TOYOTA SIENNA 2007 Service Repair Manual

SIENNA 2007

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57466/w960_57466-0.png

TOYOTA SIENNA 2007 Service Repair Manual

Trending: Trans, radio, fuse box, height, ignition, coolant, sensor

Page 201 of 3000

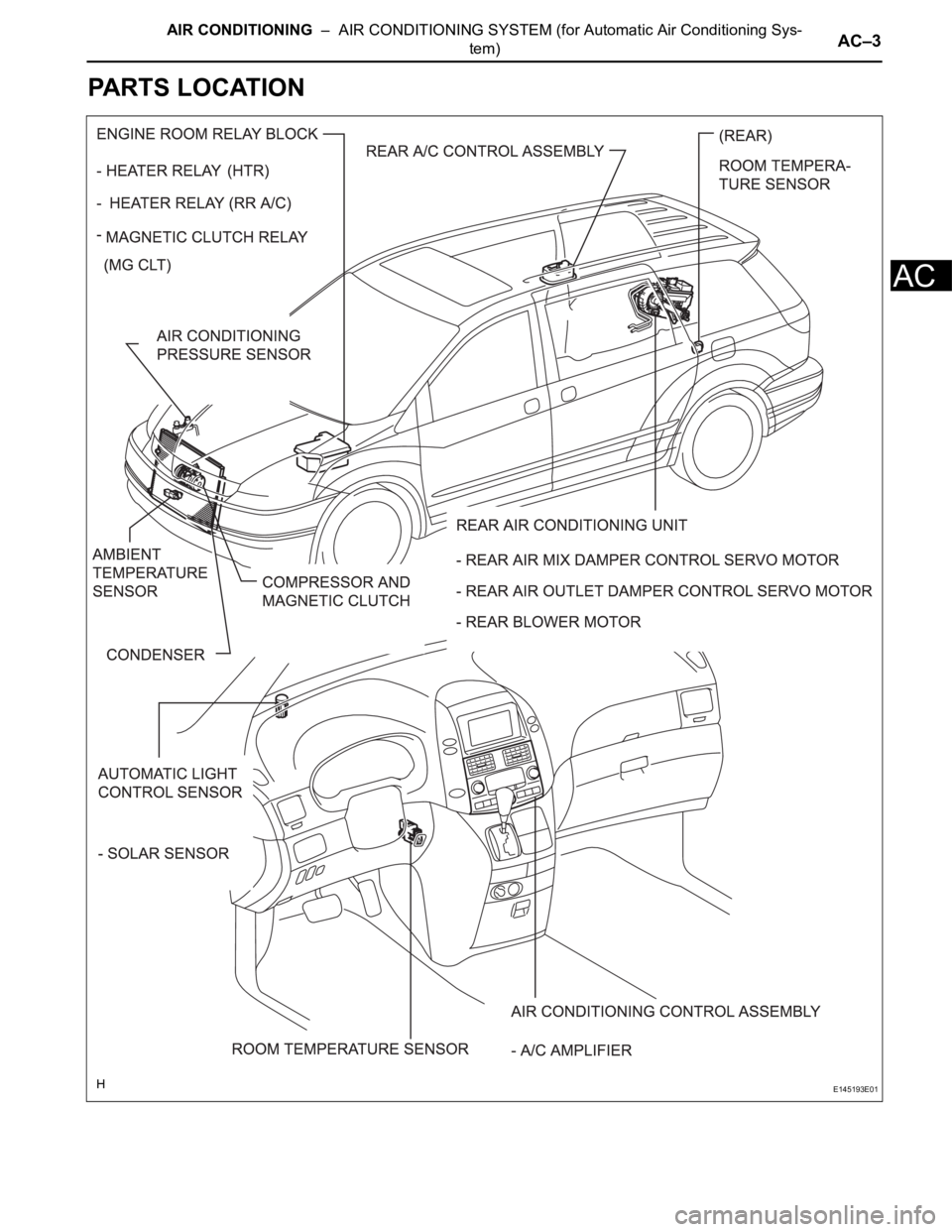

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–3

AC

PARTS LOCATION

E145193E01

Page 202 of 3000

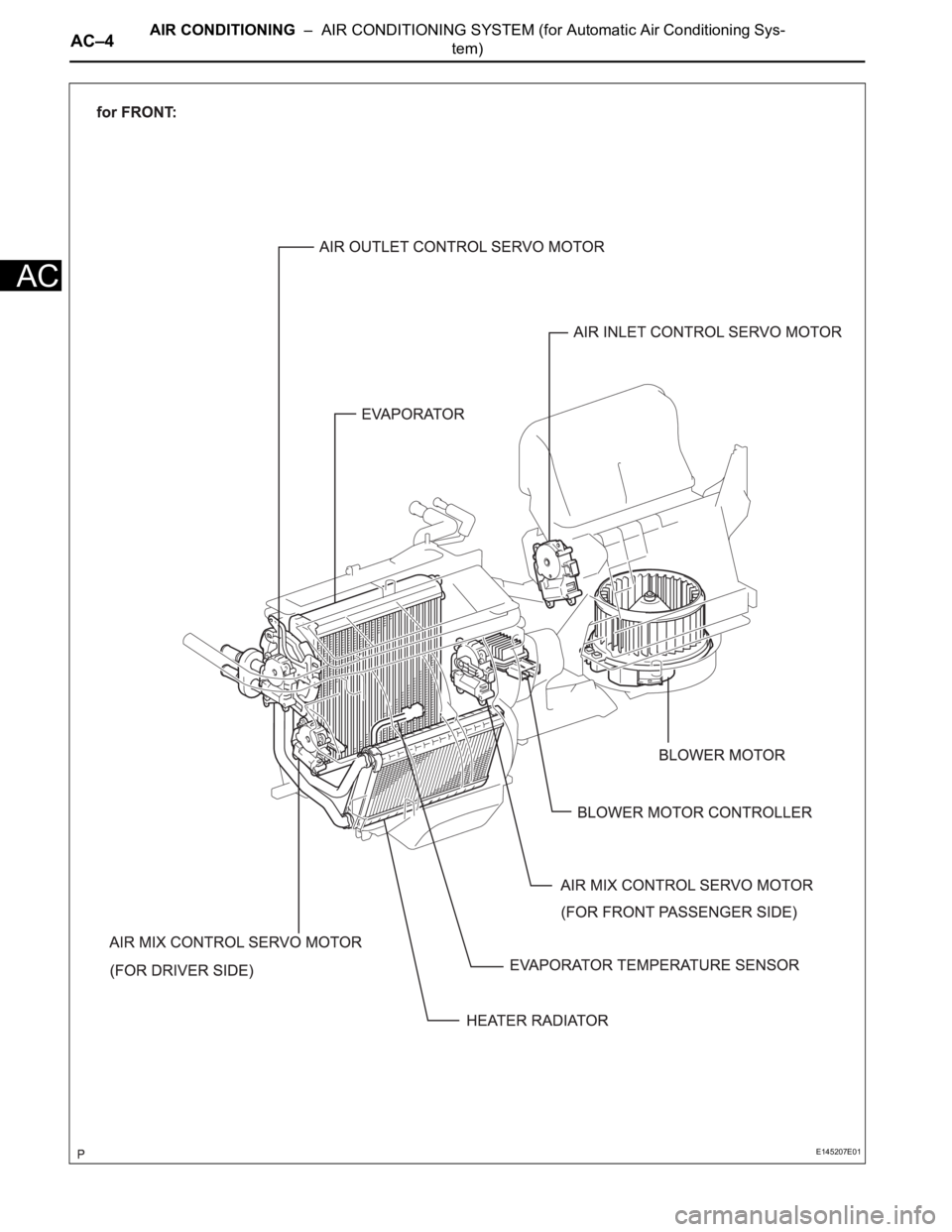

AC–4AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

E145207E01

Page 203 of 3000

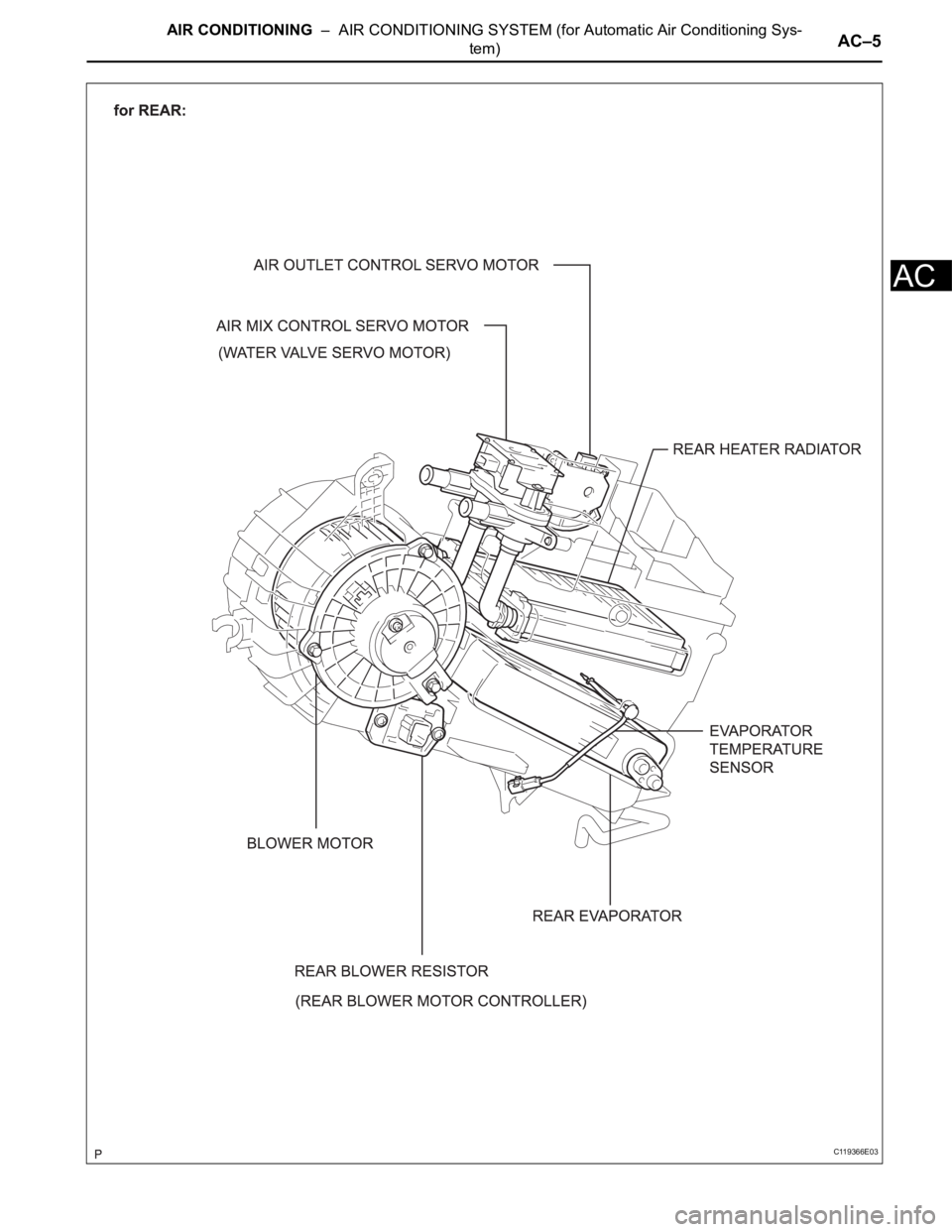

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–5

AC

C119366E03

Page 204 of 3000

AIR CONDITIONING – COMPRESSOR AND MAGNETIC CLUTCHAC–227

AC

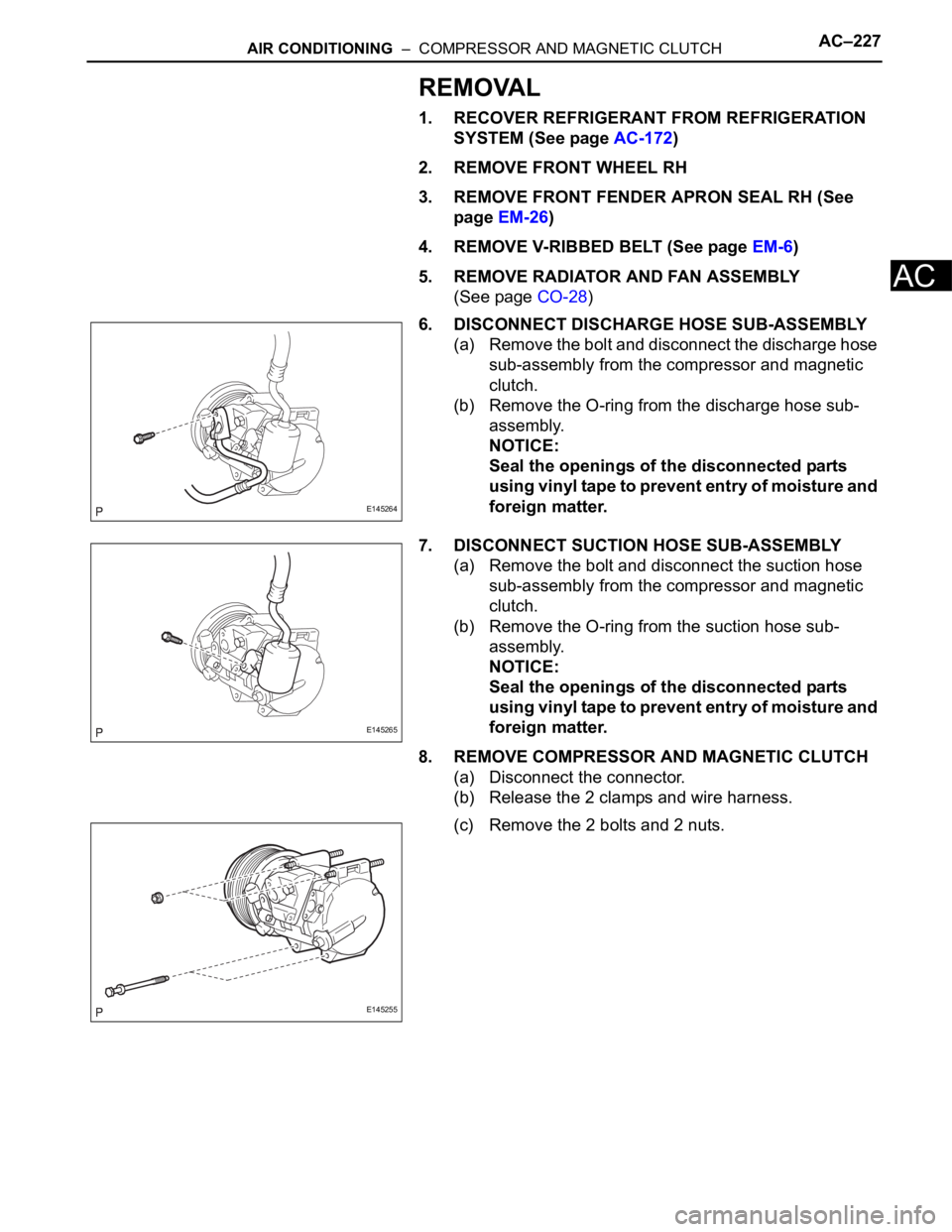

REMOVAL

1. RECOVER REFRIGERANT FROM REFRIGERATION

SYSTEM (See page AC-172)

2. REMOVE FRONT WHEEL RH

3. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

4. REMOVE V-RIBBED BELT (See page EM-6)

5. REMOVE RADIATOR AND FAN ASSEMBLY

(See page CO-28)

6. DISCONNECT DISCHARGE HOSE SUB-ASSEMBLY

(a) Remove the bolt and disconnect the discharge hose

sub-assembly from the compressor and magnetic

clutch.

(b) Remove the O-ring from the discharge hose sub-

assembly.

NOTICE:

Seal the openings of the disconnected parts

using vinyl tape to prevent entry of moisture and

foreign matter.

7. DISCONNECT SUCTION HOSE SUB-ASSEMBLY

(a) Remove the bolt and disconnect the suction hose

sub-assembly from the compressor and magnetic

clutch.

(b) Remove the O-ring from the suction hose sub-

assembly.

NOTICE:

Seal the openings of the disconnected parts

using vinyl tape to prevent entry of moisture and

foreign matter.

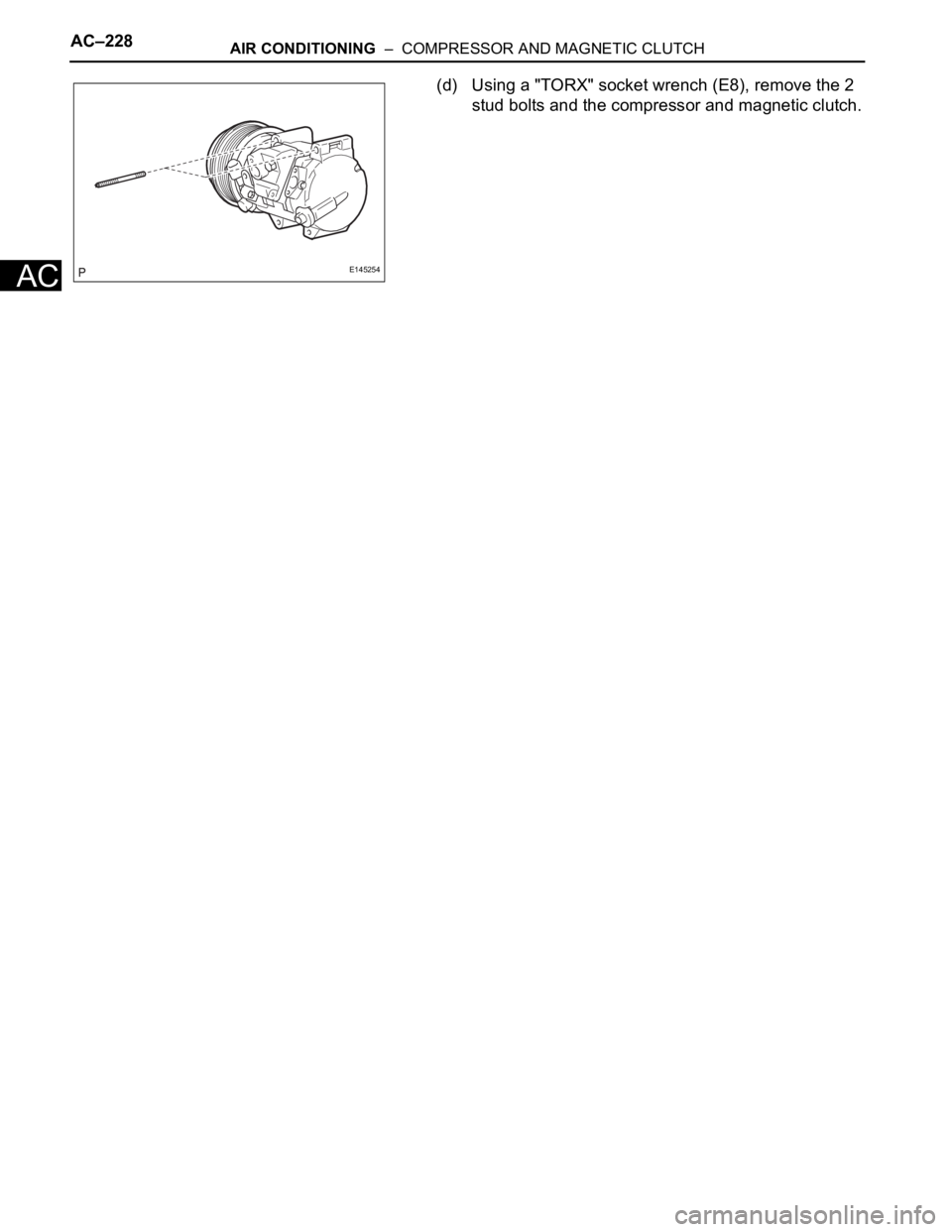

8. REMOVE COMPRESSOR AND MAGNETIC CLUTCH

(a) Disconnect the connector.

(b) Release the 2 clamps and wire harness.

(c) Remove the 2 bolts and 2 nuts.

E145264

E145265

E145255

Page 205 of 3000

AC–228AIR CONDITIONING – COMPRESSOR AND MAGNETIC CLUTCH

AC

(d) Using a "TORX" socket wrench (E8), remove the 2

stud bolts and the compressor and magnetic clutch.

E145254

Page 206 of 3000

AC–236AIR CONDITIONING – CONDENSER

AC

ON-VEHICLE INSPECTION

1. INSPECT COOLER CONDENSER CORE

(a) If the fin of the cooler condenser core is dirty, clean

it with water and dry it with compressed air.

NOTICE:

Do not damage the fin of the cooler condenser

core.

(b) If the fin of the cooler condenser core is bent, make

it straight using a screwdriver or pliers.

2. INSPECT CONDENSER FOR LEAKAGE OF

REFRIGERANT

(a) Using a halogen leak detector, check the pipe joints

for gas leakage.

(b) If gas leakage is detected in a joint, check the

torque of the joint.

Page 207 of 3000

AIR CONDITIONING – CONDENSERAC–237

AC

REMOVAL

1. RECOVER REFRIGERANT FROM REFRIGERATION

SYSTEM (See page AC-172)

2. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

3. REMOVE FRONT BUMPER ASSEMBLY (See page

ET-3)

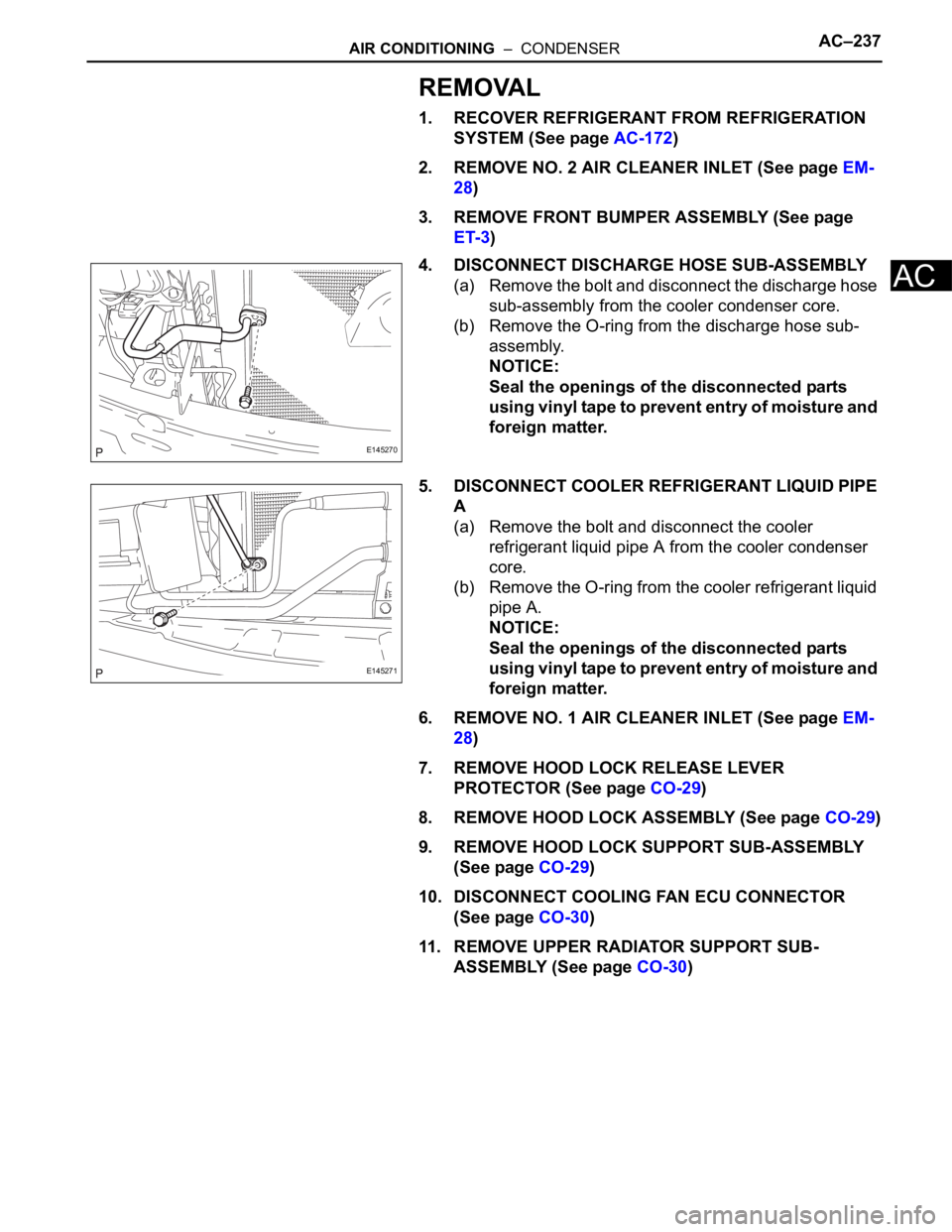

4. DISCONNECT DISCHARGE HOSE SUB-ASSEMBLY

(a) Remove the bolt and disconnect the discharge hose

sub-assembly from the cooler condenser core.

(b) Remove the O-ring from the discharge hose sub-

assembly.

NOTICE:

Seal the openings of the disconnected parts

using vinyl tape to prevent entry of moisture and

foreign matter.

5. DISCONNECT COOLER REFRIGERANT LIQUID PIPE

A

(a) Remove the bolt and disconnect the cooler

refrigerant liquid pipe A from the cooler condenser

core.

(b) Remove the O-ring from the cooler refrigerant liquid

pipe A.

NOTICE:

Seal the openings of the disconnected parts

using vinyl tape to prevent entry of moisture and

foreign matter.

6. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

7. REMOVE HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-29)

8. REMOVE HOOD LOCK ASSEMBLY (See page CO-29)

9. REMOVE HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-29)

10. DISCONNECT COOLING FAN ECU CONNECTOR

(See page CO-30)

11. REMOVE UPPER RADIATOR SUPPORT SUB-

ASSEMBLY (See page CO-30)

E145270

E145271

Page 208 of 3000

AC–238AIR CONDITIONING – CONDENSER

AC

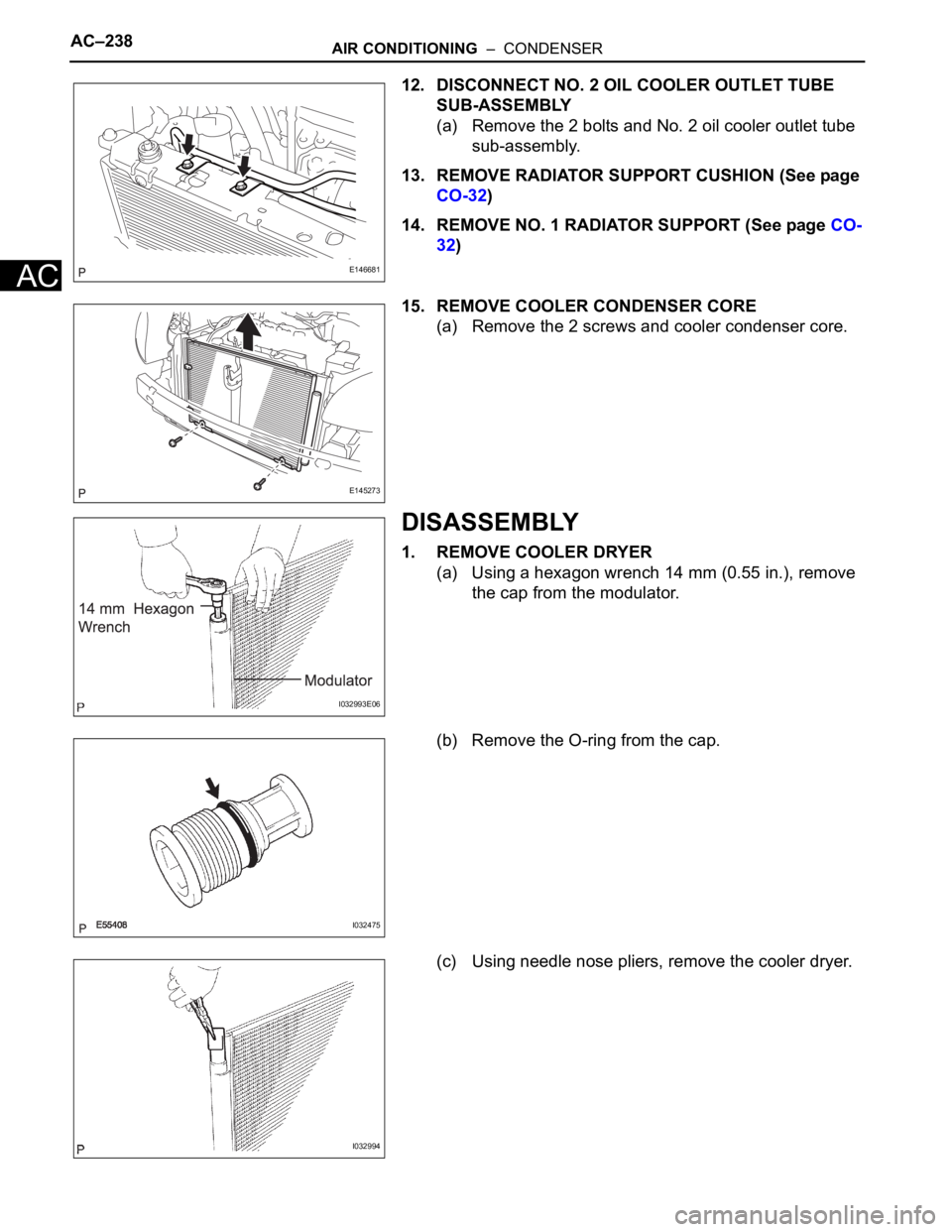

12. DISCONNECT NO. 2 OIL COOLER OUTLET TUBE

SUB-ASSEMBLY

(a) Remove the 2 bolts and No. 2 oil cooler outlet tube

sub-assembly.

13. REMOVE RADIATOR SUPPORT CUSHION (See page

CO-32)

14. REMOVE NO. 1 RADIATOR SUPPORT (See page CO-

32)

15. REMOVE COOLER CONDENSER CORE

(a) Remove the 2 screws and cooler condenser core.

DISASSEMBLY

1. REMOVE COOLER DRYER

(a) Using a hexagon wrench 14 mm (0.55 in.), remove

the cap from the modulator.

(b) Remove the O-ring from the cap.

(c) Using needle nose pliers, remove the cooler dryer.

E146681

E145273

I032993E06

I032475

I032994

Page 209 of 3000

AIR CONDITIONING – CONDENSERAC–239

AC

REASSEMBLY

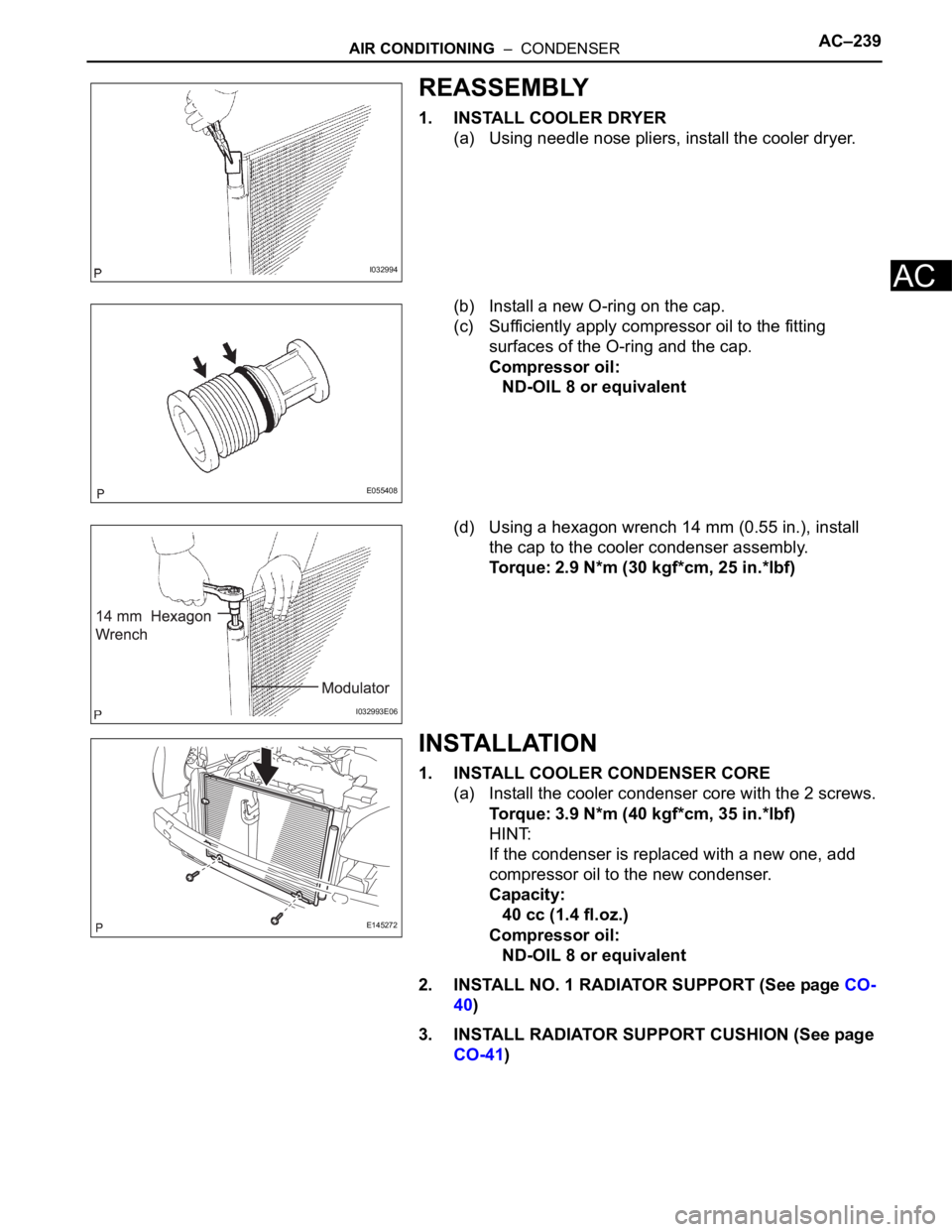

1. INSTALL COOLER DRYER

(a) Using needle nose pliers, install the cooler dryer.

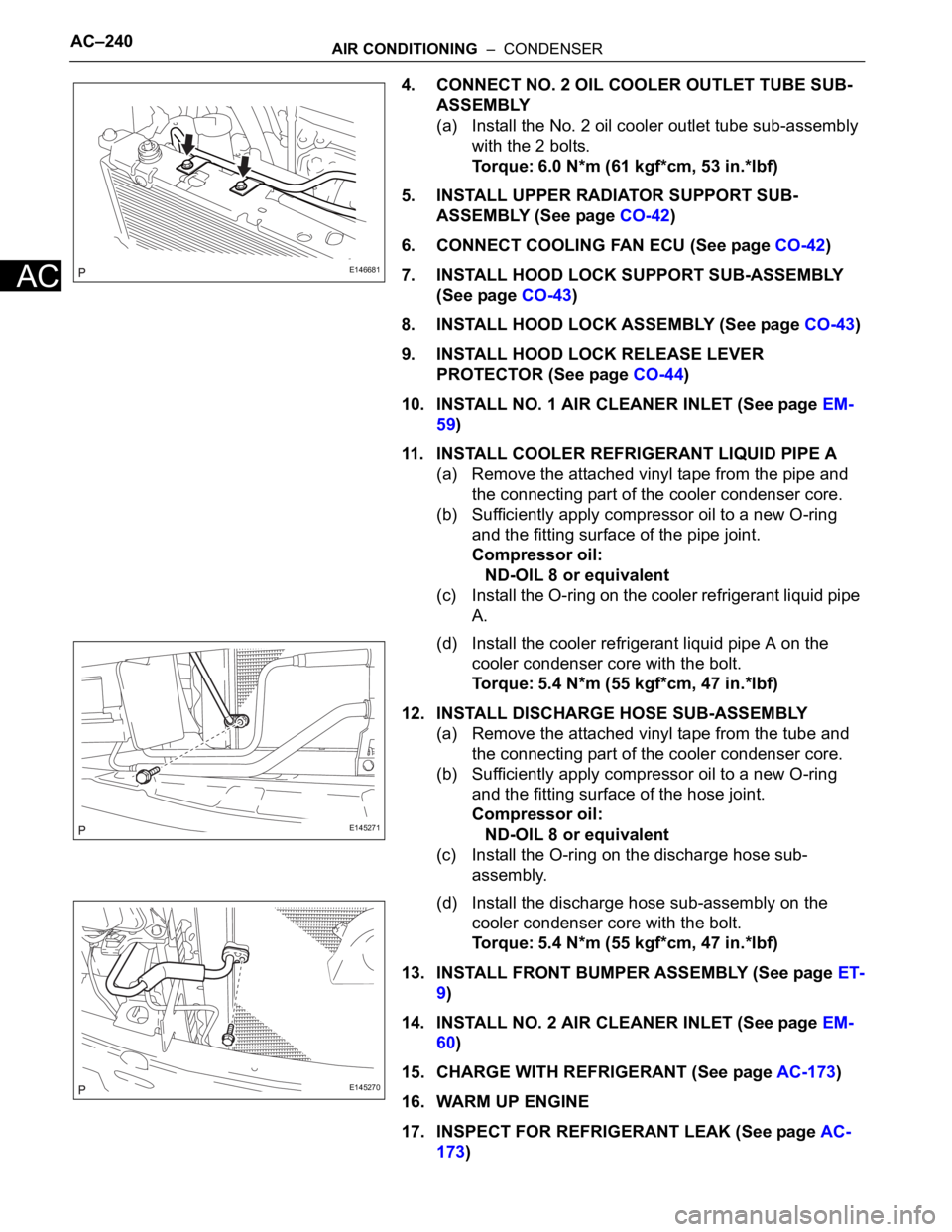

(b) Install a new O-ring on the cap.

(c) Sufficiently apply compressor oil to the fitting

surfaces of the O-ring and the cap.

Compressor oil:

ND-OIL 8 or equivalent

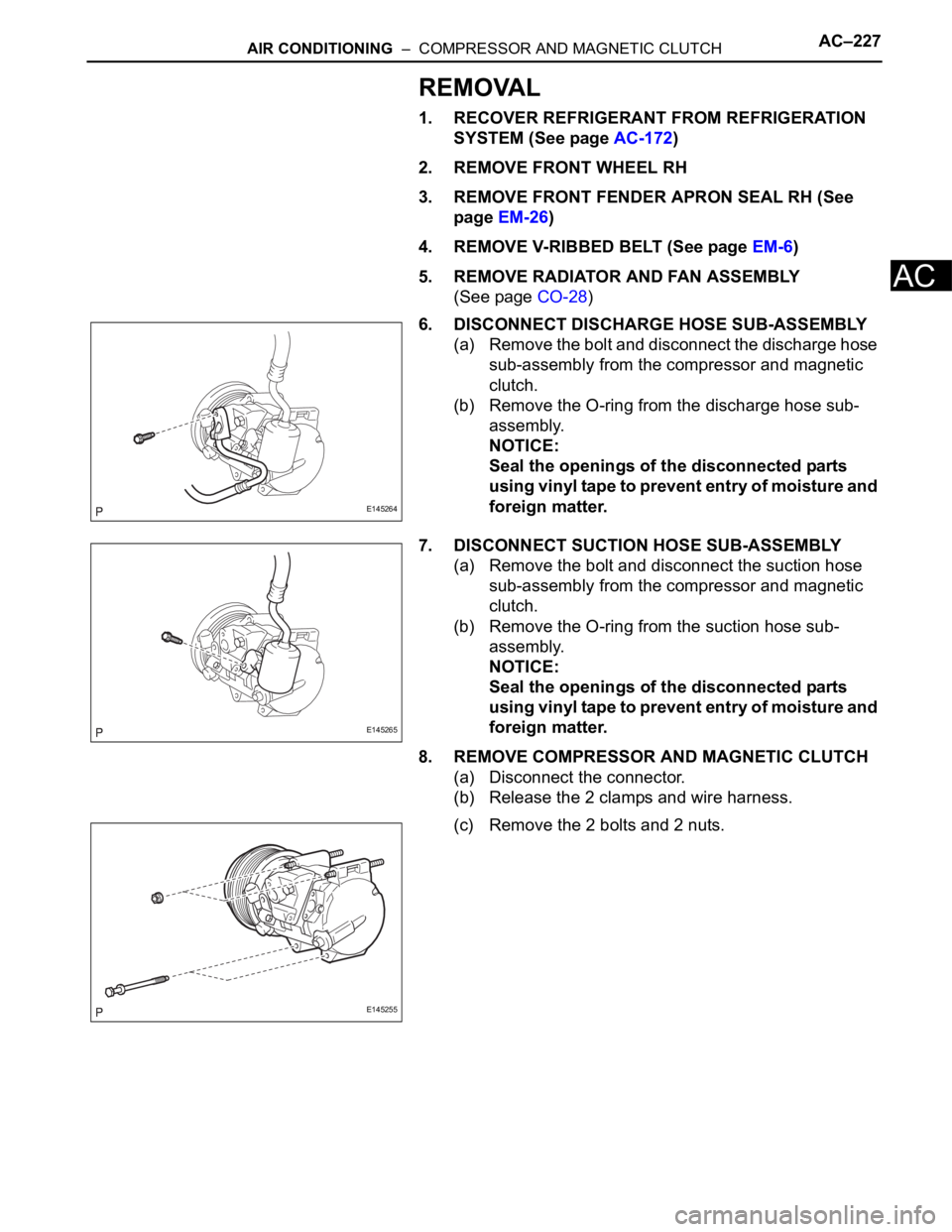

(d) Using a hexagon wrench 14 mm (0.55 in.), install

the cap to the cooler condenser assembly.

Torque: 2.9 N*m (30 kgf*cm, 25 in.*lbf)

INSTALLATION

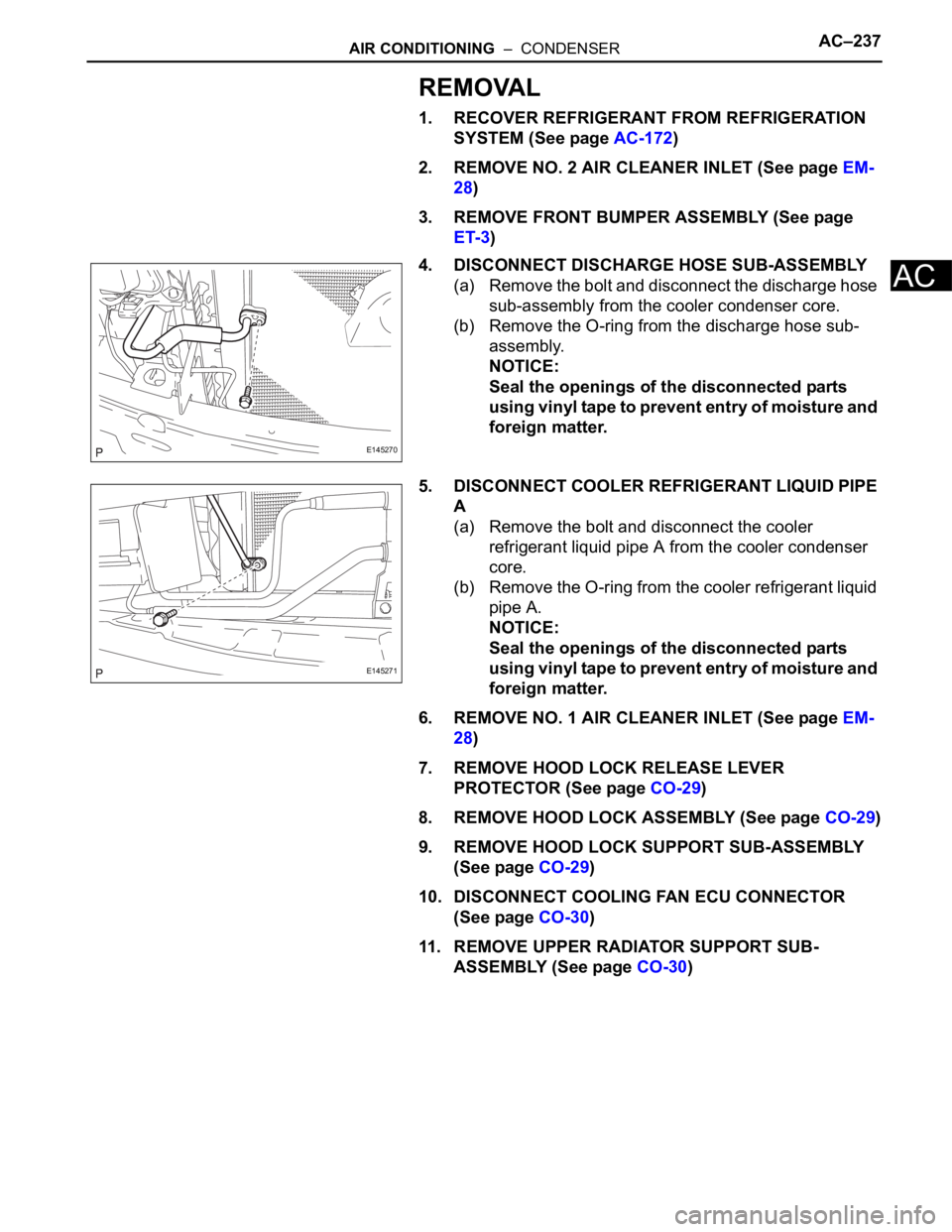

1. INSTALL COOLER CONDENSER CORE

(a) Install the cooler condenser core with the 2 screws.

Torque: 3.9 N*m (40 kgf*cm, 35 in.*lbf)

HINT:

If the condenser is replaced with a new one, add

compressor oil to the new condenser.

Capacity:

40 cc (1.4 fl.oz.)

Compressor oil:

ND-OIL 8 or equivalent

2. INSTALL NO. 1 RADIATOR SUPPORT (See page CO-

40)

3. INSTALL RADIATOR SUPPORT CUSHION (See page

CO-41)

I032994

E055408

I032993E06

E145272

Page 210 of 3000

AC–240AIR CONDITIONING – CONDENSER

AC

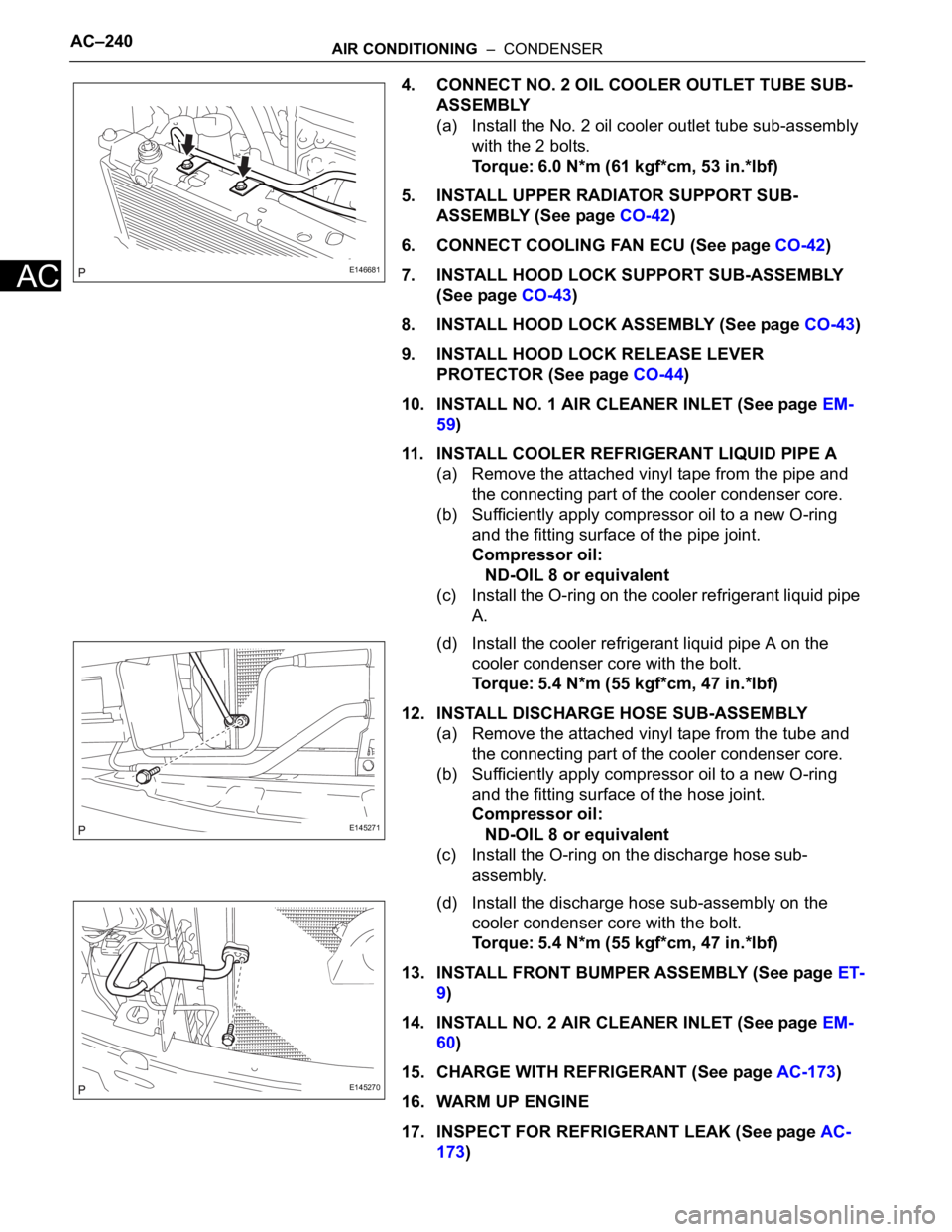

4. CONNECT NO. 2 OIL COOLER OUTLET TUBE SUB-

ASSEMBLY

(a) Install the No. 2 oil cooler outlet tube sub-assembly

with the 2 bolts.

Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

5. INSTALL UPPER RADIATOR SUPPORT SUB-

ASSEMBLY (See page CO-42)

6. CONNECT COOLING FAN ECU (See page CO-42)

7. INSTALL HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-43)

8. INSTALL HOOD LOCK ASSEMBLY (See page CO-43)

9. INSTALL HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-44)

10. INSTALL NO. 1 AIR CLEANER INLET (See page EM-

59)

11. INSTALL COOLER REFRIGERANT LIQUID PIPE A

(a) Remove the attached vinyl tape from the pipe and

the connecting part of the cooler condenser core.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the pipe joint.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant liquid pipe

A.

(d) Install the cooler refrigerant liquid pipe A on the

cooler condenser core with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 47 in.*lbf)

12. INSTALL DISCHARGE HOSE SUB-ASSEMBLY

(a) Remove the attached vinyl tape from the tube and

the connecting part of the cooler condenser core.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the hose joint.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the discharge hose sub-

assembly.

(d) Install the discharge hose sub-assembly on the

cooler condenser core with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 47 in.*lbf)

13. INSTALL FRONT BUMPER ASSEMBLY (See page ET-

9)

14. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

15. CHARGE WITH REFRIGERANT (See page AC-173)

16. WARM UP ENGINE

17. INSPECT FOR REFRIGERANT LEAK (See page AC-

173)

E146681

E145271

E145270

Trending: maintenance reset, run flat, load capacity, immobilizer system, clock, rear hub, warning light