drain bolt TOYOTA SIENNA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1028 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–81

EM

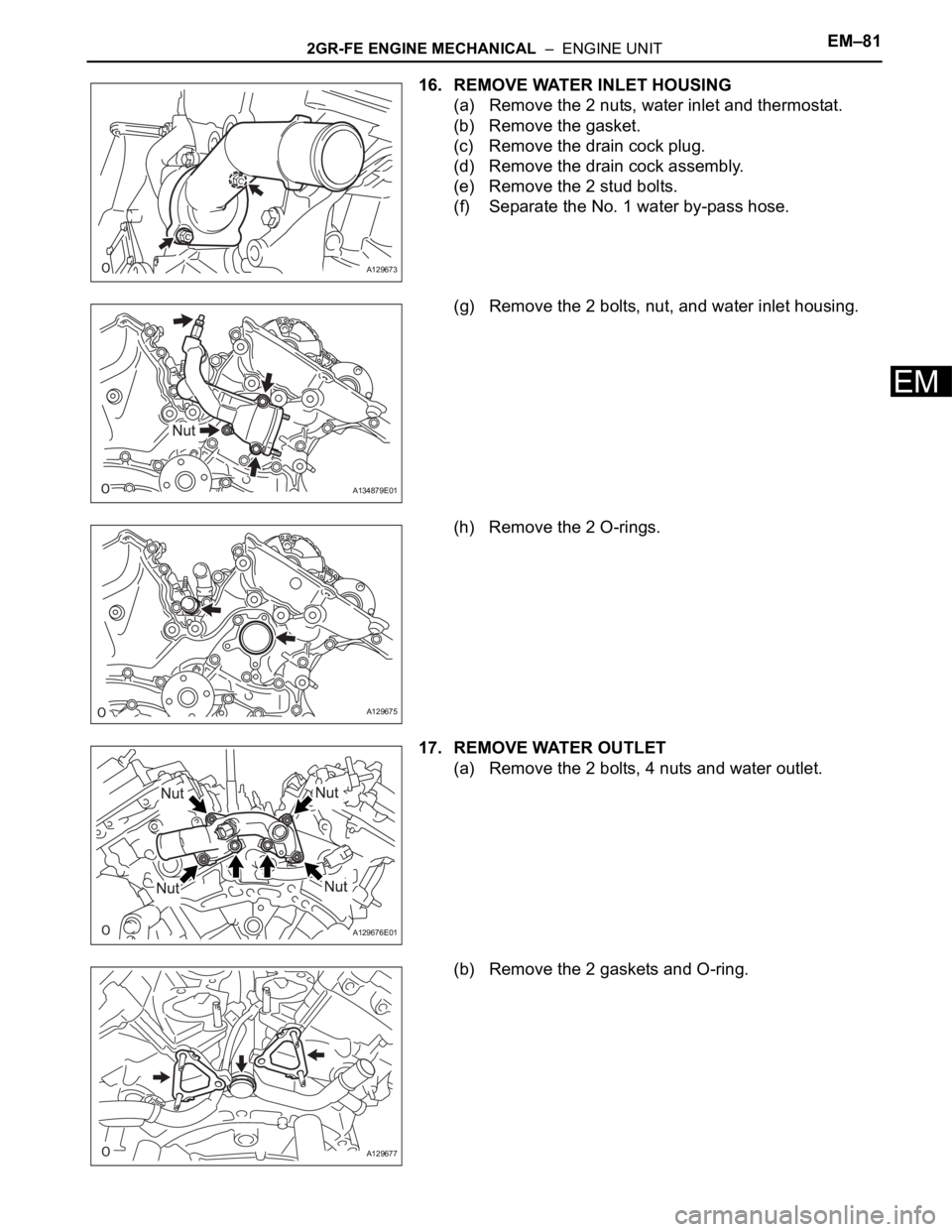

16. REMOVE WATER INLET HOUSING

(a) Remove the 2 nuts, water inlet and thermostat.

(b) Remove the gasket.

(c) Remove the drain cock plug.

(d) Remove the drain cock assembly.

(e) Remove the 2 stud bolts.

(f) Separate the No. 1 water by-pass hose.

(g) Remove the 2 bolts, nut, and water inlet housing.

(h) Remove the 2 O-rings.

17. REMOVE WATER OUTLET

(a) Remove the 2 bolts, 4 nuts and water outlet.

(b) Remove the 2 gaskets and O-ring.

A129673

A134879E01

A129675

A129676E01

A129677

Page 1105 of 3000

EM–1582GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

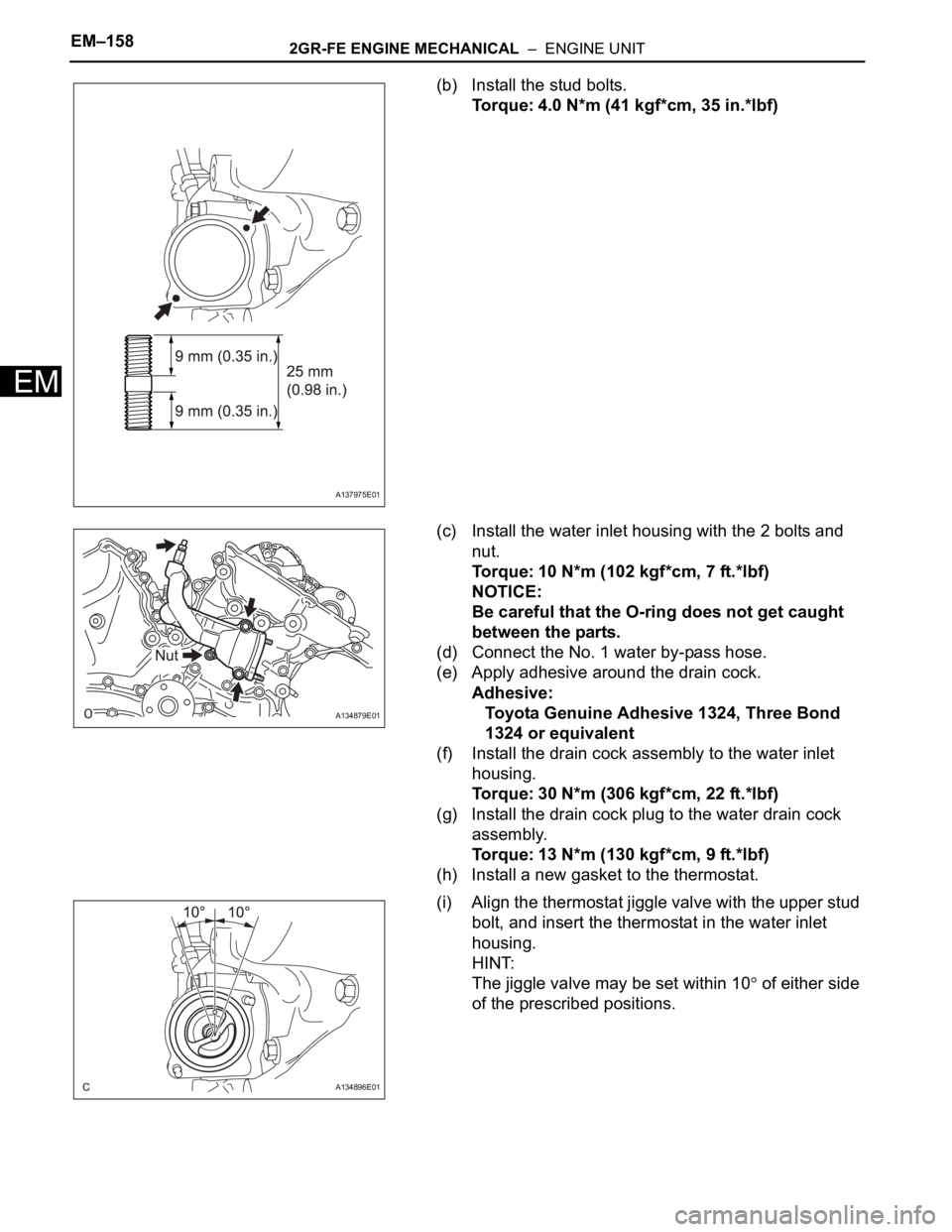

(b) Install the stud bolts.

Torque: 4.0 N*m (41 kgf*cm, 35 in.*lbf)

(c) Install the water inlet housing with the 2 bolts and

nut.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

NOTICE:

Be careful that the O-ring does not get caught

between the parts.

(d) Connect the No. 1 water by-pass hose.

(e) Apply adhesive around the drain cock.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond

1324 or equivalent

(f) Install the drain cock assembly to the water inlet

housing.

Torque: 30 N*m (306 kgf*cm, 22 ft.*lbf)

(g) Install the drain cock plug to the water drain cock

assembly.

Torque: 13 N*m (130 kgf*cm, 9 ft.*lbf)

(h) Install a new gasket to the thermostat.

(i) Align the thermostat jiggle valve with the upper stud

bolt, and insert the thermostat in the water inlet

housing.

HINT:

The jiggle valve may be set within 10

of either side

of the prescribed positions.

A137975E01

A134879E01

A134896E01

Page 1109 of 3000

EM–1622GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

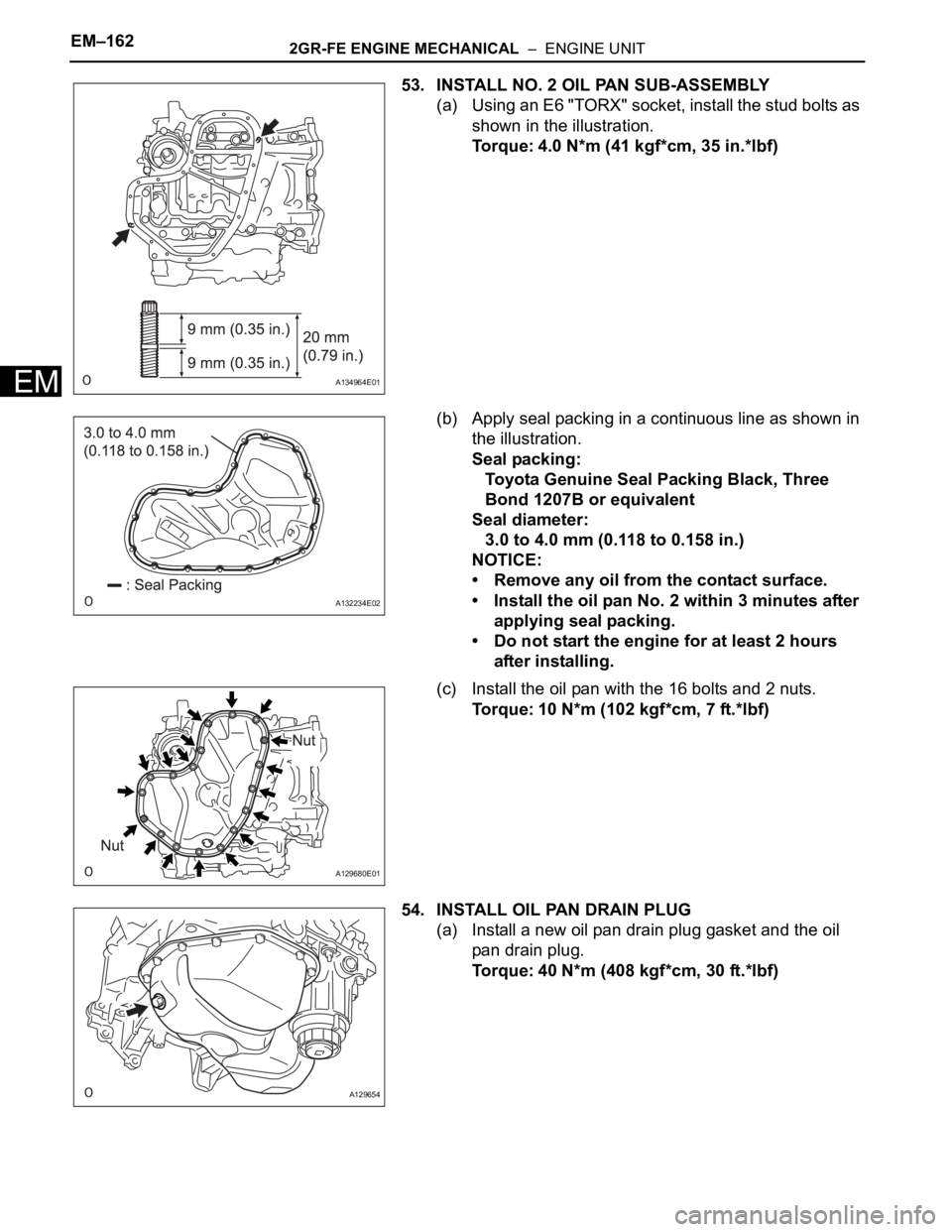

53. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY

(a) Using an E6 "TORX" socket, install the stud bolts as

shown in the illustration.

Torque: 4.0 N*m (41 kgf*cm, 35 in.*lbf)

(b) Apply seal packing in a continuous line as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three

Bond 1207B or equivalent

Seal diameter:

3.0 to 4.0 mm (0.118 to 0.158 in.)

NOTICE:

• Remove any oil from the contact surface.

• Install the oil pan No. 2 within 3 minutes after

applying seal packing.

• Do not start the engine for at least 2 hours

after installing.

(c) Install the oil pan with the 16 bolts and 2 nuts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

54. INSTALL OIL PAN DRAIN PLUG

(a) Install a new oil pan drain plug gasket and the oil

pan drain plug.

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf)

A134964E01

A132234E02

A129680E01

A129654

Page 1114 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–167

EM

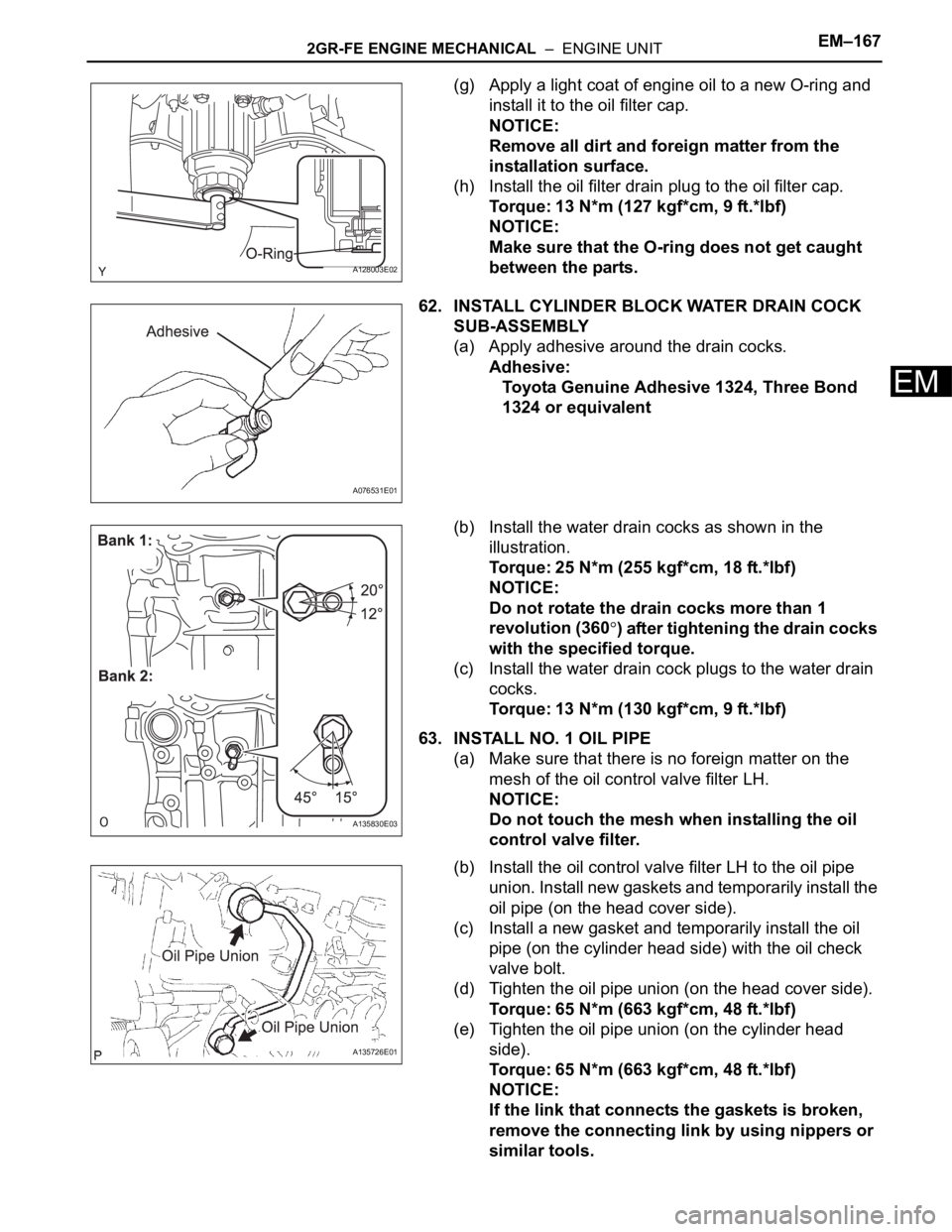

(g) Apply a light coat of engine oil to a new O-ring and

install it to the oil filter cap.

NOTICE:

Remove all dirt and foreign matter from the

installation surface.

(h) Install the oil filter drain plug to the oil filter cap.

Torque: 13 N*m (127 kgf*cm, 9 ft.*lbf)

NOTICE:

Make sure that the O-ring does not get caught

between the parts.

62. INSTALL CYLINDER BLOCK WATER DRAIN COCK

SUB-ASSEMBLY

(a) Apply adhesive around the drain cocks.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond

1324 or equivalent

(b) Install the water drain cocks as shown in the

illustration.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

NOTICE:

Do not rotate the drain cocks more than 1

revolution (360

) after tightening the drain cocks

with the specified torque.

(c) Install the water drain cock plugs to the water drain

cocks.

Torque: 13 N*m (130 kgf*cm, 9 ft.*lbf)

63. INSTALL NO. 1 OIL PIPE

(a) Make sure that there is no foreign matter on the

mesh of the oil control valve filter LH.

NOTICE:

Do not touch the mesh when installing the oil

control valve filter.

(b) Install the oil control valve filter LH to the oil pipe

union. Install new gaskets and temporarily install the

oil pipe (on the head cover side).

(c) Install a new gasket and temporarily install the oil

pipe (on the cylinder head side) with the oil check

valve bolt.

(d) Tighten the oil pipe union (on the head cover side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

(e) Tighten the oil pipe union (on the cylinder head

side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

NOTICE:

If the link that connects the gaskets is broken,

remove the connecting link by using nippers or

similar tools.

A128003E02

A076531E01

A135830E03

A135726E01

Page 1119 of 3000

2GR-FE FUEL – FUEL INJECTORFU–13

FU

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

See page FU-1.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. REMOVE NO. 1 ENGINE UNDER COVER

4. DRAIN ENGINE COOLANT (See page CO-6)

5. REMOVE FRONT WIPER ARM HEAD CAP (See page

WW-4)

6. REMOVE FRONT WIPER ARM RH (See page WW-4)

7. REMOVE FRONT WIPER ARM LH (See page WW-4)

8. REMOVE COWL TOP VENTILATOR LOUVER SUB-

ASSEMBLY (See page WW-4)

9. REMOVE WINDSHIELD WIPER MOTOR AND LINK

ASSEMBLY (See page WW-4)

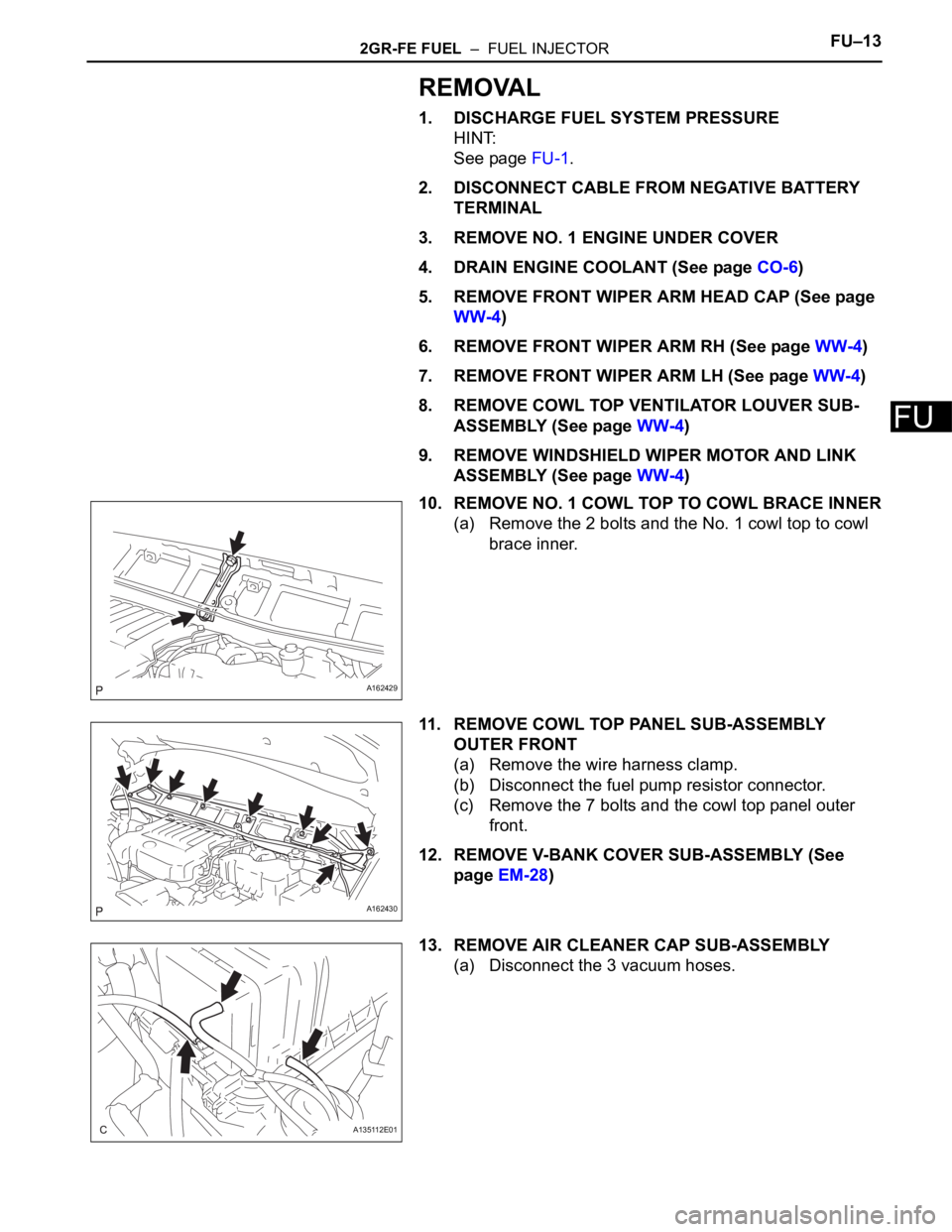

10. REMOVE NO. 1 COWL TOP TO COWL BRACE INNER

(a) Remove the 2 bolts and the No. 1 cowl top to cowl

brace inner.

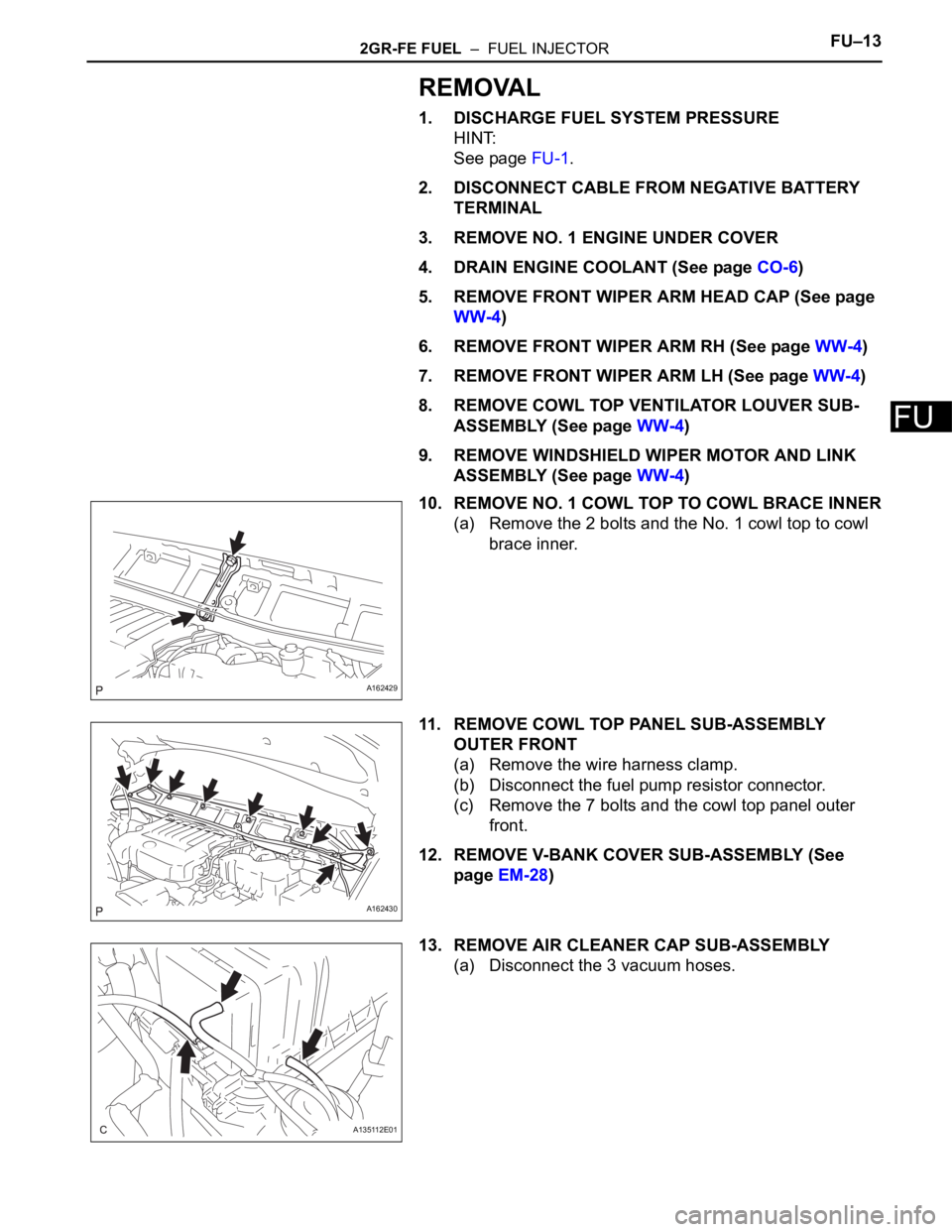

11. REMOVE COWL TOP PANEL SUB-ASSEMBLY

OUTER FRONT

(a) Remove the wire harness clamp.

(b) Disconnect the fuel pump resistor connector.

(c) Remove the 7 bolts and the cowl top panel outer

front.

12. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

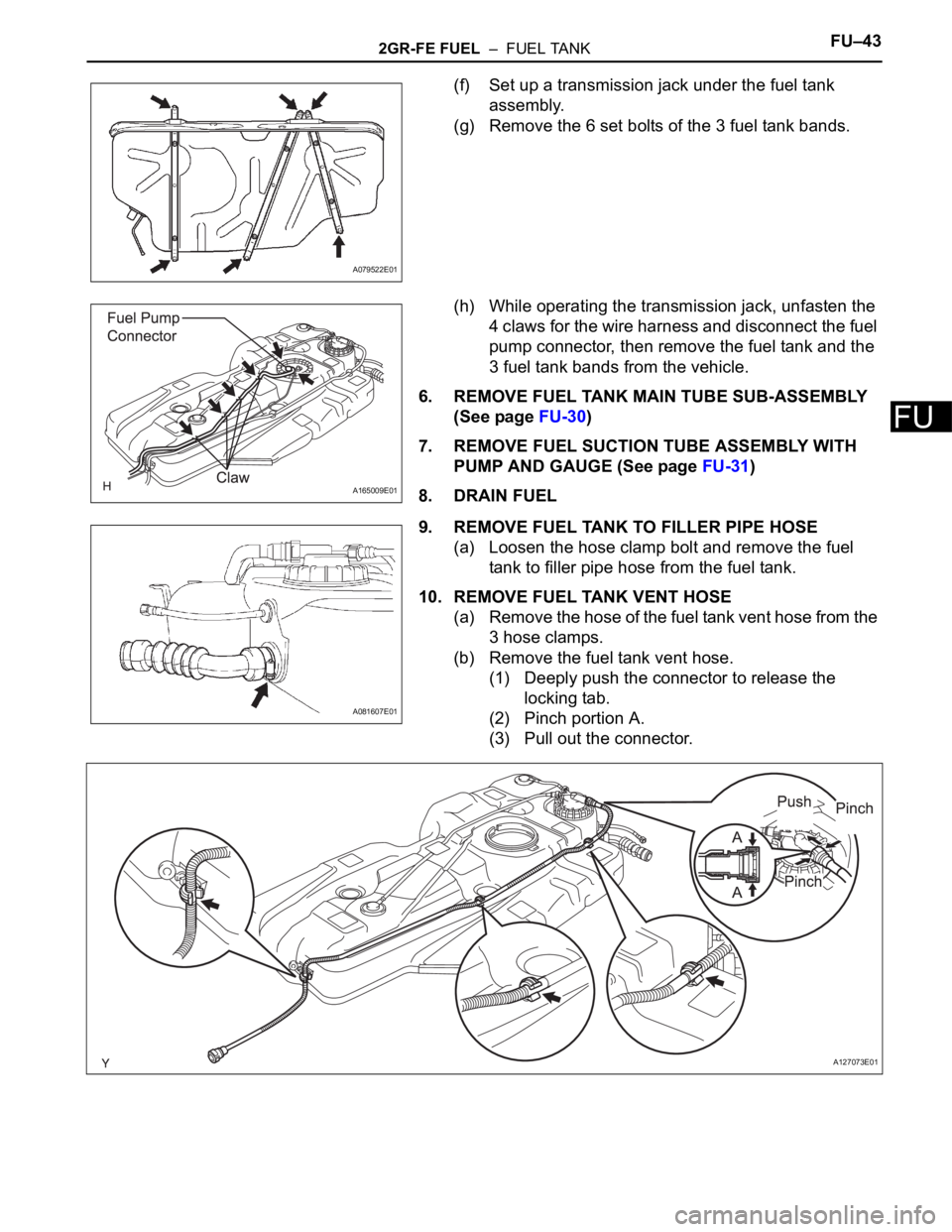

13. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disconnect the 3 vacuum hoses.

A162429

A162430

A135112E01

Page 1134 of 3000

2GR-FE FUEL – FUEL INJECTORFU–13

FU

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

See page FU-1.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. REMOVE NO. 1 ENGINE UNDER COVER

4. DRAIN ENGINE COOLANT (See page CO-6)

5. REMOVE FRONT WIPER ARM HEAD CAP (See page

WW-4)

6. REMOVE FRONT WIPER ARM RH (See page WW-4)

7. REMOVE FRONT WIPER ARM LH (See page WW-4)

8. REMOVE COWL TOP VENTILATOR LOUVER SUB-

ASSEMBLY (See page WW-4)

9. REMOVE WINDSHIELD WIPER MOTOR AND LINK

ASSEMBLY (See page WW-4)

10. REMOVE NO. 1 COWL TOP TO COWL BRACE INNER

(a) Remove the 2 bolts and the No. 1 cowl top to cowl

brace inner.

11. REMOVE COWL TOP PANEL SUB-ASSEMBLY

OUTER FRONT

(a) Remove the wire harness clamp.

(b) Disconnect the fuel pump resistor connector.

(c) Remove the 7 bolts and the cowl top panel outer

front.

12. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

13. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disconnect the 3 vacuum hoses.

A162429

A162430

A135112E01

Page 1163 of 3000

2GR-FE FUEL – FUEL TANKFU–43

FU

(f) Set up a transmission jack under the fuel tank

assembly.

(g) Remove the 6 set bolts of the 3 fuel tank bands.

(h) While operating the transmission jack, unfasten the

4 claws for the wire harness and disconnect the fuel

pump connector, then remove the fuel tank and the

3 fuel tank bands from the vehicle.

6. REMOVE FUEL TANK MAIN TUBE SUB-ASSEMBLY

(See page FU-30)

7. REMOVE FUEL SUCTION TUBE ASSEMBLY WITH

PUMP AND GAUGE (See page FU-31)

8. DRAIN FUEL

9. REMOVE FUEL TANK TO FILLER PIPE HOSE

(a) Loosen the hose clamp bolt and remove the fuel

tank to filler pipe hose from the fuel tank.

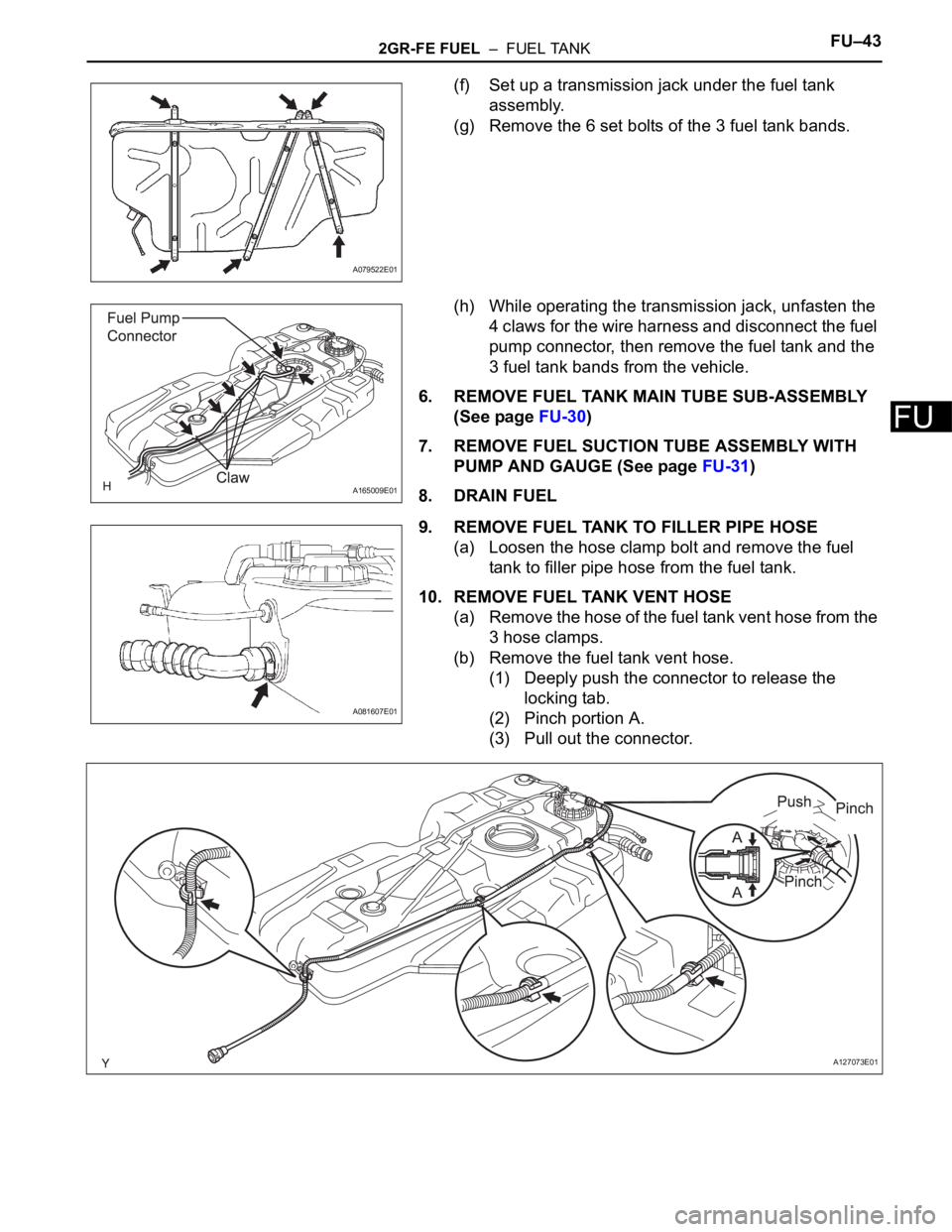

10. REMOVE FUEL TANK VENT HOSE

(a) Remove the hose of the fuel tank vent hose from the

3 hose clamps.

(b) Remove the fuel tank vent hose.

(1) Deeply push the connector to release the

locking tab.

(2) Pinch portion A.

(3) Pull out the connector.

A079522E01

A165009E01

A081607E01

A127073E01

Page 1166 of 3000

2GR-FE FUEL – FUEL TANKFU–43

FU

(f) Set up a transmission jack under the fuel tank

assembly.

(g) Remove the 6 set bolts of the 3 fuel tank bands.

(h) While operating the transmission jack, unfasten the

4 claws for the wire harness and disconnect the fuel

pump connector, then remove the fuel tank and the

3 fuel tank bands from the vehicle.

6. REMOVE FUEL TANK MAIN TUBE SUB-ASSEMBLY

(See page FU-30)

7. REMOVE FUEL SUCTION TUBE ASSEMBLY WITH

PUMP AND GAUGE (See page FU-31)

8. DRAIN FUEL

9. REMOVE FUEL TANK TO FILLER PIPE HOSE

(a) Loosen the hose clamp bolt and remove the fuel

tank to filler pipe hose from the fuel tank.

10. REMOVE FUEL TANK VENT HOSE

(a) Remove the hose of the fuel tank vent hose from the

3 hose clamps.

(b) Remove the fuel tank vent hose.

(1) Deeply push the connector to release the

locking tab.

(2) Pinch portion A.

(3) Pull out the connector.

A079522E01

A165009E01

A081607E01

A127073E01

Page 1235 of 3000

CO–122GR-FE COOLING – WATER PUMP

CO

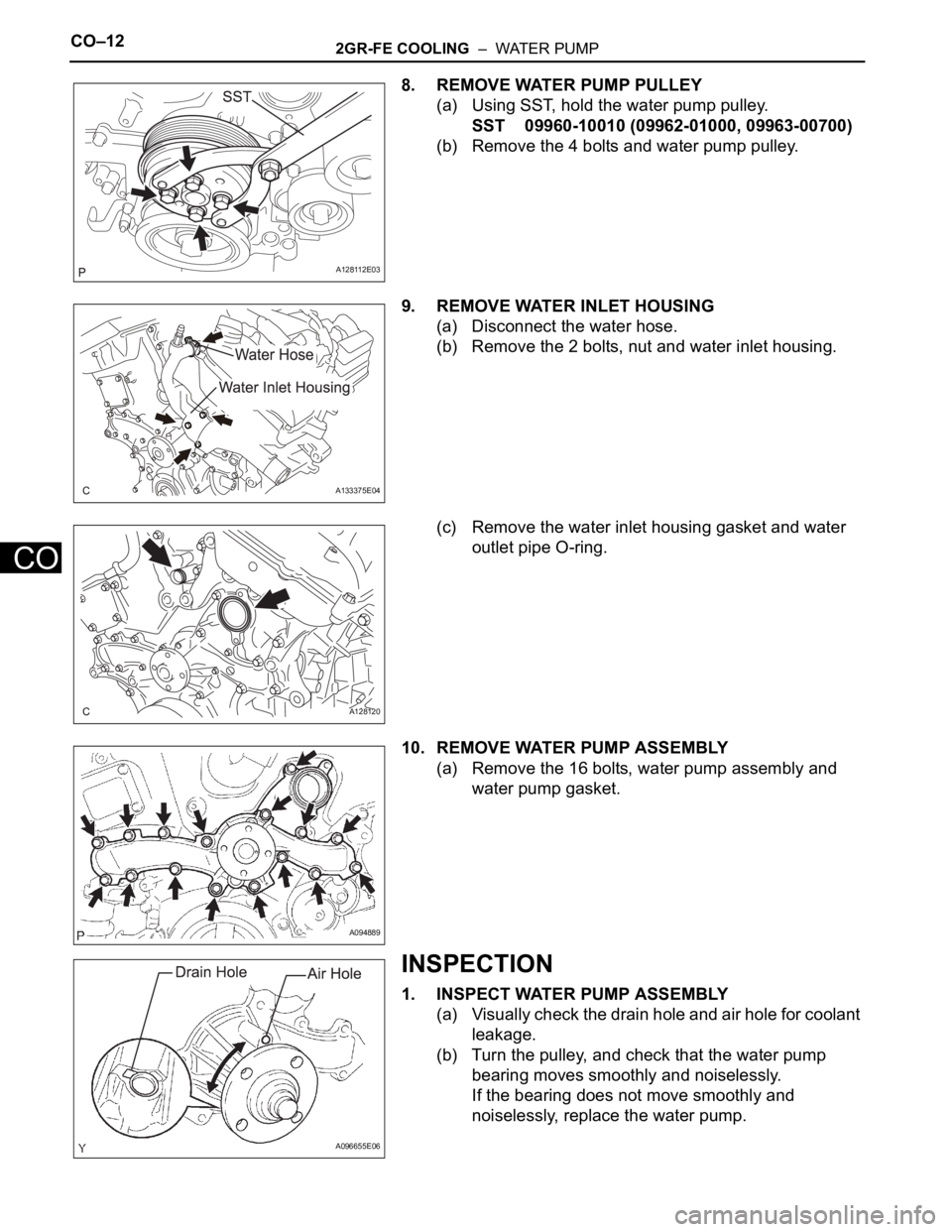

8. REMOVE WATER PUMP PULLEY

(a) Using SST, hold the water pump pulley.

SST 09960-10010 (09962-01000, 09963-00700)

(b) Remove the 4 bolts and water pump pulley.

9. REMOVE WATER INLET HOUSING

(a) Disconnect the water hose.

(b) Remove the 2 bolts, nut and water inlet housing.

(c) Remove the water inlet housing gasket and water

outlet pipe O-ring.

10. REMOVE WATER PUMP ASSEMBLY

(a) Remove the 16 bolts, water pump assembly and

water pump gasket.

INSPECTION

1. INSPECT WATER PUMP ASSEMBLY

(a) Visually check the drain hole and air hole for coolant

leakage.

(b) Turn the pulley, and check that the water pump

bearing moves smoothly and noiselessly.

If the bearing does not move smoothly and

noiselessly, replace the water pump.

A128112E03

A133375E04

A128120

A094889

A096655E06

Page 1250 of 3000

2GR-FE COOLING – RADIATORCO–35

CO

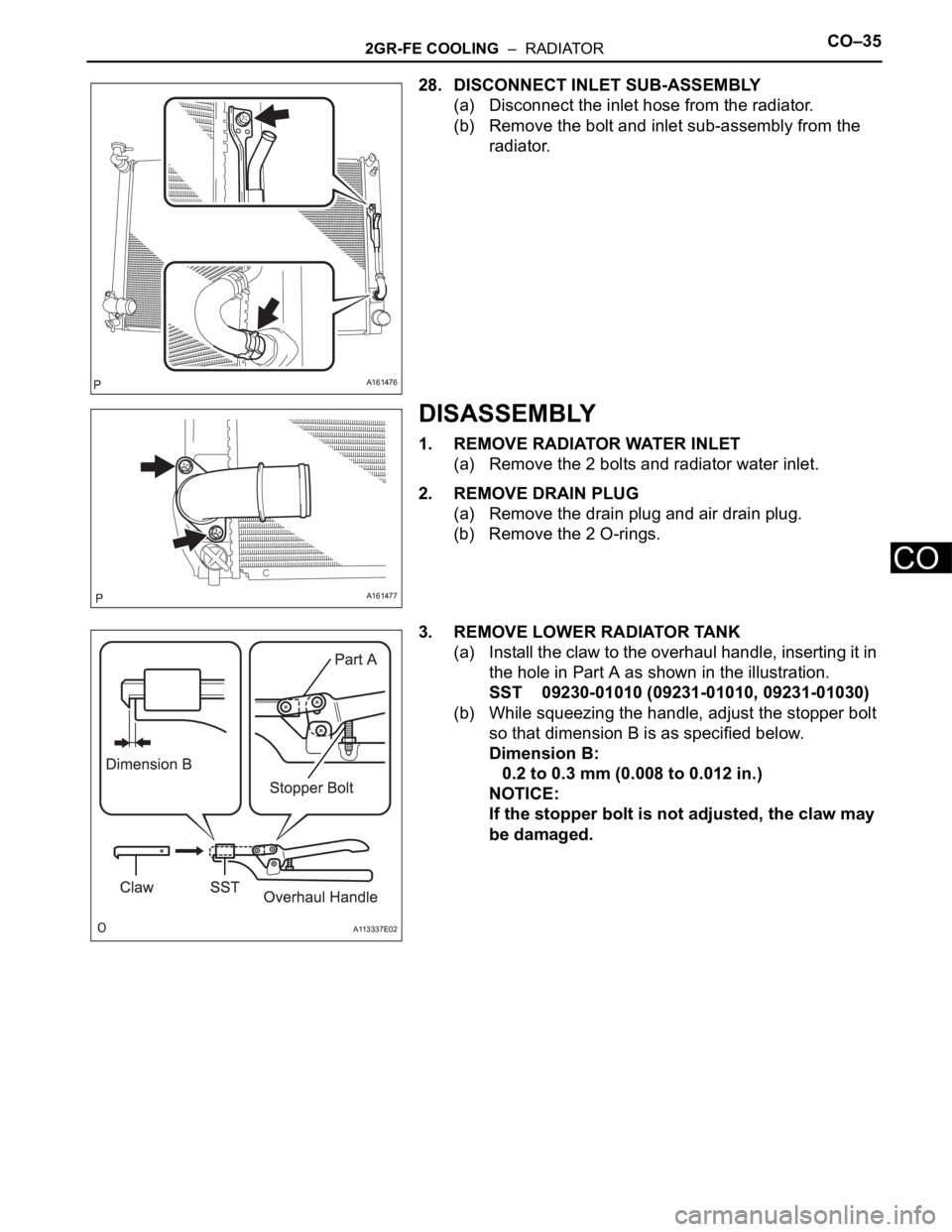

28. DISCONNECT INLET SUB-ASSEMBLY

(a) Disconnect the inlet hose from the radiator.

(b) Remove the bolt and inlet sub-assembly from the

radiator.

DISASSEMBLY

1. REMOVE RADIATOR WATER INLET

(a) Remove the 2 bolts and radiator water inlet.

2. REMOVE DRAIN PLUG

(a) Remove the drain plug and air drain plug.

(b) Remove the 2 O-rings.

3. REMOVE LOWER RADIATOR TANK

(a) Install the claw to the overhaul handle, inserting it in

the hole in Part A as shown in the illustration.

SST 09230-01010 (09231-01010, 09231-01030)

(b) While squeezing the handle, adjust the stopper bolt

so that dimension B is as specified below.

Dimension B:

0.2 to 0.3 mm (0.008 to 0.012 in.)

NOTICE:

If the stopper bolt is not adjusted, the claw may

be damaged.

A161476

A161477

A113337E02