brake sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2460 of 3000

BC–98BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

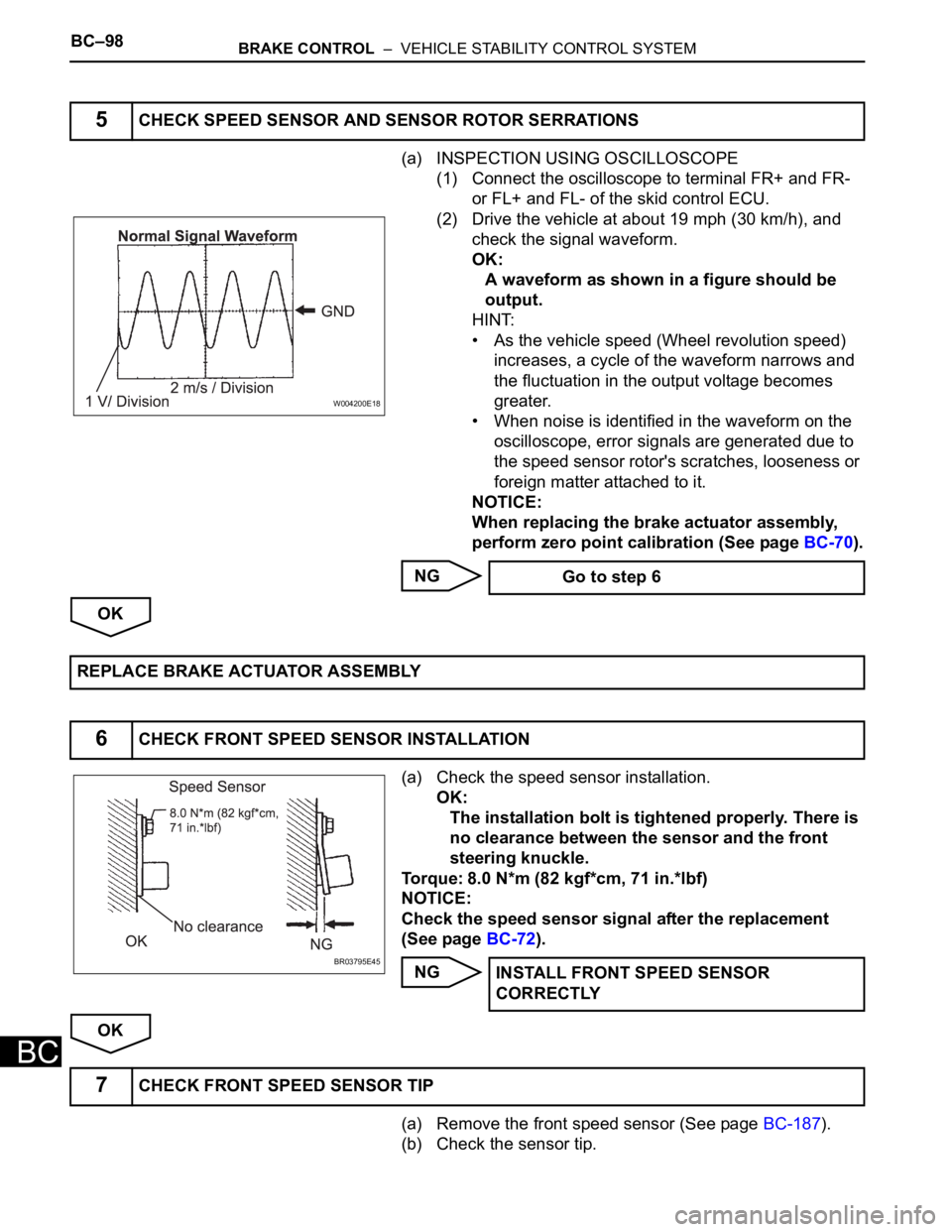

(a) INSPECTION USING OSCILLOSCOPE

(1) Connect the oscilloscope to terminal FR+ and FR-

or FL+ and FL- of the skid control ECU.

(2) Drive the vehicle at about 19 mph (30 km/h), and

check the signal waveform.

OK:

A waveform as shown in a figure should be

output.

HINT:

• As the vehicle speed (Wheel revolution speed)

increases, a cycle of the waveform narrows and

the fluctuation in the output voltage becomes

greater.

• When noise is identified in the waveform on the

oscilloscope, error signals are generated due to

the speed sensor rotor's scratches, looseness or

foreign matter attached to it.

NOTICE:

When replacing the brake actuator assembly,

perform zero point calibration (See page BC-70).

NG

OK

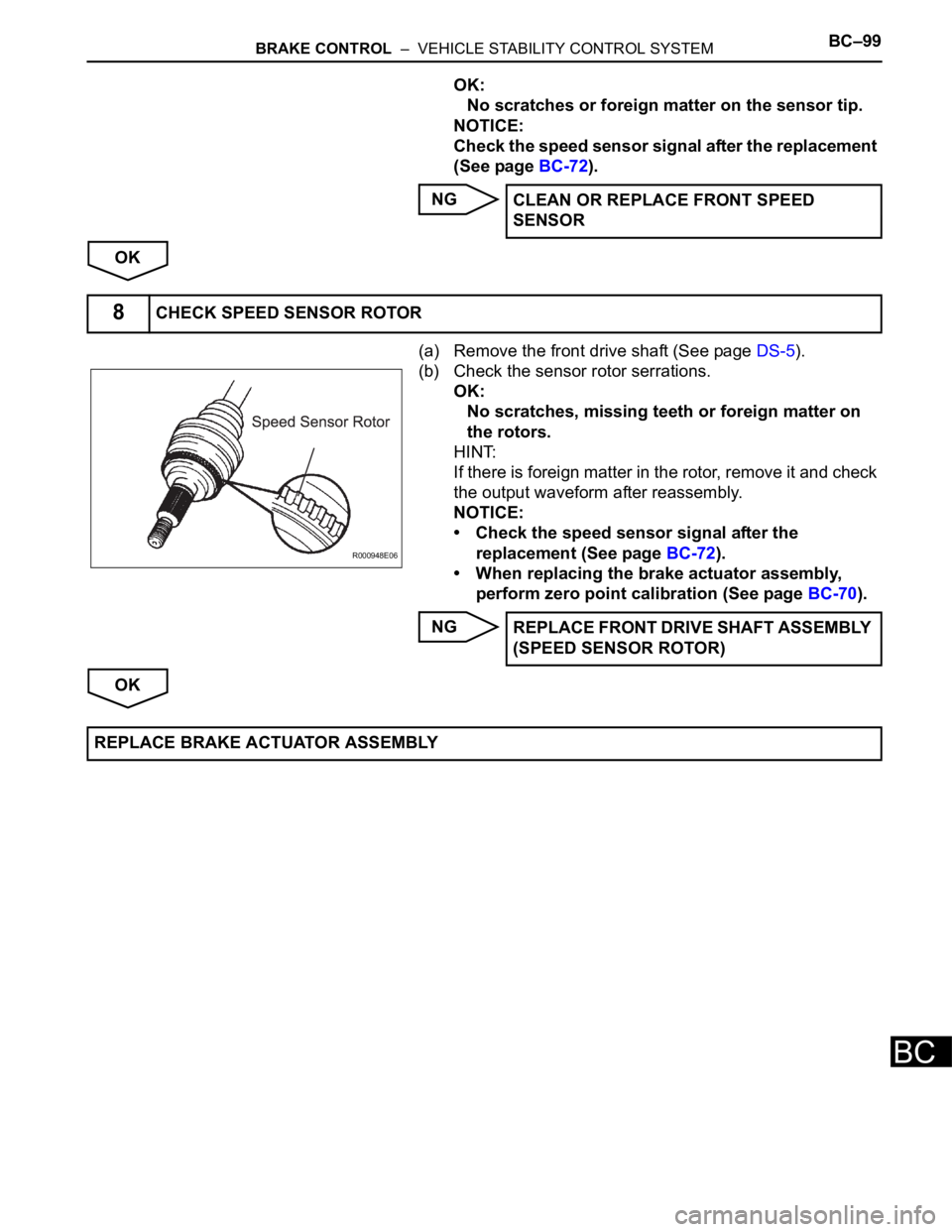

(a) Check the speed sensor installation.

OK:

The installation bolt is tightened properly. There is

no clearance between the sensor and the front

steering knuckle.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

NOTICE:

Check the speed sensor signal after the replacement

(See page BC-72).

NG

OK

(a) Remove the front speed sensor (See page BC-187).

(b) Check the sensor tip.

5CHECK SPEED SENSOR AND SENSOR ROTOR SERRATIONS

W004200E18

Go to step 6

REPLACE BRAKE ACTUATOR ASSEMBLY

6CHECK FRONT SPEED SENSOR INSTALLATION

BR03795E45INSTALL FRONT SPEED SENSOR

CORRECTLY

7CHECK FRONT SPEED SENSOR TIP

Page 2461 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–99

BC

OK:

No scratches or foreign matter on the sensor tip.

NOTICE:

Check the speed sensor signal after the replacement

(See page BC-72).

NG

OK

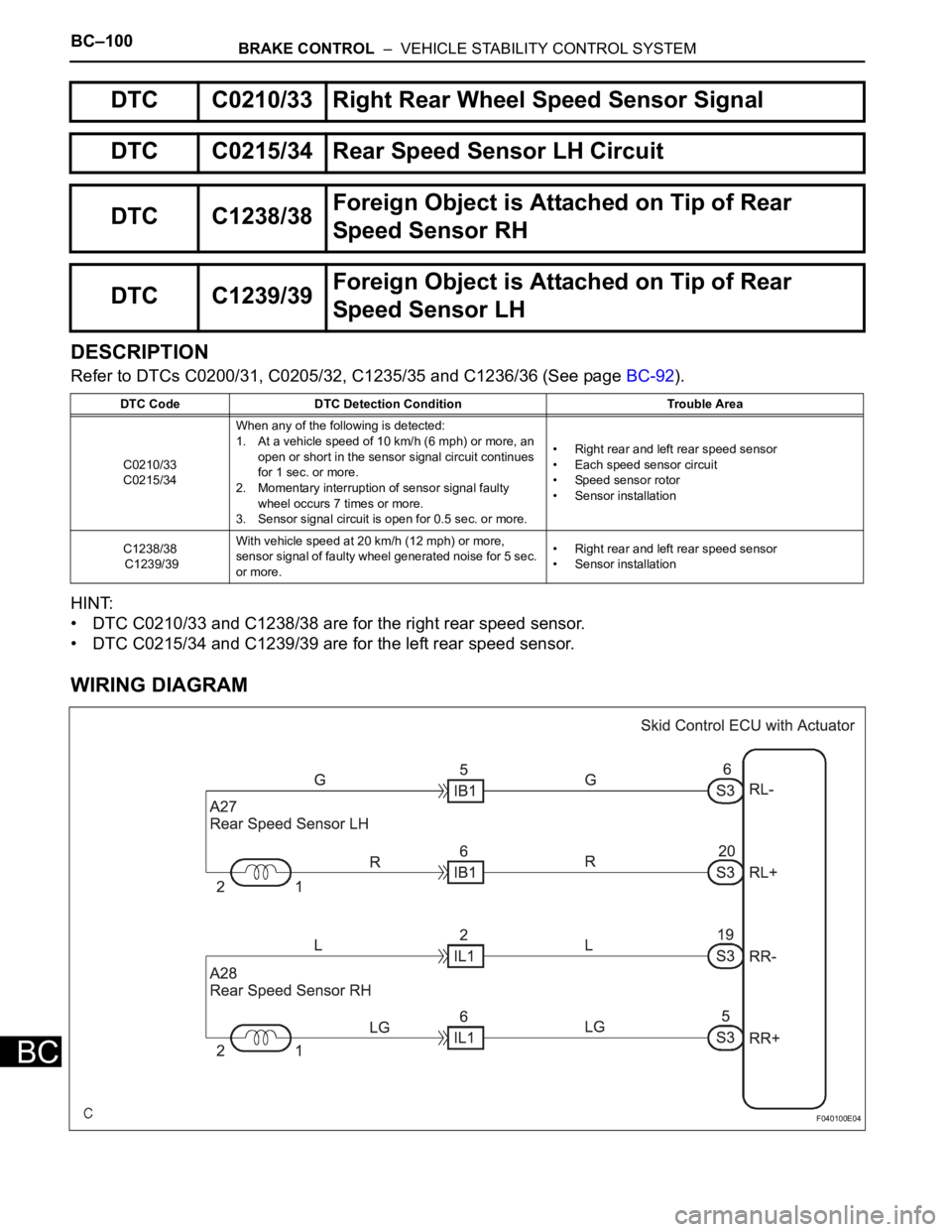

(a) Remove the front drive shaft (See page DS-5).

(b) Check the sensor rotor serrations.

OK:

No scratches, missing teeth or foreign matter on

the rotors.

HINT:

If there is foreign matter in the rotor, remove it and check

the output waveform after reassembly.

NOTICE:

• Check the speed sensor signal after the

replacement (See page BC-72).

• When replacing the brake actuator assembly,

perform zero point calibration (See page BC-70).

NG

OKCLEAN OR REPLACE FRONT SPEED

SENSOR

8CHECK SPEED SENSOR ROTOR

R000948E06

REPLACE FRONT DRIVE SHAFT ASSEMBLY

(SPEED SENSOR ROTOR)

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2462 of 3000

BC–100BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

DESCRIPTION

Refer to DTCs C0200/31, C0205/32, C1235/35 and C1236/36 (See page BC-92).

HINT:

• DTC C0210/33 and C1238/38 are for the right rear speed sensor.

• DTC C0215/34 and C1239/39 are for the left rear speed sensor.

WIRING DIAGRAM

DTC C0210/33 Right Rear Wheel Speed Sensor Signal

DTC C0215/34 Rear Speed Sensor LH Circuit

DTC C1238/38Foreign Object is Attached on Tip of Rear

Speed Sensor RH

DTC C1239/39Foreign Object is Attached on Tip of Rear

Speed Sensor LH

DTC Code DTC Detection Condition Trouble Area

C0210/33

C0215/34When any of the following is detected:

1. At a vehicle speed of 10 km/h (6 mph) or more, an

open or short in the sensor signal circuit continues

for 1 sec. or more.

2. Momentary interruption of sensor signal faulty

wheel occurs 7 times or more.

3. Sensor signal circuit is open for 0.5 sec. or more.• Right rear and left rear speed sensor

• Each speed sensor circuit

• Speed sensor rotor

• Sensor installation

C1238/38

C1239/39With vehicle speed at 20 km/h (12 mph) or more,

sensor signal of faulty wheel generated noise for 5 sec.

or more. • Right rear and left rear speed sensor

• Sensor installation

F040100E04

Page 2463 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–101

BC

INSPECTION PROCEDURE

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Select the DATA LIST mode on the intelligent tester.

ABS / VSC:

(d) Check that there is no difference between the speed

value output from the speed sensor displayed by the

intelligent tester and the speed value displayed on the

speedometer when driving the vehicle.

OK:

There is almost no difference in the displayed

speed value.

HINT:

There is tolerance of +- 10 % in the speedometer

indication.

NG

OK

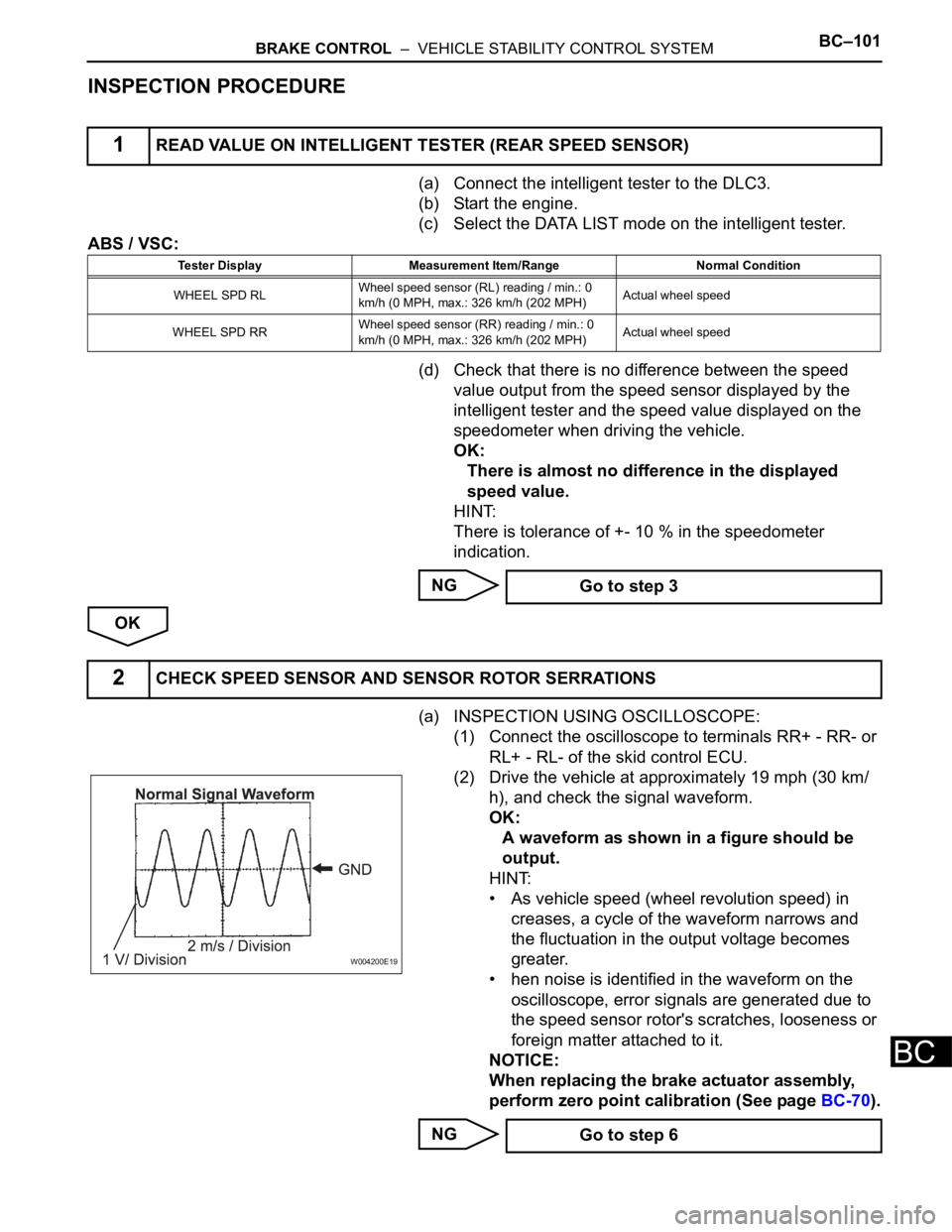

(a) INSPECTION USING OSCILLOSCOPE:

(1) Connect the oscilloscope to terminals RR+ - RR- or

RL+ - RL- of the skid control ECU.

(2) Drive the vehicle at approximately 19 mph (30 km/

h), and check the signal waveform.

OK:

A waveform as shown in a figure should be

output.

HINT:

• As vehicle speed (wheel revolution speed) in

creases, a cycle of the waveform narrows and

the fluctuation in the output voltage becomes

greater.

• hen noise is identified in the waveform on the

oscilloscope, error signals are generated due to

the speed sensor rotor's scratches, looseness or

foreign matter attached to it.

NOTICE:

When replacing the brake actuator assembly,

perform zero point calibration (See page BC-70).

NG

1READ VALUE ON INTELLIGENT TESTER (REAR SPEED SENSOR)

Tester Display Measurement Item/Range Normal Condition

WHEEL SPD RLWheel speed sensor (RL) reading / min.: 0

km/h (0 MPH, max.: 326 km/h (202 MPH)Actual wheel speed

WHEEL SPD RRWheel speed sensor (RR) reading / min.: 0

km/h (0 MPH, max.: 326 km/h (202 MPH)Actual wheel speed

Go to step 3

2CHECK SPEED SENSOR AND SENSOR ROTOR SERRATIONS

W004200E19

Go to step 6

Page 2464 of 3000

BC–102BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

OK

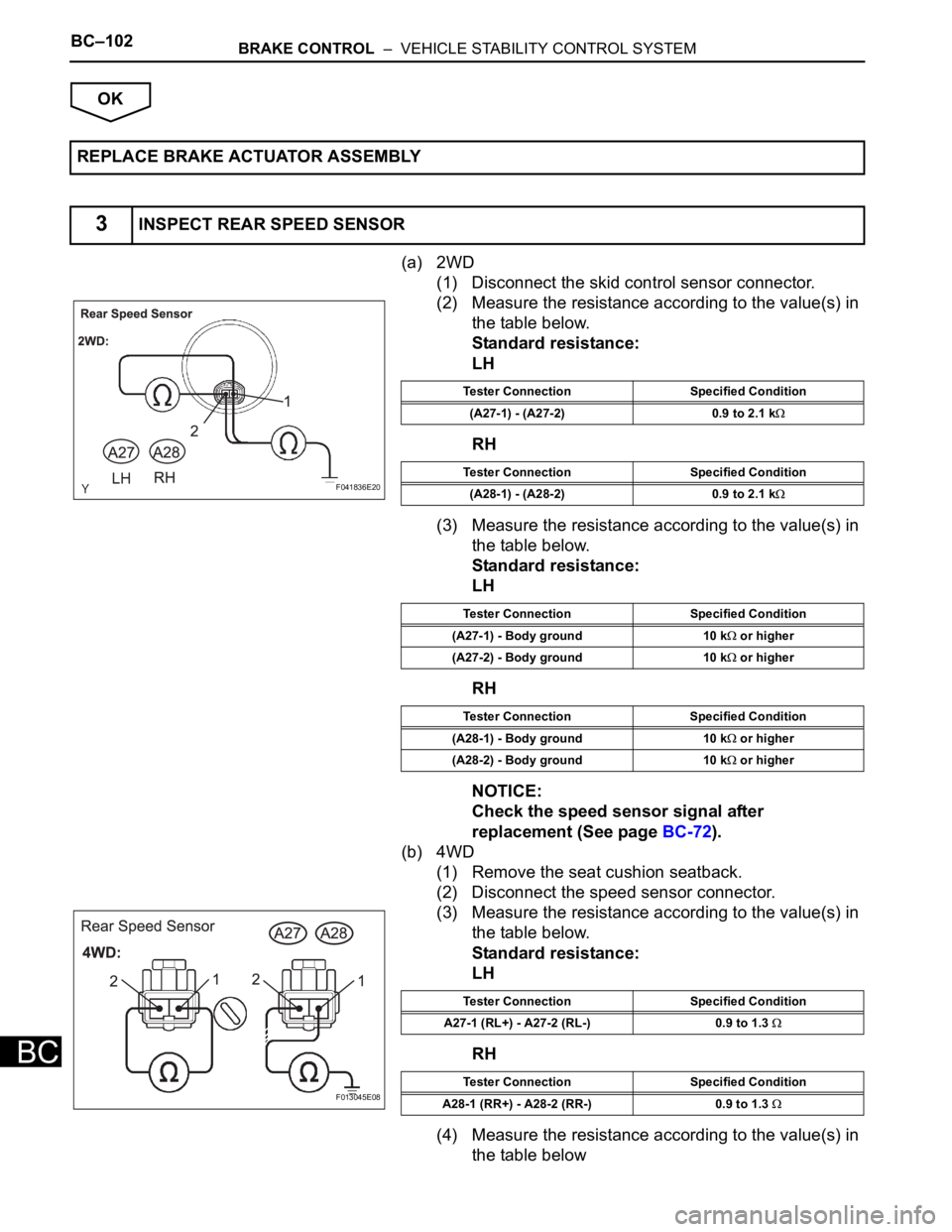

(a) 2WD

(1) Disconnect the skid control sensor connector.

(2) Measure the resistance according to the value(s) in

the table below.

Standard resistance:

LH

RH

(3) Measure the resistance according to the value(s) in

the table below.

Standard resistance:

LH

RH

NOTICE:

Check the speed sensor signal after

replacement (See page BC-72).

(b) 4WD

(1) Remove the seat cushion seatback.

(2) Disconnect the speed sensor connector.

(3) Measure the resistance according to the value(s) in

the table below.

Standard resistance:

LH

RH

(4) Measure the resistance according to the value(s) in

the table below REPLACE BRAKE ACTUATOR ASSEMBLY

3INSPECT REAR SPEED SENSOR

F041836E20

Tester Connection Specified Condition

(A27-1) - (A27-2) 0.9 to 2.1 k

Tester Connection Specified Condition

(A28-1) - (A28-2) 0.9 to 2.1 k

Tester Connection Specified Condition

(A27-1) - Body ground 10 k

or higher

(A27-2) - Body ground 10 k

or higher

Tester Connection Specified Condition

(A28-1) - Body ground 10 k

or higher

(A28-2) - Body ground 10 k

or higher

F013045E08

Tester Connection Specified Condition

A27-1 (RL+) - A27-2 (RL-) 0.9 to 1.3

Tester Connection Specified Condition

A28-1 (RR+) - A28-2 (RR-) 0.9 to 1.3

Page 2465 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–103

BC

Standard resistance:

LH

RH

NOTICE:

Check the speed sensor signal after the

replacement. (See page BC-72)

NG

OK

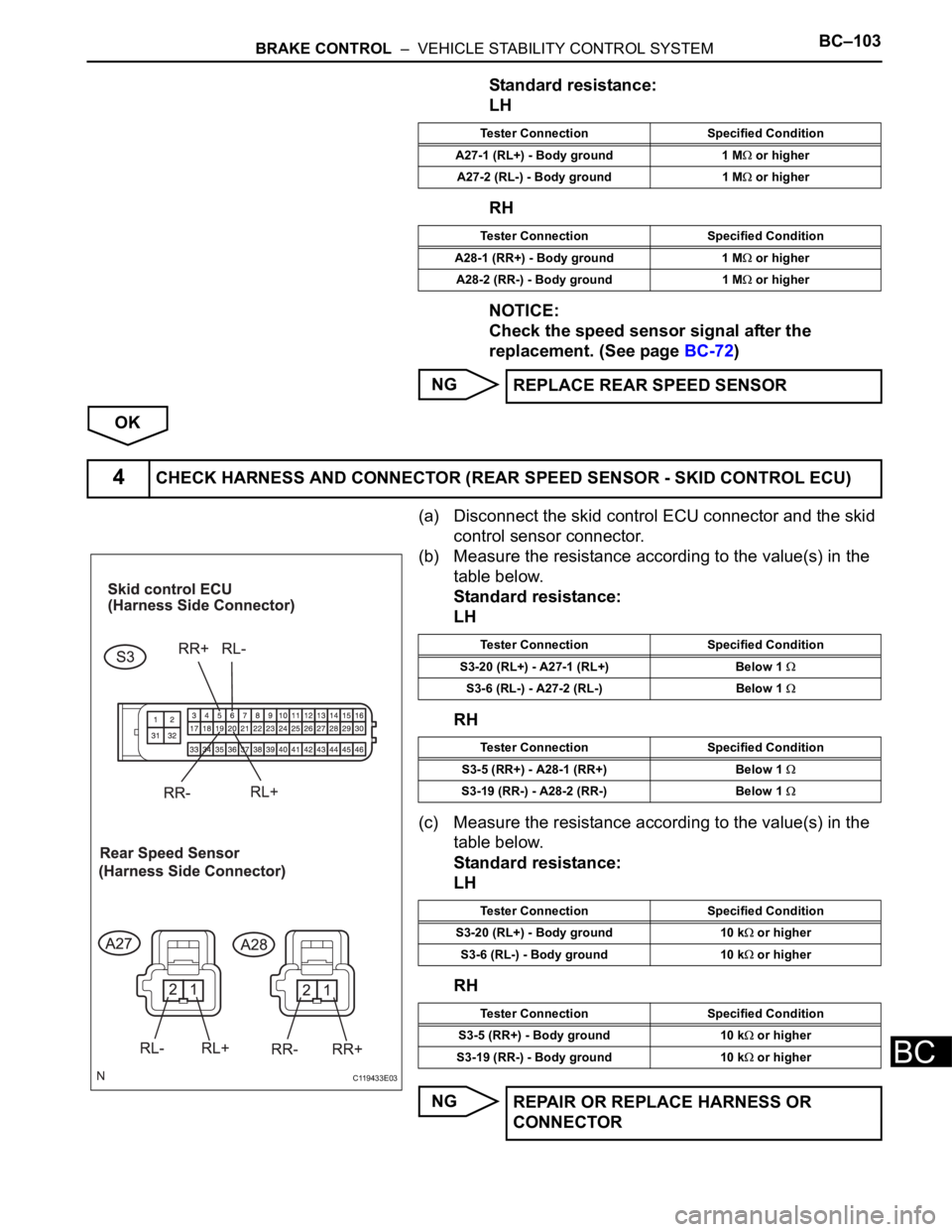

(a) Disconnect the skid control ECU connector and the skid

control sensor connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

LH

RH

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

LH

RH

NG

Tester Connection Specified Condition

A27-1 (RL+) - Body ground 1 M

or higher

A27-2 (RL-) - Body ground 1 M

or higher

Tester Connection Specified Condition

A28-1 (RR+) - Body ground 1 M

or higher

A28-2 (RR-) - Body ground 1 M

or higher

REPLACE REAR SPEED SENSOR

4CHECK HARNESS AND CONNECTOR (REAR SPEED SENSOR - SKID CONTROL ECU)

C119433E03

Tester Connection Specified Condition

S3-20 (RL+) - A27-1 (RL+) Below 1

S3-6 (RL-) - A27-2 (RL-) Below 1

Tester Connection Specified Condition

S3-5 (RR+) - A28-1 (RR+) Below 1

S3-19 (RR-) - A28-2 (RR-) Below 1

Tester Connection Specified Condition

S3-20 (RL+) - Body ground 10 k

or higher

S3-6 (RL-) - Body ground 10 k

or higher

Tester Connection Specified Condition

S3-5 (RR+) - Body ground 10 k

or higher

S3-19 (RR-) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

Page 2466 of 3000

BC–104BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

OK

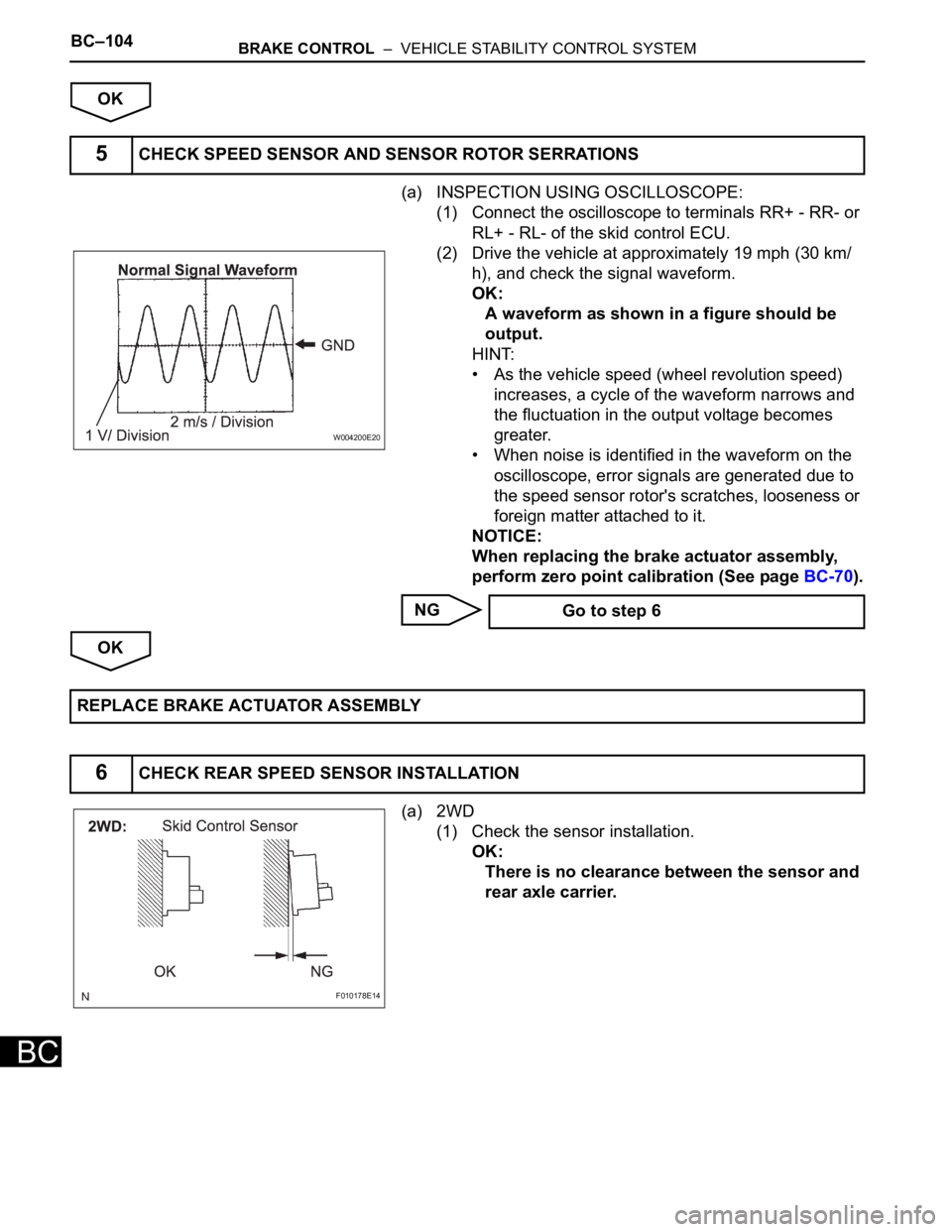

(a) INSPECTION USING OSCILLOSCOPE:

(1) Connect the oscilloscope to terminals RR+ - RR- or

RL+ - RL- of the skid control ECU.

(2) Drive the vehicle at approximately 19 mph (30 km/

h), and check the signal waveform.

OK:

A waveform as shown in a figure should be

output.

HINT:

• As the vehicle speed (wheel revolution speed)

increases, a cycle of the waveform narrows and

the fluctuation in the output voltage becomes

greater.

• When noise is identified in the waveform on the

oscilloscope, error signals are generated due to

the speed sensor rotor's scratches, looseness or

foreign matter attached to it.

NOTICE:

When replacing the brake actuator assembly,

perform zero point calibration (See page BC-70).

NG

OK

(a) 2WD

(1) Check the sensor installation.

OK:

There is no clearance between the sensor and

rear axle carrier.

5CHECK SPEED SENSOR AND SENSOR ROTOR SERRATIONS

W004200E20

Go to step 6

REPLACE BRAKE ACTUATOR ASSEMBLY

6CHECK REAR SPEED SENSOR INSTALLATION

F010178E14

Page 2467 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–105

BC

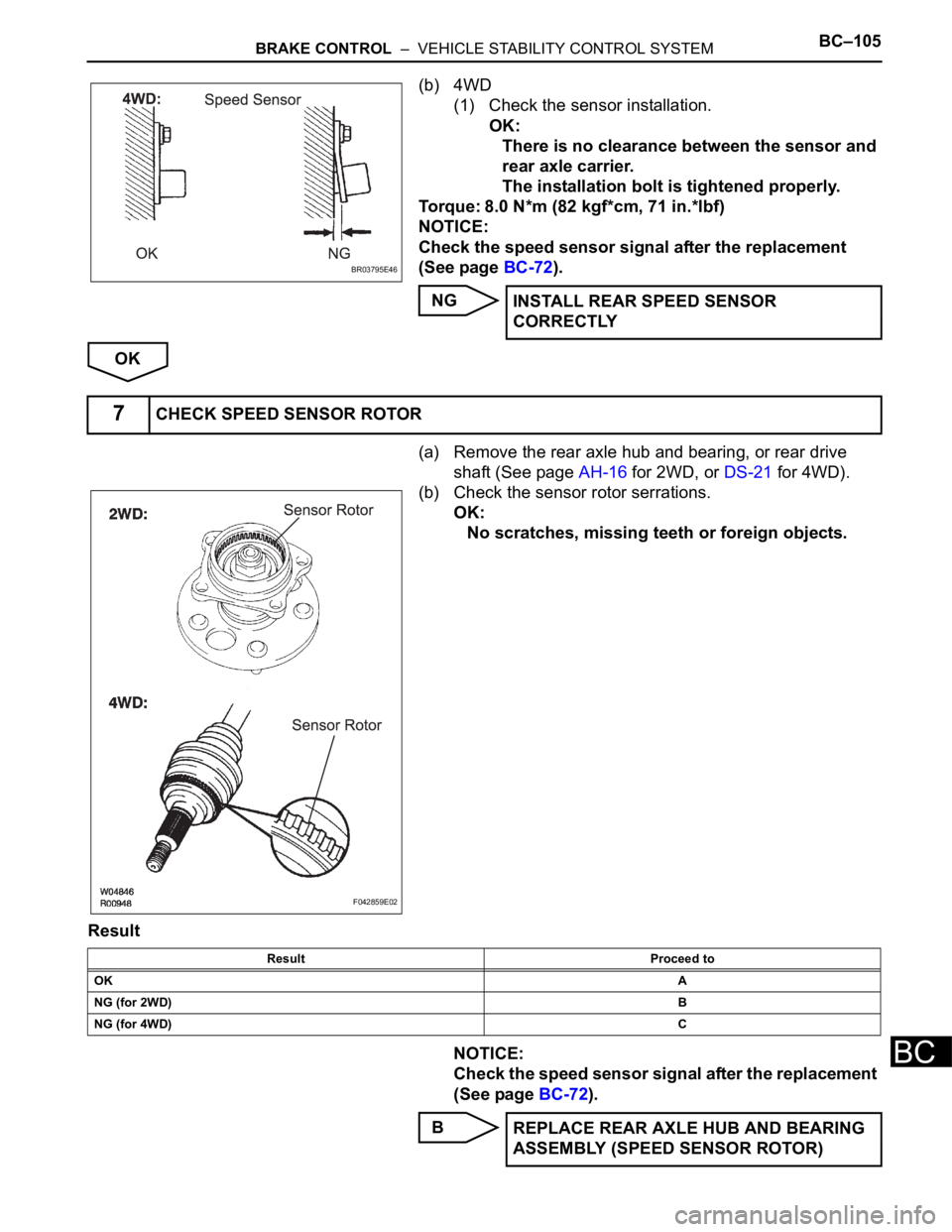

(b) 4WD

(1) Check the sensor installation.

OK:

There is no clearance between the sensor and

rear axle carrier.

The installation bolt is tightened properly.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

NOTICE:

Check the speed sensor signal after the replacement

(See page BC-72).

NG

OK

(a) Remove the rear axle hub and bearing, or rear drive

shaft (See page AH-16 for 2WD, or DS-21 for 4WD).

(b) Check the sensor rotor serrations.

OK:

No scratches, missing teeth or foreign objects.

Result

NOTICE:

Check the speed sensor signal after the replacement

(See page BC-72).

B

BR03795E46

INSTALL REAR SPEED SENSOR

CORRECTLY

7CHECK SPEED SENSOR ROTOR

F042859E02

Result Proceed to

OKA

NG (for 2WD)B

NG (for 4WD)C

REPLACE REAR AXLE HUB AND BEARING

ASSEMBLY (SPEED SENSOR ROTOR)

Page 2468 of 3000

BC–106BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

C

A

(a) Remove the rear speed sensor (See page BC-190 for

2WD or BC-194 for 4WD).

(b) Check the sensor tip.

OK:

No scratches or foreign matter on the sensor tip.

NOTICE:

• Check the speed sensor signal after the

replacement (See page BC-72).

• When replacing the brake actuator assembly,

perform zero point calibration (See page BC-70).

NG

OKREPLACE REAR DRIVE SHAFT ASSEMBLY

(SPEED SENSOR ROTOR)

8CHECK REAR SPEED SENSOR TIP

CLEAN OR REPLACE REAR SPEED

SENSOR

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2481 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–119

BC

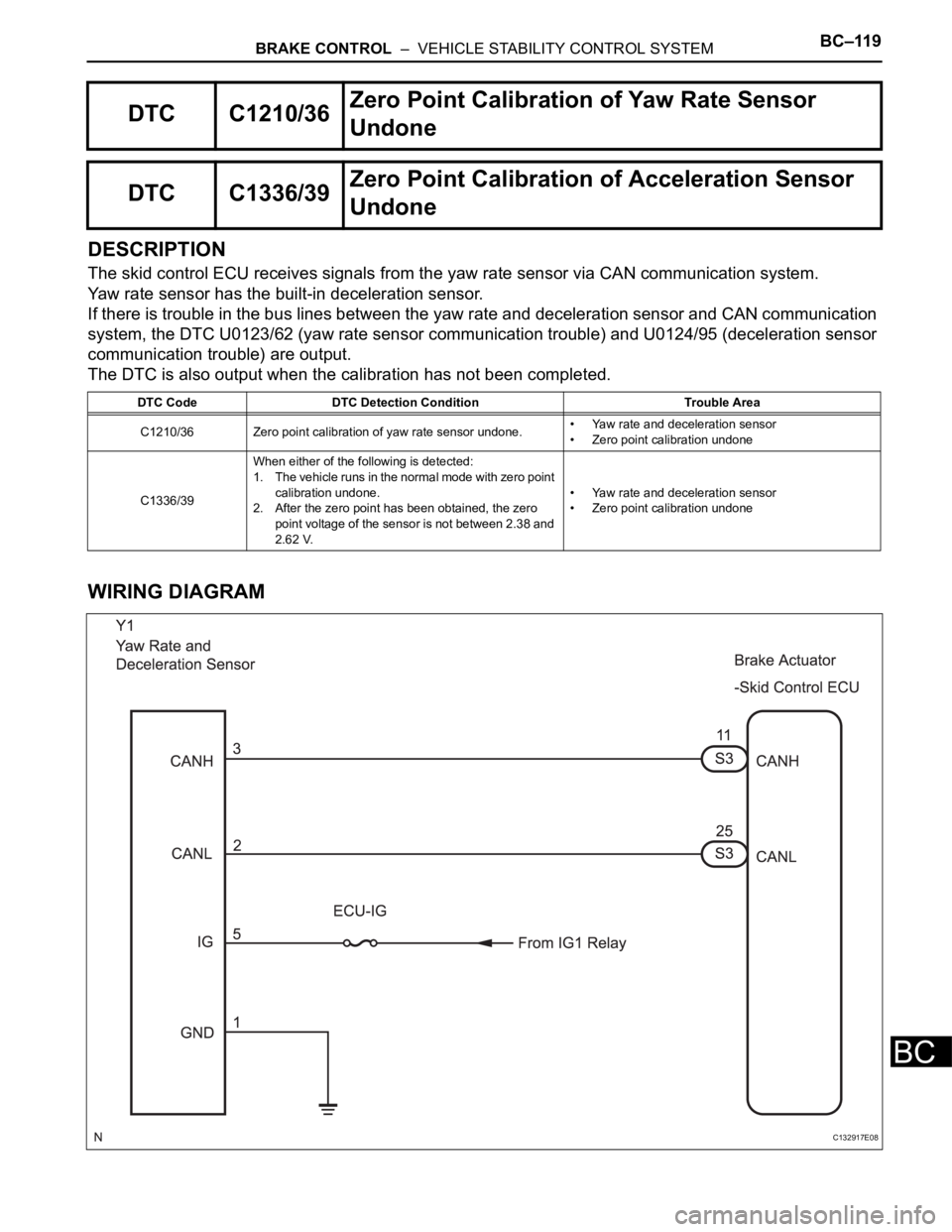

DESCRIPTION

The skid control ECU receives signals from the yaw rate sensor via CAN communication system.

Yaw rate sensor has the built-in deceleration sensor.

If there is trouble in the bus lines between the yaw rate and deceleration sensor and CAN communication

system, the DTC U0123/62 (yaw rate sensor communication trouble) and U0124/95 (deceleration sensor

communication trouble) are output.

The DTC is also output when the calibration has not been completed.

WIRING DIAGRAM

DTC C1210/36Zero Point Calibration of Yaw Rate Sensor

Undone

DTC C1336/39Zero Point Calibration of Acceleration Sensor

Undone

DTC Code DTC Detection Condition Trouble Area

C1210/36 Zero point calibration of yaw rate sensor undone.• Yaw rate and deceleration sensor

• Zero point calibration undone

C1336/39When either of the following is detected:

1. The vehicle runs in the normal mode with zero point

calibration undone.

2. After the zero point has been obtained, the zero

point voltage of the sensor is not between 2.38 and

2.62 V.• Yaw rate and deceleration sensor

• Zero point calibration undone

C132917E08