brake sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2482 of 3000

BC–120BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

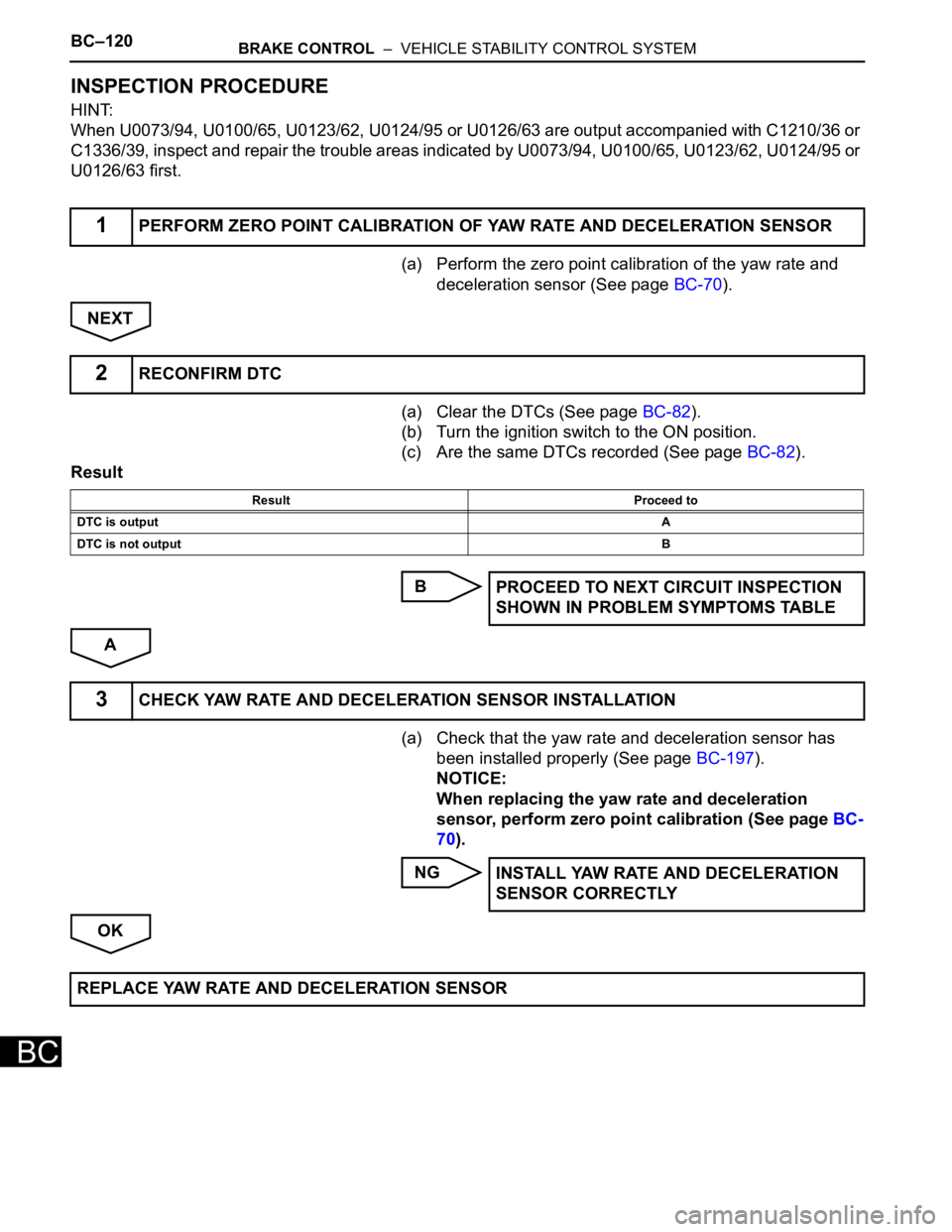

INSPECTION PROCEDURE

HINT:

When U0073/94, U0100/65, U0123/62, U0124/95 or U0126/63 are output accompanied with C1210/36 or

C1336/39, inspect and repair the trouble areas indicated by U0073/94, U0100/65, U0123/62, U0124/95 or

U0126/63 first.

(a) Perform the zero point calibration of the yaw rate and

deceleration sensor (See page BC-70).

NEXT

(a) Clear the DTCs (See page BC-82).

(b) Turn the ignition switch to the ON position.

(c) Are the same DTCs recorded (See page BC-82).

Result

B

A

(a) Check that the yaw rate and deceleration sensor has

been installed properly (See page BC-197).

NOTICE:

When replacing the yaw rate and deceleration

sensor, perform zero point calibration (See page BC-

70).

NG

OK

1PERFORM ZERO POINT CALIBRATION OF YAW RATE AND DECELERATION SENSOR

2RECONFIRM DTC

Result Proceed to

DTC is outputA

DTC is not outputB

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

3CHECK YAW RATE AND DECELERATION SENSOR INSTALLATION

INSTALL YAW RATE AND DECELERATION

SENSOR CORRECTLY

REPLACE YAW RATE AND DECELERATION SENSOR

Page 2484 of 3000

BC–122BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

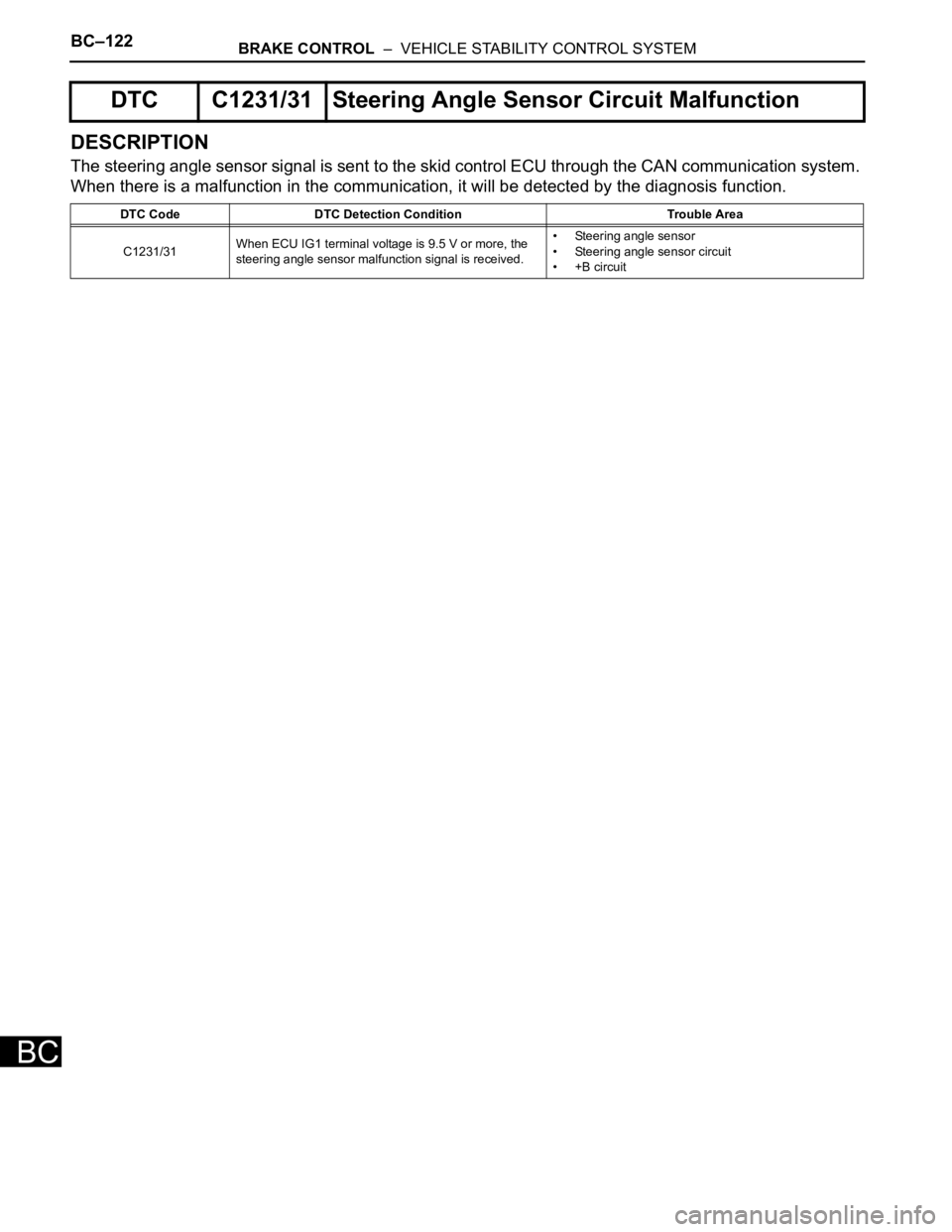

DESCRIPTION

The steering angle sensor signal is sent to the skid control ECU through the CAN communication system.

When there is a malfunction in the communication, it will be detected by the diagnosis function.

DTC C1231/31 Steering Angle Sensor Circuit Malfunction

DTC Code DTC Detection Condition Trouble Area

C1231/31When ECU IG1 terminal voltage is 9.5 V or more, the

steering angle sensor malfunction signal is received.• Steering angle sensor

• Steering angle sensor circuit

•+B circuit

Page 2486 of 3000

BC–124BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

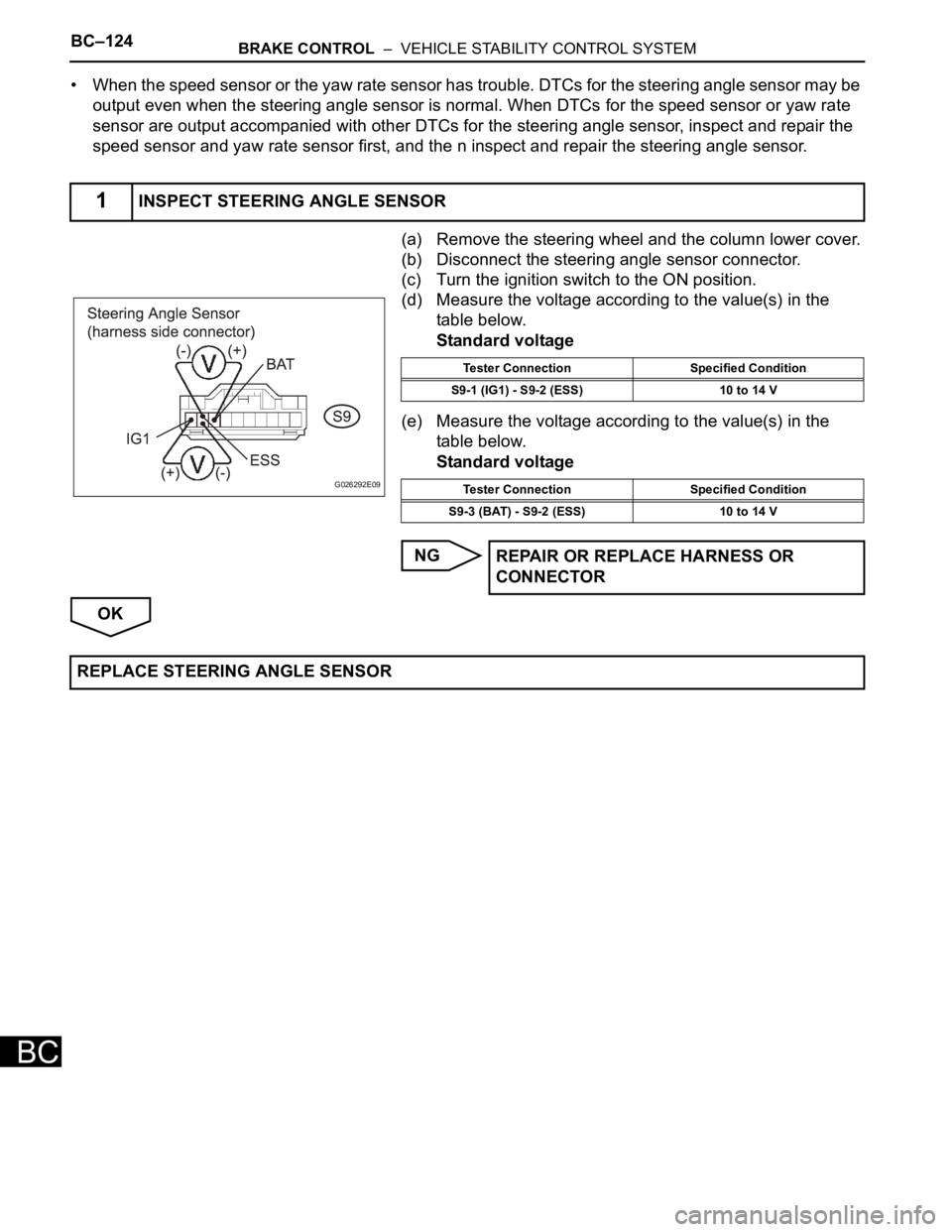

• When the speed sensor or the yaw rate sensor has trouble. DTCs for the steering angle sensor may be

output even when the steering angle sensor is normal. When DTCs for the speed sensor or yaw rate

sensor are output accompanied with other DTCs for the steering angle sensor, inspect and repair the

speed sensor and yaw rate sensor first, and the n inspect and repair the steering angle sensor.

(a) Remove the steering wheel and the column lower cover.

(b) Disconnect the steering angle sensor connector.

(c) Turn the ignition switch to the ON position.

(d) Measure the voltage according to the value(s) in the

table below.

Standard voltage

(e) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

1INSPECT STEERING ANGLE SENSOR

G026292E09

Tester Connection Specified Condition

S9-1 (IG1) - S9-2 (ESS) 10 to 14 V

Tester Connection Specified Condition

S9-3 (BAT) - S9-2 (ESS) 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR

REPLACE STEERING ANGLE SENSOR

Page 2487 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–125

BC

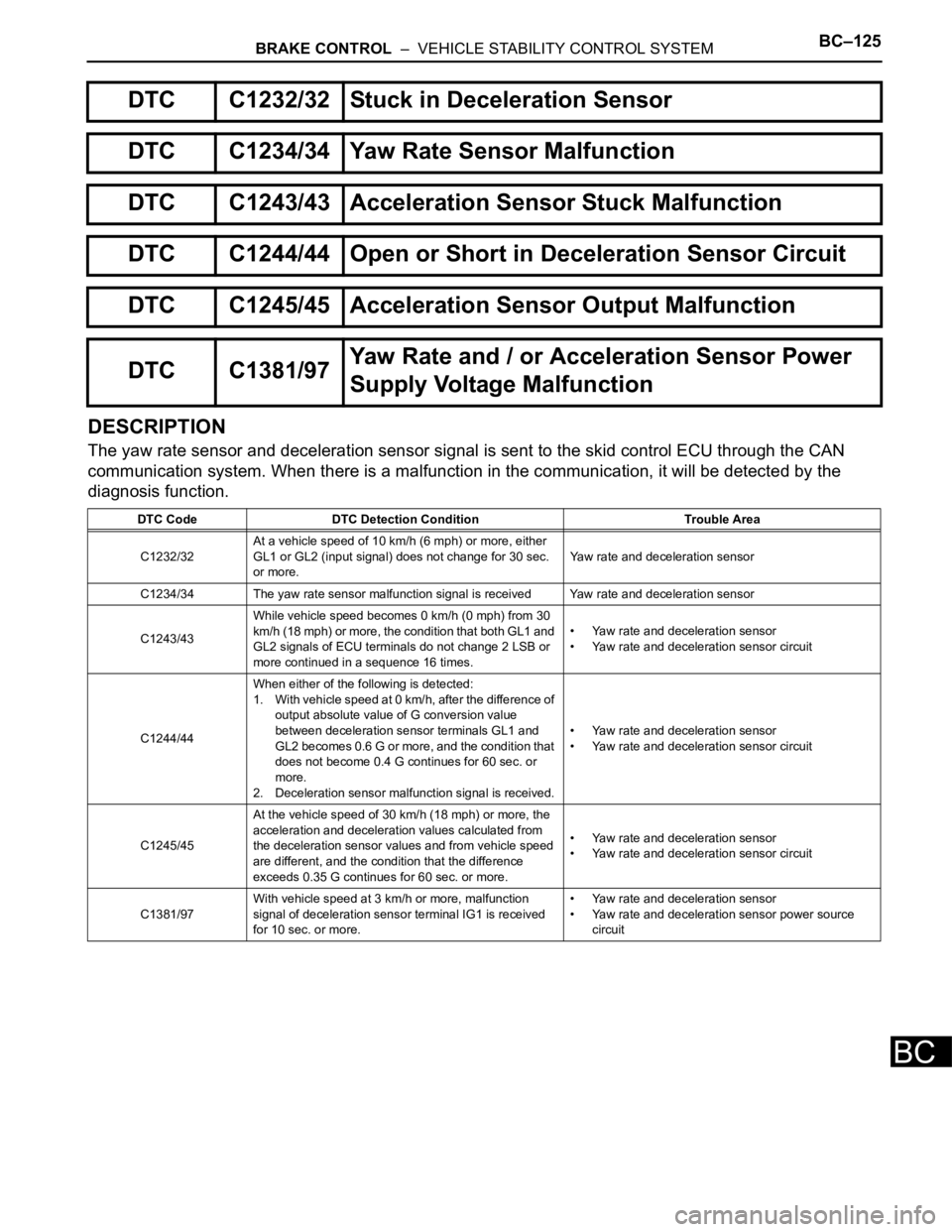

DESCRIPTION

The yaw rate sensor and deceleration sensor signal is sent to the skid control ECU through the CAN

communication system. When there is a malfunction in the communication, it will be detected by the

diagnosis function.

DTC C1232/32 Stuck in Deceleration Sensor

DTC C1234/34 Yaw Rate Sensor Malfunction

DTC C1243/43 Acceleration Sensor Stuck Malfunction

DTC C1244/44 Open or Short in Deceleration Sensor Circuit

DTC C1245/45 Acceleration Sensor Output Malfunction

DTC C1381/97Yaw Rate and / or Acceleration Sensor Power

Supply Voltage Malfunction

DTC Code DTC Detection Condition Trouble Area

C1232/32At a vehicle speed of 10 km/h (6 mph) or more, either

GL1 or GL2 (input signal) does not change for 30 sec.

or more.Yaw rate and deceleration sensor

C1234/34 The yaw rate sensor malfunction signal is received Yaw rate and deceleration sensor

C1243/43While vehicle speed becomes 0 km/h (0 mph) from 30

km/h (18 mph) or more, the condition that both GL1 and

GL2 signals of ECU terminals do not change 2 LSB or

more continued in a sequence 16 times.• Yaw rate and deceleration sensor

• Yaw rate and deceleration sensor circuit

C1244/44When either of the following is detected:

1. With vehicle speed at 0 km/h, after the difference of

output absolute value of G conversion value

between deceleration sensor terminals GL1 and

GL2 becomes 0.6 G or more, and the condition that

does not become 0.4 G continues for 60 sec. or

more.

2. Deceleration sensor malfunction signal is received.• Yaw rate and deceleration sensor

• Yaw rate and deceleration sensor circuit

C1245/45At the vehicle speed of 30 km/h (18 mph) or more, the

acceleration and deceleration values calculated from

the deceleration sensor values and from vehicle speed

are different, and the condition that the difference

exceeds 0.35 G continues for 60 sec. or more.• Yaw rate and deceleration sensor

• Yaw rate and deceleration sensor circuit

C1381/97With vehicle speed at 3 km/h or more, malfunction

signal of deceleration sensor terminal IG1 is received

for 10 sec. or more.• Yaw rate and deceleration sensor

• Yaw rate and deceleration sensor power source

circuit

Page 2488 of 3000

BC–126BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

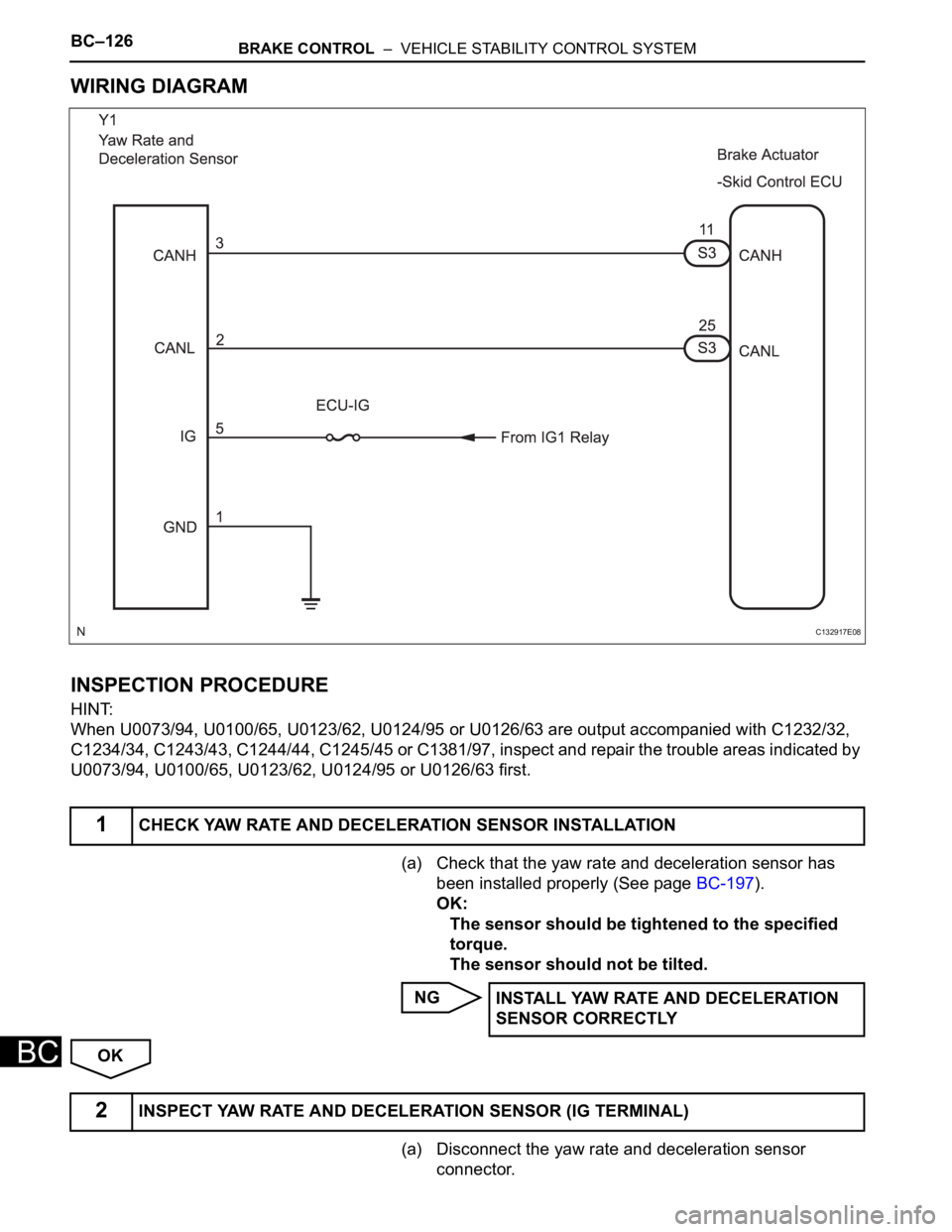

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

When U0073/94, U0100/65, U0123/62, U0124/95 or U0126/63 are output accompanied with C1232/32,

C1234/34, C1243/43, C1244/44, C1245/45 or C1381/97, inspect and repair the trouble areas indicated by

U0073/94, U0100/65, U0123/62, U0124/95 or U0126/63 first.

(a) Check that the yaw rate and deceleration sensor has

been installed properly (See page BC-197).

OK:

The sensor should be tightened to the specified

torque.

The sensor should not be tilted.

NG

OK

(a) Disconnect the yaw rate and deceleration sensor

connector.

1CHECK YAW RATE AND DECELERATION SENSOR INSTALLATION

C132917E08

INSTALL YAW RATE AND DECELERATION

SENSOR CORRECTLY

2INSPECT YAW RATE AND DECELERATION SENSOR (IG TERMINAL)

Page 2489 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–127

BC

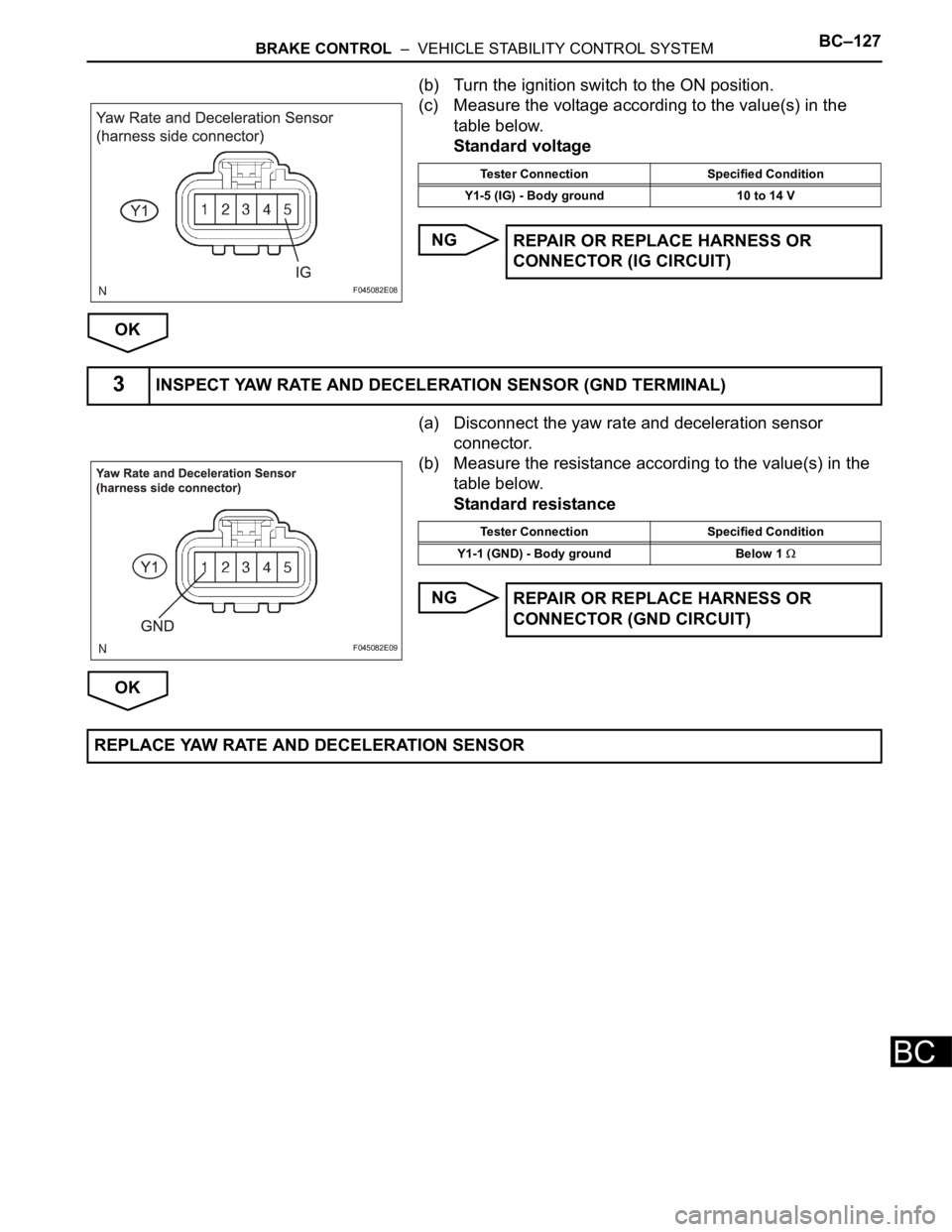

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

(a) Disconnect the yaw rate and deceleration sensor

connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

F045082E08

Tester Connection Specified Condition

Y1-5 (IG) - Body ground 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR (IG CIRCUIT)

3INSPECT YAW RATE AND DECELERATION SENSOR (GND TERMINAL)

F045082E09

Tester Connection Specified Condition

Y1-1 (GND) - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (GND CIRCUIT)

REPLACE YAW RATE AND DECELERATION SENSOR

Page 2493 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–131

BC

DESCRIPTION

Master cylinder pressure sensor is connected to the skid control ECU in the actuator.

INSPECTION PROCEDURE

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Select the DATA LIST mode on the intelligent tester.

ABS / VSC:

(d) Check that the brake fluid pressure value of the master

cylinder pressure sensor indicated on the intelligent

tester, changes when the brake pedal is depressed.

OK:

Brake fluid pressure value should change.

NOTICE:

When replacing the brake actuator assembly,

perform zero point calibration (See page BC-70).

NG

OK

DTC C1246/46 Master Cylinder Pressure Sensor Malfunction

DTC Code DTC Detection Condition Trouble Area

C1246/46When any of the following is detected:

1. When the vehicle speed is 7 km/h (4 mph) or more

and PMC terminal voltage of skid control ECU

exceeds 0.86 V, the condition that the voltage does

not change by 0.005 V or more continues for 30

sec.

2. Noise in terminal PMC of skid control ECU occurs 7

times or more within 5 sec.

3. When the stop light switch is off, the condition that

PMC terminal voltage of skid control ECU is 0.86 V

or more, or less than 0.3 V continues for 5 sec. or

more.

4. When IG1 terminal voltage is between 9.5 and 17.2

V, the condition that the VCM terminal voltage of

skid control ECU is out of the range from 4.4 to 5.6

V continues for 1.2 sec. or more.

5. When VCM terminal voltage of skid control ECU is

between 4.4 and 5.6 V, the condition that the PMC

terminal voltage of skid control ECU is out of the

range from 0.14 to 4.85 V continues for 1.2 sec. or

more.• Master cylinder pressure sensor

• Master cylinder pressure sensor circuit

1READ VALUE ON INTELLIGENT TESTER (MASTER CYLINDER PRESSURE SENSOR)

Tester Display Measurement Item/Range Normal Condition

MAS CYL PRS 1Master cylinder pressure sensor 1 reading /

min.: 0 V, max.: 5 VWhen brake pedal is released : 0.3 to 0.9 V

Go to step 2

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2502 of 3000

BC–140BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

DESCRIPTION

The skid control ECU acquires steering angle sensor zero point every time the ignition switch is turned to

the ON position and the vehicle is driven at 35 km/h (22 mph) or more for approximately 5 seconds. The

ECU also stores the previous zero point.

If front wheel alignment or steering wheel position is adjusted without disconnecting the negative battery

terminal, or if yaw rate and deceleration sensor zero point is not acquired after the adjustments have been

completed, the skid control ECU detects the difference between the previous zero point and newly

acquired zero point and outputs this DTC to indicate a poor adjustment.

Warning of the steering angle sensor zero point malfunction will be cancelled by turning the ignition switch

off.

INSPECTION PROCEDURE

NOTICE:

When replacing the brake actuator assembly, perform zero point calibration (See page BC-70).

(a) Perform zero point calibration of the yaw rate and

deceleration sensor (See page BC-70).

HINT:

• When the stored zero point of the yaw rate and

deceleration sensor is erased, steering angle sensor

zero point will also be erased.

• If the zero point and output value of the yaw rate and

deceleration sensor and the output value of the speed

sensors are not normal, steering angle sensor zero

point cannot be acquired normally even if the vehicle

is driven straight ahead at 35 km/h (22 mph) or more.

NEXT

(a) Drive the vehicle straight ahead at 35 km/h (22 mph) or

more for at least 5 seconds.

(b) Check that the centered position of the steering wheel is

correctly set while driving straight ahead.

HINT:

If front wheel alignment and steering position are

adjusted as a result of abnormal centered position of the

steering wheel, acquire yaw rate and deceleration

sensor zero point again after the adjustments are

completed.

DTC C1290/66 Steering Angle Sensor Zero Point Malfunction

DTC Code DTC Detection Condition Trouble Area

C1290/66The steering angle sensor zero point calibration position

vastly differs from the recorded value• Yaw rate and deceleration sensor zero point

calibration incomplete

• Poor adjustment of the centered position of the

steering wheel

• Poor adjustment of front wheel alignment

1PERFORM ZERO POINT CALIBRATION OF YAW RATE AND DECELERATION SENSOR

2CHECK STEERING ANGLE SENSOR ZERO POINT CALIBRATION

Page 2504 of 3000

BC–142BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

INSPECTION PROCEDURE

Refer to CAN communication system (See page CA-7).

DTC U0073/94 Control Module Communication Bus OFF

DTC U0100/65 Lost Communication with ECM / PCM

DTC U0123/62Lost Communication with Yaw Rate Sensor

Module

DTC U0124/95Lost Communication with Lateral Acceleration

Sensor Module

DTC U0126/63Lost Communication with Steering Angle Sen-

sor Module

Page 2539 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–177

BC

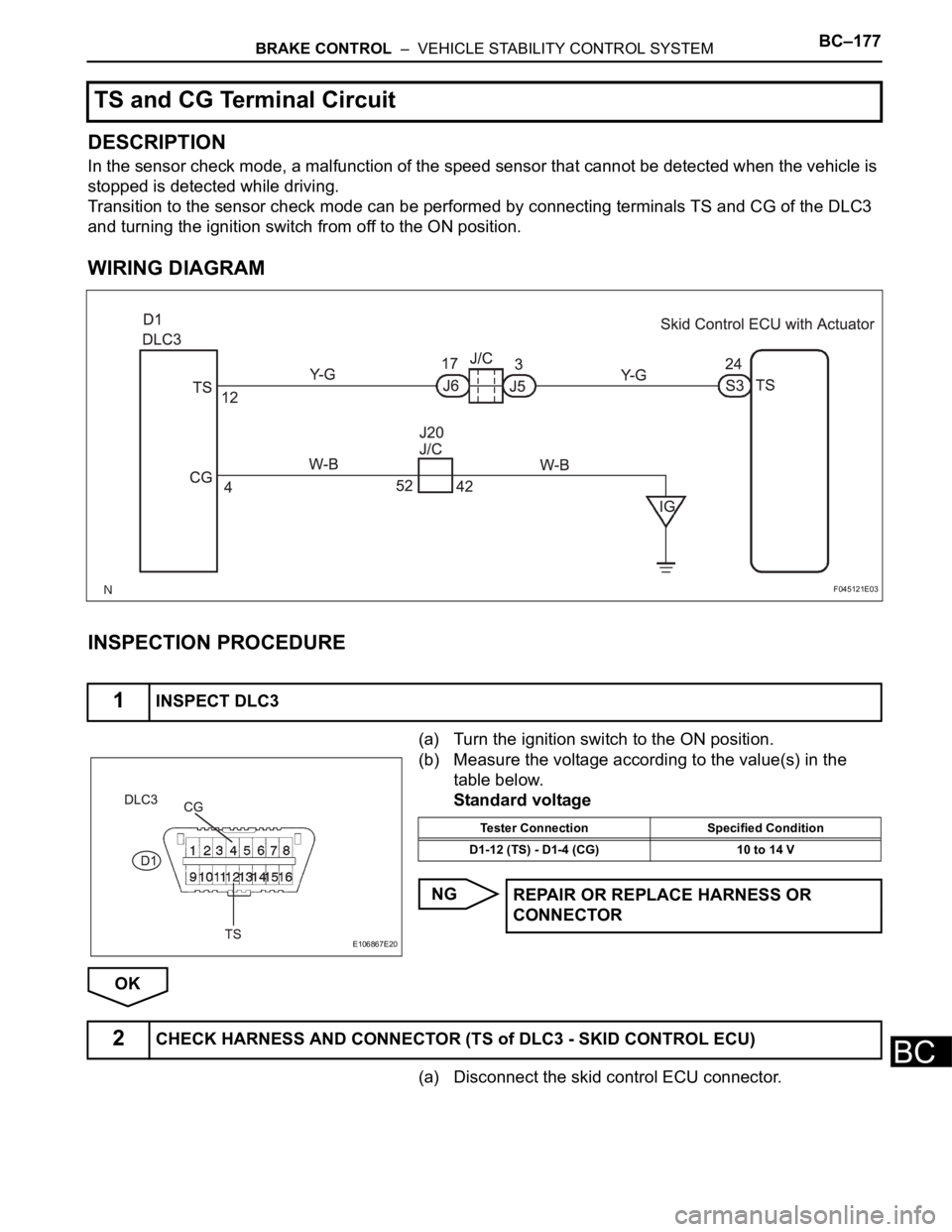

DESCRIPTION

In the sensor check mode, a malfunction of the speed sensor that cannot be detected when the vehicle is

stopped is detected while driving.

Transition to the sensor check mode can be performed by connecting terminals TS and CG of the DLC3

and turning the ignition switch from off to the ON position.

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

(a) Disconnect the skid control ECU connector.

TS and CG Terminal Circuit

1INSPECT DLC3

F045121E03

E106867E20

Tester Connection Specified Condition

D1-12 (TS) - D1-4 (CG) 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR

2CHECK HARNESS AND CONNECTOR (TS of DLC3 - SKID CONTROL ECU)