TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1891 of 3000

AX–208U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

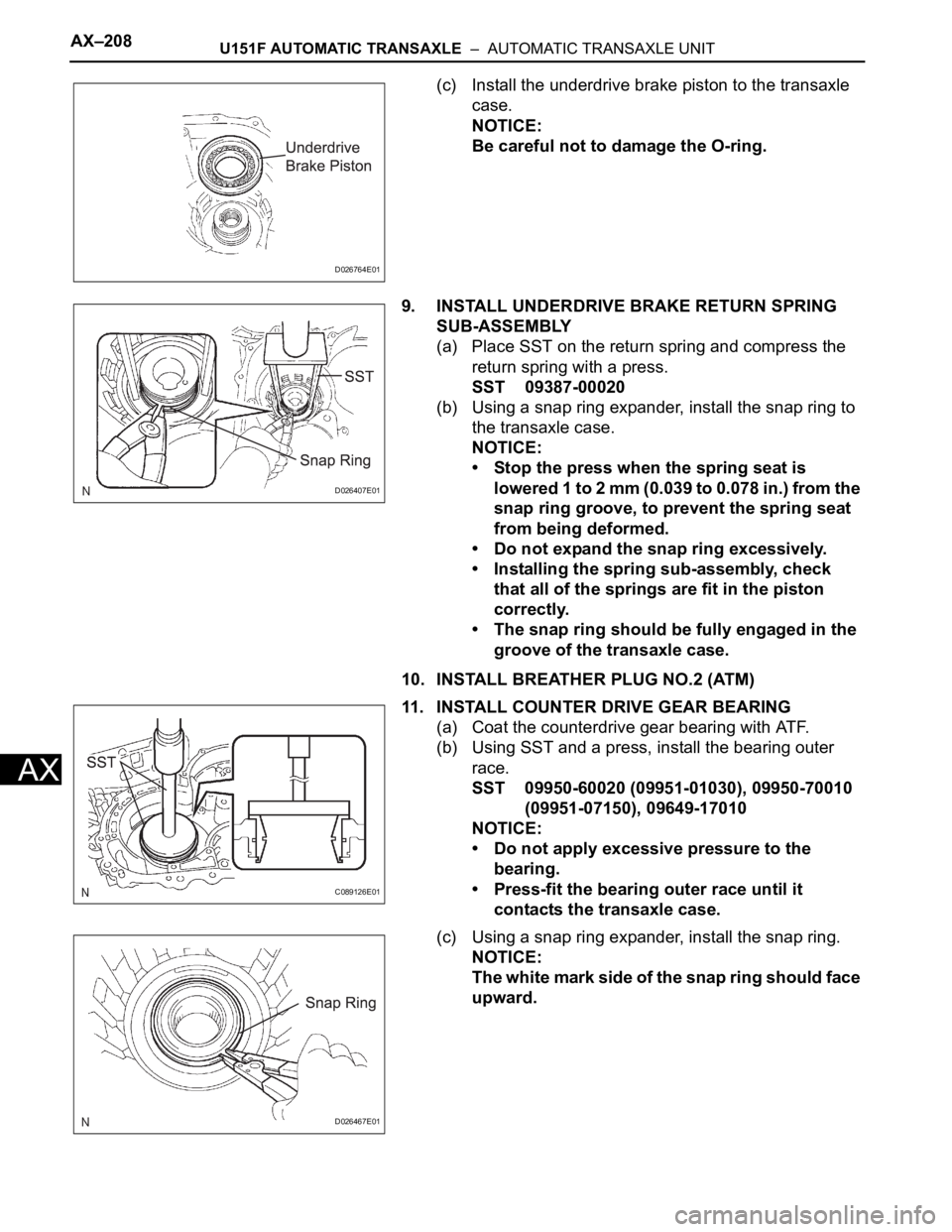

(c) Install the underdrive brake piston to the transaxle

case.

NOTICE:

Be careful not to damage the O-ring.

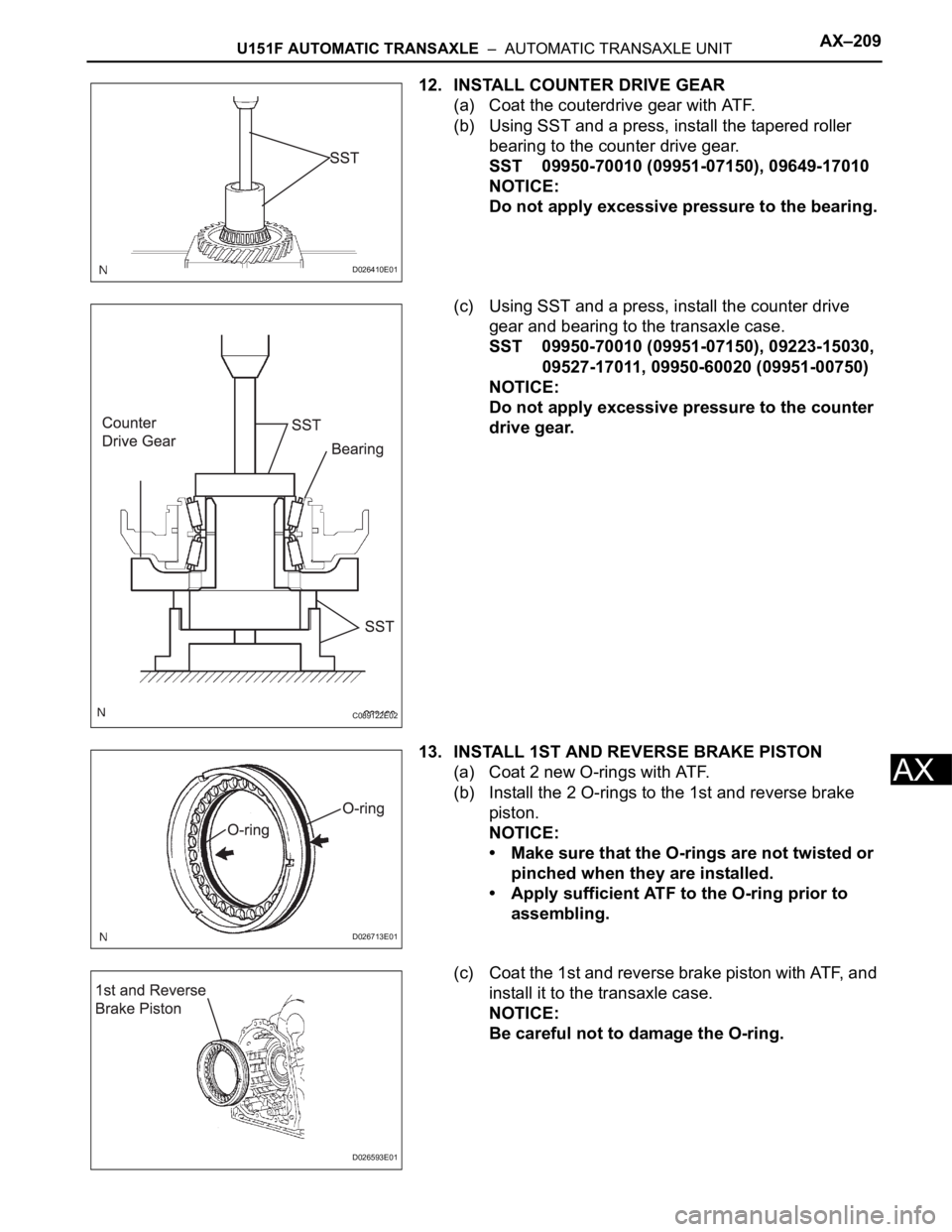

9. INSTALL UNDERDRIVE BRAKE RETURN SPRING

SUB-ASSEMBLY

(a) Place SST on the return spring and compress the

return spring with a press.

SST 09387-00020

(b) Using a snap ring expander, install the snap ring to

the transaxle case.

NOTICE:

• Stop the press when the spring seat is

lowered 1 to 2 mm (0.039 to 0.078 in.) from the

snap ring groove, to prevent the spring seat

from being deformed.

• Do not expand the snap ring excessively.

• Installing the spring sub-assembly, check

that all of the springs are fit in the piston

correctly.

• The snap ring should be fully engaged in the

groove of the transaxle case.

10. INSTALL BREATHER PLUG NO.2 (ATM)

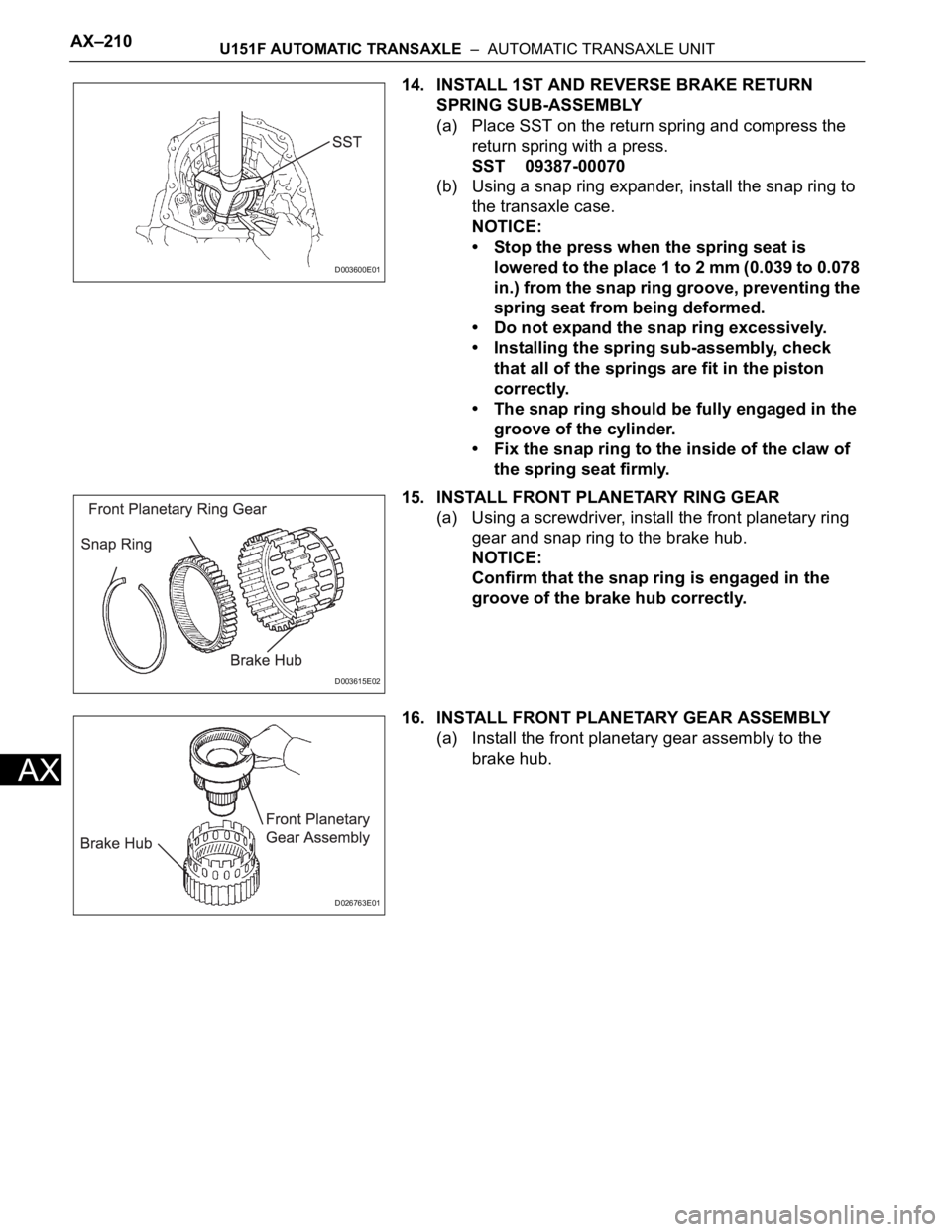

11. INSTALL COUNTER DRIVE GEAR BEARING

(a) Coat the counterdrive gear bearing with ATF.

(b) Using SST and a press, install the bearing outer

race.

SST 09950-60020 (09951-01030), 09950-70010

(09951-07150), 09649-17010

NOTICE:

• Do not apply excessive pressure to the

bearing.

• Press-fit the bearing outer race until it

contacts the transaxle case.

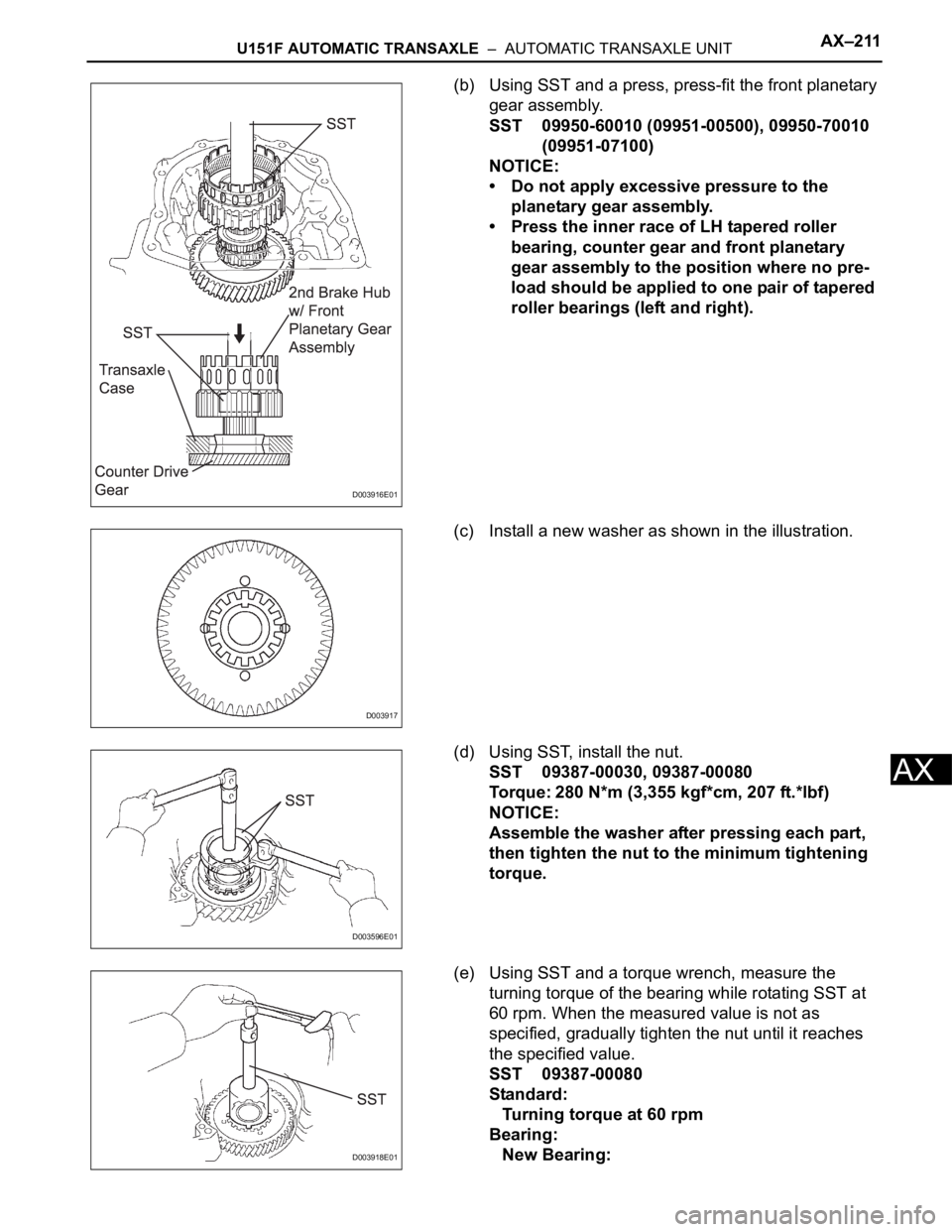

(c) Using a snap ring expander, install the snap ring.

NOTICE:

The white mark side of the snap ring should face

upward.

D026764E01

D026407E01

C089126E01

D026467E01

Page 1892 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–209

AX

12. INSTALL COUNTER DRIVE GEAR

(a) Coat the couterdrive gear with ATF.

(b) Using SST and a press, install the tapered roller

bearing to the counter drive gear.

SST 09950-70010 (09951-07150), 09649-17010

NOTICE:

Do not apply excessive pressure to the bearing.

(c) Using SST and a press, install the counter drive

gear and bearing to the transaxle case.

SST 09950-70010 (09951-07150), 09223-15030,

09527-17011, 09950-60020 (09951-00750)

NOTICE:

Do not apply excessive pressure to the counter

drive gear.

13. INSTALL 1ST AND REVERSE BRAKE PISTON

(a) Coat 2 new O-rings with ATF.

(b) Install the 2 O-rings to the 1st and reverse brake

piston.

NOTICE:

• Make sure that the O-rings are not twisted or

pinched when they are installed.

• Apply sufficient ATF to the O-ring prior to

assembling.

(c) Coat the 1st and reverse brake piston with ATF, and

install it to the transaxle case.

NOTICE:

Be careful not to damage the O-ring.

D026410E01

C089122E02

D026713E01

D026593E01

Page 1893 of 3000

AX–210U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

14. INSTALL 1ST AND REVERSE BRAKE RETURN

SPRING SUB-ASSEMBLY

(a) Place SST on the return spring and compress the

return spring with a press.

SST 09387-00070

(b) Using a snap ring expander, install the snap ring to

the transaxle case.

NOTICE:

• Stop the press when the spring seat is

lowered to the place 1 to 2 mm (0.039 to 0.078

in.) from the snap ring groove, preventing the

spring seat from being deformed.

• Do not expand the snap ring excessively.

• Installing the spring sub-assembly, check

that all of the springs are fit in the piston

correctly.

• The snap ring should be fully engaged in the

groove of the cylinder.

• Fix the snap ring to the inside of the claw of

the spring seat firmly.

15. INSTALL FRONT PLANETARY RING GEAR

(a) Using a screwdriver, install the front planetary ring

gear and snap ring to the brake hub.

NOTICE:

Confirm that the snap ring is engaged in the

groove of the brake hub correctly.

16. INSTALL FRONT PLANETARY GEAR ASSEMBLY

(a) Install the front planetary gear assembly to the

brake hub.

D003600E01

D003615E02

D026763E01

Page 1894 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–211

AX

(b) Using SST and a press, press-fit the front planetary

gear assembly.

SST 09950-60010 (09951-00500), 09950-70010

(09951-07100)

NOTICE:

• Do not apply excessive pressure to the

planetary gear assembly.

• Press the inner race of LH tapered roller

bearing, counter gear and front planetary

gear assembly to the position where no pre-

load should be applied to one pair of tapered

roller bearings (left and right).

(c) Install a new washer as shown in the illustration.

(d) Using SST, install the nut.

SST 09387-00030, 09387-00080

Torque: 280 N*m (3,355 kgf*cm, 207 ft.*lbf)

NOTICE:

Assemble the washer after pressing each part,

then tighten the nut to the minimum tightening

torque.

(e) Using SST and a torque wrench, measure the

turning torque of the bearing while rotating SST at

60 rpm. When the measured value is not as

specified, gradually tighten the nut until it reaches

the specified value.

SST 09387-00080

Standard:

Turning torque at 60 rpm

Bearing:

New Bearing:

D003916E01

D003917

D003596E01

D003918E01

Page 1895 of 3000

AX–212U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

0.51 to 1.02 N*m (5.1 to 10.0 kgf*cm, 4.4 to 8.7

in.*lbf)

Used Bearing:

0.26 to 0.51 N*m (2.7 to 5.2 kgf*cm, 2.3 to 4.5

in.*lbf)

HINT:

Use a torque wrench with a fulcrum length of 160

mm (6.3 in.).

(f) Tighten the nut gradually until the specified turning

torque of tapered roller bearing is measured.

Torque: 350 N*m (3,569 kgf*cm, 258 ft.*lbf)

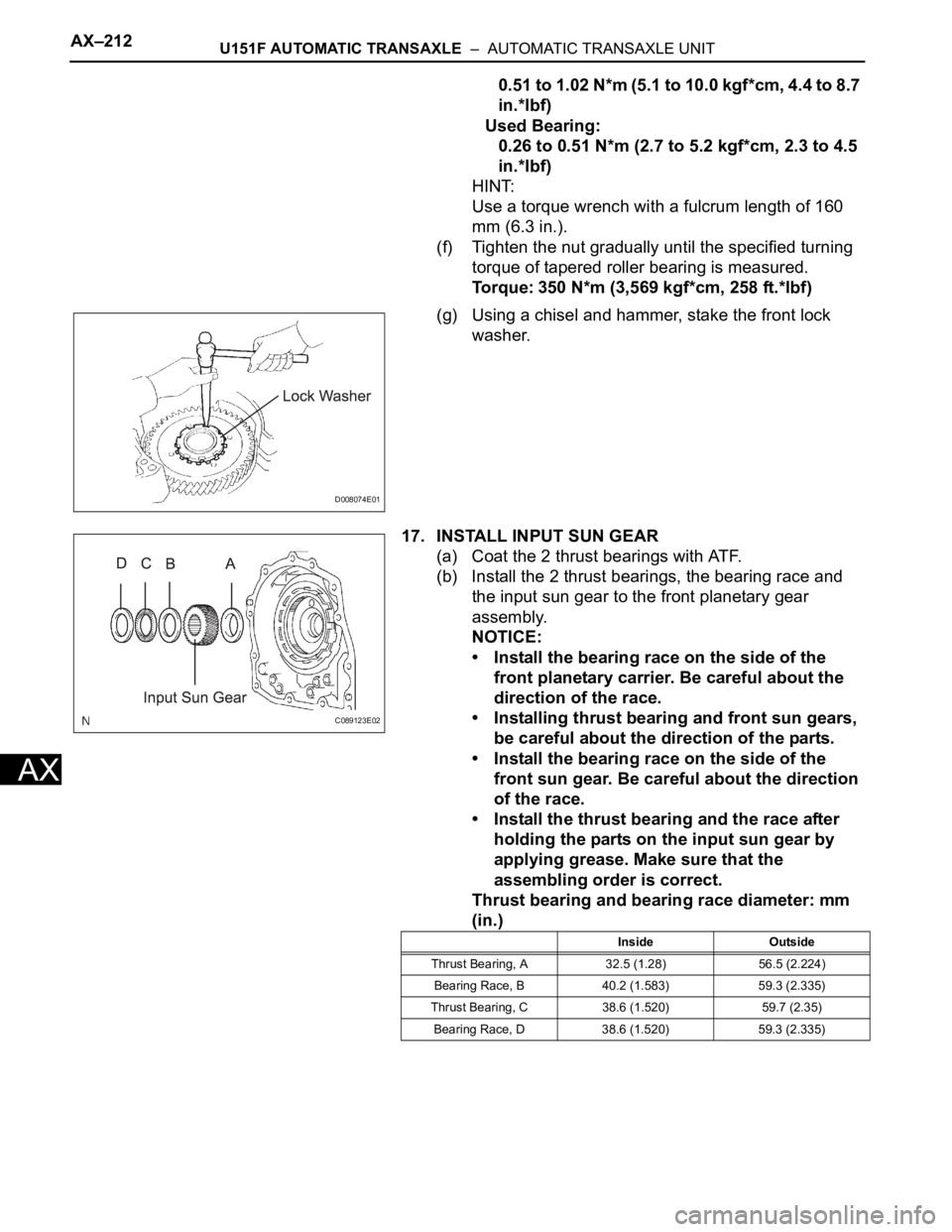

(g) Using a chisel and hammer, stake the front lock

washer.

17. INSTALL INPUT SUN GEAR

(a) Coat the 2 thrust bearings with ATF.

(b) Install the 2 thrust bearings, the bearing race and

the input sun gear to the front planetary gear

assembly.

NOTICE:

• Install the bearing race on the side of the

front planetary carrier. Be careful about the

direction of the race.

• Installing thrust bearing and front sun gears,

be careful about the direction of the parts.

• Install the bearing race on the side of the

front sun gear. Be careful about the direction

of the race.

• Install the thrust bearing and the race after

holding the parts on the input sun gear by

applying grease. Make sure that the

assembling order is correct.

Thrust bearing and bearing race diameter: mm

(in.)

D008074E01

C089123E02

Inside Outside

Thrust Bearing, A 32.5 (1.28) 56.5 (2.224)

Bearing Race, B 40.2 (1.583) 59.3 (2.335)

Thrust Bearing, C 38.6 (1.520) 59.7 (2.35)

Bearing Race, D 38.6 (1.520) 59.3 (2.335)

Page 1896 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–213

AX

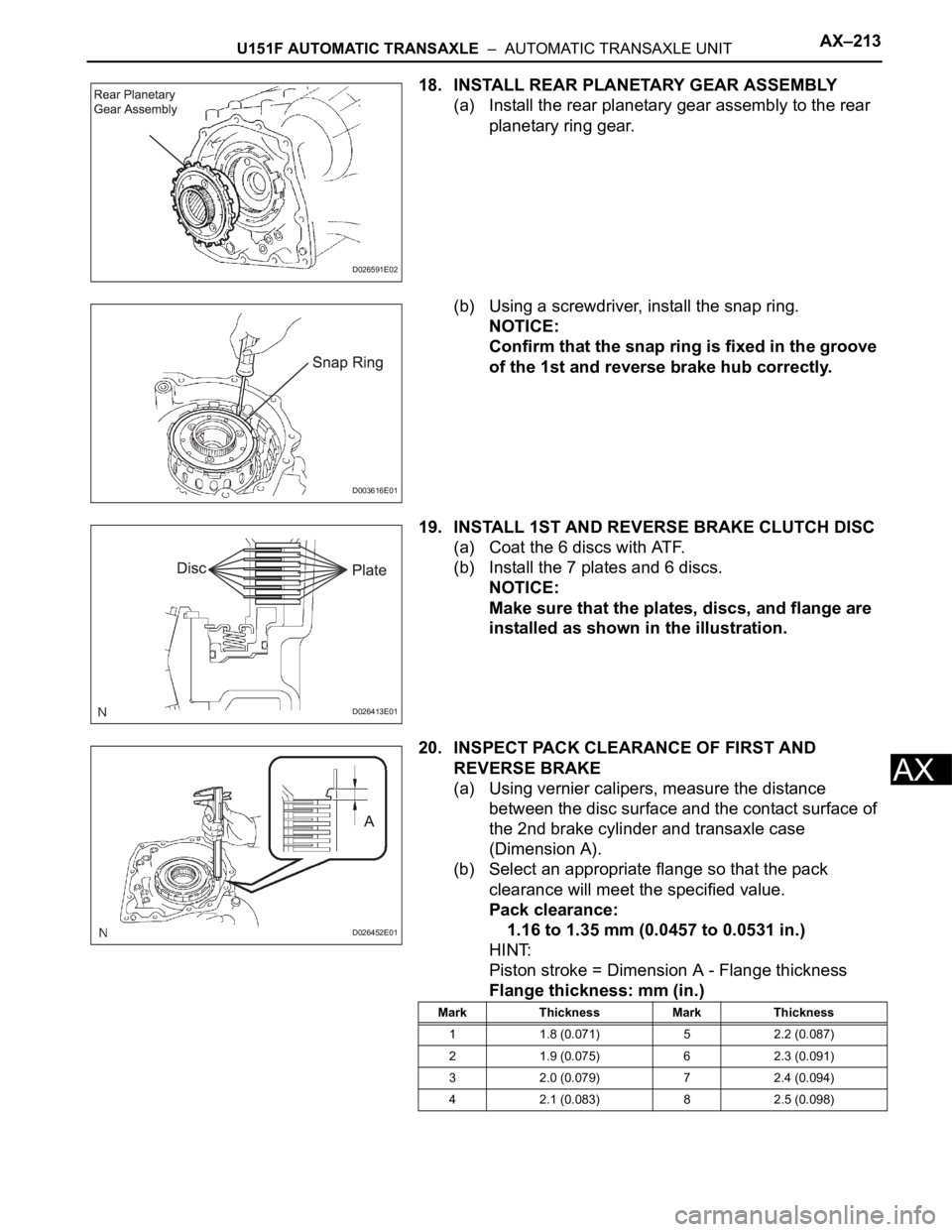

18. INSTALL REAR PLANETARY GEAR ASSEMBLY

(a) Install the rear planetary gear assembly to the rear

planetary ring gear.

(b) Using a screwdriver, install the snap ring.

NOTICE:

Confirm that the snap ring is fixed in the groove

of the 1st and reverse brake hub correctly.

19. INSTALL 1ST AND REVERSE BRAKE CLUTCH DISC

(a) Coat the 6 discs with ATF.

(b) Install the 7 plates and 6 discs.

NOTICE:

Make sure that the plates, discs, and flange are

installed as shown in the illustration.

20. INSPECT PACK CLEARANCE OF FIRST AND

REVERSE BRAKE

(a) Using vernier calipers, measure the distance

between the disc surface and the contact surface of

the 2nd brake cylinder and transaxle case

(Dimension A).

(b) Select an appropriate flange so that the pack

clearance will meet the specified value.

Pack clearance:

1.16 to 1.35 mm (0.0457 to 0.0531 in.)

HINT:

Piston stroke = Dimension A - Flange thickness

Flange thickness: mm (in.)

D026591E02

D003616E01

D026413E01

D026452E01

Mark Thickness Mark Thickness

1 1.8 (0.071) 5 2.2 (0.087)

2 1.9 (0.075) 6 2.3 (0.091)

3 2.0 (0.079) 7 2.4 (0.094)

4 2.1 (0.083) 8 2.5 (0.098)

Page 1897 of 3000

AX–214U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

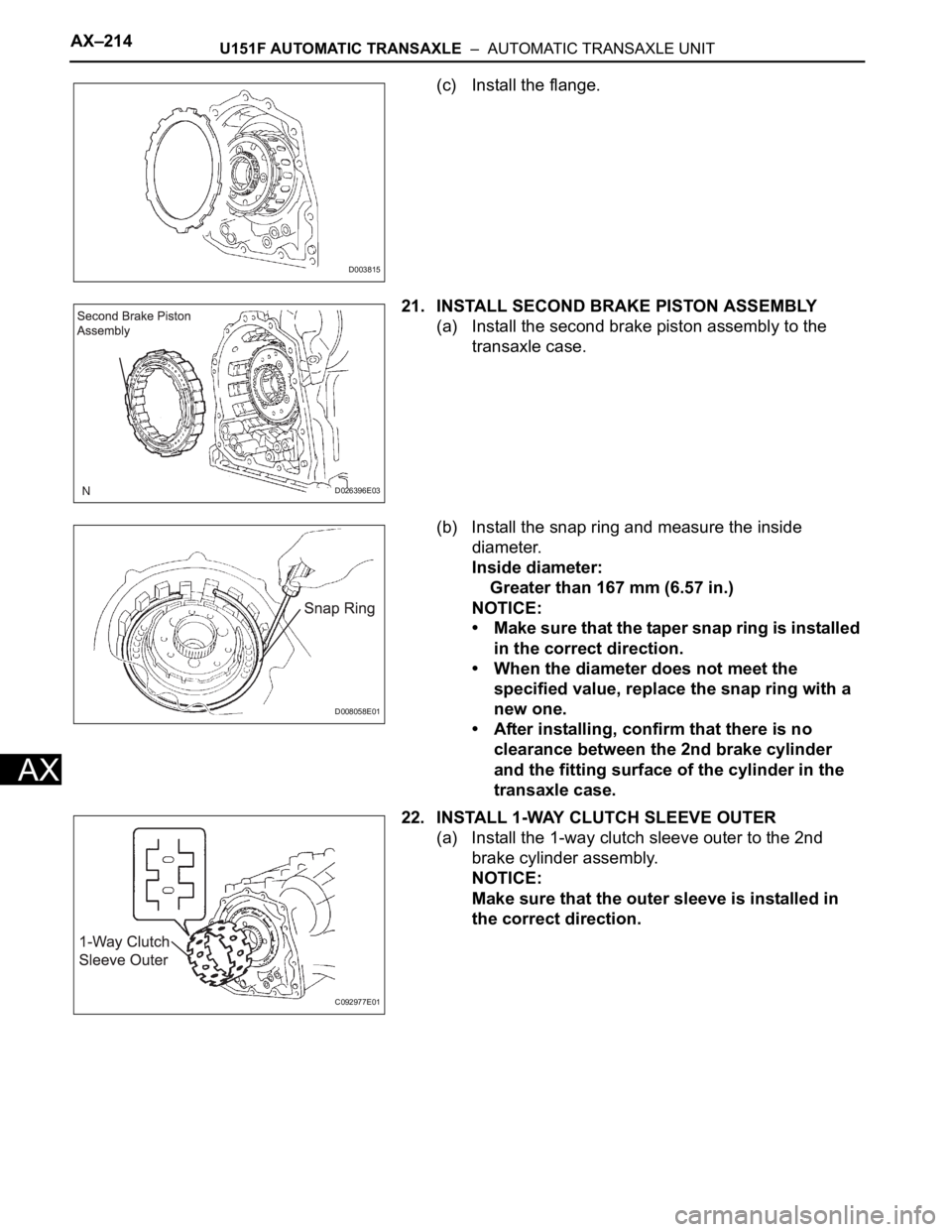

(c) Install the flange.

21. INSTALL SECOND BRAKE PISTON ASSEMBLY

(a) Install the second brake piston assembly to the

transaxle case.

(b) Install the snap ring and measure the inside

diameter.

Inside diameter:

Greater than 167 mm (6.57 in.)

NOTICE:

• Make sure that the taper snap ring is installed

in the correct direction.

• When the diameter does not meet the

specified value, replace the snap ring with a

new one.

• After installing, confirm that there is no

clearance between the 2nd brake cylinder

and the fitting surface of the cylinder in the

transaxle case.

22. INSTALL 1-WAY CLUTCH SLEEVE OUTER

(a) Install the 1-way clutch sleeve outer to the 2nd

brake cylinder assembly.

NOTICE:

Make sure that the outer sleeve is installed in

the correct direction.

D003815

D026396E03

D008058E01

C092977E01

Page 1898 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–215

AX

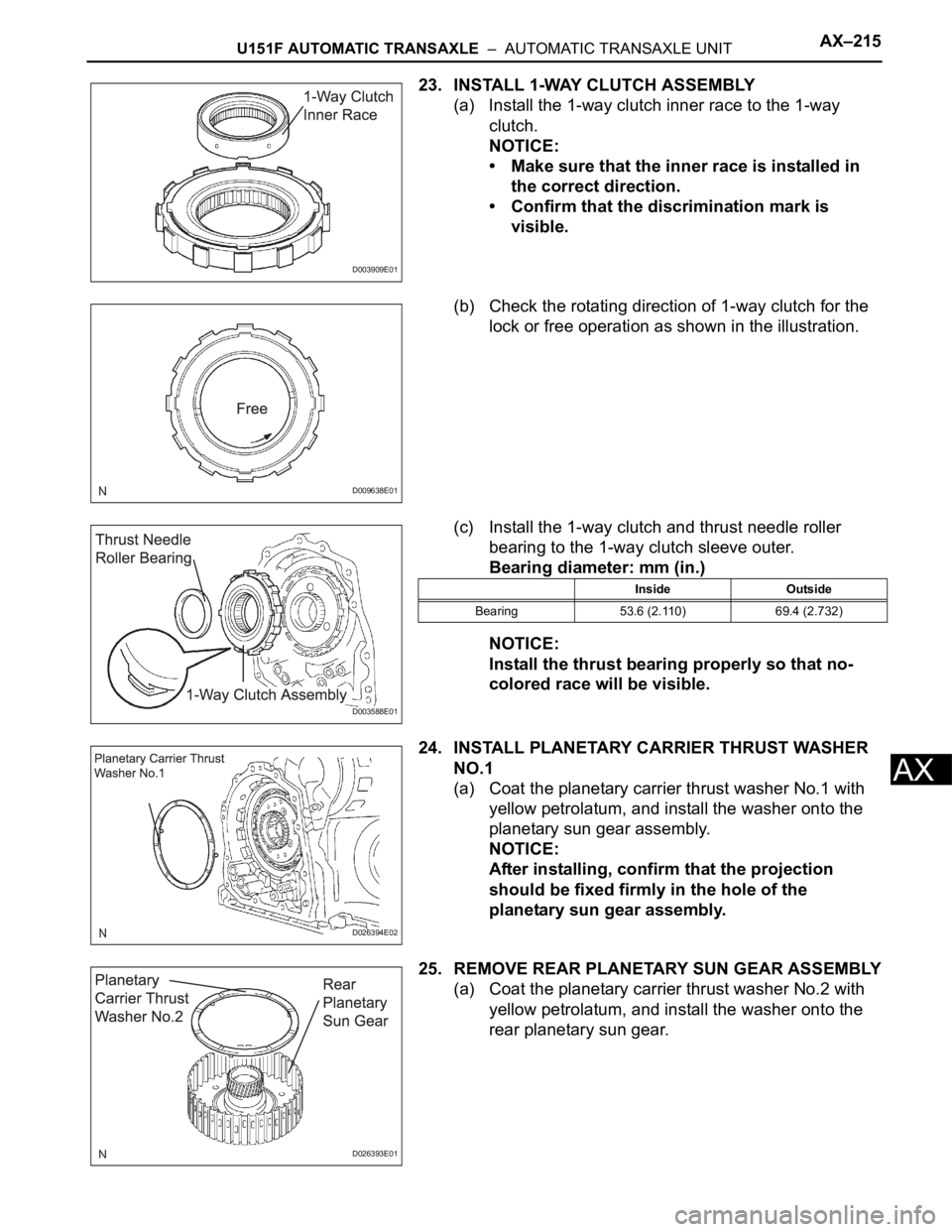

23. INSTALL 1-WAY CLUTCH ASSEMBLY

(a) Install the 1-way clutch inner race to the 1-way

clutch.

NOTICE:

• Make sure that the inner race is installed in

the correct direction.

• Confirm that the discrimination mark is

visible.

(b) Check the rotating direction of 1-way clutch for the

lock or free operation as shown in the illustration.

(c) Install the 1-way clutch and thrust needle roller

bearing to the 1-way clutch sleeve outer.

Bearing diameter: mm (in.)

NOTICE:

Install the thrust bearing properly so that no-

colored race will be visible.

24. INSTALL PLANETARY CARRIER THRUST WASHER

NO.1

(a) Coat the planetary carrier thrust washer No.1 with

yellow petrolatum, and install the washer onto the

planetary sun gear assembly.

NOTICE:

After installing, confirm that the projection

should be fixed firmly in the hole of the

planetary sun gear assembly.

25. REMOVE REAR PLANETARY SUN GEAR ASSEMBLY

(a) Coat the planetary carrier thrust washer No.2 with

yellow petrolatum, and install the washer onto the

rear planetary sun gear.

D003909E01

D009638E01

D003588E01

Inside Outside

Bearing 53.6 (2.110) 69.4 (2.732)

D026394E02

D026393E01

Page 1899 of 3000

AX–216U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

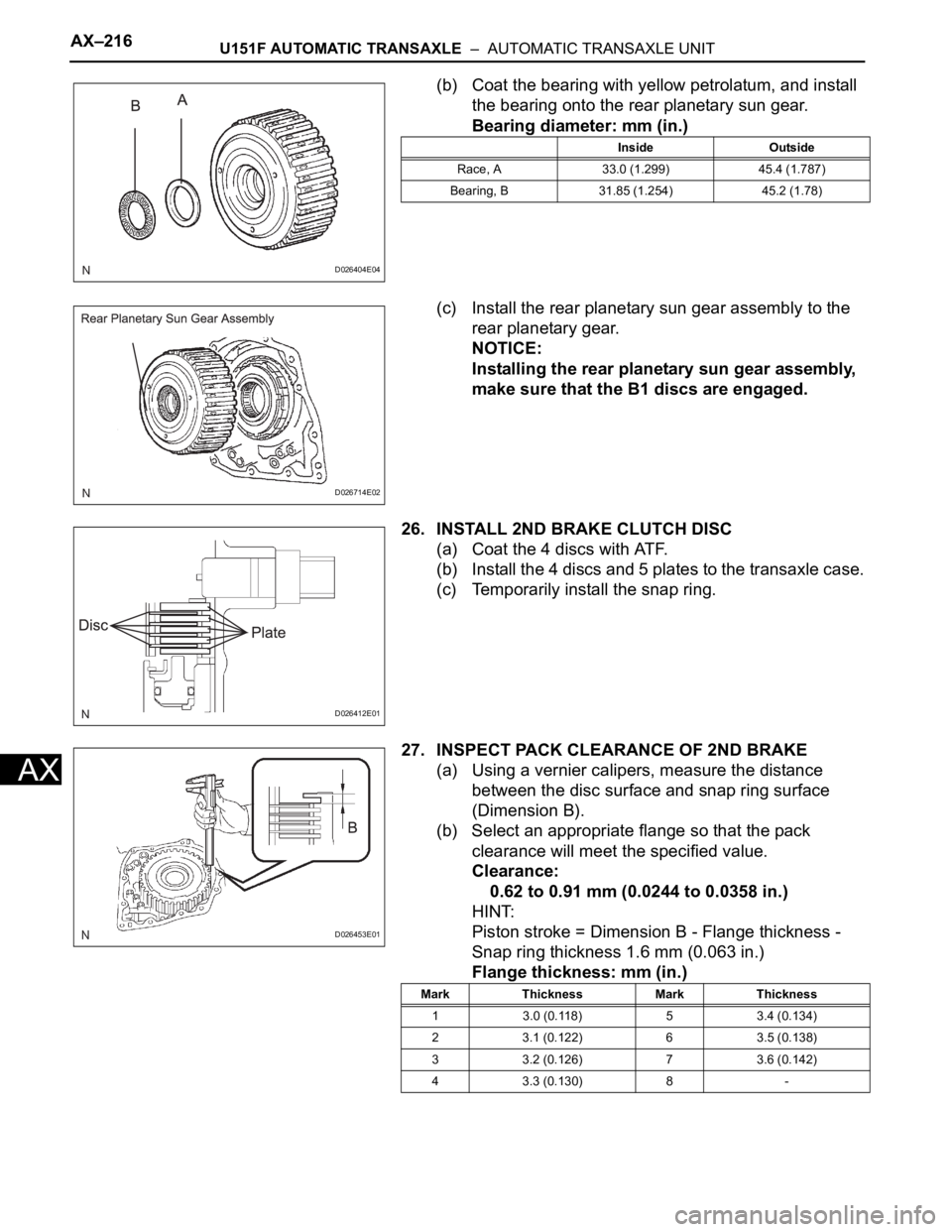

(b) Coat the bearing with yellow petrolatum, and install

the bearing onto the rear planetary sun gear.

Bearing diameter: mm (in.)

(c) Install the rear planetary sun gear assembly to the

rear planetary gear.

NOTICE:

Installing the rear planetary sun gear assembly,

make sure that the B1 discs are engaged.

26. INSTALL 2ND BRAKE CLUTCH DISC

(a) Coat the 4 discs with ATF.

(b) Install the 4 discs and 5 plates to the transaxle case.

(c) Temporarily install the snap ring.

27. INSPECT PACK CLEARANCE OF 2ND BRAKE

(a) Using a vernier calipers, measure the distance

between the disc surface and snap ring surface

(Dimension B).

(b) Select an appropriate flange so that the pack

clearance will meet the specified value.

Clearance:

0.62 to 0.91 mm (0.0244 to 0.0358 in.)

HINT:

Piston stroke = Dimension B - Flange thickness -

Snap ring thickness 1.6 mm (0.063 in.)

Flange thickness: mm (in.)

D026404E04

Inside Outside

Race, A 33.0 (1.299) 45.4 (1.787)

Bearing, B 31.85 (1.254) 45.2 (1.78)

D026714E02

D026412E01

D026453E01

Mark Thickness Mark Thickness

1 3.0 (0.118) 5 3.4 (0.134)

2 3.1 (0.122) 6 3.5 (0.138)

3 3.2 (0.126) 7 3.6 (0.142)

4 3.3 (0.130) 8 -

Page 1900 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–217

AX

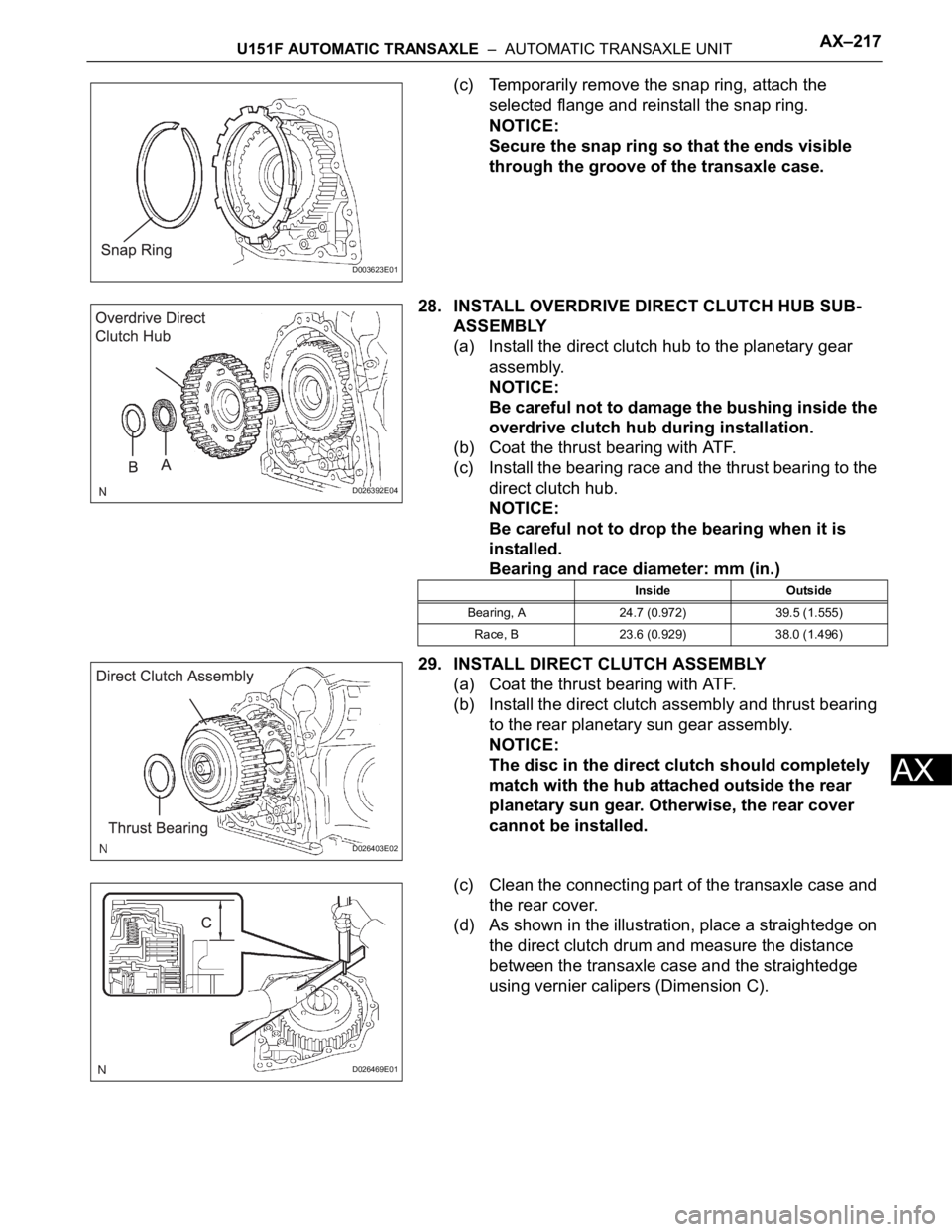

(c) Temporarily remove the snap ring, attach the

selected flange and reinstall the snap ring.

NOTICE:

Secure the snap ring so that the ends visible

through the groove of the transaxle case.

28. INSTALL OVERDRIVE DIRECT CLUTCH HUB SUB-

ASSEMBLY

(a) Install the direct clutch hub to the planetary gear

assembly.

NOTICE:

Be careful not to damage the bushing inside the

overdrive clutch hub during installation.

(b) Coat the thrust bearing with ATF.

(c) Install the bearing race and the thrust bearing to the

direct clutch hub.

NOTICE:

Be careful not to drop the bearing when it is

installed.

Bearing and race diameter: mm (in.)

29. INSTALL DIRECT CLUTCH ASSEMBLY

(a) Coat the thrust bearing with ATF.

(b) Install the direct clutch assembly and thrust bearing

to the rear planetary sun gear assembly.

NOTICE:

The disc in the direct clutch should completely

match with the hub attached outside the rear

planetary sun gear. Otherwise, the rear cover

cannot be installed.

(c) Clean the connecting part of the transaxle case and

the rear cover.

(d) As shown in the illustration, place a straightedge on

the direct clutch drum and measure the distance

between the transaxle case and the straightedge

using vernier calipers (Dimension C).

D003623E01

D026392E04

Inside Outside

Bearing, A 24.7 (0.972) 39.5 (1.555)

Race, B 23.6 (0.929) 38.0 (1.496)

D026403E02

D026469E01