fuse TOYOTA SIENNA 2007 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 419 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–113

ES

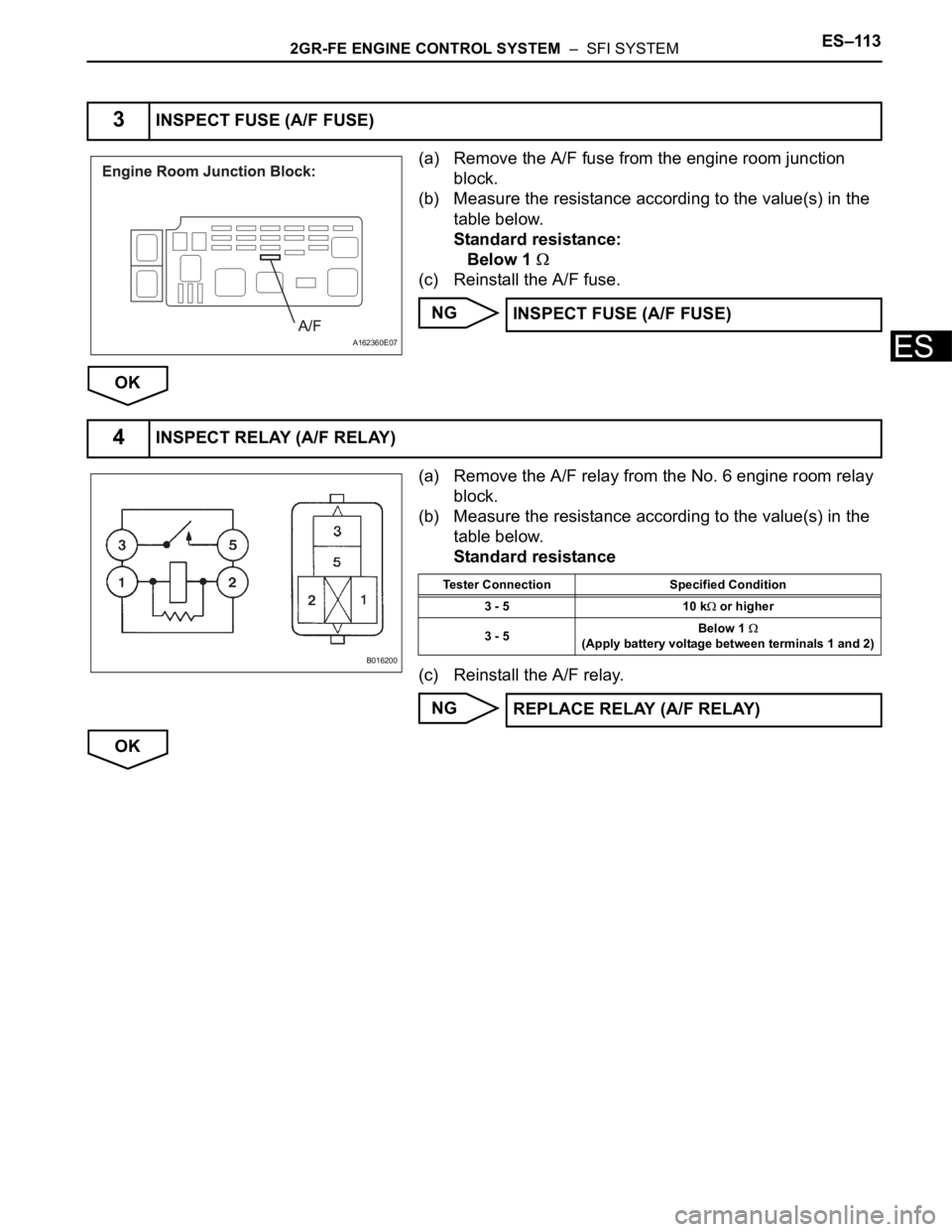

(a) Remove the A/F fuse from the engine room junction

block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Below 1

(c) Reinstall the A/F fuse.

NG

OK

(a) Remove the A/F relay from the No. 6 engine room relay

block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reinstall the A/F relay.

NG

OK

3INSPECT FUSE (A/F FUSE)

A162360E07

INSPECT FUSE (A/F FUSE)

4INSPECT RELAY (A/F RELAY)

B016200

Tester Connection Specified Condition

3 - 5 10 k

or higher

3 - 5Below 1

(Apply battery voltage between terminals 1 and 2)

REPLACE RELAY (A/F RELAY)

Page 427 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–121

ES

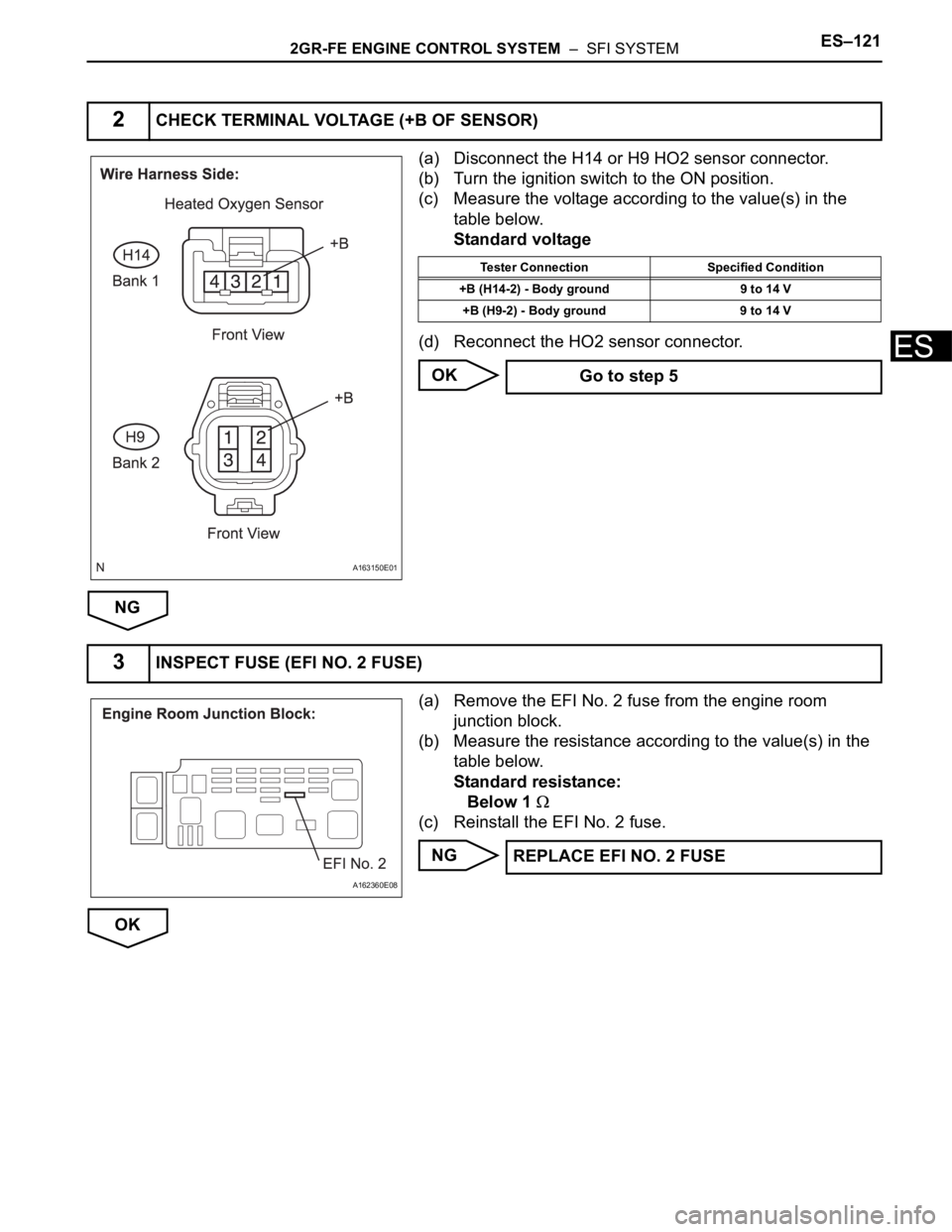

(a) Disconnect the H14 or H9 HO2 sensor connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

(d) Reconnect the HO2 sensor connector.

OK

NG

(a) Remove the EFI No. 2 fuse from the engine room

junction block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Below 1

(c) Reinstall the EFI No. 2 fuse.

NG

OK

2CHECK TERMINAL VOLTAGE (+B OF SENSOR)

A163150E01

Tester Connection Specified Condition

+B (H14-2) - Body ground 9 to 14 V

+B (H9-2) - Body ground 9 to 14 V

Go to step 5

3INSPECT FUSE (EFI NO. 2 FUSE)

A162360E08

REPLACE EFI NO. 2 FUSE

Page 434 of 3000

ES–1282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

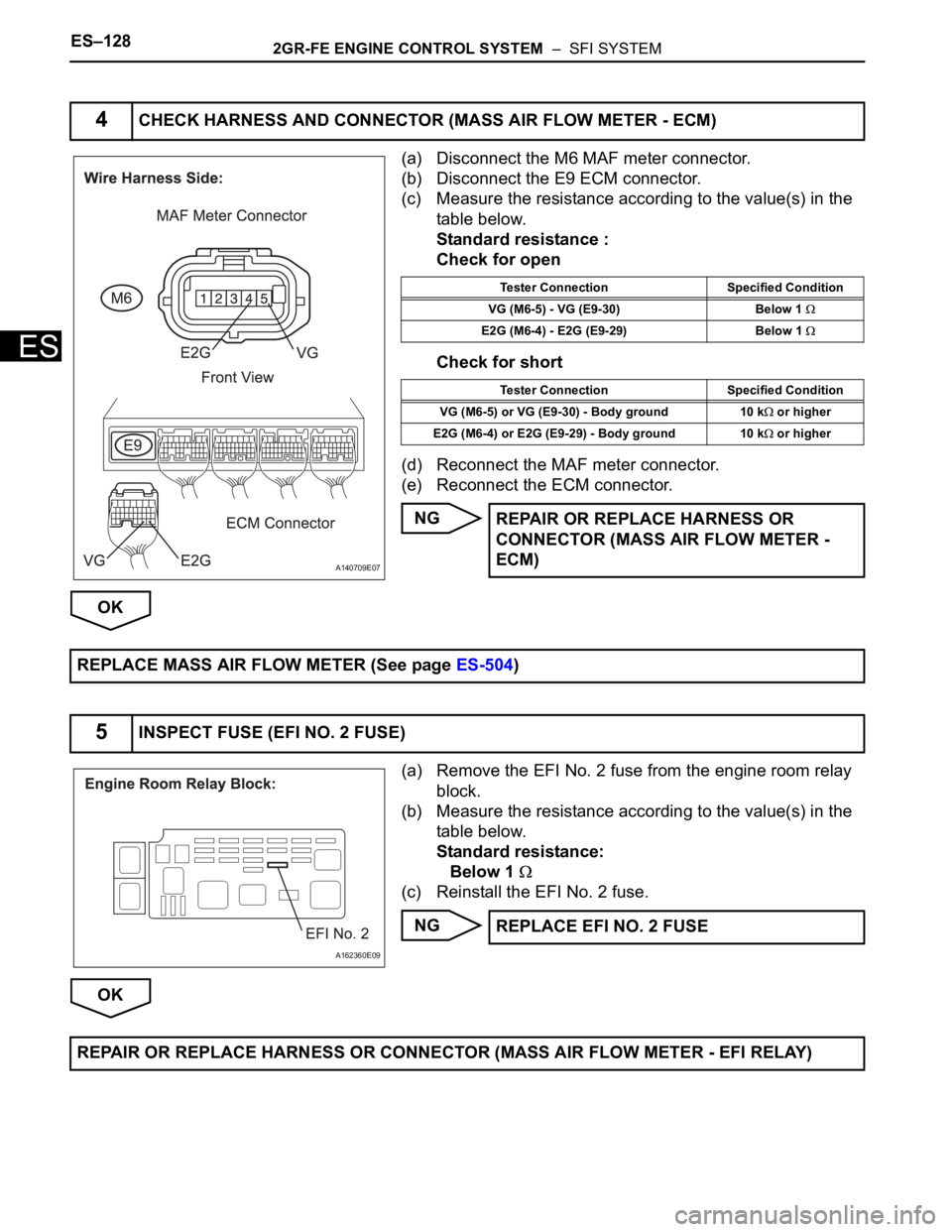

(a) Disconnect the M6 MAF meter connector.

(b) Disconnect the E9 ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance :

Check for open

Check for short

(d) Reconnect the MAF meter connector.

(e) Reconnect the ECM connector.

NG

OK

(a) Remove the EFI No. 2 fuse from the engine room relay

block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Below 1

(c) Reinstall the EFI No. 2 fuse.

NG

OK

4CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM)

A140709E07

Tester Connection Specified Condition

VG (M6-5) - VG (E9-30) Below 1

E2G (M6-4) - E2G (E9-29) Below 1

Tester Connection Specified Condition

VG (M6-5) or VG (E9-30) - Body ground 10 k

or higher

E2G (M6-4) or E2G (E9-29) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (MASS AIR FLOW METER -

ECM)

REPLACE MASS AIR FLOW METER (See page ES-504)

5INSPECT FUSE (EFI NO. 2 FUSE)

A162360E09

REPLACE EFI NO. 2 FUSE

REPAIR OR REPLACE HARNESS OR CONNECTOR (MASS AIR FLOW METER - EFI RELAY)

Page 589 of 3000

ES–2962GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

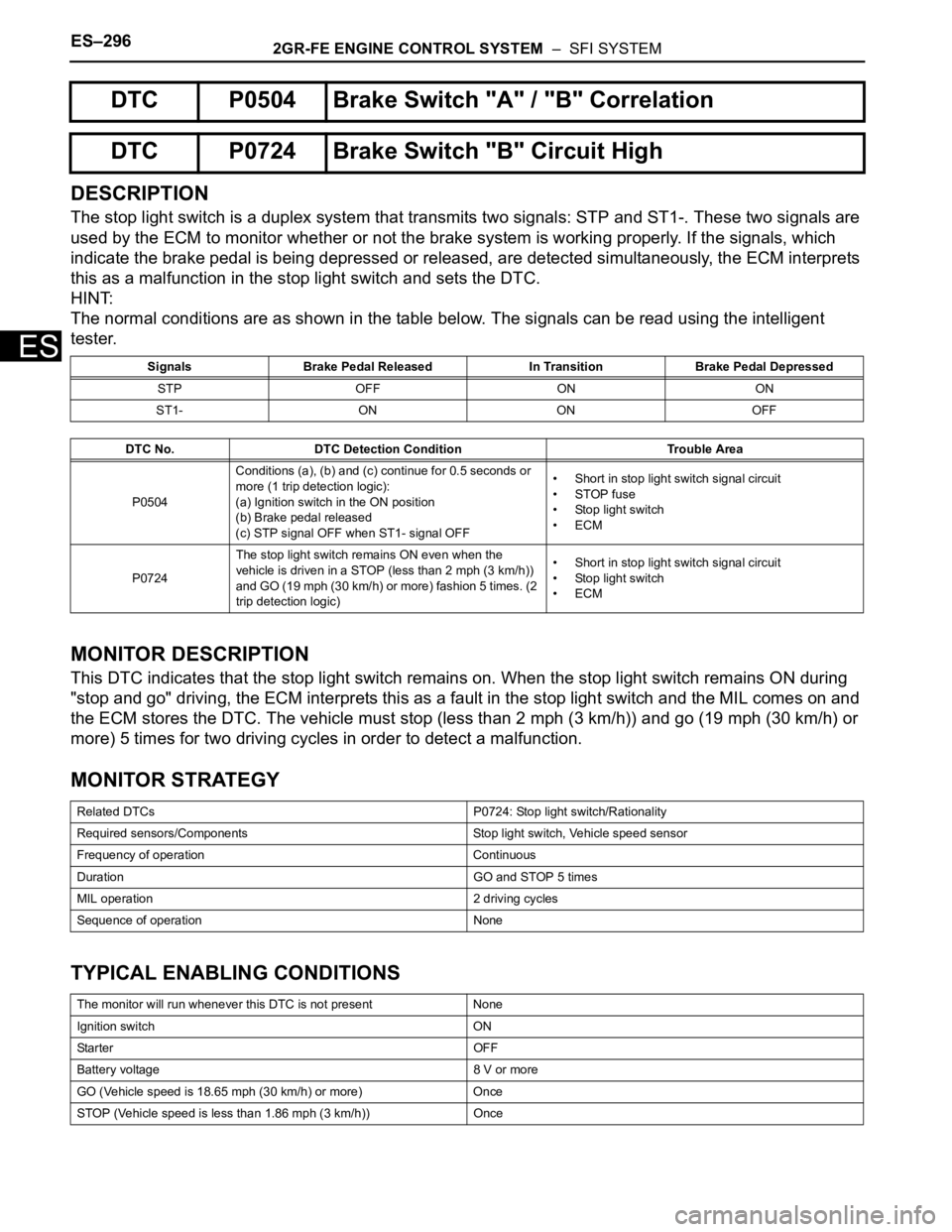

DESCRIPTION

The stop light switch is a duplex system that transmits two signals: STP and ST1-. These two signals are

used by the ECM to monitor whether or not the brake system is working properly. If the signals, which

indicate the brake pedal is being depressed or released, are detected simultaneously, the ECM interprets

this as a malfunction in the stop light switch and sets the DTC.

HINT:

The normal conditions are as shown in the table below. The signals can be read using the intelligent

tester.

MONITOR DESCRIPTION

This DTC indicates that the stop light switch remains on. When the stop light switch remains ON during

"stop and go" driving, the ECM interprets this as a fault in the stop light switch and the MIL comes on and

the ECM stores the DTC. The vehicle must stop (less than 2 mph (3 km/h)) and go (19 mph (30 km/h) or

more) 5 times for two driving cycles in order to detect a malfunction.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

DTC P0504 Brake Switch "A" / "B" Correlation

DTC P0724 Brake Switch "B" Circuit High

Signals Brake Pedal Released In Transition Brake Pedal Depressed

STP OFF ON ON

ST1- ON ON OFF

DTC No. DTC Detection Condition Trouble Area

P0504Conditions (a), (b) and (c) continue for 0.5 seconds or

more (1 trip detection logic):

(a) Ignition switch in the ON position

(b) Brake pedal released

(c) STP signal OFF when ST1- signal OFF• Short in stop light switch signal circuit

• STOP fuse

• Stop light switch

•ECM

P0724The stop light switch remains ON even when the

vehicle is driven in a STOP (less than 2 mph (3 km/h))

and GO (19 mph (30 km/h) or more) fashion 5 times. (2

trip detection logic)• Short in stop light switch signal circuit

• Stop light switch

•ECM

Related DTCs P0724: Stop light switch/Rationality

Required sensors/Components Stop light switch, Vehicle speed sensor

Frequency of operation Continuous

Duration GO and STOP 5 times

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present None

Ignition switch ON

Starter OFF

Battery voltage 8 V or more

GO (Vehicle speed is 18.65 mph (30 km/h) or more) Once

STOP (Vehicle speed is less than 1.86 mph (3 km/h)) Once

Page 609 of 3000

ES–3162GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

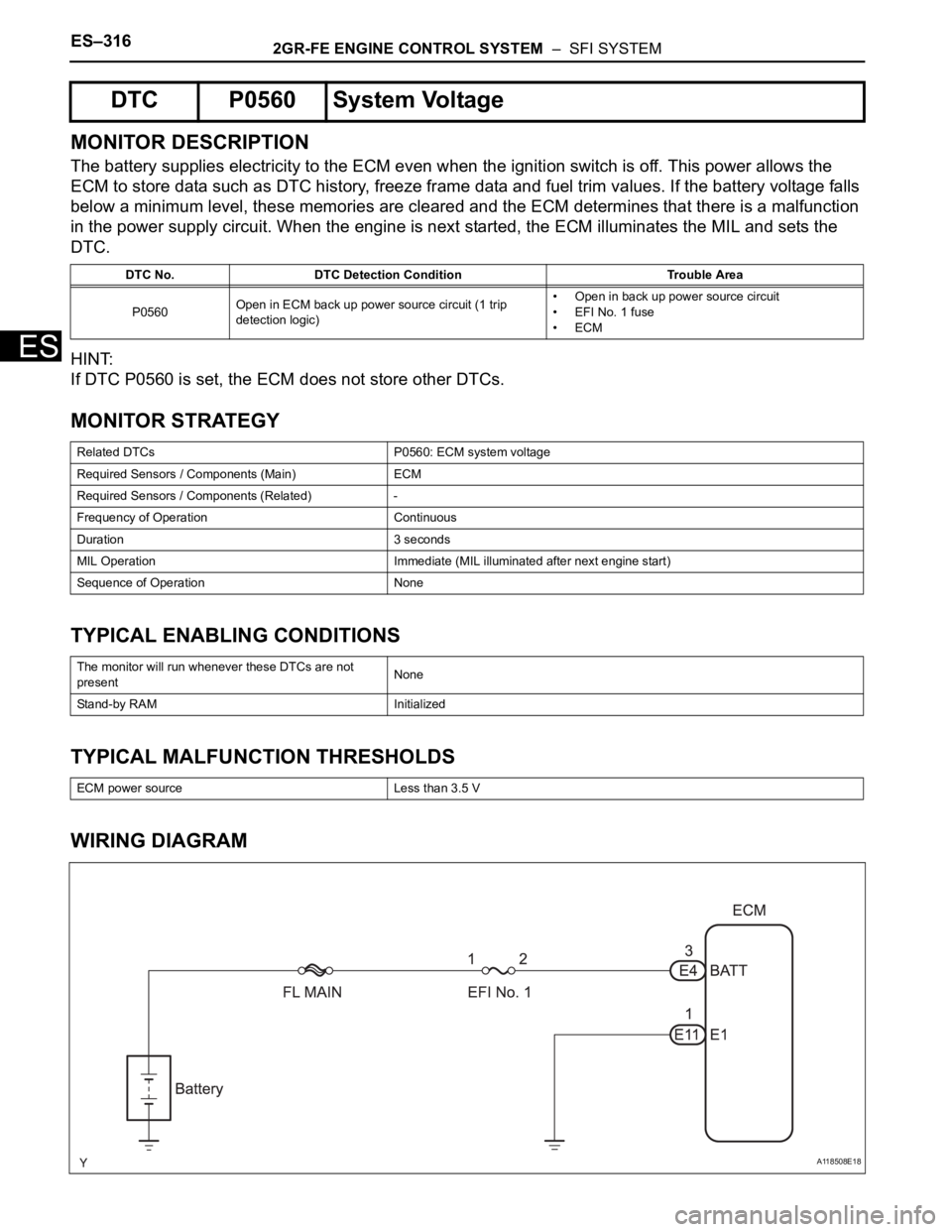

MONITOR DESCRIPTION

The battery supplies electricity to the ECM even when the ignition switch is off. This power allows the

ECM to store data such as DTC history, freeze frame data and fuel trim values. If the battery voltage falls

below a minimum level, these memories are cleared and the ECM determines that there is a malfunction

in the power supply circuit. When the engine is next started, the ECM illuminates the MIL and sets the

DTC.

HINT:

If DTC P0560 is set, the ECM does not store other DTCs.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

WIRING DIAGRAM

DTC P0560 System Voltage

DTC No. DTC Detection Condition Trouble Area

P0560Open in ECM back up power source circuit (1 trip

detection logic)• Open in back up power source circuit

• EFI No. 1 fuse

•ECM

Related DTCs P0560: ECM system voltage

Required Sensors / Components (Main) ECM

Required Sensors / Components (Related) -

Frequency of Operation Continuous

Duration 3 seconds

MIL Operation Immediate (MIL illuminated after next engine start)

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Stand-by RAM Initialized

ECM power source Less than 3.5 V

A118508E18

Page 610 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–317

ES

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

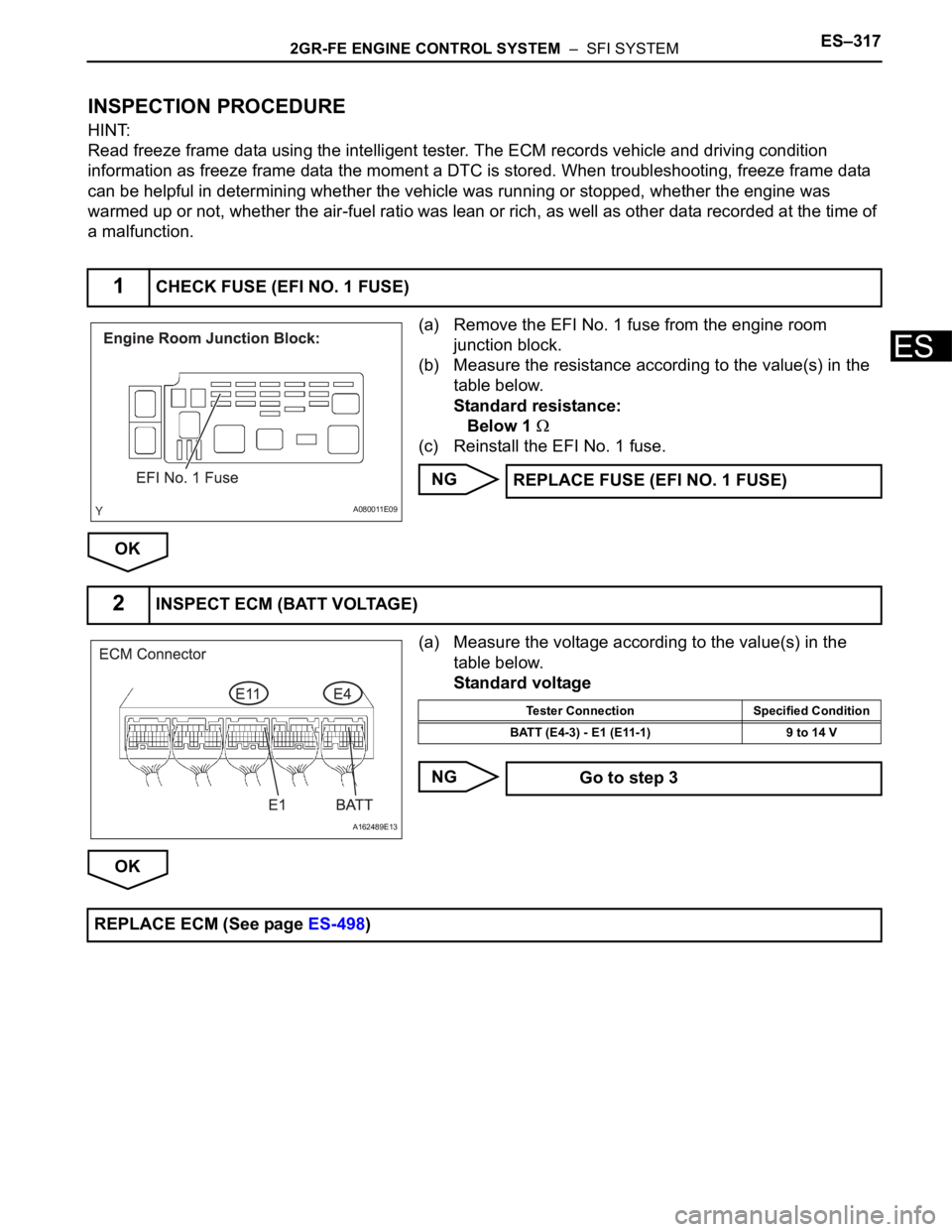

(a) Remove the EFI No. 1 fuse from the engine room

junction block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Below 1

(c) Reinstall the EFI No. 1 fuse.

NG

OK

(a) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

1CHECK FUSE (EFI NO. 1 FUSE)

A080011E09

REPLACE FUSE (EFI NO. 1 FUSE)

2INSPECT ECM (BATT VOLTAGE)

A162489E13

Tester Connection Specified Condition

BATT (E4-3) - E1 (E11-1) 9 to 14 V

Go to step 3

REPLACE ECM (See page ES-498)

Page 611 of 3000

ES–3182GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

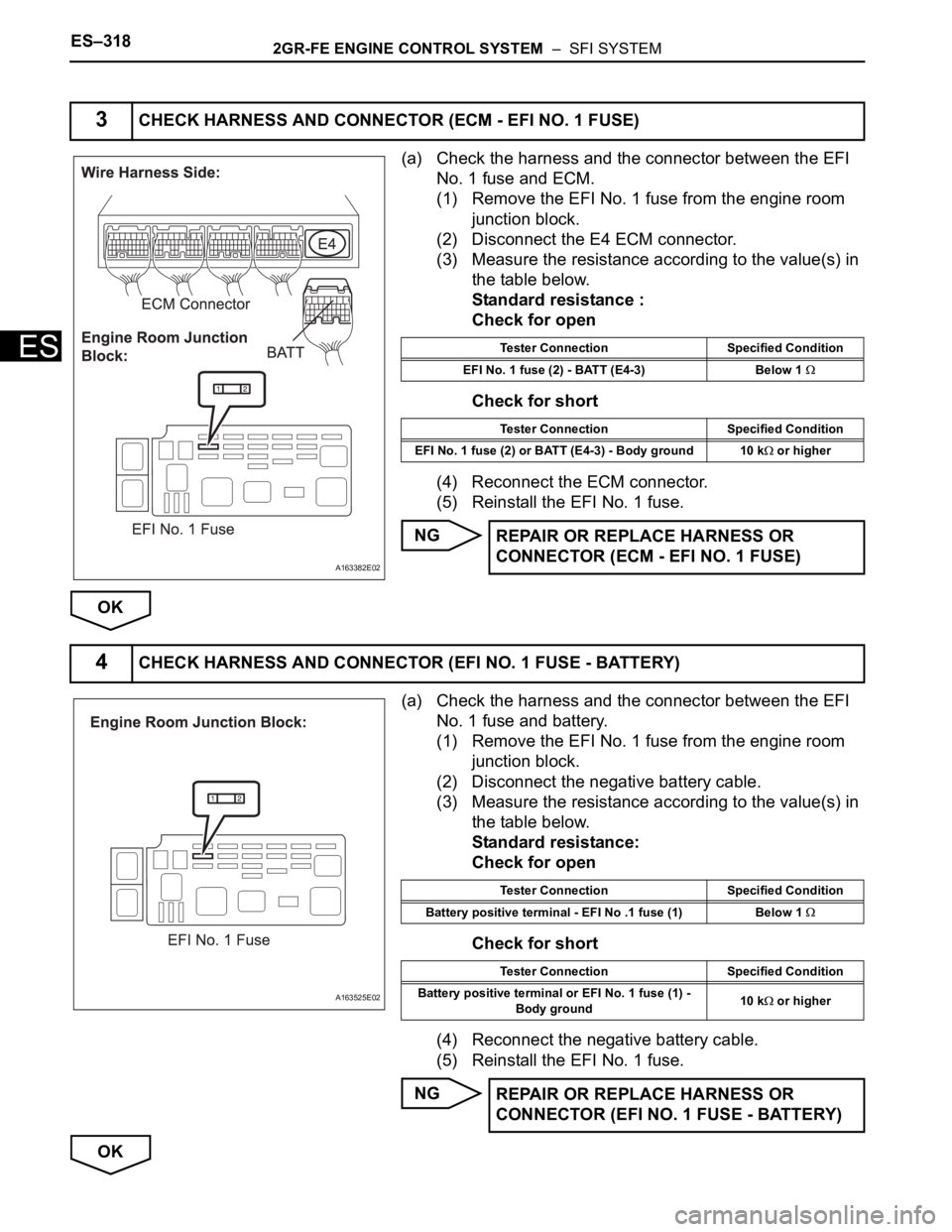

(a) Check the harness and the connector between the EFI

No. 1 fuse and ECM.

(1) Remove the EFI No. 1 fuse from the engine room

junction block.

(2) Disconnect the E4 ECM connector.

(3) Measure the resistance according to the value(s) in

the table below.

Standard resistance :

Check for open

Check for short

(4) Reconnect the ECM connector.

(5) Reinstall the EFI No. 1 fuse.

NG

OK

(a) Check the harness and the connector between the EFI

No. 1 fuse and battery.

(1) Remove the EFI No. 1 fuse from the engine room

junction block.

(2) Disconnect the negative battery cable.

(3) Measure the resistance according to the value(s) in

the table below.

Standard resistance:

Check for open

Check for short

(4) Reconnect the negative battery cable.

(5) Reinstall the EFI No. 1 fuse.

NG

OK

3CHECK HARNESS AND CONNECTOR (ECM - EFI NO. 1 FUSE)

A163382E02

Tester Connection Specified Condition

EFI No. 1 fuse (2) - BATT (E4-3) Below 1

Tester Connection Specified Condition

EFI No. 1 fuse (2) or BATT (E4-3) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (ECM - EFI NO. 1 FUSE)

4CHECK HARNESS AND CONNECTOR (EFI NO. 1 FUSE - BATTERY)

A163525E02

Tester Connection Specified Condition

Battery positive terminal - EFI No .1 fuse (1) Below 1

Tester Connection Specified Condition

Battery positive terminal or EFI No. 1 fuse (1) -

Body ground10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (EFI NO. 1 FUSE - BATTERY)

Page 637 of 3000

ES–3442GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

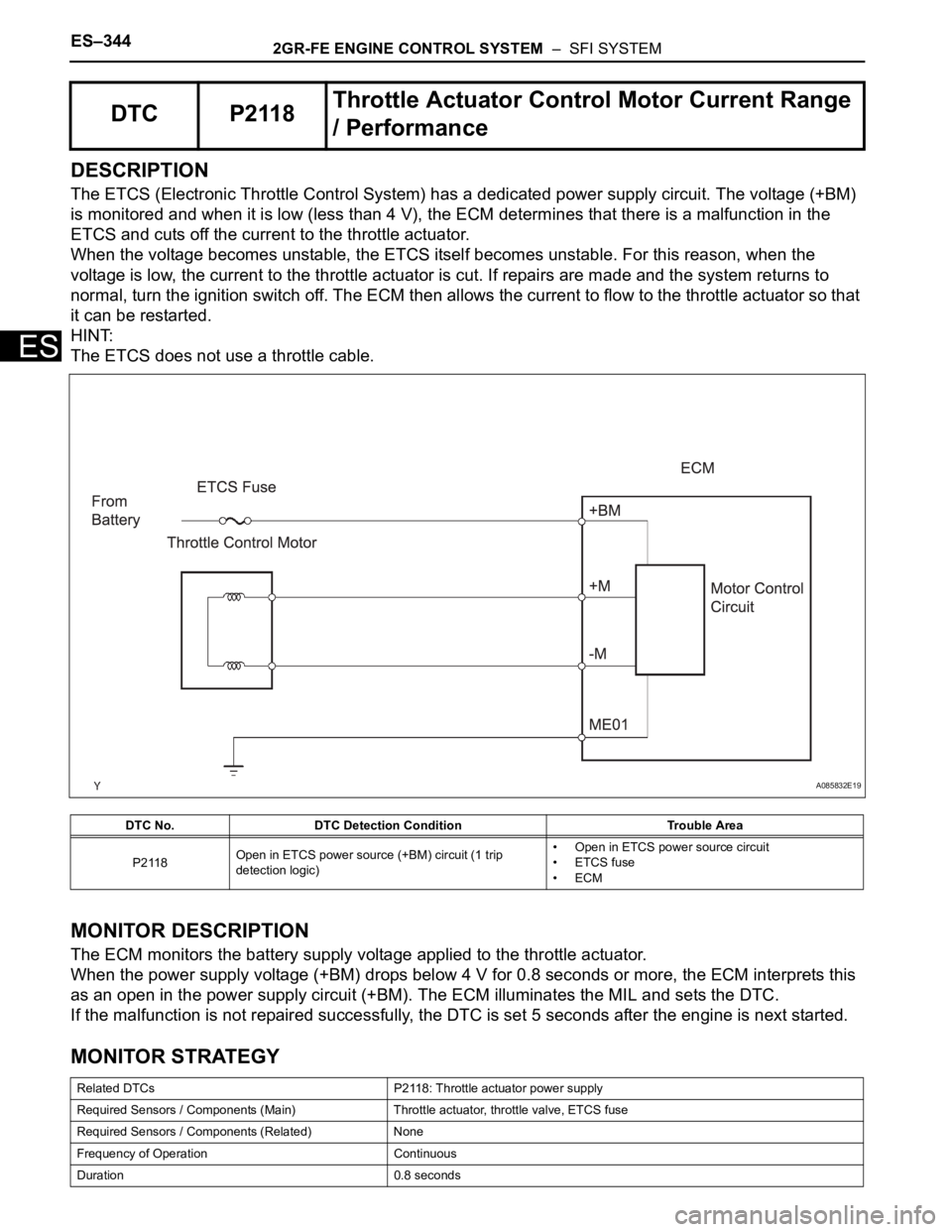

DESCRIPTION

The ETCS (Electronic Throttle Control System) has a dedicated power supply circuit. The voltage (+BM)

is monitored and when it is low (less than 4 V), the ECM determines that there is a malfunction in the

ETCS and cuts off the current to the throttle actuator.

When the voltage becomes unstable, the ETCS itself becomes unstable. For this reason, when the

voltage is low, the current to the throttle actuator is cut. If repairs are made and the system returns to

normal, turn the ignition switch off. The ECM then allows the current to flow to the throttle actuator so that

it can be restarted.

HINT:

The ETCS does not use a throttle cable.

MONITOR DESCRIPTION

The ECM monitors the battery supply voltage applied to the throttle actuator.

When the power supply voltage (+BM) drops below 4 V for 0.8 seconds or more, the ECM interprets this

as an open in the power supply circuit (+BM). The ECM illuminates the MIL and sets the DTC.

If the malfunction is not repaired successfully, the DTC is set 5 seconds after the engine is next started.

MONITOR STRATEGY

DTC P2118Throttle Actuator Control Motor Current Range

/ Performance

DTC No. DTC Detection Condition Trouble Area

P2118Open in ETCS power source (+BM) circuit (1 trip

detection logic)• Open in ETCS power source circuit

• ETCS fuse

•ECM

Related DTCs P2118: Throttle actuator power supply

Required Sensors / Components (Main) Throttle actuator, throttle valve, ETCS fuse

Required Sensors / Components (Related) None

Frequency of Operation Continuous

Duration 0.8 seconds

A085832E19

Page 639 of 3000

ES–3462GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

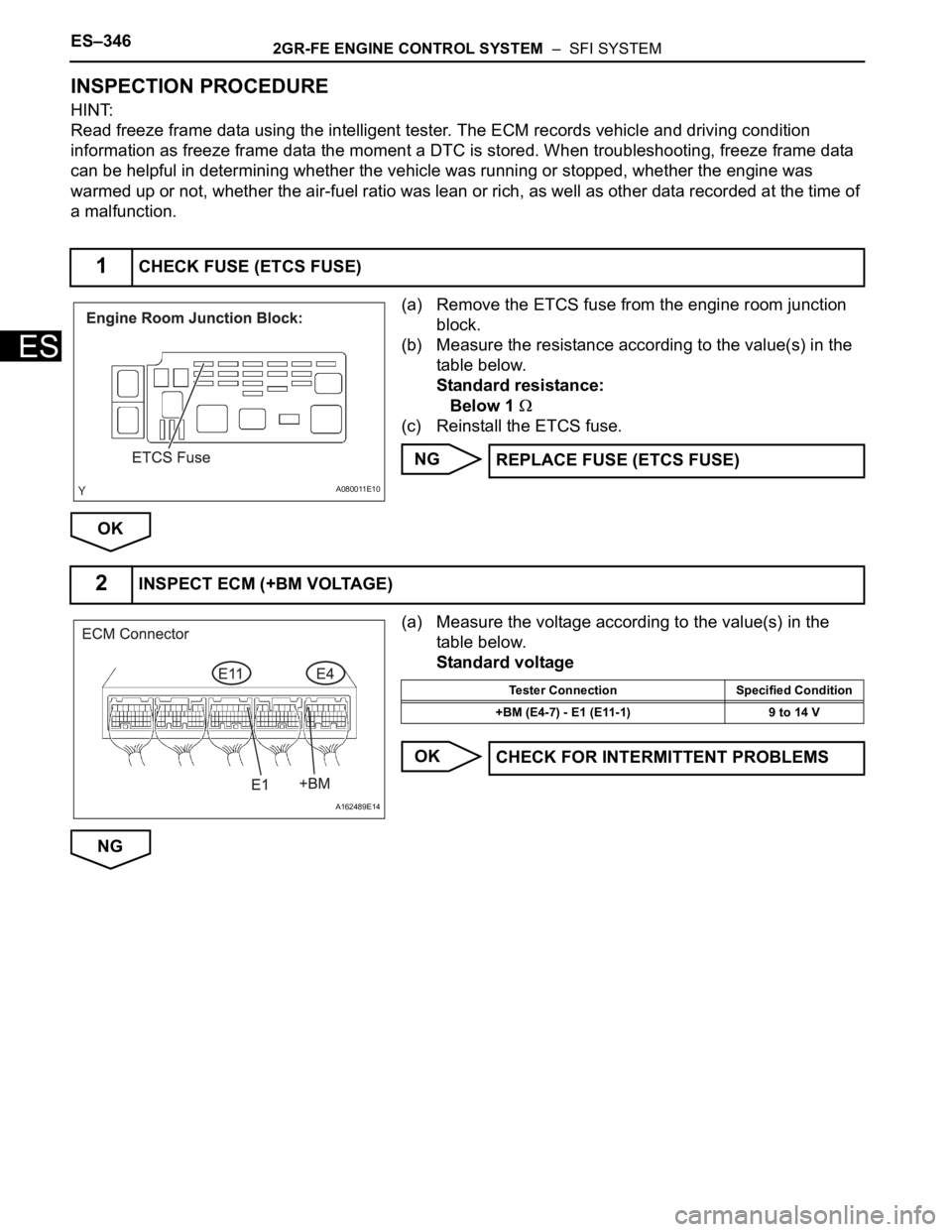

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

(a) Remove the ETCS fuse from the engine room junction

block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Below 1

(c) Reinstall the ETCS fuse.

NG

OK

(a) Measure the voltage according to the value(s) in the

table below.

Standard voltage

OK

NG

1CHECK FUSE (ETCS FUSE)

A080011E10

REPLACE FUSE (ETCS FUSE)

2INSPECT ECM (+BM VOLTAGE)

A162489E14

Tester Connection Specified Condition

+BM (E4-7) - E1 (E11-1) 9 to 14 V

CHECK FOR INTERMITTENT PROBLEMS

Page 640 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–347

ES

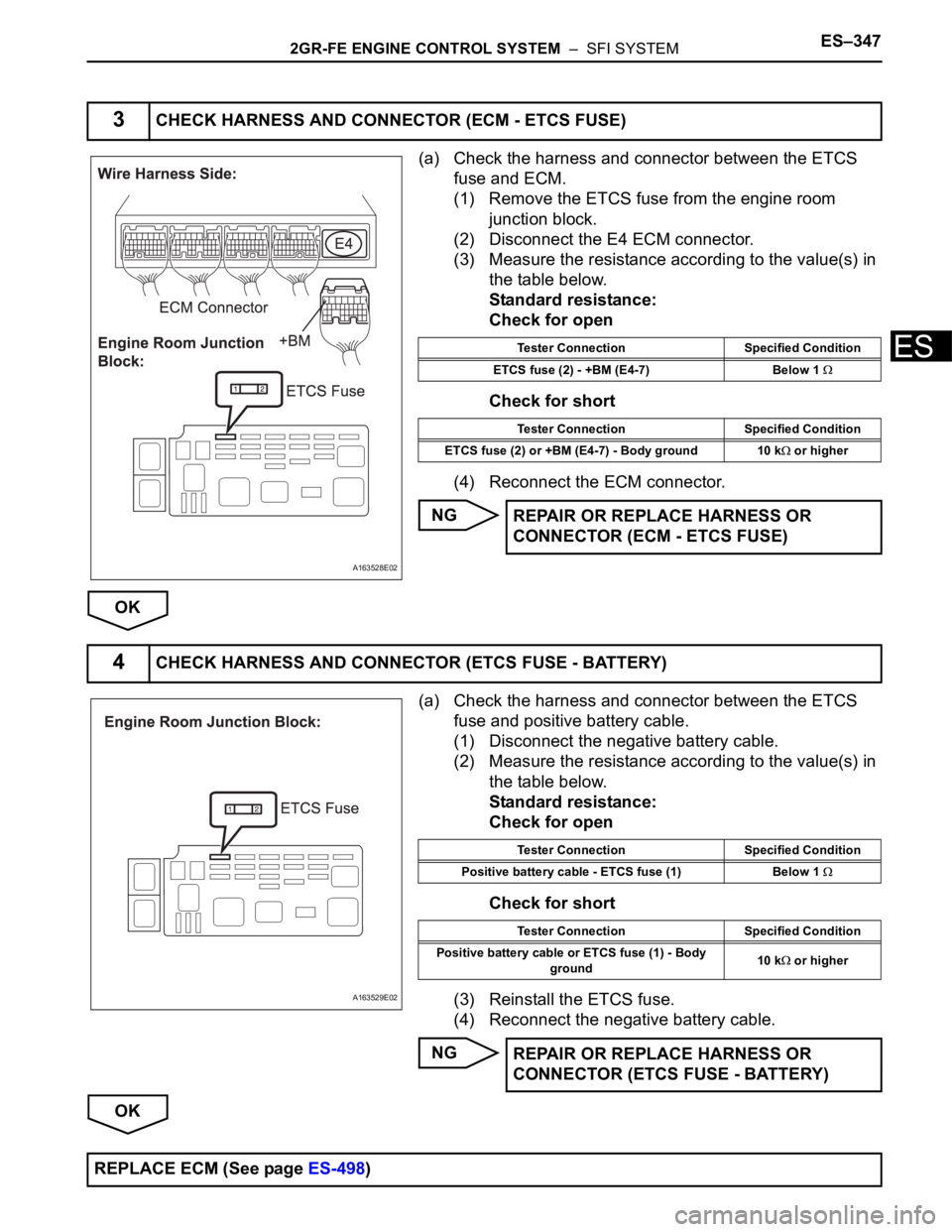

(a) Check the harness and connector between the ETCS

fuse and ECM.

(1) Remove the ETCS fuse from the engine room

junction block.

(2) Disconnect the E4 ECM connector.

(3) Measure the resistance according to the value(s) in

the table below.

Standard resistance:

Check for open

Check for short

(4) Reconnect the ECM connector.

NG

OK

(a) Check the harness and connector between the ETCS

fuse and positive battery cable.

(1) Disconnect the negative battery cable.

(2) Measure the resistance according to the value(s) in

the table below.

Standard resistance:

Check for open

Check for short

(3) Reinstall the ETCS fuse.

(4) Reconnect the negative battery cable.

NG

OK

3CHECK HARNESS AND CONNECTOR (ECM - ETCS FUSE)

A163528E02

Tester Connection Specified Condition

ETCS fuse (2) - +BM (E4-7) Below 1

Tester Connection Specified Condition

ETCS fuse (2) or +BM (E4-7) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (ECM - ETCS FUSE)

4CHECK HARNESS AND CONNECTOR (ETCS FUSE - BATTERY)

A163529E02

Tester Connection Specified Condition

Positive battery cable - ETCS fuse (1) Below 1

Tester Connection Specified Condition

Positive battery cable or ETCS fuse (1) - Body

ground10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (ETCS FUSE - BATTERY)

REPLACE ECM (See page ES-498)