service TOYOTA SIENNA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 222 of 3000

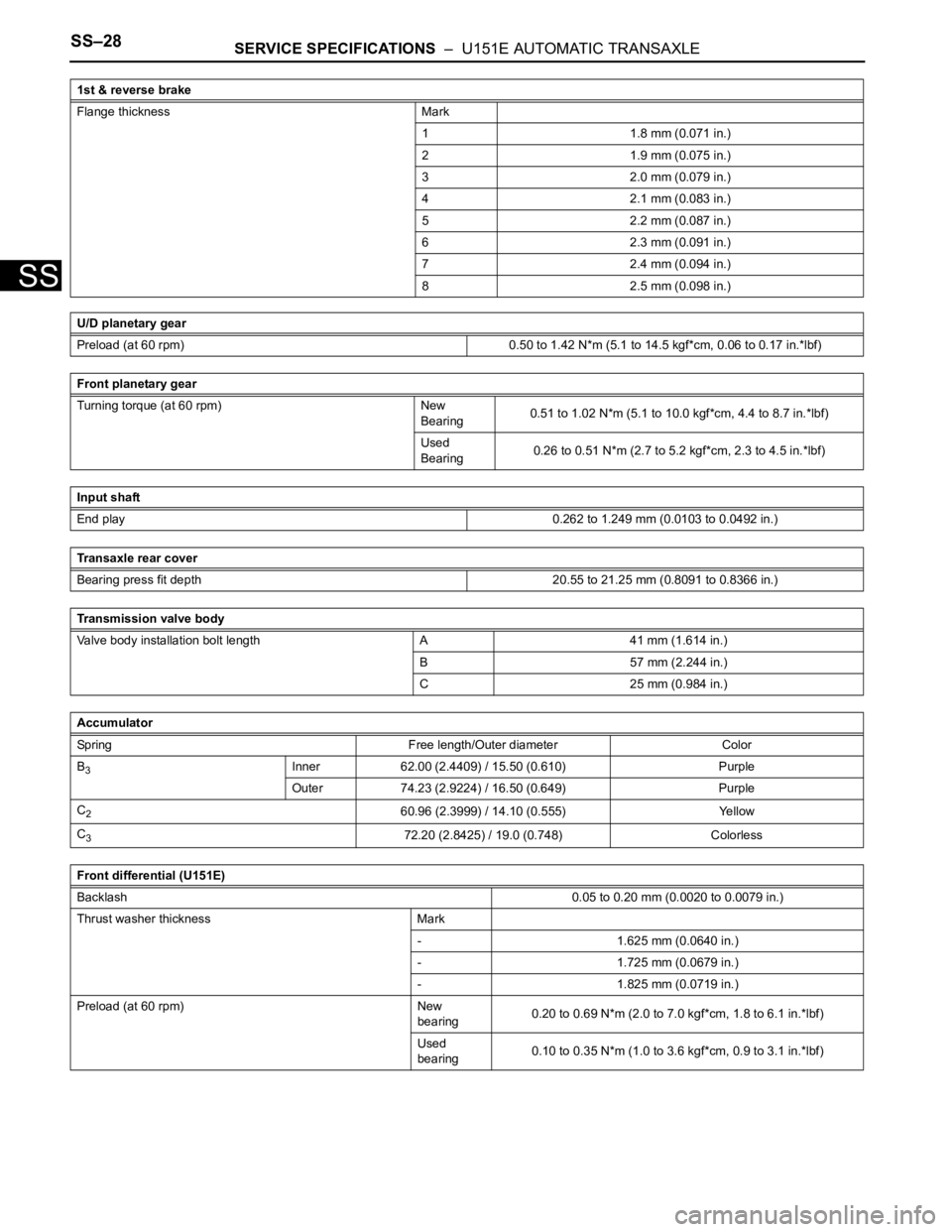

SS–28SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSAXLE

SS

Flange thickness Mark

1 1.8 mm (0.071 in.)

2 1.9 mm (0.075 in.)

3 2.0 mm (0.079 in.)

4 2.1 mm (0.083 in.)

5 2.2 mm (0.087 in.)

6 2.3 mm (0.091 in.)

7 2.4 mm (0.094 in.)

8 2.5 mm (0.098 in.)

U/D planetary gear

Preload (at 60 rpm) 0.50 to 1.42 N*m (5.1 to 14.5 kgf*cm, 0.06 to 0.17 in.*lbf)

Front planetary gear

Turning torque (at 60 rpm) New

Bearing0.51 to 1.02 N*m (5.1 to 10.0 kgf*cm, 4.4 to 8.7 in.*lbf)

Used

Bearing0.26 to 0.51 N*m (2.7 to 5.2 kgf*cm, 2.3 to 4.5 in.*lbf)

Input shaft

End play0.262 to 1.249 mm (0.0103 to 0.0492 in.)

Transaxle rear cover

Bearing press fit depth 20.55 to 21.25 mm (0.8091 to 0.8366 in.)

Transmission valve body

Valve body installation bolt length A 41 mm (1.614 in.)

B 57 mm (2.244 in.)

C 25 mm (0.984 in.)

Accumulator

Spring Free length/Outer diameter Color

B

3Inner 62.00 (2.4409) / 15.50 (0.610) Purple

Outer 74.23 (2.9224) / 16.50 (0.649) Purple

C

260.96 (2.3999) / 14.10 (0.555) Yellow

C

372.20 (2.8425) / 19.0 (0.748) Colorless

Front differential (U151E)

Backlash0.05 to 0.20 mm (0.0020 to 0.0079 in.)

Thrust washer thickness Mark

- 1.625 mm (0.0640 in.)

- 1.725 mm (0.0679 in.)

- 1.825 mm (0.0719 in.)

Preload (at 60 rpm) New

bearing0.20 to 0.69 N*m (2.0 to 7.0 kgf*cm, 1.8 to 6.1 in.*lbf)

Used

bearing0.10 to 0.35 N*m (1.0 to 3.6 kgf*cm, 0.9 to 3.1 in.*lbf) 1st & reverse brake

Page 223 of 3000

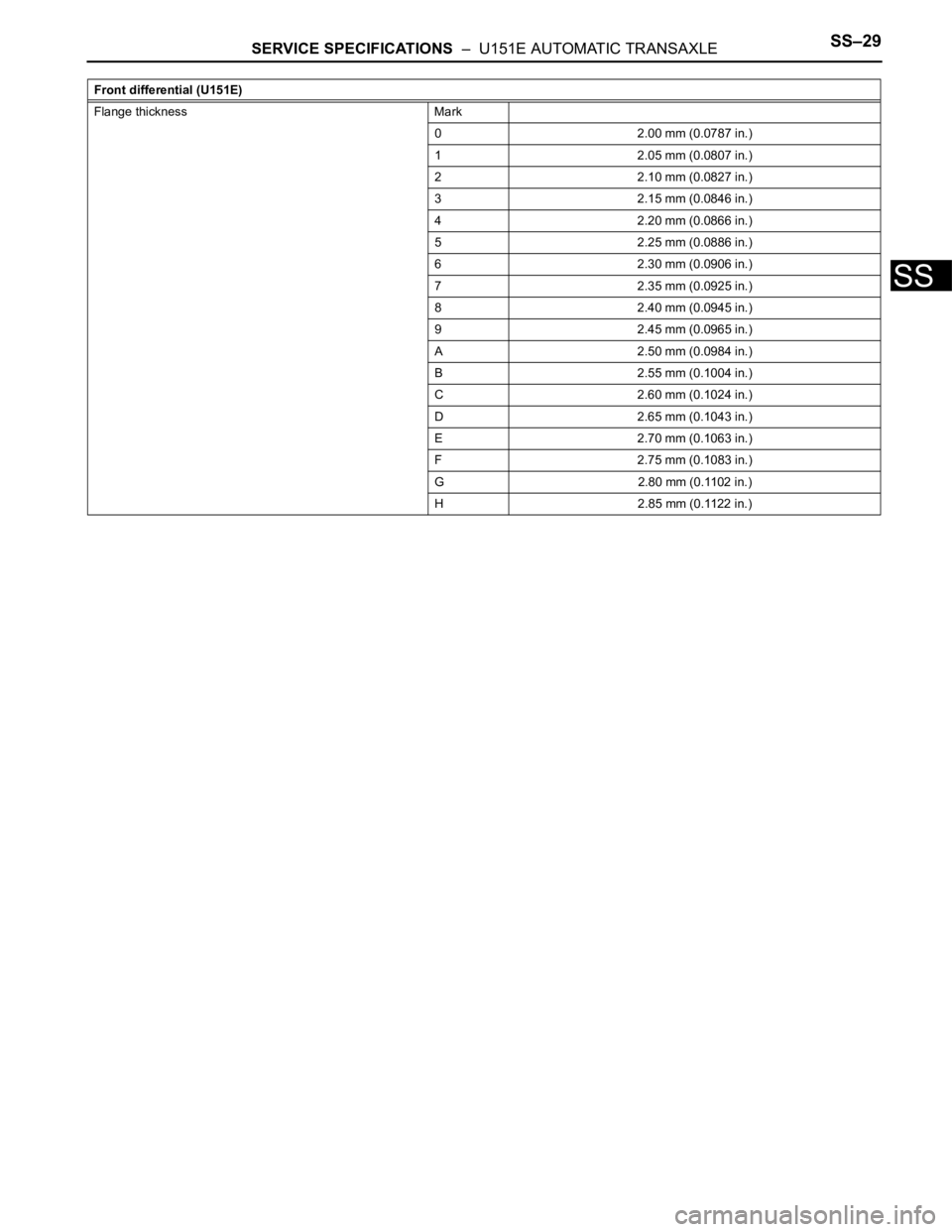

SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSAXLESS–29

SS

Flange thickness Mark

0 2.00 mm (0.0787 in.)

1 2.05 mm (0.0807 in.)

2 2.10 mm (0.0827 in.)

3 2.15 mm (0.0846 in.)

4 2.20 mm (0.0866 in.)

5 2.25 mm (0.0886 in.)

6 2.30 mm (0.0906 in.)

7 2.35 mm (0.0925 in.)

8 2.40 mm (0.0945 in.)

9 2.45 mm (0.0965 in.)

A 2.50 mm (0.0984 in.)

B 2.55 mm (0.1004 in.)

C 2.60 mm (0.1024 in.)

D 2.65 mm (0.1043 in.)

E 2.70 mm (0.1063 in.)

F 2.75 mm (0.1083 in.)

G 2.80 mm (0.1102 in.)

H 2.85 mm (0.1122 in.) Front differential (U151E)

Page 224 of 3000

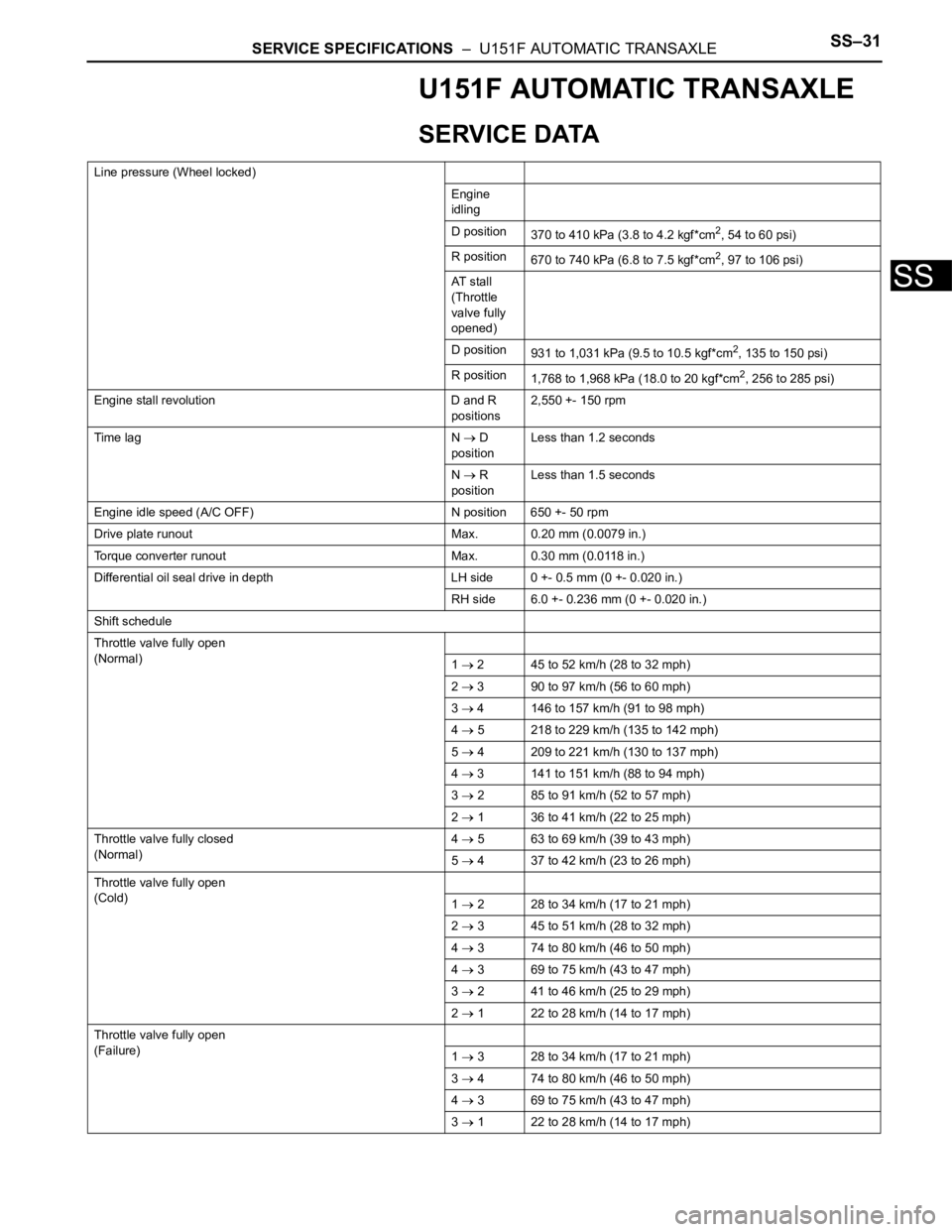

SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSAXLESS–31

SS

U151F AUTOMATIC TRANSAXLE

SERVICE DATA

Line pressure (Wheel locked)

Engine

idling

D position

370 to 410 kPa (3.8 to 4.2 kgf*cm

2, 54 to 60 psi)

R position

670 to 740 kPa (6.8 to 7.5 kgf*cm

2, 97 to 106 psi)

AT s t a l l

(Throttle

valve fully

opened)

D position

931 to 1,031 kPa (9.5 to 10.5 kgf*cm

2, 135 to 150 psi)

R position

1,768 to 1,968 kPa (18.0 to 20 kgf*cm

2, 256 to 285 psi)

Engine stall revolution D and R

positions2,550 +- 150 rpm

Time lag N

D

positionLess than 1.2 seconds

N

R

positionLess than 1.5 seconds

Engine idle speed (A/C OFF) N position 650 +- 50 rpm

Drive plate runout Max. 0.20 mm (0.0079 in.)

Torque converter runout Max. 0.30 mm (0.0118 in.)

Differential oil seal drive in depth LH side 0 +- 0.5 mm (0 +- 0.020 in.)

RH side 6.0 +- 0.236 mm (0 +- 0.020 in.)

Shift schedule

Throttle valve fully open

(Normal)

1

2 45 to 52 km/h (28 to 32 mph)

2

3 90 to 97 km/h (56 to 60 mph)

3

4 146 to 157 km/h (91 to 98 mph)

4

5 218 to 229 km/h (135 to 142 mph)

5

4 209 to 221 km/h (130 to 137 mph)

4

3 141 to 151 km/h (88 to 94 mph)

3

2 85 to 91 km/h (52 to 57 mph)

2

1 36 to 41 km/h (22 to 25 mph)

Throttle valve fully closed

(Normal)4

5 63 to 69 km/h (39 to 43 mph)

5

4 37 to 42 km/h (23 to 26 mph)

Throttle valve fully open

(Cold)

1

2 28 to 34 km/h (17 to 21 mph)

2

3 45 to 51 km/h (28 to 32 mph)

4

3 74 to 80 km/h (46 to 50 mph)

4

3 69 to 75 km/h (43 to 47 mph)

3

2 41 to 46 km/h (25 to 29 mph)

2

1 22 to 28 km/h (14 to 17 mph)

Throttle valve fully open

(Failure)

1

3 28 to 34 km/h (17 to 21 mph)

3

4 74 to 80 km/h (46 to 50 mph)

4

3 69 to 75 km/h (43 to 47 mph)

3

1 22 to 28 km/h (14 to 17 mph)

Page 225 of 3000

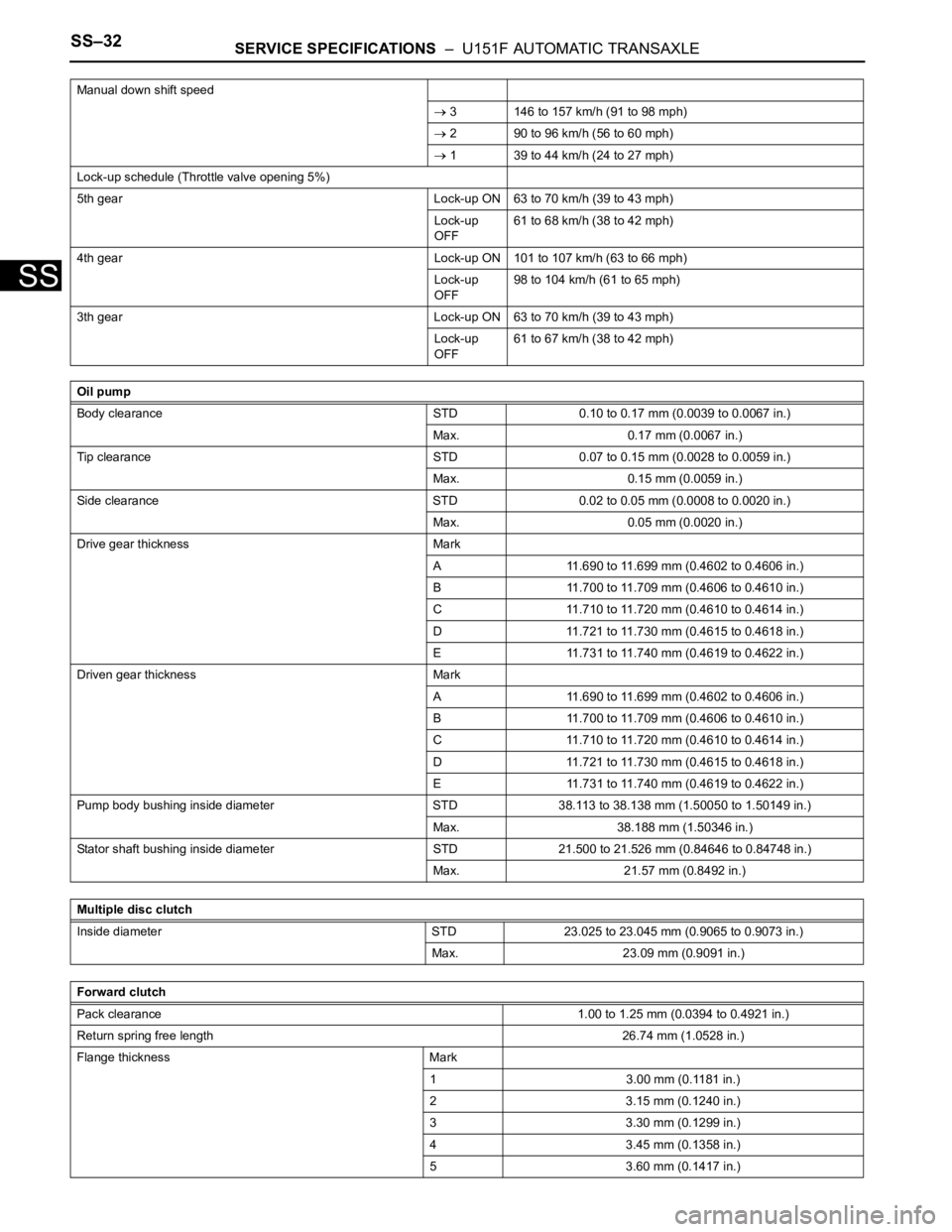

SS–32SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSAXLE

SS

Manual down shift speed

3 146 to 157 km/h (91 to 98 mph)

2 90 to 96 km/h (56 to 60 mph)

1 39 to 44 km/h (24 to 27 mph)

Lock-up schedule (Throttle valve opening 5%)

5th gear Lock-up ON 63 to 70 km/h (39 to 43 mph)

Lock-up

OFF61 to 68 km/h (38 to 42 mph)

4th gear Lock-up ON 101 to 107 km/h (63 to 66 mph)

Lock-up

OFF98 to 104 km/h (61 to 65 mph)

3th gear Lock-up ON 63 to 70 km/h (39 to 43 mph)

Lock-up

OFF61 to 67 km/h (38 to 42 mph)

Oil pump

Body clearance STD 0.10 to 0.17 mm (0.0039 to 0.0067 in.)

Max. 0.17 mm (0.0067 in.)

Tip clearance STD 0.07 to 0.15 mm (0.0028 to 0.0059 in.)

Max. 0.15 mm (0.0059 in.)

Side clearance STD 0.02 to 0.05 mm (0.0008 to 0.0020 in.)

Max. 0.05 mm (0.0020 in.)

Drive gear thickness Mark

A 11.690 to 11.699 mm (0.4602 to 0.4606 in.)

B 11.700 to 11.709 mm (0.4606 to 0.4610 in.)

C 11.710 to 11.720 mm (0.4610 to 0.4614 in.)

D 11.721 to 11.730 mm (0.4615 to 0.4618 in.)

E 11.731 to 11.740 mm (0.4619 to 0.4622 in.)

Driven gear thickness Mark

A 11.690 to 11.699 mm (0.4602 to 0.4606 in.)

B 11.700 to 11.709 mm (0.4606 to 0.4610 in.)

C 11.710 to 11.720 mm (0.4610 to 0.4614 in.)

D 11.721 to 11.730 mm (0.4615 to 0.4618 in.)

E 11.731 to 11.740 mm (0.4619 to 0.4622 in.)

Pump body bushing inside diameter STD 38.113 to 38.138 mm (1.50050 to 1.50149 in.)

Max. 38.188 mm (1.50346 in.)

Stator shaft bushing inside diameter STD 21.500 to 21.526 mm (0.84646 to 0.84748 in.)

Max. 21.57 mm (0.8492 in.)

Multiple disc clutch

Inside diameter STD 23.025 to 23.045 mm (0.9065 to 0.9073 in.)

Max. 23.09 mm (0.9091 in.)

Forward clutch

Pack clearance1.00 to 1.25 mm (0.0394 to 0.4921 in.)

Return spring free length26.74 mm (1.0528 in.)

Flange thickness Mark

1 3.00 mm (0.1181 in.)

2 3.15 mm (0.1240 in.)

3 3.30 mm (0.1299 in.)

4 3.45 mm (0.1358 in.)

5 3.60 mm (0.1417 in.)

Page 226 of 3000

SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSAXLESS–33

SS

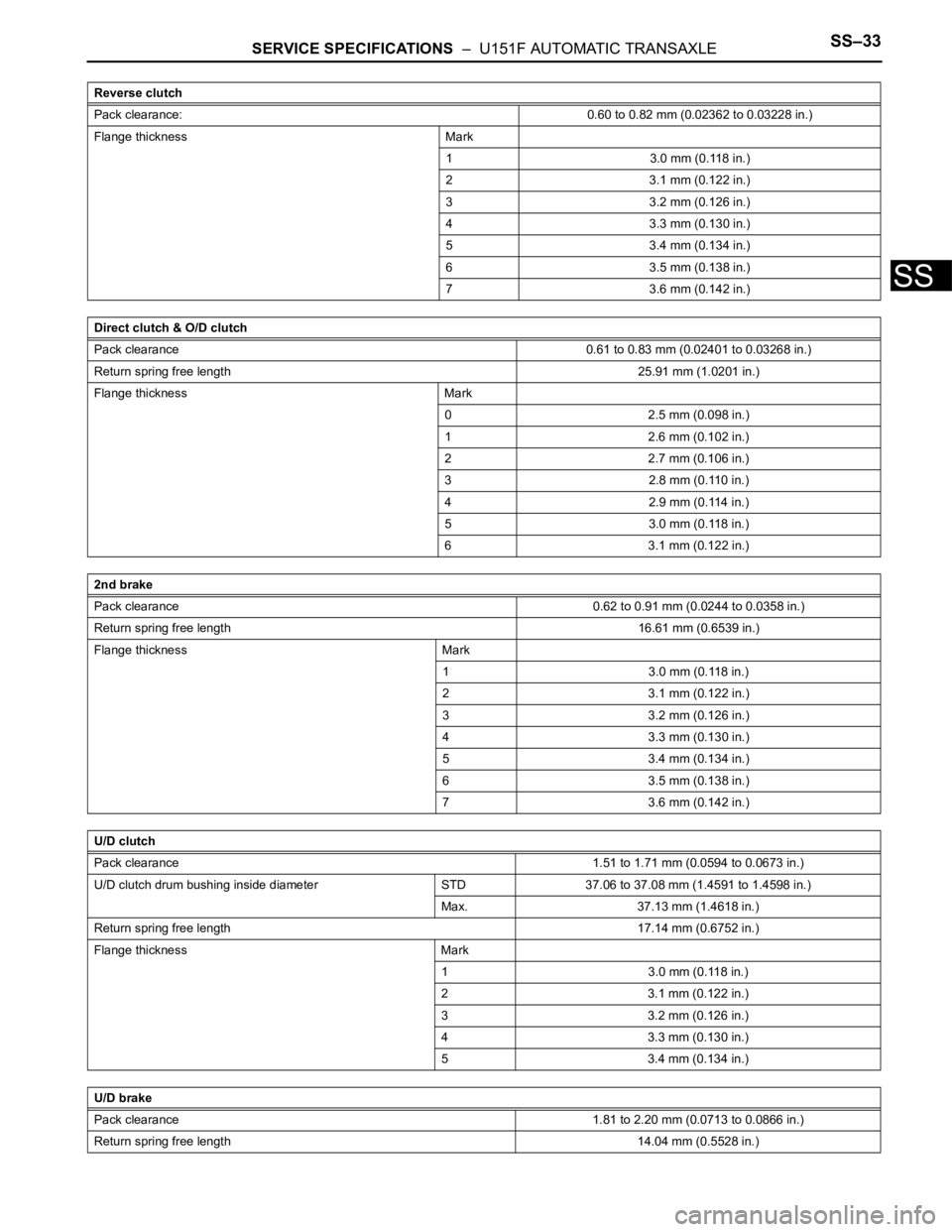

Reverse clutch

Pack clearance:0.60 to 0.82 mm (0.02362 to 0.03228 in.)

Flange thickness Mark

1 3.0 mm (0.118 in.)

2 3.1 mm (0.122 in.)

3 3.2 mm (0.126 in.)

4 3.3 mm (0.130 in.)

5 3.4 mm (0.134 in.)

6 3.5 mm (0.138 in.)

7 3.6 mm (0.142 in.)

Direct clutch & O/D clutch

Pack clearance0.61 to 0.83 mm (0.02401 to 0.03268 in.)

Return spring free length25.91 mm (1.0201 in.)

Flange thickness Mark

0 2.5 mm (0.098 in.)

1 2.6 mm (0.102 in.)

2 2.7 mm (0.106 in.)

3 2.8 mm (0.110 in.)

4 2.9 mm (0.114 in.)

5 3.0 mm (0.118 in.)

6 3.1 mm (0.122 in.)

2nd brake

Pack clearance0.62 to 0.91 mm (0.0244 to 0.0358 in.)

Return spring free length16.61 mm (0.6539 in.)

Flange thickness Mark

1 3.0 mm (0.118 in.)

2 3.1 mm (0.122 in.)

3 3.2 mm (0.126 in.)

4 3.3 mm (0.130 in.)

5 3.4 mm (0.134 in.)

6 3.5 mm (0.138 in.)

7 3.6 mm (0.142 in.)

U/D clutch

Pack clearance1.51 to 1.71 mm (0.0594 to 0.0673 in.)

U/D clutch drum bushing inside diameter STD 37.06 to 37.08 mm (1.4591 to 1.4598 in.)

Max. 37.13 mm (1.4618 in.)

Return spring free length17.14 mm (0.6752 in.)

Flange thickness Mark

1 3.0 mm (0.118 in.)

2 3.1 mm (0.122 in.)

3 3.2 mm (0.126 in.)

4 3.3 mm (0.130 in.)

5 3.4 mm (0.134 in.)

U/D brake

Pack clearance1.81 to 2.20 mm (0.0713 to 0.0866 in.)

Return spring free length14.04 mm (0.5528 in.)

Page 227 of 3000

SS–34SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSAXLE

SS

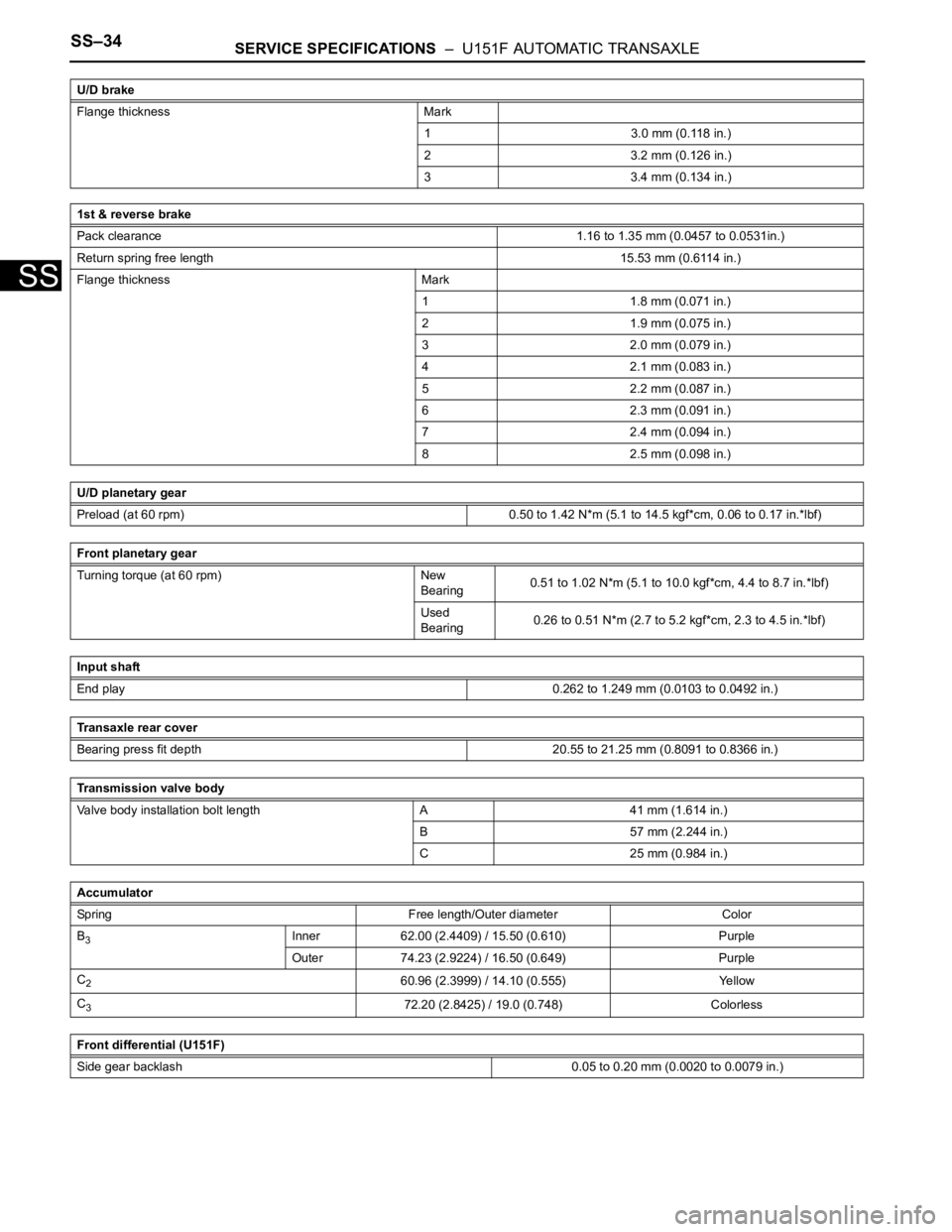

Flange thickness Mark

1 3.0 mm (0.118 in.)

2 3.2 mm (0.126 in.)

3 3.4 mm (0.134 in.)

1st & reverse brake

Pack clearance1.16 to 1.35 mm (0.0457 to 0.0531in.)

Return spring free length15.53 mm (0.6114 in.)

Flange thickness Mark

1 1.8 mm (0.071 in.)

2 1.9 mm (0.075 in.)

3 2.0 mm (0.079 in.)

4 2.1 mm (0.083 in.)

5 2.2 mm (0.087 in.)

6 2.3 mm (0.091 in.)

7 2.4 mm (0.094 in.)

8 2.5 mm (0.098 in.)

U/D planetary gear

Preload (at 60 rpm) 0.50 to 1.42 N*m (5.1 to 14.5 kgf*cm, 0.06 to 0.17 in.*lbf)

Front planetary gear

Turning torque (at 60 rpm) New

Bearing0.51 to 1.02 N*m (5.1 to 10.0 kgf*cm, 4.4 to 8.7 in.*lbf)

Used

Bearing0.26 to 0.51 N*m (2.7 to 5.2 kgf*cm, 2.3 to 4.5 in.*lbf)

Input shaft

End play0.262 to 1.249 mm (0.0103 to 0.0492 in.)

Transaxle rear cover

Bearing press fit depth 20.55 to 21.25 mm (0.8091 to 0.8366 in.)

Transmission valve body

Valve body installation bolt length A 41 mm (1.614 in.)

B 57 mm (2.244 in.)

C 25 mm (0.984 in.)

Accumulator

Spring Free length/Outer diameter Color

B

3Inner 62.00 (2.4409) / 15.50 (0.610) Purple

Outer 74.23 (2.9224) / 16.50 (0.649) Purple

C

260.96 (2.3999) / 14.10 (0.555) Yellow

C

372.20 (2.8425) / 19.0 (0.748) Colorless

Front differential (U151F)

Side gear backlash 0.05 to 0.20 mm (0.0020 to 0.0079 in.) U/D brake

Page 228 of 3000

SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSAXLESS–35

SS

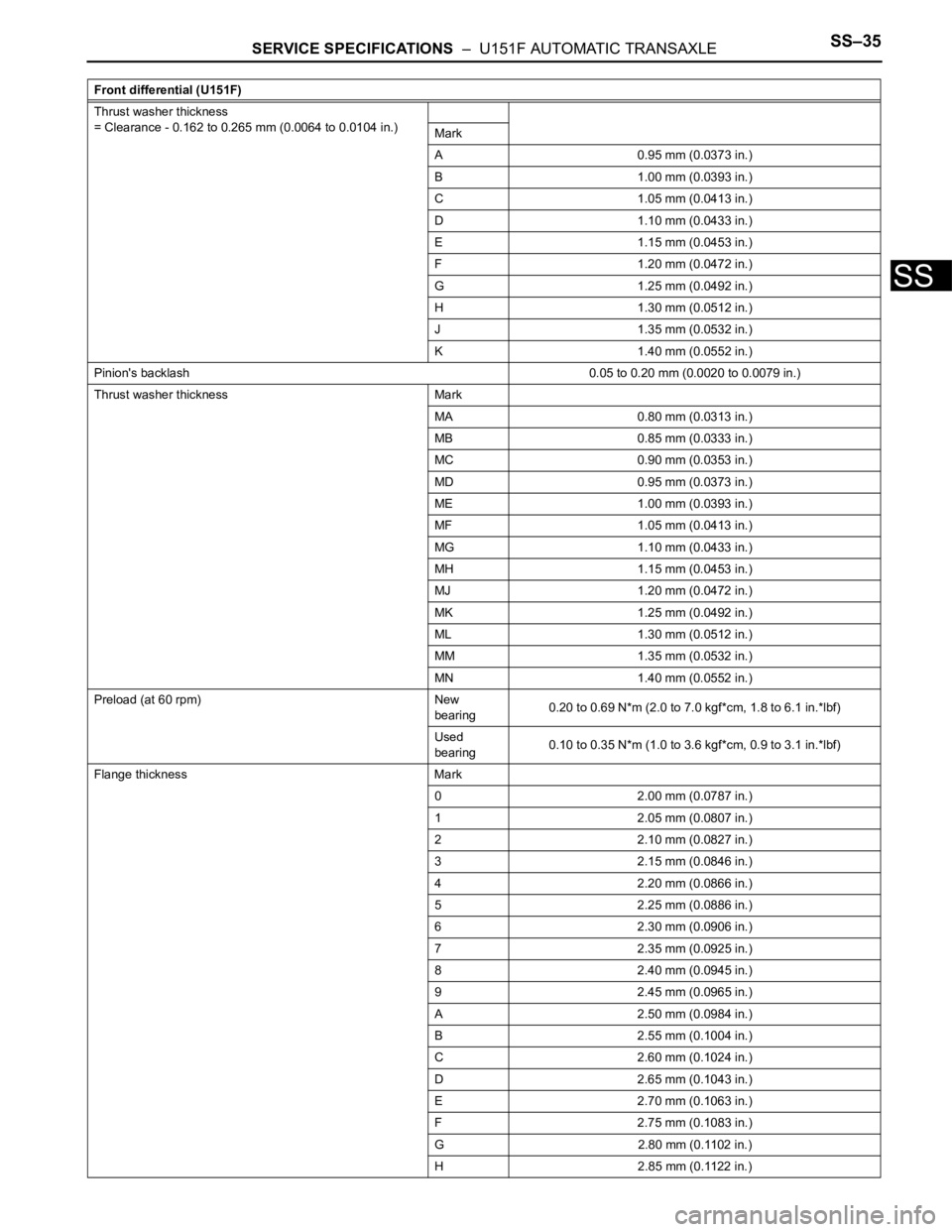

Thrust washer thickness

= Clearance - 0.162 to 0.265 mm (0.0064 to 0.0104 in.)

Mark

A 0.95 mm (0.0373 in.)

B 1.00 mm (0.0393 in.)

C 1.05 mm (0.0413 in.)

D 1.10 mm (0.0433 in.)

E 1.15 mm (0.0453 in.)

F 1.20 mm (0.0472 in.)

G 1.25 mm (0.0492 in.)

H 1.30 mm (0.0512 in.)

J 1.35 mm (0.0532 in.)

K 1.40 mm (0.0552 in.)

Pinion's backlash0.05 to 0.20 mm (0.0020 to 0.0079 in.)

Thrust washer thickness Mark

MA 0.80 mm (0.0313 in.)

MB 0.85 mm (0.0333 in.)

MC 0.90 mm (0.0353 in.)

MD 0.95 mm (0.0373 in.)

ME 1.00 mm (0.0393 in.)

MF 1.05 mm (0.0413 in.)

MG 1.10 mm (0.0433 in.)

MH 1.15 mm (0.0453 in.)

MJ 1.20 mm (0.0472 in.)

MK 1.25 mm (0.0492 in.)

ML 1.30 mm (0.0512 in.)

MM 1.35 mm (0.0532 in.)

MN 1.40 mm (0.0552 in.)

Preload (at 60 rpm) New

bearing0.20 to 0.69 N*m (2.0 to 7.0 kgf*cm, 1.8 to 6.1 in.*lbf)

Used

bearing0.10 to 0.35 N*m (1.0 to 3.6 kgf*cm, 0.9 to 3.1 in.*lbf)

Flange thickness Mark

0 2.00 mm (0.0787 in.)

1 2.05 mm (0.0807 in.)

2 2.10 mm (0.0827 in.)

3 2.15 mm (0.0846 in.)

4 2.20 mm (0.0866 in.)

5 2.25 mm (0.0886 in.)

6 2.30 mm (0.0906 in.)

7 2.35 mm (0.0925 in.)

8 2.40 mm (0.0945 in.)

9 2.45 mm (0.0965 in.)

A 2.50 mm (0.0984 in.)

B 2.55 mm (0.1004 in.)

C 2.60 mm (0.1024 in.)

D 2.65 mm (0.1043 in.)

E 2.70 mm (0.1063 in.)

F 2.75 mm (0.1083 in.)

G 2.80 mm (0.1102 in.)

H 2.85 mm (0.1122 in.) Front differential (U151F)

Page 229 of 3000

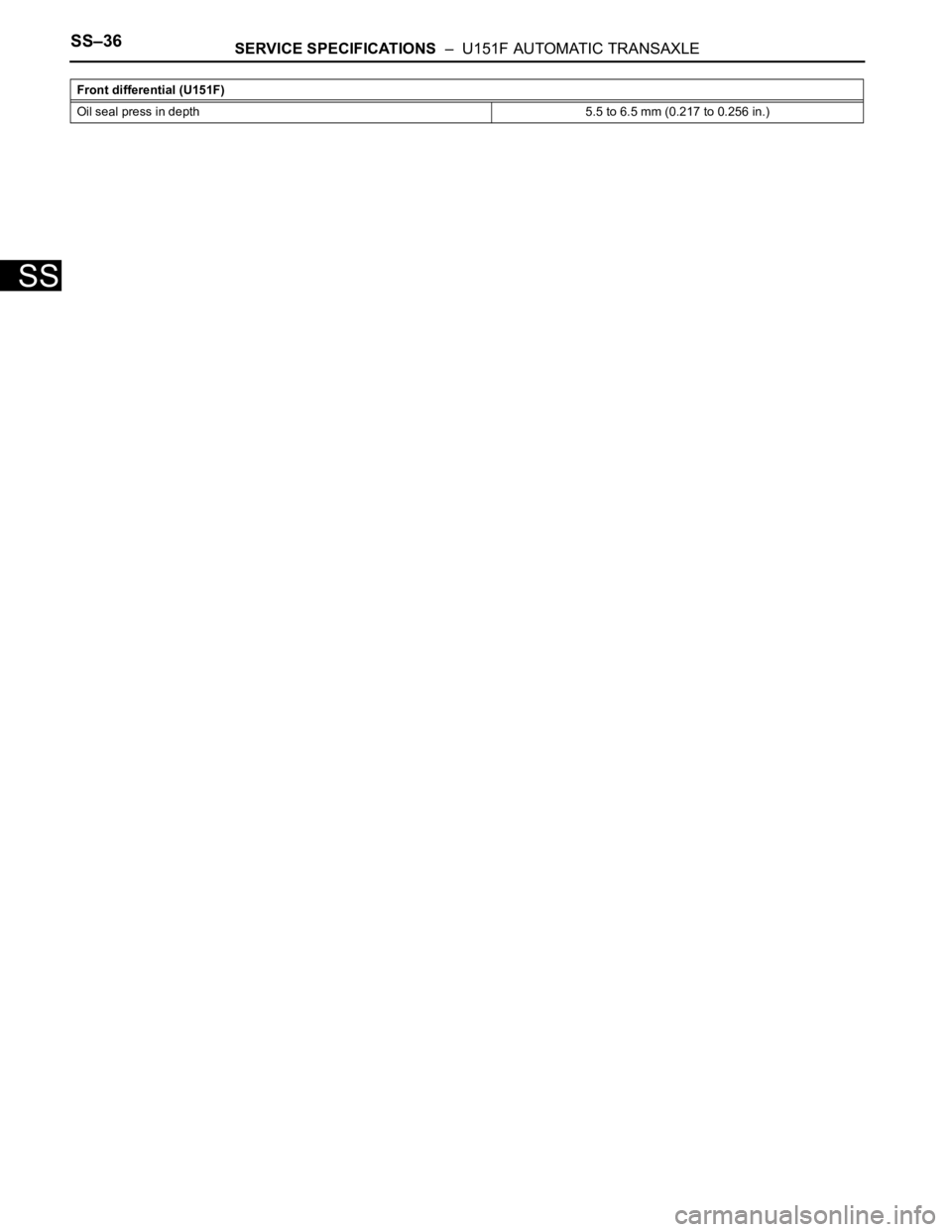

SS–36SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSAXLE

SS

Oil seal press in depth 5.5 to 6.5 mm (0.217 to 0.256 in.) Front differential (U151F)

Page 361 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–43

ES

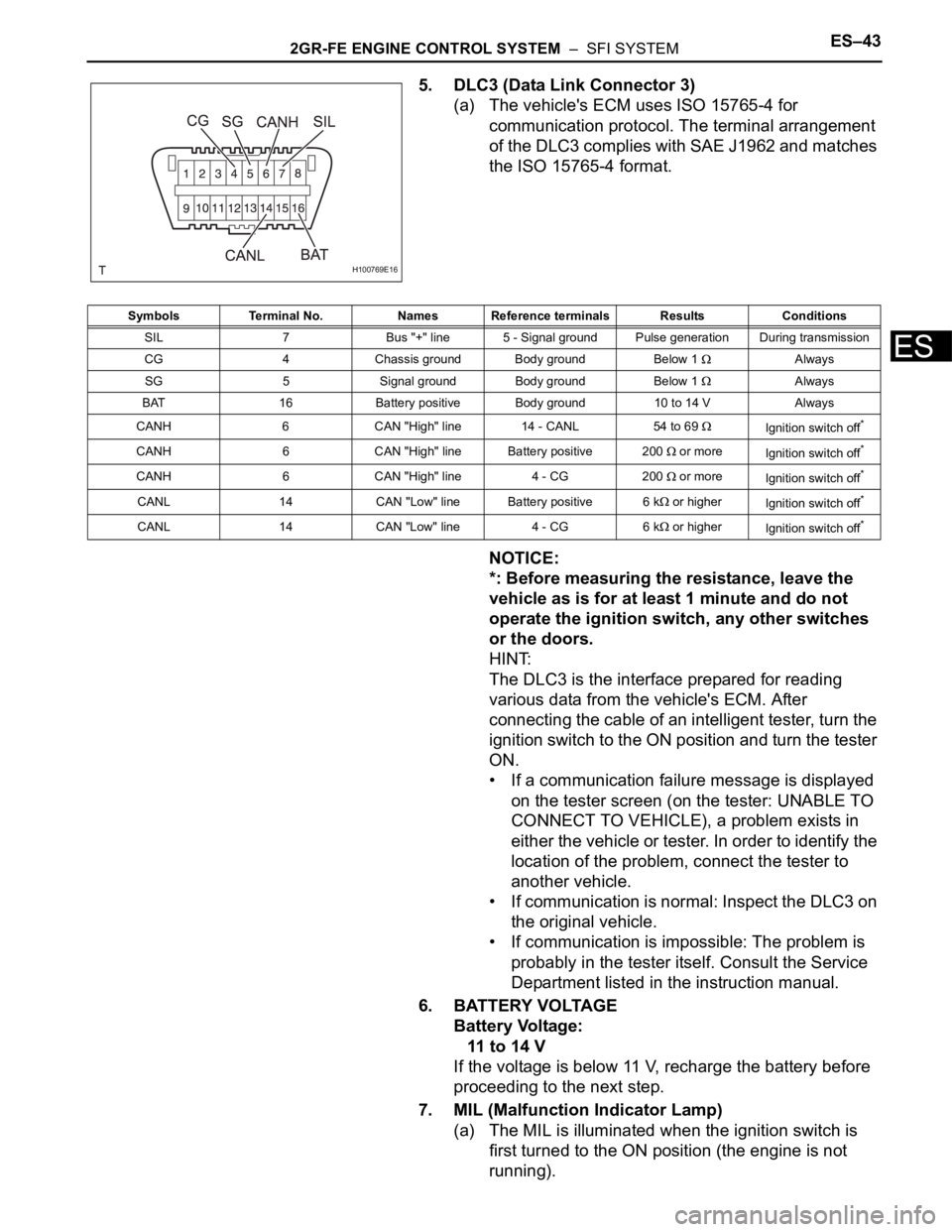

5. DLC3 (Data Link Connector 3)

(a) The vehicle's ECM uses ISO 15765-4 for

communication protocol. The terminal arrangement

of the DLC3 complies with SAE J1962 and matches

the ISO 15765-4 format.

NOTICE:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

operate the ignition switch, any other switches

or the doors.

HINT:

The DLC3 is the interface prepared for reading

various data from the vehicle's ECM. After

connecting the cable of an intelligent tester, turn the

ignition switch to the ON position and turn the tester

ON.

• If a communication failure message is displayed

on the tester screen (on the tester: UNABLE TO

CONNECT TO VEHICLE), a problem exists in

either the vehicle or tester. In order to identify the

location of the problem, connect the tester to

another vehicle.

• If communication is normal: Inspect the DLC3 on

the original vehicle.

• If communication is impossible: The problem is

probably in the tester itself. Consult the Service

Department listed in the instruction manual.

6. BATTERY VOLTAGE

Battery Voltage:

11 to 14 V

If the voltage is below 11 V, recharge the battery before

proceeding to the next step.

7. MIL (Malfunction Indicator Lamp)

(a) The MIL is illuminated when the ignition switch is

first turned to the ON position (the engine is not

running).

H100769E16

Symbols Terminal No. Names Reference terminals Results Conditions

SIL 7 Bus "+" line 5 - Signal ground Pulse generation During transmission

CG 4 Chassis ground Body ground Below 1

Always

SG 5 Signal ground Body ground Below 1

Always

BAT 16 Battery positive Body ground 10 to 14 V Always

CANH 6 CAN "High" line 14 - CANL 54 to 69

Ignition switch off*

CANH 6 CAN "High" line Battery positive 200 or more

Ignition switch off*

CANH 6 CAN "High" line 4 - CG 200 or more

Ignition switch off*

CANL 14 CAN "Low" line Battery positive 6 k or higher

Ignition switch off*

CANL 14 CAN "Low" line 4 - CG 6 k or higher

Ignition switch off*

Page 705 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–419

ES

Cut-off valve Located in fuel tank. Valve floats and closes when fuel tank is 100% full.

Purge VSV (Vacuum Switching Valve)Opens or closes line between canister and intake manifold. ECM uses purge VSV to control EVAP

purge flow. In order to discharge EVAP absorbed by canister to intake manifold, ECM opens purge

VSV. EVAP discharge volume to intake manifold is controlled by purge VSV duty cycle ratio

(current-carrying time). (Open: ON, Close: OFF)

Refueling valveControls EVAP pressure from fuel tank to canister. Valve consists of diaphragm, spring and

restrictor (diameter: 0.08 inch). When fuel vapor and pressure inside fuel tank increase, valve

opens. While EVAP is purged, valve closes and restrictor prevents a large amount of vacuum from

affecting pressure in fuel tank. Valve is opened while refueling. When valve is open, adding fuel into

fuel tank is possible.

Roll-over valveLocated in fuel tank. Valve closes by its own weight when vehicle overturns to prevent fuel from

spilling out.

Service port Used for connecting vacuum gauge for inspecting EVAP system.

Soak timerBuilt into ECM. To ensure accurate EVAP monitor, measures 5 hours (+/- 15 min.) after ignition

switch is turned off. This allows fuel to cool down, stabilizing Fuel Tank Pressure (FTP). When

approx. 5 hours elapsed, ECM activates.

Canister pump module Consists of (a) to (d) below. Pump module cannot be disassembled.

(a) Vent valveVents and closes EVAP system. When ECM turns valve ON, EVAP system is closed. When ECM

turns valve OFF, EVAP system is vented. Negative pressure (vacuum) is created in EVAP system

to check for EVAP leaks by closing purge VSV and vent valve (closed), and operating vacuum

pump are turned on (refer to fig. 1).

(b) Canister pressure sensorIndicates pressure as voltages. ECM supplies regulated 5 V to pressure sensor, and uses feedback

from sensor to monitor EVAP system pressure (refer to fig 2).

(c) Vacuum pump Creates negative pressure (vacuum) in EVAP system for leak check.

(d) 0.02 inch orificeHas an opening with 0.02 inch diameter. Vacuum is produced through orifice by closing purge VSV,

turning off vent valve and operating vacuum pump, to monitor 0.02 inch leak pressure. 0.02 inch

leak pressure indicates a small leak of EVAP. Component Operation