relay TOYOTA RAV4 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1343 of 2000

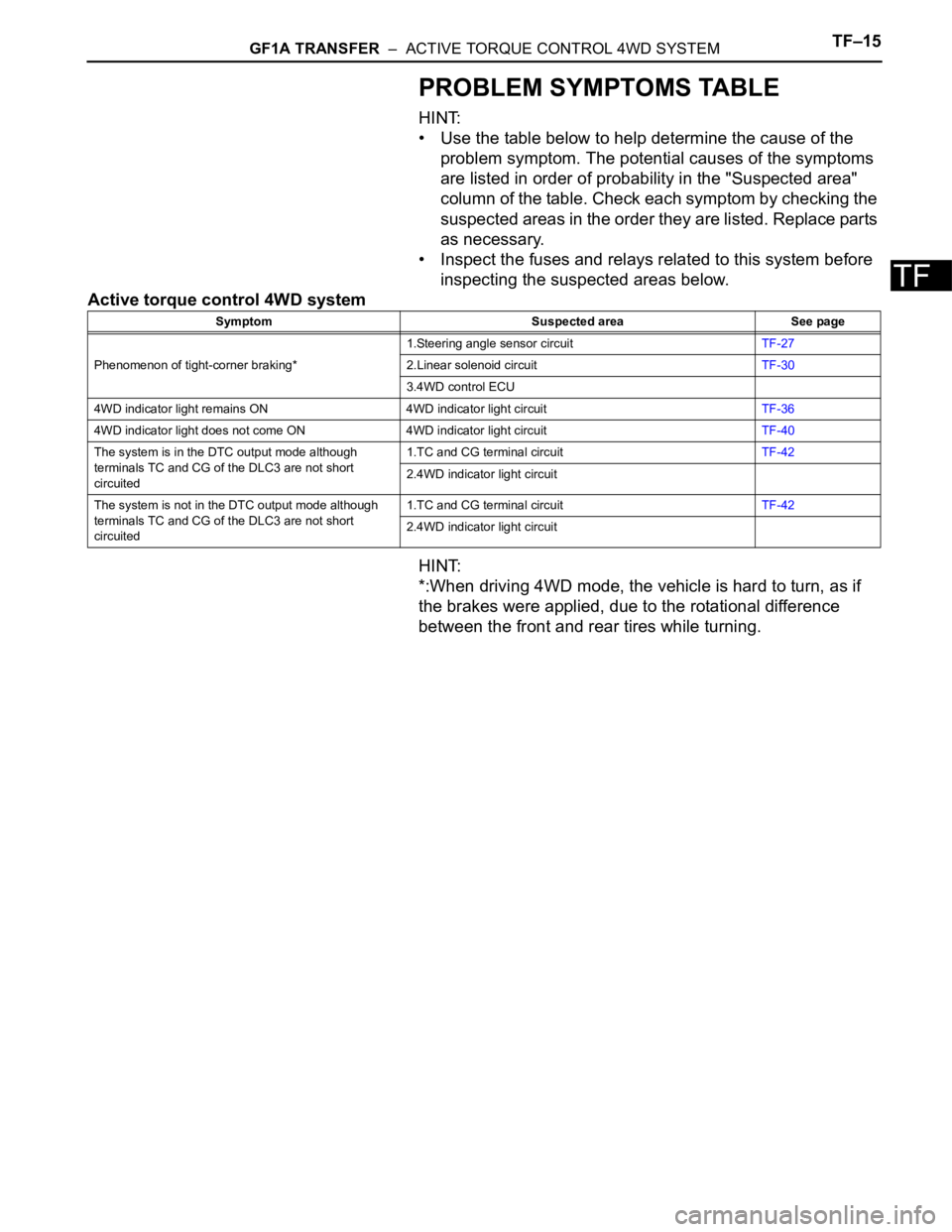

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–15

TF

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

Active torque control 4WD system

HINT:

*:When driving 4WD mode, the vehicle is hard to turn, as if

the brakes were applied, due to the rotational difference

between the front and rear tires while turning.

Symptom Suspected area See page

Phenomenon of tight-corner braking*1.Steering angle sensor circuitTF-27

2.Linear solenoid circuitTF-30

3.4WD control ECU

4WD indicator light remains ON 4WD indicator light circuitTF-36

4WD indicator light does not come ON 4WD indicator light circuitTF-40

The system is in the DTC output mode although

terminals TC and CG of the DLC3 are not short

circuited1.TC and CG terminal circuitTF-42

2.4WD indicator light circuit

The system is not in the DTC output mode although

terminals TC and CG of the DLC3 are not short

circuited1.TC and CG terminal circuitTF-42

2.4WD indicator light circuit

Page 1490 of 2000

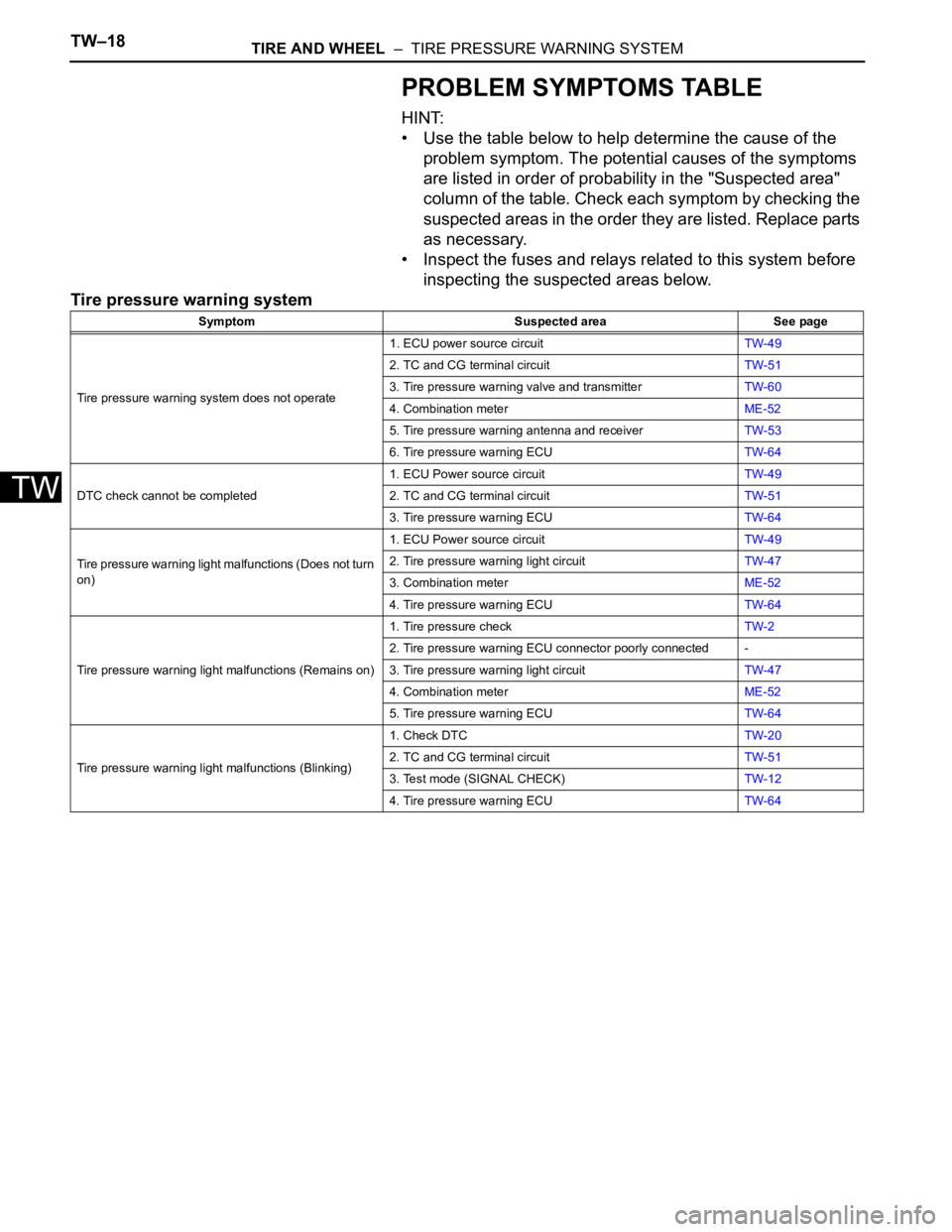

TW–18TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

Tire pressure warning system

Symptom Suspected area See page

Tire pressure warning system does not operate1. ECU power source circuitTW-49

2. TC and CG terminal circuitTW-51

3. Tire pressure warning valve and transmitterTW-60

4. Combination meterME-52

5. Tire pressure warning antenna and receiverTW-53

6. Tire pressure warning ECUTW-64

DTC check cannot be completed1. ECU Power source circuitTW-49

2. TC and CG terminal circuitTW-51

3. Tire pressure warning ECUTW-64

Tire pressure warning light malfunctions (Does not turn

on)1. ECU Power source circuitTW-49

2. Tire pressure warning light circuitTW-47

3. Combination meterME-52

4. Tire pressure warning ECUTW-64

Tire pressure warning light malfunctions (Remains on)1. Tire pressure checkTW-2

2. Tire pressure warning ECU connector poorly connected -

3. Tire pressure warning light circuitTW-47

4. Combination meterME-52

5. Tire pressure warning ECUTW-64

Tire pressure warning light malfunctions (Blinking)1. Check DTCTW-20

2. TC and CG terminal circuitTW-51

3. Test mode (SIGNAL CHECK)TW-12

4. Tire pressure warning ECUTW-64

Page 1522 of 2000

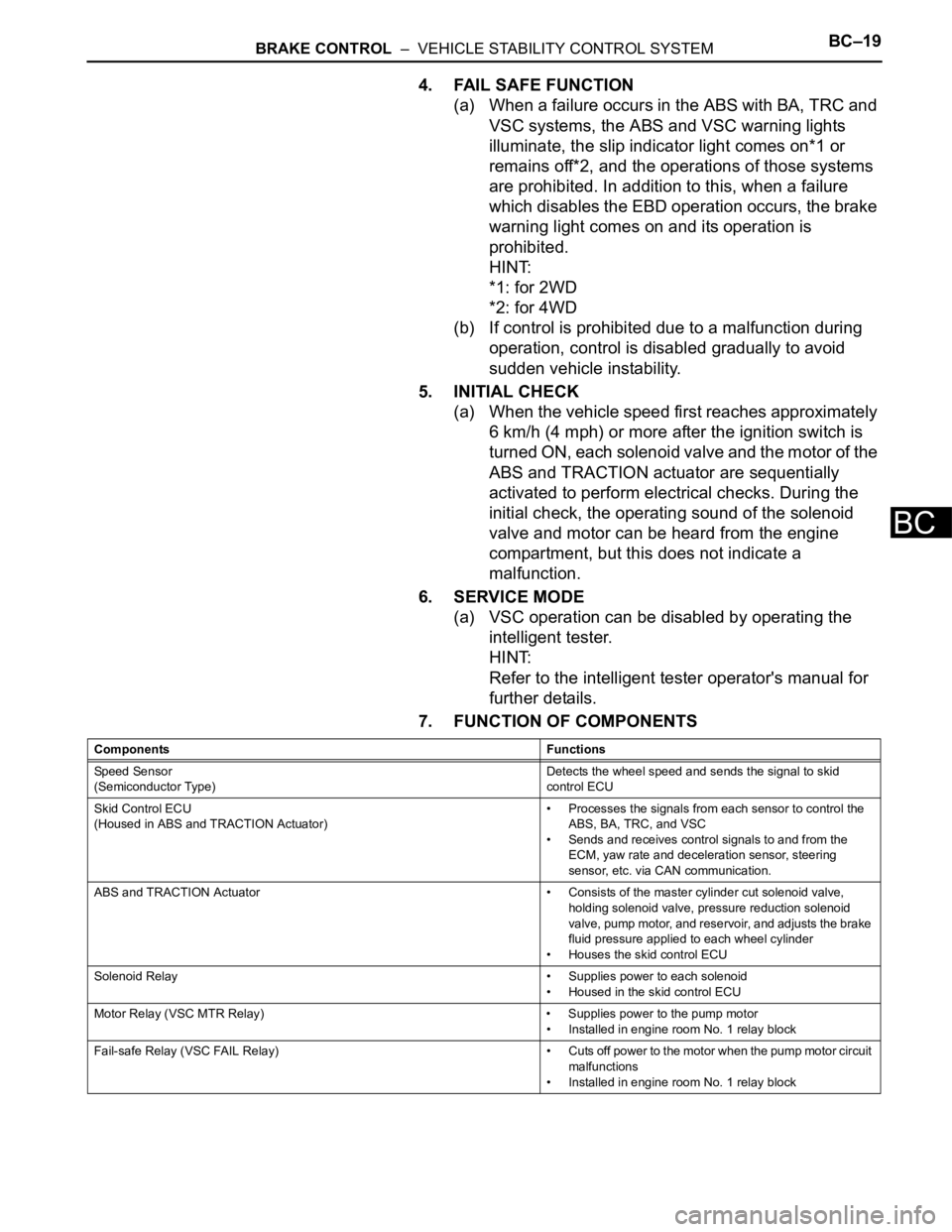

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–19

BC

4. FAIL SAFE FUNCTION

(a) When a failure occurs in the ABS with BA, TRC and

VSC systems, the ABS and VSC warning lights

illuminate, the slip indicator light comes on*1 or

remains off*2, and the operations of those systems

are prohibited. In addition to this, when a failure

which disables the EBD operation occurs, the brake

warning light comes on and its operation is

prohibited.

HINT:

*1: for 2WD

*2: for 4WD

(b) If control is prohibited due to a malfunction during

operation, control is disabled gradually to avoid

sudden vehicle instability.

5. INITIAL CHECK

(a) When the vehicle speed first reaches approximately

6 km/h (4 mph) or more after the ignition switch is

turned ON, each solenoid valve and the motor of the

ABS and TRACTION actuator are sequentially

activated to perform electrical checks. During the

initial check, the operating sound of the solenoid

valve and motor can be heard from the engine

compartment, but this does not indicate a

malfunction.

6. SERVICE MODE

(a) VSC operation can be disabled by operating the

intelligent tester.

HINT:

Refer to the intelligent tester operator's manual for

further details.

7. FUNCTION OF COMPONENTS

Components Functions

Speed Sensor

(Semiconductor Type)Detects the wheel speed and sends the signal to skid

control ECU

Skid Control ECU

(Housed in ABS and TRACTION Actuator)• Processes the signals from each sensor to control the

ABS, BA, TRC, and VSC

• Sends and receives control signals to and from the

ECM, yaw rate and deceleration sensor, steering

sensor, etc. via CAN communication.

ABS and TRACTION Actuator • Consists of the master cylinder cut solenoid valve,

holding solenoid valve, pressure reduction solenoid

valve, pump motor, and reservoir, and adjusts the brake

fluid pressure applied to each wheel cylinder

• Houses the skid control ECU

Solenoid Relay • Supplies power to each solenoid

• Housed in the skid control ECU

Motor Relay (VSC MTR Relay) • Supplies power to the pump motor

• Installed in engine room No. 1 relay block

Fail-safe Relay (VSC FAIL Relay) • Cuts off power to the motor when the pump motor circuit

malfunctions

• Installed in engine room No. 1 relay block

Page 1545 of 2000

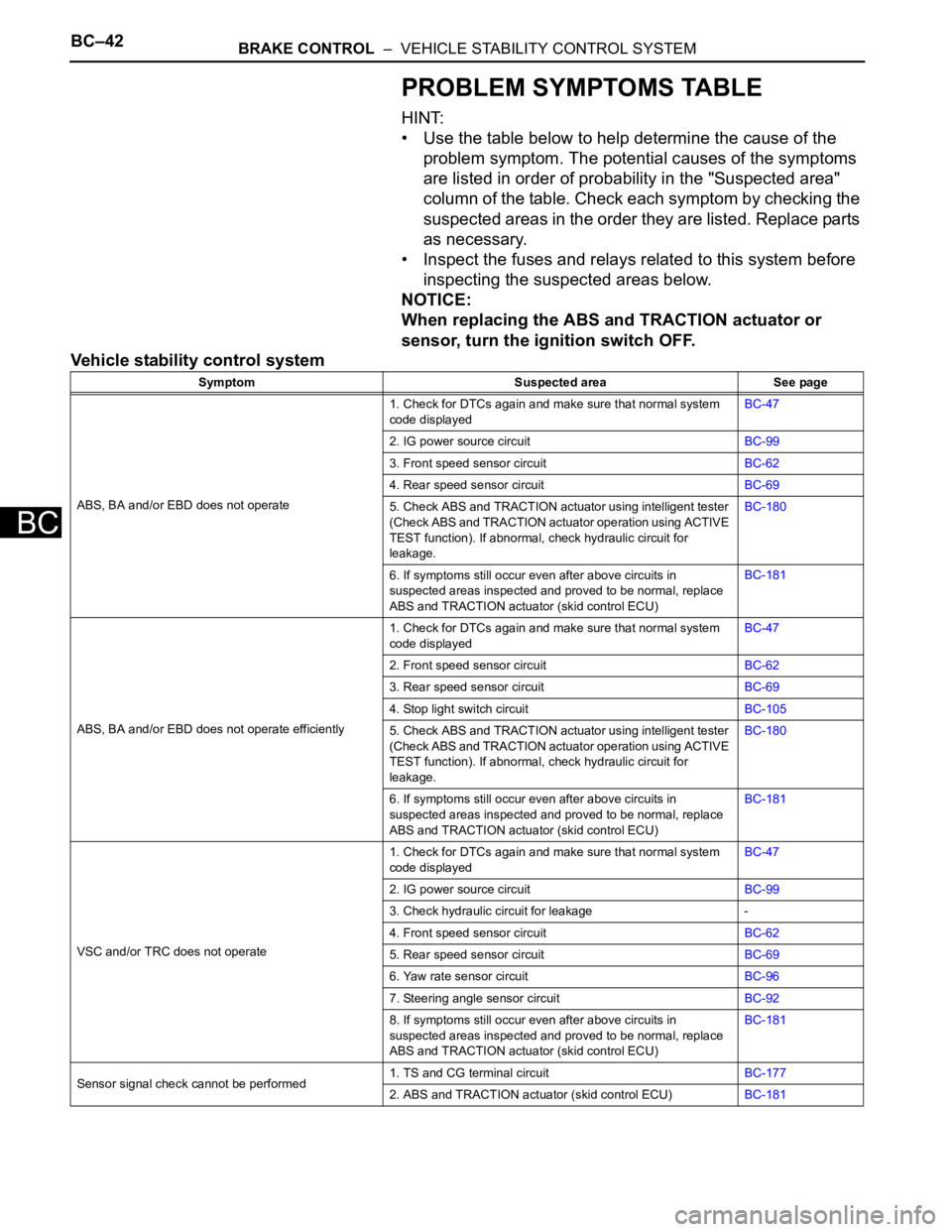

BC–42BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

NOTICE:

When replacing the ABS and TRACTION actuator or

sensor, turn the ignition switch OFF.

Vehicle stability control system

Symptom Suspected area See page

ABS, BA and/or EBD does not operate1. Check for DTCs again and make sure that normal system

code displayedBC-47

2. IG power source circuitBC-99

3. Front speed sensor circuitBC-62

4. Rear speed sensor circuitBC-69

5. Check ABS and TRACTION actuator using intelligent tester

(Check ABS and TRACTION actuator operation using ACTIVE

TEST function). If abnormal, check hydraulic circuit for

leakage.BC-180

6. If symptoms still occur even after above circuits in

suspected areas inspected and proved to be normal, replace

ABS and TRACTION actuator (skid control ECU)BC-181

ABS, BA and/or EBD does not operate efficiently1. Check for DTCs again and make sure that normal system

code displayedBC-47

2. Front speed sensor circuitBC-62

3. Rear speed sensor circuitBC-69

4. Stop light switch circuitBC-105

5. Check ABS and TRACTION actuator using intelligent tester

(Check ABS and TRACTION actuator operation using ACTIVE

TEST function). If abnormal, check hydraulic circuit for

leakage.BC-180

6. If symptoms still occur even after above circuits in

suspected areas inspected and proved to be normal, replace

ABS and TRACTION actuator (skid control ECU)BC-181

VSC and/or TRC does not operate1. Check for DTCs again and make sure that normal system

code displayedBC-47

2. IG power source circuitBC-99

3. Check hydraulic circuit for leakage -

4. Front speed sensor circuitBC-62

5. Rear speed sensor circuitBC-69

6. Yaw rate sensor circuitBC-96

7. Steering angle sensor circuitBC-92

8. If symptoms still occur even after above circuits in

suspected areas inspected and proved to be normal, replace

ABS and TRACTION actuator (skid control ECU)BC-181

Sensor signal check cannot be performed1. TS and CG terminal circuitBC-177

2. ABS and TRACTION actuator (skid control ECU)BC-181

Page 1547 of 2000

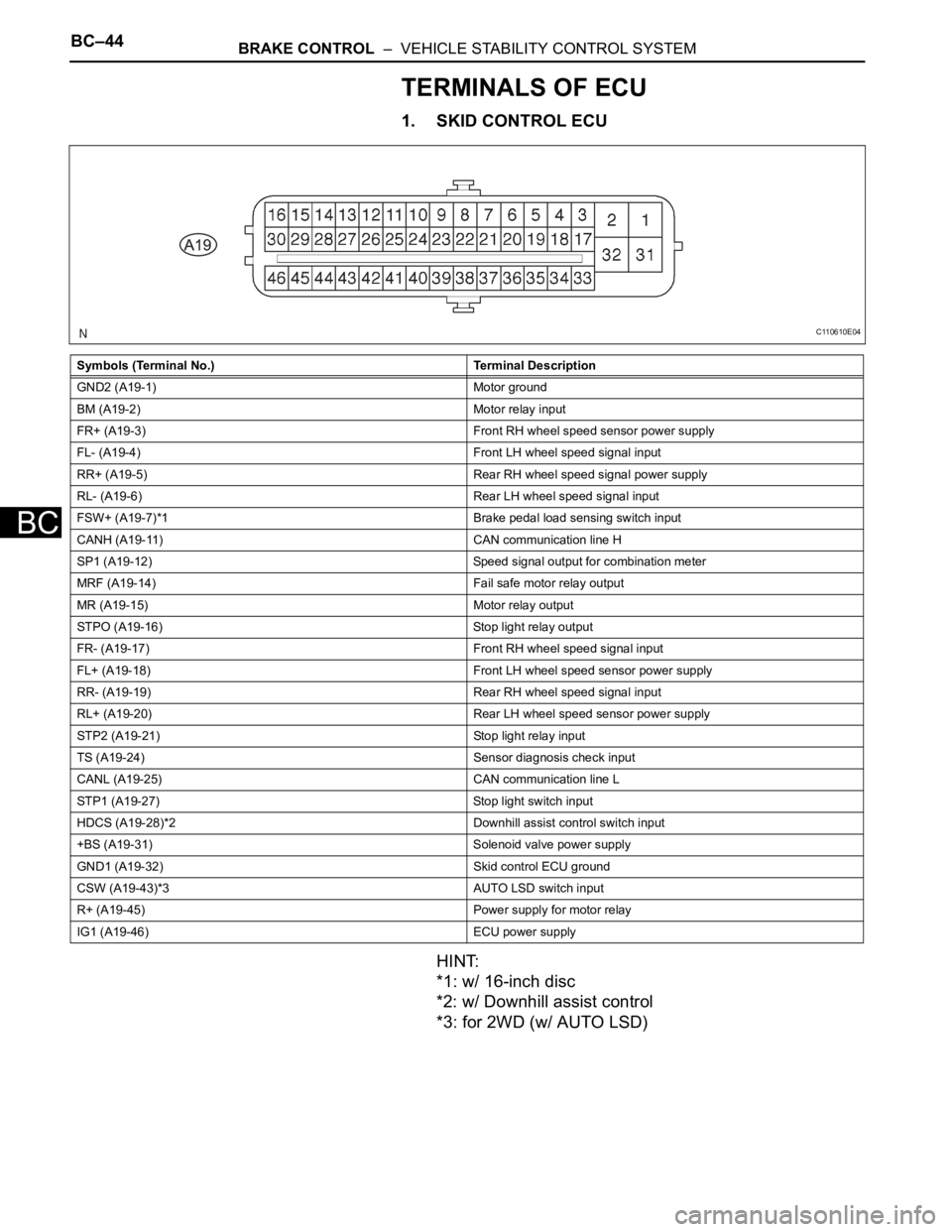

BC–44BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

TERMINALS OF ECU

1. SKID CONTROL ECU

HINT:

*1: w/ 16-inch disc

*2: w/ Downhill assist control

*3: for 2WD (w/ AUTO LSD)

Symbols (Terminal No.) Terminal Description

GND2 (A19-1) Motor ground

BM (A19-2) Motor relay input

FR+ (A19-3) Front RH wheel speed sensor power supply

FL- (A19-4) Front LH wheel speed signal input

RR+ (A19-5) Rear RH wheel speed signal power supply

RL- (A19-6) Rear LH wheel speed signal input

FSW+ (A19-7)*1 Brake pedal load sensing switch input

CANH (A19-11) CAN communication line H

SP1 (A19-12) Speed signal output for combination meter

MRF (A19-14) Fail safe motor relay output

MR (A19-15) Motor relay output

STPO (A19-16) Stop light relay output

FR- (A19-17) Front RH wheel speed signal input

FL+ (A19-18) Front LH wheel speed sensor power supply

RR- (A19-19) Rear RH wheel speed signal input

RL+ (A19-20) Rear LH wheel speed sensor power supply

STP2 (A19-21) Stop light relay input

TS (A19-24) Sensor diagnosis check input

CANL (A19-25) CAN communication line L

STP1 (A19-27) Stop light switch input

HDCS (A19-28)*2 Downhill assist control switch input

+BS (A19-31) Solenoid valve power supply

GND1 (A19-32) Skid control ECU ground

CSW (A19-43)*3 AUTO LSD switch input

R+ (A19-45) Power supply for motor relay

IG1 (A19-46) ECU power supply

C110610E04

Page 1548 of 2000

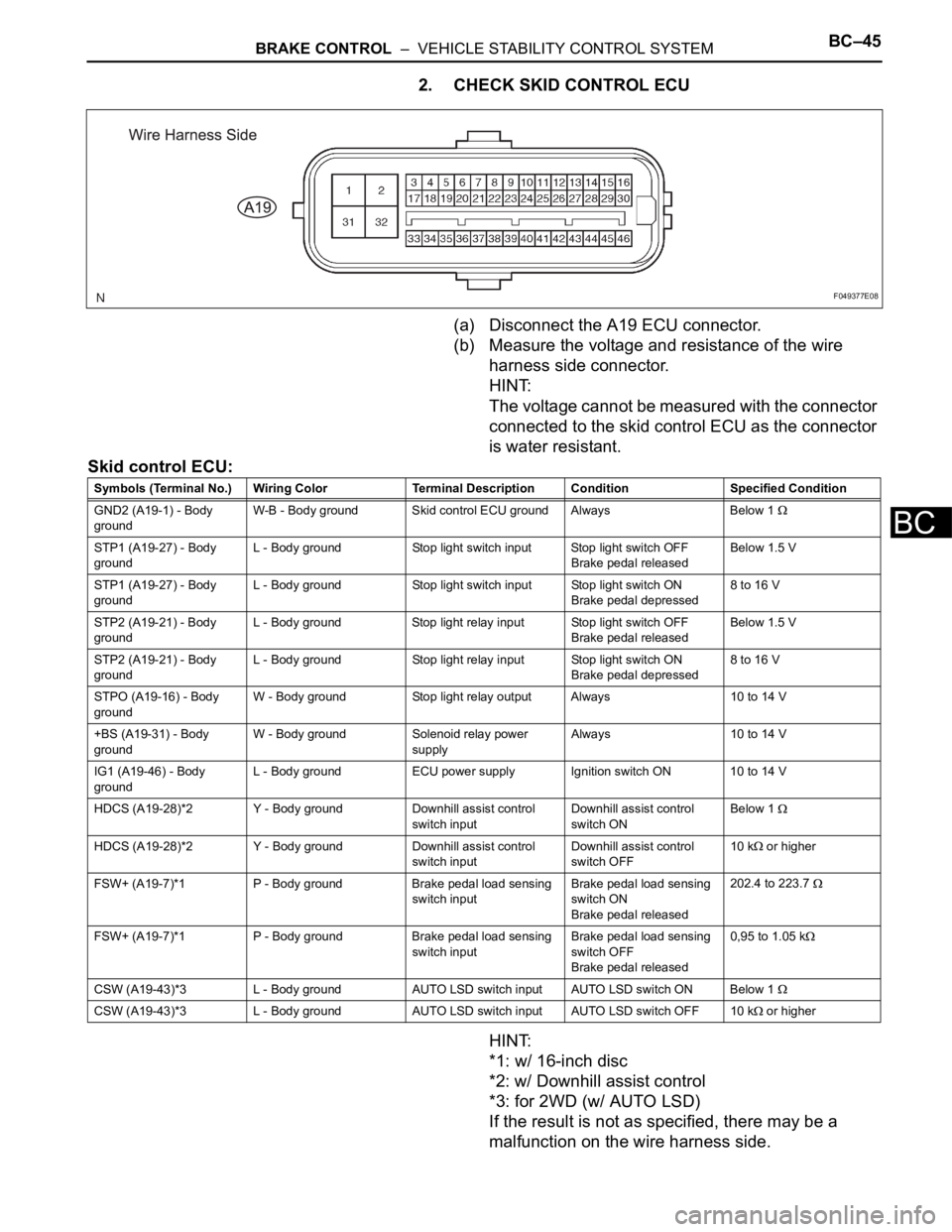

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–45

BC

2. CHECK SKID CONTROL ECU

(a) Disconnect the A19 ECU connector.

(b) Measure the voltage and resistance of the wire

harness side connector.

HINT:

The voltage cannot be measured with the connector

connected to the skid control ECU as the connector

is water resistant.

Skid control ECU:

HINT:

*1: w/ 16-inch disc

*2: w/ Downhill assist control

*3: for 2WD (w/ AUTO LSD)

If the result is not as specified, there may be a

malfunction on the wire harness side.

F049377E08

Symbols (Terminal No.) Wiring Color Terminal Description ConditionSpecified Condition

GND2 (A19-1) - Body

groundW-B - Body ground Skid control ECU ground Always Below 1

STP1 (A19-27) - Body

groundL - Body ground Stop light switch input Stop light switch OFF

Brake pedal releasedBelow 1.5 V

STP1 (A19-27) - Body

groundL - Body ground Stop light switch input Stop light switch ON

Brake pedal depressed8 to 16 V

STP2 (A19-21) - Body

groundL - Body ground Stop light relay input Stop light switch OFF

Brake pedal releasedBelow 1.5 V

STP2 (A19-21) - Body

groundL - Body ground Stop light relay input Stop light switch ON

Brake pedal depressed8 to 16 V

STPO (A19-16) - Body

groundW - Body ground Stop light relay output Always 10 to 14 V

+BS (A19-31) - Body

groundW - Body ground Solenoid relay power

supplyAlways 10 to 14 V

IG1 (A19-46) - Body

groundL - Body ground ECU power supply Ignition switch ON 10 to 14 V

HDCS (A19-28)*2 Y - Body ground Downhill assist control

switch inputDownhill assist control

switch ONBelow 1

HDCS (A19-28)*2 Y - Body ground Downhill assist control

switch inputDownhill assist control

switch OFF10 k or higher

FSW+ (A19-7)*1 P - Body ground Brake pedal load sensing

switch inputBrake pedal load sensing

switch ON

Brake pedal released202.4 to 223.7

FSW+ (A19-7)*1 P - Body ground Brake pedal load sensing

switch inputBrake pedal load sensing

switch OFF

Brake pedal released0,95 to 1.05 k

CSW (A19-43)*3 L - Body ground AUTO LSD switch input AUTO LSD switch ON Below 1

CSW (A19-43)*3 L - Body ground AUTO LSD switch input AUTO LSD switch OFF 10 k or higher

Page 1561 of 2000

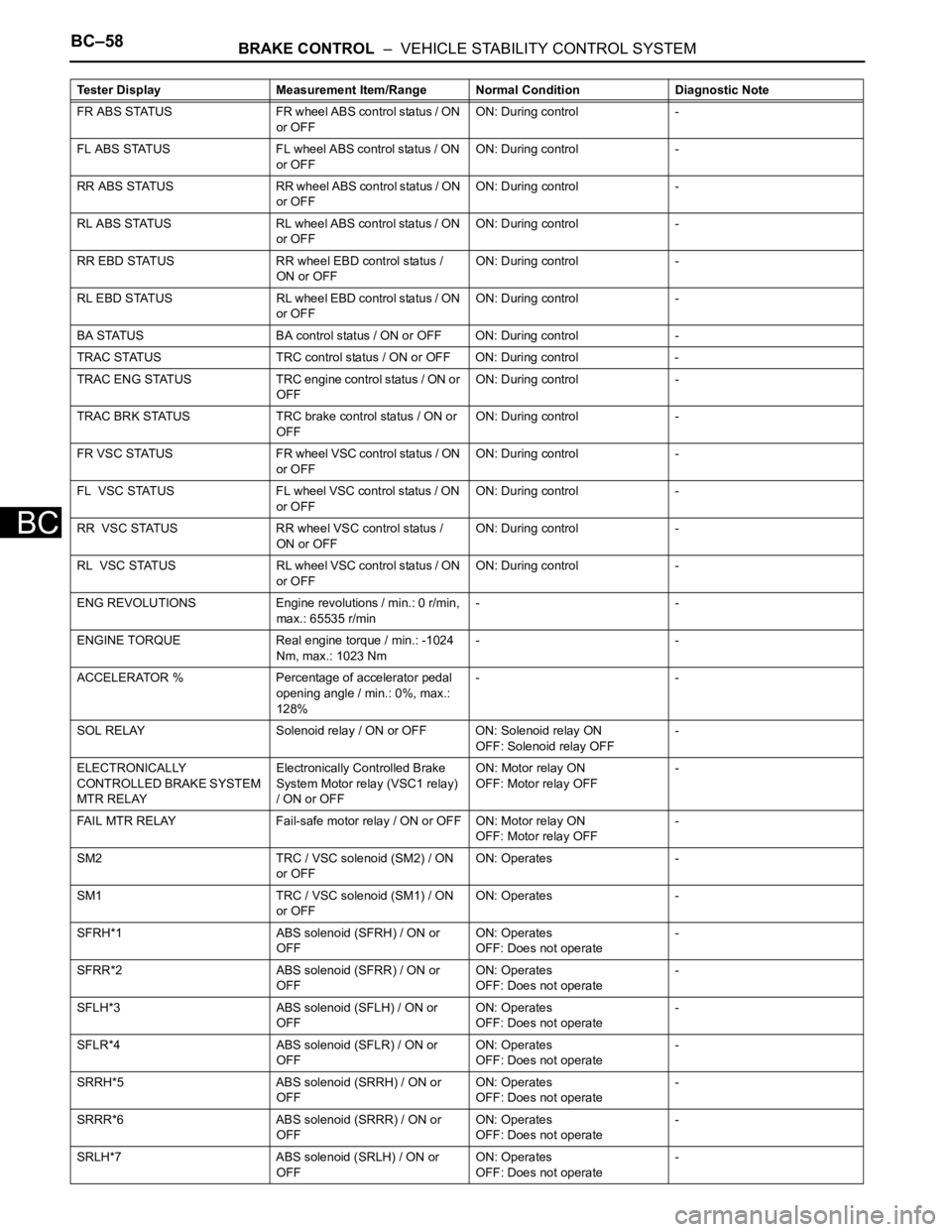

BC–58BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

FR ABS STATUS FR wheel ABS control status / ON

or OFFON: During control -

FL ABS STATUS FL wheel ABS control status / ON

or OFFON: During control -

RR ABS STATUS RR wheel ABS control status / ON

or OFFON: During control -

RL ABS STATUS RL wheel ABS control status / ON

or OFFON: During control -

RR EBD STATUS RR wheel EBD control status /

ON or OFFON: During control -

RL EBD STATUS RL wheel EBD control status / ON

or OFFON: During control -

BA STATUS BA control status / ON or OFF ON: During control -

TRAC STATUS TRC control status / ON or OFF ON: During control -

TRAC ENG STATUS TRC engine control status / ON or

OFFON: During control -

TRAC BRK STATUS TRC brake control status / ON or

OFFON: During control -

FR VSC STATUS FR wheel VSC control status / ON

or OFFON: During control -

FL VSC STATUS FL wheel VSC control status / ON

or OFFON: During control -

RR VSC STATUS RR wheel VSC control status /

ON or OFFON: During control -

RL VSC STATUS RL wheel VSC control status / ON

or OFFON: During control -

ENG REVOLUTIONS Engine revolutions / min.: 0 r/min,

max.: 65535 r/min--

ENGINE TORQUE Real engine torque / min.: -1024

Nm, max.: 1023 Nm--

ACCELERATOR % Percentage of accelerator pedal

opening angle / min.: 0%, max.:

128%--

SOL RELAY Solenoid relay / ON or OFF ON: Solenoid relay ON

OFF: Solenoid relay OFF-

ELECTRONICALLY

CONTROLLED BRAKE SYSTEM

MTR RELAYElectronically Controlled Brake

System Motor relay (VSC1 relay)

/ ON or OFFON: Motor relay ON

OFF: Motor relay OFF-

FAIL MTR RELAY Fail-safe motor relay / ON or OFF ON: Motor relay ON

OFF: Motor relay OFF-

SM2 TRC / VSC solenoid (SM2) / ON

or OFFON: Operates -

SM1 TRC / VSC solenoid (SM1) / ON

or OFFON: Operates -

SFRH*1 ABS solenoid (SFRH) / ON or

OFFON: Operates

OFF: Does not operate-

SFRR*2 ABS solenoid (SFRR) / ON or

OFFON: Operates

OFF: Does not operate-

SFLH*3 ABS solenoid (SFLH) / ON or

OFFON: Operates

OFF: Does not operate-

SFLR*4 ABS solenoid (SFLR) / ON or

OFFON: Operates

OFF: Does not operate-

SRRH*5 ABS solenoid (SRRH) / ON or

OFFON: Operates

OFF: Does not operate-

SRRR*6 ABS solenoid (SRRR) / ON or

OFFON: Operates

OFF: Does not operate-

SRLH*7 ABS solenoid (SRLH) / ON or

OFFON: Operates

OFF: Does not operate- Tester Display Measurement Item/Range Normal Condition Diagnostic Note

Page 1563 of 2000

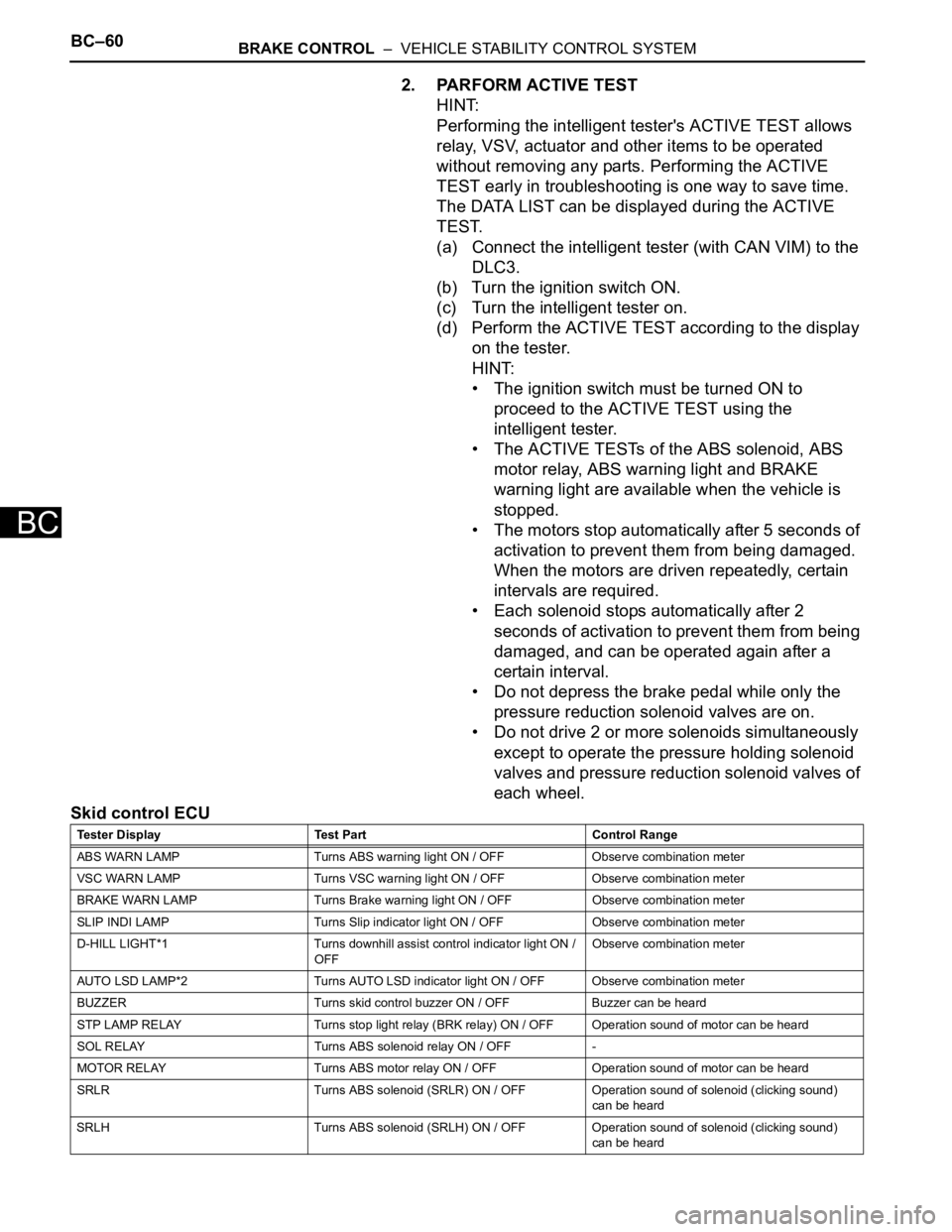

BC–60BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

2. PARFORM ACTIVE TEST

HINT:

Performing the intelligent tester's ACTIVE TEST allows

relay, VSV, actuator and other items to be operated

without removing any parts. Performing the ACTIVE

TEST early in troubleshooting is one way to save time.

The DATA LIST can be displayed during the ACTIVE

TEST.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON.

(c) Turn the intelligent tester on.

(d) Perform the ACTIVE TEST according to the display

on the tester.

HINT:

• The ignition switch must be turned ON to

proceed to the ACTIVE TEST using the

intelligent tester.

• The ACTIVE TESTs of the ABS solenoid, ABS

motor relay, ABS warning light and BRAKE

warning light are available when the vehicle is

stopped.

• The motors stop automatically after 5 seconds of

activation to prevent them from being damaged.

When the motors are driven repeatedly, certain

intervals are required.

• Each solenoid stops automatically after 2

seconds of activation to prevent them from being

damaged, and can be operated again after a

certain interval.

• Do not depress the brake pedal while only the

pressure reduction solenoid valves are on.

• Do not drive 2 or more solenoids simultaneously

except to operate the pressure holding solenoid

valves and pressure reduction solenoid valves of

each wheel.

Skid control ECU

Tester Display Test Part Control Range

ABS WARN LAMP Turns ABS warning light ON / OFF Observe combination meter

VSC WARN LAMP Turns VSC warning light ON / OFF Observe combination meter

BRAKE WARN LAMP Turns Brake warning light ON / OFF Observe combination meter

SLIP INDI LAMP Turns Slip indicator light ON / OFF Observe combination meter

D-HILL LIGHT*1 Turns downhill assist control indicator light ON /

OFFObserve combination meter

AUTO LSD LAMP*2 Turns AUTO LSD indicator light ON / OFF Observe combination meter

BUZZER Turns skid control buzzer ON / OFF Buzzer can be heard

STP LAMP RELAY Turns stop light relay (BRK relay) ON / OFF Operation sound of motor can be heard

SOL RELAY Turns ABS solenoid relay ON / OFF -

MOTOR RELAY Turns ABS motor relay ON / OFF Operation sound of motor can be heard

SRLR Turns ABS solenoid (SRLR) ON / OFF Operation sound of solenoid (clicking sound)

can be heard

SRLH Turns ABS solenoid (SRLH) ON / OFF Operation sound of solenoid (clicking sound)

can be heard

Page 1616 of 2000

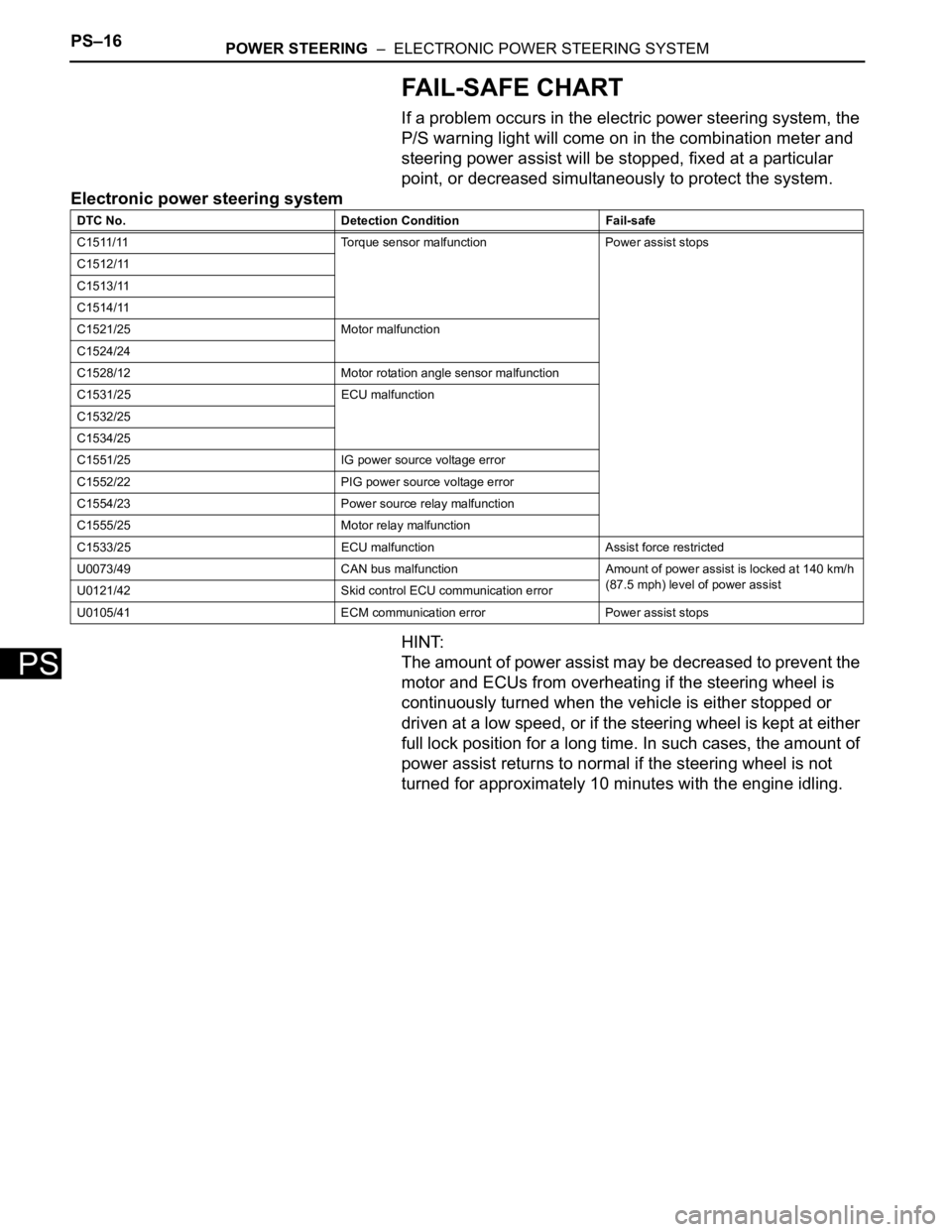

PS–16POWER STEERING – ELECTRONIC POWER STEERING SYSTEM

PS

FAIL-SAFE CHART

If a problem occurs in the electric power steering system, the

P/S warning light will come on in the combination meter and

steering power assist will be stopped, fixed at a particular

point, or decreased simultaneously to protect the system.

Electronic power steering system

HINT:

The amount of power assist may be decreased to prevent the

motor and ECUs from overheating if the steering wheel is

continuously turned when the vehicle is either stopped or

driven at a low speed, or if the steering wheel is kept at either

full lock position for a long time. In such cases, the amount of

power assist returns to normal if the steering wheel is not

turned for approximately 10 minutes with the engine idling.

DTC No. Detection Condition Fail-safe

C1511/11 Torque sensor malfunction Power assist stops

C1512/11

C1513/11

C1514/11

C1521/25 Motor malfunction

C1524/24

C1528/12 Motor rotation angle sensor malfunction

C1531/25 ECU malfunction

C1532/25

C1534/25

C1551/25 IG power source voltage error

C1552/22 PIG power source voltage error

C1554/23 Power source relay malfunction

C1555/25 Motor relay malfunction

C1533/25 ECU malfunction Assist force restricted

U0073/49 CAN bus malfunction Amount of power assist is locked at 140 km/h

(87.5 mph) level of power assist

U0121/42 Skid control ECU communication error

U0105/41 ECM communication error Power assist stops

Page 1618 of 2000

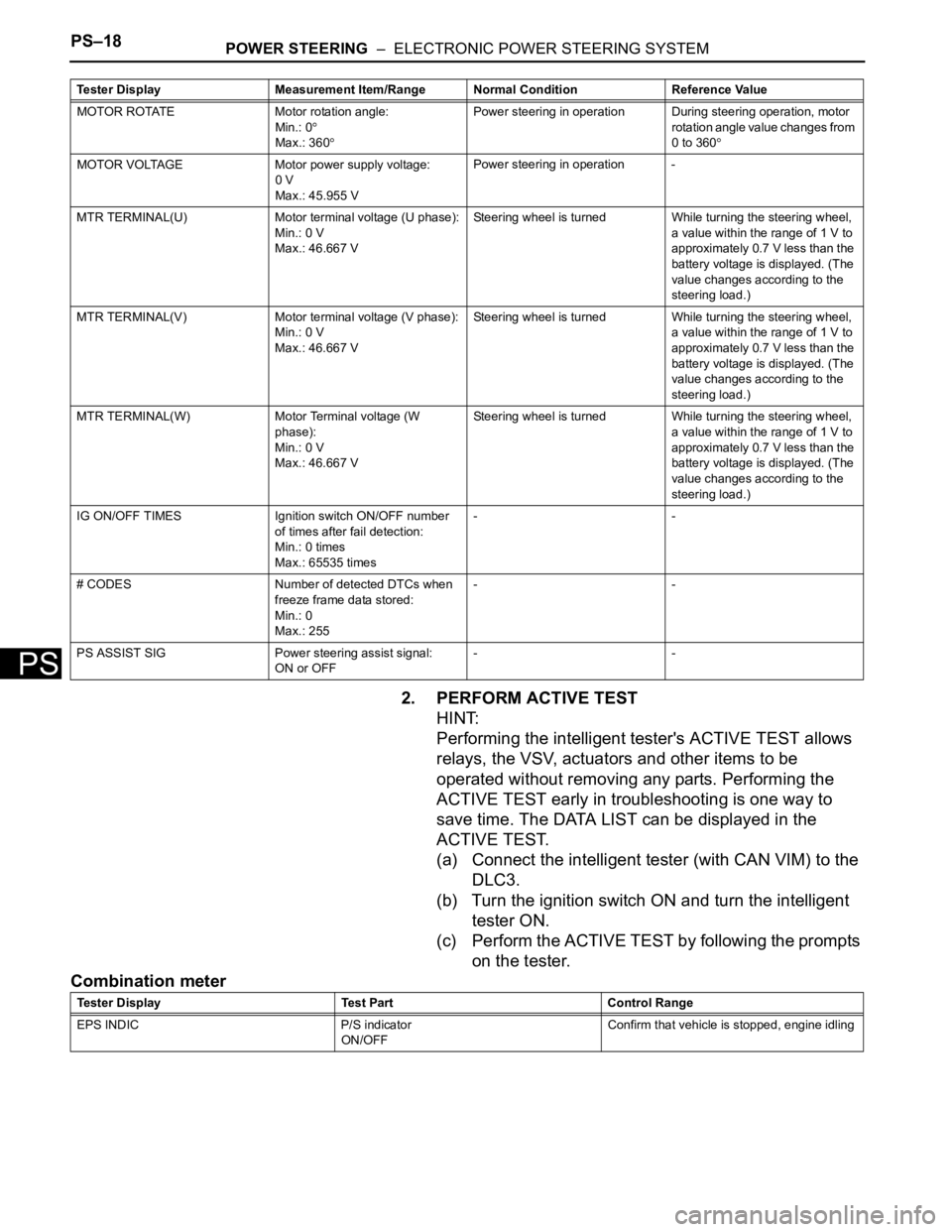

PS–18POWER STEERING – ELECTRONIC POWER STEERING SYSTEM

PS

2. PERFORM ACTIVE TEST

HINT:

Performing the intelligent tester's ACTIVE TEST allows

relays, the VSV, actuators and other items to be

operated without removing any parts. Performing the

ACTIVE TEST early in troubleshooting is one way to

save time. The DATA LIST can be displayed in the

ACTIVE TEST.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON and turn the intelligent

tester ON.

(c) Perform the ACTIVE TEST by following the prompts

on the tester.

Combination meter

MOTOR ROTATE Motor rotation angle:

Min.: 0

Max.: 360

Power steering in operation During steering operation, motor

rotation angle value changes from

0 to 360

MOTOR VOLTAGE Motor power supply voltage:

0 V

Max.: 45.955 VPower steering in operation -

MTR TERMINAL(U) Motor terminal voltage (U phase):

Min.: 0 V

Max.: 46.667 VSteering wheel is turned While turning the steering wheel,

a value within the range of 1 V to

approximately 0.7 V less than the

battery voltage is displayed. (The

value changes according to the

steering load.)

MTR TERMINAL(V) Motor terminal voltage (V phase):

Min.: 0 V

Max.: 46.667 VSteering wheel is turned While turning the steering wheel,

a value within the range of 1 V to

approximately 0.7 V less than the

battery voltage is displayed. (The

value changes according to the

steering load.)

MTR TERMINAL(W) Motor Terminal voltage (W

phase):

Min.: 0 V

Max.: 46.667 VSteering wheel is turned While turning the steering wheel,

a value within the range of 1 V to

approximately 0.7 V less than the

battery voltage is displayed. (The

value changes according to the

steering load.)

IG ON/OFF TIMES Ignition switch ON/OFF number

of times after fail detection:

Min.: 0 times

Max.: 65535 times--

# CODES Number of detected DTCs when

freeze frame data stored:

Min.: 0

Max.: 255 --

PS ASSIST SIG Power steering assist signal:

ON or OFF-- Tester Display Measurement Item/Range Normal Condition Reference Value

Tester Display Test Part Control Range

EPS INDIC P/S indicator

ON/OFFConfirm that vehicle is stopped, engine idling