from

combination meterDriving at 20 km/h (12 mph) Pulse generation (see

waveform 8)

STA (A9-48) - E1 (B30-81) LG - BR Starter signal Cranking 5.5 V or more

NSW (B30-62) - E1 (B30-81) G-R - BR Starter relay control Ignition switch ON Below 1.5 V

Cranking 6.0 V or more

STP (A9-36) - E1 (B30-81) L - BR Stop light switch Brake pedal depressed 7.5 to 14 V

Brake pedal released Below 1.5 V

ST1- (A9-35) - E1 (B30-81) GR - BR Stop light switch

(opposite to STP terminal)Ignition switch ON,

Brake pedal depressedBelow 1.5 V

Ignition switch ON,

Brake pedal released7.5 to 14 V

M+ (B30-19) - ME01 (B30-20) G - BR Throttle actuator Idling with warm engine Pulse generation (see

waveform 9)

M- (B30-18) - ME01 (B30-20) R - BR Throttle actuator Idling with warm engine Pulse generation (see

waveform 10)

FC (A9-7) - E1 (B30-81) W - BR Fuel pump control Ignition switch ON 9 to 14 V

Idling Below 1.5 V

FPR (B30-59) - E1 (B30-81) W - BR Fuel pump control Cranking 9 to 14 V

FPR (B30-59) - E1 (B30-81) W - BR Fuel pump control Idling 9 to 14 V

W (A9-24) - E1 (B30-81) R - BR MIL Ignition switch ON Below 1.5 V

Idling 9 to 14 V

TC (A9-27) - E1 (B30-81) G - BR Terminal TC of DLC3 Ignition switch ON 9 to 14 V

TACH (A9-15) - E1 (B30-81) GR - BR Engine speed Idling Pulse generation (see

waveform 11)

VPMP (A9-42) - E1 (B30-81) W - BR Vent valve (built into

canister pump module)Ignition switch ON 9 to 14 V

MPMP (A9-34) - E1 (B30-81) B - BR Leak detection pump (built

into canister pump

module)Leak detection pump OFF Below 3 V

Leak detection pump ON 9 to 14 V

VCPP (B30-75) - EPPM (B30-76) V - BR Power source for canister

pressure sensor (specific

voltage)Ignition switch ON 4.5 to 5.5 V Symbol (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

Page 561 of 2000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–37

ES

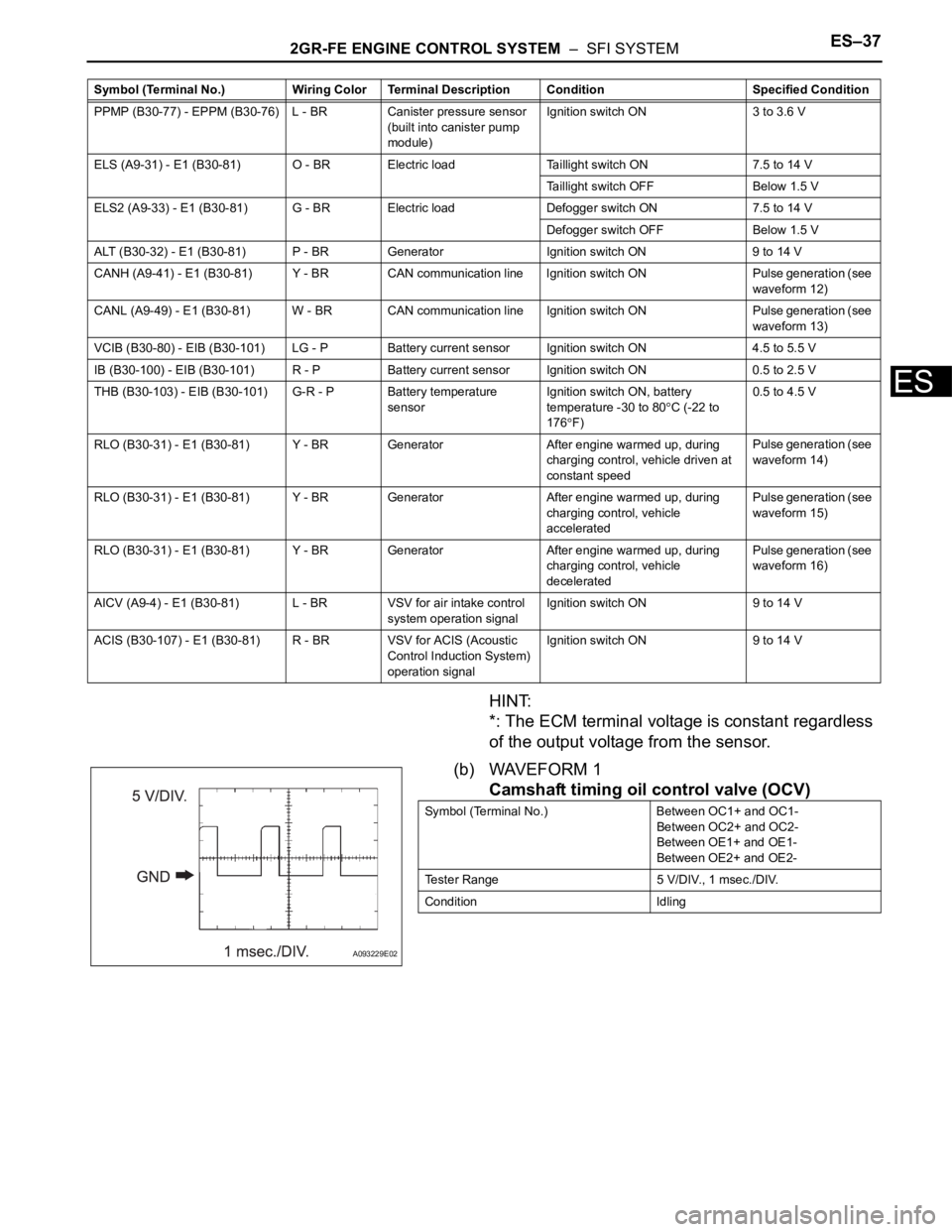

HINT:

*: The ECM terminal voltage is constant regardless

of the output voltage from the sensor.

(b) WAVEFORM 1

Camshaft timing oil control valve (OCV)

PPMP (B30-77) - EPPM (B30-76) L - BR Canister pressure sensor

(built into canister pump

module)Ignition switch ON 3 to 3.6 V

ELS (A9-31) - E1 (B30-81) O - BR Electric load Taillight switch ON7.5 to 14 V

Taillight switch OFF Below 1.5 V

ELS2 (A9-33) - E1 (B30-81) G - BR Electric load Defogger switch ON7.5 to 14 V

Defogger switch OFF Below 1.5 V

ALT (B30-32) - E1 (B30-81) P - BR Generator Ignition switch ON 9 to 14 V

CANH (A9-41) - E1 (B30-81) Y - BR CAN communication line Ignition switch ON Pulse generation (see

waveform 12)

CANL (A9-49) - E1 (B30-81) W - BR CAN communication line Ignition switch ON Pulse generation (see

waveform 13)

VCIB (B30-80) - EIB (B30-101) LG - P Battery current sensor Ignition switch ON 4.5 to 5.5 V

IB (B30-100) - EIB (B30-101) R - P Battery current sensor Ignition switch ON 0.5 to 2.5 V

THB (B30-103) - EIB (B30-101) G-R - P Battery temperature

sensorIgnition switch ON, battery

temperature -30 to 80

C (-22 to

176

F)0.5 to 4.5 V

RLO (B30-31) - E1 (B30-81) Y - BR Generator After engine warmed up, during

charging control, vehicle driven at

constant speedPulse generation (see

waveform 14)

RLO (B30-31) - E1 (B30-81) Y - BR Generator After engine warmed up, during

charging control, vehicle

acceleratedPulse generation (see

waveform 15)

RLO (B30-31) - E1 (B30-81) Y - BR Generator After engine warmed up, during

charging control, vehicle

deceleratedPulse generation (see

waveform 16)

AICV (A9-4) - E1 (B30-81) L - BR VSV for air intake control

system operation signalIgnition switch ON 9 to 14 V

ACIS (B30-107) - E1 (B30-81) R - BR VSV for ACIS (Acoustic

Control Induction System)

operation signalIgnition switch ON 9 to 14 V Symbol (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

A093229E02

Symbol (Terminal No.) Between OC1+ and OC1-

Between OC2+ and OC2-

Between OE1+ and OE1-

Between OE2+ and OE2-

Tester Range 5 V/DIV., 1 msec./DIV.

Condition Idling

Page 677 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–31

EM

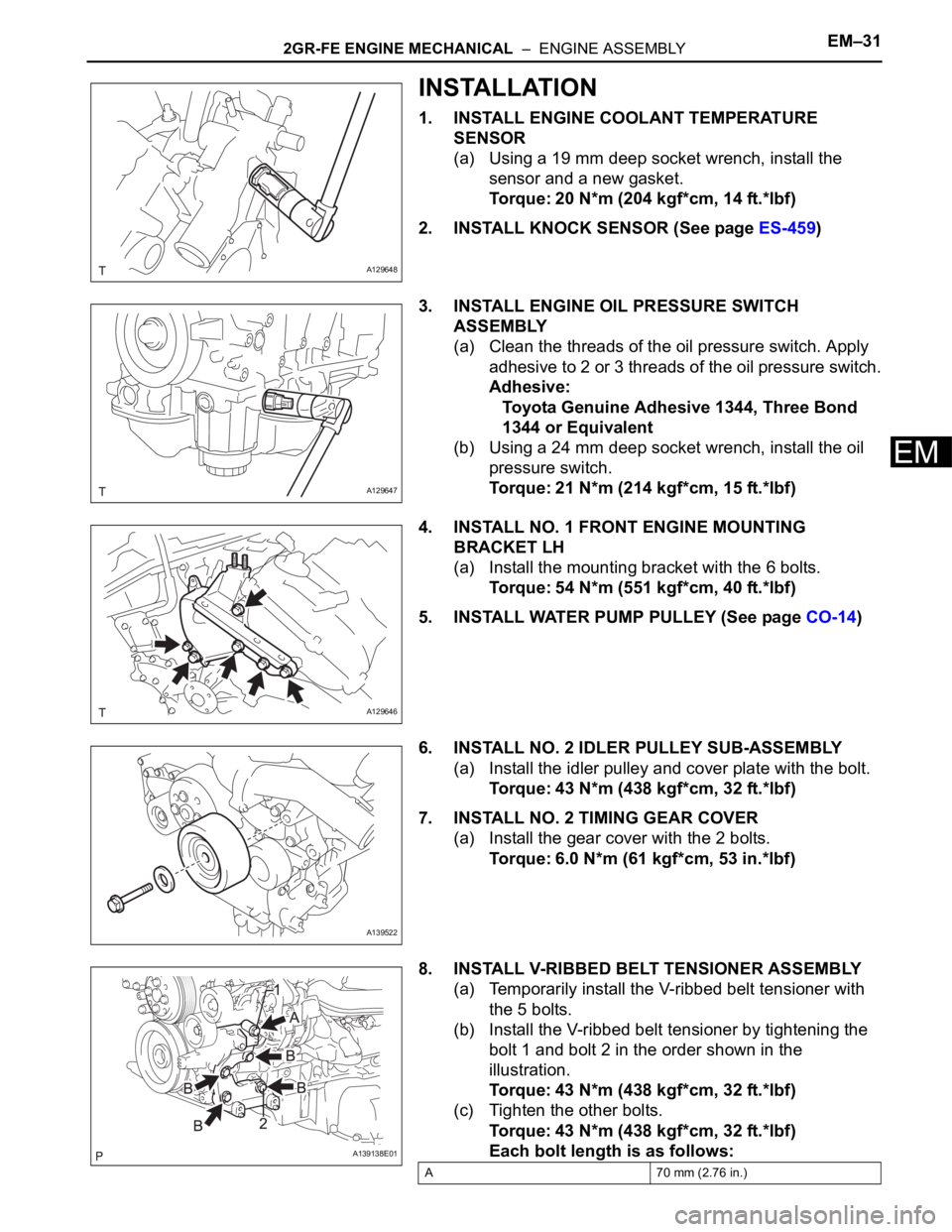

INSTALLATION

1. INSTALL ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using a 19 mm deep socket wrench, install the

sensor and a new gasket.

Torque: 20 N*m (204 kgf*cm, 14 ft.*lbf)

2. INSTALL KNOCK SENSOR (See page ES-459)

3. INSTALL ENGINE OIL PRESSURE SWITCH

ASSEMBLY

(a) Clean the threads of the oil pressure switch. Apply

adhesive to 2 or 3 threads of the oil pressure switch.

Adhesive:

Toyota Genuine Adhesive 1344, Three Bond

1344 or Equivalent

(b) Using a 24 mm deep socket wrench, install the oil

pressure switch.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

4. INSTALL NO. 1 FRONT ENGINE MOUNTING

BRACKET LH

(a) Install the mounting bracket with the 6 bolts.

Torque: 54 N*m (551 kgf*cm, 40 ft.*lbf)

5. INSTALL WATER PUMP PULLEY (See page CO-14)

6. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

(a) Install the idler pulley and cover plate with the bolt.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

7. INSTALL NO. 2 TIMING GEAR COVER

(a) Install the gear cover with the 2 bolts.

Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

8. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

(a) Temporarily install the V-ribbed belt tensioner with

the 5 bolts.

(b) Install the V-ribbed belt tensioner by tightening the

bolt 1 and bolt 2 in the order shown in the

illustration.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(c) Tighten the other bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

Each bolt length is as follows:

A129648

A129647

A129646

A139522

A139138E01

A 70 mm (2.76 in.)

Page 832 of 2000

EC–82GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

EC

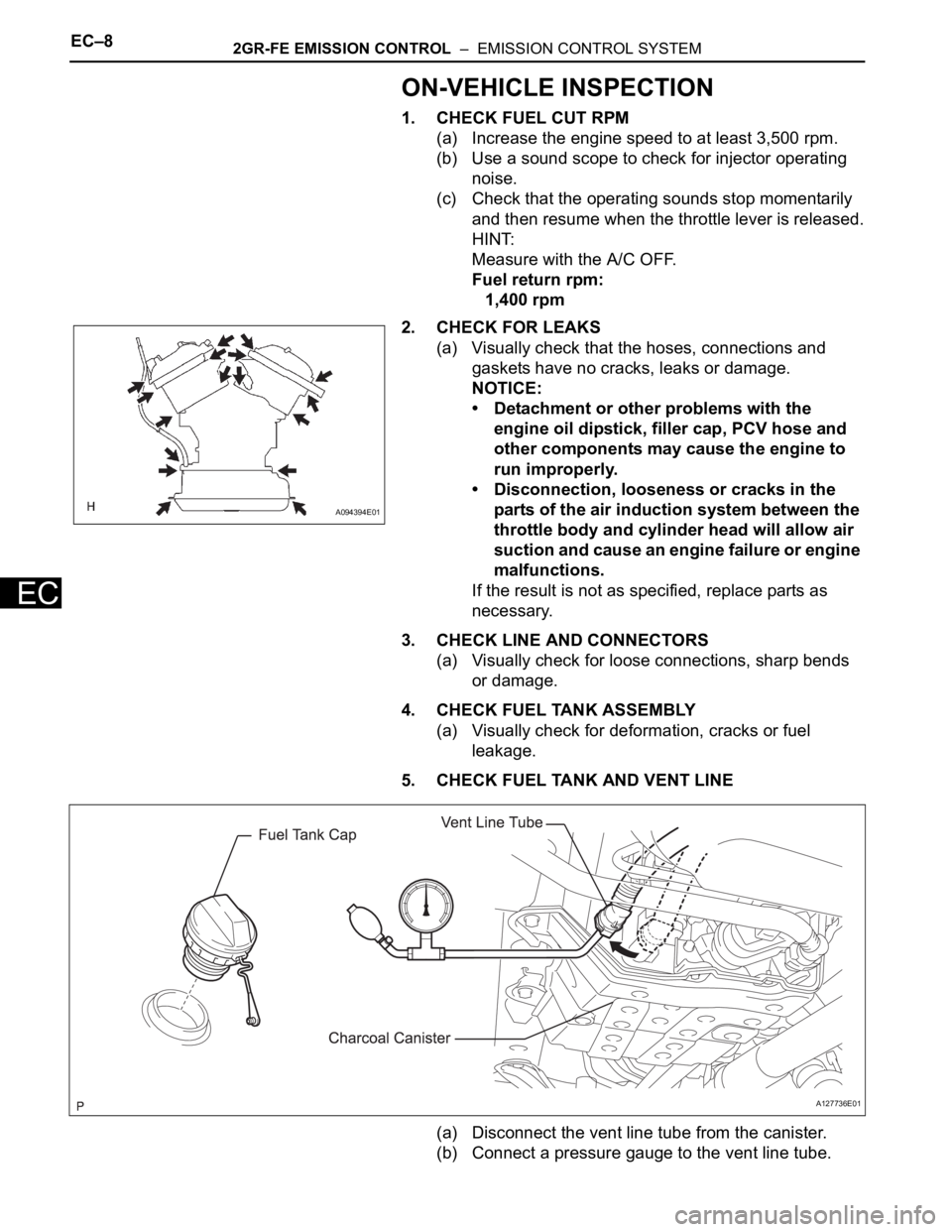

ON-VEHICLE INSPECTION

1. CHECK FUEL CUT RPM

(a) Increase the engine speed to at least 3,500 rpm.

(b) Use a sound scope to check for injector operating

noise.

(c) Check that the operating sounds stop momentarily

and then resume when the throttle lever is released.

HINT:

Measure with the A/C OFF.

Fuel return rpm:

1,400 rpm

2. CHECK FOR LEAKS

(a) Visually check that the hoses, connections and

gaskets have no cracks, leaks or damage.

NOTICE:

• Detachment or other problems with the

engine oil dipstick, filler cap, PCV hose and

other components may cause the engine to

run improperly.

• Disconnection, looseness or cracks in the

parts of the air induction system between the

throttle body and cylinder head will allow air

suction and cause an engine failure or engine

malfunctions.

If the result is not as specified, replace parts as

necessary.

3. CHECK LINE AND CONNECTORS

(a) Visually check for loose connections, sharp bends

or damage.

4. CHECK FUEL TANK ASSEMBLY

(a) Visually check for deformation, cracks or fuel

leakage.

5. CHECK FUEL TANK AND VENT LINE

(a) Disconnect the vent line tube from the canister.

(b) Connect a pressure gauge to the vent line tube.

A094394E01

A127736E01

Page 954 of 2000

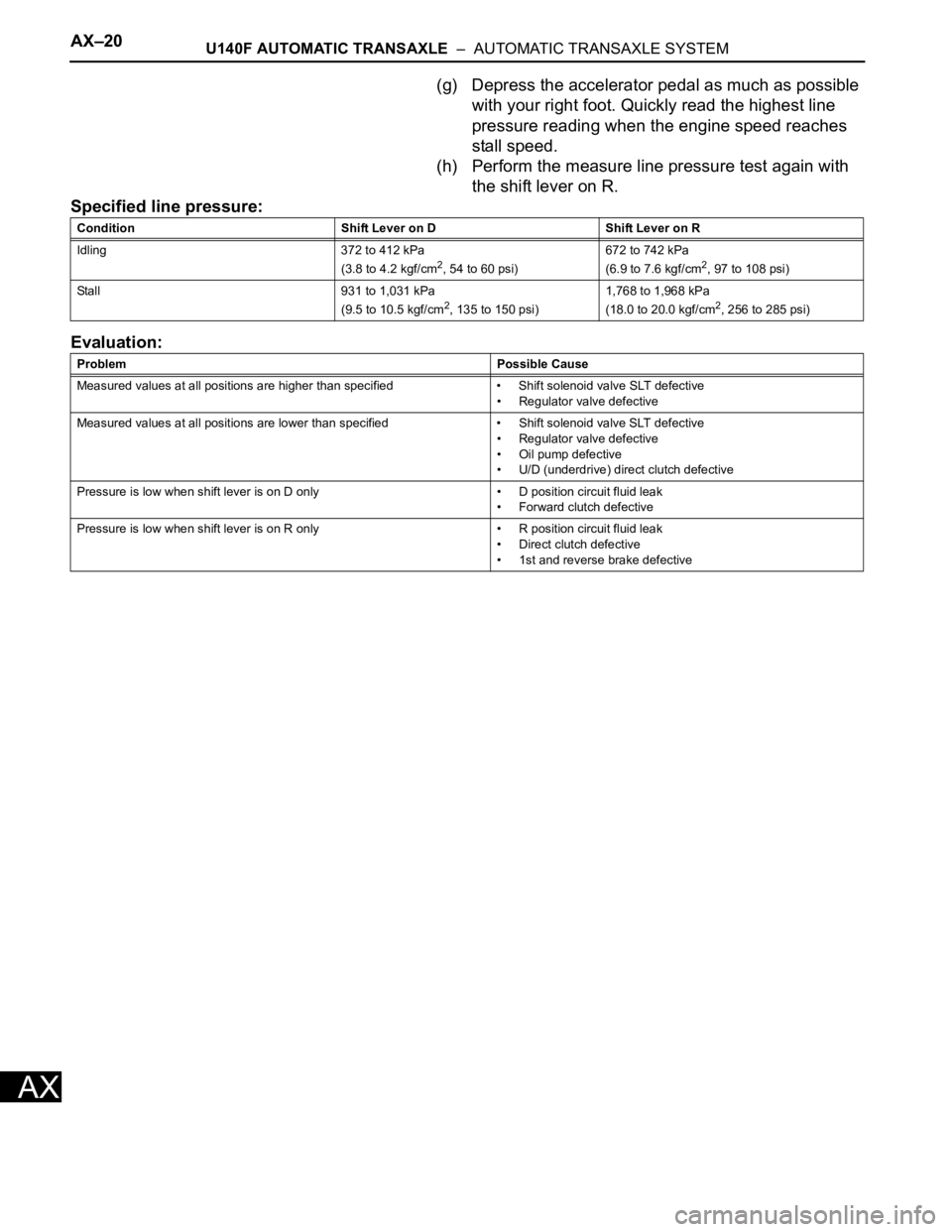

AX–20U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(g) Depress the accelerator pedal as much as possible

with your right foot. Quickly read the highest line

pressure reading when the engine speed reaches

stall speed.

(h) Perform the measure line pressure test again with

the shift lever on R.

Specified line pressure:

Evaluation:

Condition Shift Lever on D Shift Lever on R

Idling 372 to 412 kPa

(3.8 to 4.2 kgf/cm

2, 54 to 60 psi)672 to 742 kPa

(6.9 to 7.6 kgf/cm2, 97 to 108 psi)

Stall 931 to 1,031 kPa

(9.5 to 10.5 kgf/cm

2, 135 to 150 psi)1,768 to 1,968 kPa

(18.0 to 20.0 kgf/cm2, 256 to 285 psi)

Problem Possible Cause

Measured values at all positions are higher than specified • Shift solenoid valve SLT defective

• Regulator valve defective

Measured values at all positions are lower than specified • Shift solenoid valve SLT defective

• Regulator valve defective

• Oil pump defective

• U/D (underdrive) direct clutch defective

Pressure is low when shift lever is on D only • D position circuit fluid leak

• Forward clutch defective

Pressure is low when shift lever is on R only • R position circuit fluid leak

• Direct clutch defective

• 1st and reverse brake defective

Page 1037 of 2000

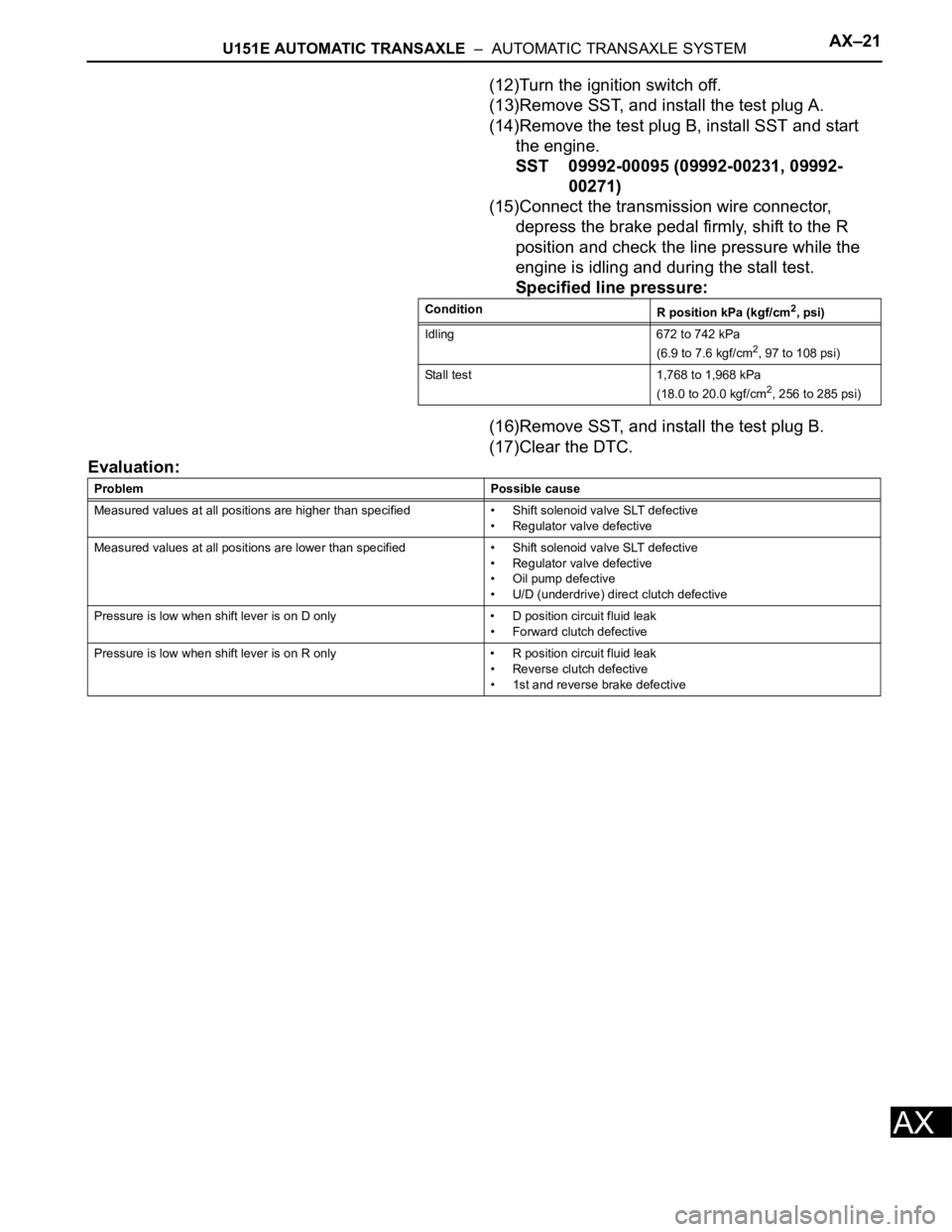

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–21

AX

(12)Turn the ignition switch off.

(13)Remove SST, and install the test plug A.

(14)Remove the test plug B, install SST and start

the engine.

SST 09992-00095 (09992-00231, 09992-

00271)

(15)Connect the transmission wire connector,

depress the brake pedal firmly, shift to the R

position and check the line pressure while the

engine is idling and during the stall test.

Specified line pressure:

(16)Remove SST, and install the test plug B.

(17)Clear the DTC.

Evaluation:

Condition

R position kPa (kgf/cm2, psi)

Idling 672 to 742 kPa

(6.9 to 7.6 kgf/cm

2, 97 to 108 psi)

Stall test 1,768 to 1,968 kPa

(18.0 to 20.0 kgf/cm

2, 256 to 285 psi)

Problem Possible cause

Measured values at all positions are higher than specified • Shift solenoid valve SLT defective

• Regulator valve defective

Measured values at all positions are lower than specified • Shift solenoid valve SLT defective

• Regulator valve defective

• Oil pump defective

• U/D (underdrive) direct clutch defective

Pressure is low when shift lever is on D only • D position circuit fluid leak

• Forward clutch defective

Pressure is low when shift lever is on R only • R position circuit fluid leak

• Reverse clutch defective

• 1st and reverse brake defective

Page 1140 of 2000

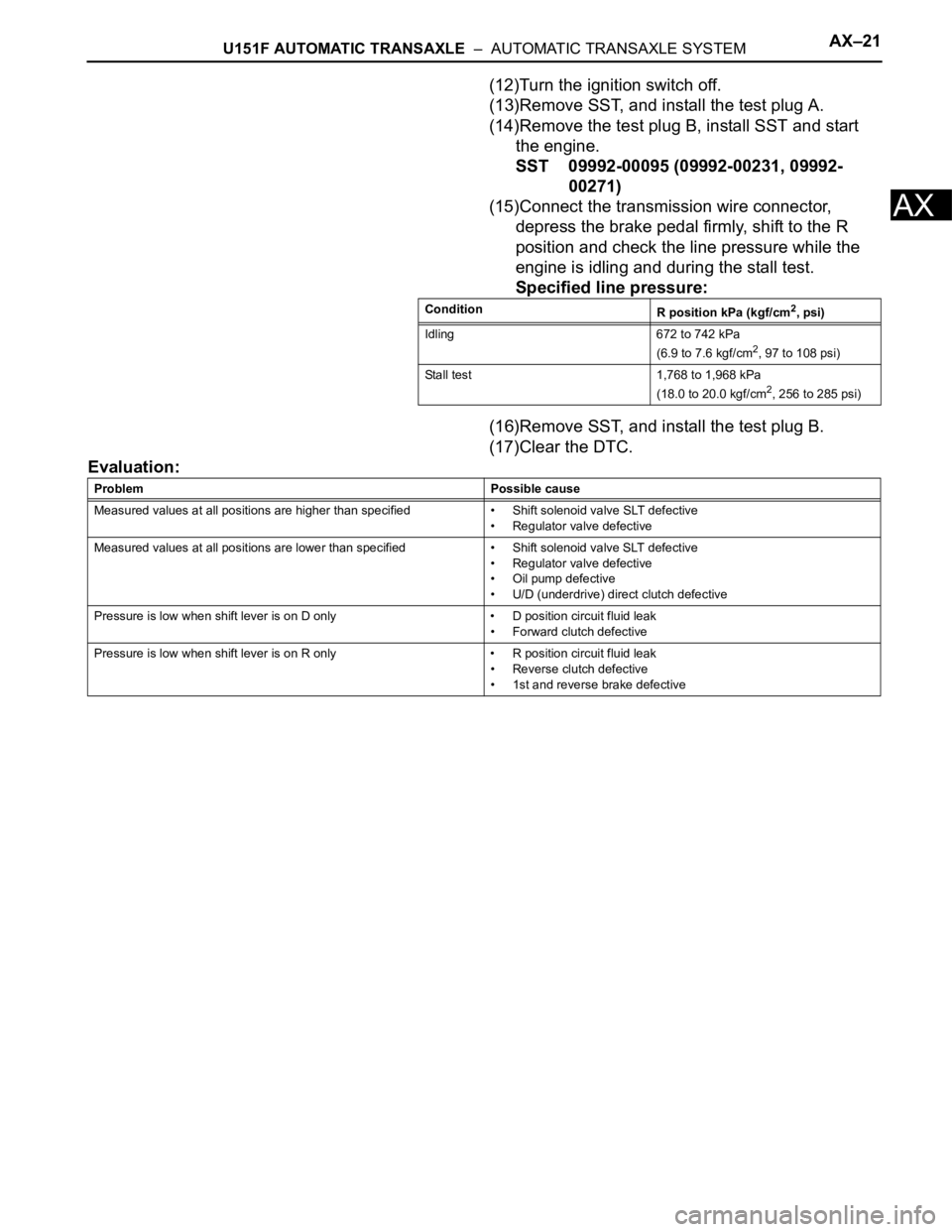

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–21

AX

(12)Turn the ignition switch off.

(13)Remove SST, and install the test plug A.

(14)Remove the test plug B, install SST and start

the engine.

SST 09992-00095 (09992-00231, 09992-

00271)

(15)Connect the transmission wire connector,

depress the brake pedal firmly, shift to the R

position and check the line pressure while the

engine is idling and during the stall test.

Specified line pressure:

(16)Remove SST, and install the test plug B.

(17)Clear the DTC.

Evaluation:

Condition

R position kPa (kgf/cm2, psi)

Idling 672 to 742 kPa

(6.9 to 7.6 kgf/cm

2, 97 to 108 psi)

Stall test 1,768 to 1,968 kPa

(18.0 to 20.0 kgf/cm

2, 256 to 285 psi)

Problem Possible cause

Measured values at all positions are higher than specified • Shift solenoid valve SLT defective

• Regulator valve defective

Measured values at all positions are lower than specified • Shift solenoid valve SLT defective

• Regulator valve defective

• Oil pump defective

• U/D (underdrive) direct clutch defective

Pressure is low when shift lever is on D only • D position circuit fluid leak

• Forward clutch defective

Pressure is low when shift lever is on R only • R position circuit fluid leak

• Reverse clutch defective

• 1st and reverse brake defective