TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 321 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–253

ES

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

Exhaust Camshaft Sensor Range Check / Rationality (While starting engine):

Exhaust Camshaft Sensor Range Check / Rationality (After starting engine):

Exhaust Camshaft Sensor Range Check (Chattering, Low voltage, High voltage):

TYPICAL MALFUNCTION THRESHOLDS

Exhaust Camshaft Sensor Range Check / Rationality (While starting engine):

Exhaust Camshaft Sensor Range Check / Rationality (After starting engine):

Exhaust Camshaft Sensor Range Check (Chattering):

Related DTCsP0365: Exhaust camshaft sensor (Bank 1) range check / rationality (while starting

engine)

P0365: Exhaust camshaft sensor (Bank 1) range check / rationality (after starting

engine)

P0365: Exhaust camshaft sensor (Bank 1) range check (chattering)

P0367: Exhaust camshaft sensor (Bank 1) range check (low voltage)

P0368: Exhaust camshaft sensor (Bank 1) range check (high voltage)

P0390: Exhaust camshaft sensor (Bank 2) range check / rationality (while starting

engine)

P0390: Exhaust camshaft sensor (Bank 2) range check / rationality (after starting

engine)

P0390: Exhaust camshaft sensor (Bank 2) range check (chattering)

P0392: Exhaust camshaft sensor (Bank 2) range check (low voltage)

P0393: Exhaust camshaft sensor (Bank 2) range check (high voltage)

Required Sensors / Components (Main) Exhaust camshaft sensor (Bank 1 and 2)

Required Sensors / Components (Related) Exhaust camshaft sensor

Frequency of Operation Continuous

Duration5 seconds: Exhaust camshaft sensor range check / rationality (After starting engine)

4 seconds: Others

MIL Operation2 driving cycles: Exhaust camshaft sensor range check / rationality (After starting

engine)

Immediate: Others

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Sta r t e r ON

Battery voltage while starter is ON at least once Less than 11 V

Engine RPM 600 rpm or more

Sta r t e r OF F

Battery voltage 8 V or more

Ignition Switch ON

Sta r t e r OF F

Ignition Switch ON and time after ignition switch is OFF

to ON2 seconds or more

Battery voltage 8 V or more

Exhaust camshaft sensor signal No signal

Exhaust camshaft sensor signal No signal

Exhaust camshaft sensor signal Less than 0.3 V, or more than 4.7 V

Page 322 of 3000

ES–2542GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

Exhaust Camshaft Sensor Range Check (Low voltage):

Exhaust Camshaft Sensor Range Check (High voltage):

WIRING DIAGRAM

Refer to DTC P0335 (See page ES-222).

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

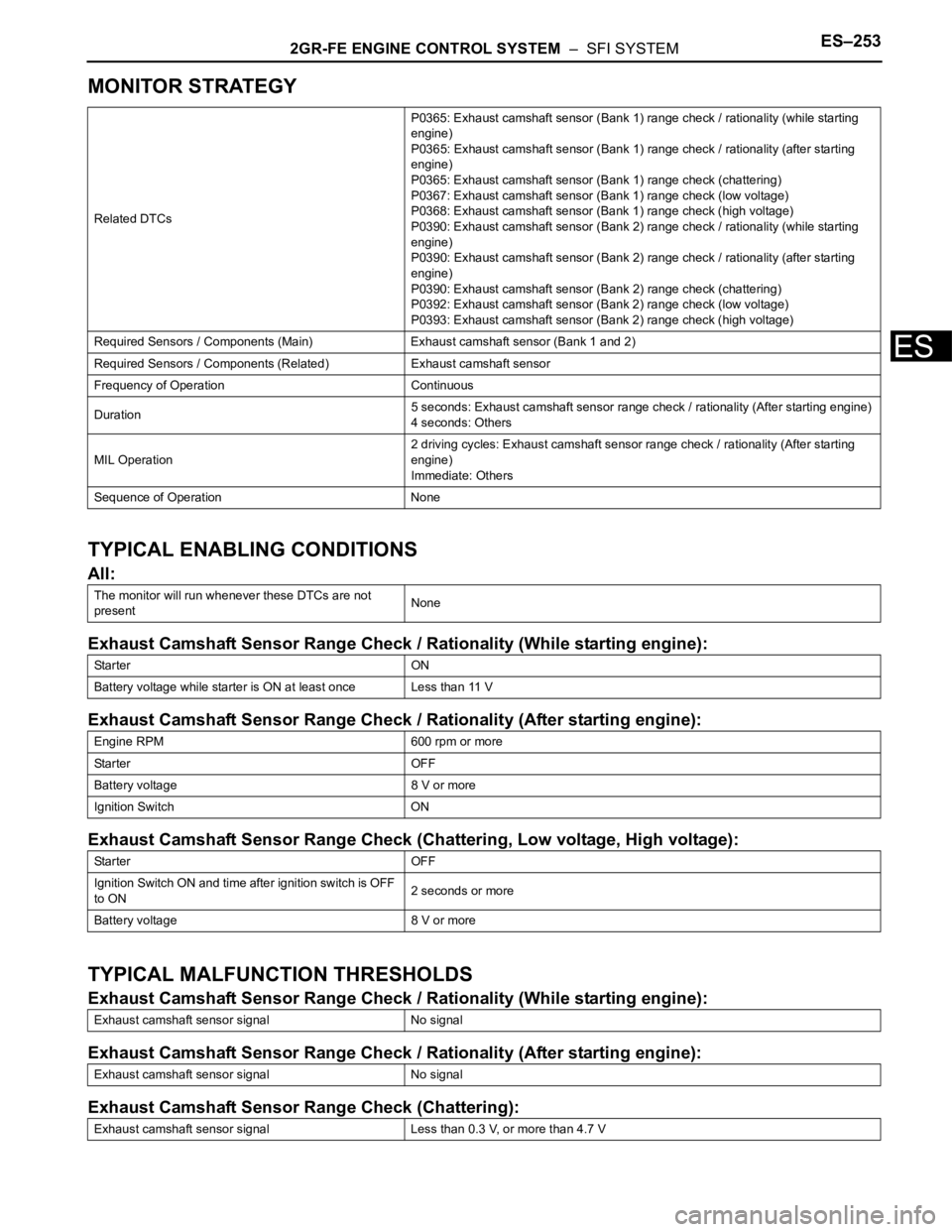

(a) Disconnect the C21 or C20 VVT sensor connector.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

Exhaust camshaft sensor signal Less than 0.3 V

Exhaust camshaft sensor signal More than 4.7 V

1CHECK VVT SENSOR FOR EXHAUST CAMSHAFT (SENSOR POWER SOURCE)

A107149E59

Tester Connection Specified Condition

VC2 (C20-3) - Body ground 4.5 to 5.0 V

VC2 (C21-3) - Body ground 4.5 to 5.0 V

Go to step 7

Page 323 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–255

ES

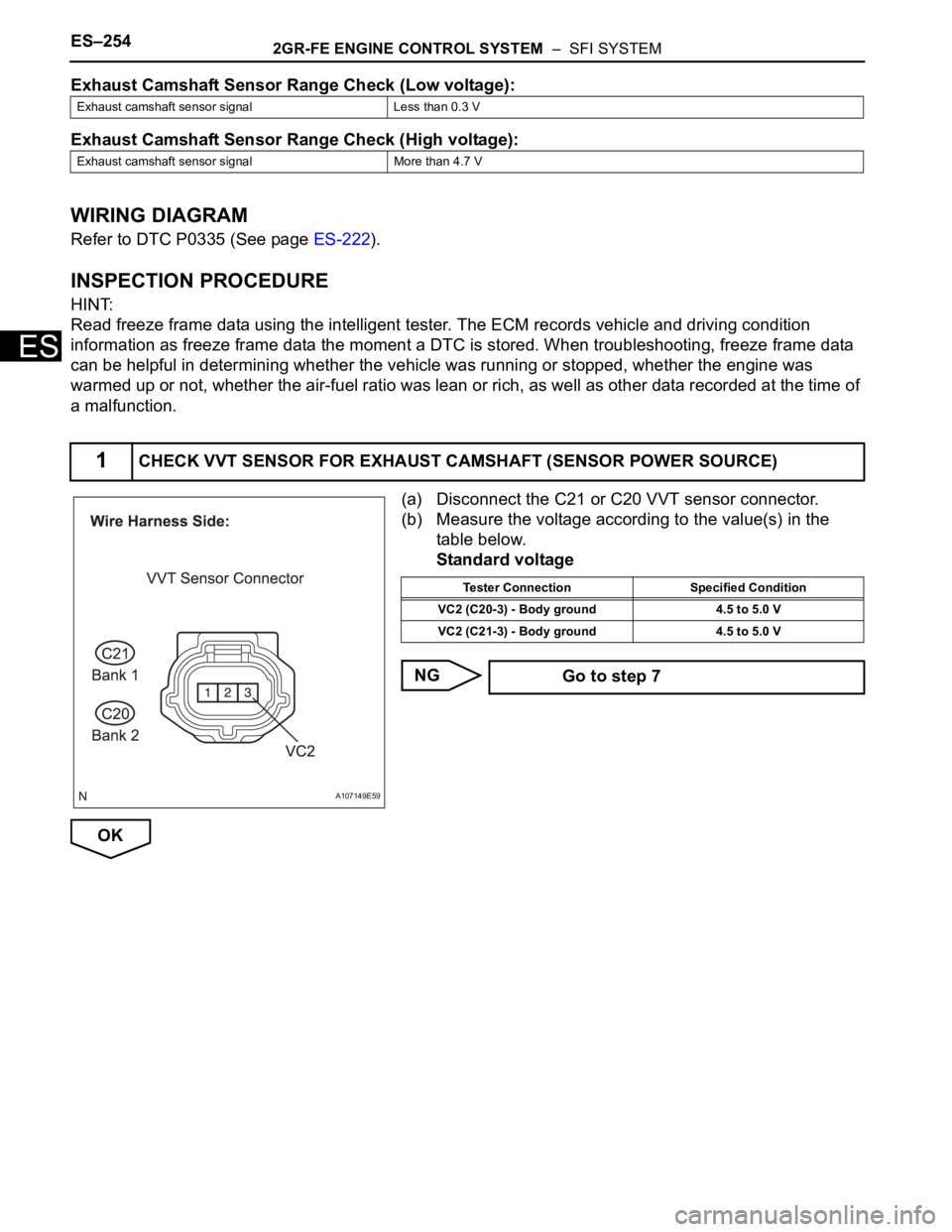

(a) Disconnect the C21 or C20 VVT sensor for exhaust

camshaft connector.

(b) Disconnect the E11 ECM connector.

(c) Measure the resistance between the wire harness side

connectors.

Standard resistance:

Check for open

Check for short

NG

OK

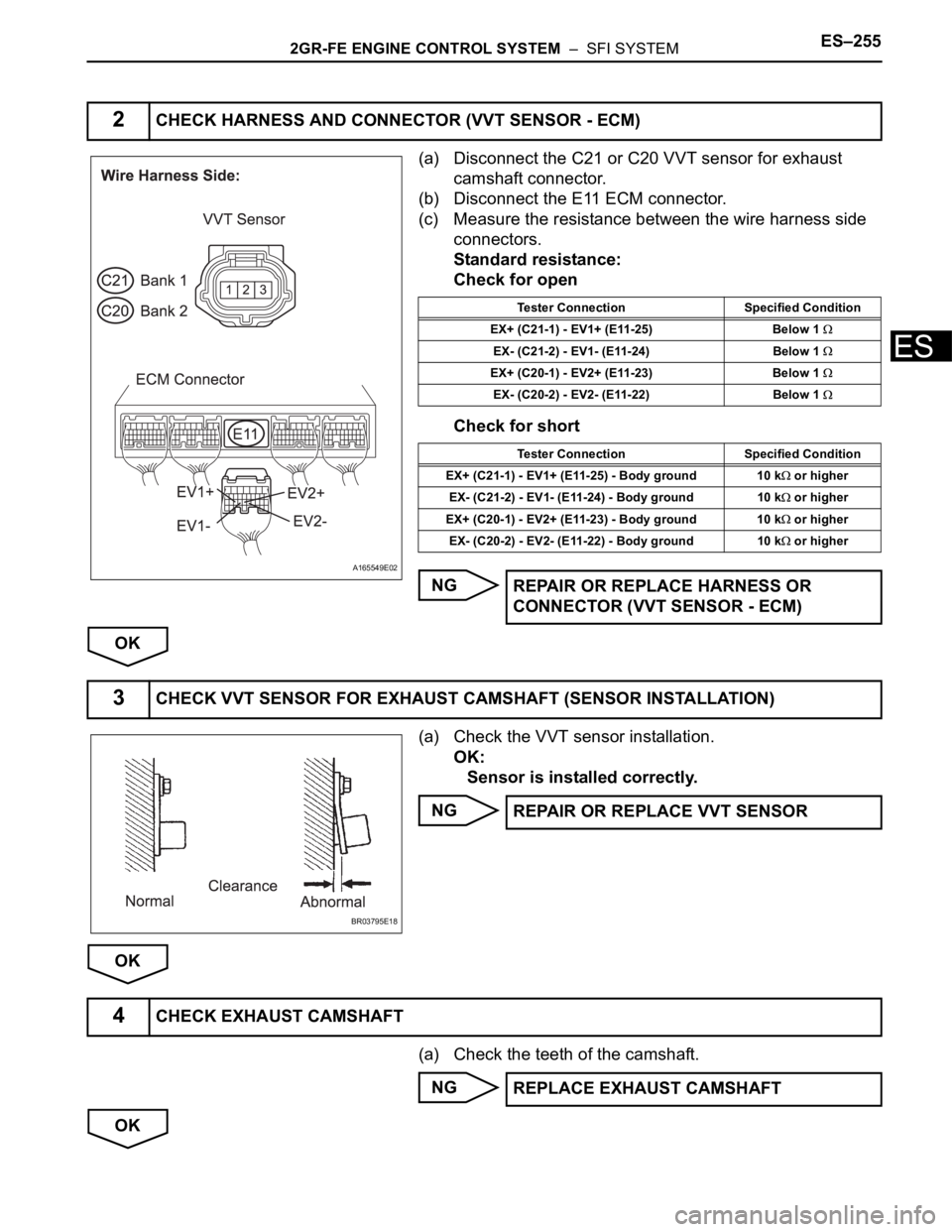

(a) Check the VVT sensor installation.

OK:

Sensor is installed correctly.

NG

OK

(a) Check the teeth of the camshaft.

NG

OK

2CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM)

A165549E02

Tester Connection Specified Condition

EX+ (C21-1) - EV1+ (E11-25) Below 1

EX- (C21-2) - EV1- (E11-24) Below 1

EX+ (C20-1) - EV2+ (E11-23) Below 1

EX- (C20-2) - EV2- (E11-22) Below 1

Tester Connection Specified Condition

EX+ (C21-1) - EV1+ (E11-25) - Body ground 10 k

or higher

EX- (C21-2) - EV1- (E11-24) - Body ground 10 k

or higher

EX+ (C20-1) - EV2+ (E11-23) - Body ground 10 k

or higher

EX- (C20-2) - EV2- (E11-22) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (VVT SENSOR - ECM)

3CHECK VVT SENSOR FOR EXHAUST CAMSHAFT (SENSOR INSTALLATION)

BR03795E18

REPAIR OR REPLACE VVT SENSOR

4CHECK EXHAUST CAMSHAFT

REPLACE EXHAUST CAMSHAFT

Page 324 of 3000

ES–2562GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(a) Replace the VVT sensor (See page ES-509).

NEXT

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the intelligent tester on.

(d) Clear the DTCs.

(e) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC / INFO / PENDING CODES.

(f) Read the DTCs.

Result

HINT:

If the engine does not start, replace the ECM.

B

A

5REPLACE VVT SENSOR (FOR EXHAUST CAMSHAFT)

6CHECK WHETHER DTC OUTPUT RECURS

Display (DTC Output) Proceed to

No output A

P0365, P0352, P0353, P0354, P0355 or P0356 B

REPLACE ECM (See page ES-498)

END

Page 325 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–257

ES

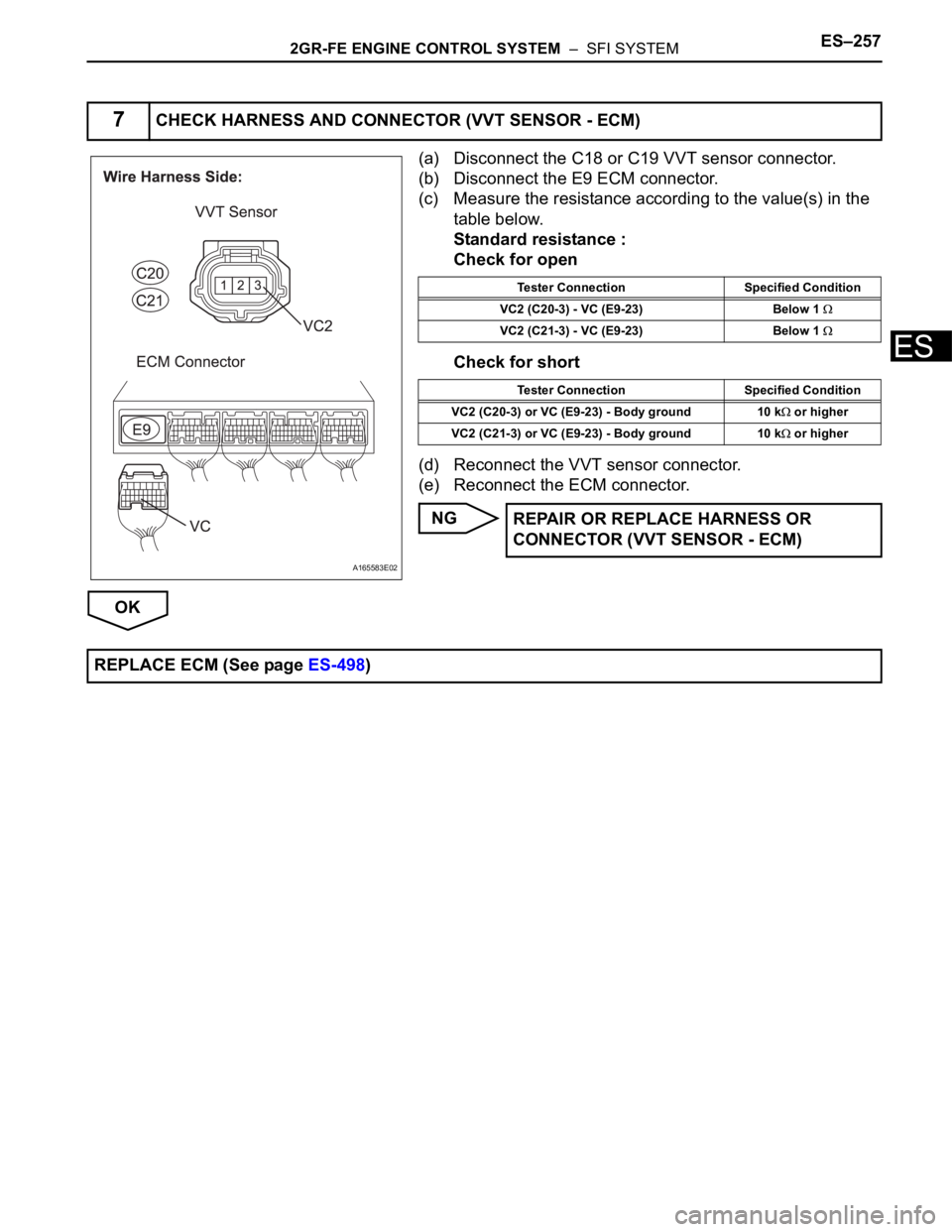

(a) Disconnect the C18 or C19 VVT sensor connector.

(b) Disconnect the E9 ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance :

Check for open

Check for short

(d) Reconnect the VVT sensor connector.

(e) Reconnect the ECM connector.

NG

OK

7CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM)

A165583E02

Tester Connection Specified Condition

VC2 (C20-3) - VC (E9-23) Below 1

VC2 (C21-3) - VC (E9-23) Below 1

Tester Connection Specified Condition

VC2 (C20-3) or VC (E9-23) - Body ground 10 k

or higher

VC2 (C21-3) or VC (E9-23) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (VVT SENSOR - ECM)

REPLACE ECM (See page ES-498)

Page 326 of 3000

ES–2582GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

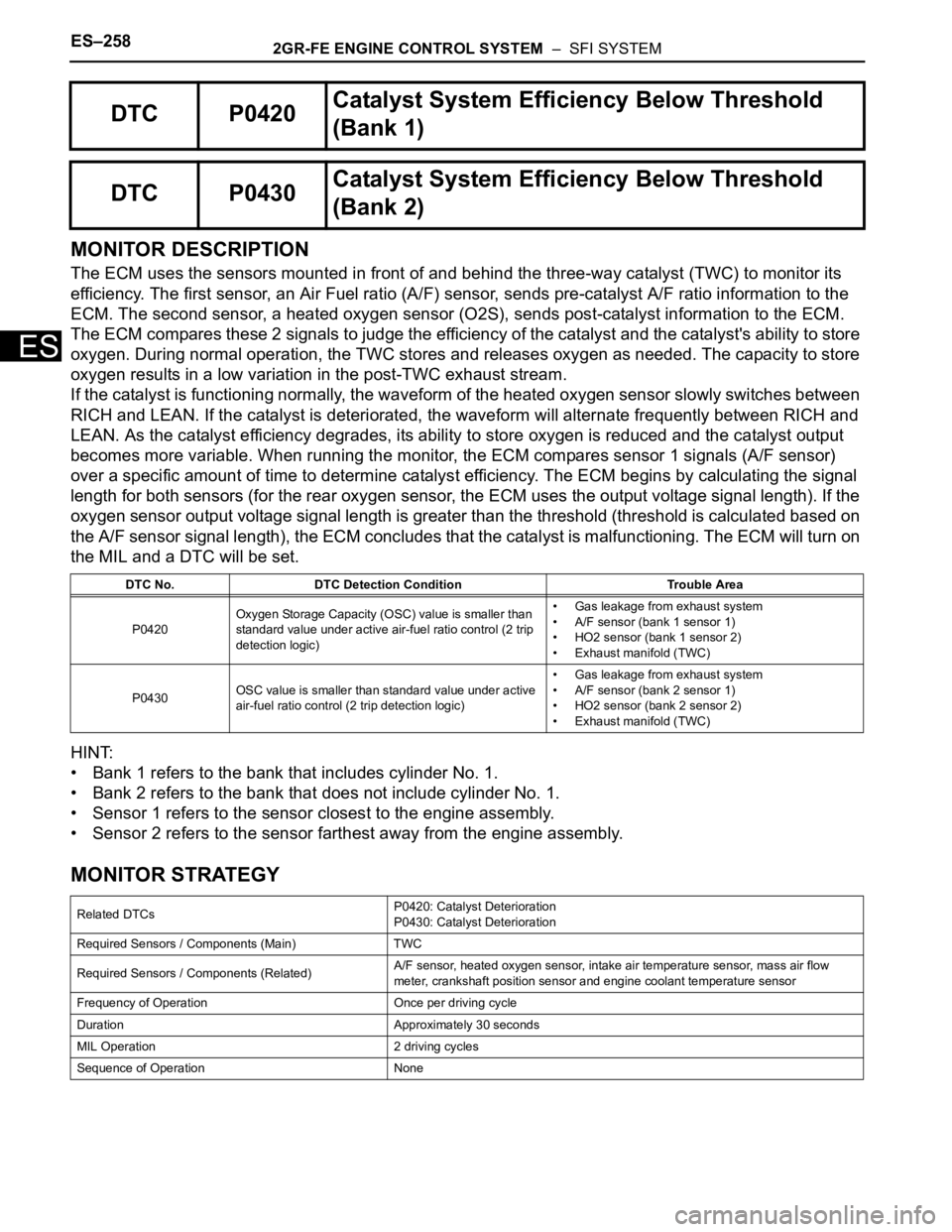

MONITOR DESCRIPTION

The ECM uses the sensors mounted in front of and behind the three-way catalyst (TWC) to monitor its

efficiency. The first sensor, an Air Fuel ratio (A/F) sensor, sends pre-catalyst A/F ratio information to the

ECM. The second sensor, a heated oxygen sensor (O2S), sends post-catalyst information to the ECM.

The ECM compares these 2 signals to judge the efficiency of the catalyst and the catalyst's ability to store

oxygen. During normal operation, the TWC stores and releases oxygen as needed. The capacity to store

oxygen results in a low variation in the post-TWC exhaust stream.

If the catalyst is functioning normally, the waveform of the heated oxygen sensor slowly switches between

RICH and LEAN. If the catalyst is deteriorated, the waveform will alternate frequently between RICH and

LEAN. As the catalyst efficiency degrades, its ability to store oxygen is reduced and the catalyst output

becomes more variable. When running the monitor, the ECM compares sensor 1 signals (A/F sensor)

over a specific amount of time to determine catalyst efficiency. The ECM begins by calculating the signal

length for both sensors (for the rear oxygen sensor, the ECM uses the output voltage signal length). If the

oxygen sensor output voltage signal length is greater than the threshold (threshold is calculated based on

the A/F sensor signal length), the ECM concludes that the catalyst is malfunctioning. The ECM will turn on

the MIL and a DTC will be set.

HINT:

• Bank 1 refers to the bank that includes cylinder No. 1.

• Bank 2 refers to the bank that does not include cylinder No. 1.

• Sensor 1 refers to the sensor closest to the engine assembly.

• Sensor 2 refers to the sensor farthest away from the engine assembly.

MONITOR STRATEGY

DTC P0420Catalyst System Efficiency Below Threshold

(Bank 1)

DTC P0430Catalyst System Efficiency Below Threshold

(Bank 2)

DTC No. DTC Detection Condition Trouble Area

P0420Oxygen Storage Capacity (OSC) value is smaller than

standard value under active air-fuel ratio control (2 trip

detection logic)• Gas leakage from exhaust system

• A/F sensor (bank 1 sensor 1)

• HO2 sensor (bank 1 sensor 2)

• Exhaust manifold (TWC)

P0430OSC value is smaller than standard value under active

air-fuel ratio control (2 trip detection logic)• Gas leakage from exhaust system

• A/F sensor (bank 2 sensor 1)

• HO2 sensor (bank 2 sensor 2)

• Exhaust manifold (TWC)

Related DTCsP0420: Catalyst Deterioration

P0430: Catalyst Deterioration

Required Sensors / Components (Main) TWC

Required Sensors / Components (Related)A/F sensor, heated oxygen sensor, intake air temperature sensor, mass air flow

meter, crankshaft position sensor and engine coolant temperature sensor

Frequency of Operation Once per driving cycle

Duration Approximately 30 seconds

MIL Operation 2 driving cycles

Sequence of Operation None

Page 327 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–259

ES

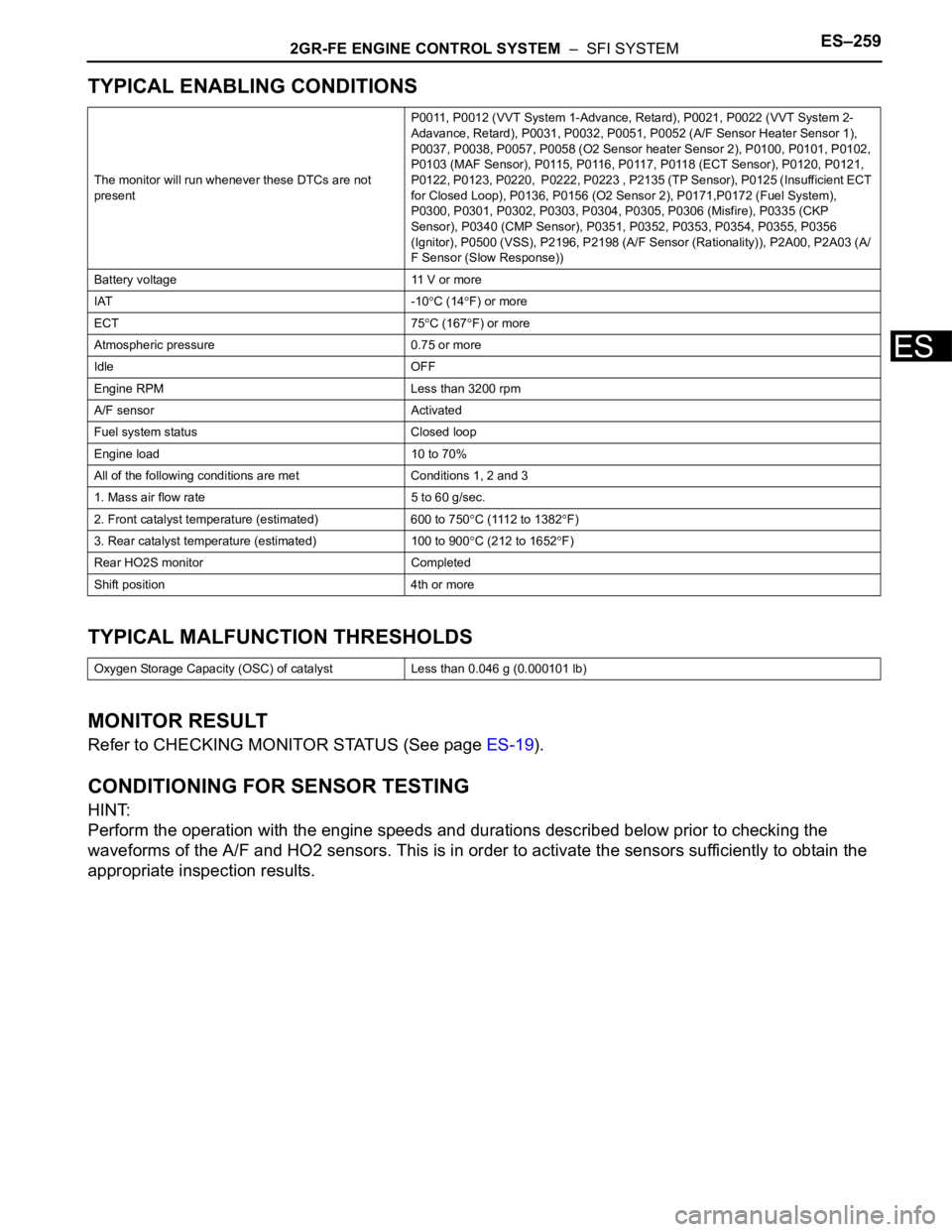

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

CONDITIONING FOR SENSOR TESTING

HINT:

Perform the operation with the engine speeds and durations described below prior to checking the

waveforms of the A/F and HO2 sensors. This is in order to activate the sensors sufficiently to obtain the

appropriate inspection results.

The monitor will run whenever these DTCs are not

presentP0011, P0012 (VVT System 1-Advance, Retard), P0021, P0022 (VVT System 2-

Adavance, Retard), P0031, P0032, P0051, P0052 (A/F Sensor Heater Sensor 1),

P0037, P0038, P0057, P0058 (O2 Sensor heater Sensor 2), P0100, P0101, P0102,

P0103 (MAF Sensor), P0115, P0116, P0117, P0118 (ECT Sensor), P0120, P0121,

P0122, P0123, P0220, P0222, P0223 , P2135 (TP Sensor), P0125 (Insufficient ECT

for Closed Loop), P0136, P0156 (O2 Sensor 2), P0171,P0172 (Fuel System),

P0300, P0301, P0302, P0303, P0304, P0305, P0306 (Misfire), P0335 (CKP

Sensor), P0340 (CMP Sensor), P0351, P0352, P0353, P0354, P0355, P0356

(Ignitor), P0500 (VSS), P2196, P2198 (A/F Sensor (Rationality)), P2A00, P2A03 (A/

F Sensor (Slow Response))

Battery voltage 11 V or more

IAT -10

C (14F) or more

ECT 75

C (167F) or more

Atmospheric pressure 0.75 or more

Idle OFF

Engine RPM Less than 3200 rpm

A/F sensor Activated

Fuel system status Closed loop

Engine load 10 to 70%

All of the following conditions are met Conditions 1, 2 and 3

1. Mass air flow rate 5 to 60 g/sec.

2. Front catalyst temperature (estimated) 600 to 750

C (1112 to 1382F)

3. Rear catalyst temperature (estimated) 100 to 900

C (212 to 1652F)

Rear HO2S monitor Completed

Shift position 4th or more

Oxygen Storage Capacity (OSC) of catalyst Less than 0.046 g (0.000101 lb)

Page 328 of 3000

ES–2602GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

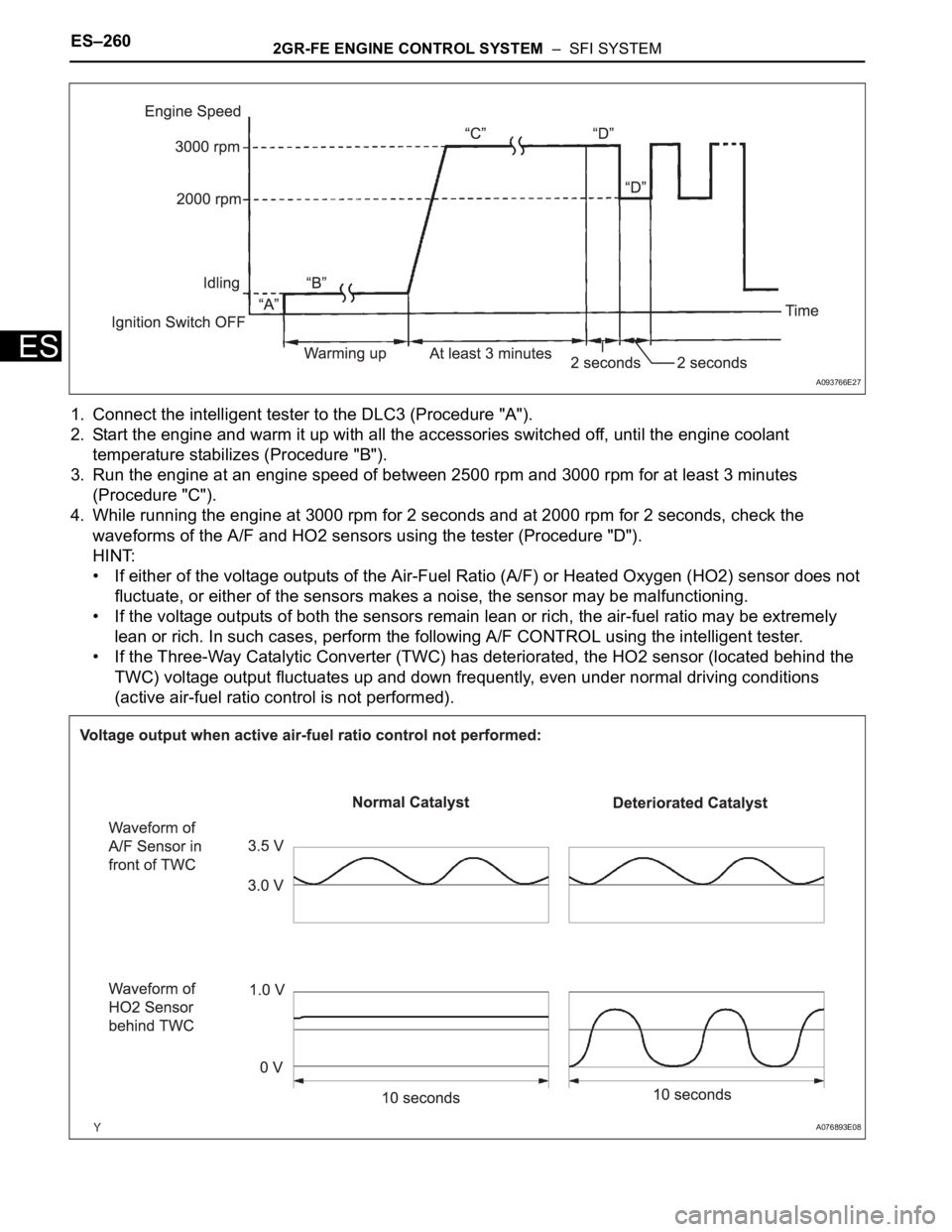

1. Connect the intelligent tester to the DLC3 (Procedure "A").

2. Start the engine and warm it up with all the accessories switched off, until the engine coolant

temperature stabilizes (Procedure "B").

3. Run the engine at an engine speed of between 2500 rpm and 3000 rpm for at least 3 minutes

(Procedure "C").

4. While running the engine at 3000 rpm for 2 seconds and at 2000 rpm for 2 seconds, check the

waveforms of the A/F and HO2 sensors using the tester (Procedure "D").

HINT:

• If either of the voltage outputs of the Air-Fuel Ratio (A/F) or Heated Oxygen (HO2) sensor does not

fluctuate, or either of the sensors makes a noise, the sensor may be malfunctioning.

• If the voltage outputs of both the sensors remain lean or rich, the air-fuel ratio may be extremely

lean or rich. In such cases, perform the following A/F CONTROL using the intelligent tester.

• If the Three-Way Catalytic Converter (TWC) has deteriorated, the HO2 sensor (located behind the

TWC) voltage output fluctuates up and down frequently, even under normal driving conditions

(active air-fuel ratio control is not performed).

A093766E27

A076893E08

Page 329 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–261

ES

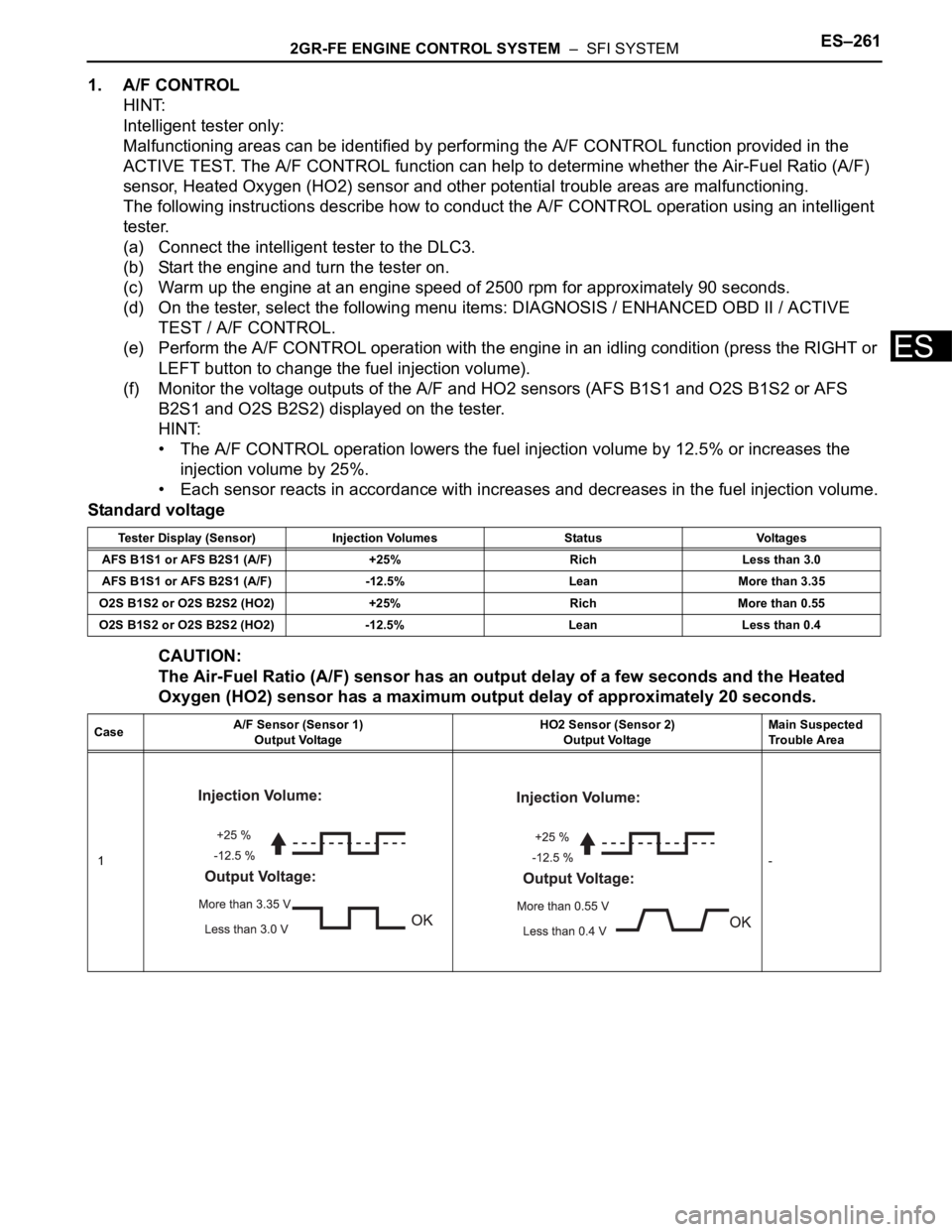

1. A/F CONTROL

HINT:

Intelligent tester only:

Malfunctioning areas can be identified by performing the A/F CONTROL function provided in the

ACTIVE TEST. The A/F CONTROL function can help to determine whether the Air-Fuel Ratio (A/F)

sensor, Heated Oxygen (HO2) sensor and other potential trouble areas are malfunctioning.

The following instructions describe how to conduct the A/F CONTROL operation using an intelligent

tester.

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine at an engine speed of 2500 rpm for approximately 90 seconds.

(d) On the tester, select the following menu items: DIAGNOSIS / ENHANCED OBD II / ACTIVE

TEST / A/F CONTROL.

(e) Perform the A/F CONTROL operation with the engine in an idling condition (press the RIGHT or

LEFT button to change the fuel injection volume).

(f) Monitor the voltage outputs of the A/F and HO2 sensors (AFS B1S1 and O2S B1S2 or AFS

B2S1 and O2S B2S2) displayed on the tester.

HINT:

• The A/F CONTROL operation lowers the fuel injection volume by 12.5% or increases the

injection volume by 25%.

• Each sensor reacts in accordance with increases and decreases in the fuel injection volume.

Standard voltage

CAUTION:

The Air-Fuel Ratio (A/F) sensor has an output delay of a few seconds and the Heated

Oxygen (HO2) sensor has a maximum output delay of approximately 20 seconds.

Tester Display (Sensor) Injection Volumes Status Voltages

AFS B1S1 or AFS B2S1 (A/F) +25% Rich Less than 3.0

AFS B1S1 or AFS B2S1 (A/F) -12.5% Lean More than 3.35

O2S B1S2 or O2S B2S2 (HO2) +25% Rich More than 0.55

O2S B1S2 or O2S B2S2 (HO2) -12.5% Lean Less than 0.4

CaseA/F Sensor (Sensor 1)

Output VoltageHO2 Sensor (Sensor 2)

Output VoltageMain Suspected

Trouble Area

1-

Page 330 of 3000

ES–2622GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

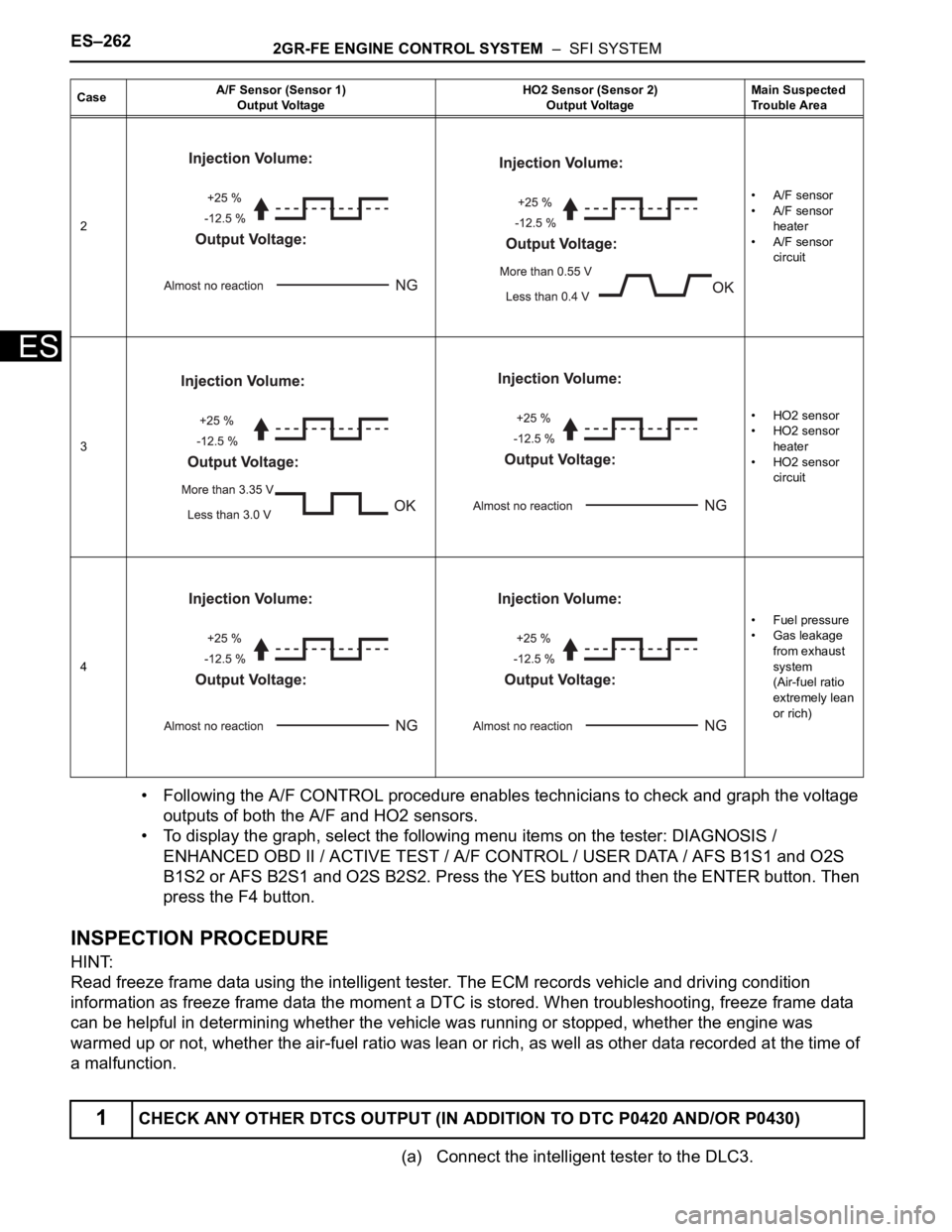

• Following the A/F CONTROL procedure enables technicians to check and graph the voltage

outputs of both the A/F and HO2 sensors.

• To display the graph, select the following menu items on the tester: DIAGNOSIS /

ENHANCED OBD II / ACTIVE TEST / A/F CONTROL / USER DATA / AFS B1S1 and O2S

B1S2 or AFS B2S1 and O2S B2S2. Press the YES button and then the ENTER button. Then

press the F4 button.

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

(a) Connect the intelligent tester to the DLC3.

2• A/F sensor

• A/F sensor

heater

• A/F sensor

circuit

3• HO2 sensor

• HO2 sensor

heater

• HO2 sensor

circuit

4•Fuel pressure

• Gas leakage

from exhaust

system

(Air-fuel ratio

extremely lean

or rich)

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0420 AND/OR P0430)

CaseA/F Sensor (Sensor 1)

Output VoltageHO2 Sensor (Sensor 2)

Output VoltageMain Suspected

Trouble Area