TOYOTA SIENNA 2007 Service Repair Manual

SIENNA 2007

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57466/w960_57466-0.png

TOYOTA SIENNA 2007 Service Repair Manual

Trending: inflation pressure, lower control arm, maintenance, charging, headlight aiming, open gas tank, oil type

Page 2411 of 3000

BC–50BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

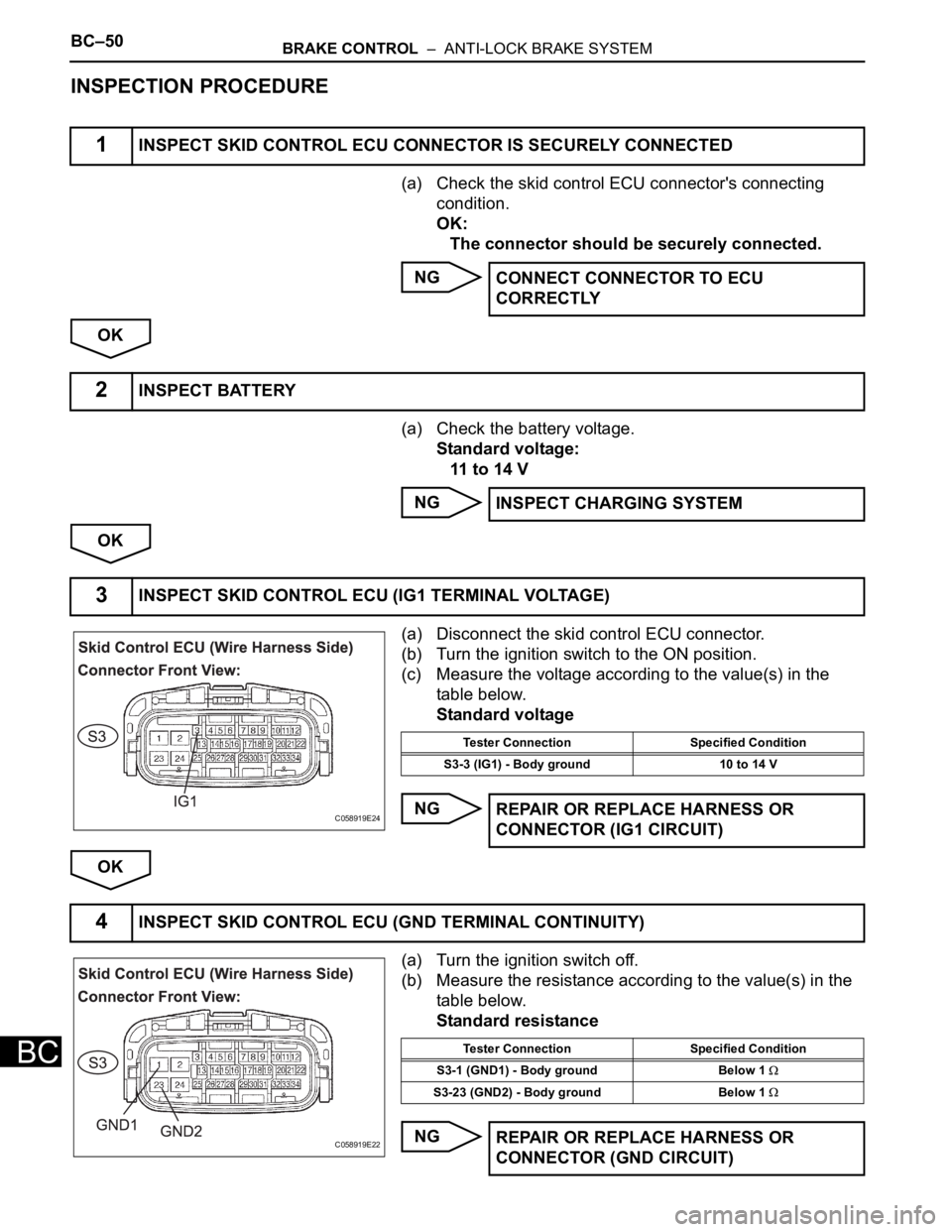

INSPECTION PROCEDURE

(a) Check the skid control ECU connector's connecting

condition.

OK:

The connector should be securely connected.

NG

OK

(a) Check the battery voltage.

Standard voltage:

11 to 14 V

NG

OK

(a) Disconnect the skid control ECU connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

(a) Turn the ignition switch off.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

1INSPECT SKID CONTROL ECU CONNECTOR IS SECURELY CONNECTED

CONNECT CONNECTOR TO ECU

CORRECTLY

2INSPECT BATTERY

INSPECT CHARGING SYSTEM

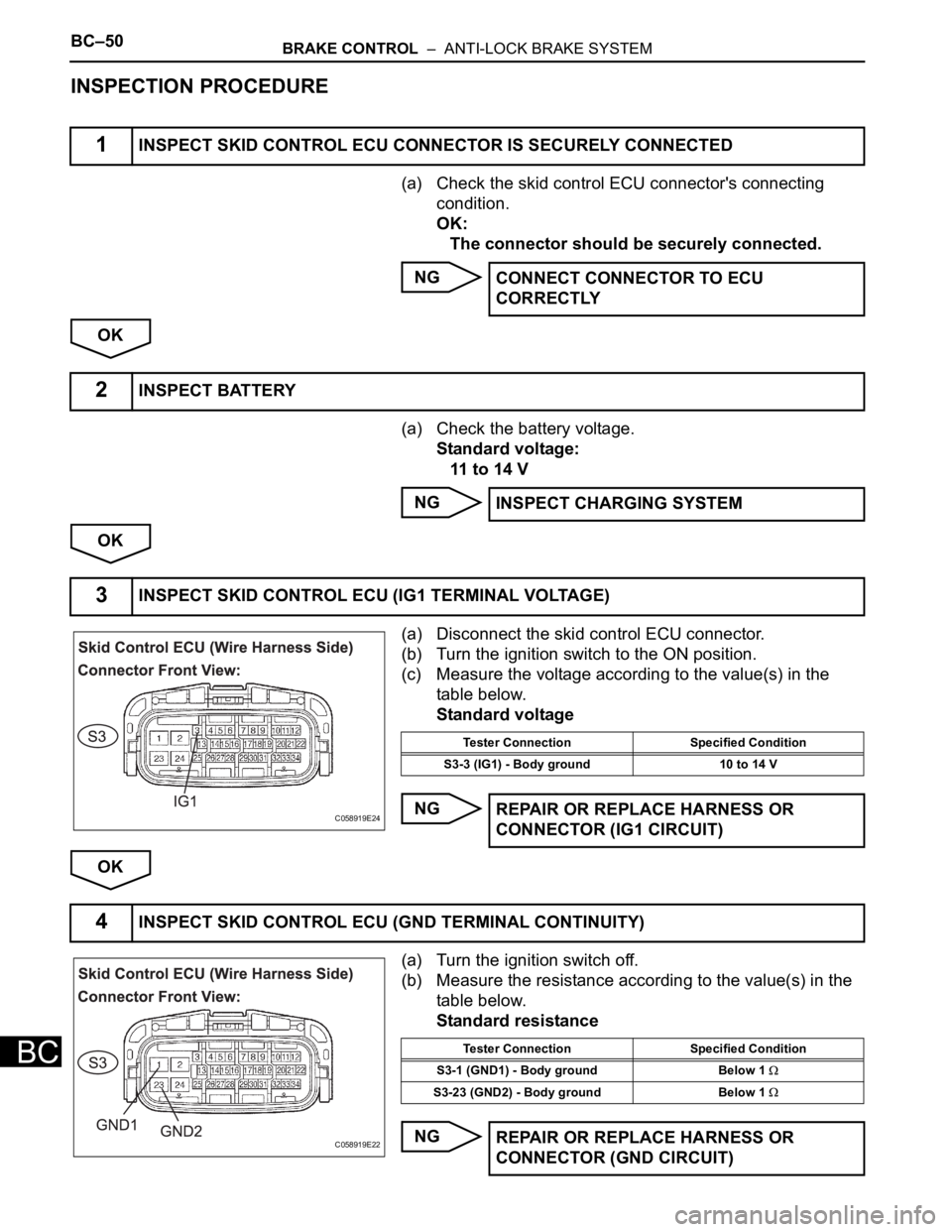

3INSPECT SKID CONTROL ECU (IG1 TERMINAL VOLTAGE)

C058919E24

Tester Connection Specified Condition

S3-3 (IG1) - Body ground 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR (IG1 CIRCUIT)

4INSPECT SKID CONTROL ECU (GND TERMINAL CONTINUITY)

C058919E22

Tester Connection Specified Condition

S3-1 (GND1) - Body ground Below 1

S3-23 (GND2) - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (GND CIRCUIT)

Page 2412 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–51

BC

OK

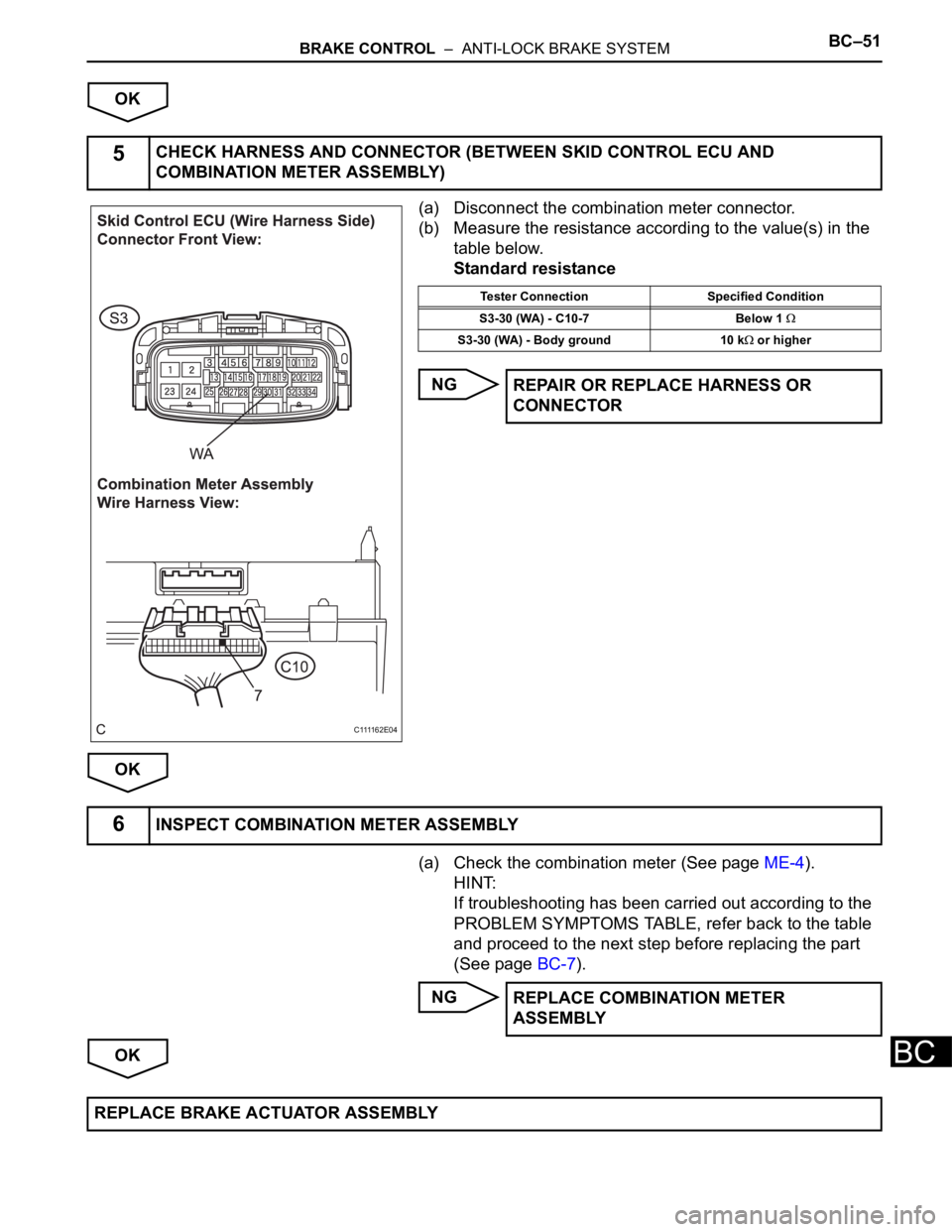

(a) Disconnect the combination meter connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Check the combination meter (See page ME-4).

HINT:

If troubleshooting has been carried out according to the

PROBLEM SYMPTOMS TABLE, refer back to the table

and proceed to the next step before replacing the part

(See page BC-7).

NG

OK

5CHECK HARNESS AND CONNECTOR (BETWEEN SKID CONTROL ECU AND

COMBINATION METER ASSEMBLY)

C 1111 6 2 E 0 4

Tester Connection Specified Condition

S3-30 (WA) - C10-7 Below 1

S3-30 (WA) - Body ground 10 k or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

6INSPECT COMBINATION METER ASSEMBLY

REPLACE COMBINATION METER

ASSEMBLY

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2413 of 3000

BC–52BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

WIRING DIAGRAM

See page BC-47.

INSPECTION PROCEDURE

(a) Disconnect the skid control ECU connector.

(b) Turn the ignition switch to the ON position.

(c) Check that the ABS warning light comes on.

OK:

ABS warning light comes on.

HINT:

If troubleshooting has been carried out according to the

PROBLEM SYMPTOMS TABLE, refer back to the table

and proceed to the next step (See page BC-7).

NG

OK

ABS Warning Light does not Come ON

1INSPECT ABS WARNING LIGHT

Go to step 2

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2414 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–53

BC

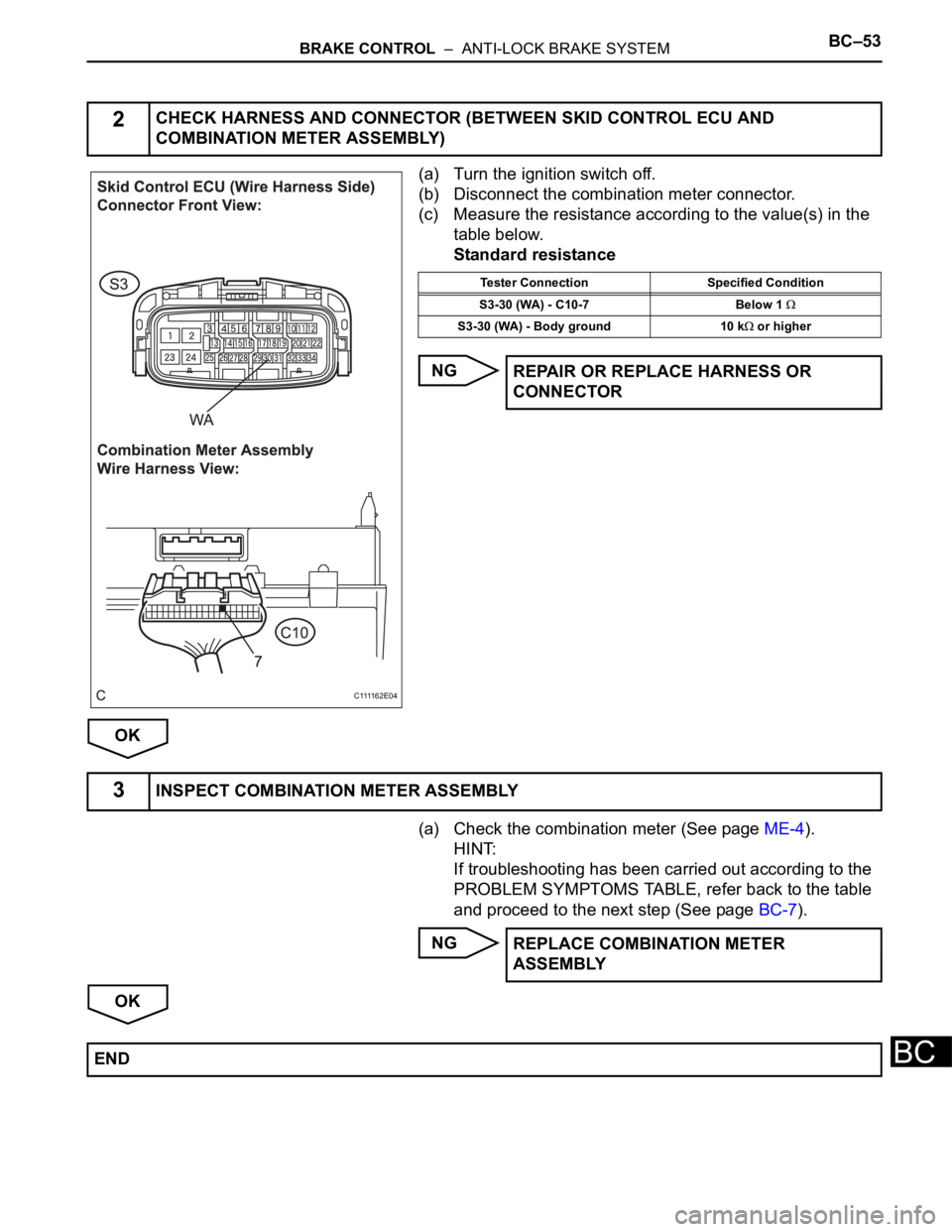

(a) Turn the ignition switch off.

(b) Disconnect the combination meter connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Check the combination meter (See page ME-4).

HINT:

If troubleshooting has been carried out according to the

PROBLEM SYMPTOMS TABLE, refer back to the table

and proceed to the next step (See page BC-7).

NG

OK

2CHECK HARNESS AND CONNECTOR (BETWEEN SKID CONTROL ECU AND

COMBINATION METER ASSEMBLY)

C 1111 6 2 E 0 4

Tester Connection Specified Condition

S3-30 (WA) - C10-7 Below 1

S3-30 (WA) - Body ground 10 k or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

3INSPECT COMBINATION METER ASSEMBLY

REPLACE COMBINATION METER

ASSEMBLY

END

Page 2415 of 3000

BC–54BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

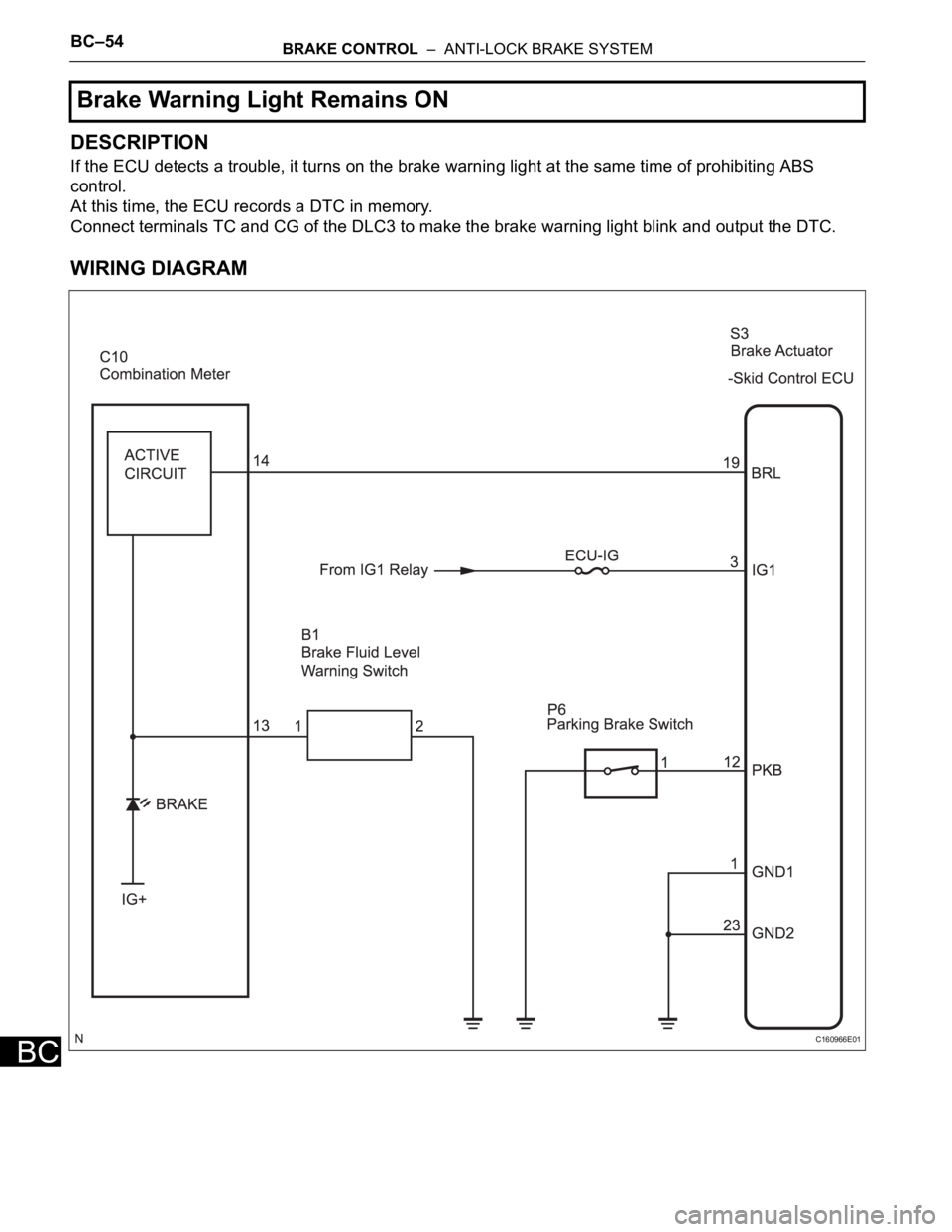

DESCRIPTION

If the ECU detects a trouble, it turns on the brake warning light at the same time of prohibiting ABS

control.

At this time, the ECU records a DTC in memory.

Connect terminals TC and CG of the DLC3 to make the brake warning light blink and output the DTC.

WIRING DIAGRAM

Brake Warning Light Remains ON

C160966E01

Page 2416 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–55

BC

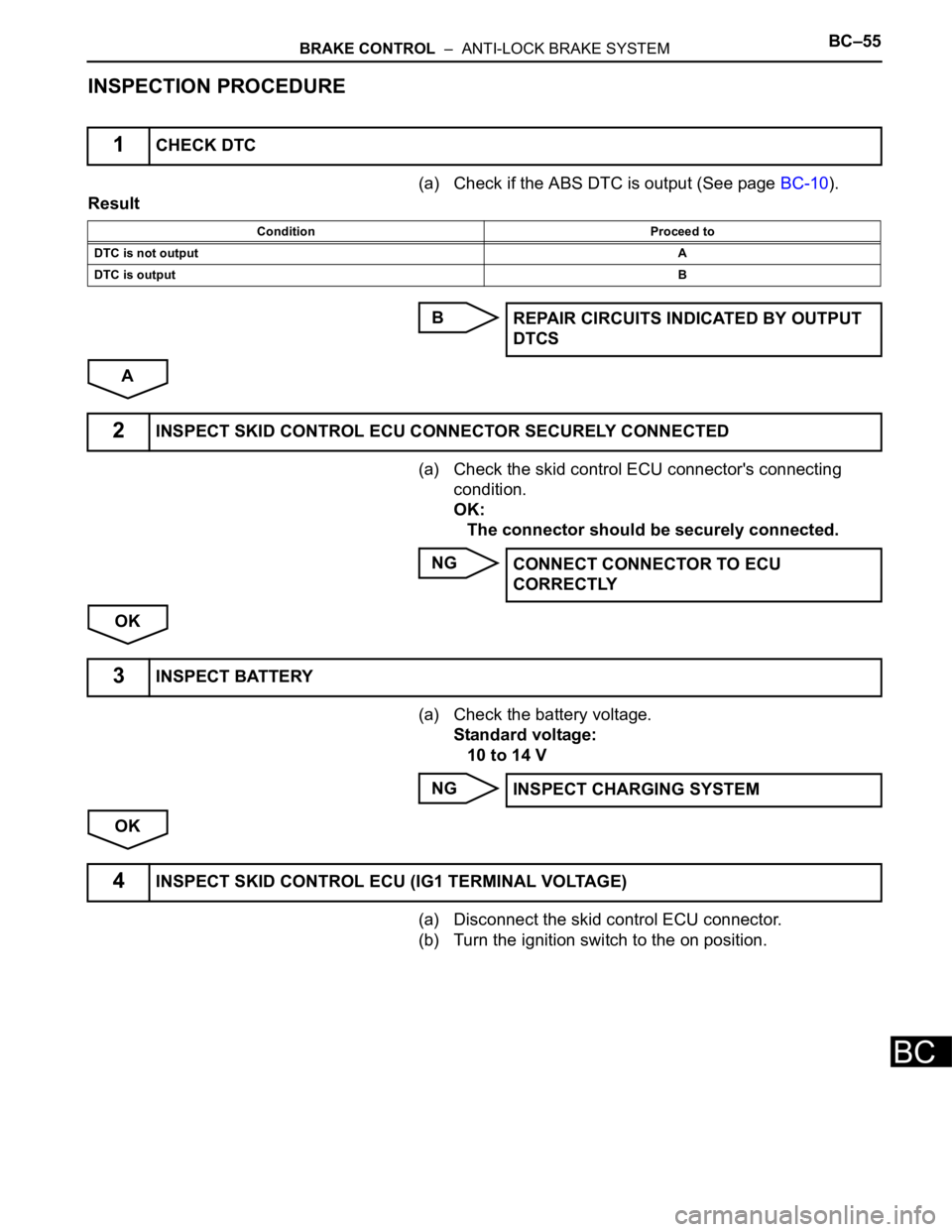

INSPECTION PROCEDURE

(a) Check if the ABS DTC is output (See page BC-10).

Result

B

A

(a) Check the skid control ECU connector's connecting

condition.

OK:

The connector should be securely connected.

NG

OK

(a) Check the battery voltage.

Standard voltage:

10 to 14 V

NG

OK

(a) Disconnect the skid control ECU connector.

(b) Turn the ignition switch to the on position.

1CHECK DTC

Condition Proceed to

DTC is not outputA

DTC is outputB

REPAIR CIRCUITS INDICATED BY OUTPUT

DTCS

2INSPECT SKID CONTROL ECU CONNECTOR SECURELY CONNECTED

CONNECT CONNECTOR TO ECU

CORRECTLY

3INSPECT BATTERY

INSPECT CHARGING SYSTEM

4INSPECT SKID CONTROL ECU (IG1 TERMINAL VOLTAGE)

Page 2417 of 3000

BC–56BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

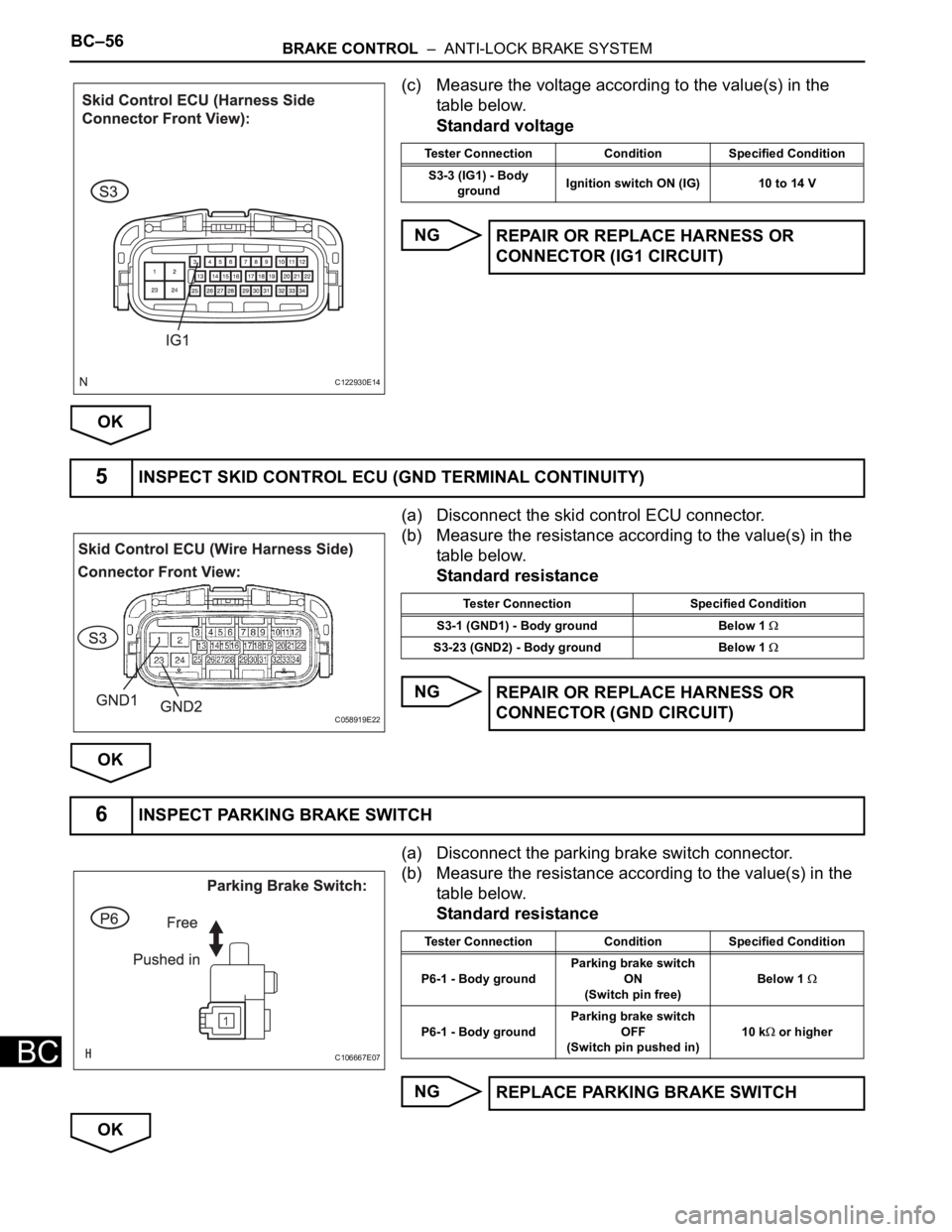

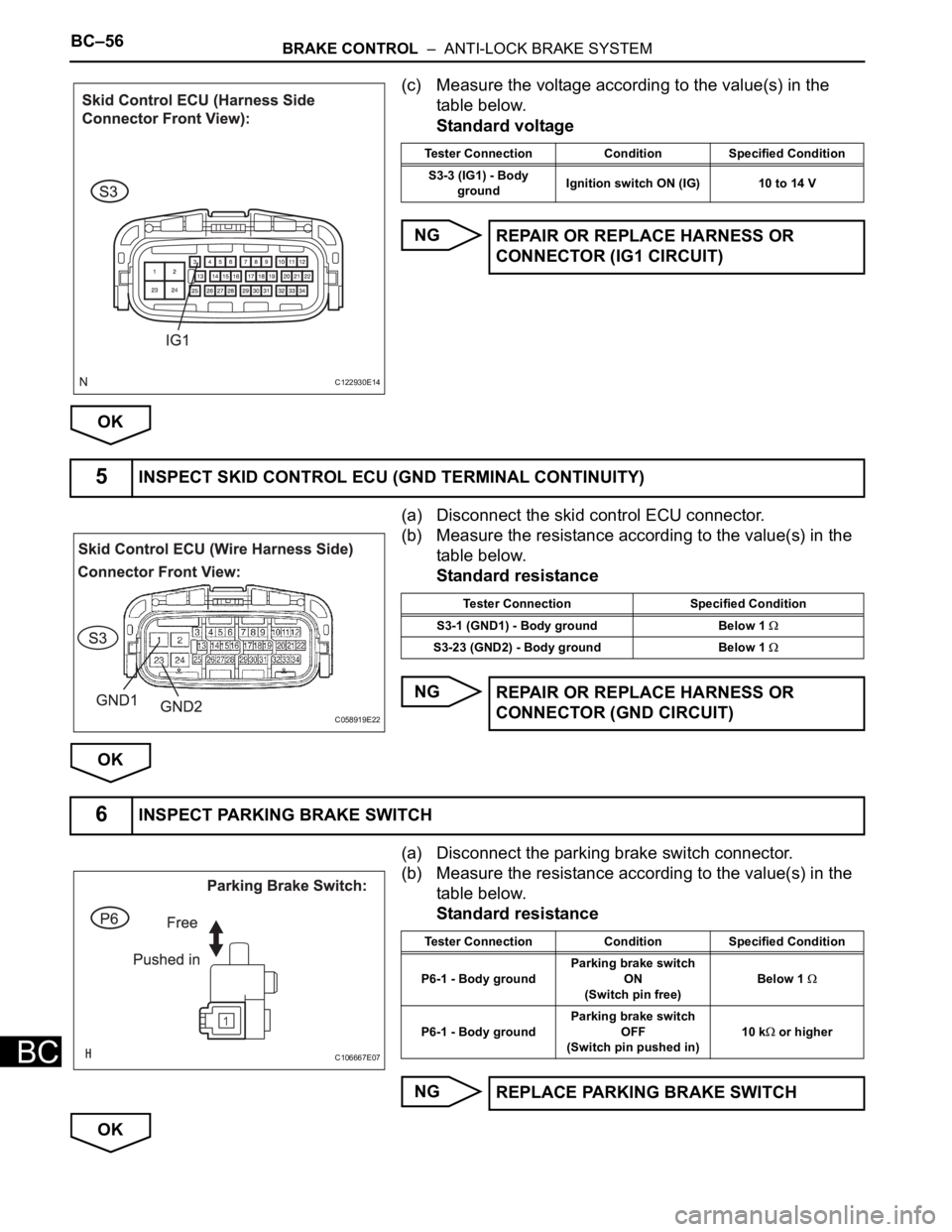

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

(a) Disconnect the skid control ECU connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Disconnect the parking brake switch connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

C122930E14

Tester Connection Condition Specified Condition

S3-3 (IG1) - Body

groundIgnition switch ON (IG) 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR (IG1 CIRCUIT)

5INSPECT SKID CONTROL ECU (GND TERMINAL CONTINUITY)

C058919E22

Tester Connection Specified Condition

S3-1 (GND1) - Body ground Below 1

S3-23 (GND2) - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (GND CIRCUIT)

6INSPECT PARKING BRAKE SWITCH

C106667E07

Tester Connection Condition Specified Condition

P6-1 - Body groundParking brake switch

ON

(Switch pin free)Below 1

P6-1 - Body groundParking brake switch

OFF

(Switch pin pushed in)10 k or higher

REPLACE PARKING BRAKE SWITCH

Page 2418 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–57

BC

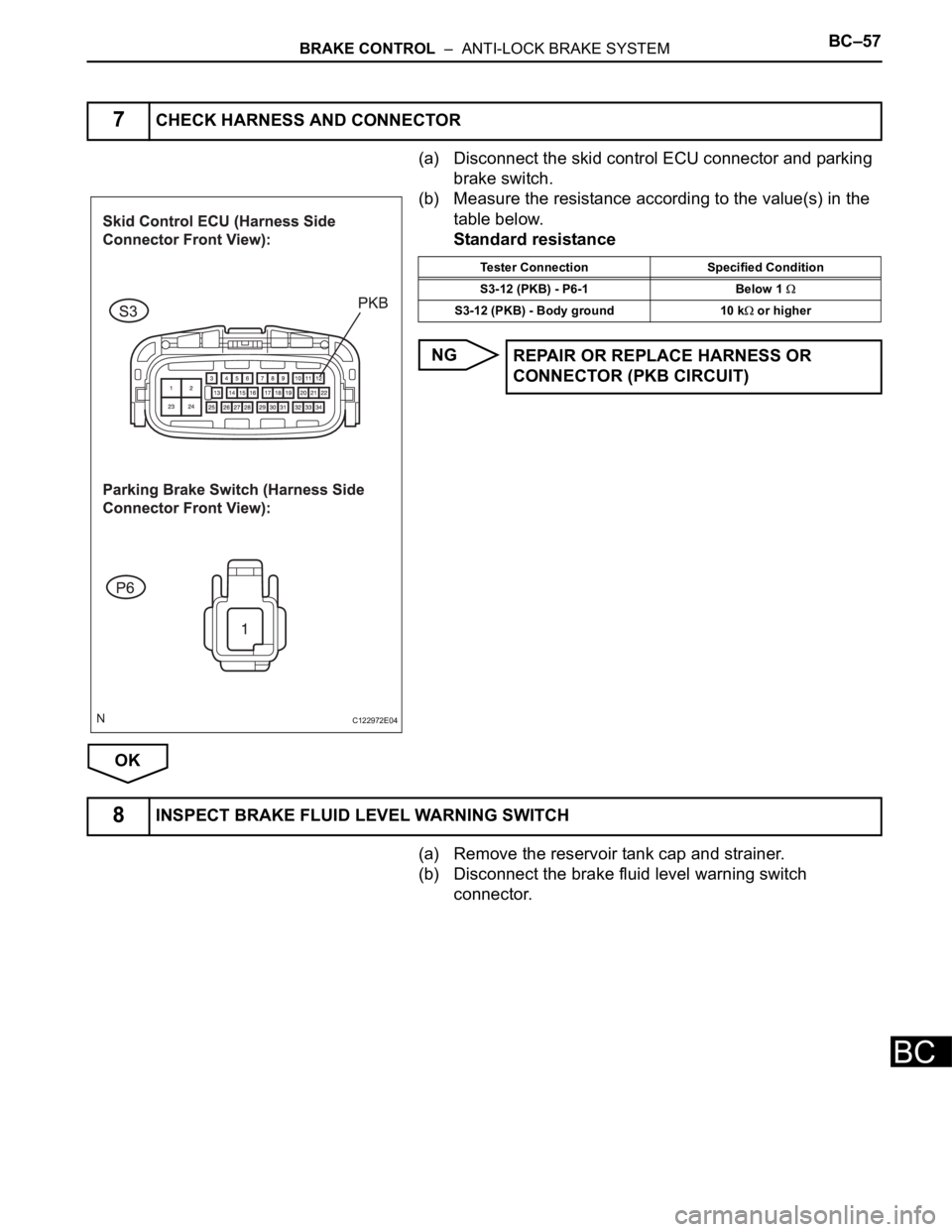

(a) Disconnect the skid control ECU connector and parking

brake switch.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Remove the reservoir tank cap and strainer.

(b) Disconnect the brake fluid level warning switch

connector.

7CHECK HARNESS AND CONNECTOR

C122972E04

Tester Connection Specified Condition

S3-12 (PKB) - P6-1 Below 1

S3-12 (PKB) - Body ground 10 k or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (PKB CIRCUIT)

8INSPECT BRAKE FLUID LEVEL WARNING SWITCH

Page 2419 of 3000

BC–58BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

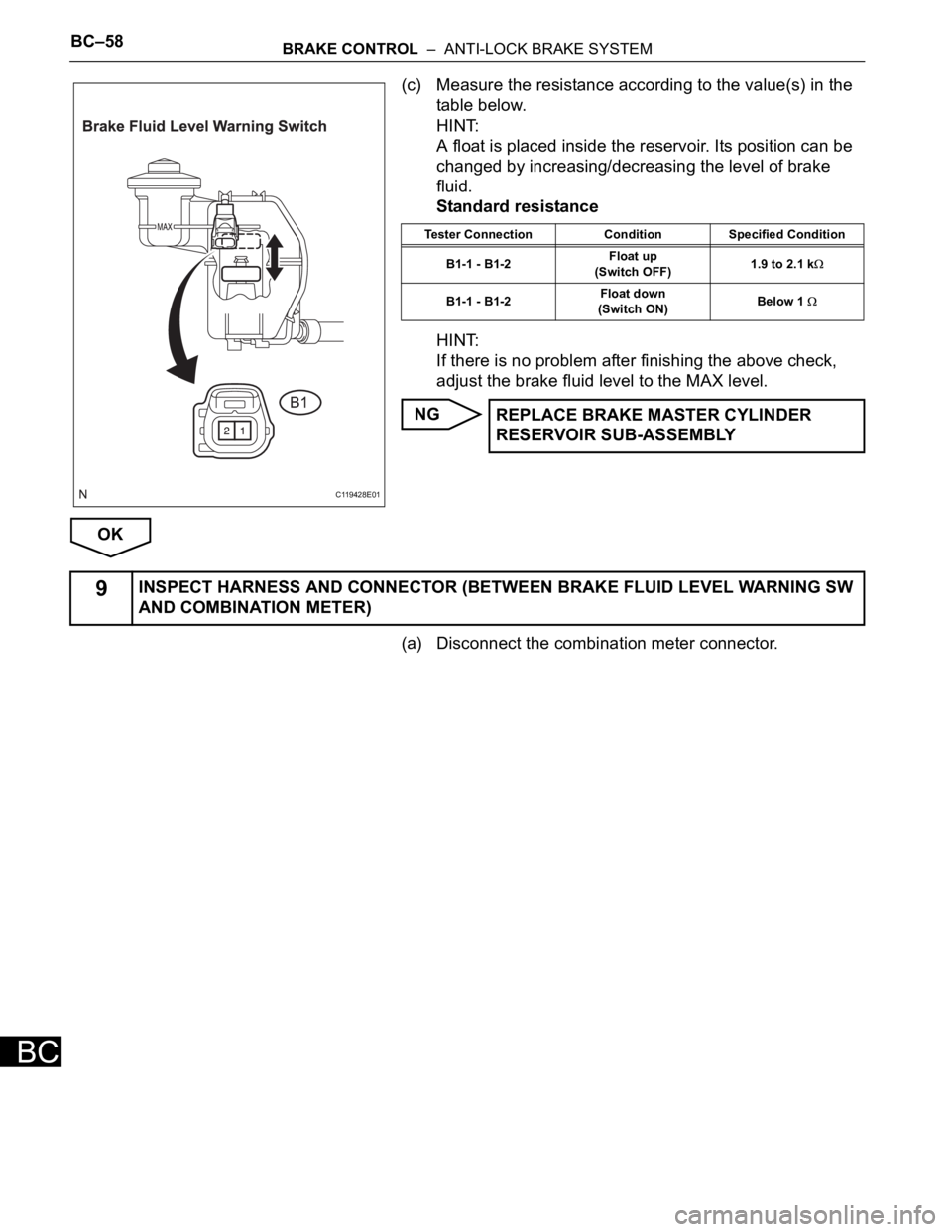

(c) Measure the resistance according to the value(s) in the

table below.

HINT:

A float is placed inside the reservoir. Its position can be

changed by increasing/decreasing the level of brake

fluid.

Standard resistance

HINT:

If there is no problem after finishing the above check,

adjust the brake fluid level to the MAX level.

NG

OK

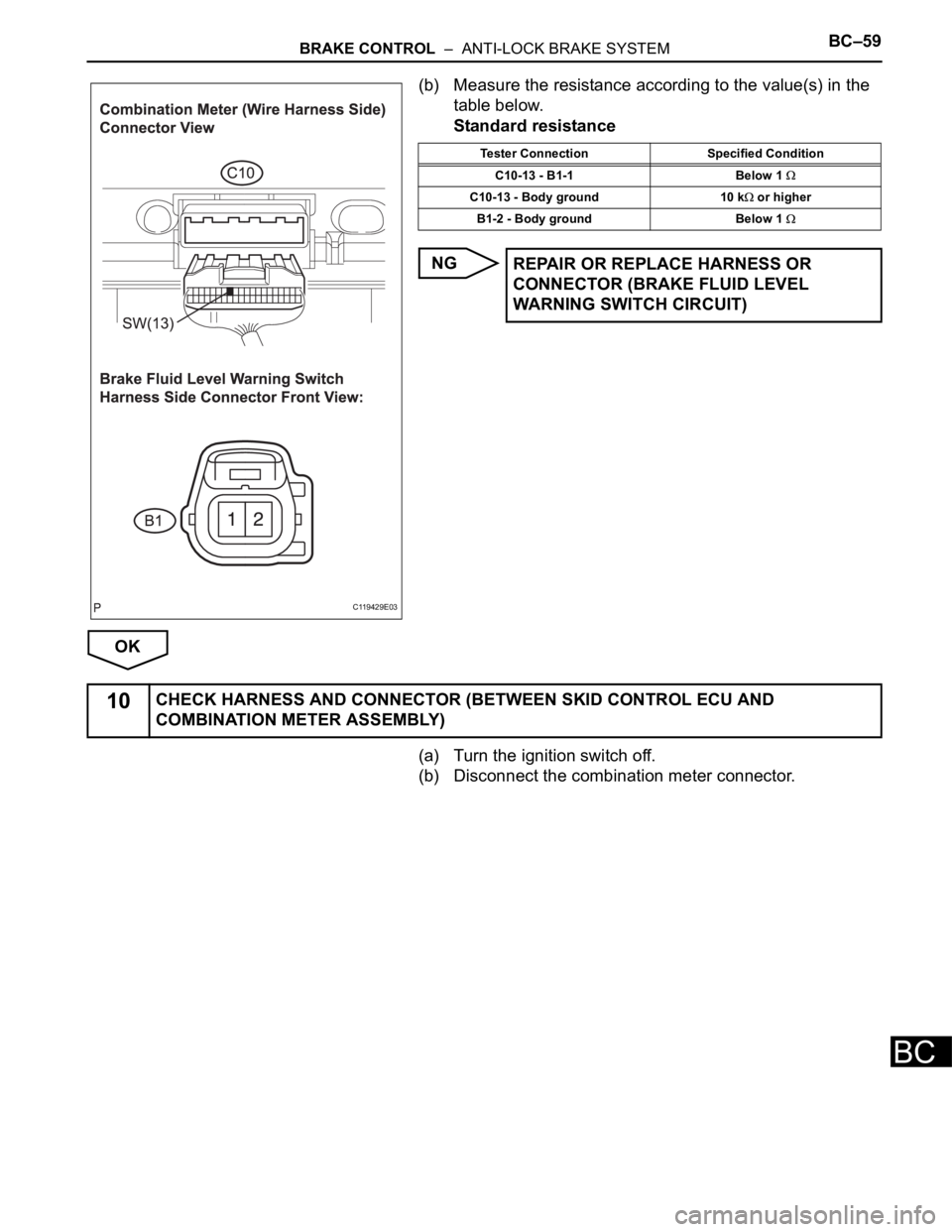

(a) Disconnect the combination meter connector.

C119428E01

Tester Connection Condition Specified Condition

B1-1 - B1-2Float up

(Switch OFF)1.9 to 2.1 k

B1-1 - B1-2Float down

(Switch ON)Below 1

REPLACE BRAKE MASTER CYLINDER

RESERVOIR SUB-ASSEMBLY

9INSPECT HARNESS AND CONNECTOR (BETWEEN BRAKE FLUID LEVEL WARNING SW

AND COMBINATION METER)

Page 2420 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–59

BC

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Turn the ignition switch off.

(b) Disconnect the combination meter connector.

C119429E03

Tester Connection Specified Condition

C10-13 - B1-1 Below 1

C10-13 - Body ground 10 k or higher

B1-2 - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (BRAKE FLUID LEVEL

WARNING SWITCH CIRCUIT)

10CHECK HARNESS AND CONNECTOR (BETWEEN SKID CONTROL ECU AND

COMBINATION METER ASSEMBLY)

Trending: navigation system, ESP, coolant level, regulator, spark plugs replace, check oil, Transaxle